Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Play a role in melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

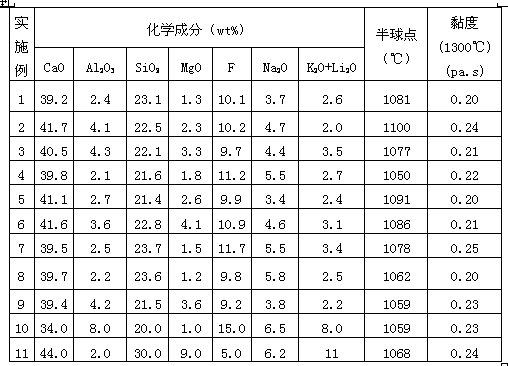

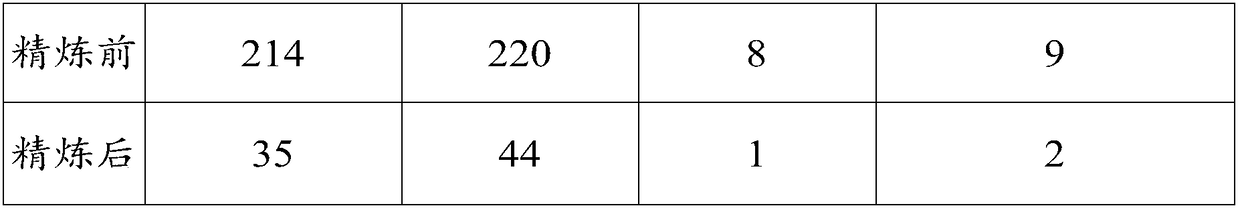

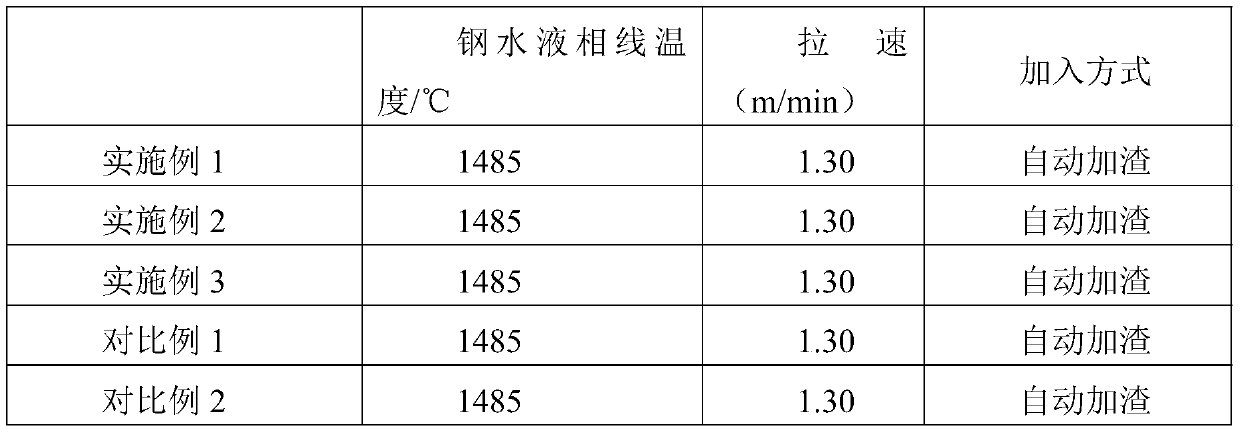

Continuous casting crystallizer mold powder of sheet billet at high casting speed

InactiveCN103639384AStrong ability to adsorb impuritiesGood glass performanceAlkali metal oxideAlkaline earth oxides

The invention discloses continuous casting crystallizer mold powder of a sheet billet at a high casting speed. The mold powder comprises chemical components in percentage by weight as follows: 34%-44% of CaO, 2%-8% of Al2O3, 20%-30% of SiO2, 1%-9% of MgO, 5%-15% of F, smaller than or equal to 6.5% of Na2O, smaller than or equal to 5% of K2O, smaller than or equal to 6% of Li2O and the balance of carbon and uncontrollable impurities. Content of CaO in the mold powder is high, content of SiO2 in the mold powder is low, accordingly, the degree of purity of molten steel can be improved, simultaneously, MgO and CaO in the mold powder are alkaline earth metal oxides, Li2O, Na2O and K2O are alkali metal oxides, the melting temperature is low, the fluxing effect is achieved, the usage amount of a fluxing agent can be reduced, the probability of various crystal precipitation is reduced, so that the glass performance of the mold powder is improved, and the mold powder has a good lubrication effect at the high casting speed; accurate control on F content meets requirements of surface quality at the high casting speed, and lubrication is improved by means of an appropriate amount of Al2O3; and the mold powder can meet technological requirements of continuous casting of medium carbon steel such as SS400, Q345 and the like, moreover, the mold powder components have stable performance, and sequence casting can be realized.

Owner:HEBEI IRON AND STEEL

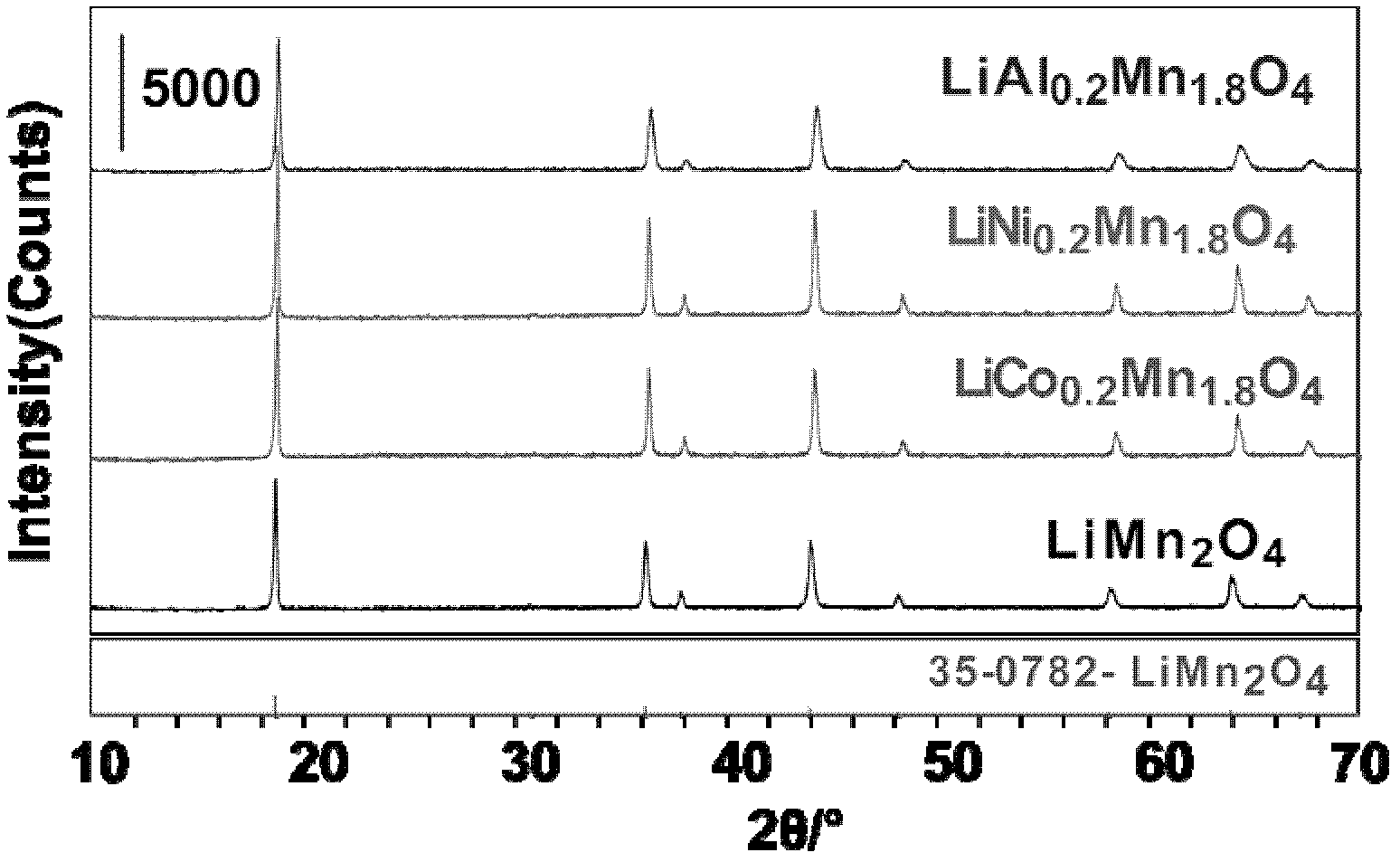

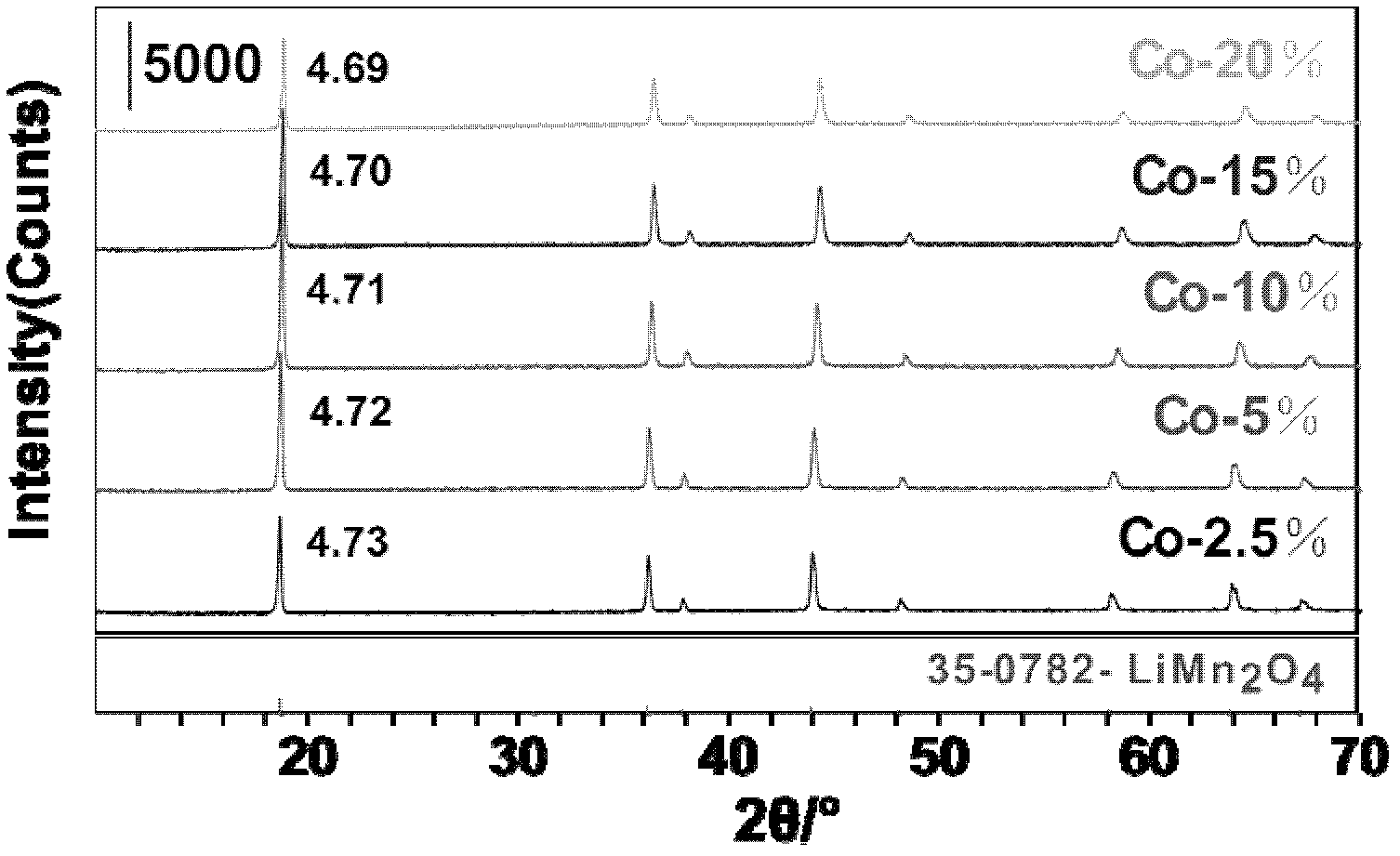

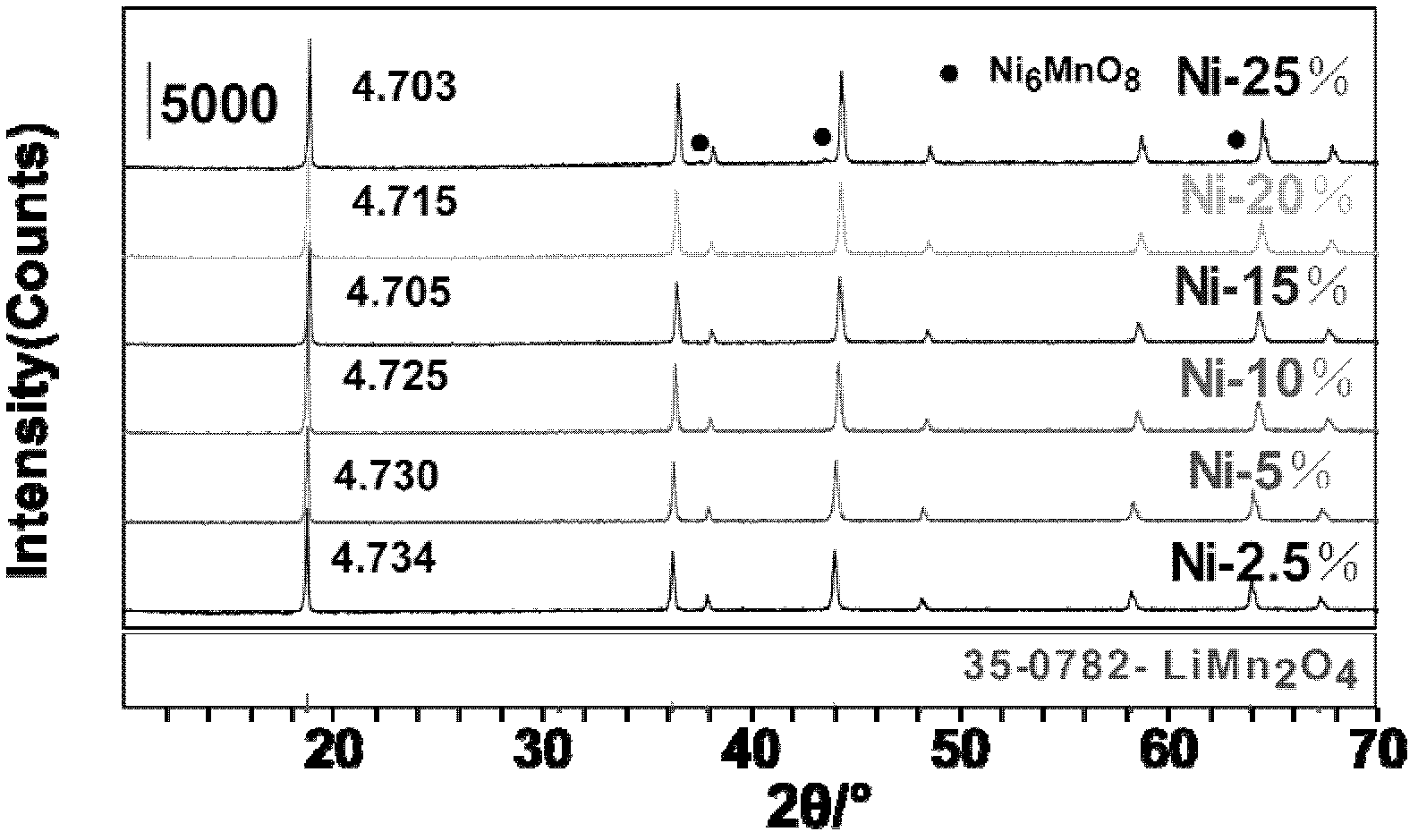

Preparation method for doped and modified spinel-type lithium manganite cathode material

InactiveCN102593460AReduce the amount of dissolutionLow melting pointCell electrodesPhysical chemistrySpinel

The invention provides a preparation method for a doped and modified spinel-type lithium manganite cathode material, which comprises the following steps of: mixing a lithium source compound, a manganese source compound, doped metal salt with a roasting accelerator to obtain a mixture; then, roasting the mixture to obtain metal element-doped spinel-type lithium manganite, wherein the roasting accelerator comprises one or more than one of acetylene black, active carbon powder, coke powder and charcoal powder. The preparation method provided by the invention is low in roasting temperature and is short in roasting time, and meanwhile, the obtained doped and modified spinel-type lithium manganite is stable in product quality and is uniform in performance.

