Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Overcoming many processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

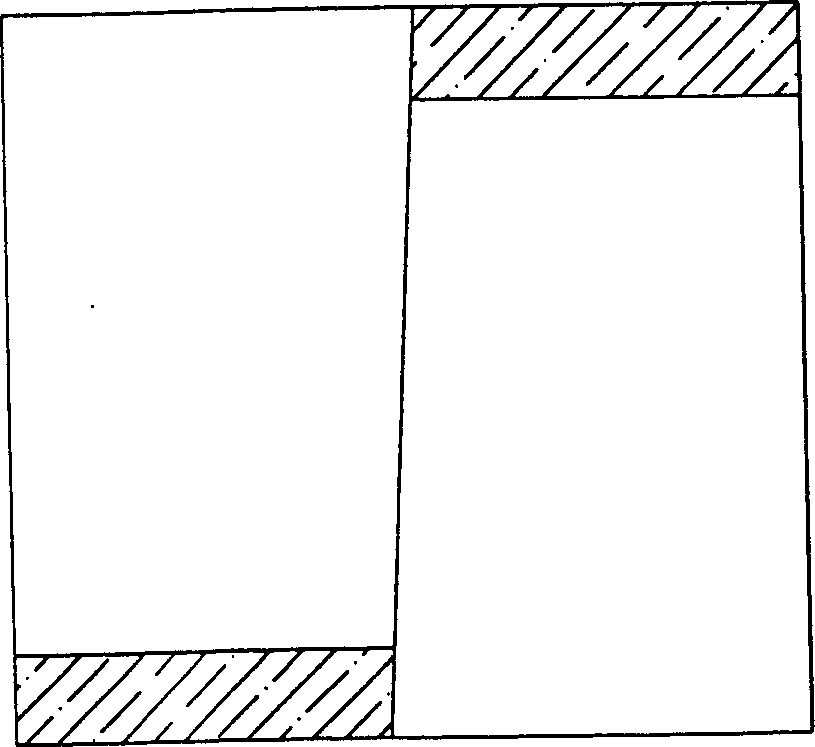

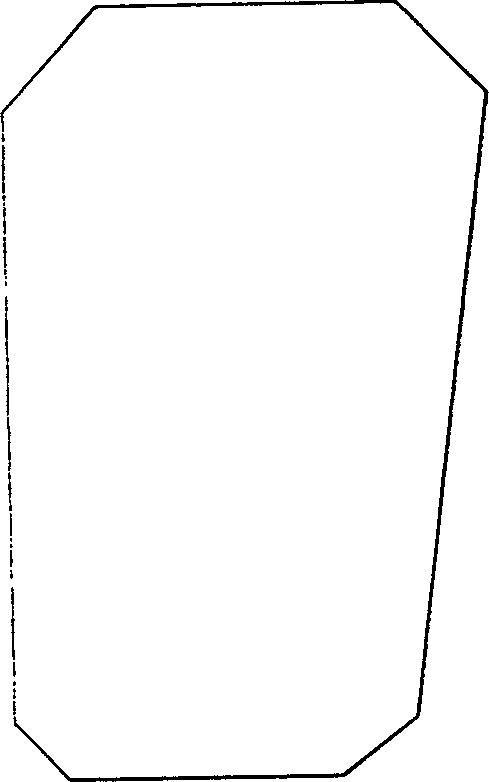

Integral stretching technology of double (three)-tank stainless steel water tanks

The invention is a stainless steel double-tanked (three-tanked) water tank stretching technique, including the working procedures such as batching, shearing angle, first stretching, shearing side, washing, annealing, second stretching, cutting side, punching hole, surface processing, etc. The water tank made by the working procedures forms a through structure without welding, reducing production cost and avoiding the problems of water leakage and of affecting fastness, thus heightening the whole quality and service life of the water tank.

Owner:ZHEJIANG FRANTA

Casting process for crankshaft

InactiveCN104745917AOvercoming many processesIncrease productivityCrankshaftsFoundry mouldsComposite materialMolding sand

The invention discloses a casting process for a crankshaft. The casting process comprises a molding process and a smelting and casting process. The molding process comprises the following steps of: adopting resin sand for molding, wherein the resin sand comprises 1% of resin, 0.4% of a curing agent and the balance of molding sand; performing transverse molding during the molding, and after mould arrangement and mould assembly, lifting the whole mould vertically to form a resin sand mould. The smelting and casting process comprises the following steps of: preparing casting liquid by using C, Si, Mn, P, S, Mg, Re, Cu, Sn and Fe as raw materials according to a certain percentage; fully melting the raw materials to form molten iron; placing a spheroidizing agent and an inoculant into a ladle, pouring molten iron into the ladle for spheroidizing and inoculating to form the casting liquid; and pouring the casting liquid into the resin sand mold to form a crankshaft casting after solidification. Through the casting process provided by the invention, the defective rate of crankshaft products is low, the qualification ratio reaches 99% or above, and all properties can reach the standards.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Precision casting method for graphite mould-ceramic core titanium alloy

InactiveCN104550755AOvercoming many processesIncrease productivityFoundry mouldsFoundry coresGraphiteProduction cycle

The invention discloses a precision casting method for a graphite mould-ceramic core titanium alloy. The precision casting method disclosed by the invention comprises the following steps: preparing a ceramic mould core and a graphite mould shell, then, degassing the graphite mould shell and the ceramic mould core, assembling the ceramic mould core and the graphite mould shell to form a casting mould according to a casting mould shell figure, smelting, and casting. The precision casting method disclosed by the invention has the advantages that aiming at a complex three-dimensional variable-curved surface titanium alloy precise casting, a titanium alloy casting is cast by utilizing the precision casting method disclosed by the invention; therefore, the dimensional accuracy, the internal quality and the surface quality of the casting are improved; the rejection rate of the casting is greatly reduced; the casting cost of the casting is reduced; and the production period of the casting is shortened.

