Integral drawn technique for faceplate of buffet dinner stove

A furnace panel and buffet technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that affect the overall quality and service life of the panel, increase the processing steps of the dining furnace panel, and increase the production cost of the panel, so as to improve the appearance Quality and service life, good price advantage, and the effect of avoiding missing soldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Now take 1Cr18Ni9Ti stainless steel as an example to manufacture square buffet stove panels.

[0024] (1) the grade is 3042B, and the stainless steel coil material with a thickness of 1.8mm is cut into 810 × 610 sheets with a plate shear, and the four corners are cut off to form an octagonal sheet;

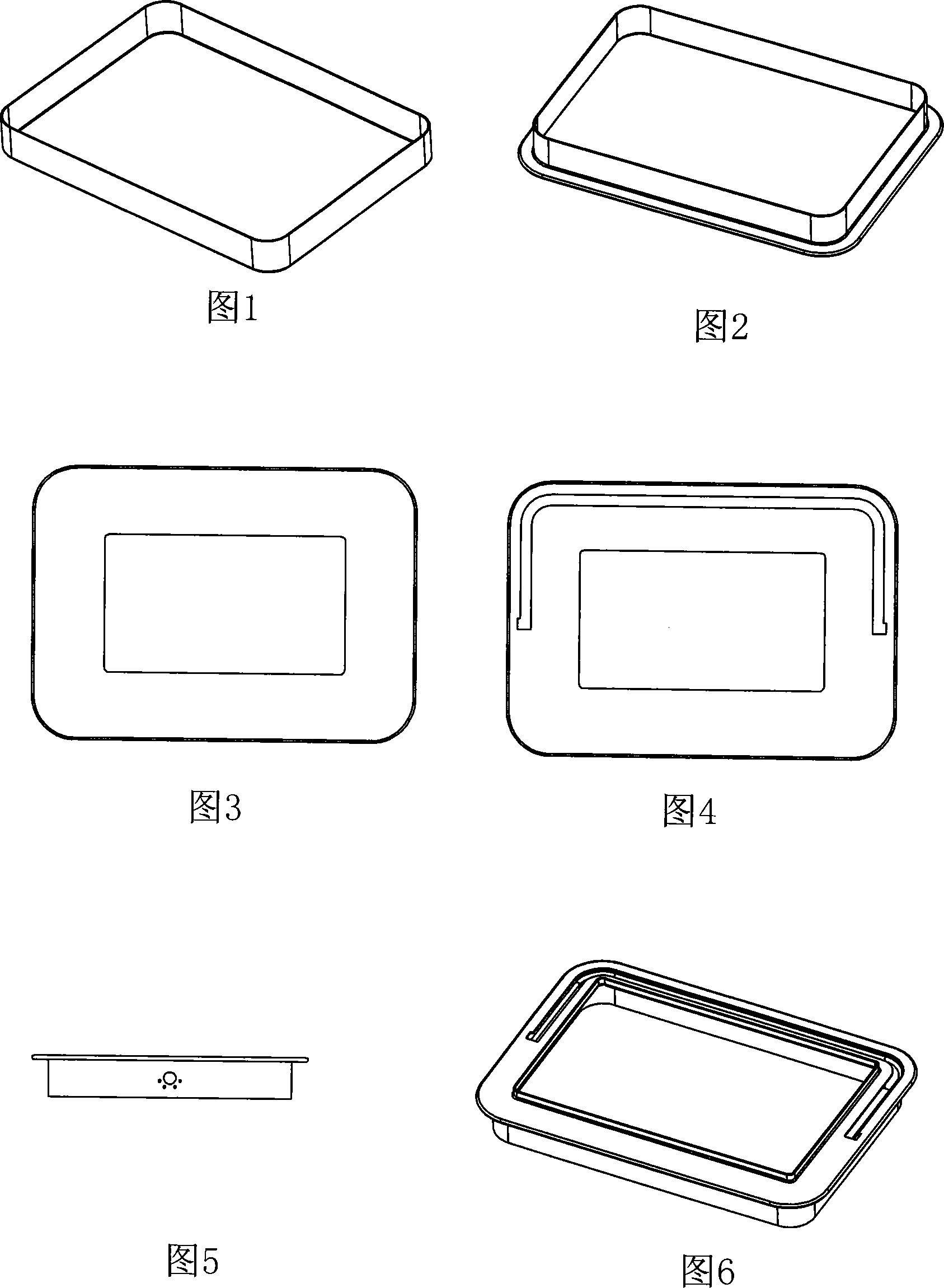

[0025] (2) Send the corner-cut material into a 315-ton hydraulic press and concave and convex molds for deep drawing, and lay a 2μm polypropylene film between the mold and the workpiece as a lubricant, and the drawing height H is 60-70mm. The deep workpiece is shown in Figure 1;