Owner:BEIJING NORMAL UNIVERSITY +1

Alloy element additive used for aluminum alloy production and preparation method thereof

ActiveCN105177335AExcellent refining functionImprove the environmentAlloy elementEnvironmentally friendly

Disclosed is an alloy element additive used for aluminum alloy production. The alloy element additive is composed of alloy element powder to be added, mgcl2-group fusion powder and an adhesive. The components comprise, by mass, 70%-90% of the alloy element powder, 10%-30% of the mgcl2-group fusion powder and 0-5% of the adhesive. The sum of the mass percents of the three components is 100%. Alloy elements are organically combined with a refining agent, so that the alloy element additive not only has an alloying function, but also has a refining effect. According to the alloy element additive and a preparation method thereof, mgcl2-group fusion serves as a fusing agent, so that not only is the fusing function to the alloy element powder achieved, but also the refining function to aluminum water is achieved, and accordingly the agent is multipurpose indeed. The alloy element additive does not contain toxic substances, thereby being safe and environmentally friendly

Owner:SHENYANG AEROSPACE UNIVERSITY

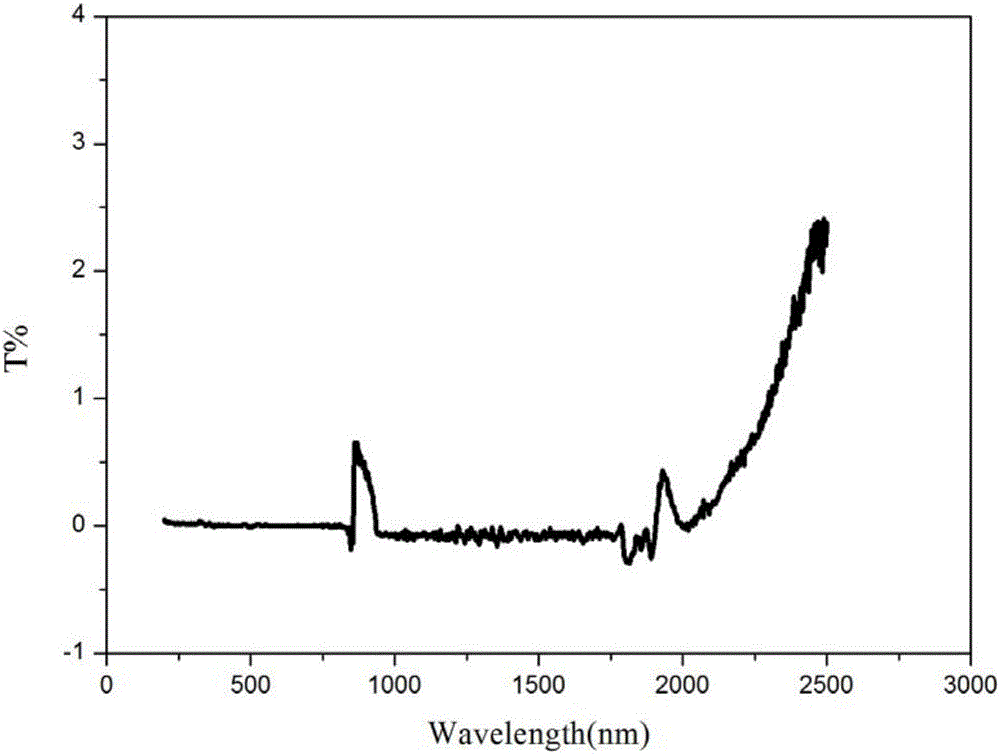

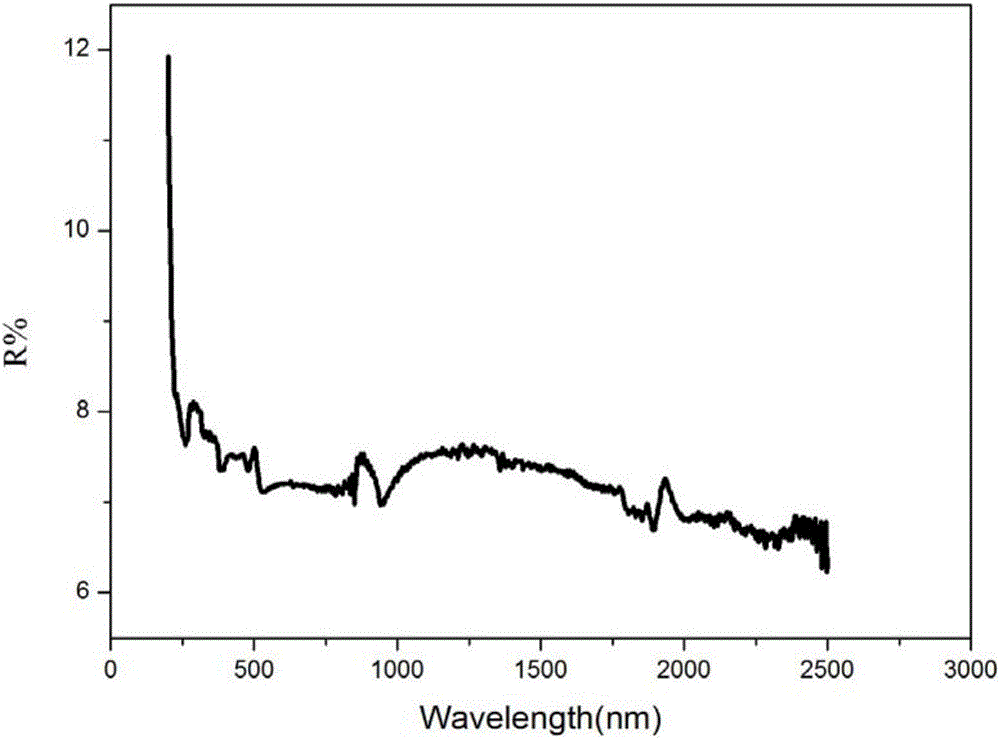

Wide-spectrum high-absorption-rate black glass and preparation method and application thereof

InactiveCN106242281AImprove absorption rateHigh light wave absorptionSolar heating energySolar heat devicesHigh absorptionAbsorption rate

The invention relates to wide-spectrum high-absorption-rate black glass and a preparation method and application thereof. The wide-spectrum high-absorption-rate black glass is prepared from the following raw materials in parts by weight: 40 to 60 parts of iron tailings, 5 to 15 parts of silicon dioxide, 2 to 5 parts of sodium carbonate, 5 to 10 parts of magnesium oxide, 10 to 20 parts of aluminum hydroxide, 0.5 to 1 part of sodium hexametaphosphate, 1 to 2 parts of potassium carbonate, 10 to 20 parts of calcium carbonate and 2 to 3 parts of titanium dioxide. The preparation steps include material proportioning, material mixing, high-temperature fusion, forming and annealing. Test results prove that the prepared black glass has the advantages that the folding resistance strength is great, and reaches 100 to 140 Mpa; a high light absorption rate is realized in the wide spectrum range of 250 nm to 2500 nm, and reaches 90 percent or higher; the black glass can be applied to the preparation of solar energy heat absorption materials, building heat insulation energy-saving materials and the like.

