Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Bulk moulding compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bulk moulding compound (BMC), bulk moulding composite, or dough moulding compound (DMC), is a ready-to-mold, glass-fiber reinforced thermoset polymer material primarily used in compression moulding, as well as in injection moulding and transfer moulding. Typical applications include demanding electrical applications, corrosion resistant needs, appliance, automotive, and transit.

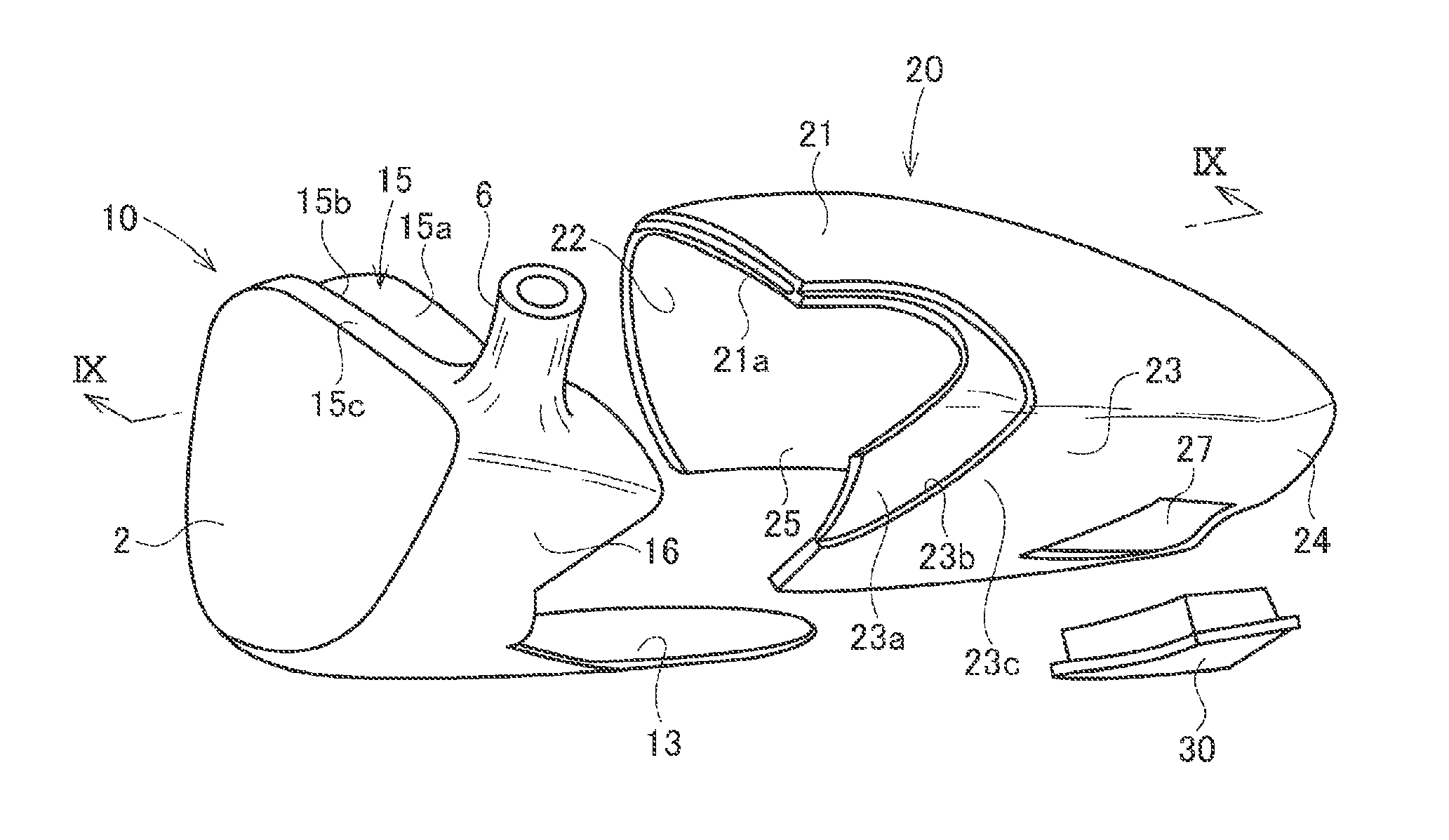

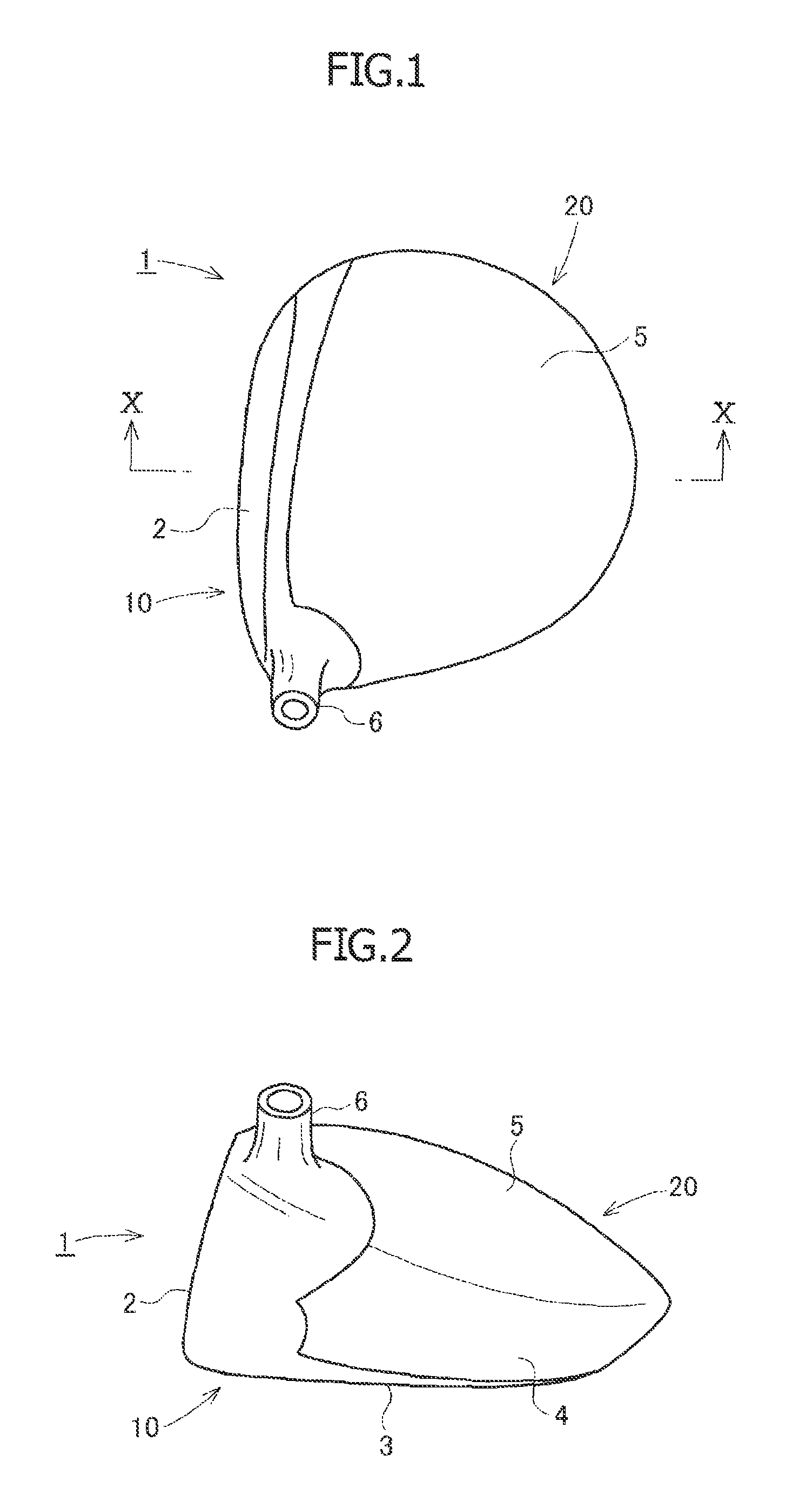

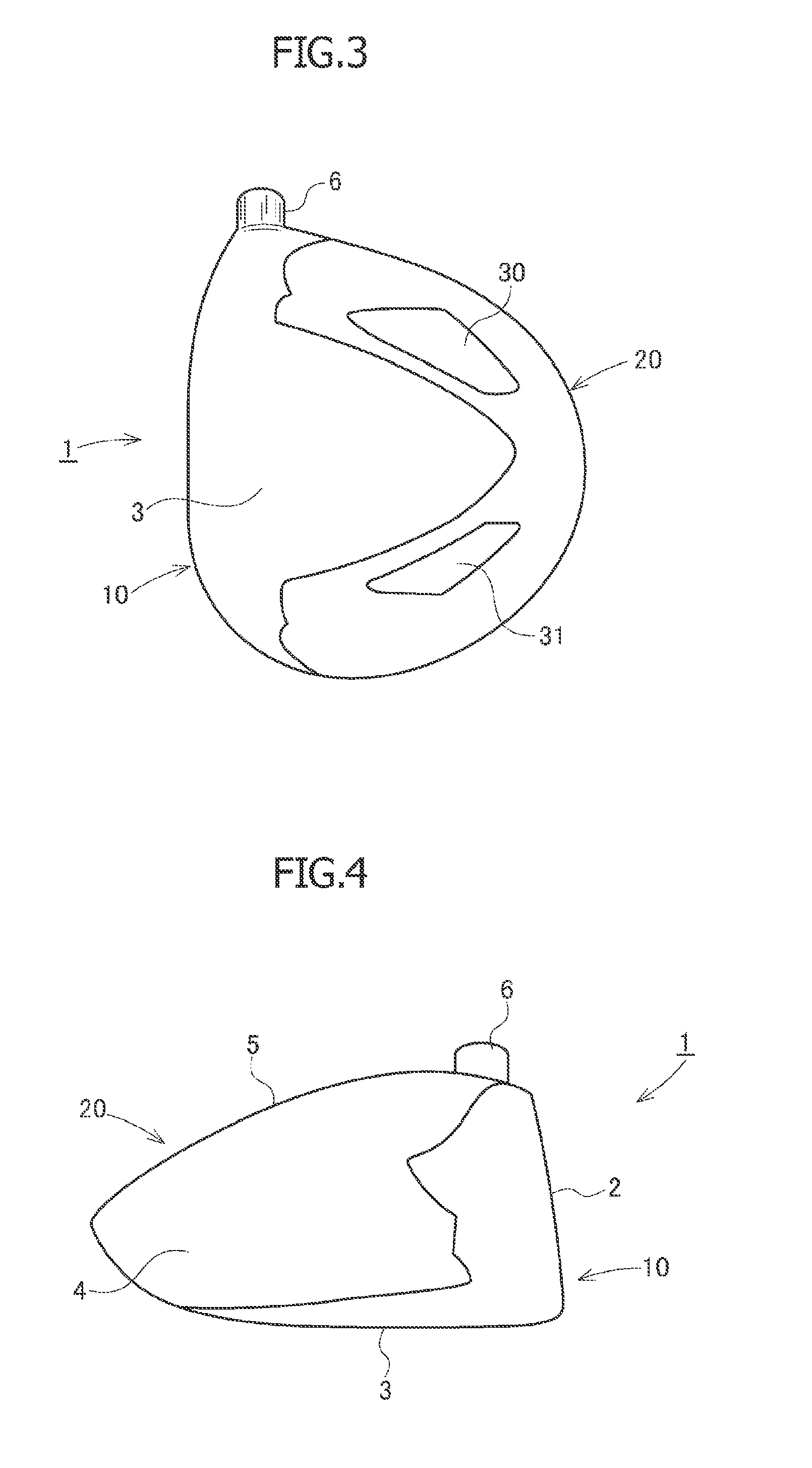

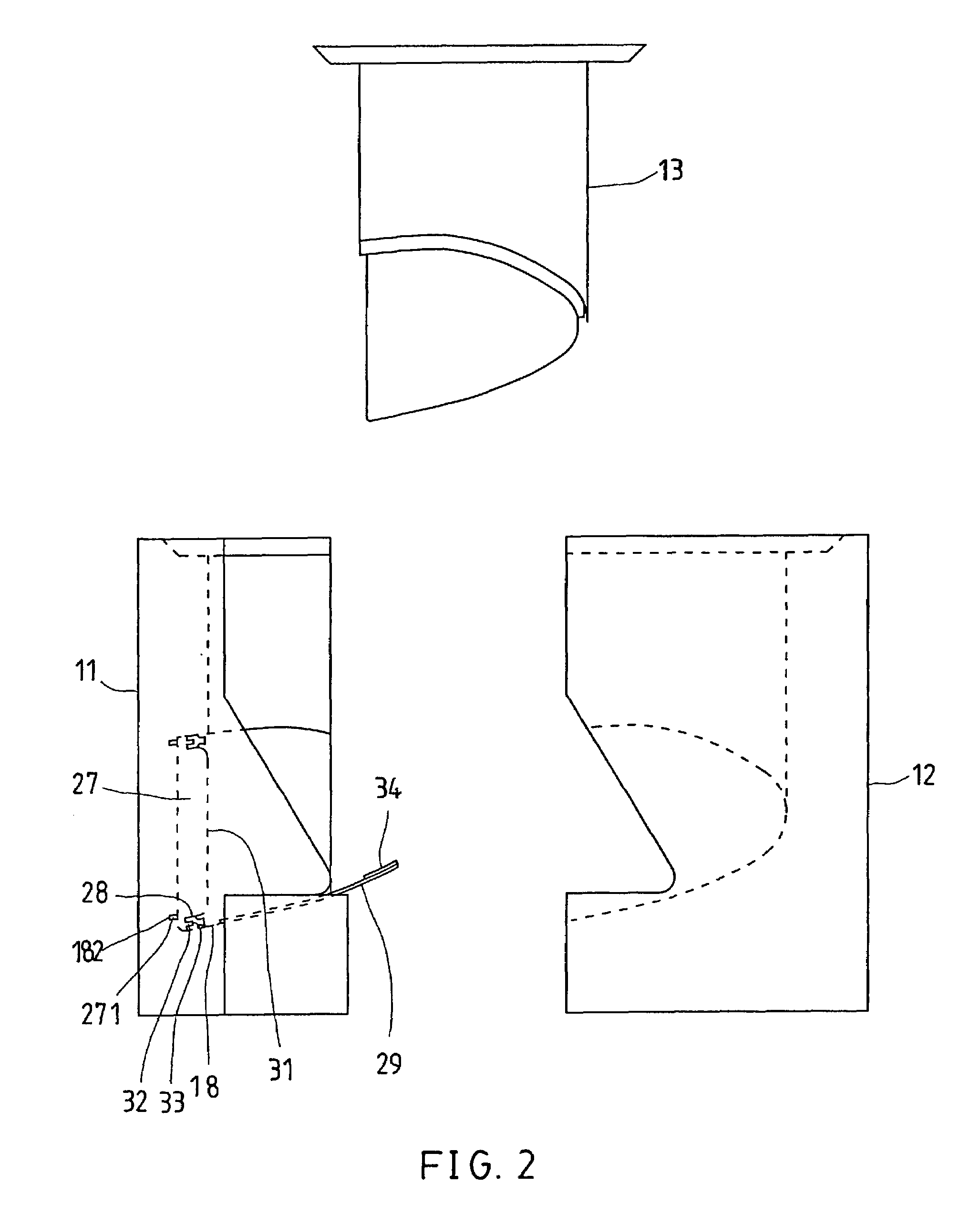

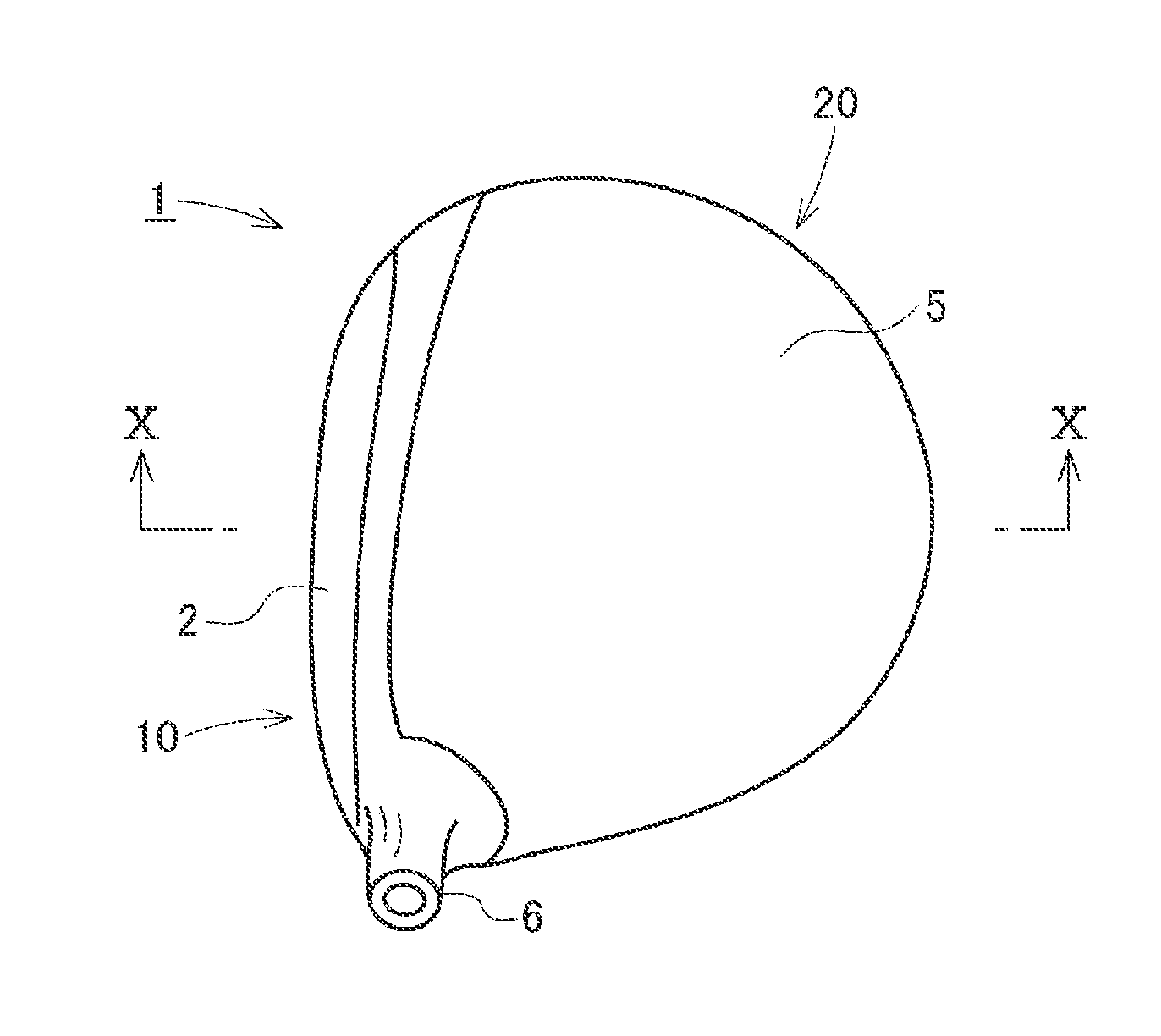

