Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "No ripple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SMC sheets and its prepn. method

InactiveCN1903563AShorten the curing timeLow molding temperatureSynthetic resin layered productsGlass/slag layered productsGlass fiberHigh surface

A SMC sheet with high surface quality and luster is composed of both surficial PE films and a core material prepared from glass fibers through immersing them in the resin paste which is proportionally from unsaturated polyester resin, low-shrinkage additive, internal demoulding agent, calcium carbonate, styrene, trigger and magnesium oxide.

Owner:北京玻钢院复合材料有限公司

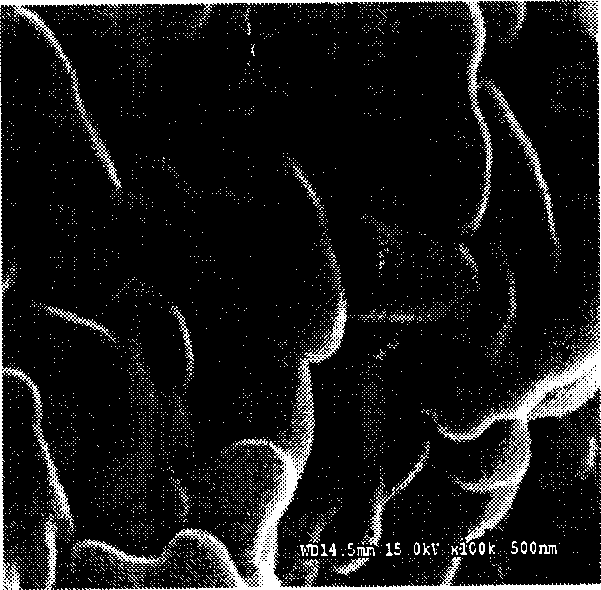

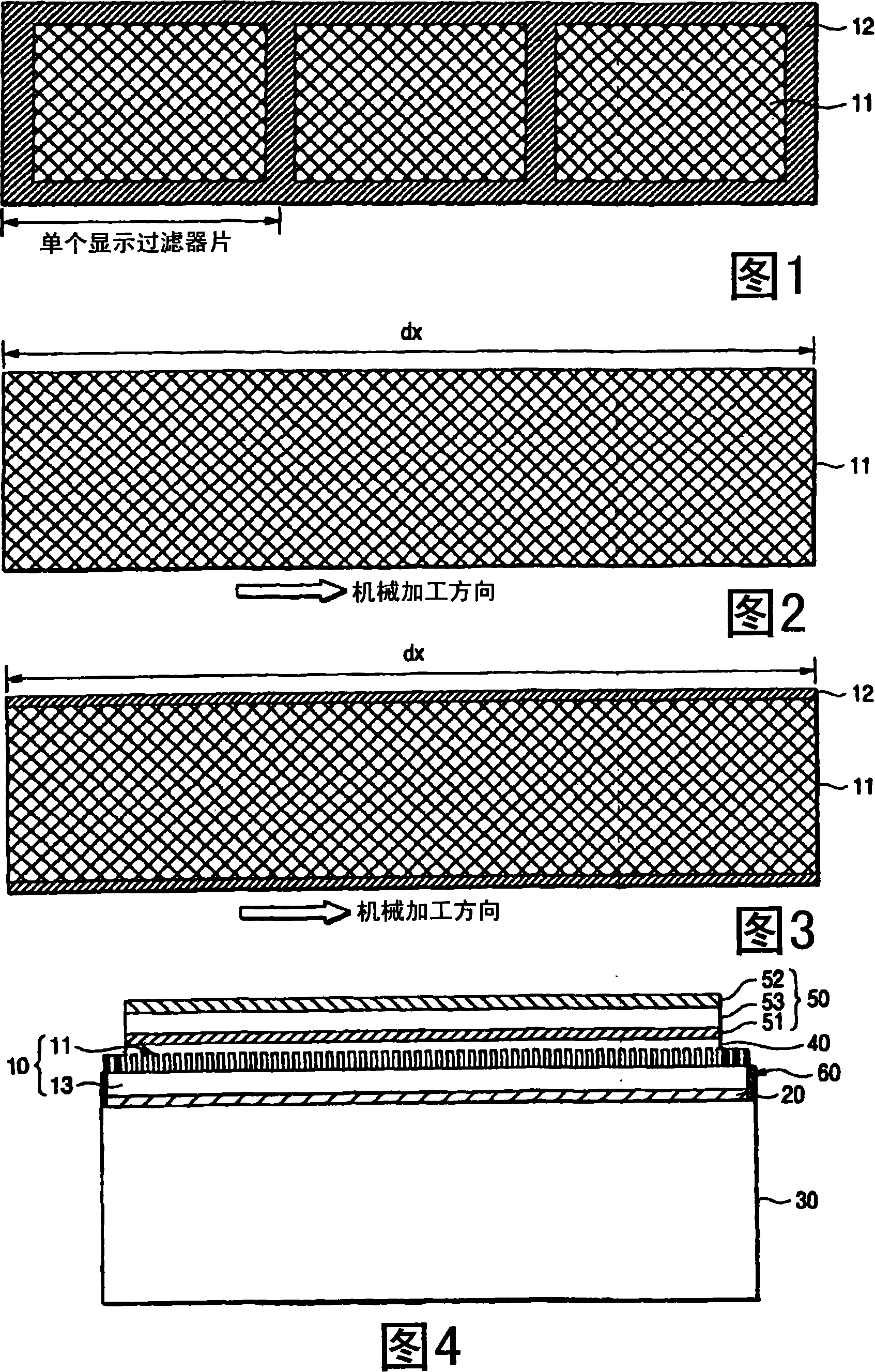

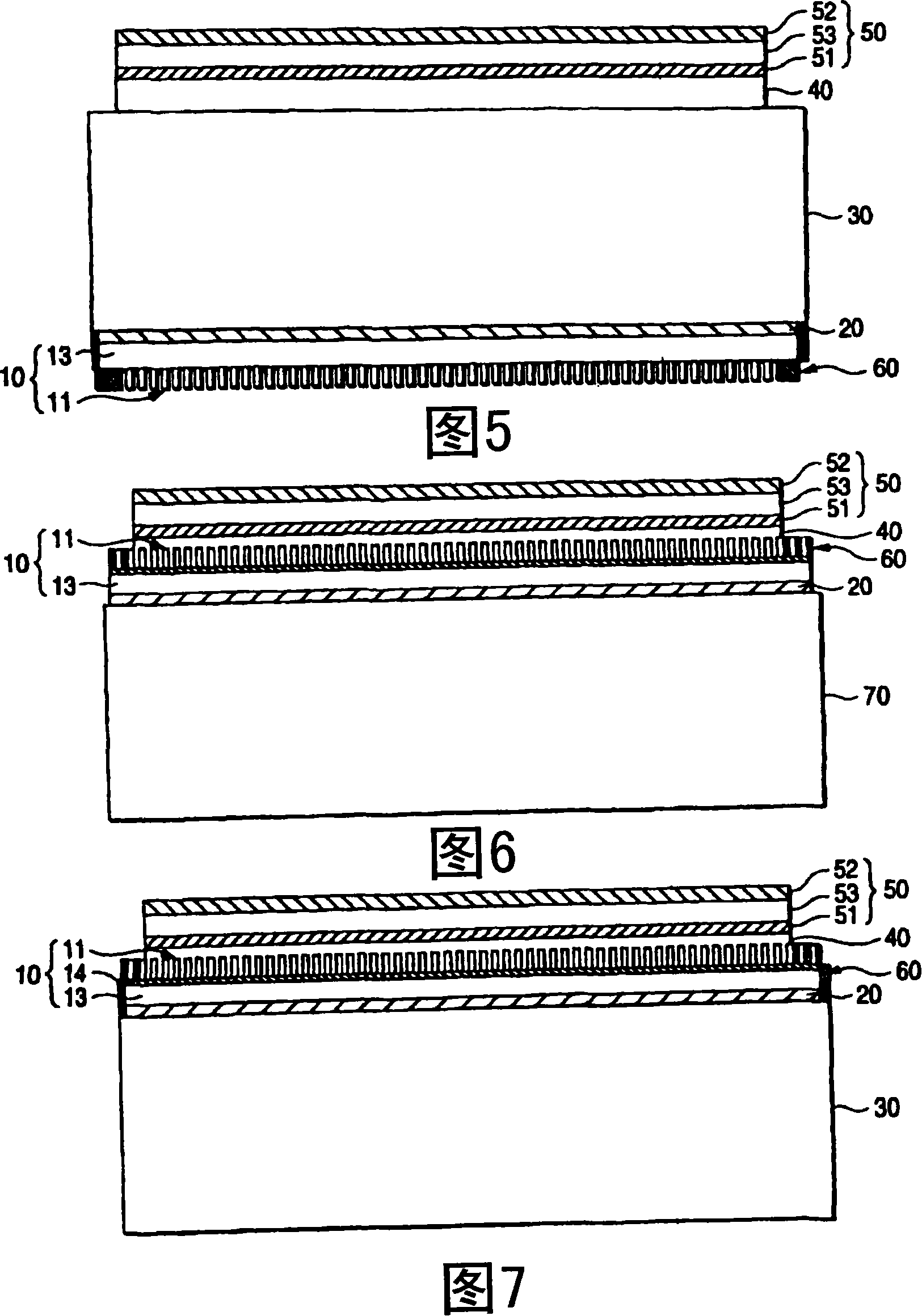

Light transmitting conductive film, light transmitting electromagnetic shield film, optical filter and method for manufaturing display filter

InactiveCN101120626AReduce lossesGood EMI shielding performanceConductive layers on insulating-supportsMagnetic/electric field screeningEngineeringPolymer thin films

A light transmitting conductive film formed by patterning a conductive metal section and a visible light transmitting section on a transparent supporting body is characterized in that the conductive metal section is formed of a 1-40[mu]m mesh-like fine wire, and the mesh pattern is continued for 3m or more. A method for manufacturing a display filter whose edge sections of at least two facing sides are mesh-like. In the method, an electromagnetic shield material (C) wherein a mesh-like geometrical pattern conductive layer (B) is continuously formed in a machining direction of a polymer film (A) on the polymer film (A) is used to cut the mesh-like section.

Owner:FUJIFILM CORP

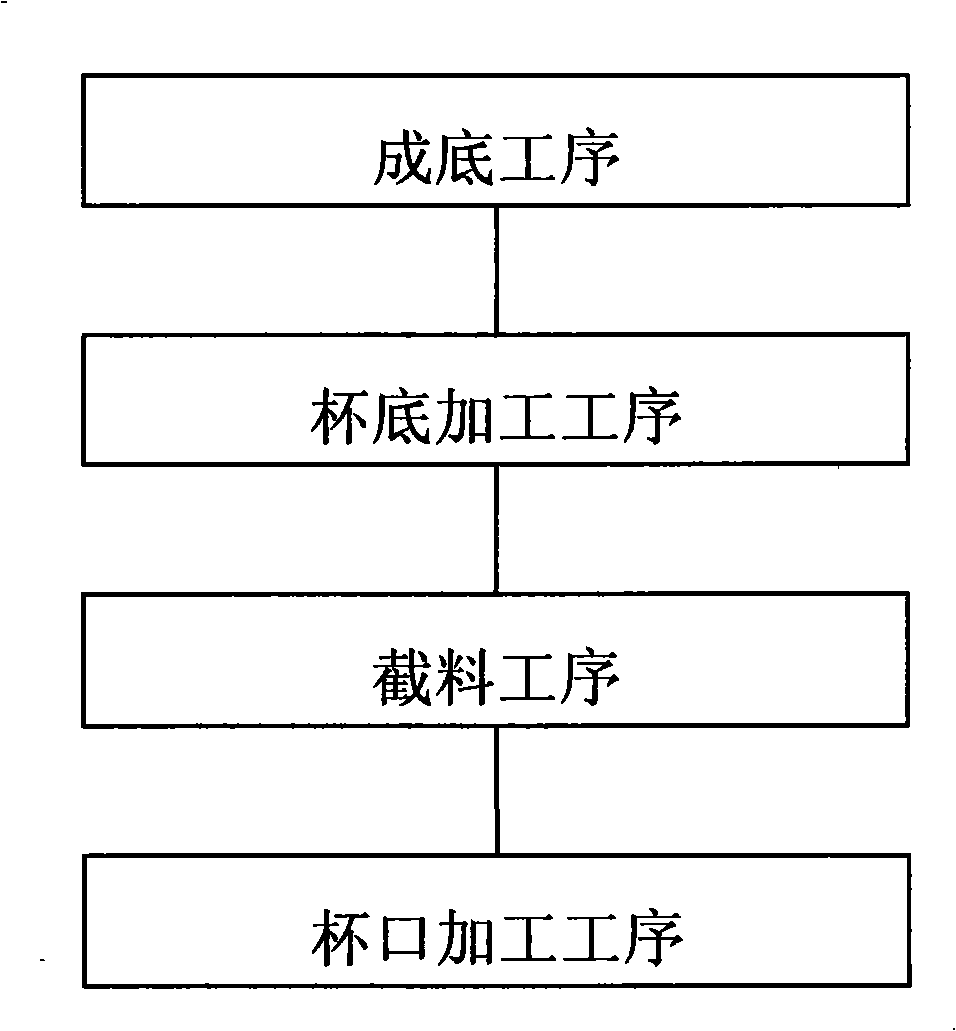

Method for preparing single layer glass by glass tube

InactiveCN101357820AGood light transparencyImprove yieldGlass reforming apparatusGlass productionCutting glassSoftening