Owner:WUHAN UNIV OF TECH

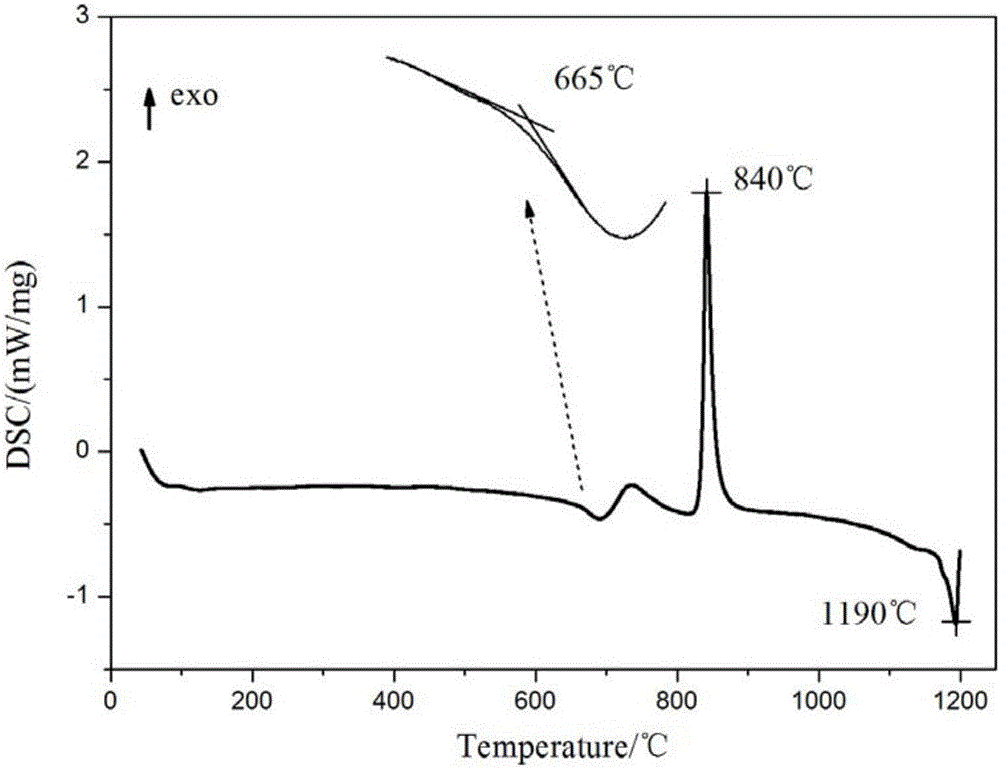

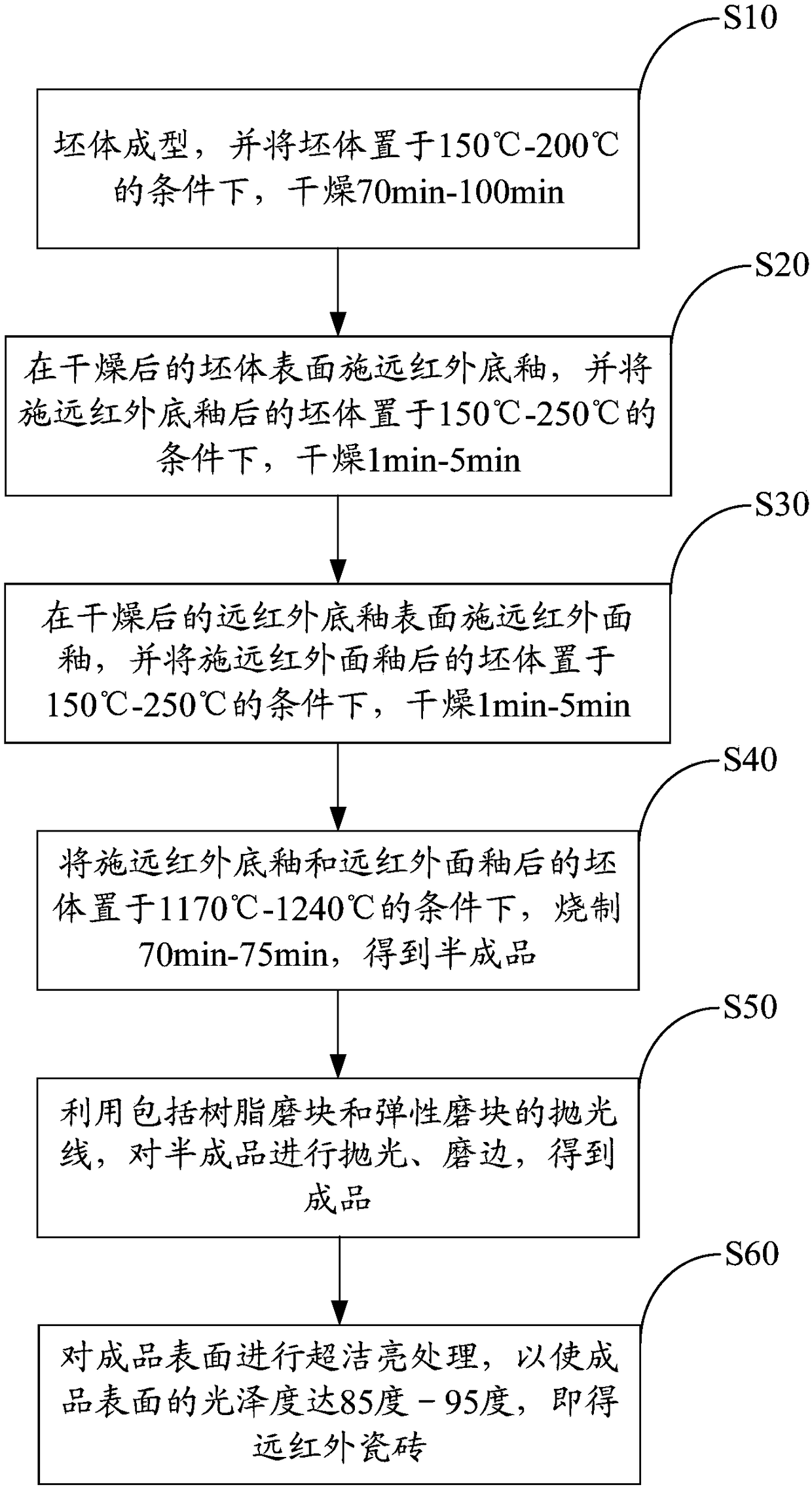

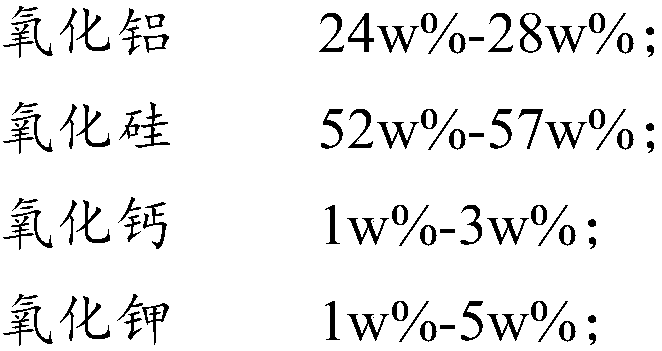

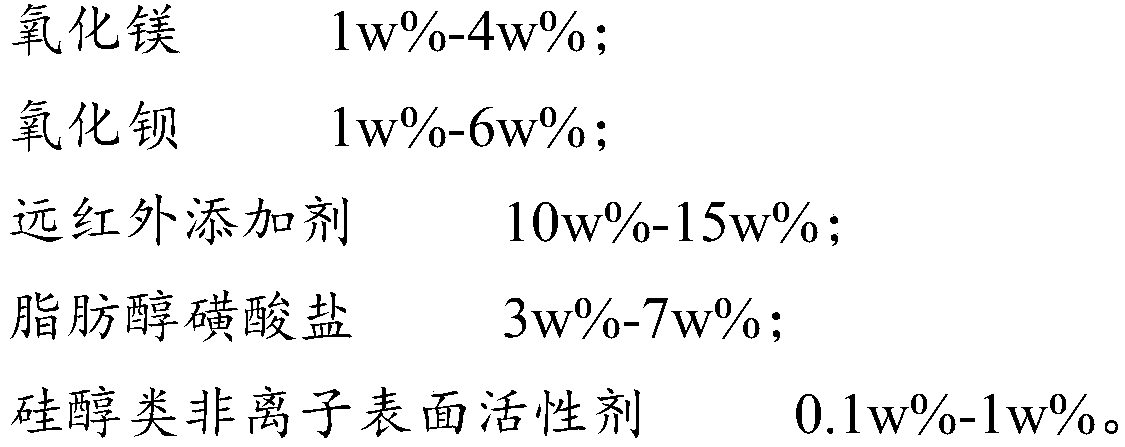

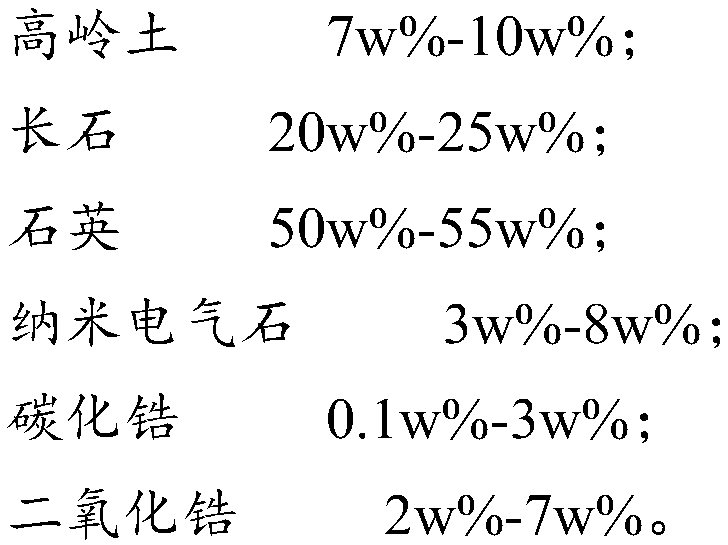

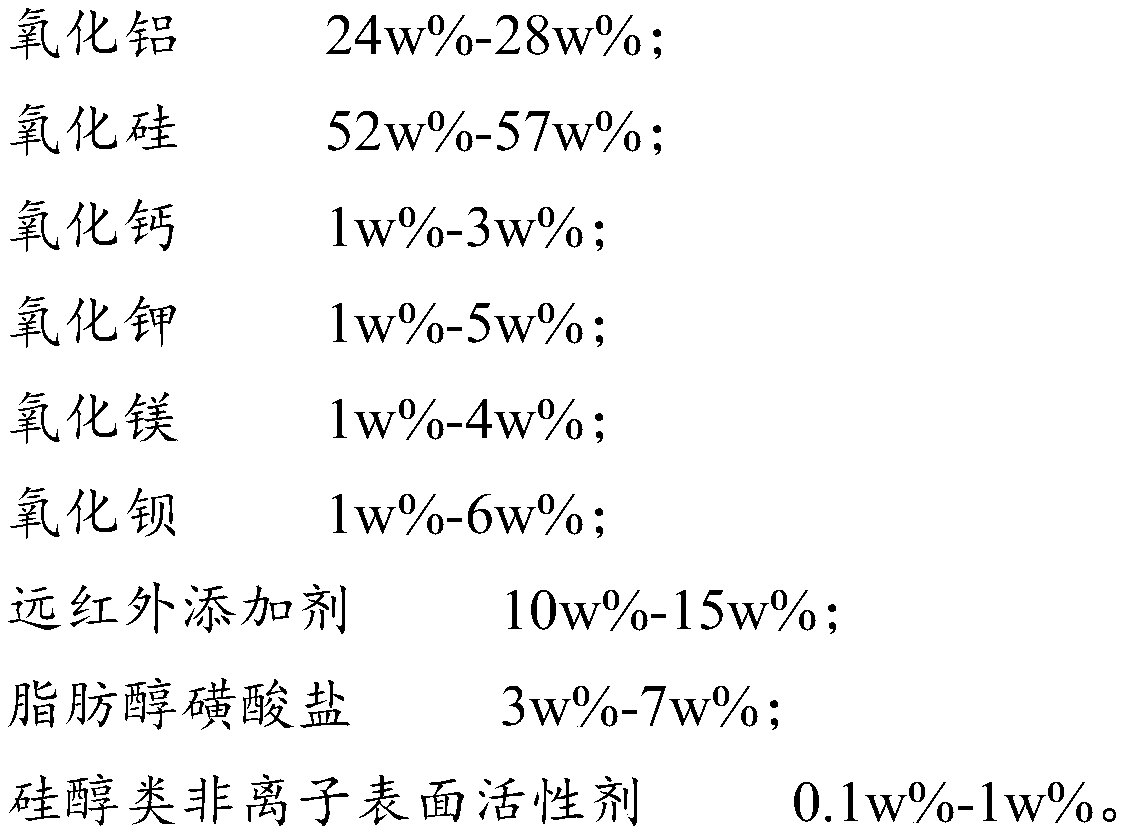

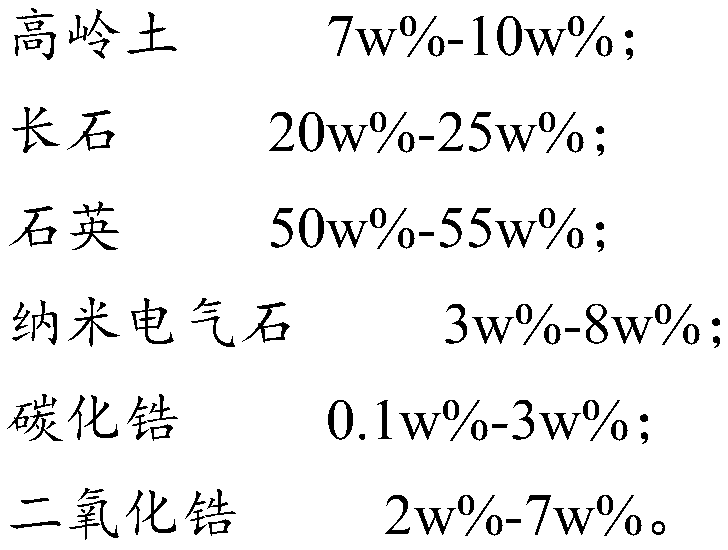

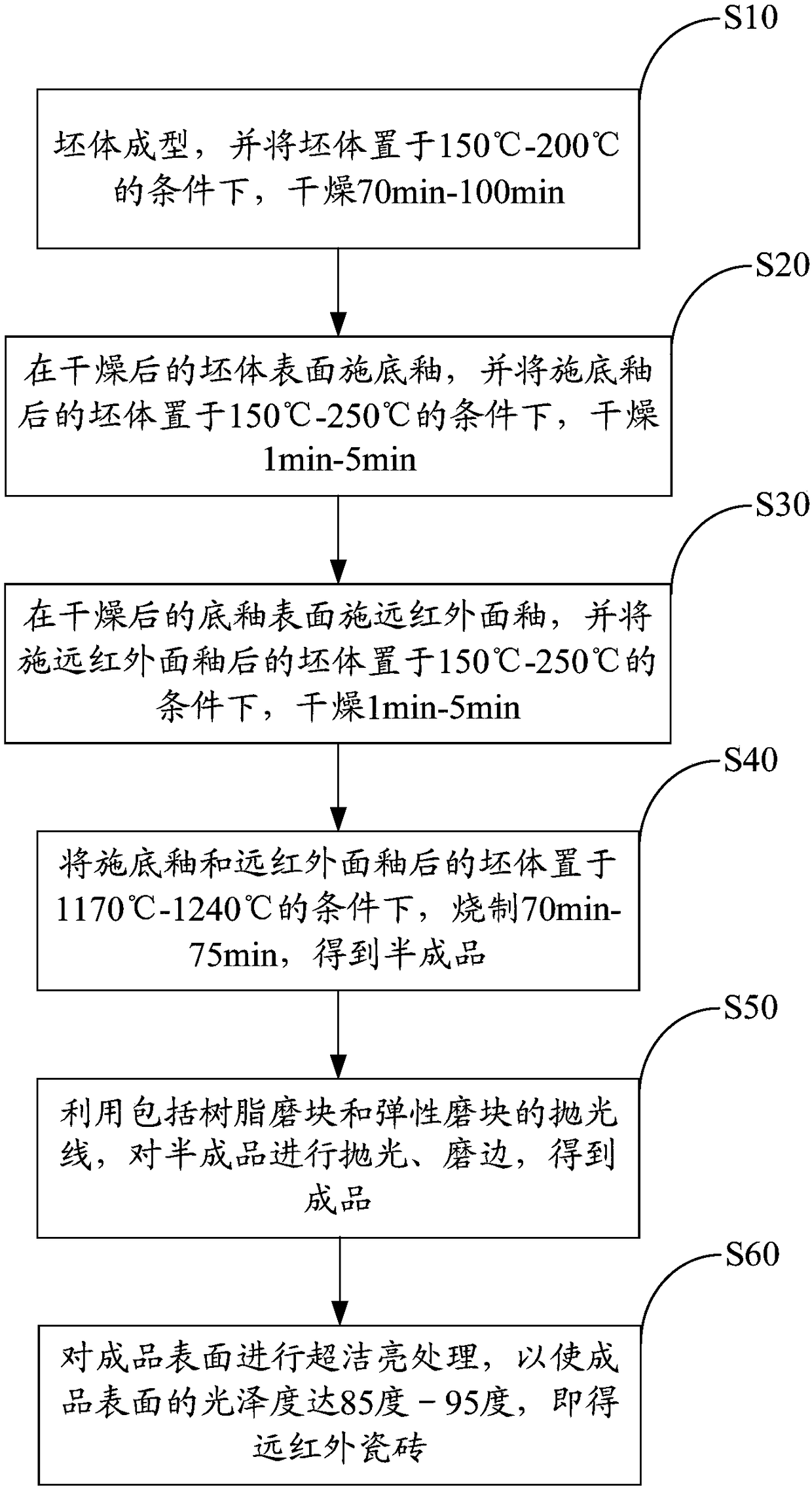

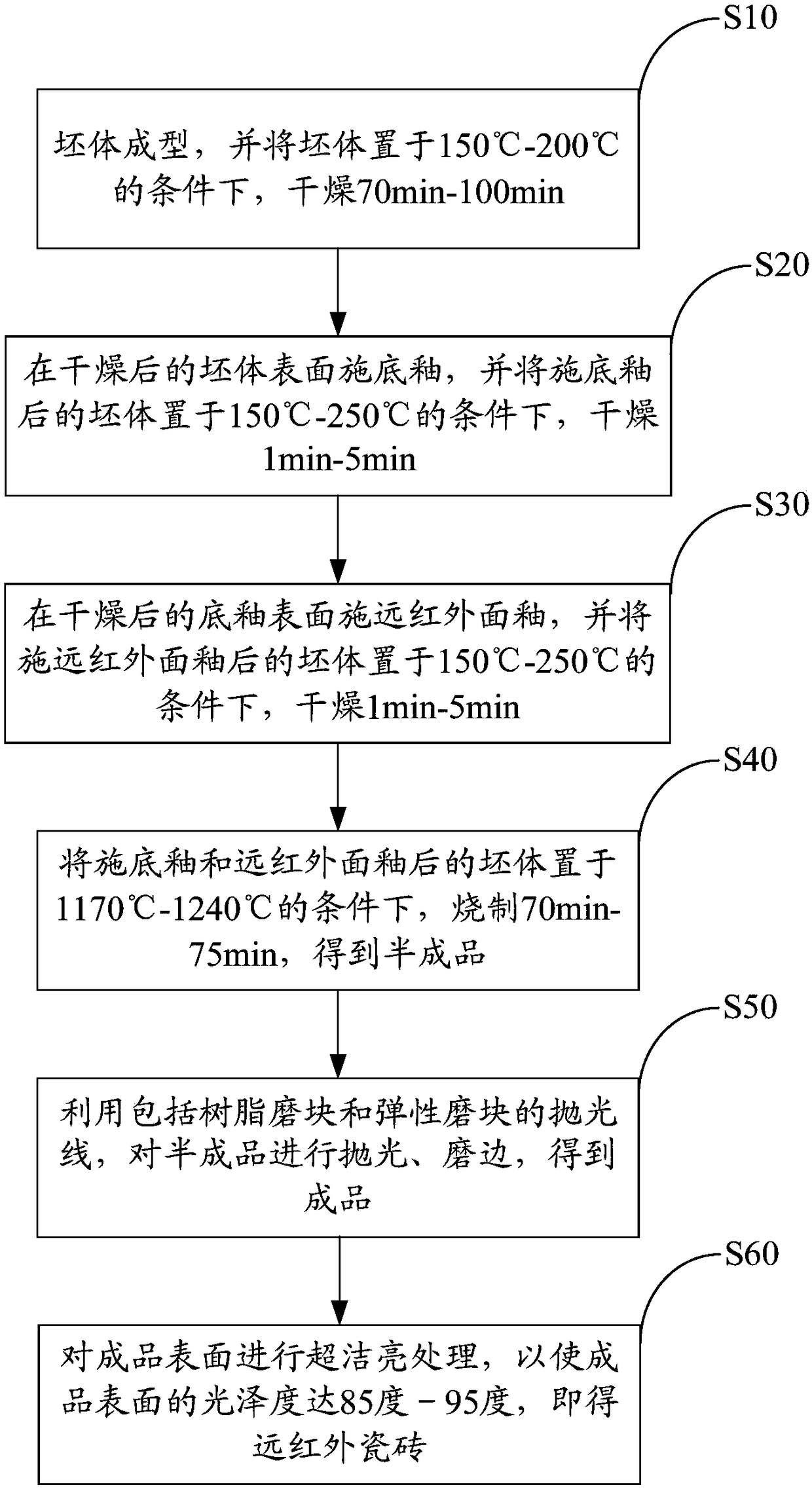

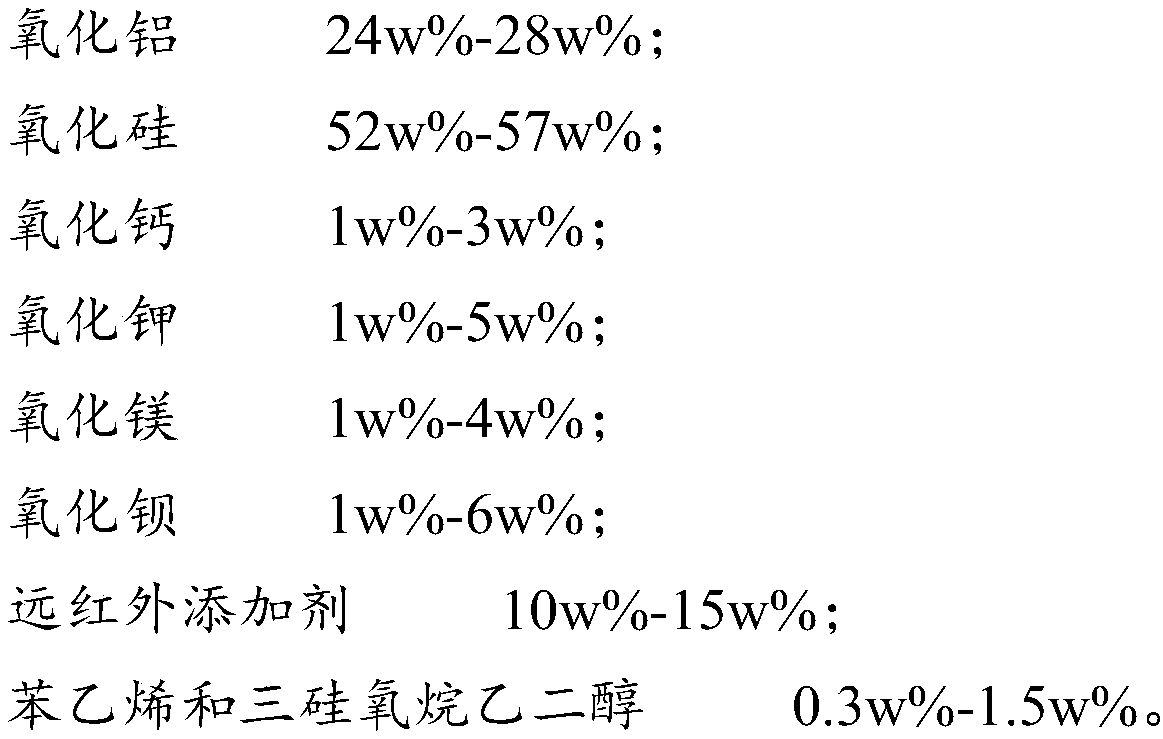

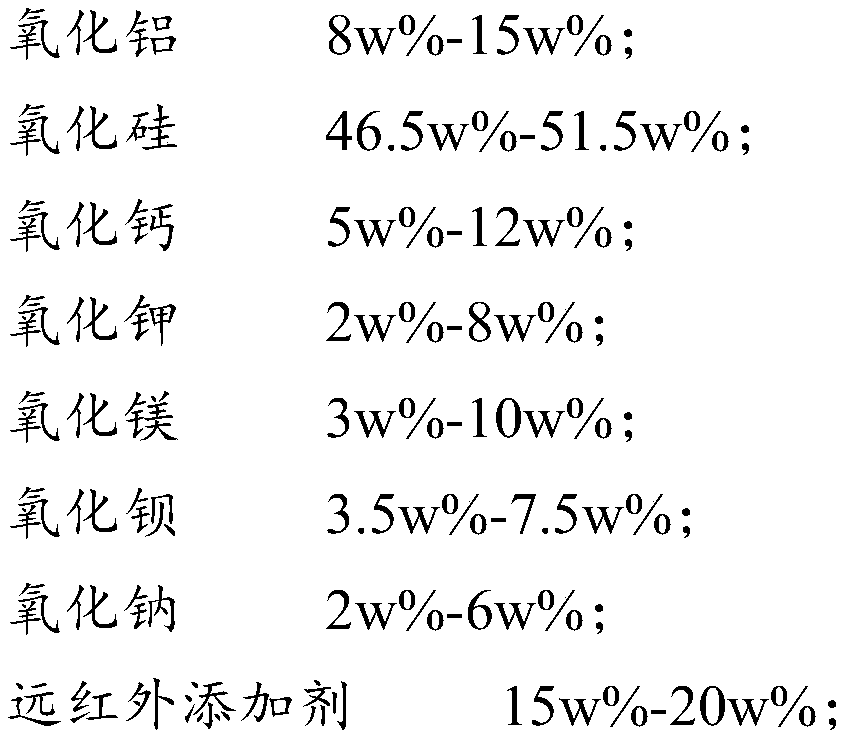

Preparation method of far infrared ceramic tile

InactiveCN108751710AWith far infrared emission functionExcellent far-infrared emissionFar infraredSilicon dioxide

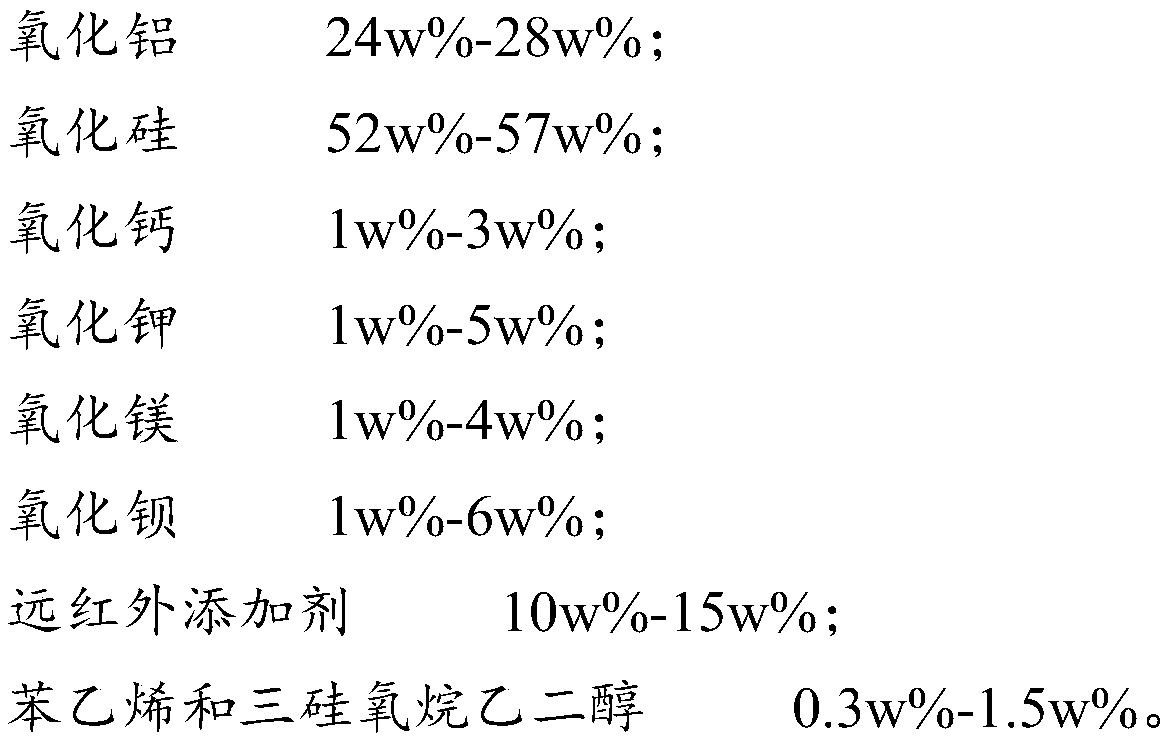

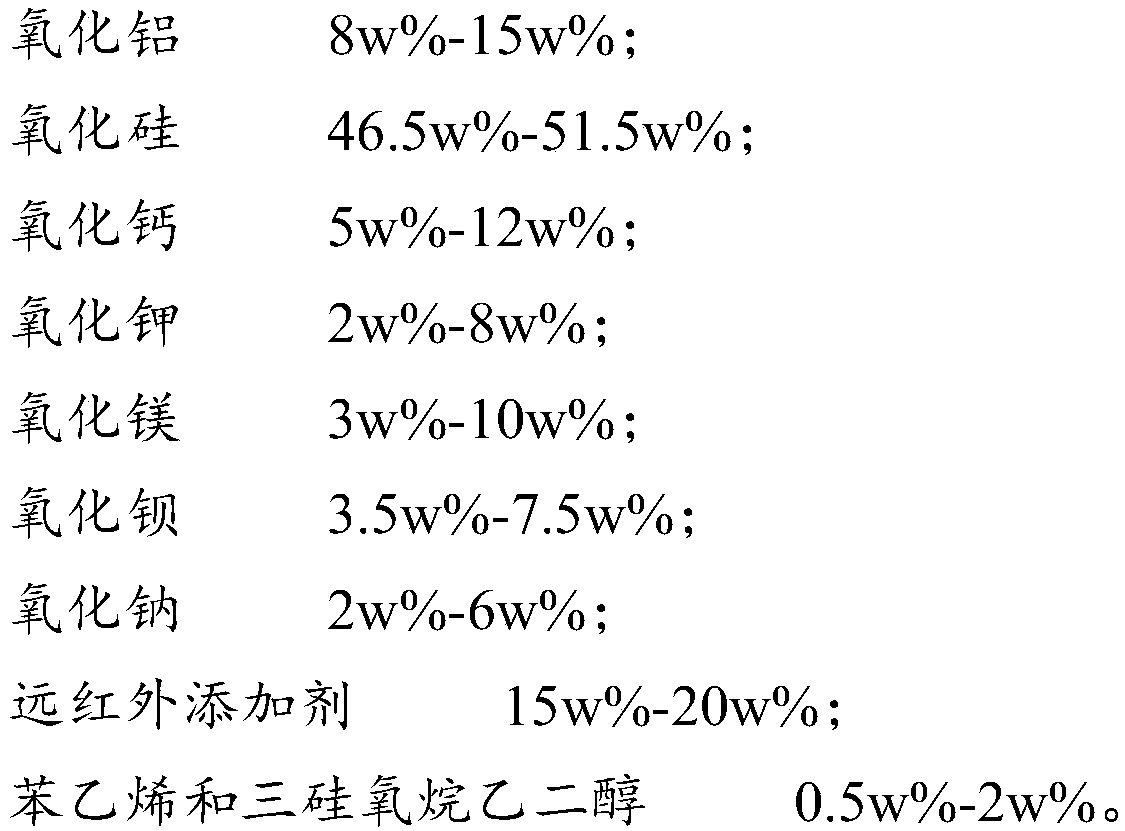

The invention discloses a preparation method of far infrared ceramic tile. The preparation method of the far infrared ceramic tile comprises the following steps: forming and drying a body; applying afar infrared ground coat on the surface of the dried body, drying; applying a far infrared cover coat on the surface of the dried far infrared ground coat, and drying; sintering, to obtain a semi-finished product; polishing and edging the semi-finished product to obtain a finished product; conducting super clean and bright treatment on the surface of the finished product, to obtain the far infrared ceramic tile. The far infrared ground coat comprises the components of aluminum oxide, silicon dioxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide and a far infrared additive; thefar infrared cover coat comprises the components of aluminum oxide, silicon dioxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide and the far infrared additive; the farinfrared additive comprises the components of kaolin, feldspar, quartz, nano-tourmaline, zirconium carbide and zirconium dioxide. Due to the technical scheme, the ceramic tile has the function of transmitting far infrared rays.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