Owner:青岛齐力铸钢有限公司

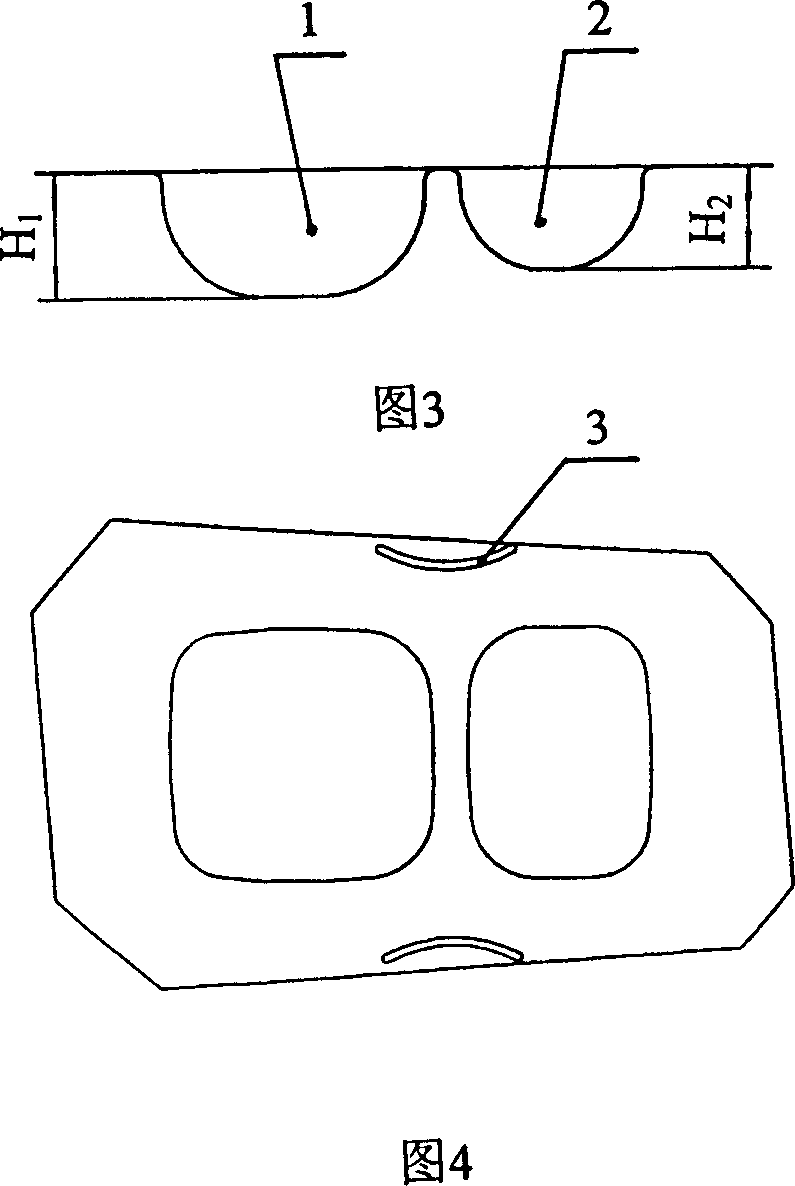

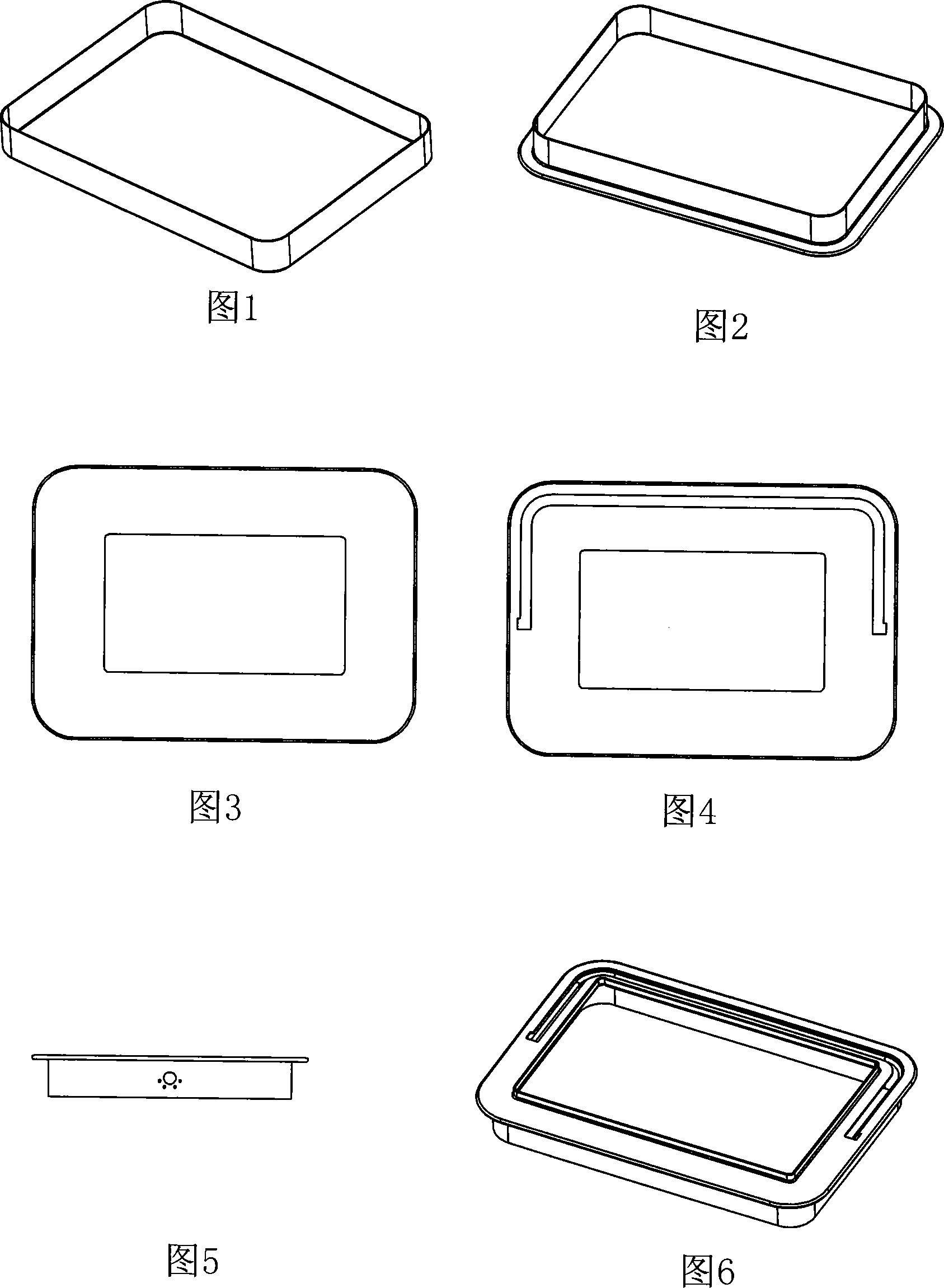

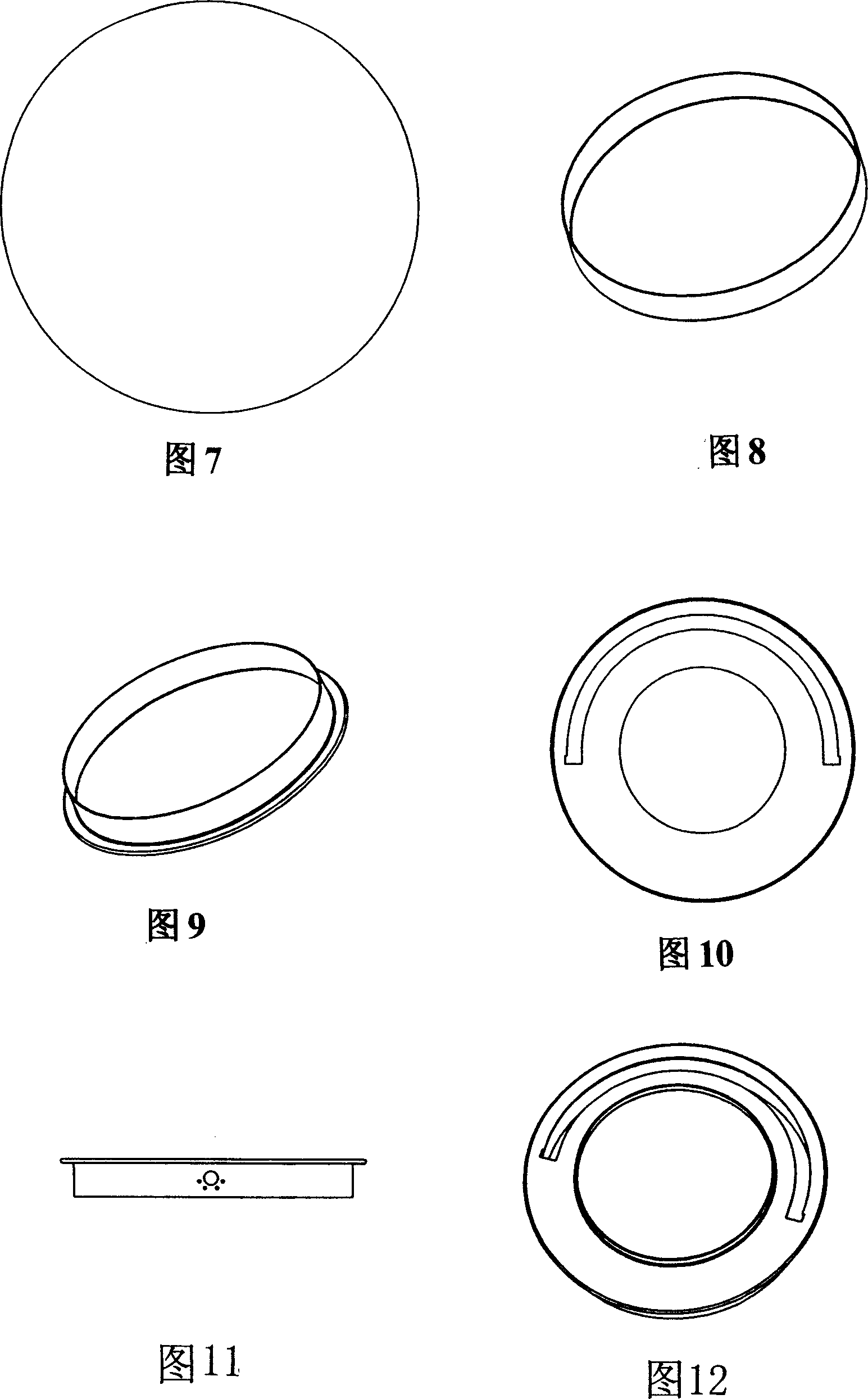

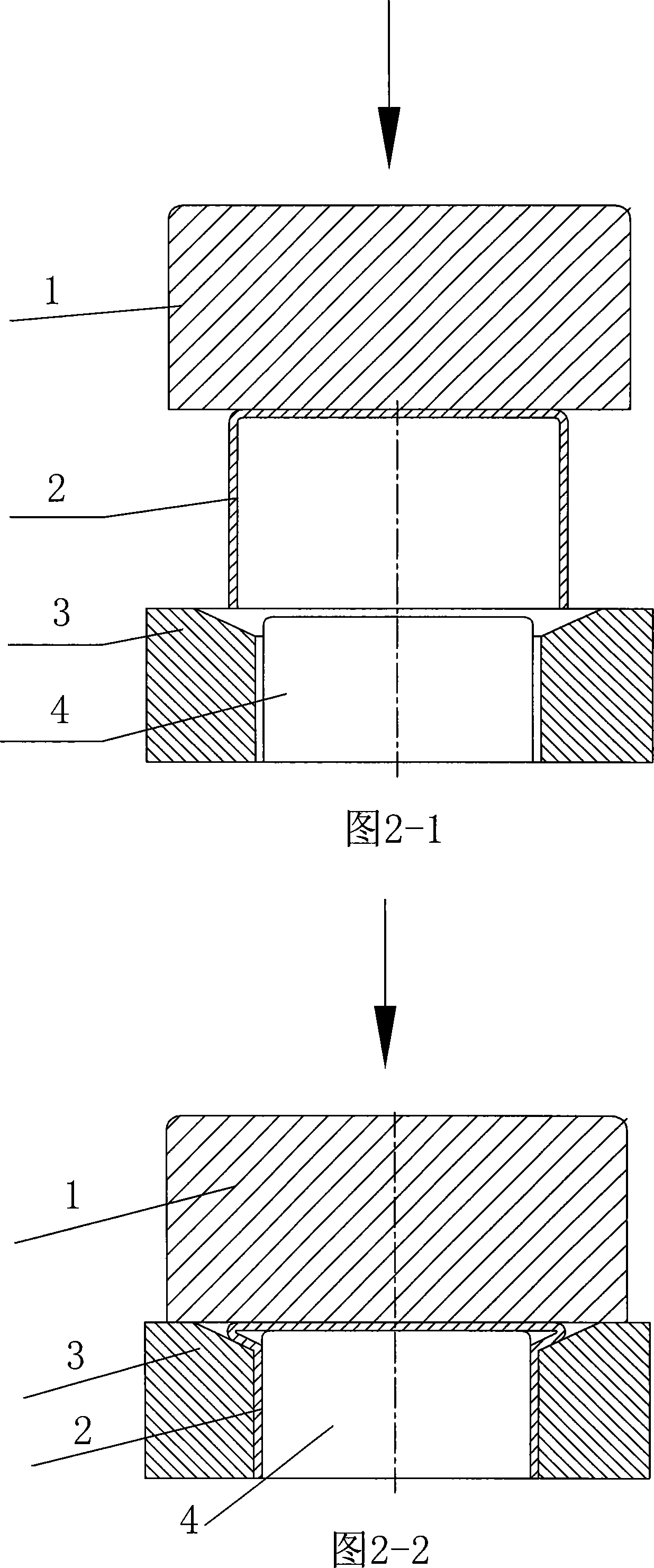

Integral drawn technique for faceplate of buffet dinner stove

InactiveCN101091976AOvercoming many processesReduce manufacturing costShaping toolsFlangingEngineering

The invention relates to a buffet meal boiler face board integer extending technology that includes the following steps: cutting the stainless coil stock to needed size sheet stock; extending the sheet stock to needed height; compressing the component to needed diameter; making square hole or circular aperture; making level slot on the top of the large hole component; taking extension and flanging of the brim of middle hole of the component; taking polishing, washing, testing and storing to the molded panel. The appearance quality and useful life is prolonged. It also makes the buffet meal boiler has better prize superiority and economic benefits in market competition.

Owner:宁波格兰特制冷设备制造有限公司

Low-pressure casting process of aluminum alloy steering joint

InactiveCN104741574AOvercoming many processesIncrease productivitySteering linkagesInvestment materialMolten metal

The invention discloses a low-pressure casting process of an aluminum alloy steering joint. The process comprises the following steps: (A) a material is selected and prepared (A356 alloy is adopted; Sr with the mass percentage of 0.04-0.05% by the total quantity of alloy liquid is added to deteriorate molten aluminum so as to refine grains in the crystallization of the molten aluminum); (B) a product is cast by a low-pressure casting mold through the steps of descending of a filter screen, mold closing, liquid rising, mold filling, pressure keeping, opening of water cooling, pressure unloading, closing of water cooling, opening of an upper mold, ejection and part taking. The process mainly solves such problems as high equipment tonnage, complex procedures in manufacturing process and high material cost of a conventional aluminum alloy steering