Preparation method for doped and modified spinel-type lithium manganite cathode material

A type of lithium manganate and spinel technology, which is applied in the field of secondary battery cathode material preparation, can solve the problems of increased reaction time, poor cycle performance and thermal stability, and unstable product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

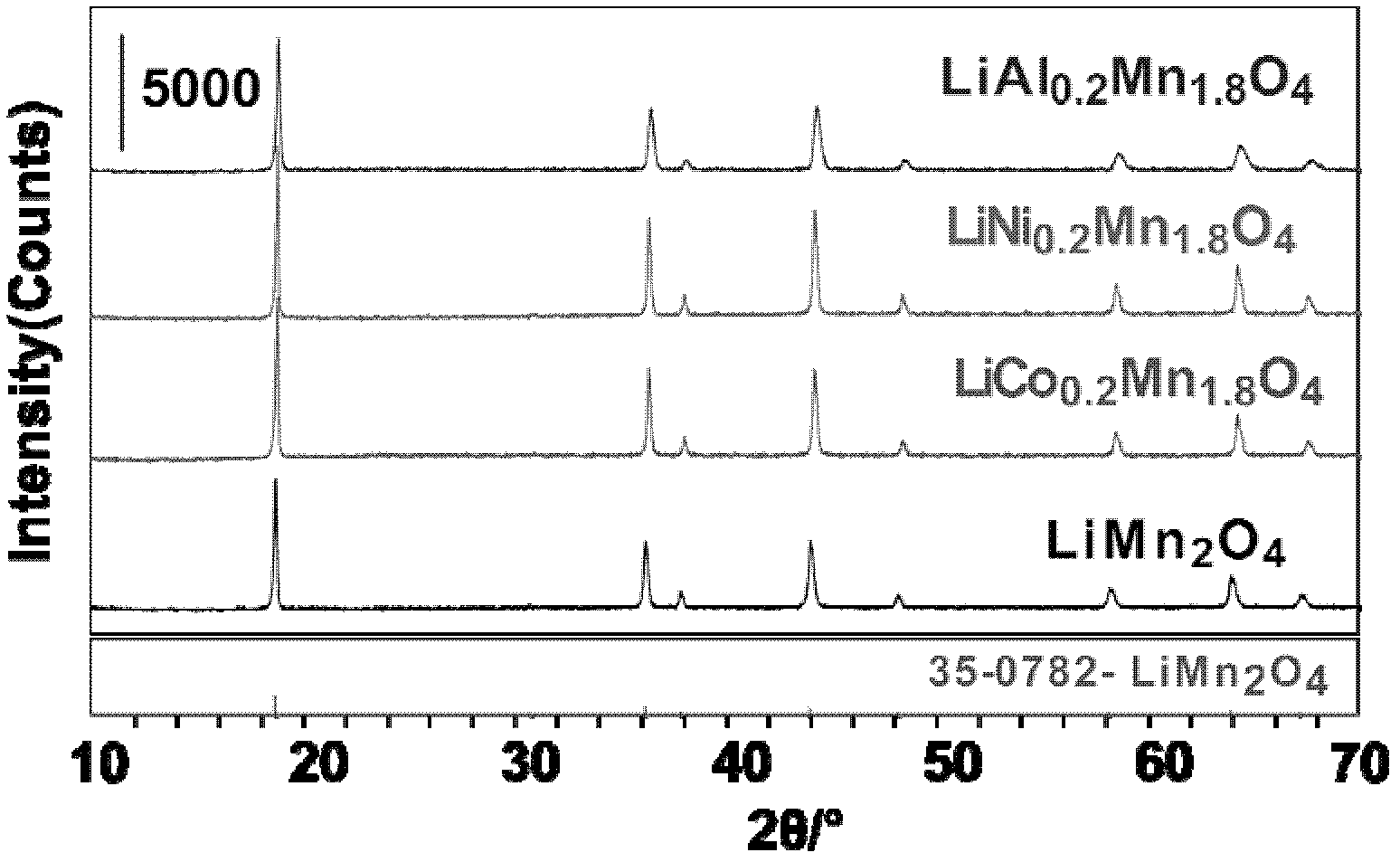

[0030] In order to solve the above problems, the invention provides a method for preparing doped modified spinel lithium manganate, comprising:

[0031] mixing the lithium source compound, the manganese source compound, the doping metal salt and the roasting accelerator to obtain a mixture;

[0032]Roasting the mixture to obtain doped modified spinel lithium manganese oxide;

[0033] Wherein, the roasting accelerator includes: one or more of acetylene black, activated carbon powder, coke powder, and charcoal powder.