The invention relates to a method for producing a single-layer glass cup by using a glass tube. The method comprises the following steps: A. material cutting process: the glass tube is cut into the glass tube material section with the height which is twice that of the finished glass cup; B. bottom forming process: the both ends of the cut glass tube material are clamped on a rotary device to locally heat the middle part of the tube material till the softening of the glass, a heat-resistant material blade with the thickness which is less than the width of a heating zone and does not have the affinity with the glass is used for cutting the middle part of the heating zone to form blanks of two cup bottoms; C. cup bottom processing process: the cup-shaped glass tube material is clamped on the rotary device, flames are used for heating the bottom part of the glass cup-shaped tube material along the transverse direction at the same time of rotation till the melting of the glass, and the cup bottoms are thickened to meet the design requirements. The method has simple production technology, greatly improved yield, good overall transparency of the cup and no need of polishing. The production efficiency is greatly improved, and the method can be used for large-scale production and family workshop operation. The equipment cost is greatly reduced, and the method can be used for the production by only using a special burning device, thereby eliminating the constraints of a kiln on the production scale and the place.

Owner:郝身峙

Global mold plastic, preparing method and uses thereof

The invention provides a bulk moulding compound (BMC) and a preparation method thereof. The material is solidified at certain speed in an injection mould, prevents surface deficiencies, such as ripples, pinholes, pockmarks, scorching, etc., does not reduce the production capability because of too long solidifying time, so the obtained BMC material can be adaptive to all kinds of injection moulds. The invention also provides an automobile lamp reflector substrate processed by such bulk moulding compound and a processing method thereof. The obtained reflector substrate not only has excellent heat resistance and mechanical strength, but also can form a neat and smooth reflective mirror without ripples and other surface deficiencies on the surface through aluminum evaporation plating. Even if the temperature of the mould is as low as 150 DEG C to 160 DEG C, satisfying effect can still be obtained.

Owner:HASCO VISION TECHNOLOGY CO LTD

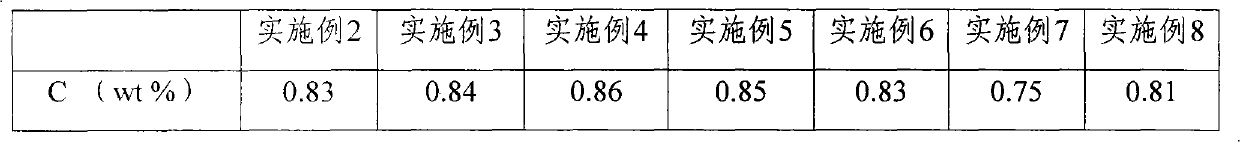

Working roll for automobile sheet cold rolling and manufacturing method thereof

ActiveCN102002644AImproved accident resistanceRaise tempering temperatureFurnace typesHeat treatment furnacesWork rollIngot

The invention discloses a cold-rolling working roll for rolling a high-quality automobile sheet, which comprises the following chemical constituents in percentage by weight: 0.70-1.00% of C, 0.4-1.50% of Si, 0.20-1.00% of Mn, 4.50-6.50% of Cr, 0.20-1.00% of Mo, 0.05-0.50% of V, 0.20-1.50% of Ni, no more than 0.025% of S and no more than 0.025% of P. The roll blank is subject to an electroslag ingot manufacturing process in a special electroslag mode, wherein the quenching holding temperature in heat treatment is 940-1020 DEG C, the cold treatment temperature is from 90 to 50 DEG C, the treatment time is 2-8h, the tempering holding temperature is 120-145 DEG C, and the holding time is 60-150h. The surface hardness of the cold-rolling roll is 90-100 HSD. The manufactured cold-rolling working roll has fine roll-surface structural homogeneity and overall performance, thereby meeting the rolling requirements of the high-quality automobile sheet.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