joint casting method, can produce casting products accordant with the requirements without needing expensive investment, is high in structure compactness of castings, is high in casting quality, and is high in production efficiency. Meanwhile, the molten metal is high in utilization rate; and the consumption of auxiliary materials is less.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Front cylinder head casting process

The invention relates to a front cylinder head casting process. The front cylinder head casting process includes the following steps that raw material inspection is conducted, wherein chemical components and the pin hole degree of raw materials are inspected; melting is conducted, wherein the raw materials are molten into liquid aluminum, and the chemical components and the mechanical performance of alloy liquid are inspected; pressure casting is conducted, wherein a front cylinder head blank is formed by the liquid aluminum through pressure casting, and the surface quality and the internal quality of a product are inspected; treatment is conducted, wherein flashes and burrs of the front cylinder head blank are removed; central hole drilling is conducted, wherein a local extruding hole is drilled through, the diameter of the hole is inspected, and whether a casting is damaged or not is inspected; shot blasting is conducted, wherein the product is hung on a hanging frame to be subjected to shot blasting, a finished product is manufactured, and whether the chromatic aberration of the finished product is consistent or not is inspected; and finished product inspection is conducted, wherein whether the finished product conforms to all indexes or not is inspected, the problems that in the prior art, a machining process is large in procedure number and large in workload are solved, and the production efficiency is improved. The raw material utilization rate is high, and the production cost is reduced. The cast finished product front cylinder head casting is environment-friendly and practical, and the labor intensity is greatly lowered.

