Wall mounting structure of assembled M-type lightgage steel joists

A light steel keel and installation structure technology, applied in building construction, covering/lining, construction, etc., can solve the problems of increasing construction costs, increasing working hours, affecting the installation of wall panels, etc., to ensure smoothness and improve installation. Quality and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

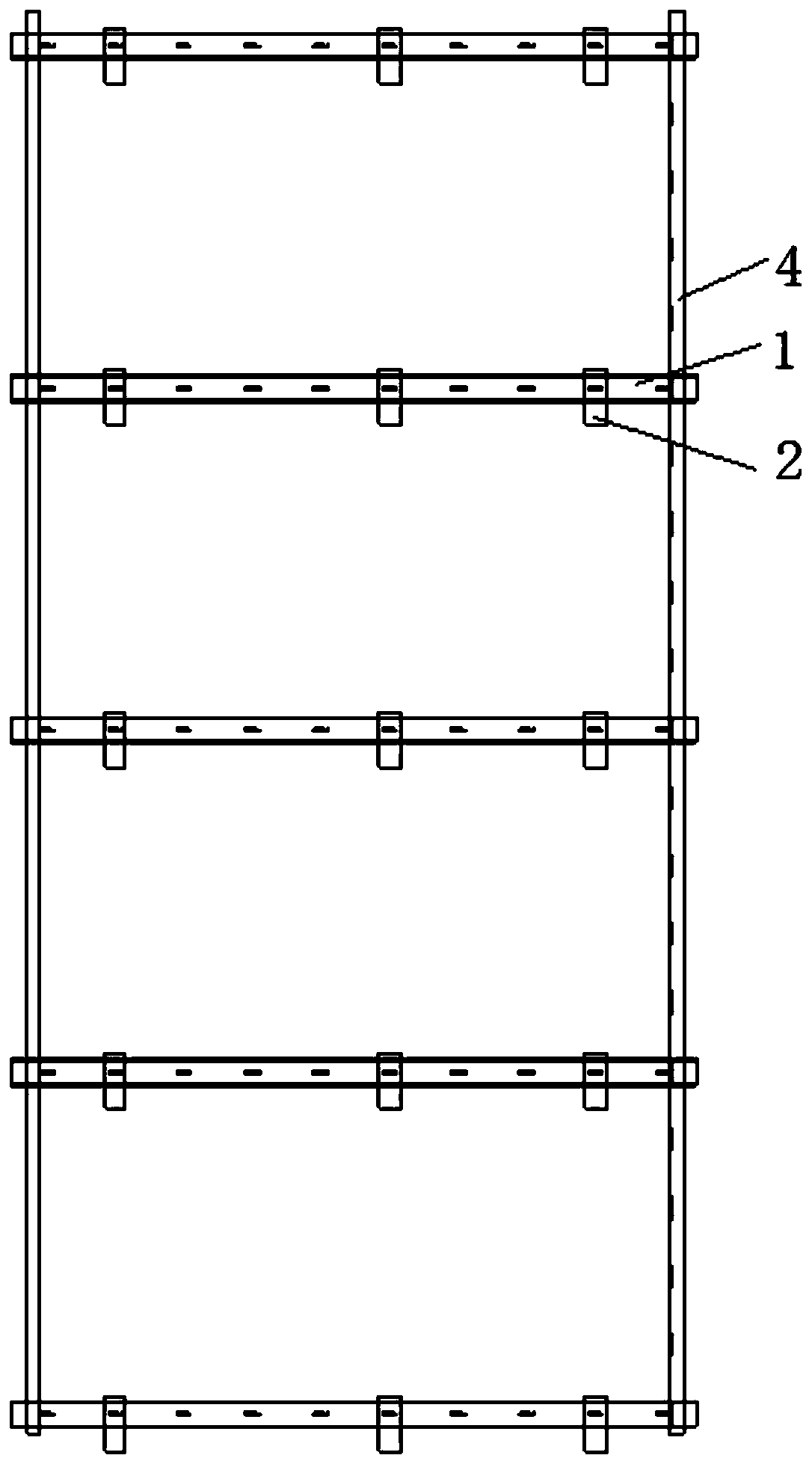

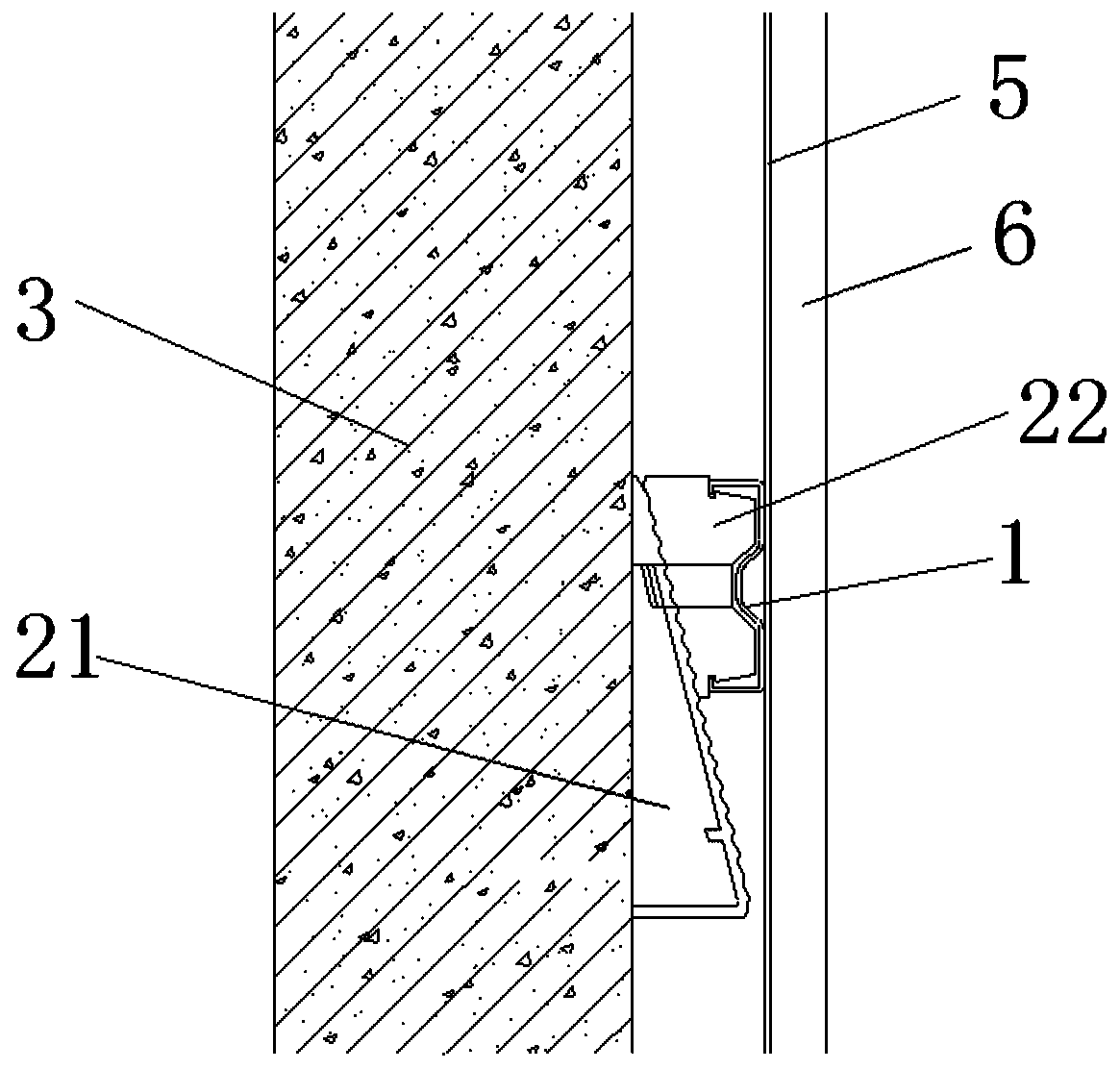

[0037] see Figure 1-2 , Figure 4-7 , the figure shows a wall installation structure of an assembled M-shaped light steel keel provided by Embodiment 1 of the present invention, which includes: M-shaped light steel keel 1, arranged along the horizontal direction, and two M-shaped light steel keels 1 The bottom of the side is provided with an inwardly bent clamping part 11; a leveling assembly 2, which includes a base 21 and a leveling seat 22 arranged on the base 21, the base 21 is fixed on the base wall 3, and the leveling seat 22 The inner clamping base 21, the outer side of which is clamped with the M-shaped light steel keel 1; the cassette 4 is arranged along the vertical direction, and both sides of the cassette 4 are uniformly and symmetrically provided with flanging buckles 41; the M-shaped light steel keel The middle position of 1 is connected with leveling assembly 2, and the leveling assembly 2 is evenly distributed along the length direction of the M-shaped light ...