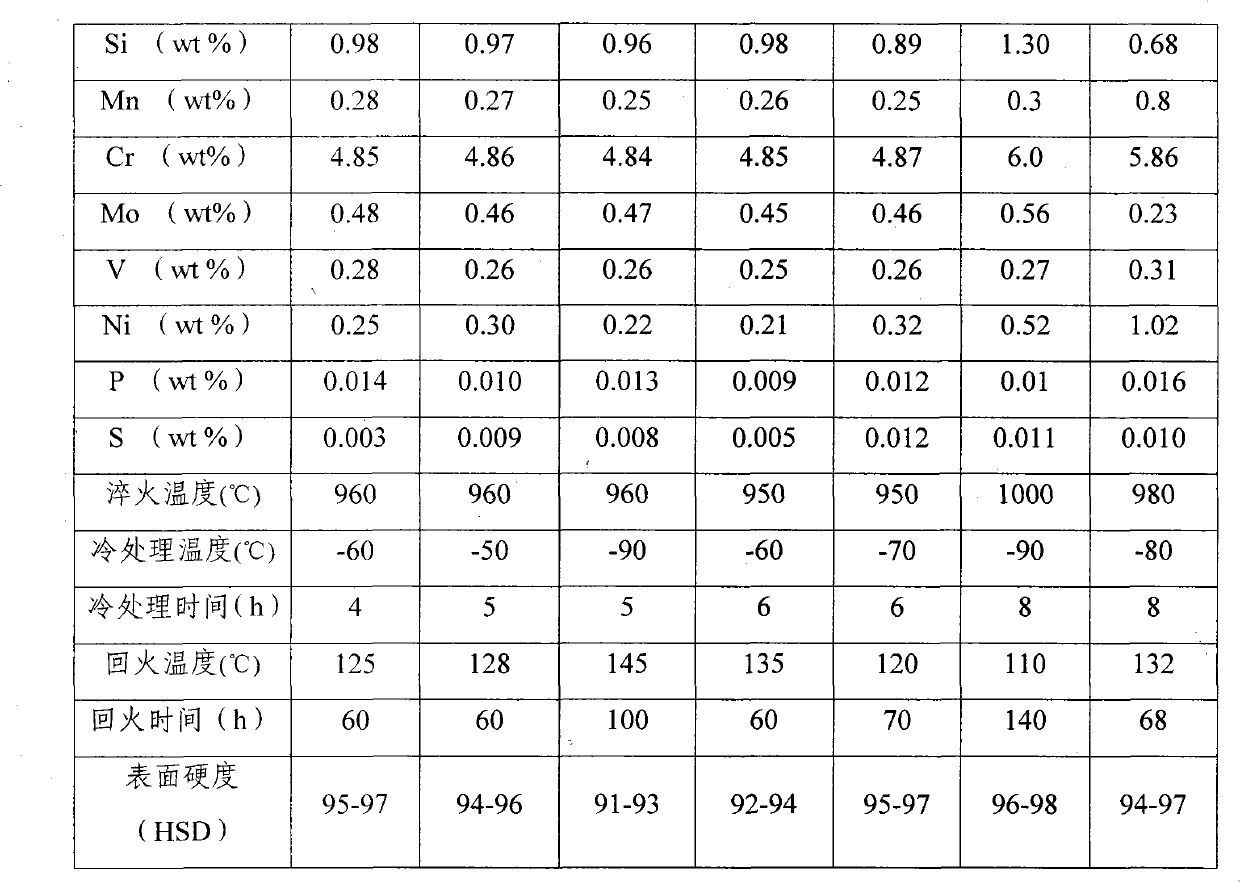

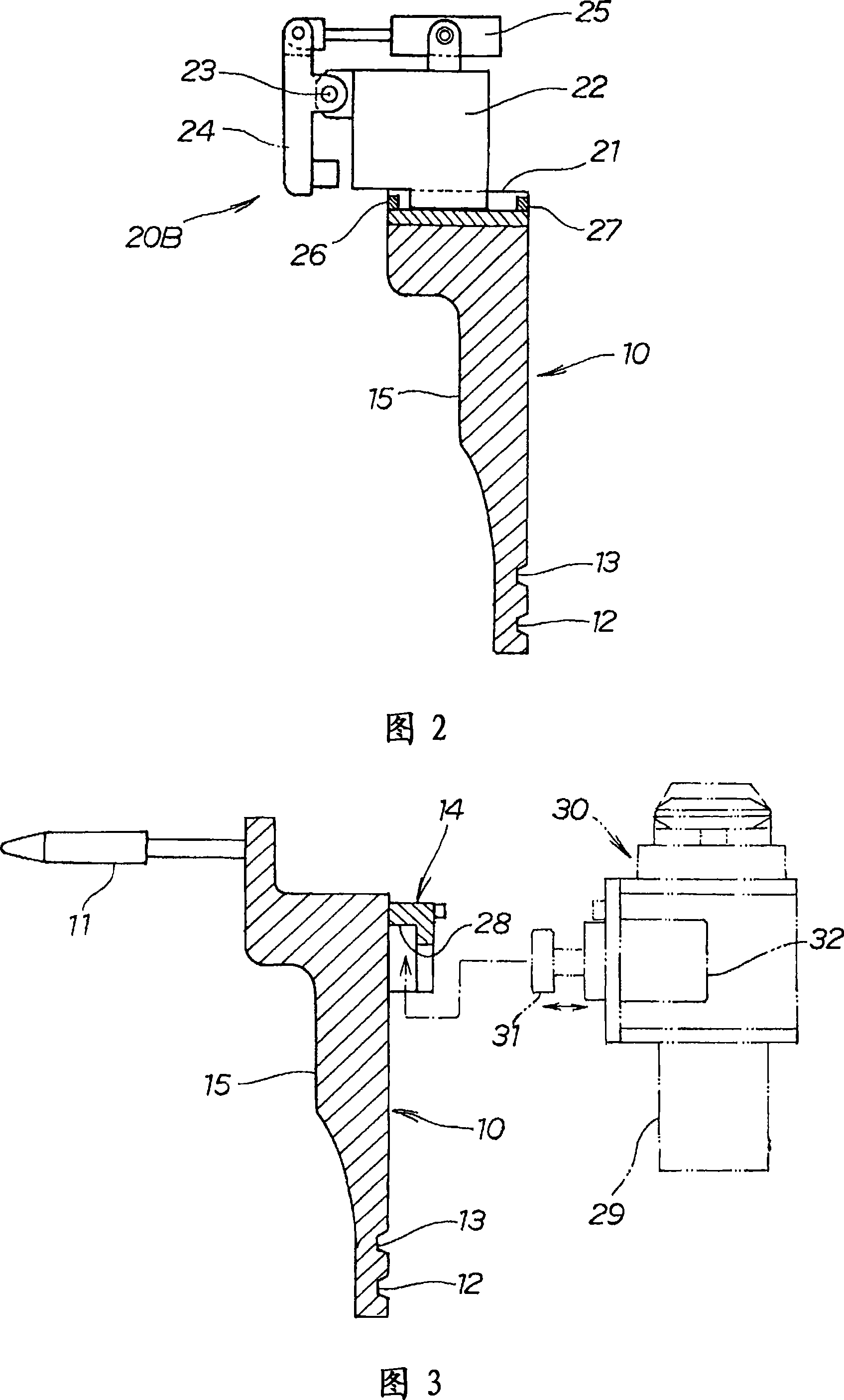

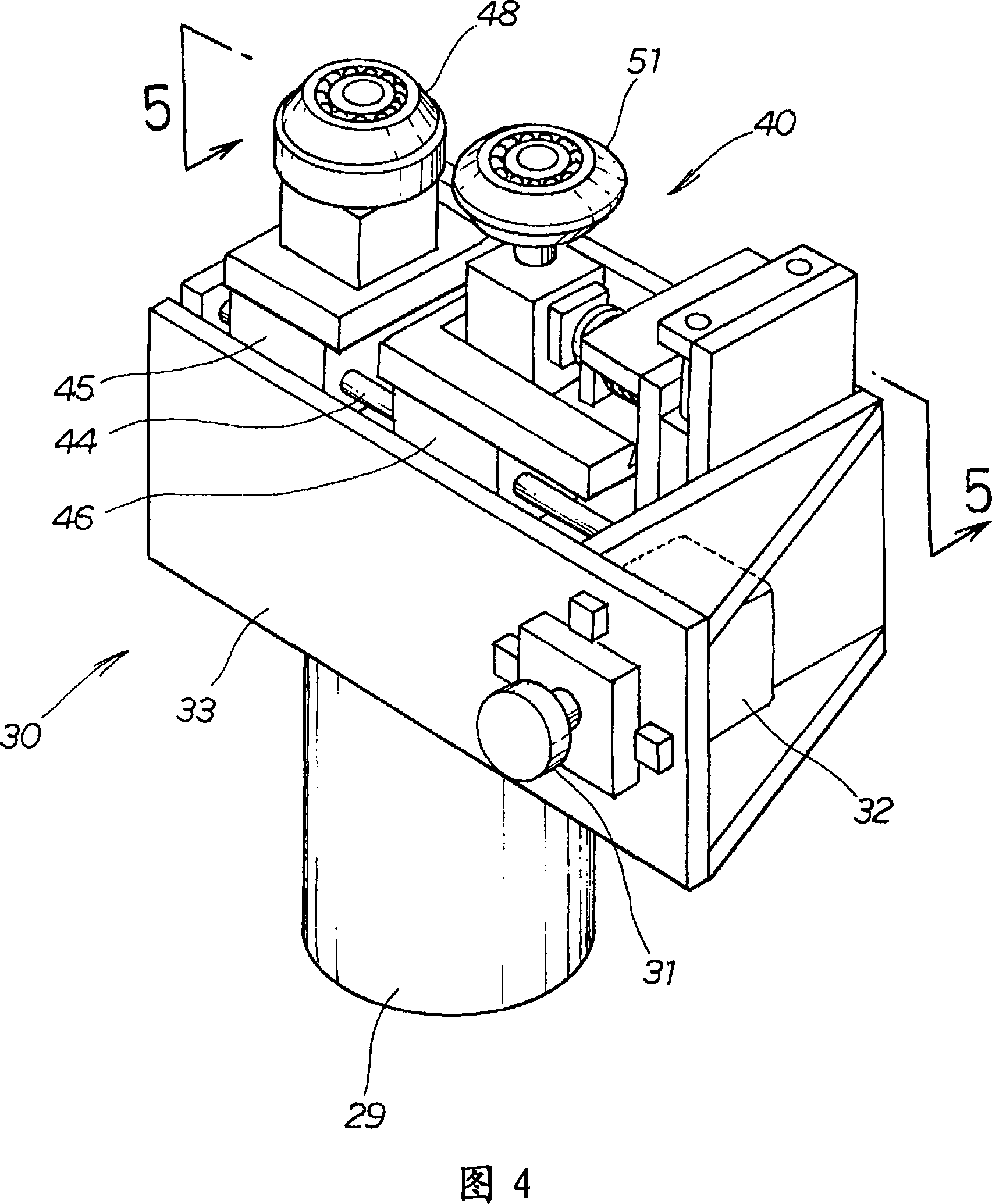

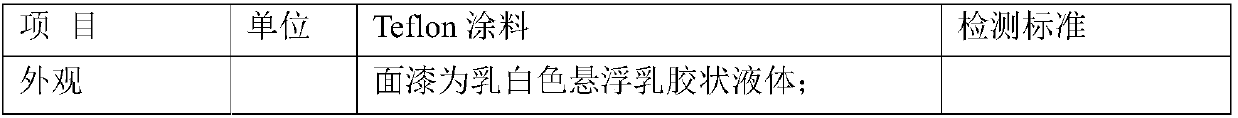

Roller hemming device and roller hemming method

A roller (48) starts to bend a standing flange (65) in the initial state of a roller hemming processing. A first plate material (63) is fitted to a receiving face (15) by the strong holding action of the roller (48) and an auxiliary roller (51) at a contact point (70) between the roller (48) and the standing flange (65). On the other hand, the receiving face (15) tends to be separated from the first plate material (63) by the reaction thereof at those portions other than the contact point (70). Since slider blocks (22) and (22) are movable along rails (21) and (21) on a receiving mold (10), the receiving mold (10) is rotated clockwise about the contact point (70) (as shown in the figure). Since the receiving mold (10) is rotated about the contact point (70), the adhesiveness of the first plate material to the receiving face at the contact point (70) can be assured. As a result, the hemming processing free from wrinkles, waving, and deformation to provide excellent shape can be achieved.

Owner:HONDA MOTOR CO LTD

Method for producing large thin-wall integral-ring vitrified grinding wheel

ActiveCN103537993AUniform product surfaceNo rippleAbrasion apparatusGrinding devicesHigh pressureGrinding wheel

The invention relates to a method for producing a large thin-wall integral-ring vitrified grinding wheel. The method for producing the large thin-wall integral-ring vitrified grinding wheel includes the following steps that first, vitrified bond, grinding material and resin are evenly mixed according to a certain proportion; second, the raw materials in the first step are filled into a mold and undergo hot press molding; third, demolding is performed; fourth, high pressure firing is performed, and the large thin-wall integral-ring vitrified grinding wheel is obtained after the firing is completed and the grinding wheel passes inspection. The integral-ring thin-wall grinding wheel with the diameter larger than 200mm and the thickness smaller than 10mm can be directly produced with the production method, yield of the products can reach 99%, and demolding yield of the products can reach 100%. Because the large thin-wall integral-ring vitrified grinding wheel produced with the production method does not have bonding seams in the prior art, the surfaces of the ground products are uniform, and corrugation does not exist.

Owner:HENAN HUAMAO NEW MATERIAL TECH DEV

Method for embedding preservation of cast specimen

InactiveCN107727479AImprove protectionSolve the phenomenon of mold branch fracturePreparing sample for investigationVacuum pumpingPolyester resin

The invention relates to a method for embedding preservation of a cast specimen. The method comprises the following steps: (1) preparation of a mold: measuring the size of a cast specimen to be embedded and making a synthetic glass specimen box with an opened end and a corresponding size as an embedding mold; (2) blending of polyester resin and bubble removal; (3) embedding: slowly pouring the polyester resin without bubbles into the specimen box until the polyester resin totally soaks the upper end of the cast specimen, then placing the specimen box into an enclosed container, filling gaps between the specimen box and the enclosed container with ice cubes, wherein the level of the ice cubes should be lower than the level of resin liquid, connecting the enclosed container with a vacuum pump, carrying out vacuum-pumping, and after bubbles are extracted from the specimen box, taking the specimen box out from the enclosed container and placing the specimen box in an environment with a temperature of 25 DEG C or below for 24 to 48 h; and (4) processing: after complete curing of the polyester resin, rubbing and polishing unwanted edges. According to the invention, the polyester resin used for embedding the cast specimen, so the phenomenon of fracture of cast branches in use of the cast specimen is overcome, and the embedded cast specimen is convenient for transport, carrying and long-term preservation.

Owner:FUJIAN UNIV OF TRADITIONAL CHINESE MEDICINE

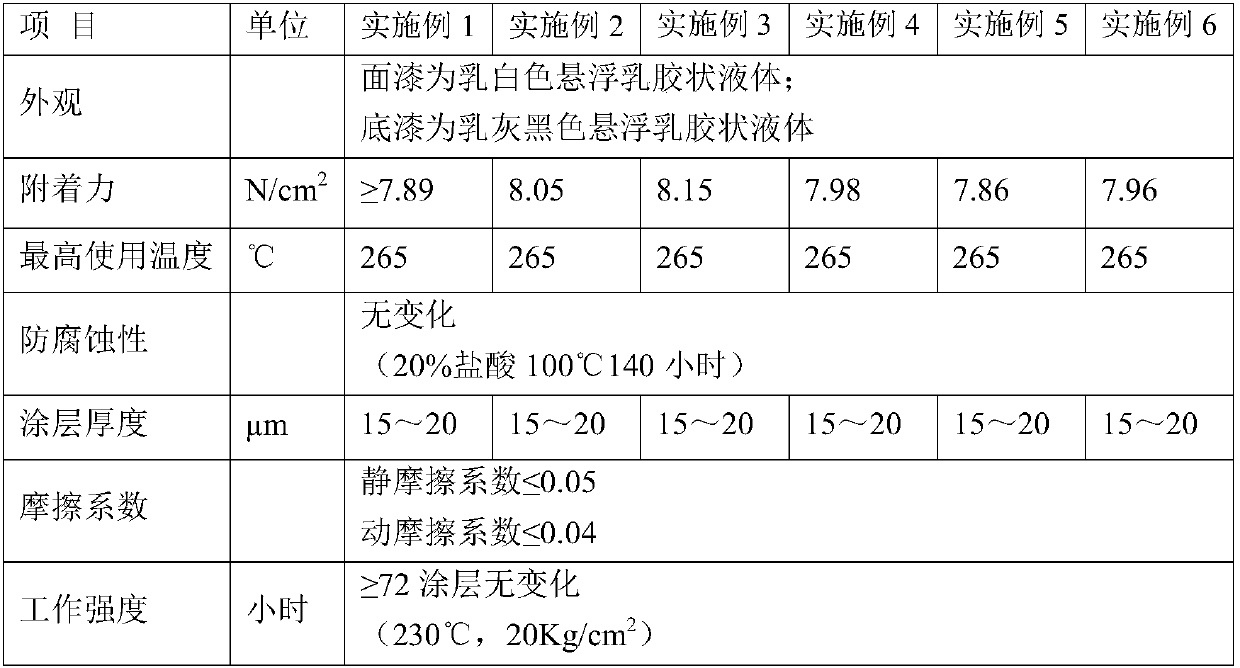

Teflon coating material and application thereof

The invention discloses a Teflon coating material and an application thereof. The Teflon coating material comprises a top coat and a primer, wherein the top coat comprises the following components inparts by weigh: 100 parts of polytetrafluoroethylene dispersion solutions, 1-5 parts of mica powder, 15-25 parts of mixed solutions, 0.1-1 part of metal oxide, 5-15 parts of binary thermoplastic copolymer dispersion solutions and 0.5-1 part of a nonionic surfactant; the primer comprises the following components in parts by weigh: 100 parts of polytetrafluoroethylene dispersion solutions, 5-10 parts of mica powder, 1-5 parts of graphite powder, 1-5 parts of metal oxide, 5-10 parts of polyphenylene sulfide, 20-40 parts of polyamic acid salt solutions, 20-40 parts of silica sol and 80-120 parts of deionized water. According to the Teflon coating material prepared by a composition, smooth, corrugated and burr-free extruded pipe products can be ensured, and the time for the coating material tocompletely adhere to the metal surface of an extrusion die is prolonged, and thus the replacement time of the extrusion die is prolonged, and the production efficiency is improved.