Microporous foam glass and preparation method thereof

InactiveCN107399913AImprove high temperature resistanceHigh compressive strengthGlass shaping apparatusAmmonia compoundsCompressive resistanceFiber

The invention discloses microporous foam glass and a preparation method thereof, and relates to the field of glass products. The foam glass is prepared from the following raw materials of crushed glass powder, mordenite zeolite, hyalophane mica, modified quartz powder, kaolin, titanium dioxide, sodium fluoride, reinforced fiber, adhesive, foaming agent and foam stabilizer. The preparation method comprises the following steps: smashing raw materials, melting, cooling, standing, foaming, annealing, foaming and polish. The production raw materials of the foam glass are wide in source, and are simple in a preparation process; the finished product of foam glass contains a large amount uniform, unique and enclosed micropores inside, so that the heat-insulation high temperature and compressive resistance of the foam glass product are improved remarkably, as well as long service life, wide application field and suitability for popularization and application are achieved.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

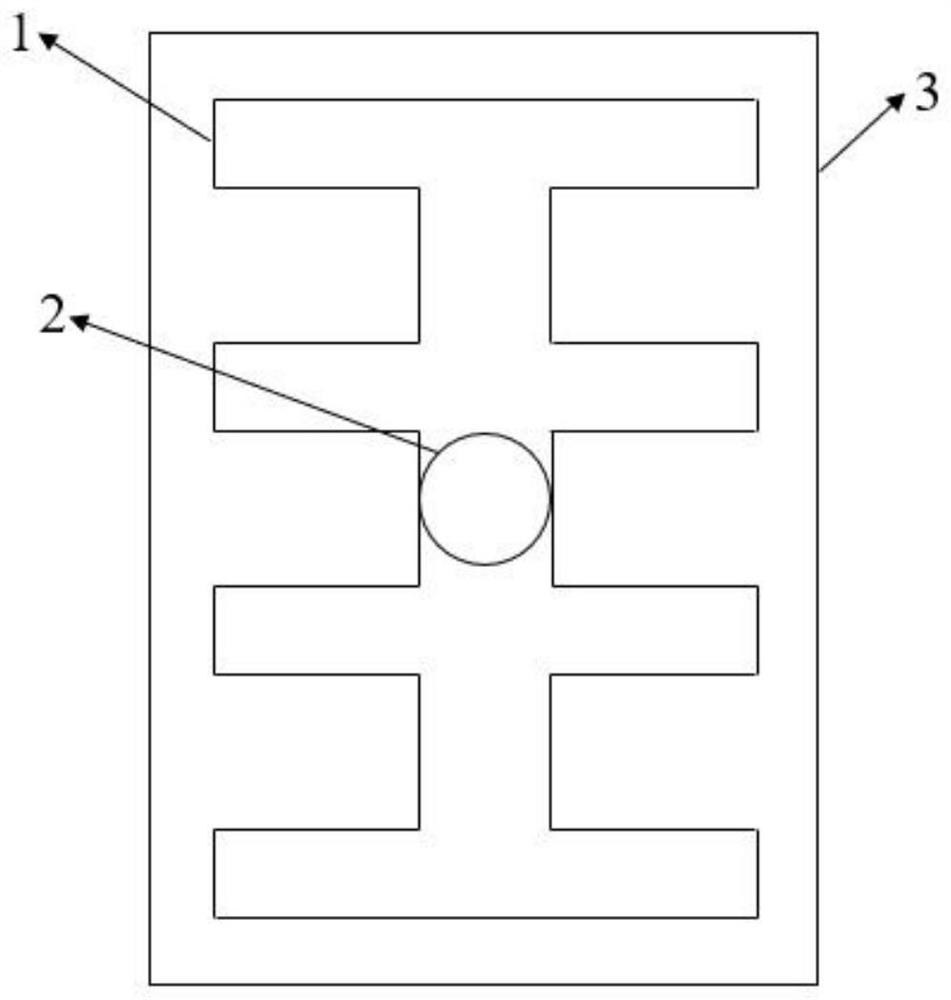

Far infrared ceramic tile

InactiveCN108752056AWith far infrared emission functionExcellent far-infrared emissionOptoelectronicsFar infrared

The invention discloses a far infrared ceramic tile. The far infrared ceramic tile comprises a green body layer, a far infrared ground coat layer and a far infrared cover coat layer which are sequentially stacked; the far infrared ground coat layer comprises the components of aluminum oxide, silicon dioxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide and a far infrared additive;the far infrared cover coat layer comprises the components of aluminum oxide, silicon dioxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide and the far infrared additive; the far infrared additive comprises the components of kaolin, feldspar, quartz, nano-tourmaline, zirconium carbide and zirconium dioxide. Due to the technical scheme, the ceramic tile has the function of transmitting far infrared rays.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

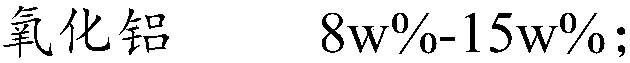

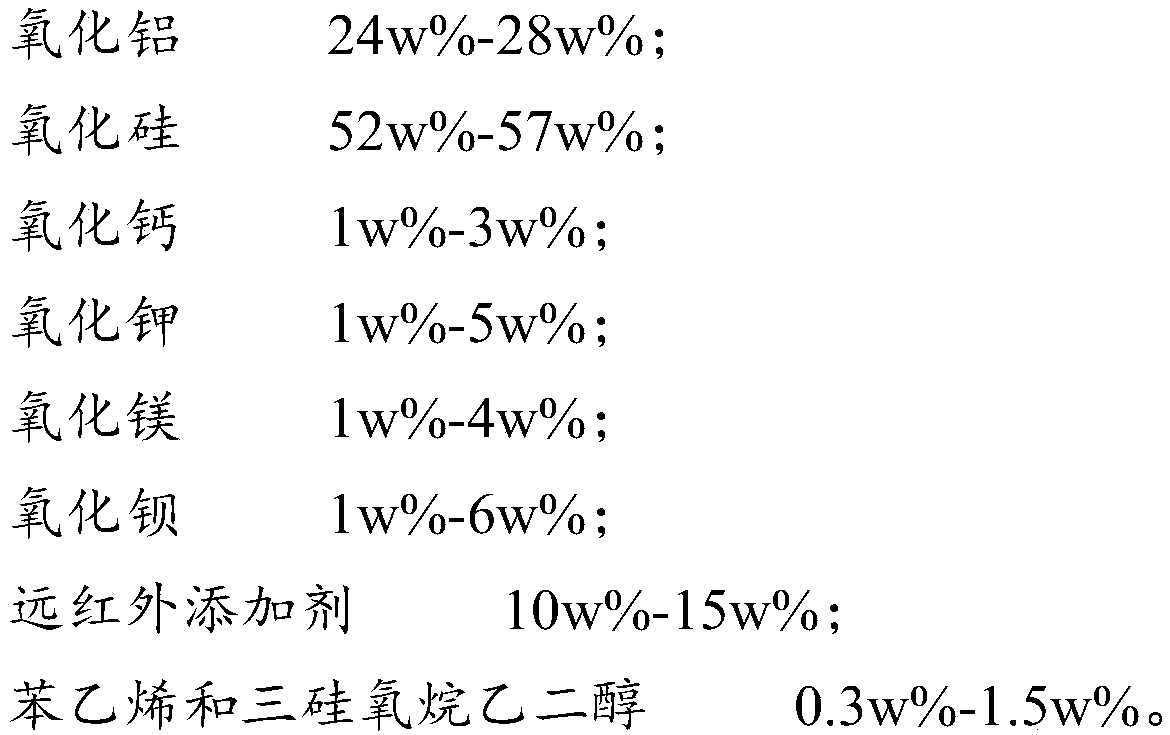

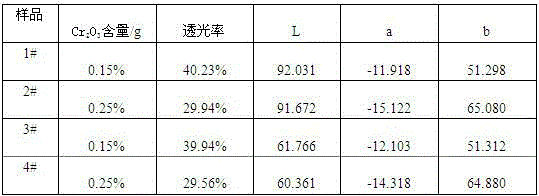

Manufacturing process of high-brightness chromium-containing glass

The invention relates to a manufacturing process of high-brightness chromium-containing glass. The manufacturing process comprises the following steps of: (1) taking silica sand, dolomite, limestone, albite, lithium carbonate, sodium nitrate and lead nitrate, mixing, uniformly stirring, then adding potassium dichromate, and then stirring uniformly to obtain glass batch; (2) melting; (3) carrying out secondary crystallization on the glass; and (4) cooling and forming to obtain a glass product. The process method of the chromium-containing glass manufactured by the invention has the advantages that by selection of a reasonable glass material formula and strict control for the heating rate in the melting process, the glass batch can be fully melted, the operation of twice crystallization is adopted, the manufactured chromium-containing glass is high in brightness and looks more sparkling, and the problem of poor brightness of the chromium-containing glass is solved.