Owner:NINGBO ZUNHANG AUTO PARTS

Processing method of resistant starch containing food raw materials

InactiveCN105614221AOvercoming many processesIncrease productivityFood preparationCost (economic)Radiation processing

The present invention discloses a processing method of resistant starch containing food raw materials. By studying quality safety controlling means and matching technologies and optimizing an radiation processing technology, the method conducts a strict fully automated control of material selection, and irradiation doses, irradiation time and an irradiation box moving mode during the irradiation process, improves processing efficiency and utilization rate of radioactive sources, reduces the economic costs and the use of preservatives, significantly reduces the microbial content of the products, and solves the problems of air producing and inflatable bags of products caused by anaerobic bacteria, so that the product quality is improved and people's body health is ensured.

Owner:吕艳

Aluminum alloy impeller centrifuge casting method

InactiveCN104624958AOvercoming many processesIncrease productivityFoundry mouldsFoundry coresWaxImpeller

The invention discloses an aluminum alloy impeller centrifuge casting method. The method comprises the following steps: making an impeller wax mold; preheating the wax mold; carrying out tool treatment; melting alloy selected for an impeller; melting Al7Si aluminum ingots; adding an Al-5Ti intermediate alloy, and melting; adding a pure Mg block, and melting; adding an Al-10Sr intermediate alloy, and melting; adding the Al-10Sr intermediate alloy into a graphite crucible, stirring a melt in the graphite crucible, and carrying out degassing refining; and carrying out centrifuge casting to realize mold filling and solidification of the above alloy melt under the action of centrifugal force, solidifying for a certain period of time, demolding, and cleaning the obtained casting. The problems of high production cost of present casting methods, and poor quality and low dimension precision of the surfaces of castings are solved in the invention.

Owner:青岛齐力铸钢有限公司

Novel synthetic process for hydrophobic polymeric flocculant

InactiveCN105646784AOvercoming many processesImprove work efficiencyWater/sewage treatment by flocculation/precipitationUreaSolubility

The invention discloses a novel synthetic process for a hydrophobic polymeric flocculant. The synthetic process comprises the following steps: sequentially dissolving methyl methacrylate, acrylamide, acrylic acid, dimethyldiallylammonium chloride, sodium hydroxide and urea in pure water, wherein the usage amount of urea is 6%; adding sodium sulfite, a foaming agent and ammonium persulfate; neutralizing acrylic acid, and carrying out uniform mixing under stirring; taking out the polymer after allowing the mixture to stand, and performing purification; subjecting the polymer to drying and performing grinding so as to obtain the hydrophobic polymeric flocculant. The synthetic process provided by the invention can successfully synthesize the hydrophobic polymeric flocculant, and has the advantages of simple process, low required raw material and labor costs, and short synthesizing time; meanwhile, the synthesized hydrophobic polymeric flocculant has excellent instant solubility and storage stability, and is free of phenomenons of thinning due to long-time preservation, microgel formation, phase separation appearing and white precipitate generation; and through the addition of urea and controlling of the usage amount of urea in the process of synthesis, flocculation effect of the synthesized hydrophobic polymeric flocculant is improved.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Centrifugal casting process of high-performance engine alloy cylinder sleeve

The invention discloses a centrifugal casting process of a high-performance engine alloy cylinder sleeve; the radiating condition in the condensation of a casting melt is improved through optimizing the mold design; tin is added in a traditional cylinder jacket material for alloying; and meanwhile, the total inoculation quantity is reduced, and ladles are properly added for inoculating, so that graphite is more refined, the pearlite stability is improved, and the wear resistance of the cylinder jacket material is improved.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

Processing technology of chicken breast meat with fresh and tender shredded meat fiber

InactiveCN105614474AOvercoming many processesIncrease productivityFood preparationChemistryMeat fibers

The invention discloses a processing technology of chicken breast meat with fresh and tender shredded meat fiber. The processing technology comprises the following steps of (1) selecting chicken breast meat without skin as a main material for standby application, wherein fascia at the top of a thick end is removed, the fat content is smaller than or equal to 4%, and the product temperature is 1-4 DEG C; (2) performing single-sided tenderization once on the processed chicken breast meat by using a tenderization machine; (3) putting the tenderized chicken breast meat in a pulping machine for pulping the tenderized chicken breast meat by using the pulping machine; (4) putting fibrous chicken breast shreds in rolling and kneading liquid, and performing high-speed and uniform stirring with a vacuum rolling and kneading machine so as to obtain stirred chicken breast meat shreds; (5) allowing the stirred chicken breast meat shreds to stand for pickling for 5-9 hours under the temperature of 0-7 DEG C, and performing deep-frying for shaping; (6) quick-freezing the shaped chicken breast meat shreds, wherein the C.T. of single frozen products is lower than or equal to minus 17 DEG C; and (7) performing packaging and warehousing. The processing technology disclosed by the invention has the positive effects that shredded meat fibers are fully reserved, through tenderization and pulping, the shredded meat fibers are separated from the raw material meat namely the chicken breast meat, through rolling, kneading and pickling, the quality of the meat is improved, and the meat is tasteful; therefore, the product value is greatly increased, and the product authenticity is greatly improved.

Owner:吕艳

Synthesis technology of methyl-etherified melamine resin

The invention discloses a synthesis technology of methyl-etherified melamine resin. The technology is characterized in that highly-methyl-etherified melamine resin is prepared from melamine, formaldehyde and methanol through a reaction adopting a nitric acid solution and a sodium hydroxide solution as auxiliary materials under a controlled pH value at a controlled temperature. The synthesis technology of the highly-methyl-etherified melamine resin is simple, and the produced resin has high content of solids, and is very suitable for producing high-grade household electrical appliance product paints, electrostatic spraying paints, container and high-grade metal decoration paints, and high-grade plastic product paints.

Owner:赵建英

Production technology of sulfuric acid by gypsum transformation decomposition method

InactiveCN105621373AOvercoming many processesImprove work efficiencySulfur compoundsAmmonium sulfateChemical industry

The invention discloses a production technology of sulfuric acid by a gypsum transformation decomposition method. Gypsum is transformed into ammonium sulfate which is easy to decompose; ammonium sulfate is decomposed to directly obtain sulfur trioxide; and sulfur trioxide is absorbed with water or dilute sulphuric acid so as to prepare sulfuric acid. Ardealite, which is used as a raw material, doesn't have to undergo any pretreatment and directly reacts to obtain calcium carbonate which is a main raw material for production of cement. Therefore, dangerous waste ardealite generated from phosphorus chemical industry can be eliminated in quantity, and the main raw material sulfuric acid which is essential to phosphorus chemical industry is obtained so as to realize cycling of sulfur. During the whole process, ''three wastes (waste gas, waste water and industrial residue)'' are not discharged, and secondary pollution is not generated at all. Actually consumed raw materials are only gypsum and carbon dioxide, thus reducing the greenhouse gas carbon dioxide and improving the environment. Required investment is little, and the technology has remarkable economic benefit.

