Method for preparing single layer glass by glass tube

A technology for glass tubes and glass cups, which is applied in the field of making single-layer glass cups with glass tubes, which can solve the problems of high production level requirements for operators, high processing costs for single cups, and high requirements for supporting facilities, so as to achieve convenient production and operation, and high-quality finished products. High efficiency and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

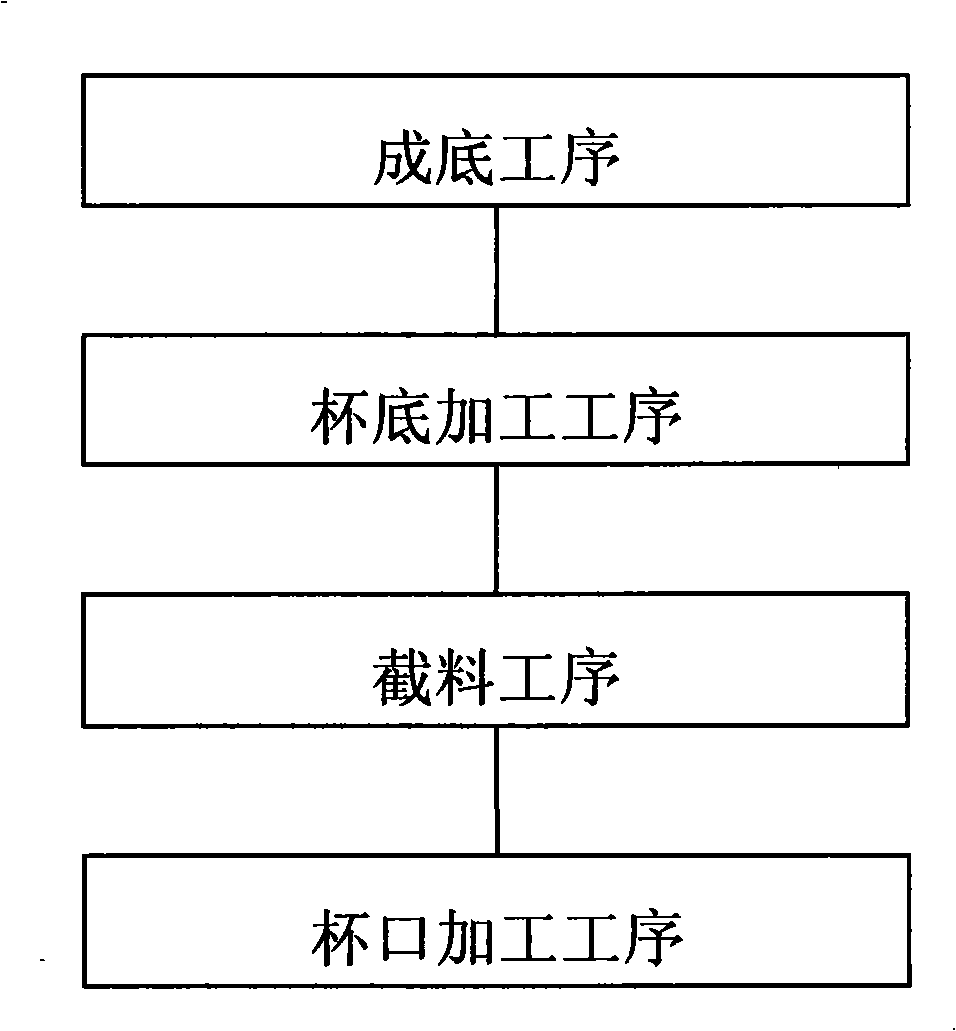

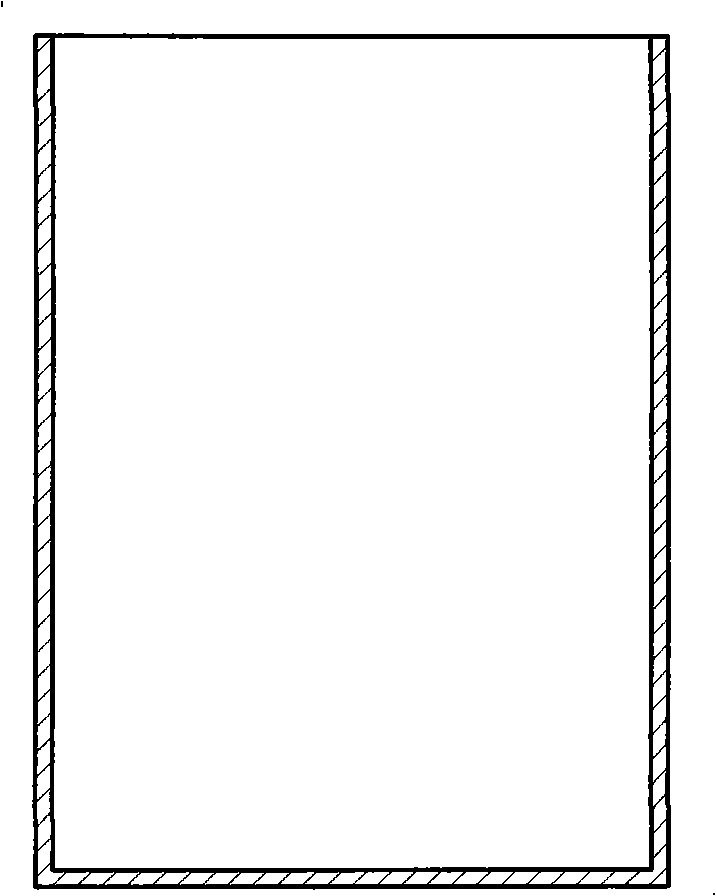

[0031] Embodiment one: see figure 1 shown, including the following steps:

[0032] A. Cutting process: Clamp both ends of the glass tube material with a diameter of 47 mm and a wall thickness of 1.8 mm on the rotating device. Both ends are supported and rotated synchronously. At the set length, use a glass knife to cut a piece horizontally along the glass tube material. The circle is roasted with fire to make it break, and the glass tube material is cut into several sections of glass tube material sections with twice the height of the finished glass cup and a length of 160 mm.

[0033] B. Bottom forming process: Firstly, the two ends of the cut glass tube are clamped on the rotating device, both ends are supported and rotated synchronously, and the speed is 50 rpm. Use a flame to locally heat the middle part of the pipe until the glass softens. The heating temperature is 820°C and the heating time is 45 seconds. Using a blade made of graphite with a thickness of 18 mm, slowl...

Embodiment 2

[0036] Embodiment two: see figure 1 As shown, it is basically the same as Example 1, and will not be repeated. The difference is that the diameter of the glass tube material is 53 millimeters, the rotating speed in the bottom forming process is 60 rpm, the heating temperature is 900 ° C, and the heating time is 40 seconds. Cut with a graphite knife with a thickness of 20 mm.

Embodiment 3

[0037] Embodiment three: see figure 1 As shown, it is basically the same as Example 1 and will not be repeated. The difference is that the diameter of the glass tube material is 58 mm and the wall thickness is 2 mm. For 35 seconds, cut with a graphite knife with a thickness of 21 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com