Wide-spectrum high-absorption-rate black glass and preparation method and application thereof

A technology of black glass and absorption rate, which is applied in the field of wide-spectrum high-absorption black glass and its preparation, can solve the problems of endangering the safety of people's lives and property, occupying large land, and cumbersome processes, etc., and achieve the realization of waste utilization and reduction of raw materials The effect of simple cost and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

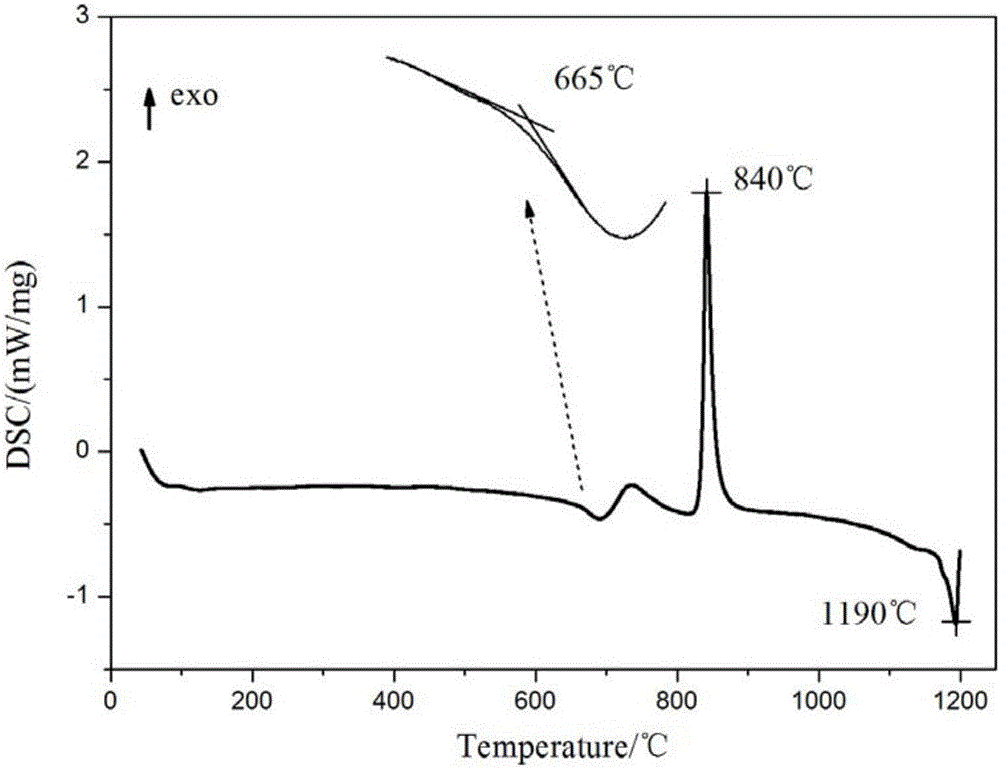

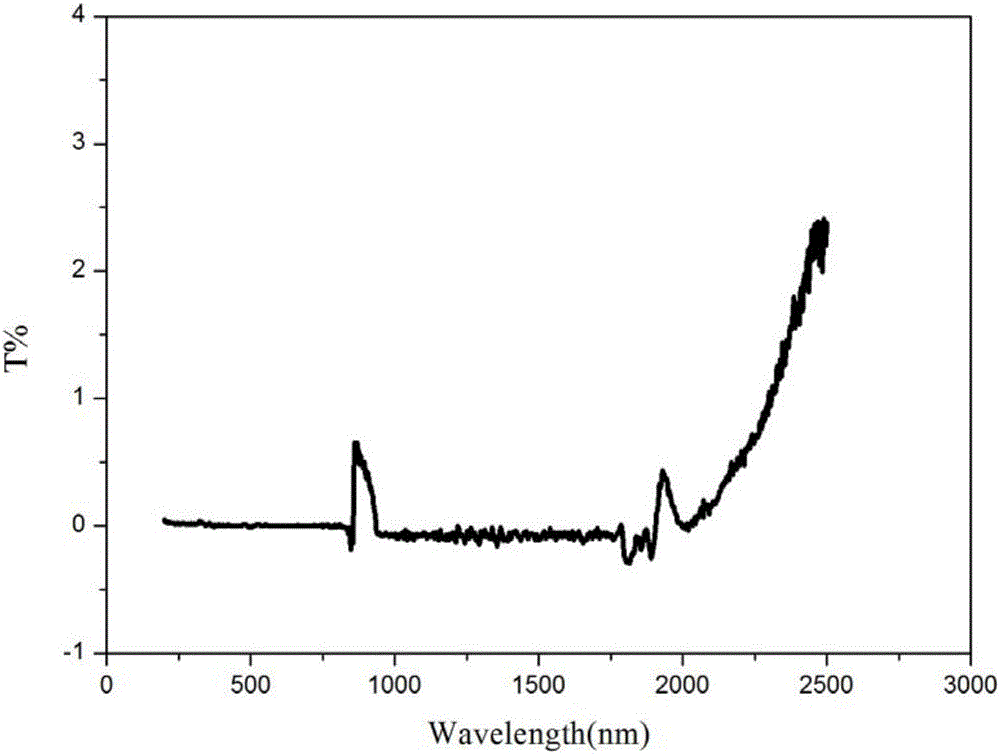

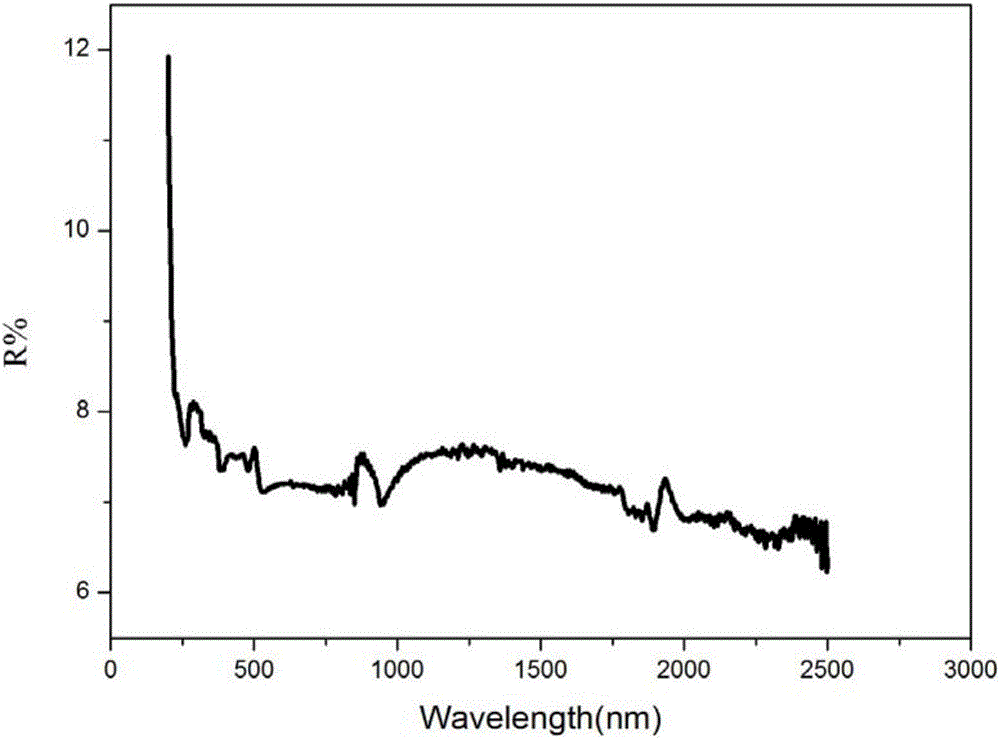

[0034] The iron tailings selected in this embodiment come from the waste of insufficient taste after the beneficiation of a certain iron ore. The X Axiosadvanced X-ray fluorescence spectrum is used to analyze its chemical composition, and it is known that its composition is calculated by mass percentage:

[0035] SiO 2 :63.76%, Al 2 o 3 :5.25%, Na 2 O: 2.93%, P 2 o 5 :0.50%, V 2 o 5 : 0.87%, BaO: 1.17%, Fe 2 o 3 : 23.49%, the rest are impurities.

[0036] Using the above-mentioned iron tailings to prepare black glass with broad spectrum and high absorption rate, the specific steps are as follows:

[0037] (1) raw material crushing: the above-mentioned iron tailings are crushed, ground, passed through a 100-mesh sieve, and dried for later use;

[0038] (2) Batching: the above-mentioned processed iron tailings and other raw materials are weighed according to the following formula:

[0039] 43.56 grams of iron tailings, 11.38 grams of silicon dioxide, 2.39 grams of sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com