Owner:PETROCHINA CO LTD

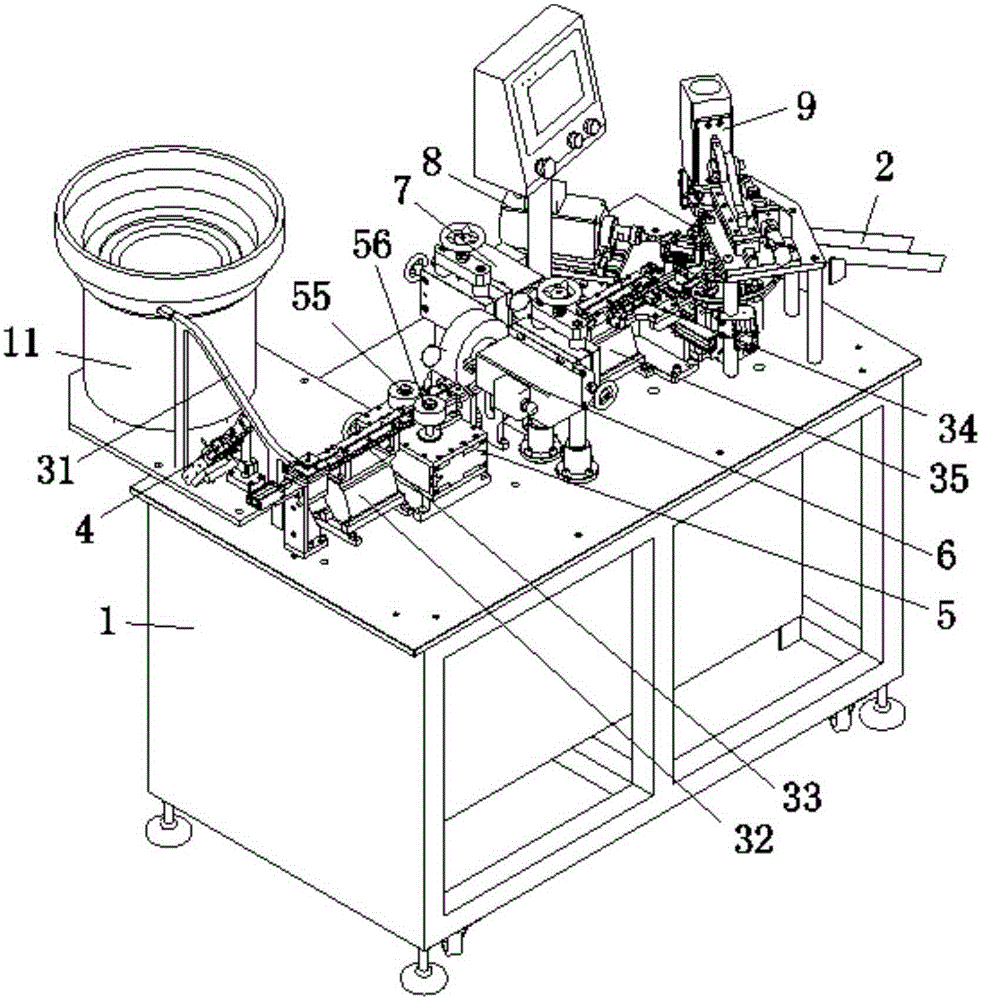

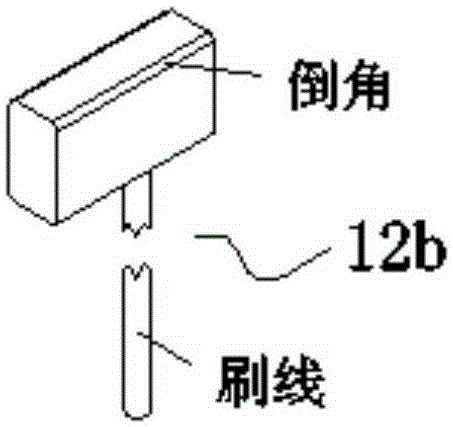

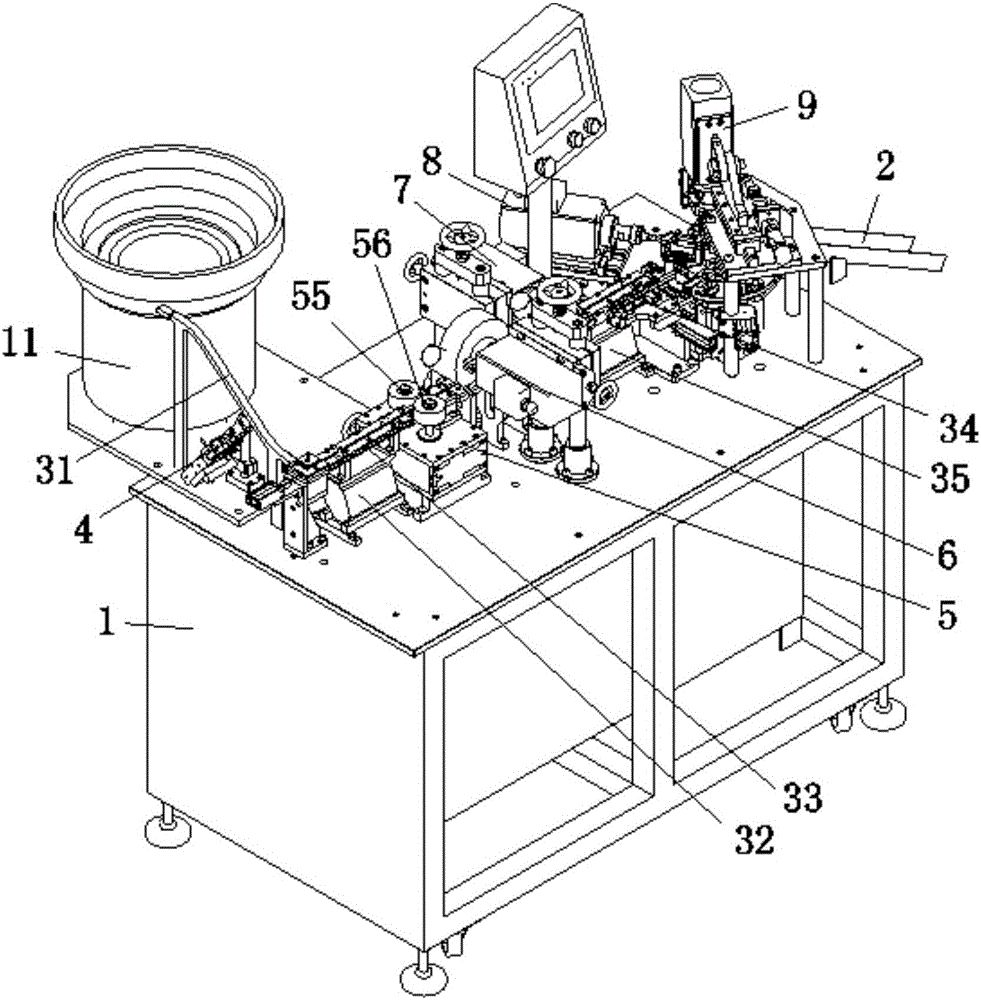

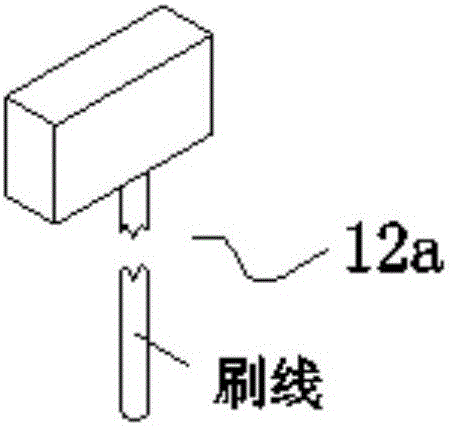

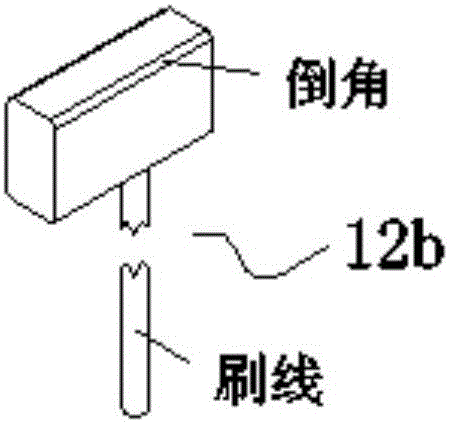

Method for head rotation and arc striking of carbon brush

ActiveCN106466799AReduce laborShorten the timeGrinding machinesGrinding feedersElectricityEngineering

The invention discloses a method for head rotation and arc striking of a carbon brush. The method comprises the following steps in sequence: the carbon brush is clamped on a fixture positioned in an introducing station; the fixture clamped with the carbon brush rotates onto a head rotating station, and a head rotating device performs the head rotation for the front end surface of the carbon brush; after head rotation, the fixture clamped with the carbon brush rotates onto an arc striking station, and an arc striking device performs arc striking for the back end surface of the carbon brush; and after arc striking, the fixture clamped with the carbon brush rotates onto a delivery station, and a delivery device discharges the carbon brush from the fixture for clamping the carbon brush. The method integrates grinding, chamfering, head rotation and arc striking, automatically finishes the procedures for the carbon brush, reduces the procedures, reduces labors and the time needed for transfer of the carbon brush, improves the production efficiency, reduces the labor cost, is stable in quality of machined products and excellent in consistency, saves electricity, reduces emission, and facilitates environmental protection.