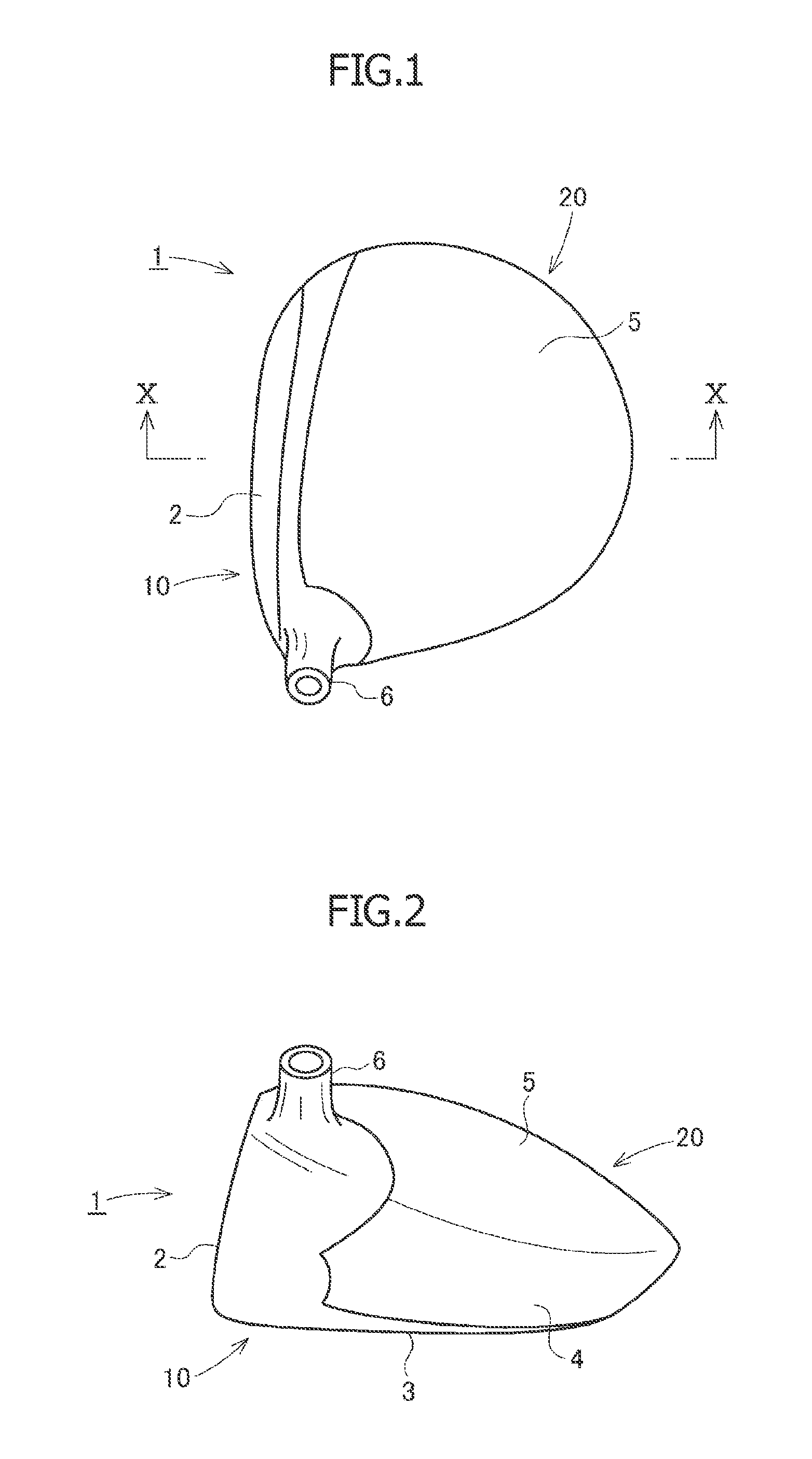

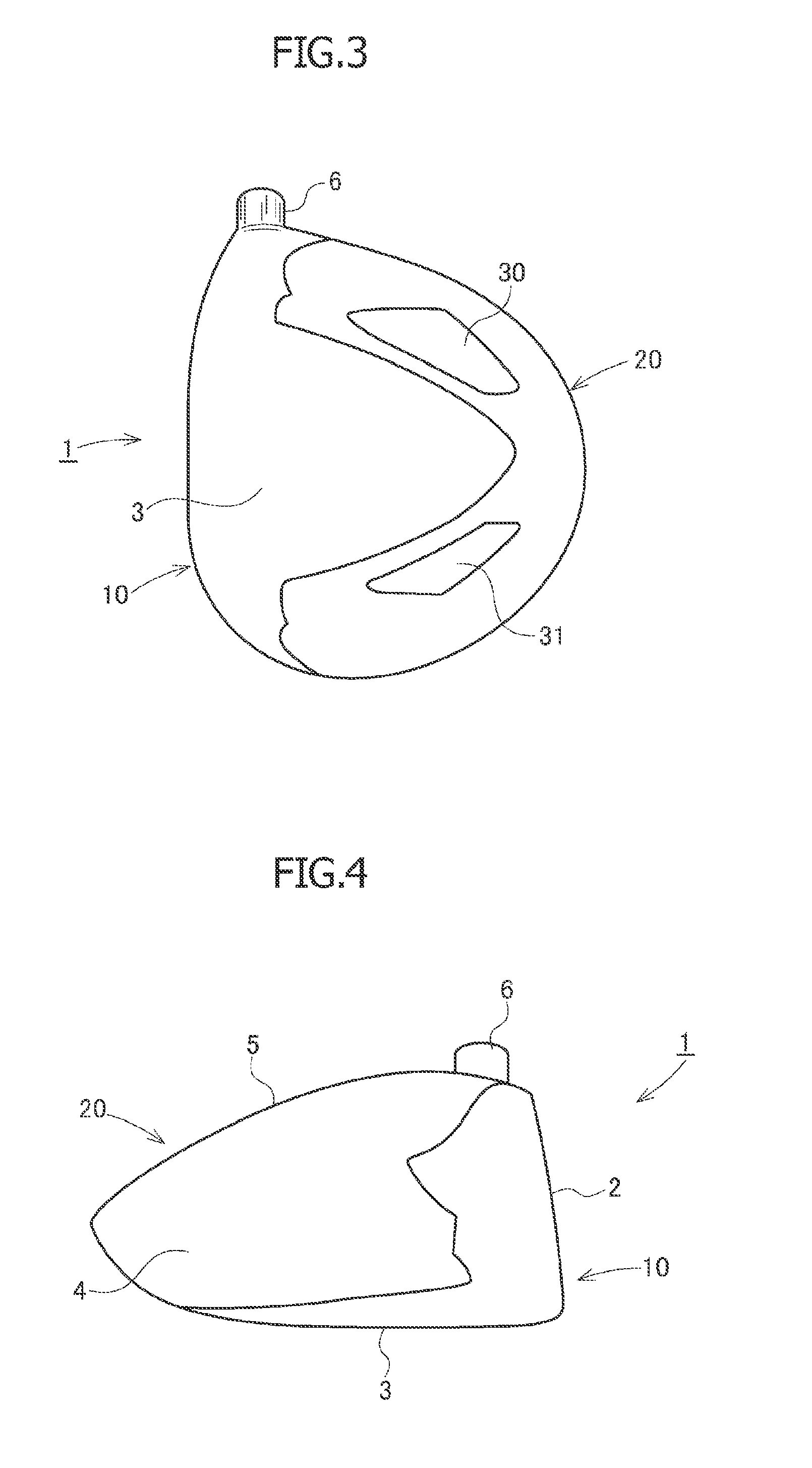

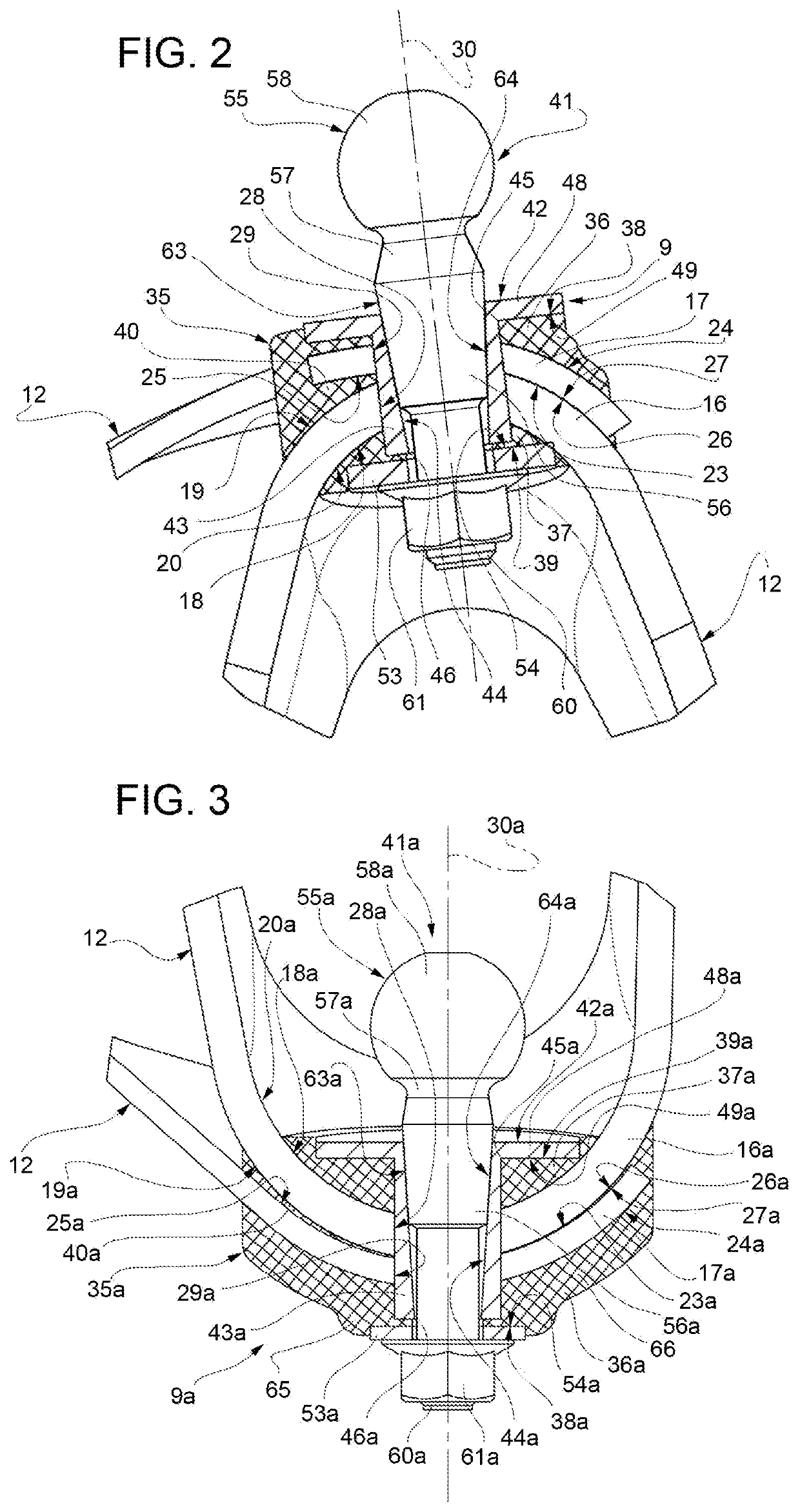

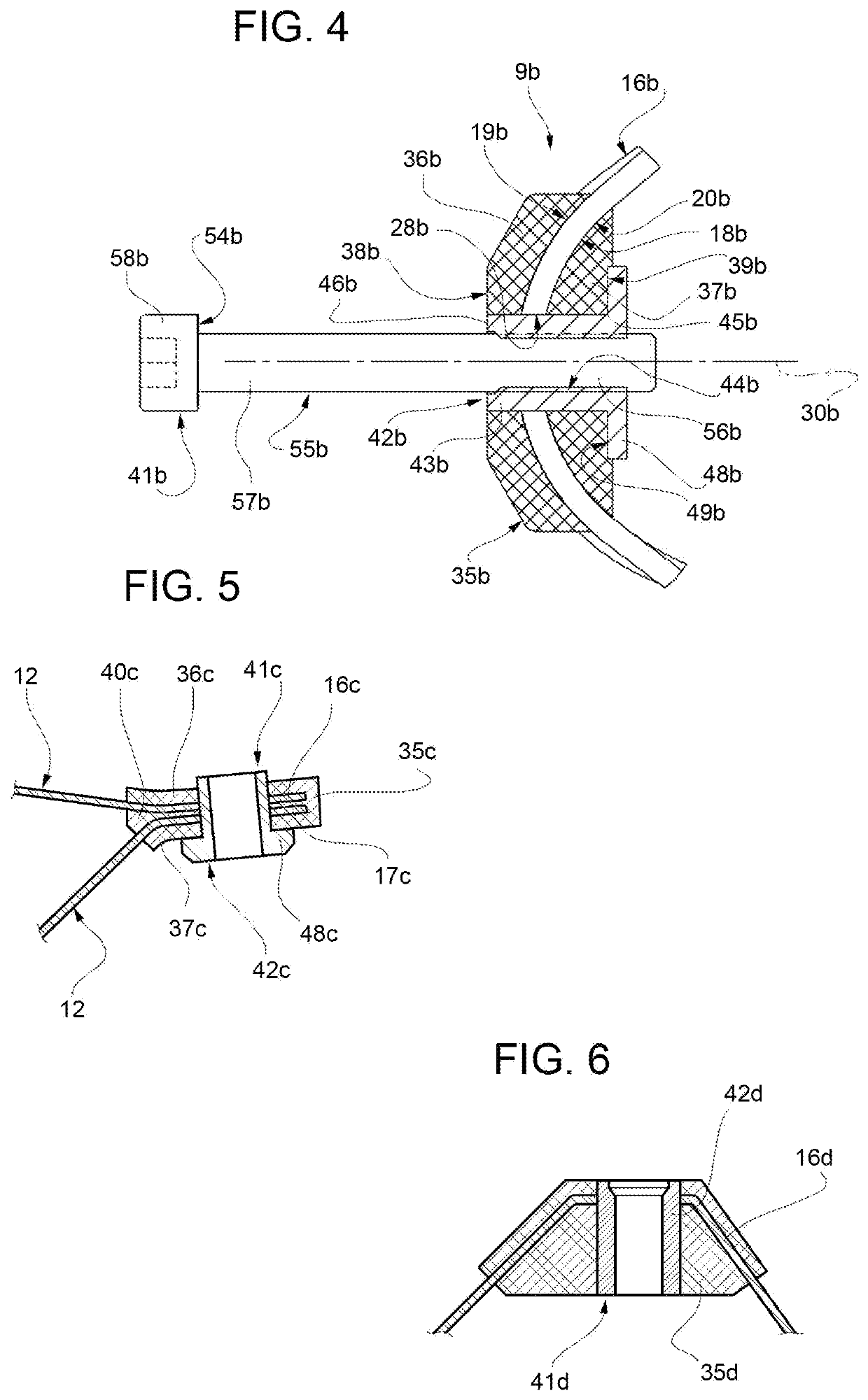

Golf club head

A hollow golf club head includes a face portion, a sole portion, a side portion, a crown portion, and a hozel portion. A main portion of the crown portion is made of a fiber reinforced resin. The fiber reinforced resin portion includes a bulk molding compound (BMC) molded body. At least the face portion, a leading edge of the crown portion continuous with the face portion, and a center portion of the sole portion in a toe-heel direction are made of a metal. Alternatively to this configuration, the face portion may be provided with a metal faceplate, a portion subsequent to the face portion may include a BMC molded body, and a rear portion of the crown portion may include a molded laminate of prepreg sheets. The height of center of gravity may be 24 mm or less.