Owner:LUOYANG INST OF SCI & TECH

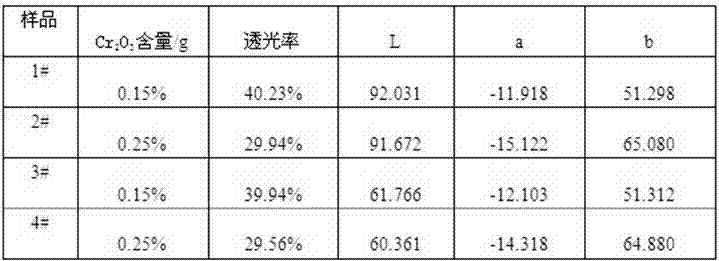

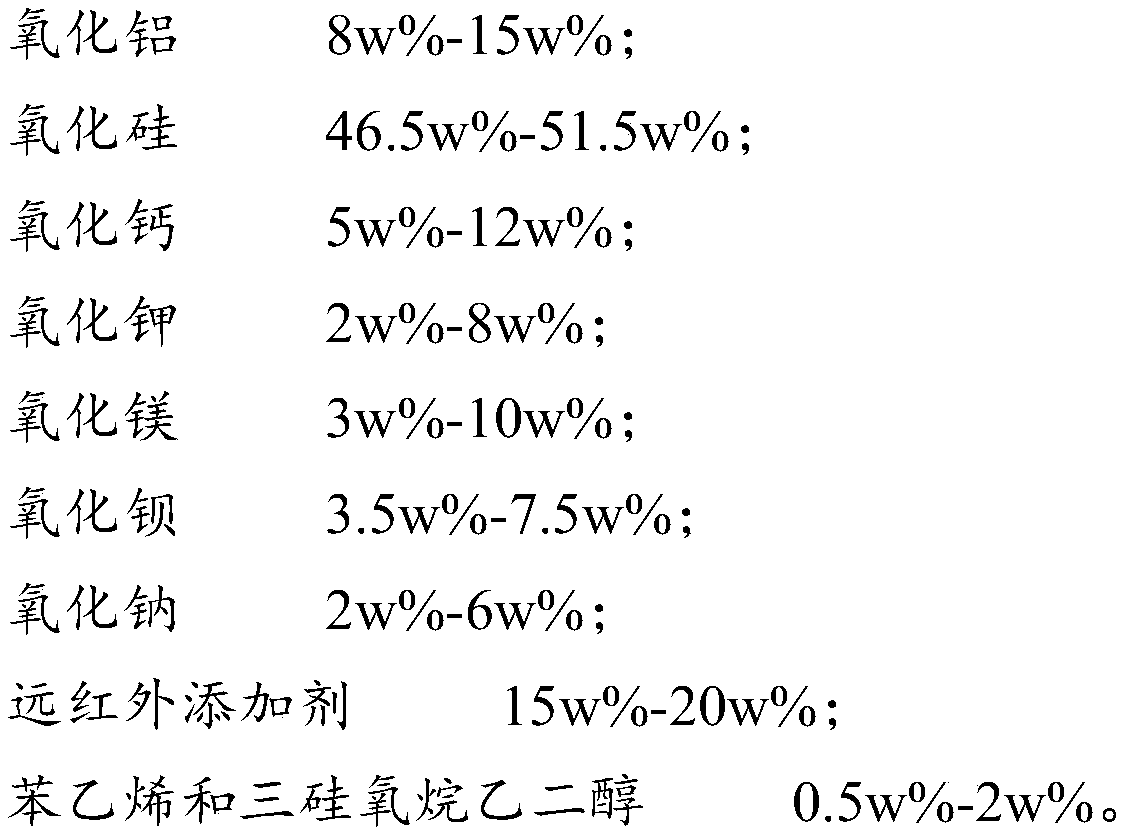

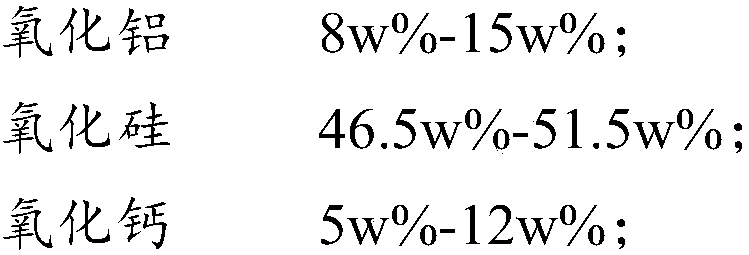

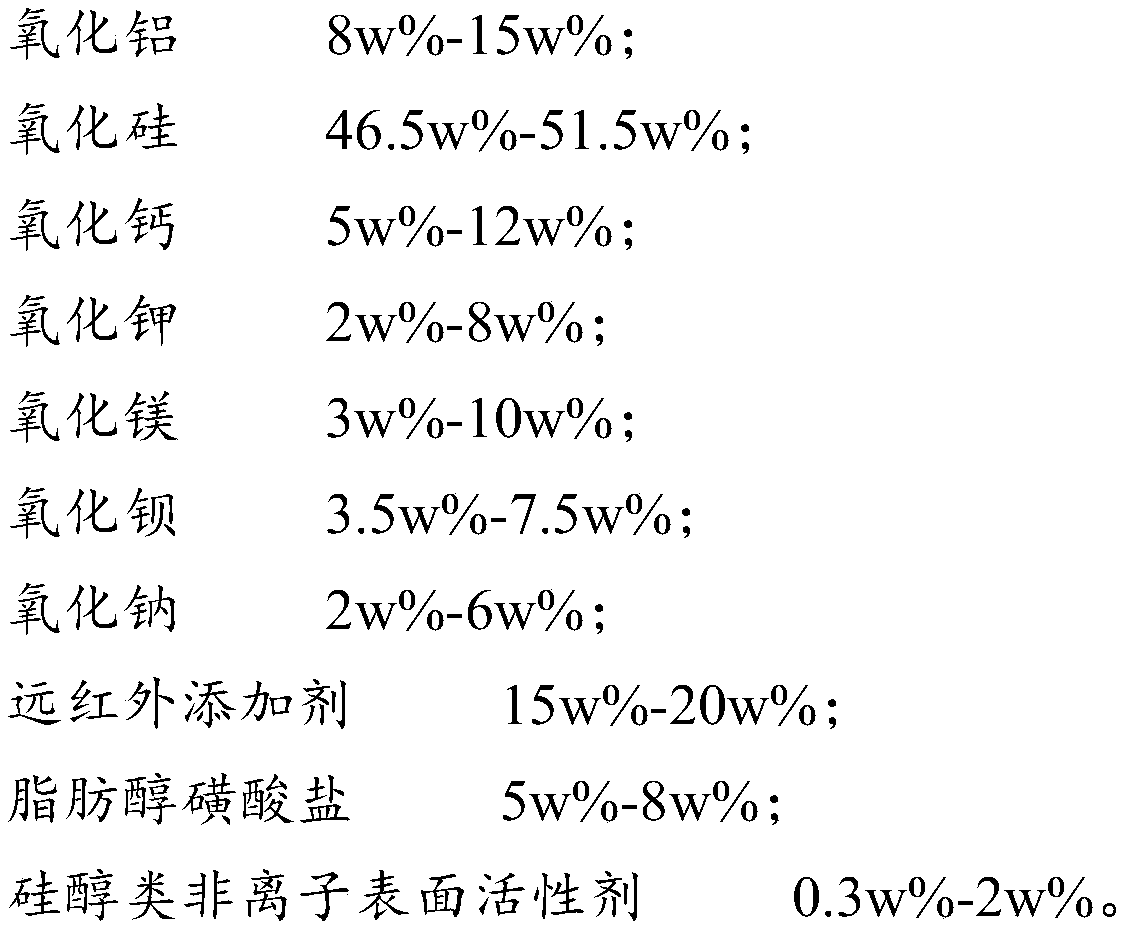

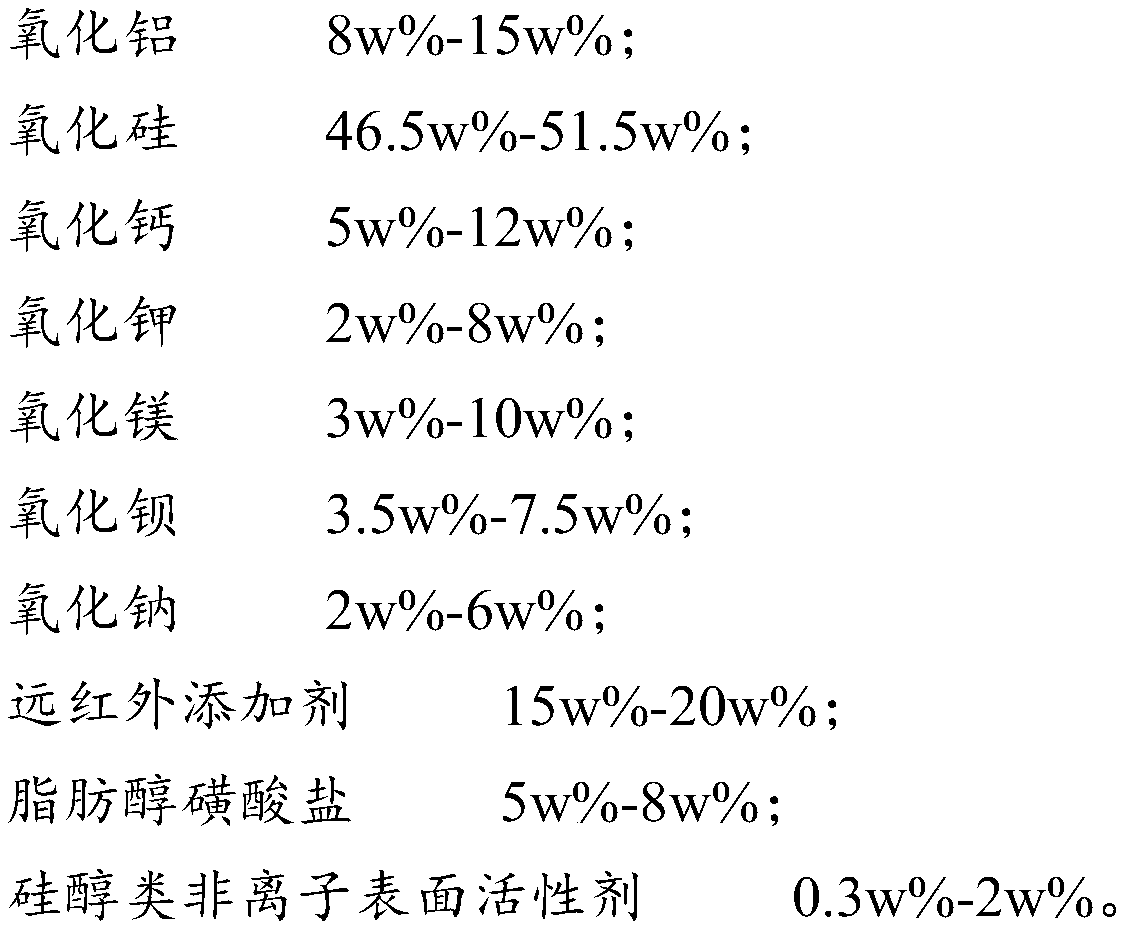

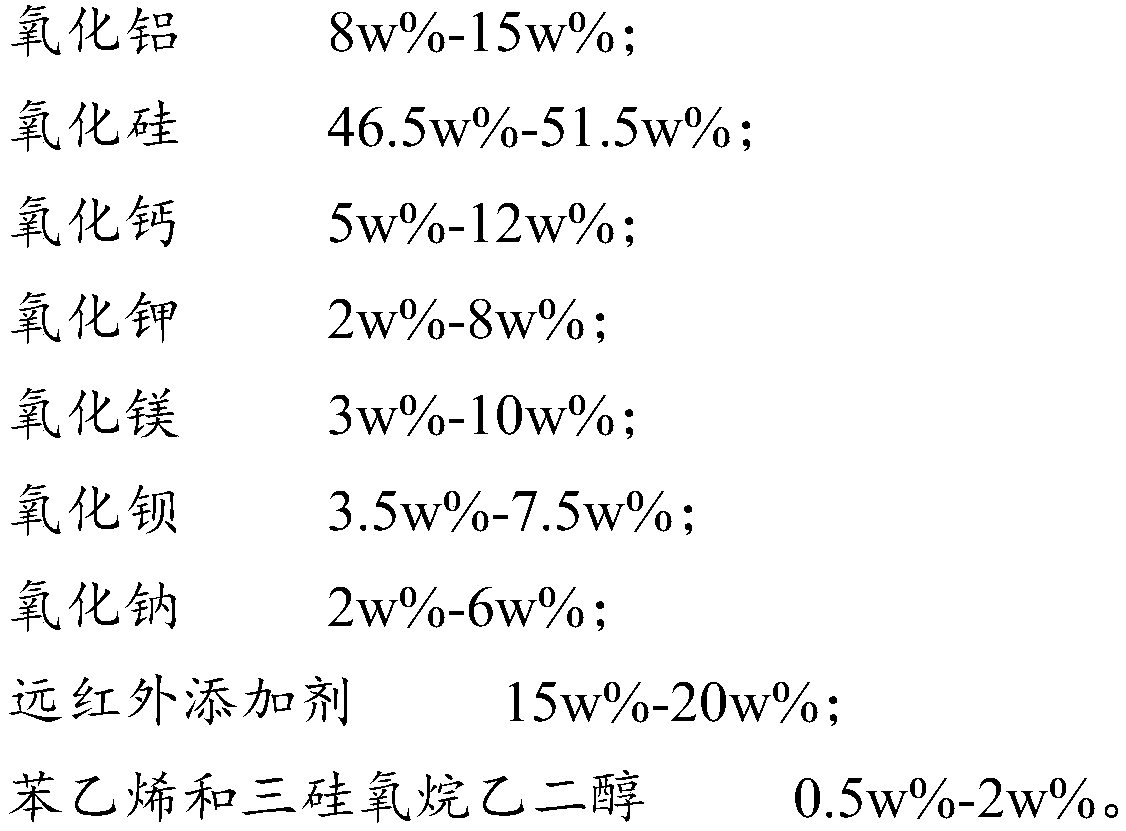

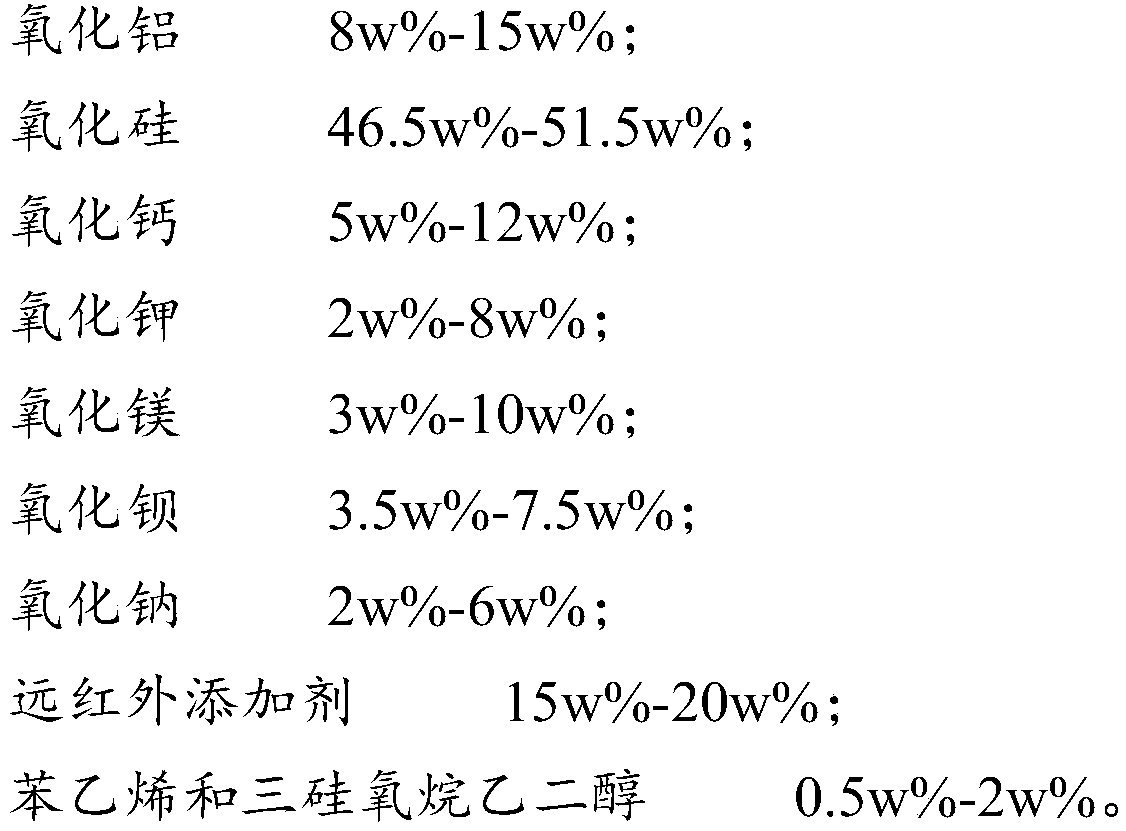

Far-infrared ceramic tile

The invention discloses a far-infrared ceramic tile. The far-infrared ceramic tile is prepared from a green body layer, a far-infrared ground glaze layer and a far-infrared surface glaze layer which are successively arranged in a stacking manner; the far-infrared ground glaze layer is prepared from the components: aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, a far-infrared additive, styrene and trisiloxane glycol; the far-infrared surface glaze layer is prepared from the components: aluminum oxide, silicon oxide, calcium oxide, potassium oxide,magnesium oxide, barium oxide, sodium oxide, far-infrared additive, styrene and trisiloxane glycol; and the far-infrared additive is prepared from the components: kaolin, feldspar, quartz, nano tourmaline, zirconium carbide, and zirconium dioxide. The far-infrared ceramic tile has the advantages that the ceramic tile is enabled to have a far-infrared transmitting function.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Low-oxidizability continuous casting covering slag

The invention discloses a low-oxidizability continuous casting covering slag comprising the following chemical components in percentage by weight: 15-25% of CaO, 20-35% of Al2O3, 10-20% of SiO2, 2-5% of Li2O+K2O, 2-10% of B2O3, F<=10%, Na2O<=10%, 5-15% of MgO+BaO+SrO, and the balance of carbon and inevitable impurities. Furthermore, the hemispheric point temperature of the continuous casting covering slag is controlled within a range from 1000 DEG C to 1200 DEG C, and the viscosity is controlled within a range from 0.2 pa. s to 0.6 pa. s. Practices show that the low-oxidizability continuous casting covering slag has good combination property and meets the requirements of continuous casting processes of steel types, i.e. TRIP (Transformation-Induced Plasticity) steel with high-content oxidizable elements i.e. Al, Ti or rare earth, and the like, silicon steel, container steel, and the like and realize the multi-furnace continuous casting.

Owner:武汉钢铁有限公司

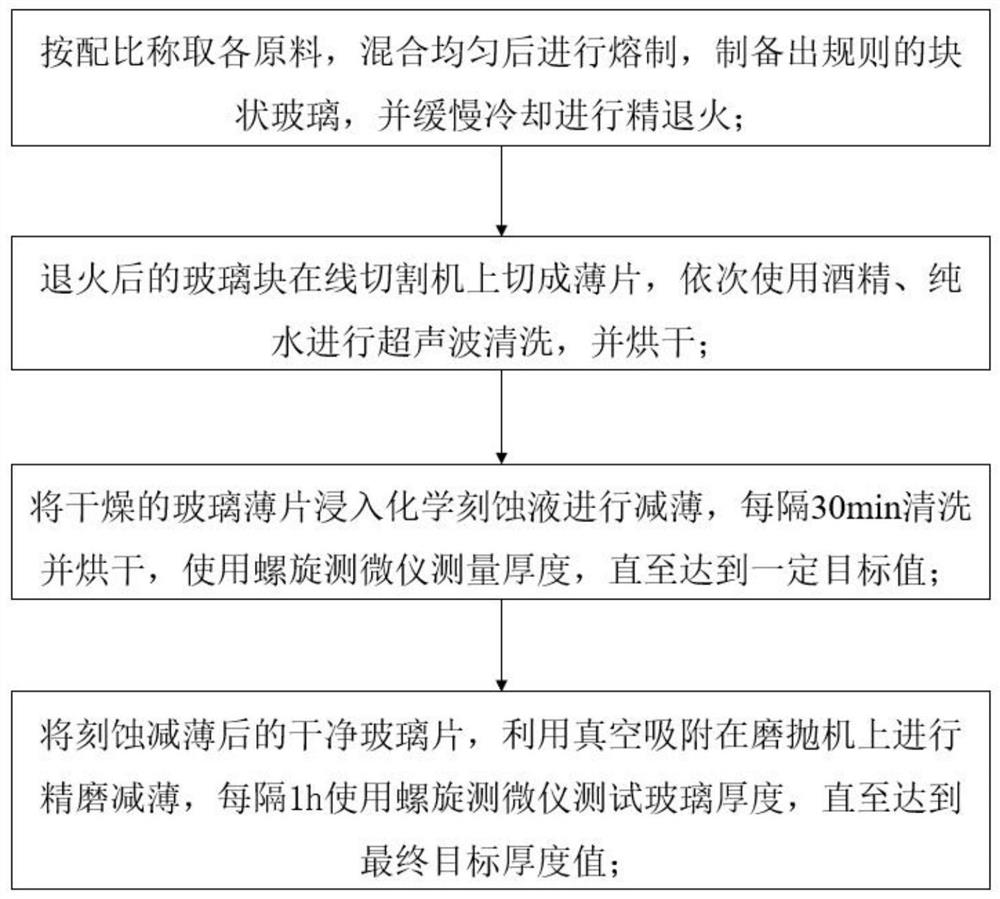

Alkali-free substrate glass and thinning method thereof

PendingCN113880429AReduce thicknessBendableLapping machinesWork carriersHydrofluoric acidAcetic acid

Alkali-free substrate glass comprises the components in percentage by mass: 58.9% to 62.5% of SiO2, 14.2% to 18.4% of Al2O3, 4.3% to 13.7% of B2O3, 1.4% to 1.9% of MgO, 4.1% to 7.6% of CaO, 1.0% to 2.1% of SrO, 0 to 8.3% of BaO and 0.1% to 0.2% of SnO2. The thinning method comprises the following steps: immersing the alkali-free substrate glass into a chemical etching solution composed of hydrofluoric acid, a glacial acetic acid surfactant and the balance being water, thinning the alkali-free substrate glass to 0.4 mm-0. 5mm, taking out the alkali-free substrate glass, and carrying out ultrasonic cleaning and drying; and placing the alkali-free substrate glass on a grinding disc of a grinding and polishing machine, and carrying out mechanical polishing, thinning the alkali-free substrate glass to 0.3 mm-0.35 mm, and thus obtaining the flexible substrate glass. The alkali-free substrate glass is reasonable in composition, the specific modulus value of the prepared alkali-free glass is moderate, the glass has good flexibility, the thinning method is convenient to operate, the alkali-free substrate glass with the thickness of 0.7 mm is thinned by combining two modes of chemical etching thinning and mechanical polishing thinning, and the flexible substrate glass with smooth surface and bendable performance is obtained.