Owner:SUZHOU RUIBEN IND FURNACE

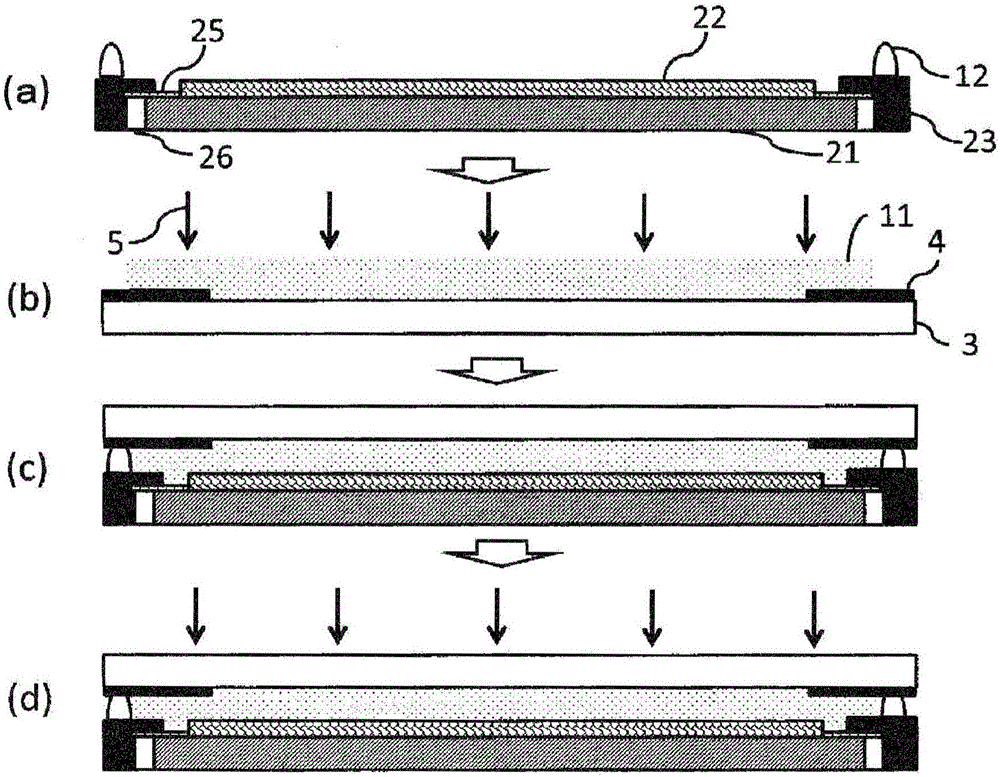

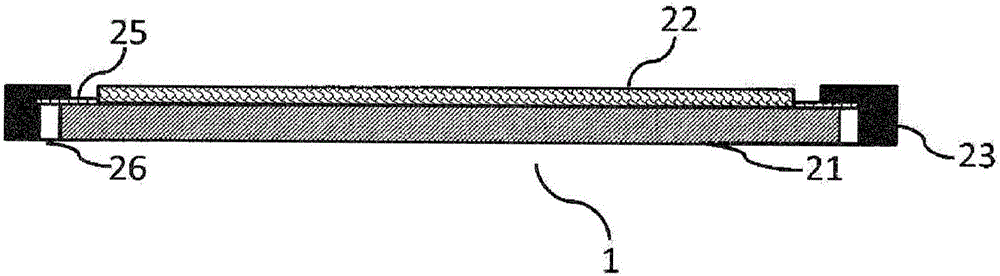

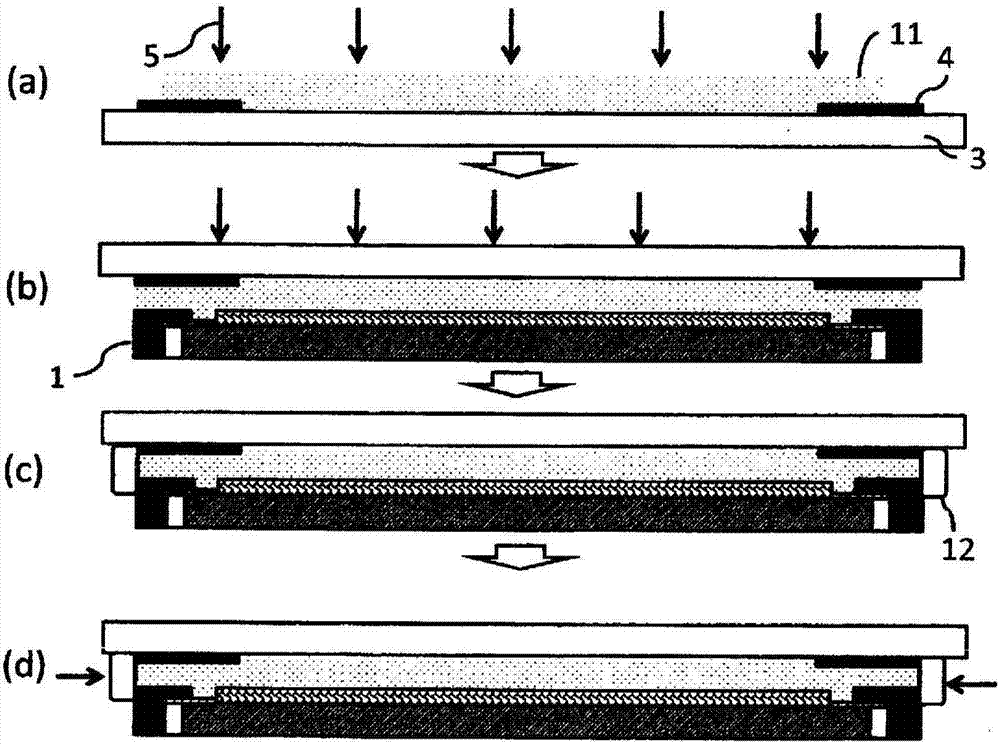

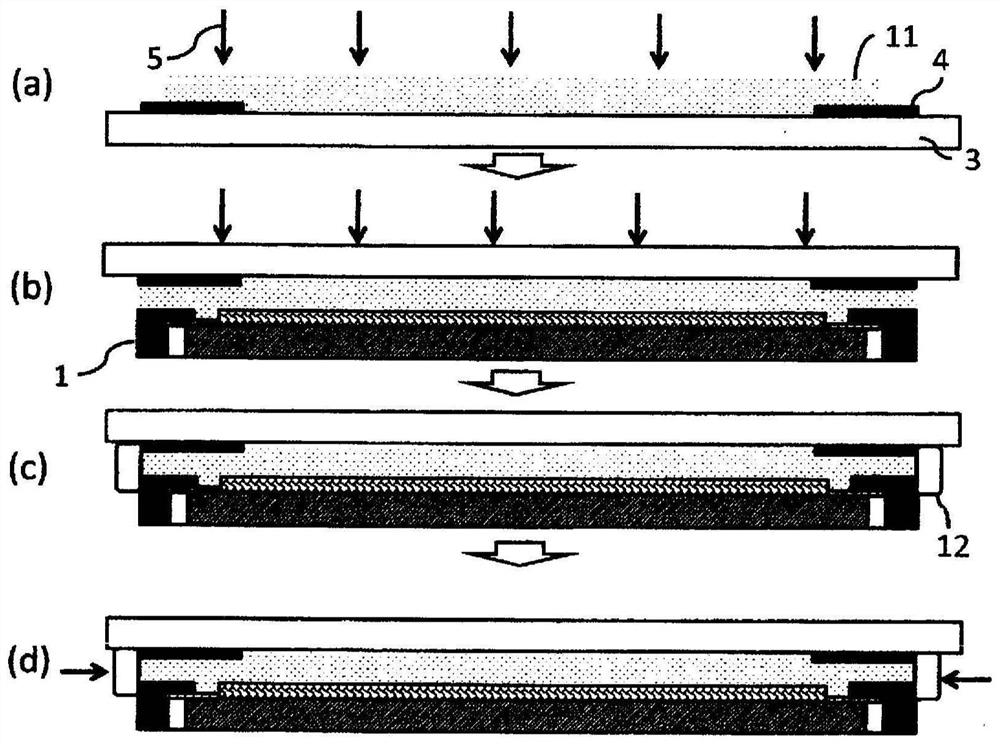

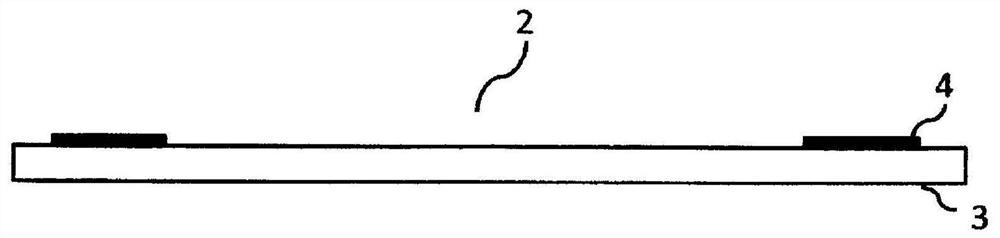

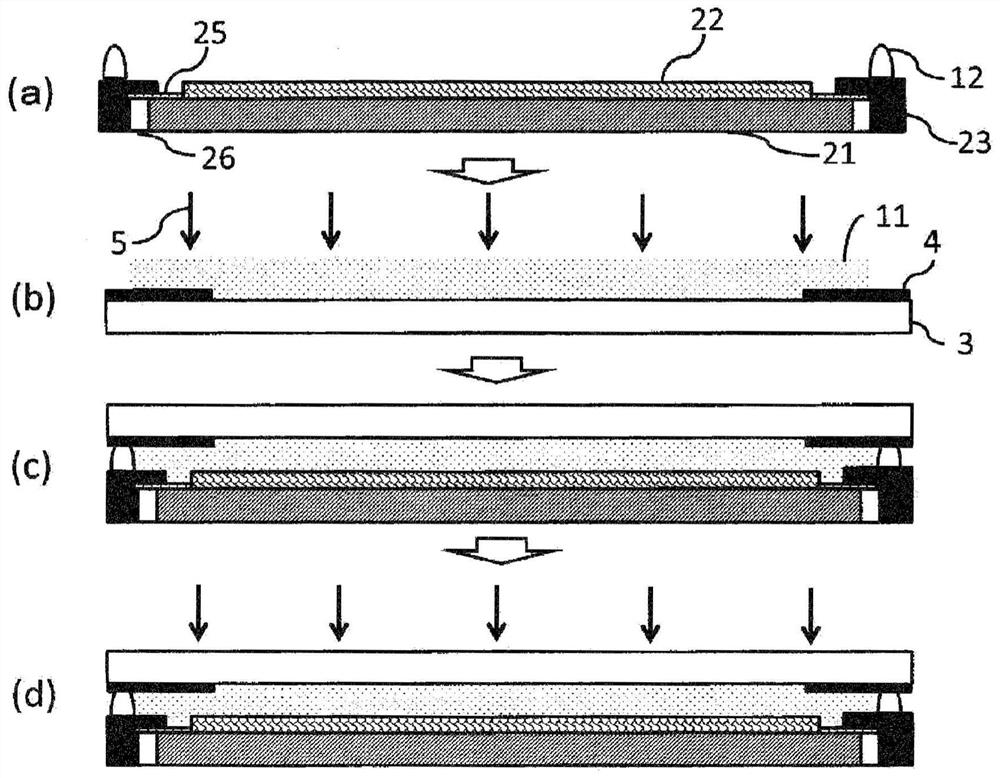

Image display device manufacturing method, hardening resin composition used therein, and image display device

Provided are an image display device manufacturing method capable of obtaining an optical member with excellent visibility without causing a ripple even if any portion is pressed, a hardening resin composition used therein, and an image display device. An image display device manufacturing method comprises: a step for demarcating an application region of a first hardening resin composition by a second hardening resin composition; a step for applying the first hardening resin composition to the application region; and a step for hardening the first hardening resin composition to bond a liquid crystal display unit and a protection plate, and a hardened material layer obtained by hardening the second hardening resin composition is laminated on a projection region of a sealing body and is not laminated on a projection region of a polarizing plate. It is preferable that the first hardening resin composition or the second hardening resin composition contain (meth)acrylate (A) and a photopolymerization initiator (B).

Owner:NIPPON KAYAKU CO LTD

Water-soluble non-toxic environment-friendly automobile coating and preparation method thereof

InactiveCN102757717AEmission reductionReduce dosagePolyurea/polyurethane coatingsPolyester coatingsEnvironmental resistanceWeather resistance

The invention relates to a water-soluble non-toxic environment-friendly automobile coating and a preparation method thereof. The automobile coating comprises, by weight, 30-60 parts of water dispersive resin, 25-45 parts of pigments and fillers, 1-5 parts of additives and 10-35 parts of water. The method includes the following steps: step one, according to a formula requirement, putting 60%-80% of the water dispersive resin, the pigments and fillers and the additives into a high-speed dispersion machine for 30-60 minutes of high-speed dispersion to obtain a mixture; step two, grinding the mixture to a fineness within 15 microns through a grinder; step three, mixing the residual water dispersive resin with the ground mixture, performing high-speed dispersion again for 10-20 minutes, and adjusting the solids content to 60%-65%; and step four, filtering through a 200-mesh filter screen to obtain a product. Compared with the prior art, the automobile coating has the advantages of being non-toxic and environment-friendly, good in flame retardance and weather resistance and the like.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

Precision high-efficiency tubing sizing sleeve

InactiveCN104669588AEfficient productionScientific and reasonable structureHigh ratePlastic materials

The invention relates to a precision high-efficiency tubing sizing sleeve. The precision high-efficiency tubing sizing sleeve comprises a water distribution base, a sizing sleeve and a flange connecting the water distribution base and the sizing sleeve, the water distribution base is provided with water inlet and outlet connectors for cooling water feeding and discharge, the cooling water enters into the water distribution base by the water inlet connector, a water ring is formed in the water distribution base, the sizing sleeve is a single-wall metal tube, the inner side of the front tube wall section is provided with a helical groove and is densely covered through holes, and the rear tube wall section is provided with a straight trough. Compared with the existing tubing sizing sleeve, the precision high-efficiency tubing sizing sleeve is suitable for pipe diameters phi of 16-1000, is suitable for production of tubes prepared from different plastic materials such as PVC and other materials, does not produce pipes with crinkles and nonuniform tube wall thickness in tube production, prevents adhesion of the tube blank to the tubing sizing sleeve, and realizes smooth outer tube walls and uniform wall thickness. The whole cooling sizing system is stable and reliable and guarantees high-rate high-precision tube production.