Embodiment 2

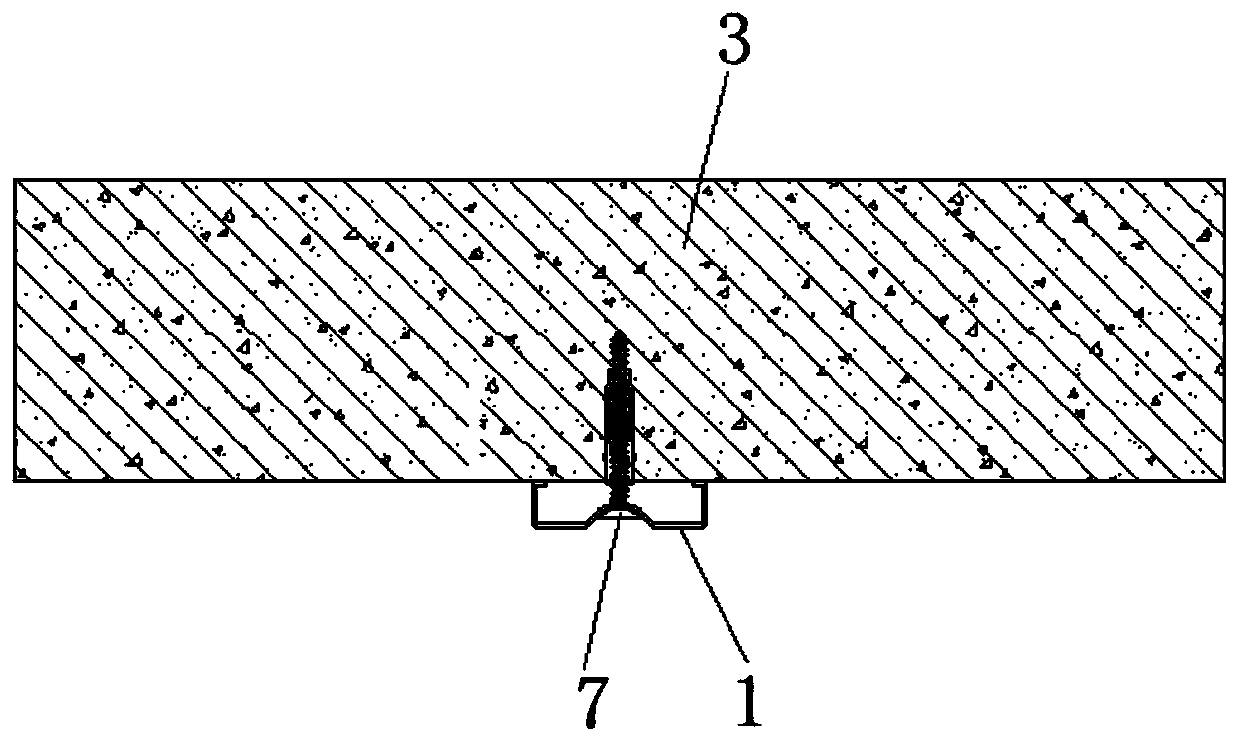

[0046] see Figure 3-4, the figure shows a wall installation structure of an assembled M-shaped light steel keel provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technologies as improvements Solution: In the middle of the top of the M-shaped light steel keel 1, an inwardly recessed connecting groove 12 is arranged, and the connecting groove 12 is arranged along the length direction of the M-shaped light steel keel 1; connecting holes 13 are evenly distributed in the connecting groove 12 , the distance between two adjacent connecting holes 13 is 100 mm. Through the setting of the above structure, the M-type light steel keel 1 can be fixedly connected with the base wall 3 through the screw 7, the screw 7 is located in the connection hole 13 in the connection groove 12, and the screw 7 will not protrude from the surface of the keel, so the screw 7 It is a subsidence connection, which c...

Embodiment 3

[0048] see figure 2 , Figure 7 , the figure shows a wall installation structure of an assembled M-shaped light steel keel provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technologies as improvements Solution: the side of the base 21 is triangular, and the inclined surface 211 is the connecting surface, and the adjusting seat 22 is clipped to the inclined surface 211; 221 is engaged with the clamping part 11; the side of the adjustment seat 22 is "M" shaped, and the card slot 221 is located on the upper and lower sides of the adjustment seat 22; along the inclined surface 211 of the base 21, the base 21 is provided with at least two connection Slot 212 ; a connecting rod 222 is arranged in the adjusting seat 22 , and the connecting rod 222 engages with the connecting groove 212 ; connecting teeth 23 are provided on the connection surfaces of the base 21 and the adjusting seat 22 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com