Owner:赵建英

Synthesis process of butyl rubber

The invention discloses a synthesis process of butyl rubber. The synthesis process is characterized in that a synthesis system comprises an LNG (liquefied natural gas) heat exchanger, a gaseous coolant buffer tank, a liquid coolant buffer tank, a flash tank I, a flash tank II, a catalyst heat exchanger, a raw material heat exchanger, a polymerization reactor heat exchanger, an air thermostat and a compressor. The synthesis process comprises the following steps: selecting a coolant meeting requirements of the synthesis process of the butyl rubber and an LNG interface condition, such as ethane and ethylene, replacing low-temperature cold contained in LNG with the coolant, and cooling a catalyst solution, cooling a mixed raw material and removing polymerization heat with the low-temperature cold in the coolant through corresponding heat exchange equipment so as to meet requirements of the synthesis process of the butyl rubber on the temperature and the cold.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

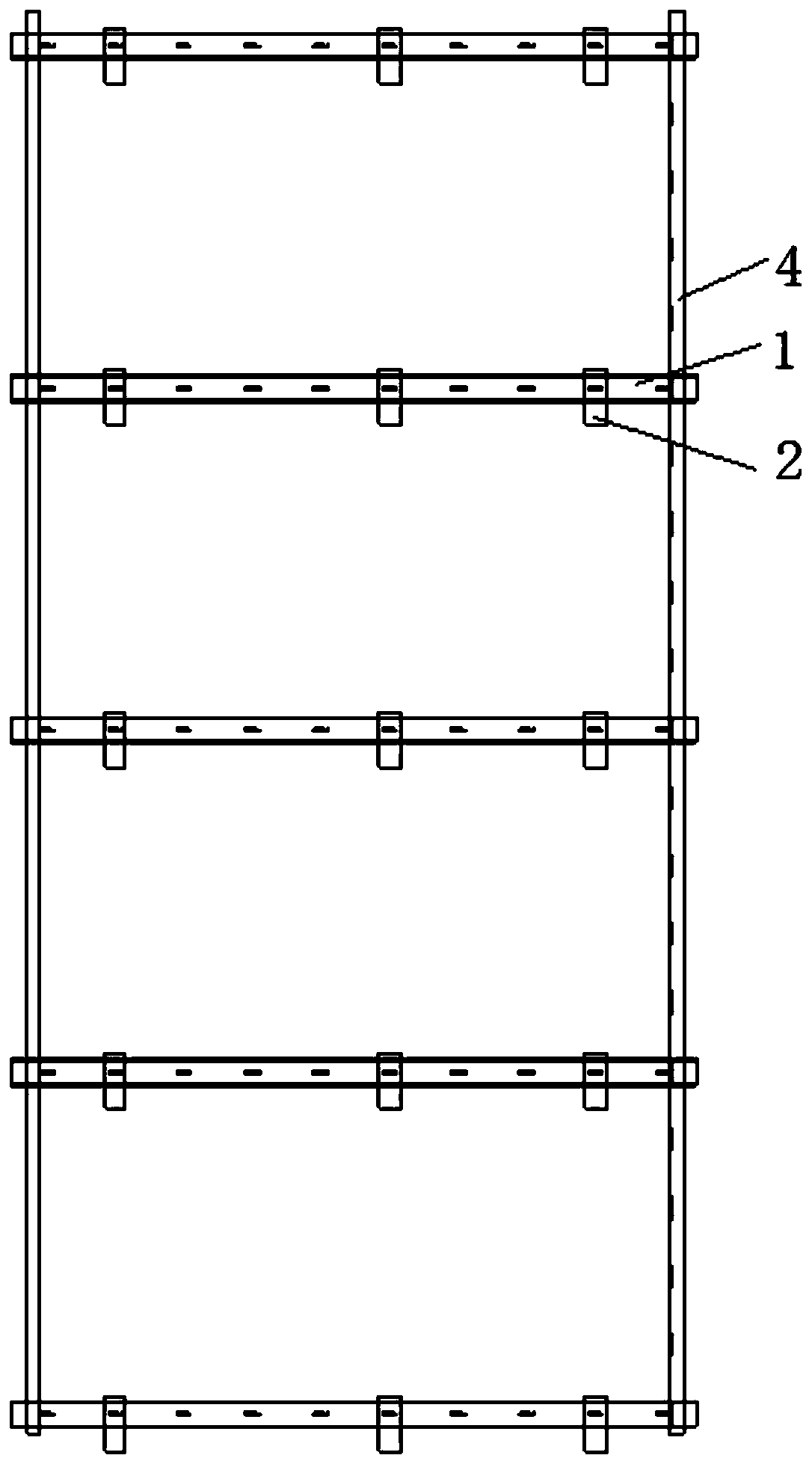

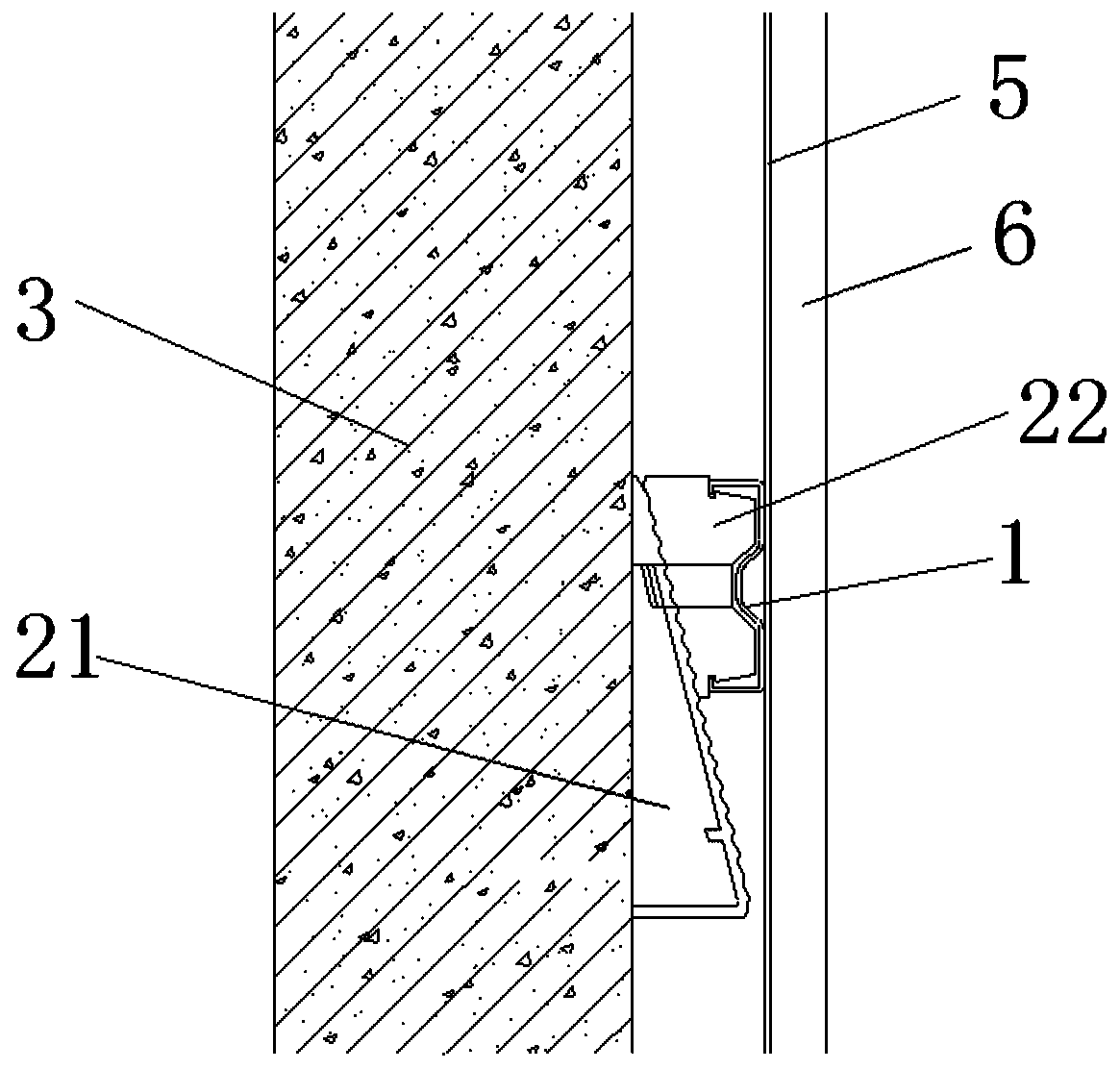

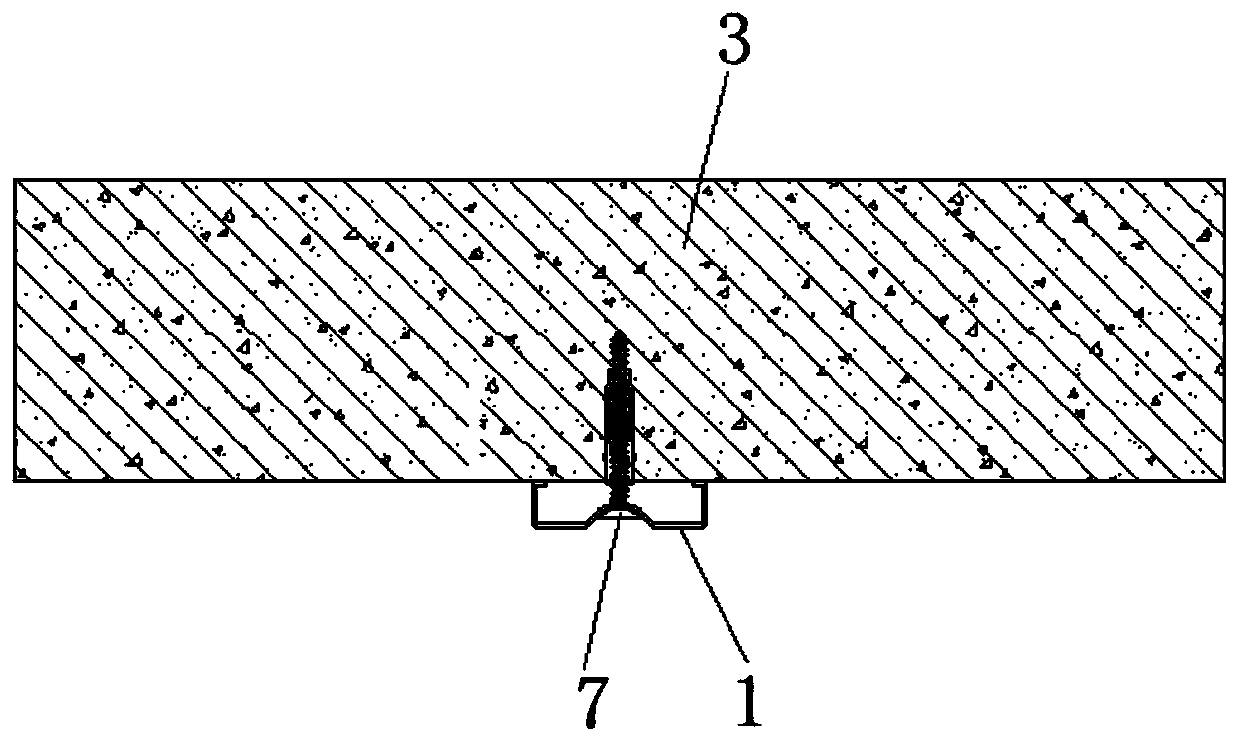

Wall mounting structure of assembled M-type lightgage steel joists

PendingCN110656747AOvercoming many processesOvercome shortcomings such as long working hoursCovering/liningsJoistMechanical engineering

The invention provides a wall mounting structure of assembled M-type lightgage steel joists. The wall mounting structure includes the M-type lightgage steel joists, leveling components, clamping belts, aluminum alloy vertical lines and wall panels; the bottoms of the two sides of each M-type lightgage steel joist are provided with clamping portions bent inwards; each leveling component includes abase and a leveling base arranged on the base, each base is fixed to a base layer wall, the inner side of each leveling base is clamped to the corresponding rbase, and the outer side of each levelingbase is clamped to the corresponding M-type lightgage steel joist; the two sides of each clamping belt are evenly and symmetrically provided with edge turning buckles; the leveling components are connected to the middle positions of the M-type light steel keels; the clamping belts are clamped on the two sides of each M-type lightgage steel joist, and the clamping portions and the edge turning buckles are clamped; the aluminum alloy vertical lines are fixedly connected to the M-type lightgage steel joists; and the wall panels are fixedly connected to the aluminum alloy vertical lines. Comparedwith the prior art, the wall mounting structure has the following advantages that