[0034] According to the present invention, the manganese source compound can refer to any manganese source compound known to those skilled in the art, preferably one or more of manganese nitrate, manganese chloride, manganese acetate, manganese sulfate or manganese carbonate, but not limited to this. The lithium source compound may refer to any lithium source compound known to those skilled in the art, preferably one or more of lithium nitrate, lithium chloride...

Embodiment 1

[0044] The embodiment is to carry out doping according to the feed ratio Li:Mn=1.2:2 (molar ratio).

[0045] Take by weighing 6.4420g mass fraction and be 50% Mn (NO 3 ) 2 solution, add 0.5093g LiCl and stir to dissolve it. Add 0.4289g AlCl 3 , continue to stir to dissolve it, then add 0.25g of acetylene black, stir evenly, and bake in an oven at 70°C for about 12 hours.

[0046] After the mixture was taken out from the oven, it was calcined in a resistance furnace at 800°C for 2h, cooled to room temperature, washed with water, and dried at 70°C to obtain an Al-doped spinel sample.

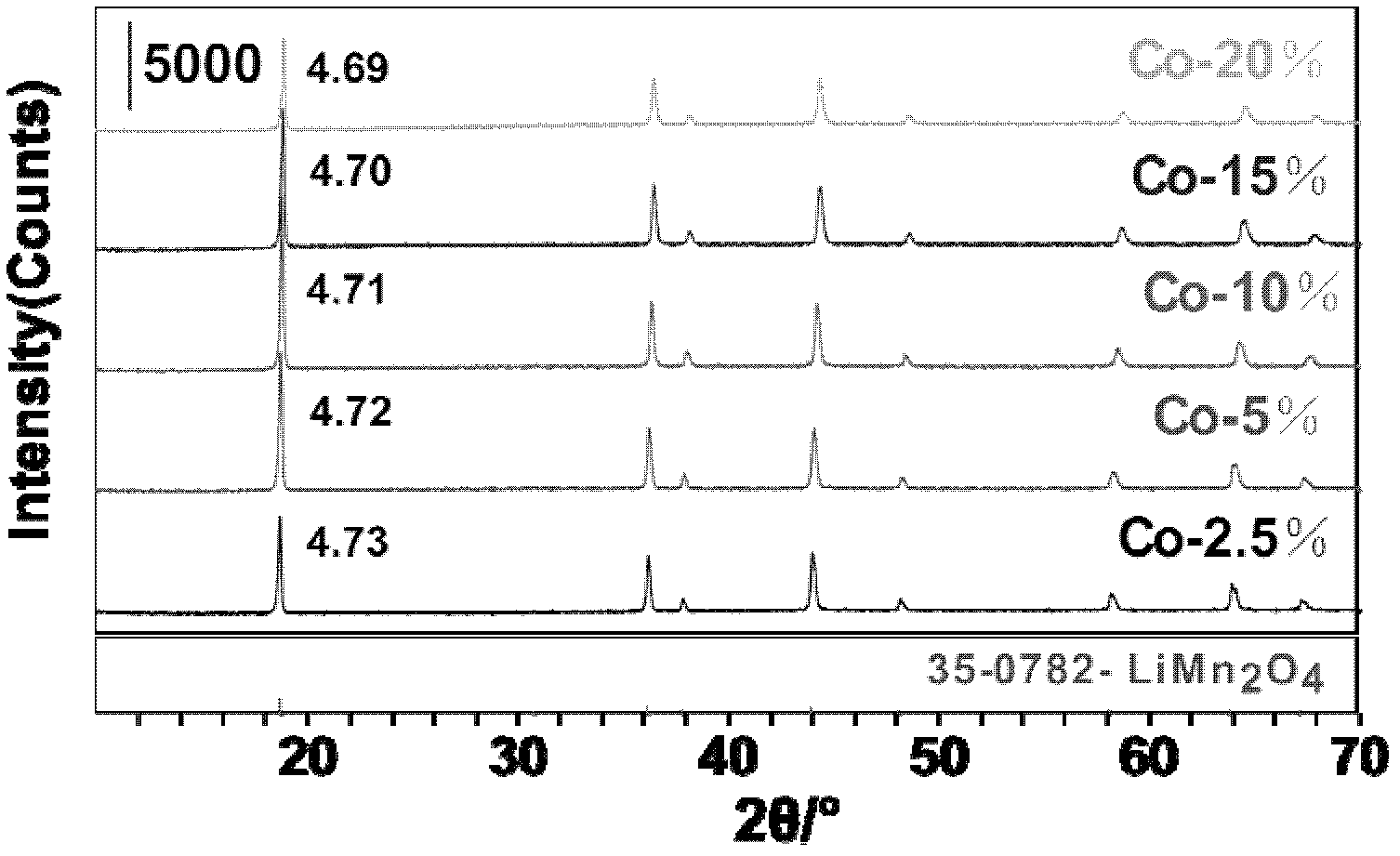

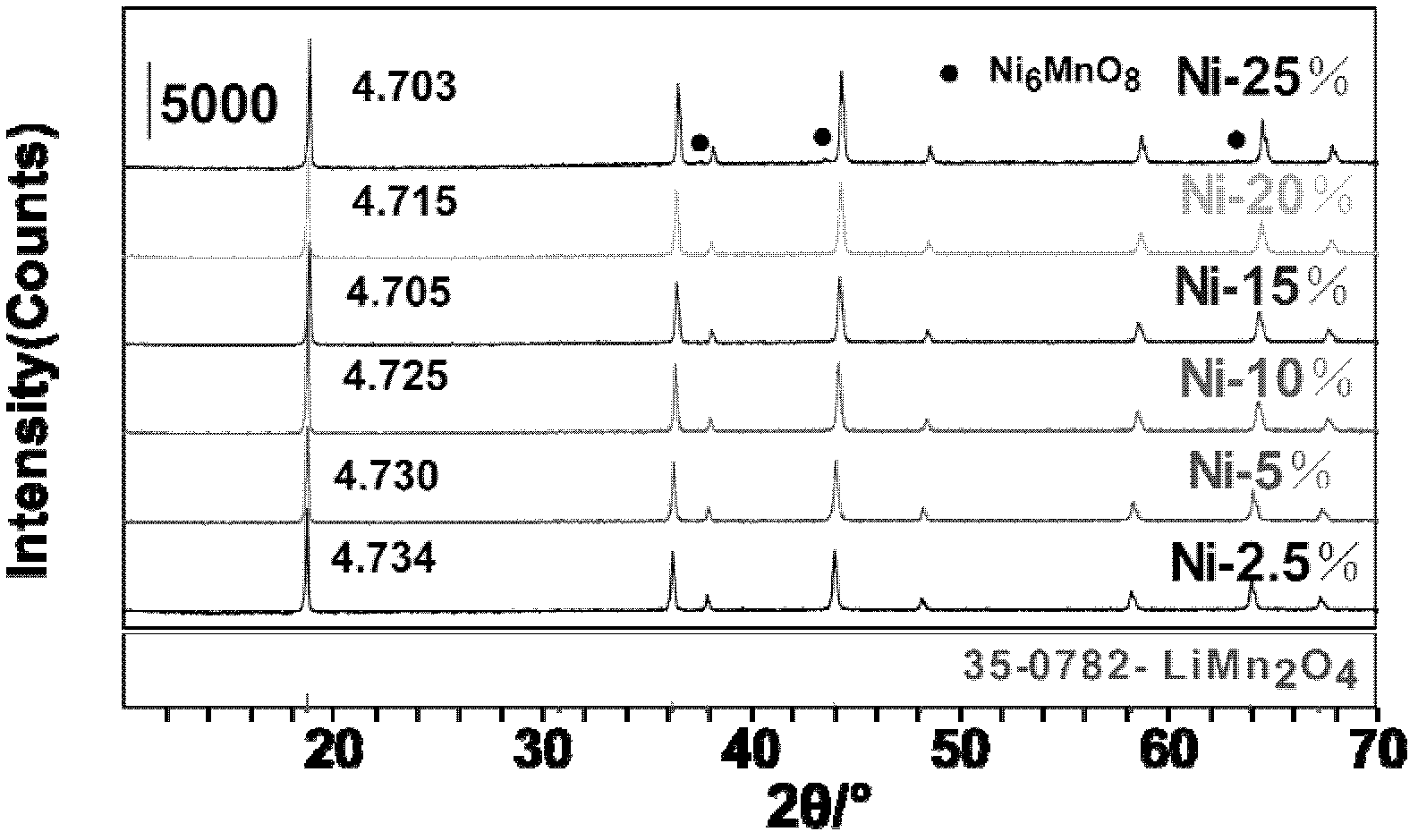

Embodiment 2

[0048] The embodiment is to carry out doping according to the feed ratio Li:Mn=1.2:2 (molar ratio).

[0049] Take by weighing 6.4420g mass fraction and be 50% Mn (NO 3 ) 2 solution, add 0.5093g LiCl and stir to dissolve it. Add 0.5816g Ni(NO 3 ) 2 , continue to stir to dissolve it, then add 0.25g of acetylene black, stir evenly, and bake in an oven at 70°C for about 12 hours.

[0050] After the mixture was taken out from the oven, it was calcined in a resistance furnace at 800°C for 2h, cooled to room temperature, washed with water, and dried at 70°C to obtain a Ni-doped spinel sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com