Manufacturing process of high-brightness chromium-containing glass

A production process and high-brightness technology, applied in the field of glass production, can solve problems such as insufficient brightness of chrome-containing glass, and achieve the effect of solving insufficient brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

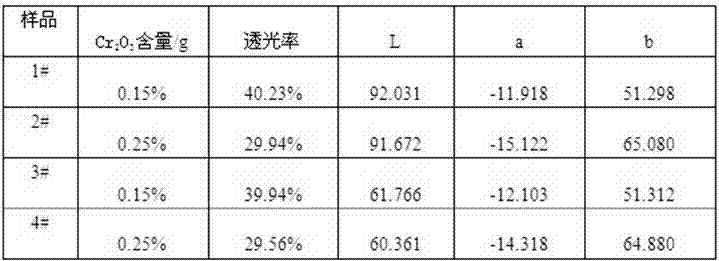

Embodiment 1

[0022] A manufacturing process of high-brightness chromium-containing glass, said process comprising the following steps:

[0023] (1) Making glass batch materials: Mix silica sand, dolomite, limestone, albite, lithium carbonate, sodium nitrate and lead nitrate and mix them evenly, then add potassium dichromate and stir evenly again to obtain glass batch materials. Each component in the obtained glass batch is represented by weight percent as oxide: SiO 2 71.35%, CaO 7.83%, MgO 4.4%, Fe 2 o 3 0.12%, Al 2 o 3 0.9%, Li 2 O 4.8%, K 2 O 0.08%, Na 2 O 9.92%, PbO 0.45% and Cr 2 o 3 0.15%.

[0024] (2) Melting: Weigh 200 grams of the prepared glass batch material, put it into a corundum crucible with a size of 80mm × 120mm, and place the crucible in a SGM3816C box-type resistance furnace for melting test. Heating is controlled to raise the temperature to 1580°C over 5 hours, and kept at this temperature for 2 hours to obtain molten glass;

[0025] (3) Crystallization: ...

Embodiment 2

[0028] A manufacturing process of high-brightness chromium-containing glass, said process comprising the following steps:

[0029] (1) Making glass batch materials: Mix silica sand, dolomite, limestone, albite, lithium carbonate, sodium nitrate and lead nitrate and mix them evenly, then add potassium dichromate and stir evenly again to obtain glass batch materials. Each component in the obtained glass batch is represented by weight percent as oxide: SiO 2 71.55%, CaO 7.5%, MgO 4.6%, Fe 2 o 3 0.12%, Al2 o 3 0.9%, Li 2 O 4.6%, K 2 O 0.07%, Na 2 O 9.94%, PbO 0.47% and Cr 2 o 3 0.25%;

[0030] (2) Melting: Weigh 200 grams of the prepared glass batch material, put it into a corundum crucible with a size of 80mm × 120mm, and place the crucible in a SGM3816C box-type resistance furnace for melting test. Heating is controlled to raise the temperature to 1580°C over 5 hours, and kept at this temperature for 2 hours to obtain molten glass;

[0031] (3) Crystallization: Tak...

Embodiment 3

[0034] A manufacturing process of high-brightness chromium-containing glass, said process comprising the following steps:

[0035] (1) Making glass batch materials: Mix silica sand, dolomite, limestone, albite, lithium carbonate, sodium nitrate and lead nitrate and mix them evenly, then add potassium dichromate and stir evenly again to obtain glass batch materials. Each component in the obtained glass batch is represented by weight percent as oxide: SiO 2 70.5%, CaO 7.96%, MgO 4.6%, Fe 2 o 3 0.1%, Al 2 o 3 1%, Li 2 O 5%, K 2 O 0.08%, Na 2 O 9.94%, PbO 0.47% and Cr 2 o 3 0.35%;

[0036] (2) Melting: Weigh 200 grams of the prepared glass batch material, put it into a corundum crucible with a size of 80mm × 120mm, and place the crucible in a SGM3816C box-type resistance furnace for melting test. Heating is controlled to raise the temperature to 1580°C over 5 hours, and kept at this temperature for 2 hours to obtain molten glass;

[0037] (3) Crystallization: Take o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com