different installation accessories can be installed in a matched manner to form an overall structural system, installation is facilitated, the installation efficiency is improved, and the construction cost is reduced; and meanwhile, the flatness of the decorative wall panels is improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Synthetic process for acid fluid thickening agent by controlling of reaction time

InactiveCN105646783AOvercoming many processesImprove work efficiencyThickenersSolvent2-Acrylamido-2-methylpropane sulfonic acid

The invention discloses a synthetic process for an acid fluid thickening agent by controlling of reaction time. The synthetic process for the acid fluid thickening agent by controlling of the reaction time comprises steps like carrying out monomer purification; dissolving a 2-acrylamido-2-methylpropane sulfonic acid (AMPS) solid in distilled water; adding acrylic acid (AA) and a diallyl dimethyl ammonium chloride (DMDAAC) solution into an obtained 2-acrylamido-2-methylpropane sulfonic acid (AMPS) solution, and carrying out stirring; adjusting a pH value; exhausting oxygen and then adding an initiator; and controlling the reaction time so as to obtain the acid fluid thickening agent. The synthetic process provided by the invention can successfully synthesize the acid fluid thickening agent and has the advantages of high synthesizing efficiency, low synthesizing cost and simple operation; the synthesized acid fluid thickening agent can be directly used without the need for removing a solvent, and is favored by the broad masses of workers in oil fields; meanwhile, through controlling of polymerization reaction time, intrinsic viscosity and conversion rate of the acid fluid thickening agent are improved.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

5-amino-1-methyl-1h-pyrazole-4-carboxylic acid ethyl ester synthesis process

InactiveCN105646357AOvercoming many processesImprove work efficiencyOrganic chemistrySolventEthyl ester

The present invention discloses a 5-amino-1-methyl-1H-pyrazole-4-carboxylic acid ethyl ester synthesis process, which is characterized in that a 40% methyl hydrazine aqueous solution and ethoxy methylene ethyl cyanoacetate are adopted as raw materials, and toluene is adopted as a solvent. According to the present invention, the raw material 40% methyl hydrazine solution has characteristics of easy obtaining, low damage on human body, high safety and low cost, the toluene is adopted as the solvent, and the synthesis process has characteristics of simple process, easy operation, substantially-shortened reaction time, high product yield, and no three-waste emission.