[0026] (3) Use a 160-ton punch to cut off the outer edge of the drawn workpiece;

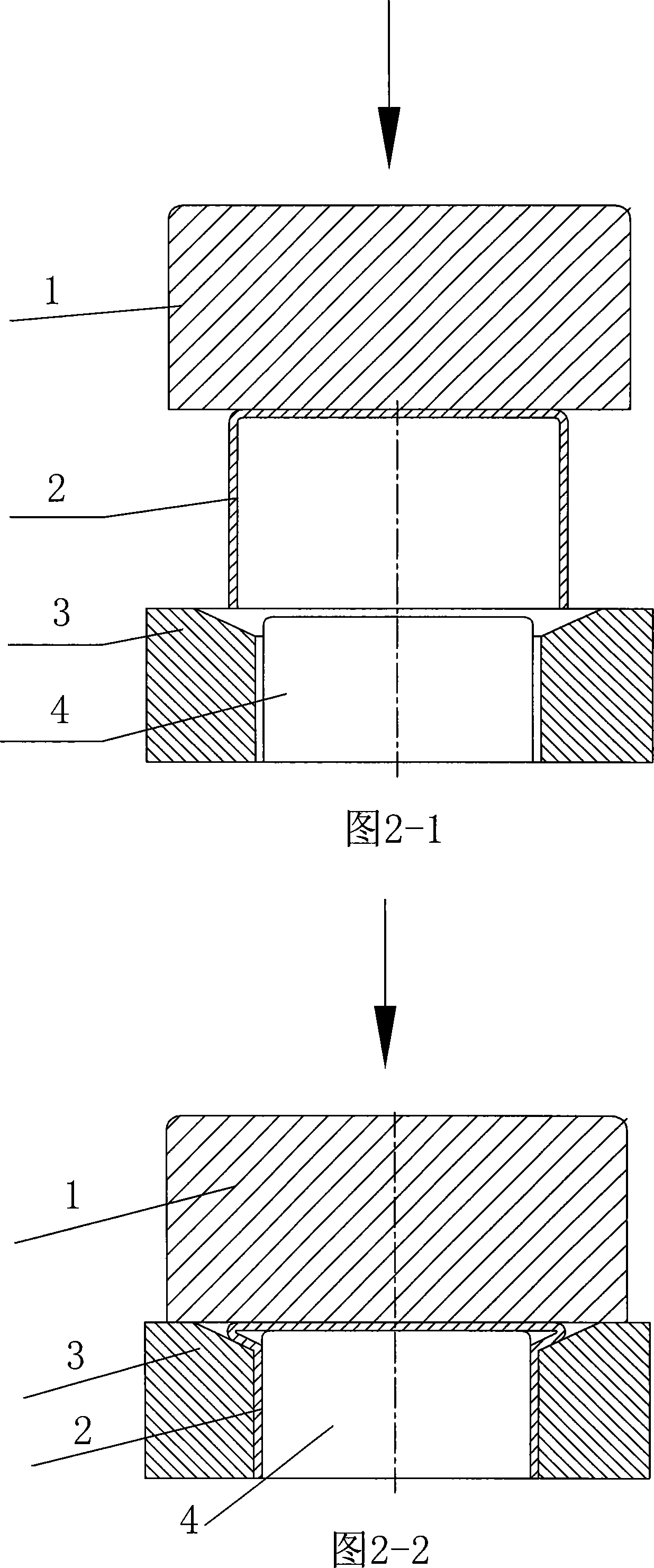

[0027] (4) Send the sheared workpiece into a 315-ton hydraulic press and a shrinking die to compress the mouth to the required diameter. The die 3 is a barrel cavity with a bell mouth, and the angle between the inner slope of the bell mouth and the inner wall of the barrel is 21° ~220 degrees, the positioning mold...

Embodiment 2

[0035] Take the 1Cr18Ni9 stainless steel plate as an example to manufacture the circular panel of the buffet stove.