Owner:IRICO DISPLAY DEVICES

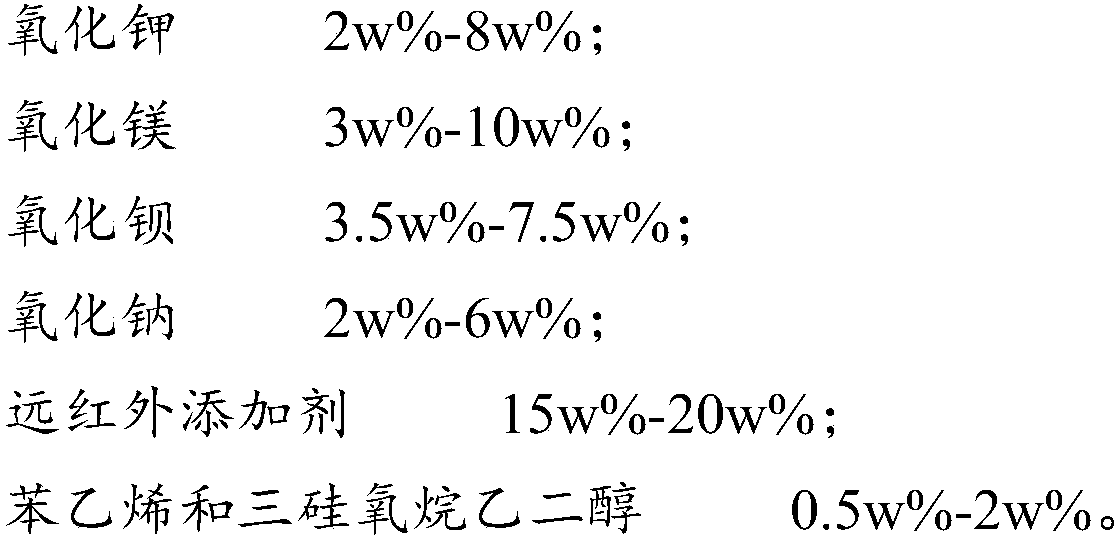

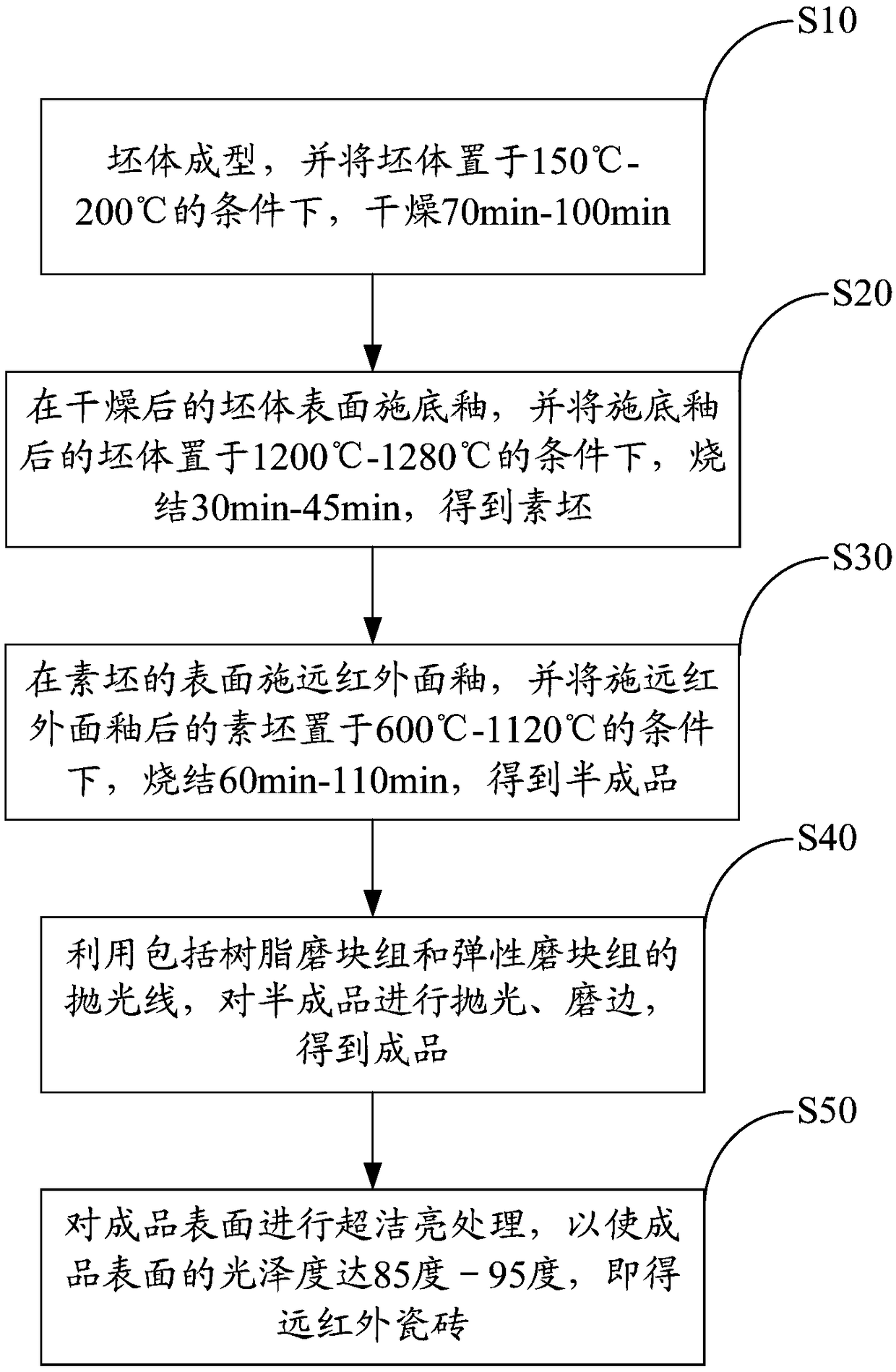

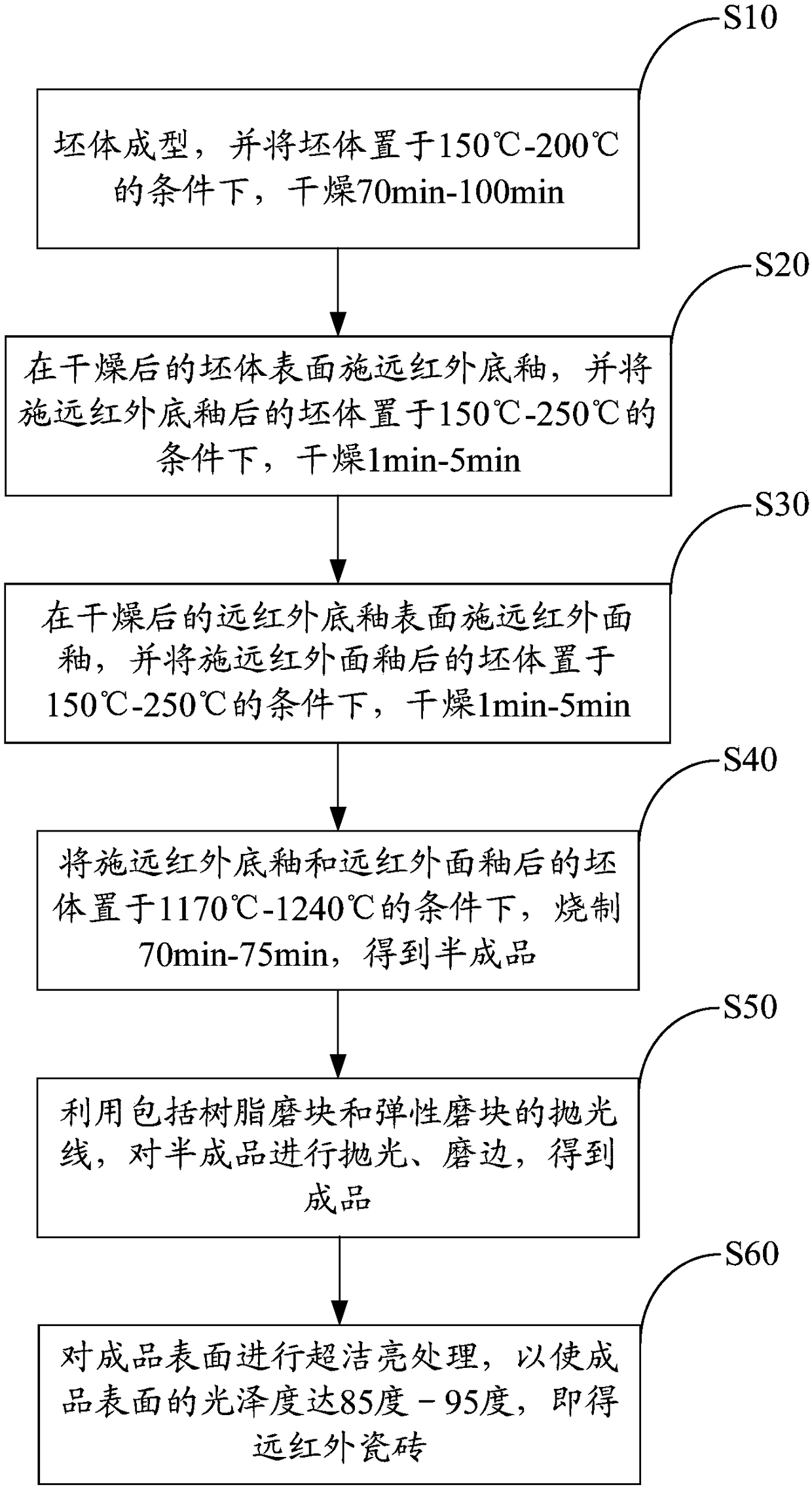

Preparation method of far-infrared ceramic tile

InactiveCN108546158AWith far infrared emission functionExcellent far-infrared emissionSilicon oxideFar infrared

The invention discloses a preparation method of a far-infrared ceramic tile. The preparation method comprises the following steps of forming a green body and drying; applying a ground glaze on the surface of the dried green body, and drying; applying a far-infrared over glaze on the surface of the dried ground glaze, and drying; firing to obtain a semi-finished product; polishing and edging the semi-finished product to obtain a finished product; performing super cleaning and brightening on the surface of the finished product to obtaining the far-infrared ceramic tile; the components of the far-infrared over glaze comprises aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide, a far-infrared additive, styrene, and trisiloxane glycol; thecomponents of the far-infrared additive comprises kaolin, feldspar, quartz, nano tourmaline, zirconium carbide, and zirconium dioxide. By adoption of the technical solution of the invention, the ceramic tile has a far-infrared ray emitting function.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Preparation method of far infrared tile

InactiveCN108658608AWith far infrared emission functionExcellent far-infrared emissionEdge grinding machinesPolishing machinesSilicon oxideFar infrared

The invention discloses a preparation method of a far infrared tile. The method comprises the following steps that green body moulding and drying are conducted; ground glaze is applied on the surfaceof a dried green body, and the green body subjected to ground glaze application is dried; far infrared cover glaze is applied on the surface of the dried ground glaze, and the green body subjected tofar infrared cover glaze application is dried; the green body subjected to ground glaze application and far infrared cover glaze application is fired to obtain a semi-finished product; by means of polishing lines containing resin abrasion blocks and elastic abrasion blocks, the semi-finished product is subjected to polishing and edging to obtain a finished product; pure bright treatment is conducted on the surface of the finished product, and then the far infrared tile is obtained; the far infrared cover glaze is prepared from the components of aluminium oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide and a far infrared additive, and the far infrared additive is prepared from the components of kaolin, feldspar, quartz, nano-tourmaline, zirconium carbide and zirconium dioxide. According to the technical scheme, the tile can have the far infrared ray emitting function.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

Instantly soluble hard alloy block and preparation method and application thereof

The invention discloses an instantly soluble hard alloy block and a preparation method and application thereof. The instantly soluble hard alloy block is made from materials in following percent by weight by binding with an adhesive: 25-35% of high carbon ferro-chrome, 0.5-1%. of rare earth, 15-40% of ferro-boron, 25-55% of ferro-vanadium, 2-6% of ferrosilicon, and 2-3% of ferronickel, wherein the adhesive is a resin adhesive. The instantly soluble hard alloy block has high hardness (Rockwell hardness HRC > / =73), good wear resistance, manufacture process simplicity, low cost, low surfacing current, convenience of selecting dimensions and shape, low time and labor consumption for a welder, etc., the problem that a quick-wear apparatus is short in life is solved, and the life of an original member is prolonged by 3-10 times.

Owner:苑俊奎

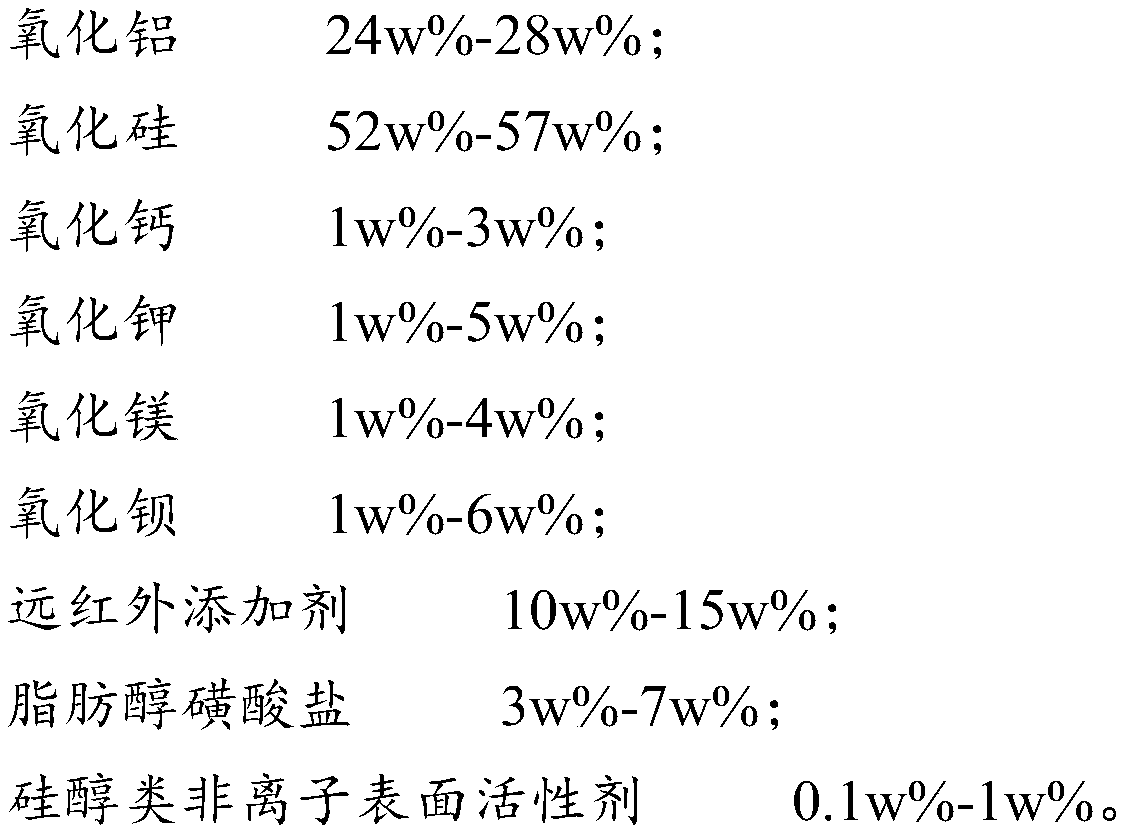

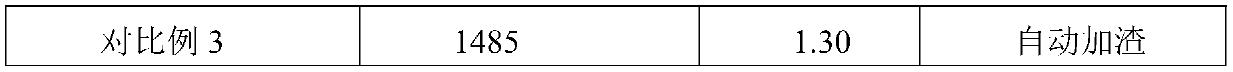

Preparation method of far-infrared ceramic tile

InactiveCN108706884AWith far infrared emission functionExcellent far-infrared emissionSilicon oxideFar infrared

The invention discloses a preparation method of a far-infrared ceramic tile. The preparation method comprises the following steps: forming a green body, and drying; applying far-infrared ground glazeonto the surface of the dried green body, sintering, and obtaining a biscuit; applying far-infrared surface glaze onto the surface of the biscuit, sintering, and obtaining a semi-finished product; polishing and trimming the semi-finished product, and obtaining a finished product; and performing the ultra-brightness treatment on the surface of the finished product, thus obtaining the far-infrared ceramic tile. The far-infrared ground glaze is prepared from the components: aluminum oxide, silicon oxide, calcium oxide, magnesium oxide, barium oxide, and a far-infrared additive; the far-infrared surface glaze is prepared from the components: aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide, and the far-infrared additive; and the far-infrared additive is prepared from the components: kaolin, feldspar, quartz, nano tourmaline, zirconium carbide, and zirconium dioxide. The far-infrared ceramic tile has the advantages that the ceramic tile is enabled to have a far-infrared transmitting function.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

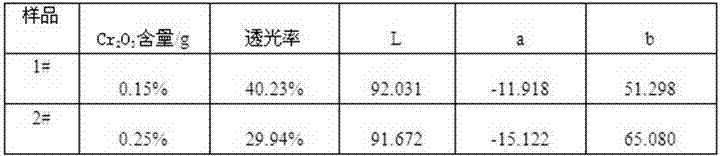

Manufacturing process of high-brightness chromium-containing glass

InactiveCN103395986BIncrease brightnessDoes not destroy macroscopic uniformityLead nitrateLithium carbonate

The invention relates to a manufacturing process of high-brightness chromium-containing glass. The manufacturing process comprises the following steps of: (1) taking silica sand, dolomite, limestone, albite, lithium carbonate, sodium nitrate and lead nitrate, mixing, uniformly stirring, then adding potassium dichromate, and then stirring uniformly to obtain glass batch; (2) melting; (3) carrying out secondary crystallization on the glass; and (4) cooling and forming to obtain a glass product. The process method of the chromium-containing glass manufactured by the invention has the advantages that by selection of a reasonable glass material formula and strict control for the heating rate in the melting process, the glass batch can be fully melted, the operation of twice crystallization is adopted, the manufactured chromium-containing glass is high in brightness and looks more sparkling, and the problem of poor brightness of the chromium-containing glass is solved.