Owner:吕艳

None-phenol basic violet synthetic process

InactiveCN105566155AOvercoming many processesImprove work efficiencyDiaryl/thriaryl methane dyesImino compound preparationSolventChemical compound

The invention discloses a non-phenol basic violet synthetic process which comprises the following steps: mixing an N,N-dimethylaniline compound with water to form a solution; using copper salt as a catalyst and carrying out emulsification by a compound non-ionic emulsifier; performing an oxidation reaction on a system at a temperature of 50 to 80 DEG C; then processing an oxidized material according to a solvent method to obtain high-purity basic violet with low copper content. The non-phenol basic violet synthetic process disclosed by the invention has the advantages of being simple in process, mild in reaction conditions and free of drainage of a great volume of waste water, and has yield of 95 percent or higher.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Method for preparing aromatic vinegar from banana

InactiveCN105624002AOvercoming many processesIncrease productivityVinegar preparationAmomum villosumGinseng

The invention discloses a method for preparing aromatic vinegar from banana. The chosen raw materials comprise fresh and tender duckling, fructus lycii, fructus jujubae, radix ginseng, rhizoma zingiberis recens, green Chinese onion, refined salt, five spices (including aniseed, fructus foeniculi, pericarpium zanthoxyli, clove and fructus amomi villosi) and honey; the preparation process comprises the steps of preparing soup stock, pickling in the soup stock, stewing and boiling, and coating honeydew, putting the duckling into a pot to be fried until the duckling obtains a golden yellow color, taking the duckling out and cutting into blocks; putting a little sesame, fructus lycii and caraway to be put in a dish. A bowl of healthcare soup can be prepared for each finished duck; the prepared product by the method is good in color, fragrance, taste and the healthcare effect; the food is delicious, and a medicinal medium having great benefit to human body is creatively added, so that healthcare duck meat and healthcare soup are obtained; an effect of healthcare and prolonging life is achieved gradually for users who eat such food in normal diets without requiring the users to take medicine or take injections; and the method can be used for preparing various meat and poultry food.

Owner:吕子玉

Method for casting gearbox shell by using V technology

InactiveCN104624974AOvercoming many processesIncrease productivityFoundry mouldsFoundry coresJoint surfaceEngineering

The invention discloses a method for casting a gearbox shell by using a V technology. The gearbox shell comprises an upper model and a lower model, a projecting part A is arranged in the upper model, the surface of the projecting part A is covered with an upper plastic surface film, upper box dry sand is arranged between the top of an upper sand box and the upper plastic surface film, and the upper box dry sand is provided with an upper plastic back film; and the lower model is provided with a projecting part B and a depressed part, the surface of the projecting part B and the depressed part is covered with a lower plastic surface film, lower box dry sand is arranged between the top of a lower sand box and the lower plastic surface film, and the lower box dry sand is provided with a lower plastic back film. The method solves the defects of long molding, box closing and joint surface polishing time, large joint surface fault box probability, high worker labor intensity and low casting yield of present technologies for making the gearbox shell through three box molding.

Owner:青岛齐力铸钢有限公司

Dimethoxymethane preparation process

InactiveCN105646165AOvercoming many processesImprove work efficiencyOrganic chemistryOrganic compound preparationChemistryOrganic chemicals

The present invention discloses a dimethoxymethane preparation process, wherein methanol and paraformaldehyde are adopted as raw materials, an acid is adopted as a catalyst, a reaction is performed in an organic solvent in an intermittent reaction manner under stirring to generate dimethoxymethane, and separation is performed to obtain the azeotrope of methanol and dimethoxymethane or the high-purity dimethoxymethane. According to the present invention, the preparation process has characteristics of rapid reaction and high conversion rate, and is suitable for the organic chemical industry field.

Owner:吕艳

Synthesis process for dithiocarbamate

InactiveCN105622476AOvercoming many processesImprove work efficiencyOrganic chemistryCarbon disulfideVacuum drying

The invention discloses a synthesis process for dithiocarbamate. The synthesis process comprises the following steps: (a) adding a certain amount of carbon disulfide, alkali lye and carbamide into a reaction vessel; (b) carrying out continuous stirring, and after uniform mixing of the above-mentioned substances, controlling temperature and adding carbon disulfide drop by drop; (c) controlling the temperature of a reaction system in a certain range; (d) then carrying out heating to a certain temperature and then carrying out reaction at a constant temperature for a certain period of time; (e) after completion of the reaction, successively carrying out stirring, cooling, crystallization and filtering; and (f) carrying out vacuum drying at 65 to 88 DEG C so as to prepare the product dithiocarbamate. According to the invention, dithiocarbamate is synthesized from carbon disulfide and carbamide according to certain technological parameters; the synthesis process has simple synthesis steps, high synthesis efficiency and low synthesis cost; the synthesized dithiocarbamate has the advantages of high efficiency, cheapness and a wide application scope; and through controlling of the pH value of the reaction system, the conversion rate of the whole process and product quality are improved.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Process for synthesizing p-bromophenol

InactiveCN105622352AOvercoming many processesImprove work efficiencyOrganic chemistryOrganic compound preparationSolventNitrogen gas

The invention discloses a process for synthesizing p-bromophenol. The process comprises the following steps of adding a certain amount of phenol and chloroform which serves as a solvent into a four-mouthed flask which is equipped with a stirrer, a thermometer, a dropping funnel and a gas absorption device, and uniformly mixing; starting up the stirrer to start stirring, inserting the thermometer and the dropping funnel into the four-mouthed flask, completely dissolving phenol in chloroform, then controlling the external temperature of the flask to be -5 DEG C or less, starting to dropwise add bromine through the dropping funnel, controlling the dropwise adding speed so as to maintain the internal reaction temperature of the flask to be 9 DEG C or less, and carrying out stirring reaction for a period of time after the dropwise adding process is ended; heating to the temperature of 12-23 DEG C after the reaction is ended, introducing nitrogen gas to completely expel hydrogen bromide gas in the four-mouthed flask, cooling to the temperature of about 6 DEG C, putting 0.14-0.22 g of p-bromophenol crystal with the purity of higher than 99.1% into the four-mouthed flask, taking the p-bromophenol crystal as a seed crystal, starting to precipitate a crude product, stirring for 22 minutes, discharging, and carrying out depressurized suction filtration by using a Buchner funnel; and washing the crude product with chloroform, then drying, and thus obtaining the p-bromophenol product. The process has the advantages of simplicity, fewer steps, easy operation, low cost, and high product quality.

Owner:赵建英

Front cylinder casting process

The invention relates to a front cylinder casting process which comprises the following steps: raw material inspection: inspecting the chemical components and pinhole degree of the raw material; smelting: smelting the raw material into molten aluminium, and inspecting the chemical components and mechanical performance of alloy liquid; pressure casting: performing pressure casting on molten aluminium to form a front cylinder blank body, and inspecting the surface quality and internal quality of a product; trimming: removing flashes and burrs of the front cylinder blank body; thermal treatment: loading the product into a thermal treatment furnace for thermal treatment, inspecting whether parameters on recording paper meet process requirements, inspecting the hardness of the product, and transferring qualified products to the next station; shot blasting: hanging the product on a hanging bracket for shot blasting to product a finished product, and inspecting whether the chromatic aberration of the product is consistent; and finished production inspection: inspecting whether a finished product meets all indexes. The front cylinder casting process can overcome the problems of many procedures and heavy workload of processing technology of the prior art, and can improve the production efficiency; the raw material utilization rate is high, and the production cost is lowered; the cast finished product front cylinder casting is environmentally friendly and practical, and the labor intensity is reduced.