Owner:SHANGHAI JINHU EXTRUSION EQUIP

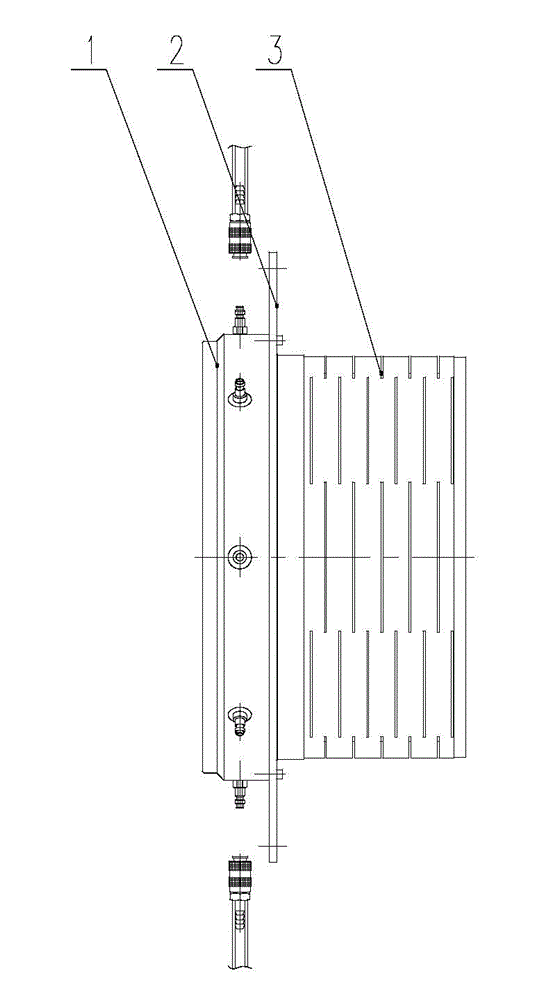

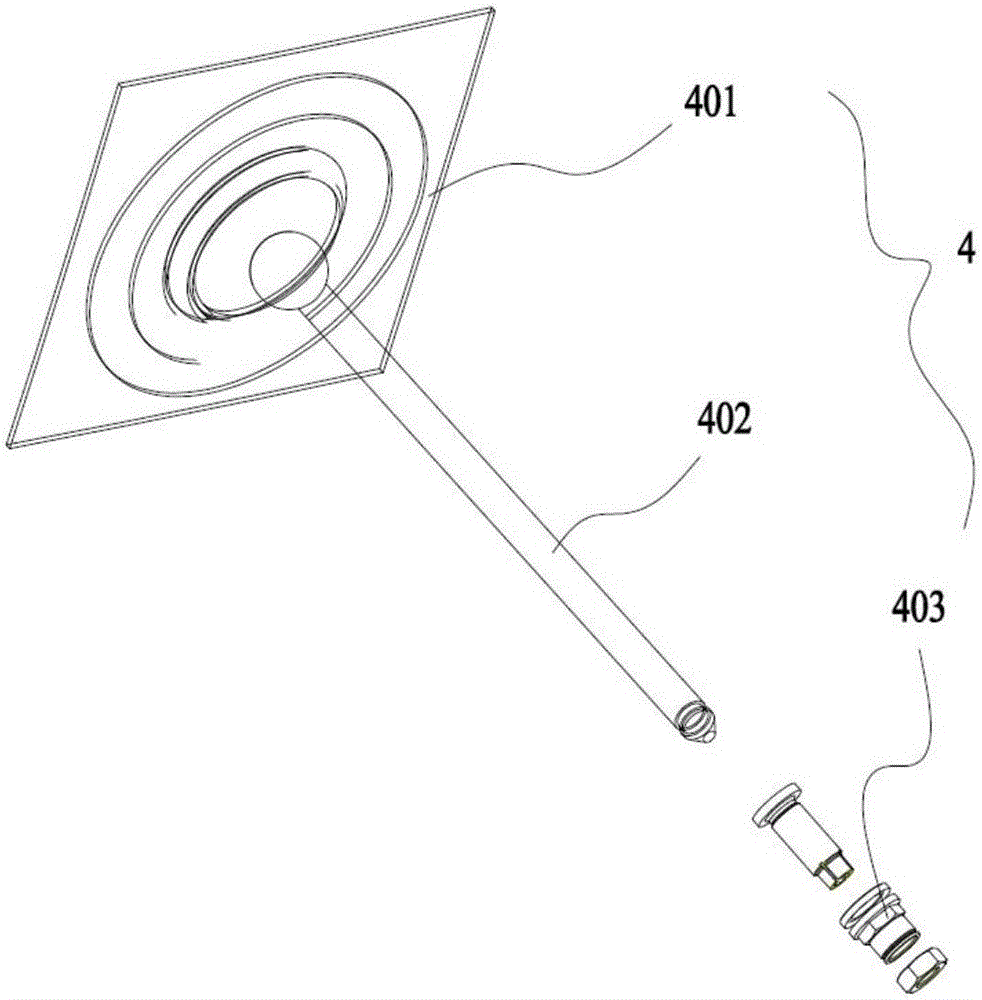

Condensing lens

The invention discloses a condensing lens.The condensing lens comprises a fixed support and a honeycomb core board assembly and a reflector which are sequentially installed on the fixed support in a stacked mode, the honeycomb core board assembly comprises a panel, a honeycomb core board and a backboard, the honeycomb core board is clamped between the panel and the backboard, the reflector is connected with the panel in a sticking mode through a pressure-sensitive adhesive, and the backboard is fixed with the fixed support.According to the condensing lens, the weight of the condensing lens is lighter than that of other types of products, and steel structure loading requirement is low; the surface is smooth and free of corrugation phenomenon, and the optical quality is optimal; the condensing lens can be suitable for batched production and manufacture, the initial capital investment is less, and the benefit can be obtained rapidly; the condensing lens is suitable for rapid and accurate focusing, and the site construction time is shortened.

Owner:ORIENTAL GREAT OCEAN NEW ENERGY TECH DEV CO LTD

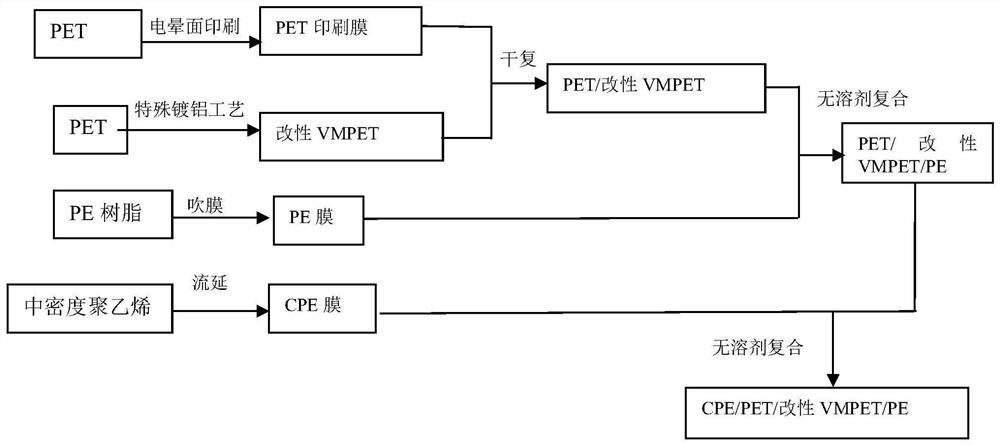

High-barrier antiskid packaging film and preparation method thereof

PendingCN113829707AGood lookingImprove stiffnessFlexible coversWrappersPolymer sciencePolyethylene terephthalate

The invention relates to the technical field of packaging materials, in particular to a high-barrier antiskid packaging film and a preparation method thereof. The packaging film is composed of a CPE film, a PET film, a modified VMPET film and a PE film which are sequentially layered, the CPE film and the PE film are prepared in a three-layer co-extrusion forming mode, and one face of the VMPET film is reversely plated with an aluminum-plated layer formed by metal aluminum, so that the barrier property, the aluminum layer adhesive force and the corona value attenuation period are all obviously improved, and under the severe high-humidity and high-temperature conditions, the interface of the packaged PET / VMPET aluminum plating layer is not layered, so that the integrity of the package is ensured, and the contents are not deteriorated; the packaging material with the CPE (heat-resistant) / PET (polyethylene terephthalate) / modified VMPET / PE (low-temperature) composite structure has the characteristics of balanced internal and external structures, flat bag shape, soft buffering of the outer-layer CPE, puncture and falling resistance, high static friction and good stacking and transporting effect, the problems of stacking slipping and unsmooth transportation are solved, and the whole large package is high in tearing strength and puncture resistance, and can resist falling and impact bag breaking.

Owner:HUANGSHAN NOVEL

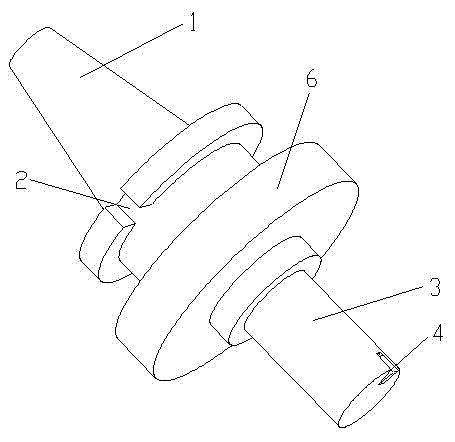

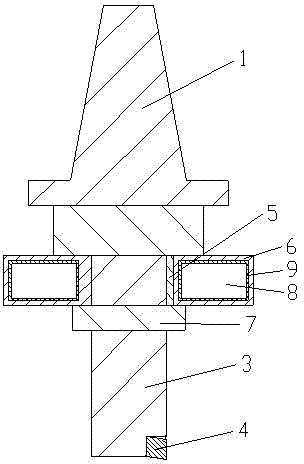

Damping boring tool

InactiveCN102896333AReduce fluctuating and eccentric cutting forcesReduce vibrationTurning toolsEngineeringCutting force

The invention discloses a damping boring tool which comprises a taper shank, a positioning clamp slot, a boring bar and a blade. The taper shank is inserted into a machine tool, the boring bar is arranged on the lower portion of the taper shank, the blade is mounted on the lower portion of the boring bar, the boring bar is connected with a damping disc through a key, a limit block is arranged below the damping disc, an annular groove is reserved in the damping disc, and an elastic damping layer is arranged on the inner wall of the damping disc and close to the annular groove. The damping boring tool has the advantages that fluctuation and eccentric cutting force of the boring tool during cutting are reduced, vibration of the boring bar is decreased effectively, surface corrugations of holes bored by the damping boring tool are avoided, processing quality of workpieces is improved, rotational speed of the machine tool can be increased on the premise of keeping the original states, and production efficiency is improved.

Owner:SUZHOU FUMAI PRECISION MACHINERY

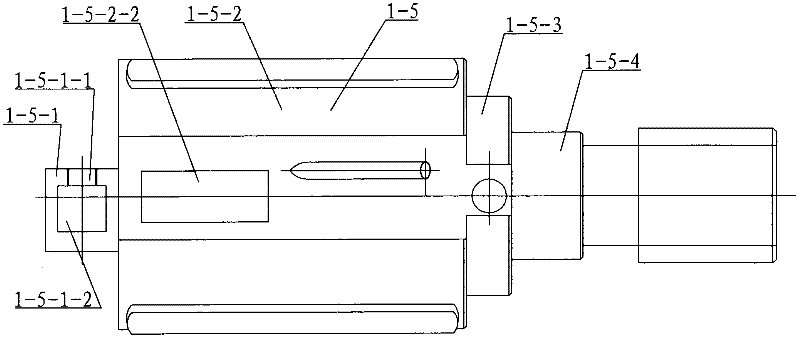

Intelligent carbon brush head rotating arcing machine

ActiveCN106475876AShorten the timeReduce processGrinding machinesGrinding work supportsElectricityEngineering

The invention discloses an intelligent carbon brush head rotating arcing machine. The machine comprises a clamp mounted in the position of a guiding-in station and used for clamping a carbon brush, a head rotating device mounted in the position of a head rotating station, an arcing device mounted in the position of an arcing station, and a guiding-out device mounted in the position of a guiding-out station. When the clamp clamping the carbon brush rotates to the head rotating station, the front end face of the carbon brush is subjected to head rotating treatment through the head rotating device; then the rear end face of the carbon brush rotated to the arcing station is subjected to arcing treatment through the arcing device; and the carbon brush transferred to the guiding-out station in a rotated mode is discharged out of the clamp used for clamping the carbon brush through the guiding-out device. According to the intelligent carbon brush head rotating arcing machine, grinding, chamfering, head rotating and arcing treatment are integrated, procedures are few, manpower and time needed by carbon brush transfer are reduced, the production efficiency is improved, the labor cost is lowered, machined products are stable in quality and good in consistency, electricity is saved, emission is reduced, and environmental protection is facilitated.