Owner:LUOYANG INST OF SCI & TECH

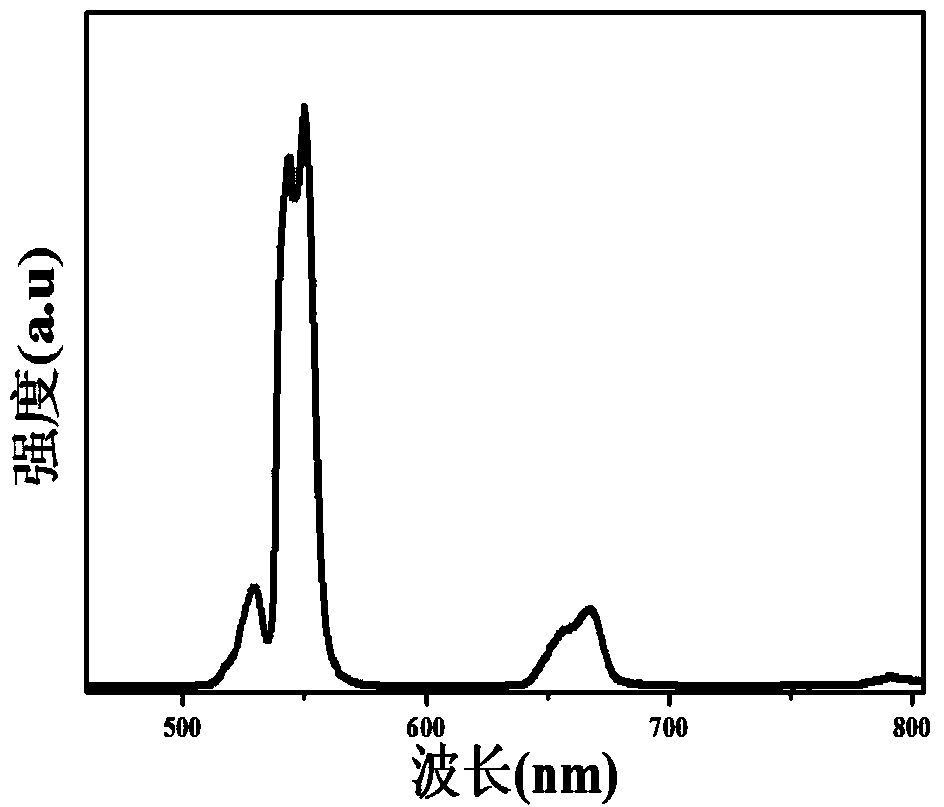

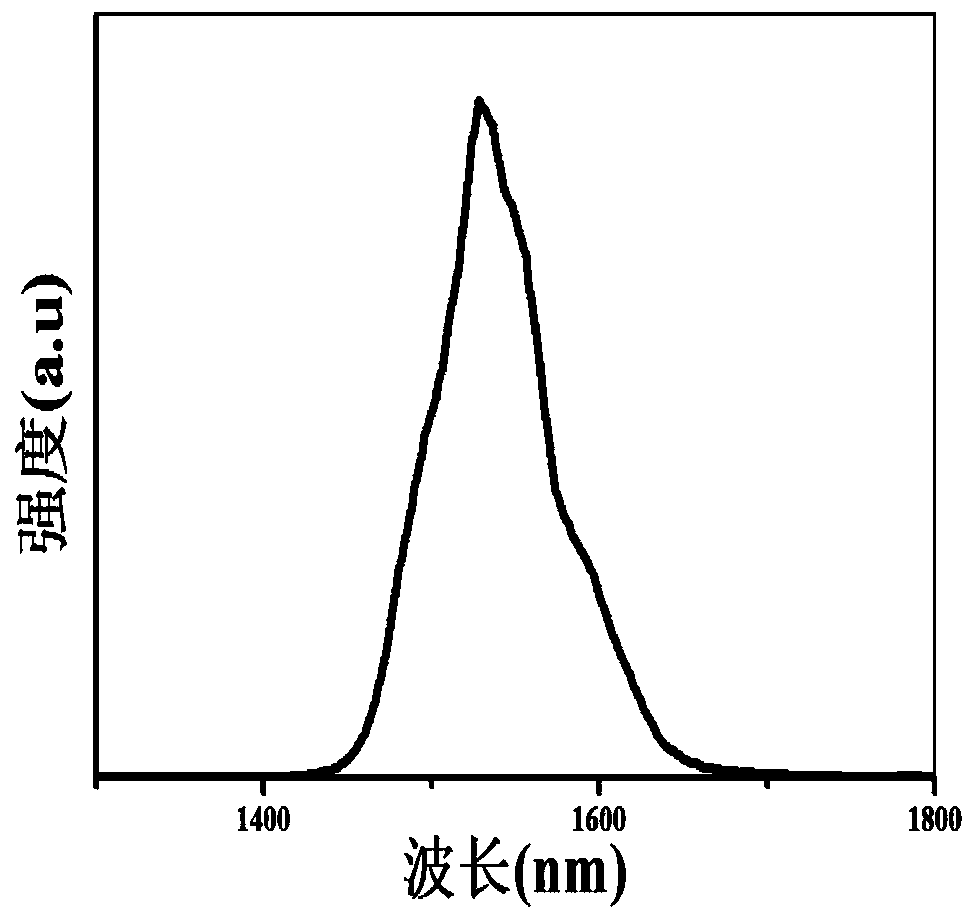

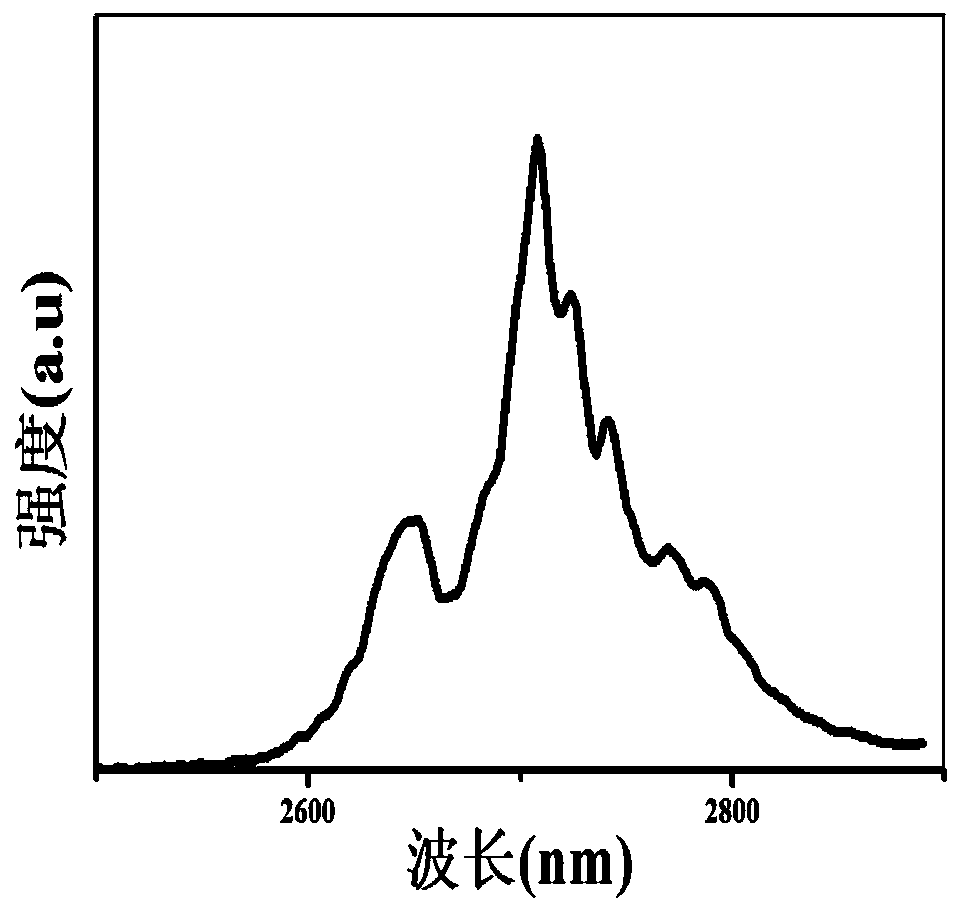

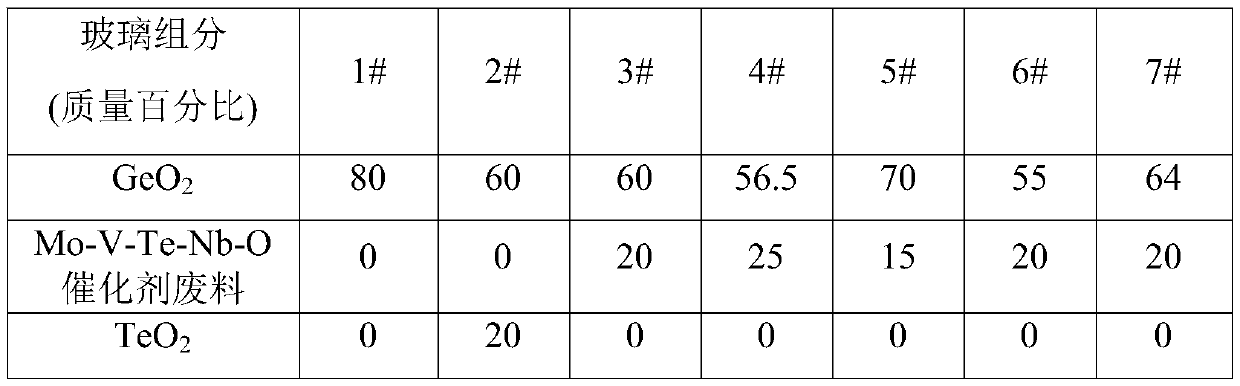

A YB-sensitized environment-friendly germanium tellurate luminescent glass and its preparation method

The invention belongs to the technical field of material science, and particularly relates to Yb-sensitized environment-friendly germanium tellurite luminescent glass and a preparation method of the luminescent glass. The glass is prepared from the following raw materials: GeO2, a Mo-V-Te-Nb-O catalyst waste material, Na2O, BaF2, YbF3 or Yb2O3, and MF3 or M2O3, wherein the M is a rare-earth light-emitting ion. According to the invention, the Mo-V-Te-Nb-O catalyst waste material is used for replacing tellurium oxide, and the problem that the mechanical property of the germanium tellurite glassis reduced due to the tellurium oxide can be effectively improved while the melting temperature is reduced. Good visible, near-infrared and mid-infrared fluorescent lights can be obtained by using theobtained rare-earth-doped environment-friendly germanium tellurite glass under the pumping of a laser diode with a wavelength of 980 nm, and meanwhile, the physical and chemical properties are excellent, the thermal stability is good, the parameter delta T is larger than or equal to 170 DEG C, and the Vickers hardness of the glass is larger than 680 kgf / mm<2>.

Owner:CHINA JILIANG UNIV

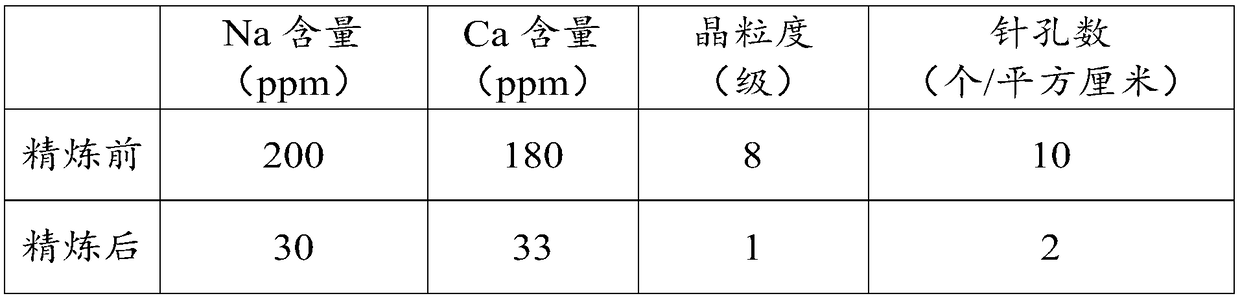

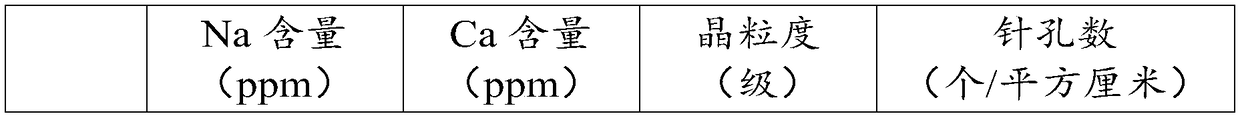

Flux for refining aluminum and aluminum alloy melts and method for refining aluminum and aluminum alloy melts

The invention provides a flux for aluminum and aluminum alloy melt refining as well as an aluminum and aluminum alloy melt refining method, and relates to the technical field of aluminum and aluminum alloy melt treatment. The flux comprises a first flux body which comprises the following components in percentage by mass: 10-20% of an alkali metal fluoroaluminate, 20-40% of an alkali metal chloride, 20-40% of an alkali metal carbonate, 5-10% of an alkali metal fluoroborate and 10-20% of a halide used for removing alkali metal, wherein the alkali metal chloride comprises NaCl and / or KCl; the alkali metal carbonate comprises Na2CO3 and / or K2CO3; the alkali metal fluoroborate comprises NaBF4 and / or KBF4; and the alkali metal halide comprises MgCl2 and / or AlF3. According to the aluminum and aluminum alloy melt refining method provided by the invention, the above flux is sprayed into an aluminum and aluminum alloy melt by adopting N2 as a carrier; and the flux can adsorb and dissolve alumina inclusions of the aluminum and aluminum alloy melt, and refine crystal grains.

Owner:SHANDONG NANSHAN ALUMINUM +1

Casting powder for PSB830 steel cast blank and preparation method of casting powder

The invention relates to the field of steelmaking, and discloses casting powder for a PSB830 steel cast blank and a preparation method of the casting powder. The casting powder is prepared from basisslag, a cosolvent and a melting rate modifier, wherein the basis slag is prepared from CaO and SiO2, the cosolvent is prepared from Al2O3, MgO, F and Na2O; and the melting rate modifier is prepared from C. The problem of cast blank surface indentation defects commonly present in current PSB830 finish-rolled threaded steel is solved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Instant dissolving cemented carbide block and its preparation method and use

The invention discloses an instantly soluble hard alloy block and a preparation method and application thereof. The instantly soluble hard alloy block is made from materials in following percent by weight by binding with an adhesive: 25-35% of high carbon ferro-chrome, 0.5-1%. of rare earth, 15-40% of ferro-boron, 25-55% of ferro-vanadium, 2-6% of ferrosilicon, and 2-3% of ferronickel, wherein the adhesive is a resin adhesive. The instantly soluble hard alloy block has high hardness (Rockwell hardness HRC > / =73), good wear resistance, manufacture process simplicity, low cost, low surfacing current, convenience of selecting dimensions and shape, low time and labor consumption for a welder, etc., the problem that a quick-wear apparatus is short in life is solved, and the life of an original member is prolonged by 3-10 times.

Owner:苑俊奎

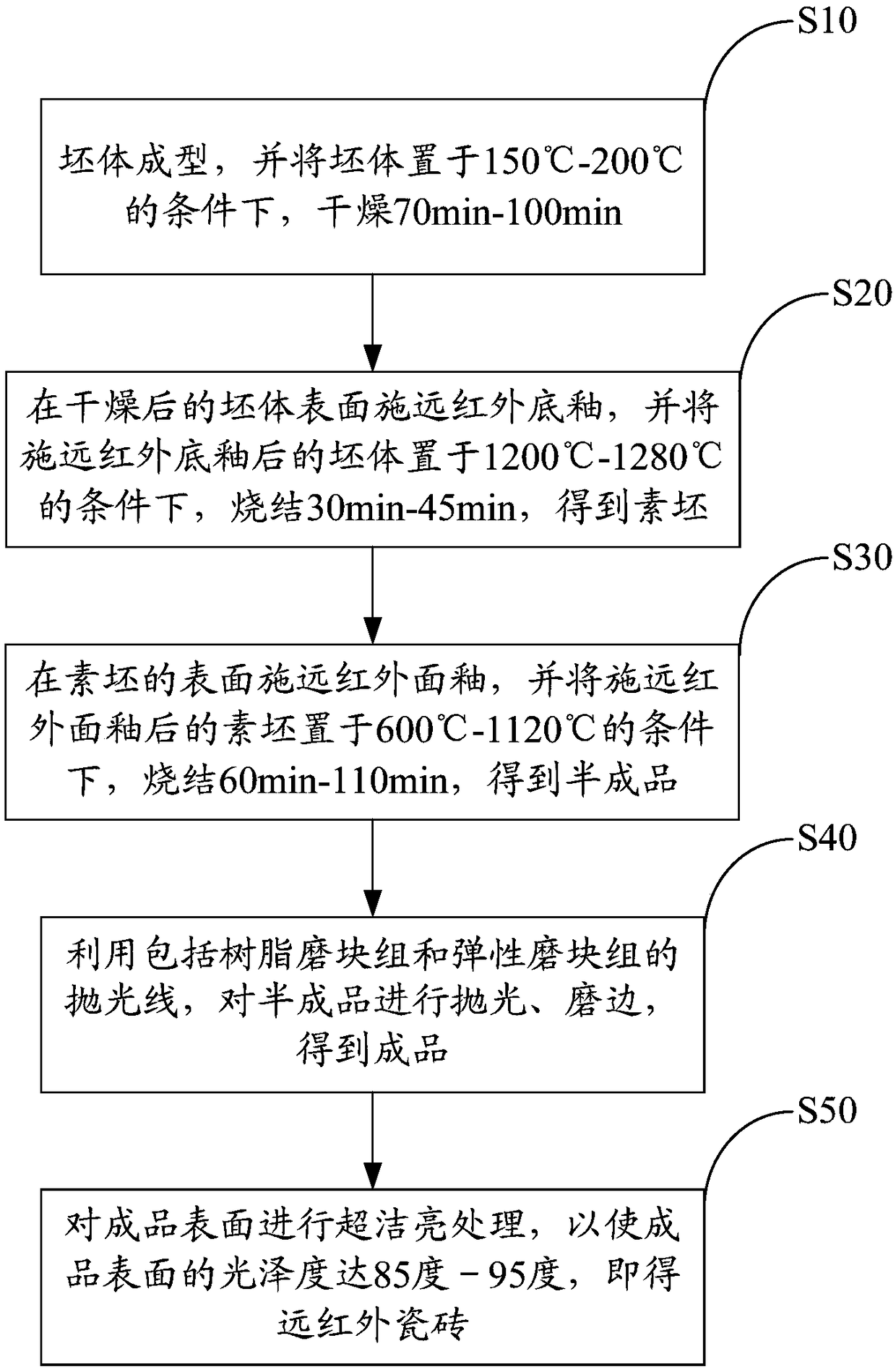

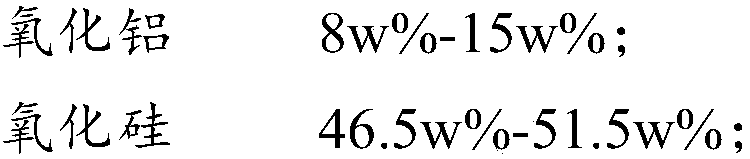

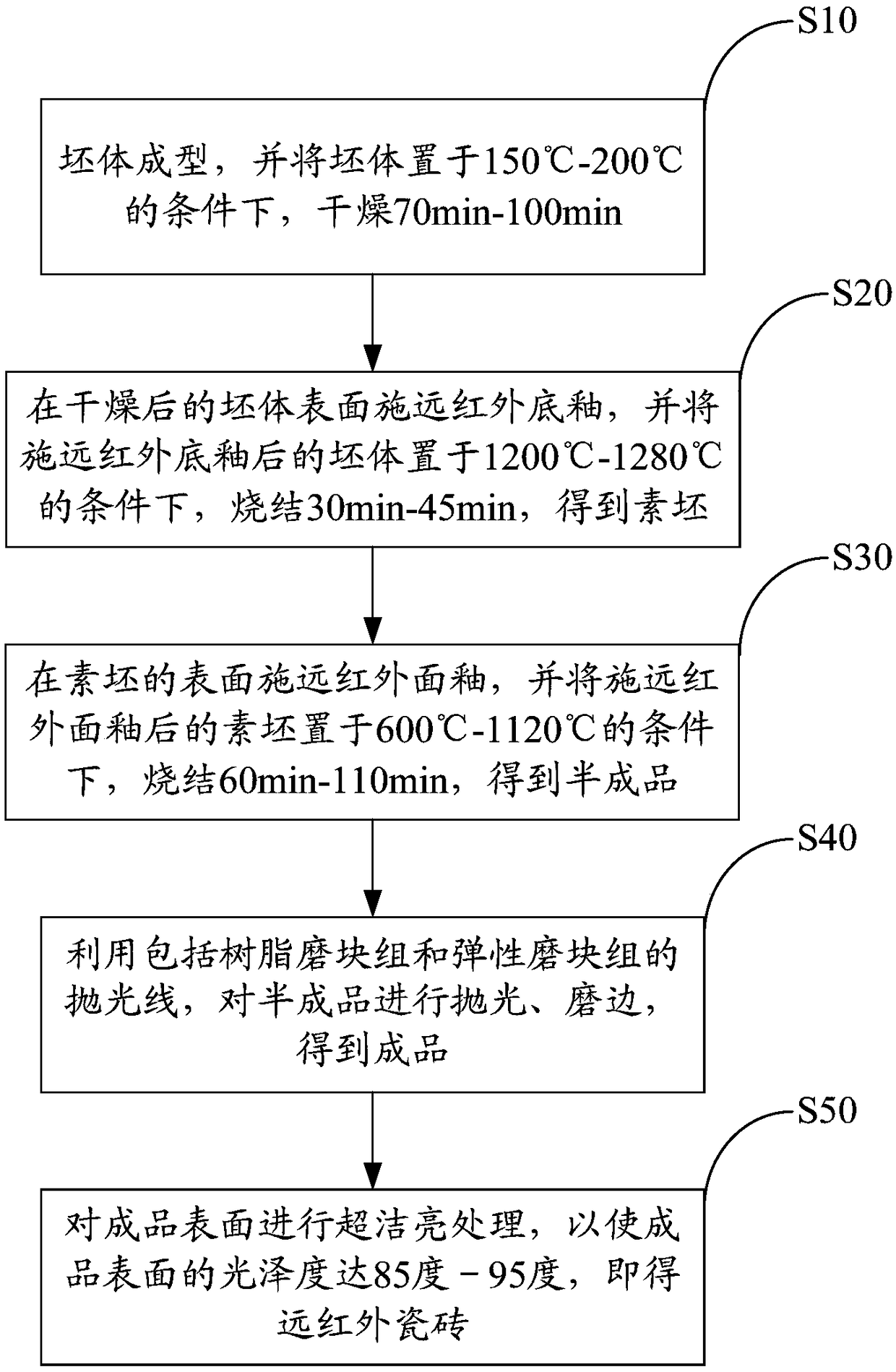

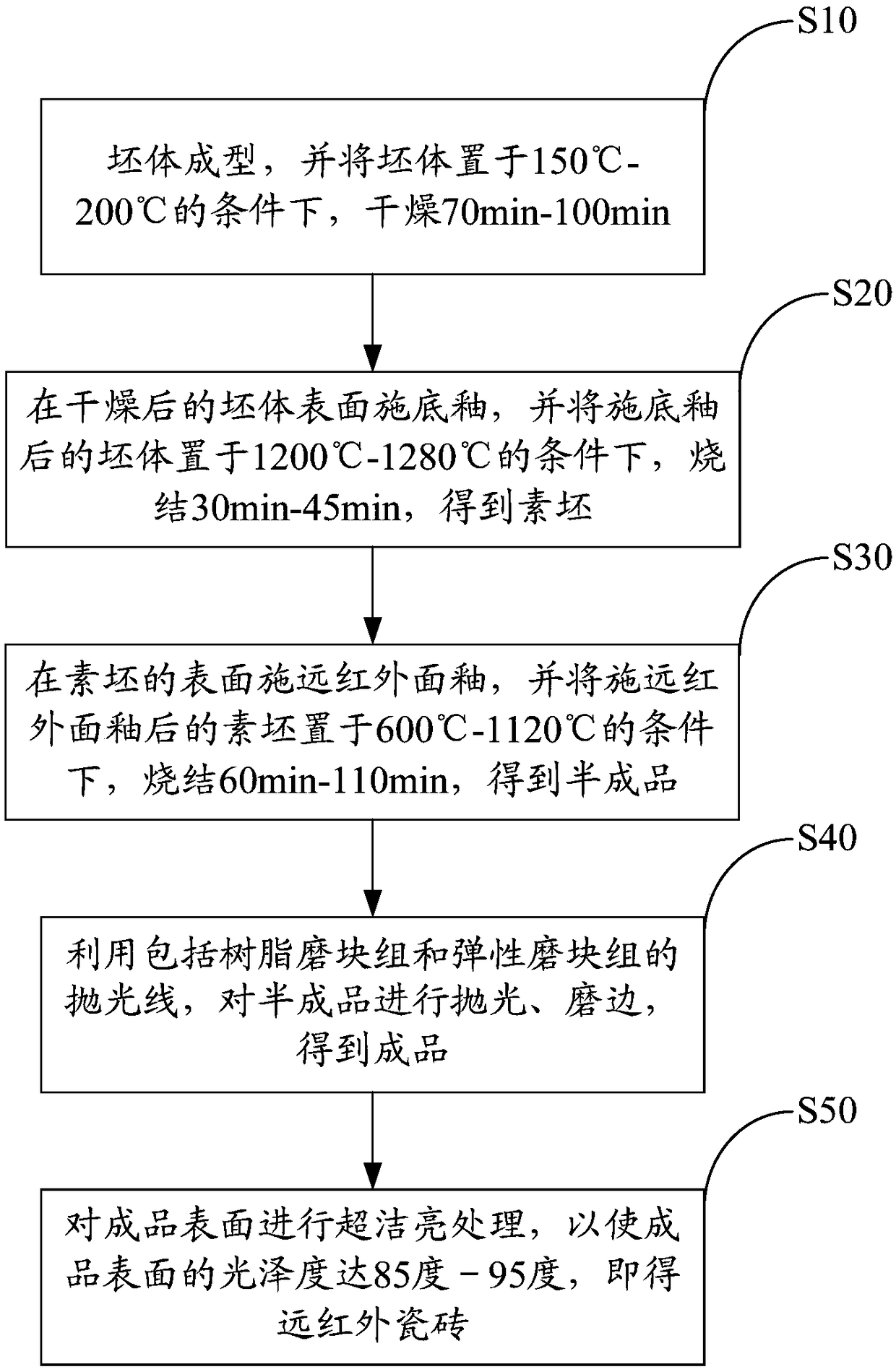

Preparation method of far-infrared ceramic tile

InactiveCN108689606AWith far infrared emission functionExcellent far-infrared emissionSilicon oxideFar infrared