Owner:NINGBO ZUNHANG AUTO PARTS

Synthesis technology for improving yield of nanometer Y type molecular sieve

InactiveCN105621443AOvercoming many processesImprove work efficiencyFaujasite aluminosilicate zeoliteIonChemistry

The invention discloses a synthesis technology for improving the yield of a nanometer Y type molecular sieve. The technology comprises the following steps: sequentially adding an organic template and an aluminum source to deionized water under stirring, stirring the organic template and the aluminum source until the organic template and the aluminum source are dissolved, and adding a silicon source and a sodium source; transferring the above synthesis system to a reaction kettle, sealing the reaction kettle, heating the reaction kettle to 90-130DEG C, and carrying out hydrothermal crystallization for 60-110h; separating the above obtained solid-liquid mixture to obtain a solid which is nanometer Y type molecular sieve, and reserving a mother liquor; and supplementing a proper amount of the reaction raw materials to the obtained mother liquor, continuously crystallizing the above material, and carrying out solid-liquid separation to obtain the nanometer Y type molecular sieve and the reaction mother liquor. Supplementation of the reaction raw materials, crystallization and solid-liquid separation are repeated to improve the yield of the nanometer Y type molecular sieve. The technology effectively utilizes unreacted silicon, aluminum, the organic template and other raw materials in the synthesis system, so the yield of the nanometer Y type molecular sieve is improved to 40% or above; and the particle size of the above product is 100nm or below, and the time required by every crystallization is short.

Owner:赵建英

Processing technology of chrysanthemum flower-pig feet

InactiveCN105614464AOvercoming many processesIncrease productivityFood preparationFlavorGinger Rhizome

The invention discloses a processing technology of chrysanthemum flower-pig feet. The technical scheme of the processing technology comprises following steps: step (1), processing the raw materials, namely soaking and washing the pig feet; for frozen raw materials, performing the processes of unfreezing, soaking and washing; and then, making a spice bag, namely adding the refined salt, the white sugar, the fresh ginger, the green Chinese onion, the monosodium glutamate, the fennel seeds, the coriander seeds, the Chinese prickly ash, the dahurian angelica roots, the white pepper corn, the laurel leaves and maltol in the accessory ingredients into the spice bag; step (2), blanching the pig feet; step (3), cleaning the blanched pig feet and removing hairs thereon; step (4), seasoning and coloring the soup; step (5), performing cooking and soaking; step (6), performing weighing and packaging; and step (7), warehousing the final product.

Owner:吕艳

Synthetic process for dodecenyl succinic anhydride

InactiveCN105646408AOvercoming many processesImprove work efficiencyOrganic chemistryDistillationAlkenylsuccinic anhydride

The invention discloses a synthetic process for dodecenyl succinic anhydride. The synthetic process comprises the following steps: (a) firstly, mixing polyisobutylene and maleic anhydride according to a certain mole ratio, and placing the mixture of the polyisobutylene and maleic anhydride into a reaction vessel; (b) adding a catalyst and an initiator into the reaction vessel, and adjusting a pH value of the reaction system to 7.5 to 9.0; (c) adjusting a temperature of the reaction system, and carrying out a reaction at a high temperature under stirring; and (d) after the completion of the reaction, carrying out distillation under a certain pressure so as to obtain a product, and carrying out cooling for a period of time so as to obtain the target product. The synthetic process provided by the invention can successfully synthesize dodecenyl succinic anhydride, and has the advantages of simplicity, high synthesizing efficiency and low synthesizing cost; meanwhile, through controlling of the pH value in the process of synthesis, product conversion rate of the whole process is improved.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Fluorocarbon resin synthesis process based on pH value control

The present invention discloses a fluorocarbon resin synthesis process based on pH value control. The fluorocarbon resin synthesis process comprises: (a) adding fluorine-containing olefin, alkenyl ester, alkenyl acid, alkenyl ether, an epoxy resin, a catalyst and an initiator into a reactor according to a certain ratio; (b) adding a solvent to the reactor, stirring, and uniformly mixing; (c) adjusting the temperature and the pH value of the reaction system, and carrying out a reaction for a certain time under a certain stirring speed, wherein the pH value is adjusted to 7.0-9.0; (d) distilling the reaction mixture at a certain temperature under a certain pressure; and (e) cooling the distilled product, drying, and grinding into powder so as to obtain the target product. According to the present invention, the fluorocarbon resin can be successfully synthesized, the synthesis efficiency is high, the synthesis cost is low, and the synthesized product has the good performance; and by controlling the pH value during the reaction process, the reaction conversion rate and the product performance are improved.

Owner:吕艳

Synthesis process for sulfurized isobutylene by vapor-phase process

InactiveCN105646444AOvercoming many processesImprove work efficiencyOrganic chemistryChemistryPollution

The invention discloses a synthesis process for sulfurized isobutylene by a vapor-phase process. The synthesis process comprises the steps: carrying out stirring and mixing on elemental sulfur and a catalyst for 10 to 20 minutes at the temperature of 460 DEG C to 550 DEG C and the pressure of 3MPa to 5MPa, so as to obtain mixed gas-phase material flow; introducing isobutene gas to the mixed gas-phase material flow, mixing the isobutene gas with the mixed gas-phase material flow, enabling the formed gas-phase mixture to enter a reactor, carrying out a reaction for 10 to 20 minutes at the temperature of 450 DEG C to 500 DEG C and the pressure of 2MPa to 9MPa, so as to obtain a reaction product; and cooling the reaction product, then, carrying out gas-liquid separation, and filtering a liquid phase, thereby obtaining the sulfurized isobutylene product. The synthesis process disclosed by the invention has the advantages of high reaction rate, high yield, simple process, low production cost, little pollution and the like. The invention provides a synthesizer for the sulfurized isobutylene by the vapor-phase process. The synthesizer is used for implementing the synthesis process for the sulfurized isobutylene by the vapor-phase process, disclosed by the invention, is beneficial to industrial production and is high in production capacity, thereby having relatively good economic benefits and a broad application prospect.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Production process of mutton Tibetan fish

InactiveCN105614503AOvercoming many processesIncrease productivityFood preparationStar AnisesIllicium verum

The invention discloses a production process of a mutton Tibetan fish. The mutton Tibetan fish has a specific ratio and a production process comprising: 1, selecting a fresh fish; 2, drying the surface of the fish by air at a cool place; 3, selecting high-quality mutton, and adding diced green onion, bruised ginger, rice wine, table salt, soy sauce, monosodium glutamate, Chinese prickly ash, star anise and clove for mixing; 4, adding the mutton into the fish belly; 5, frying the surface; 6, putting the fish into packing bags, then adding spring onion sections and ginger pieces, mixing the materials, then adding a seasoning agent and coriander, and carrying out high-temperature and high-pressure sterilization with the fish back downward; and 7, adding a seasoning sauce into each packing bag. The mutton Tibetan fish produced by using the formula process disclosed by the invention is especially delicious and mellow in taste, and can ensure that people can eat with long patience.

Owner:吕子玉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com