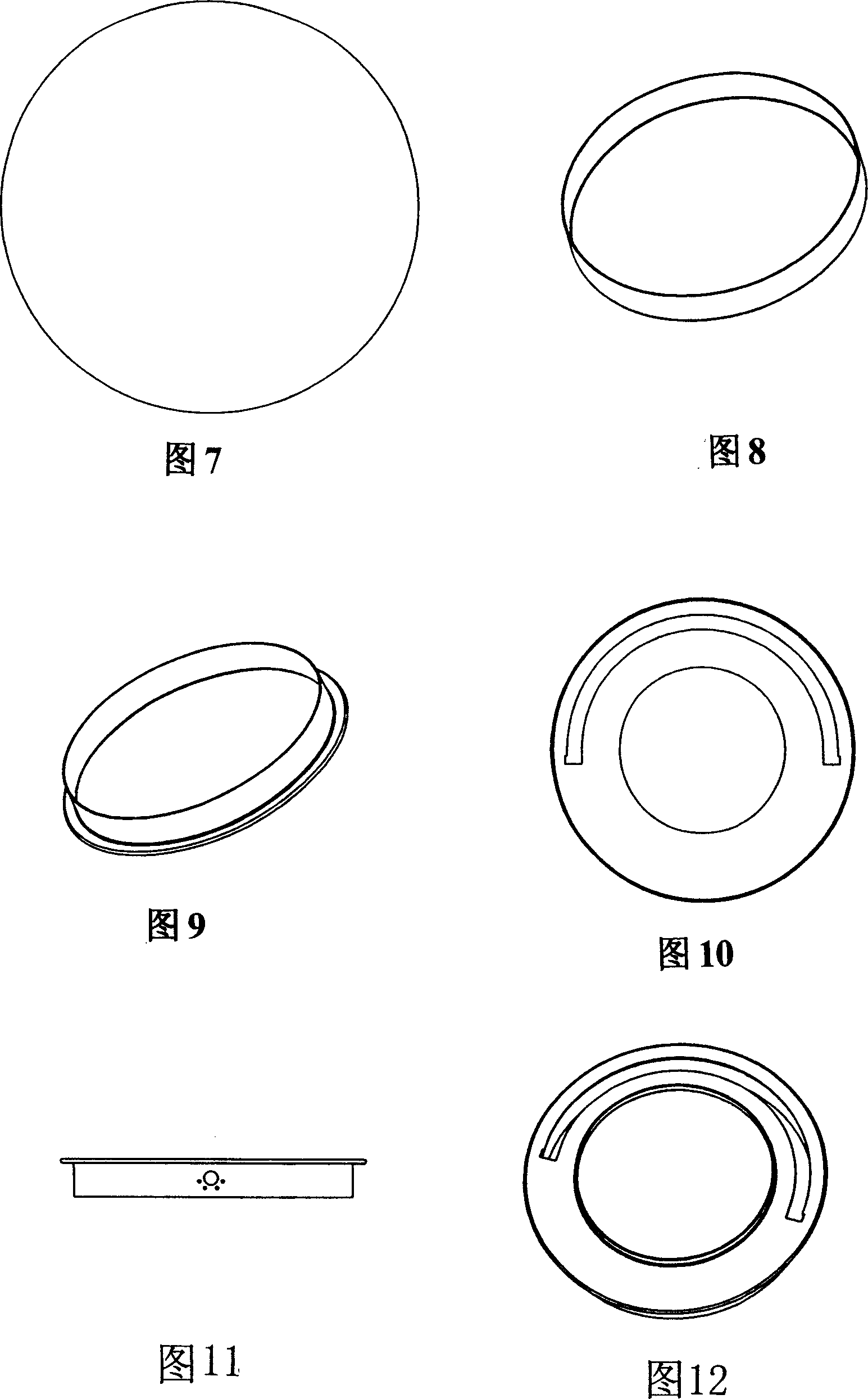

[0036] (1) Use the plate shearing machine φ640 sheet material with the stainless steel coil material with the grade of 2012B and a thickness of 1.8mm, and the workpiece shape is as shown in Figure 11;

[0037] (2) The circular piece is fed into a 315-ton hydraulic press and concave and convex molds for deep drawing. The lubricant is 1 μm polyethylene film, and the drawing height is 60-65mm. The shape of the workpiece is shown in Figure 12;

[0038] (3) Place the drawn workpiece in an electric furnace for annealing for 1 hour at an annealing temperature of 1050°C to 1080°C with 99% nitrogen concentration protection;

[0039] (4) Send the annealed workpiece into a 315-ton hydraulic press and concave and convex molds for deep drawing. The lubricant is polyethylene film, and the drawing height is 10-20mm;

[0040] (5) Use a 160-ton punch to cut off the outer edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com