Owner:SUZHOU RUIBEN IND FURNACE

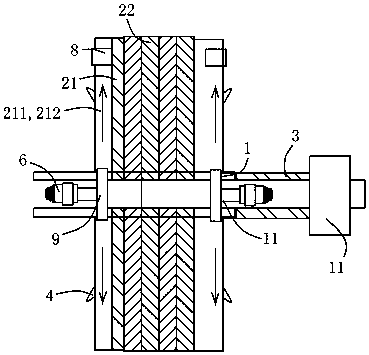

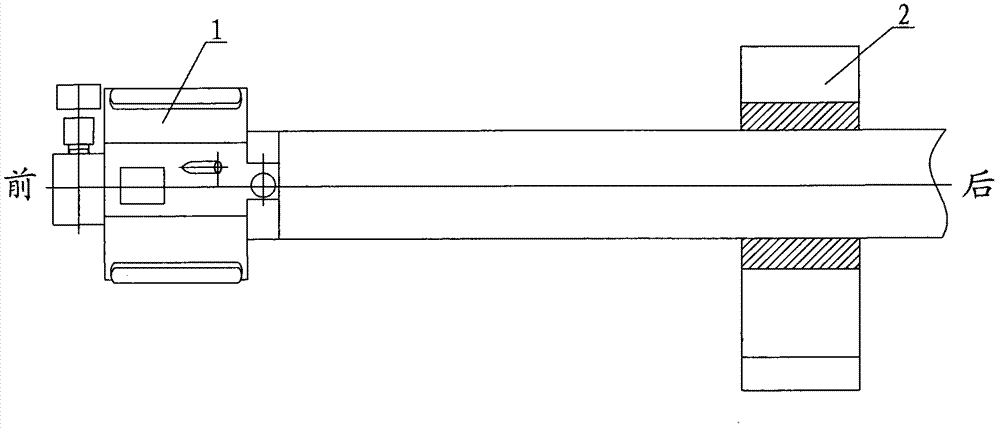

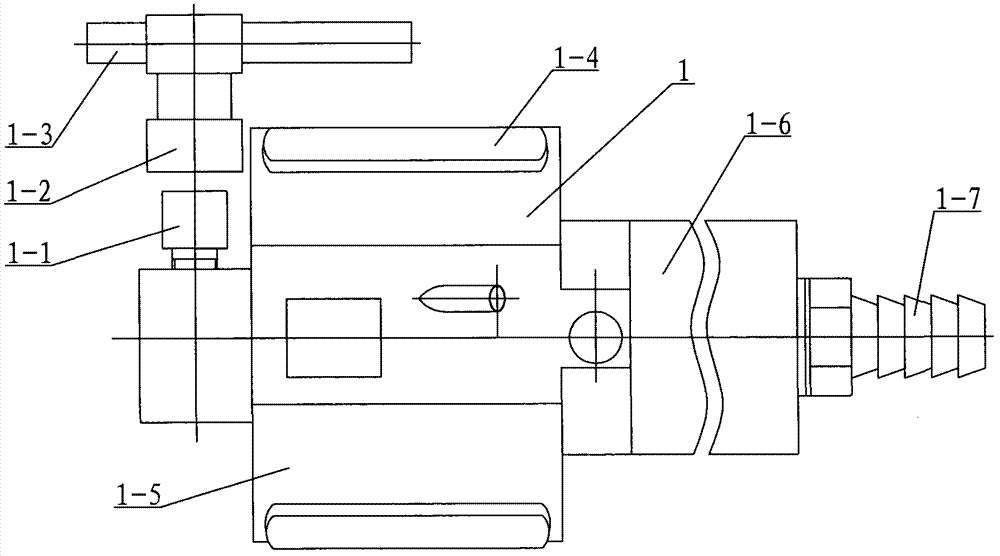

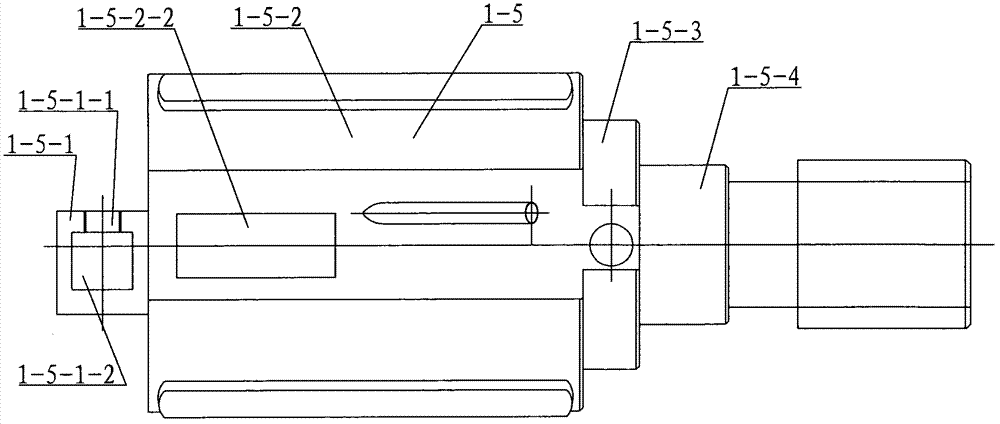

Special tool rest for machining inner bore

The invention discloses a special tool rest for machining an inner bore and relates to a tool rest for machining an inner bore, and the special tool rest can be used for solving the problem of poor machining precision because a tool trembles, the inner bore surface easily generates ripples and the inner wall of a U-turn machining workpiece on two ends is provided with a tool connecting mark when the inner bore of a spindly thin-wall sleeve is machined. The special tool rest is composed of a tool bar assembly and a permanent seat assembly, wherein the tool bar assembly is composed of a sleeve,a handle, a tool apron, a long tool bar, a joint, two support bolts and four locating blocks; the tool apron is successively provided with a tool loading section, a locating section, a transition section and a tool bar connection section along the axial direction from front to back; the cross section of the tool loading section is rectangular; each locating slot is provided with the locating block; one end of the long tool bar is connected with the tool bar connection section; the other end of the long tool bar is connected with the joint; the permanent seat is composed of a locating bolt, anupper tilting fillet, a center frame foundation, a bearing bush and a platen; the distance between the upper end surface of the platen and the lower end surface of the center frame foundation is 15mm; and the long tool bar passes through the bearing bush and moves forward and backward in the bearing bush. The special tool rest for machining the inner bore is used for machining a spindly thin-walldeep bore.

Owner:HARBIN JIANCHENG GRP

Method for producing image display device, curable resin composition to be used therein, touch panel, and image display device

ActiveCN107209410ANo rippleImprove visibilityAdhesive processesPolyureas/polyurethane adhesivesLiquid-crystal displayDisplay device

A method for producing an image display device having a protective plate adhered to a liquid crystal display unit equipped with a liquid crystal display cell, a polarizing plate, and a sealed body or a housing, the method involving: (A) a step for coating the liquid crystal display unit or the protective plate with a first curable resin composition; (B) a step for sticking the liquid crystal display unit and the protective plate to one another with the first curable resin composition interposed therebetween; and (C-I)-(C-III) the subsequently described steps which follow step (B). (C-I) a step for adhering the liquid crystal display unit and the protective plate to one another by curing the first curable resin composition; (C-II) a step for coating the outer-peripheral-side surface section of the protective plate, the sealed body or the housing with a second curable resin composition, so as to connect the liquid crystal display unit and the protective plate with one another; and (C-III) a step for, after step (C-II), providing the outer-peripheral side surface section of the protective plate, the sealed body or the liquid crystal display unit housing with a cured-article layer by curing the second curable resin composition.

Owner:NIPPON KAYAKU CO LTD

Preparation technique of self-cleaning and mildew-proof bathroom glass

InactiveCN102701601AExtended service lifeHealthy and beautiful living spaceSocial benefitsEconomic benefits

The invention discloses a preparation technique of self-cleaning and mildew-proof bathroom glass, bathroom-dedicated glass is used as a base plate, and a spray filming method is adopted to prepare the self-cleaning and mildew-proof bathroom glass, the preparation technique comprises the following steps: cleaning the glass, spraying and filming, drying the film and heat-treating the film. According to the development and industrialization of the self-cleaning and mildew-proof bathroom glass provided by the preparation technique, not only can a healthy and beautiful living space can be created for people, but also more unnecessary resource waste can be reduced, the service life of the bathroom glass can be prolonged, and the preparation technique has important social benefits, economic benefits and environmental benefits.

Owner:佛山市高明贝特尔卫浴有限公司

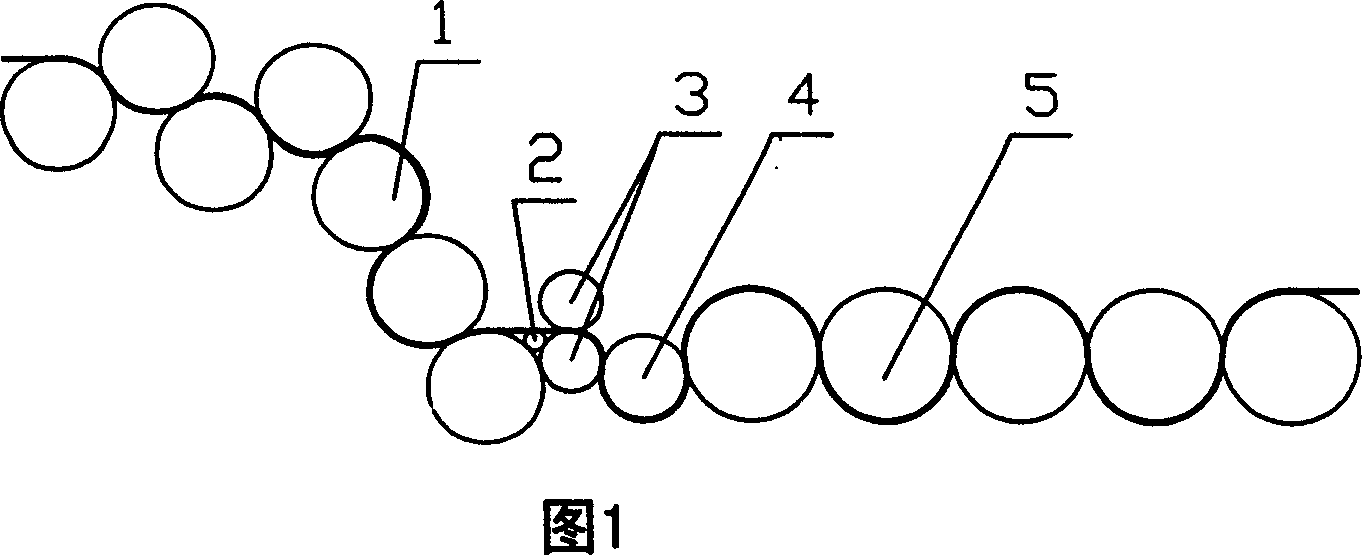

Lapping machine provided with high-speed rolling type bracket mechanism and applied to bio-based spun-bonding and hot-rolling line

The invention relates to the technical field of non-woven fabric manufacturing equipment, in particular to a lapping machine provided with a high-speed rolling type bracket mechanism and applied to a bio-based spun-bonding and hot-rolling line. The lapping machine comprises a lapping machine rack, a web curtain, a drive roller, a fabric guide roller, a pre-roller, a rubber lower support roller and an air suction bellows, wherein a horizontal rolling mechanism is arranged above a grating of the air suction bellows and comprises a bearing, a bearing block and a roller rod. During high-speed operation of the web curtain, the friction is reduced, the operation resistance is reduced, energy and power are saved, and the service life of the web curtain is prolonged; the operation stability of the web curtain is improved, the produced non-woven fabric product is stable in quality, the fabric surface is uniform and free of ripples, and uniformity of a fiber web is good.

Owner:DALIAN HUALUN CHEM FIBER ENG

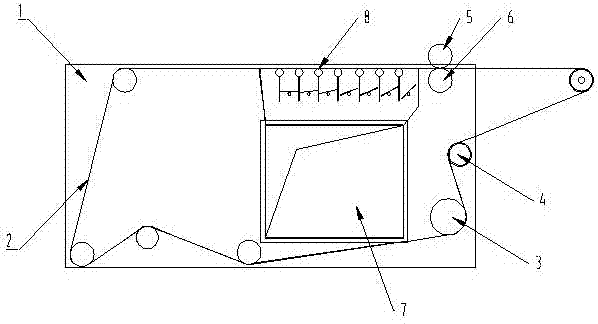

Plastic calendar and press polish machine

The invention relates to a plastic processing equipment. It adds a stripping roller and felt wrapped roll between the plastic compression roller and the cooling roller, with the stripping roller close to the last compression roller, stripping the coarsely formed product from the compression roller, delivering it to the felt wrapped roll which can press the plastic part tight through the top and down two pieces by the control mechanism. There is a clod stripping roller between the felt wrapped roller and the cold roller. It can allow the plastic parts having smooth surface without bubbles.

Owner:黄元方

Method for producing image display device, curable resin composition used in the method, touch panel, and image display device

ActiveCN107209410BNo rippleImprove visibilityAdhesive processesPolyureas/polyurethane adhesivesLiquid-crystal displayDisplay device

A method for producing an image display device having a protective plate adhered to a liquid crystal display unit equipped with a liquid crystal display cell, a polarizing plate, and a sealed body or a housing, the method involving: (A) a step for coating the liquid crystal display unit or the protective plate with a first curable resin composition; (B) a step for sticking the liquid crystal display unit and the protective plate to one another with the first curable resin composition interposed therebetween; and (C-I)-(C-III) the subsequently described steps which follow step (B). (C-I) a step for adhering the liquid crystal display unit and the protective plate to one another by curing the first curable resin composition; (C-II) a step for coating the outer-peripheral-side surface section of the protective plate, the sealed body or the housing with a second curable resin composition, so as to connect the liquid crystal display unit and the protective plate with one another; and (C-III) a step for, after step (C-II), providing the outer-peripheral side surface section of the protective plate, the sealed body or the liquid crystal display unit housing with a cured-article layer by curing the second curable resin composition.