The invention discloses a preparation method of a far-infrared ceramic tile. The preparation method comprises the following steps of forming a blank, and drying; applying bottom glaze to the surface of the dried blank, and sintering the blank after applying of bottom glaze for 30 to 45min at the temperature of 1200 to 1280 DEG C, so as to obtain a plain blank; applying far-infrared surface glaze to the surface of the plain blank, and sintering the blank after applying of far-infrared surface glaze for 60 to 110min at the temperature of 600 to 1120 DEG C, so as to obtain a semi-finished product; polishing the semi-finished product, and grinding edges, so as to obtain a finished product; performing super-bright treatment on the surface of the finished product, so as to obtain the far-infrared ceramic tile, wherein the far-infrared surface glaze comprises the following components of aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide,and the far-infrared additive; the far-infrared additive comprises the following components of kaolin, feldspar, quartz, nanometer tourmaline, zirconium carbide, and zirconium dioxide. By adopting the technical scheme, the prepared far-infrared ceramic tile is characterized in that the far-infrared ray transmission function is realized.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

Chrome-containing glass component

InactiveCN103395987BIncrease brightnessDoes not destroy macroscopic uniformityLead nitrateLithium carbonate

The invention relates to a chrome-containing glass component. The glass component comprises the following ingredients in percentage by weight: 70.5-71.8% of SiO2, 7.4-8.0% of CaO, 4.0-4.6% of MgO, 0.1-0.14% of Fe2O3, 0.8-1.0% of Al2O3, 4.6-5.0% of Li2O, 0.07-0.08% of K2O, 9.9-9.94% of Na2O, 0.43-0.47% of PbO and 0.10-0.35% of Cr2O. The chrome-containing glass component comprises the following raw materials, namely, silica sand, dolomite, limestone, albite, lithium carbonate, sodium nitrate, lead nitrate and potassium dichromate. The chrome-containing glass component which is prepared according to the formula is bright and sparkling in appearance, and is particularly applicable to manufacturing of jadeite imitations.

Owner:LUOYANG INST OF SCI & TECH

Chrome-containing glass component

InactiveCN103395987AIncrease brightnessDoes not destroy macroscopic uniformityLead nitrateLithium carbonate

The invention relates to a chrome-containing glass component. The glass component comprises the following ingredients in percentage by weight: 70.5-71.8% of SiO2, 7.4-8.0% of CaO, 4.0-4.6% of MgO, 0.1-0.14% of Fe2O3, 0.8-1.0% of Al2O3, 4.6-5.0% of Li2O, 0.07-0.08% of K2O, 9.9-9.94% of Na2O, 0.43-0.47% of PbO and 0.10-0.35% of Cr2O. The chrome-containing glass component comprises the following raw materials, namely, silica sand, dolomite, limestone, albite, lithium carbonate, sodium nitrate, lead nitrate and potassium dichromate. The chrome-containing glass component which is prepared according to the formula is bright and sparkling in appearance, and is particularly applicable to manufacturing of jadeite imitations.

Owner:LUOYANG INST OF SCI & TECH

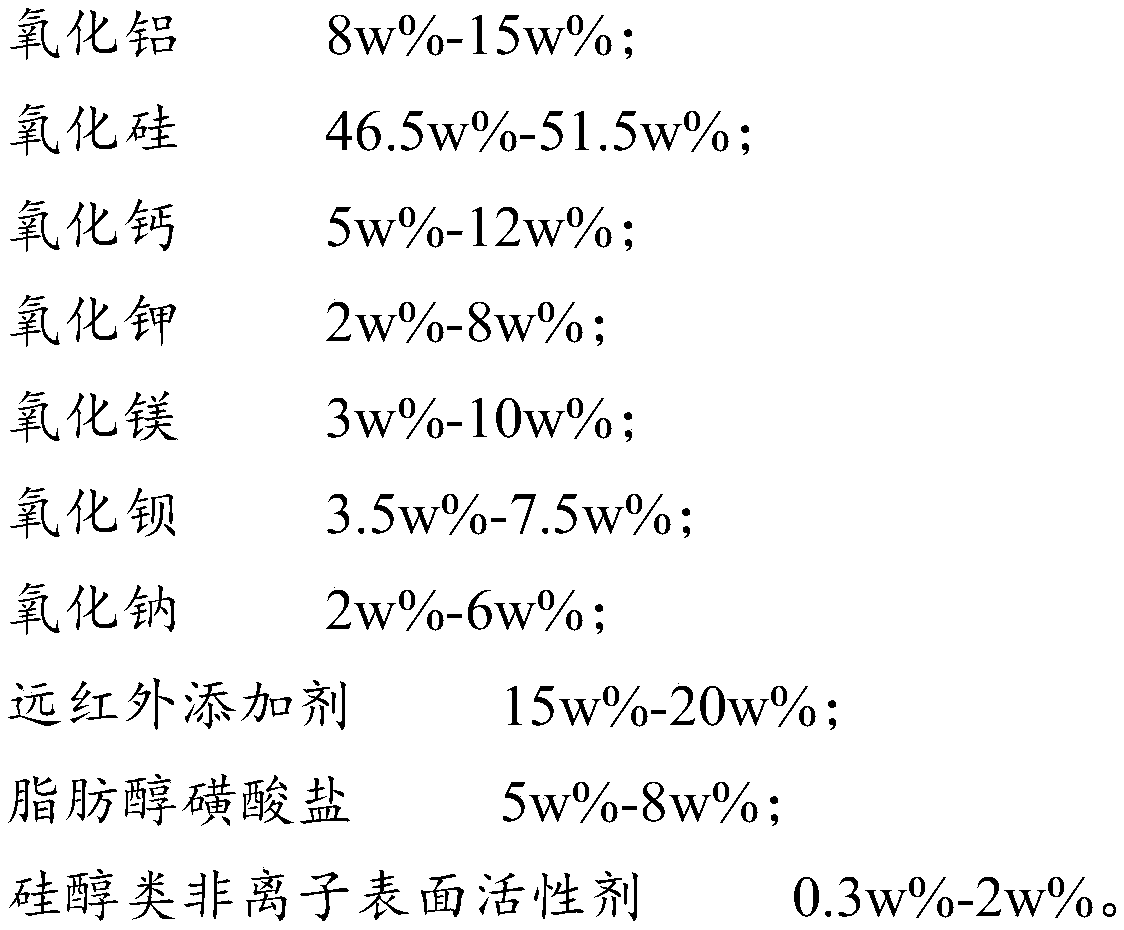

Preparation method of far-infrared ceramic tile

The invention discloses a preparation method of a far-infrared ceramic tile. The preparation method comprises the following steps of forming a blank, and drying; applying far-infrared bottom glaze tothe surface of the dried blank, and sintering, so as to obtain a biscuit; applying far-infrared surface glaze to the surface of the biscuit, and sintering, so as to obtain a semi-finished product; polishing the semi-finished product, and grinding edges, so as to obtain a finished product; performing super-bright treatment on the surface of the finished product, so as to obtain the far-infrared ceramic tile, wherein the far-infrared bottom glaze comprises the following components of aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, far-infrared additive, styrene and trisiloxane glycol; the far-infrared surface glaze comprises the following components of aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide, far-infrared additive, styrene, and trisiloxane glycol. By adopting the technical scheme, the prepared far-infrared ceramic tile has the far-infrared ray transmission function.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

A kind of alloying element additive for aluminum alloy production and preparation method thereof

Disclosed is an alloy element additive used for aluminum alloy production. The alloy element additive is composed of alloy element powder to be added, mgcl2-group fusion powder and an adhesive. The components comprise, by mass, 70%-90% of the alloy element powder, 10%-30% of the mgcl2-group fusion powder and 0-5% of the adhesive. The sum of the mass percents of the three components is 100%. Alloy elements are organically combined with a refining agent, so that the alloy element additive not only has an alloying function, but also has a refining effect. According to the alloy element additive and a preparation method thereof, mgcl2-group fusion serves as a fusing agent, so that not only is the fusing function to the alloy element powder achieved, but also the refining function to aluminum water is achieved, and accordingly the agent is multipurpose indeed. The alloy element additive does not contain toxic substances, thereby being safe and environmentally friendly

Owner:SHENYANG AEROSPACE UNIVERSITY

Preparation method of foam glass

The invention discloses a preparation method of foam glass, relating to the technical field of building materials. The preparation method adopts the following raw materials in parts by weight: cathode-ray tube, pearlite, calcium carbonate, mirabilite, foaming accelerant, foam stabilizer and borax. The preparation method comprises the following steps: A, separating a glass shell of the cathode-ray tube; B, mixing the glass shell, the perlite, the calcium carbonate, the mirabilite and the borax to obtain a mixture, and grinding the mixture in a ball mill to obtain powder; C, filtering the powder by virtue of a screen; D, uniformly mixing the powder, the foaming accelerant and the foam stabilizer, and placing the mixture into a mold; E, placing the mold into a kiln, and preheating; F, after the preheating is ended, heating the kiln; and G, annealing the kiln, and taking out the mold after the annealing. Compared with the prior art, the problem of environmental pollution caused by the abandoned waste cathode-ray tube can be solved.

Owner:广西丛欣实业有限公司

A kind of ND-sensitized environment-friendly germanium tellurate luminescent glass and preparation method thereof

The invention belongs to the technical field of material science and in particular relates to Nd-sensitized environmental-friendly germanium tellurite luminescent glass and a preparation method thereof. The glass is prepared from the following raw material components: GeO2, Mo-V-Te-Nb-O catalyst waste, Na2O, BaF2, NdF3 or Nd2O3, and MF3 or M2O3, wherein M refers to a rare earth luminescent ion. The tellurium oxide is replaced with the Mo-V-Te-Nb-O catalyst waste, and the problem that the mechanical property of germanium tellurite is reduced by tellurium oxide can be effectively improved when the melting temperature is reduced, so that the obtained rare-earth doped environmental-friendly germanium tellurite glass can obtain good visible, near-infrared and mid-infrared fluorescence under laser diode pumping with the wavelength of 808nm. Meanwhile, the physical and chemical properties are excellent, the thermal stability is high, the parameter Delta T is more than or equal to 170 DEG C, and the Vickers hardness of the glass is more than 680 kgf / mm<2>.

Owner:CHINA JILIANG UNIV

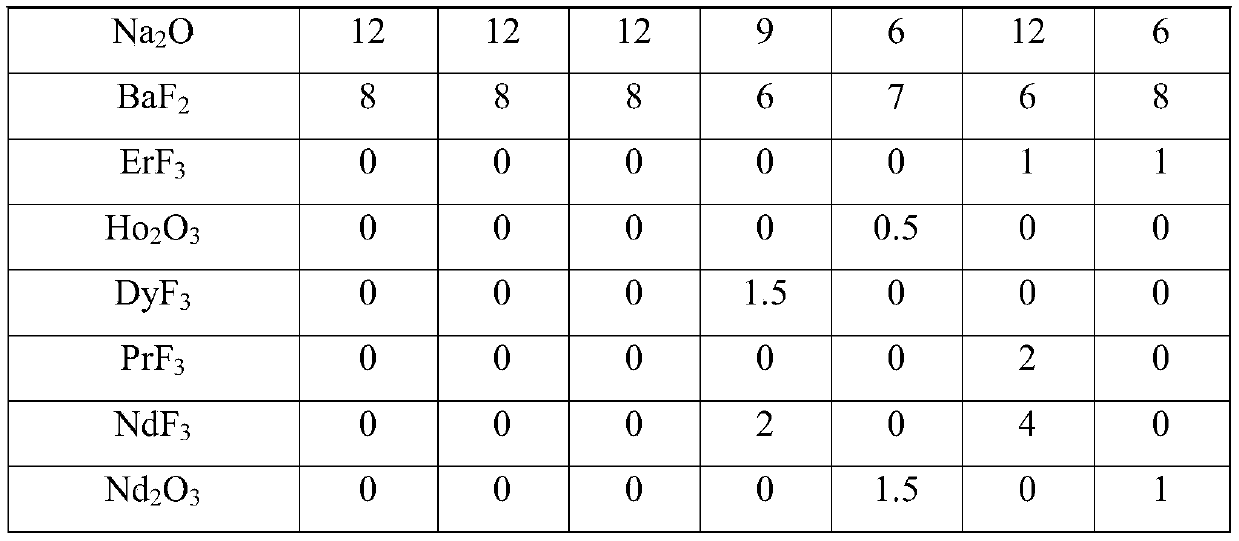

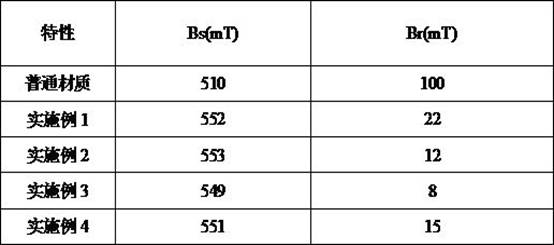

Manganese zinc ferrite core with high saturation magnetic flux density and preparation method thereof

ActiveCN110335732BReduce the amount of impuritiesUniform physical and chemical reactionsInorganic material magnetismMagnetic core manufactureManganese oxideSilicon dioxide

The invention discloses a manganese-zinc ferrite magnetic core with high saturation magnetic flux density and a preparation method thereof, belonging to the technical field of magnetic materials. Thepreparation method of the manganese-zinc ferrite magnetic core adopts manganese powder, zinc oxide powder, silicon dioxide, calcium oxide, vanadium pentoxide and ferrous powder as raw materials. The preparation method comprises the steps of: performing synthetic reaction on manganese powder, zinc oxide powder and ferrous powder with hydrochloric acid and liquid ammonia in sequence; and performingpresintering, doping and ball milling, press forming, sintering treatment and air gap cutting treatment to obtain a manganese-zinc ferrite magnetic core. According to the invention, ferrous powder, manganese powder, zinc oxide powder and the like are used as initial raw materials, and the ferrous powder, the manganese powder and the zinc oxide powder are subjected to synthetic reaction and pre-sintering treatment with hydrochloric acid and liquid ammonia in sequence, so that ferric oxide, manganese oxide and zinc oxide with less impurity content can be obtained, and the subsequent sintering treatment can enable the physicochemical reaction of each component to be uniform, thereby achieving the purposes of reducing the porosity of the magnetic core, improving the density of the magnetic core and improving the saturation magnetic flux density.

Owner:湖南艾迪奥电子科技有限公司

Preparation method of far infrared ceramic tile

InactiveCN108752055AWith far infrared emission functionExcellent far-infrared emissionFar infraredBarium peroxide

The invention discloses a preparation method of a far infrared ceramic tile. The preparation method of the far infrared ceramic tile comprises the following steps: forming and drying a body; applyinga ground coat on the surface of the dried body, and sintering, to obtain a green body; applying a far infrared cover coat on the surface of the green body, and sintering, to obtain a semi-finished product; polishing and edging the semi-finished product to obtain a finished product; conducting super clean and bright treatment on the surface of the finished product, to obtain the far infrared ceramic tile. The far infrared cover coat comprises the components of aluminum oxide, silicon dioxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide, a far infrared additive, styrene, and trisiloxane ethylene glycol; the far infrared additive comprises the components of kaolin, feldspar, quartz, nano-tourmaline, zirconium carbide, and zirconium dioxide. Due to the technicalscheme, the ceramic tile has the function of transmitting far infrared rays.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Preparation method of far-infrared ceramic tile

InactiveCN108689604AImproves strength and stabilityReduce the possibilityPotassium oxideTransmission function

The invention discloses a preparation method of a far-infrared ceramic tile. The preparation method comprises the following steps of forming a blank, and drying; applying far-infrared bottom glaze tothe surface of the dried blank, and drying; applying far-infrared surface glaze to the surface of the far-infrared bottom glaze after drying, and drying; firing, so as to obtain a semi-finished product; polishing the semi-finished product, and grinding edges, so as to obtain a finished product; performing super-bright treatment on the surface of the finished product, so as to obtain the far-infrared ceramic tile, wherein the far-infrared bottom glaze comprises is prepared from the following components of aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, far-infrared additive, styrene and trisiloxane glycol; the far-infrared surface glaze is prepared from the following components of aluminum oxide, silicon oxide, calcium oxide, potassium oxide, magnesium oxide, barium oxide, sodium oxide, far-infrared additive, styrene, and trisiloxane glycol. By adopting the technical scheme, the prepared far-infrared ceramic tile has the far-infrared ray transmission function.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com