Owner:NIPPON KAYAKU CO LTD

Water-based two-component bright transparent finishing coat

InactiveCN109957314ASolving a major problem in paintingEmission reductionPolyurea/polyurethane coatingsWater basedWax

The invention provides a water-based two-component bright transparent finishing coat. The finishing coat is composed of a component A, a component B and water; the component A comprises the followingmaterials, in parts by weight: 65-80 parts of water-based hydroxy acrylic resin, 0.2-0.5 part of a wetting agent, 0.2-0.5 part of a pH regulating agent, 0.3-1 part of a first defoaming agent, 0.2-1 part of a second defoaming agent, 0.3-1 part of a defoaming agent, 2-5 parts of a film-forming auxiliary agent, 0.5-1 part of a rheological auxiliary agent, 0.2-1 part of a third defoaming agent, 0.1-0.5 part of a levelling agent, 3-6 parts of a wax emulsion and 6-24 parts of water; the component B comprises 14-20 parts of a water-based isocyanate curing agent; and a weight ratio of the component Ato the component B to the water is 100:(14-20):15. The finishing coat provided by the invention can be widely used in hotel furniture, bathroom sanitary products and other bright-surface coatings andsolves a major difficult problem that plagues furniture coating, the VOC emission of the finishing coat is reduced, and initiatives of energy conservation and emission reduction in China are realized.

Owner:HUIZHOU CHANGRUNFA PAINT +1

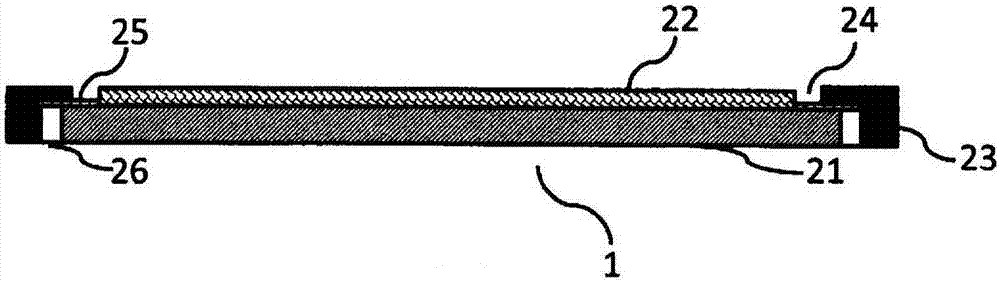

A lithium battery aluminum-plastic packaging film using aluminum foil single-sided nano-processing technology

ActiveCN104393203BAvoid bondingNot easy to wrinkleSecondary cellsJackets/cases materialsChemical treatmentPolyester

Owner:LIANYUNGANG DELIXIN PACKAGING MATERIAL

Method for manufacturing image display device and image display device

The present invention provides a method for producing an image display device, a curable resin composition used in the method, and an image display device, the production method of which can obtain an optical display device that does not cause moire and has excellent visibility even when an arbitrary part is pressed. member. As a method of manufacturing an image display device, it includes the steps of defining a coating region of the first curable resin composition with the second curable resin composition, and applying the first curable resin composition to the coating region. step, and a step of curing the first curable resin composition to bond the liquid crystal display unit to the protective plate, and laminating a cured product layer obtained by curing the second curable resin composition on the sealing body. projected area, and not laminated on the projected area of the polarizing plate. It is preferable that the said 1st curable resin composition or the said 2nd curable resin composition contains (meth)acrylate (A) and a photoinitiator (B).

Owner:NIPPON KAYAKU CO LTD

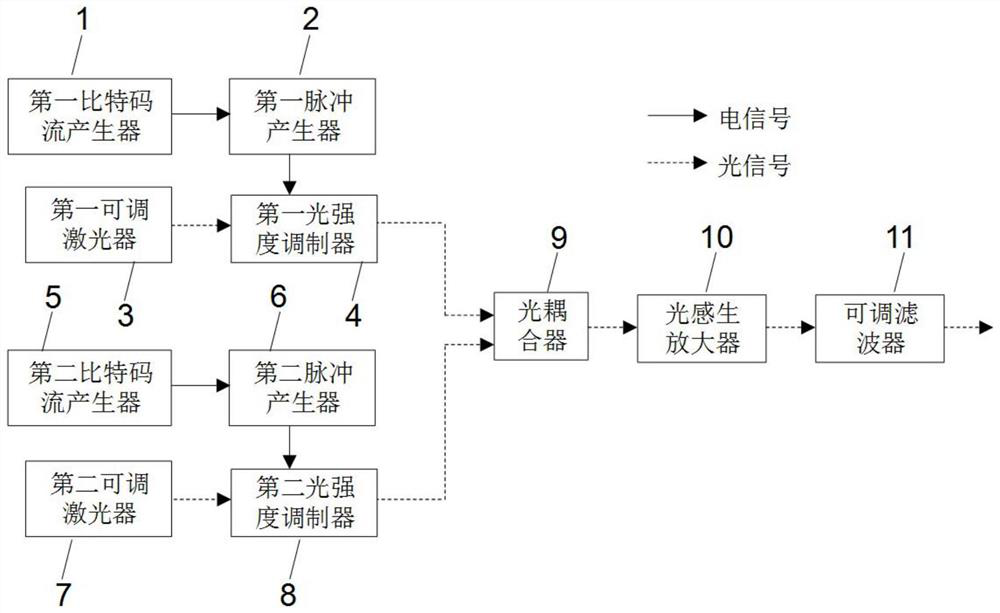

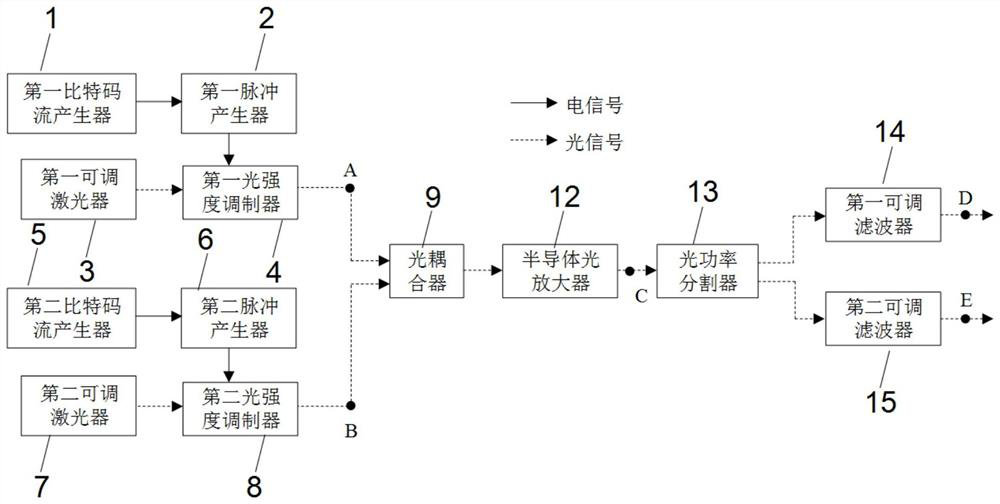

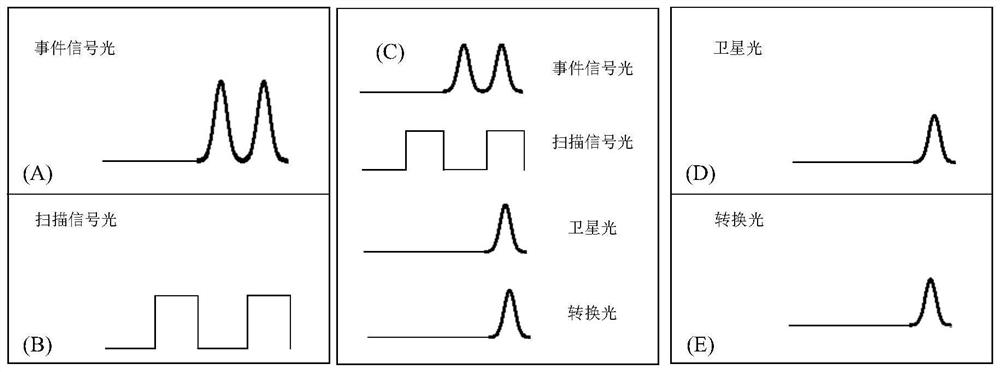

Time domain stealth method and device based on light-induced amplifier

PendingCN114355697AFlexible size adjustmentNo rippleOptical detectionNon-linear opticsTime domainTime range

The invention provides a time domain stealth method and device based on a light-induced amplifier, which only needs to detect whether an event occurs in a detection time range, and does not carry out detection in a time range which does not need detection. The device comprises an event signal light generator, a scanning signal light generator, an optical coupler, a light-sensitive amplifier and an adjustable filter, the event signal light generator and the scanning signal light generator generate event signal light and scanning signal light respectively, and the event signal light and the scanning signal light are coupled by the optical coupler and then input into the light-sensitive amplifier. When the event signal light and the scanning signal light are transmitted in the light-sensing amplifier, new-frequency light can be generated, the generated new-frequency light is filtered out through the adjustable filter, and compared with a reported time domain hiding method, the method is easy to achieve, the size of a hiding time window can be flexibly adjusted, the size is small, and integration is easy. And more than one path of time domain stealth signal light can be realized, the stealth efficiency is high, the problem of ripples in a time domain stealth window is avoided, and the stealth effect is better.

Owner:NANHAI RES STATION OF INST OF ACOUSTICS CHINESE ACADEMY OF SCI

Formula and preparation process of self-stretching high-smoothness transparent glaze slip

The invention discloses a formula of self-stretching high-smoothness transparent glaze slip in the technical fields of a formula and a preparation process of the self-stretching high-smoothness transparent glaze slip; prepared crystals are good in transparency and relatively smooth in surface, and the defects that a traditional glaze surface is large in roughness, uneven, weak in flushing function and the like can be overcome; the glaze layer of the finished product fired on the basis of the melting fluidity of a frit is in a crystal brick shape, crystal brick bodies are uniformly distributed, the surface feels smooth, pores and ripples are avoided, the finished product is prepared by a production process which is reasonably adjusted in proportion and properly controlled, and aluminum oxide is introduced, so that the initial melting temperature range is wide, and the firing process is more favorably controlled; and crystallization phase and glass phase can be effectively balanced, transparency is improved, argil is introduced into the formula, the bonding strength of a blank glaze can be enhanced, the overall quality of the product is improved, and ceramic ware made of the transparent glaze is high in glossiness and low in lead and cadmium dissolution amount and has the advantages of being attractive in appearance, healthy, environmentally friendly and the like.

Owner:福建省德化县帝窑陶瓷有限公司

Concentric installation process and mounting and dismounting assisting concentric device for inner bore of woodworking tool

InactiveCN108356933AThe processing uses the same concentricityImprove cutting performanceProfiling/shaping machinesRotary cutting toolsDynamic balanceEngineering

The invention provides a concentric installation process for an inner bore of a woodworking tool. The concentric installation process is used for installing a tool shaft provided with the inner bore and sequentially and concentrically installing at least four cutting edges outside the tool shaft so that all installed cutting edges are concentric to the inner bore of the tool shaft; a mounting anddismounting assisting concentric device for the inner bore of the woodworking tool comprises an air charging mouth and air charging grooves, wherein the air charging mouth is arranged inside the innerbore of the woodworking tool shaft; the air charging grooves are formed in the diameter direction of the cutting edges arranged at the end part of the woodworking tool; the air charging mouth is connected with two uniform-pressure air pipes through a three-way pipe; and the two uniform-pressure air pipes are symmetrically fixedly arranged inside the air charging grooves. The concentric installation process and the mounting and dismounting assisting concentric device for the inner bore of the woodworking tool realize consistent concentricity in machining and use of a cutter; the cutter is goodin dynamic balance; and the concentricity and the machining precision can also be guaranteed even when a mechanical shaft is slightly abraded.

Owner:江苏刘一刀精密机械有限公司

Special tool rest for machining inner bore

The invention discloses a special tool rest for machining an inner bore and relates to a tool rest for machining an inner bore, and the special tool rest can be used for solving the problem of poor machining precision because a tool trembles, the inner bore surface easily generates ripples and the inner wall of a U-turn machining workpiece on two ends is provided with a tool connecting mark when the inner bore of a spindly thin-wall sleeve is machined. The special tool rest is composed of a tool bar assembly and a permanent seat assembly, wherein the tool bar assembly is composed of a sleeve,a handle, a tool apron, a long tool bar, a joint, two support bolts and four locating blocks; the tool apron is successively provided with a tool loading section, a locating section, a transition section and a tool bar connection section along the axial direction from front to back; the cross section of the tool loading section is rectangular; each locating slot is provided with the locating block; one end of the long tool bar is connected with the tool bar connection section; the other end of the long tool bar is connected with the joint; the permanent seat is composed of a locating bolt, anupper tilting fillet, a center frame foundation, a bearing bush and a platen; the distance between the upper end surface of the platen and the lower end surface of the center frame foundation is 15mm; and the long tool bar passes through the bearing bush and moves forward and backward in the bearing bush. The special tool rest for machining the inner bore is used for machining a spindly thin-walldeep bore.

Owner:HARBIN JIANCHENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com