Owner:BRIDGESTONE SPORTS

Preparation of fuel cell composite bipolar plate

ActiveUS20050001352A1Improve thermal stabilityImprove mechanical propertiesNon-metal conductorsConductive materialPolymer electrolytesFuel cells

A composite bipolar plate of polymer electrolyte membrane fuel cells (PEMFC) is prepared as follows: a) preparing a bulk molding compound (BMC) material containing a vinyl ester resin and a graphite powder, the graphite powder content of BMC material ranging from 60 wt % to 80 wt %, based on the compounded mixture; b) molding the BMC material from step a) to form a bipolar plate having a desired shape at 80-200° C. and 500-4000 psi, wherein the graphite powder is of 40 mesh-80 mesh.

Owner:IND TECH RES INST +1

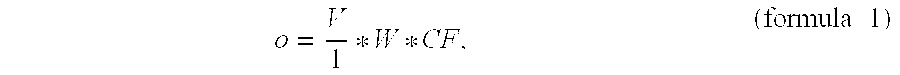

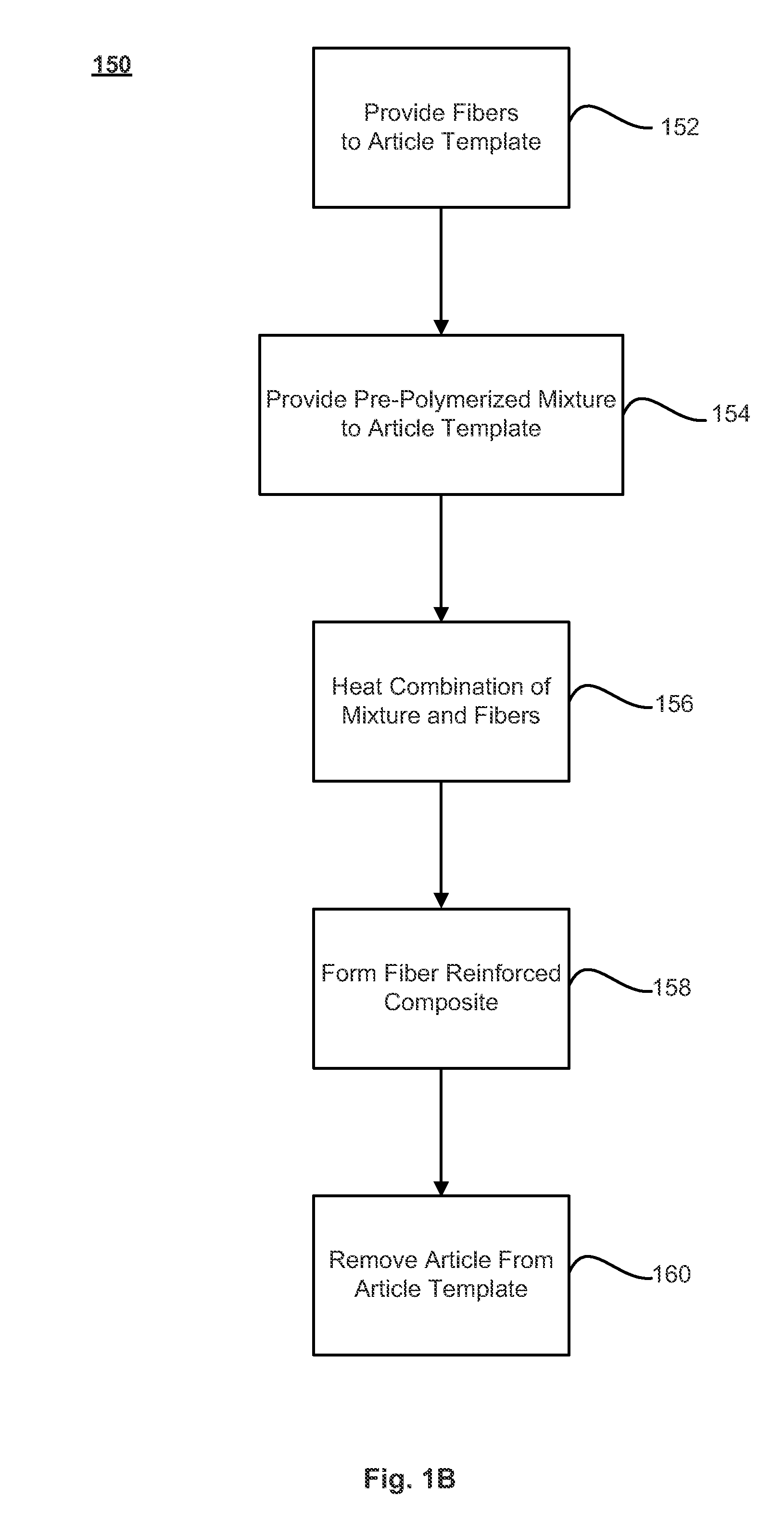

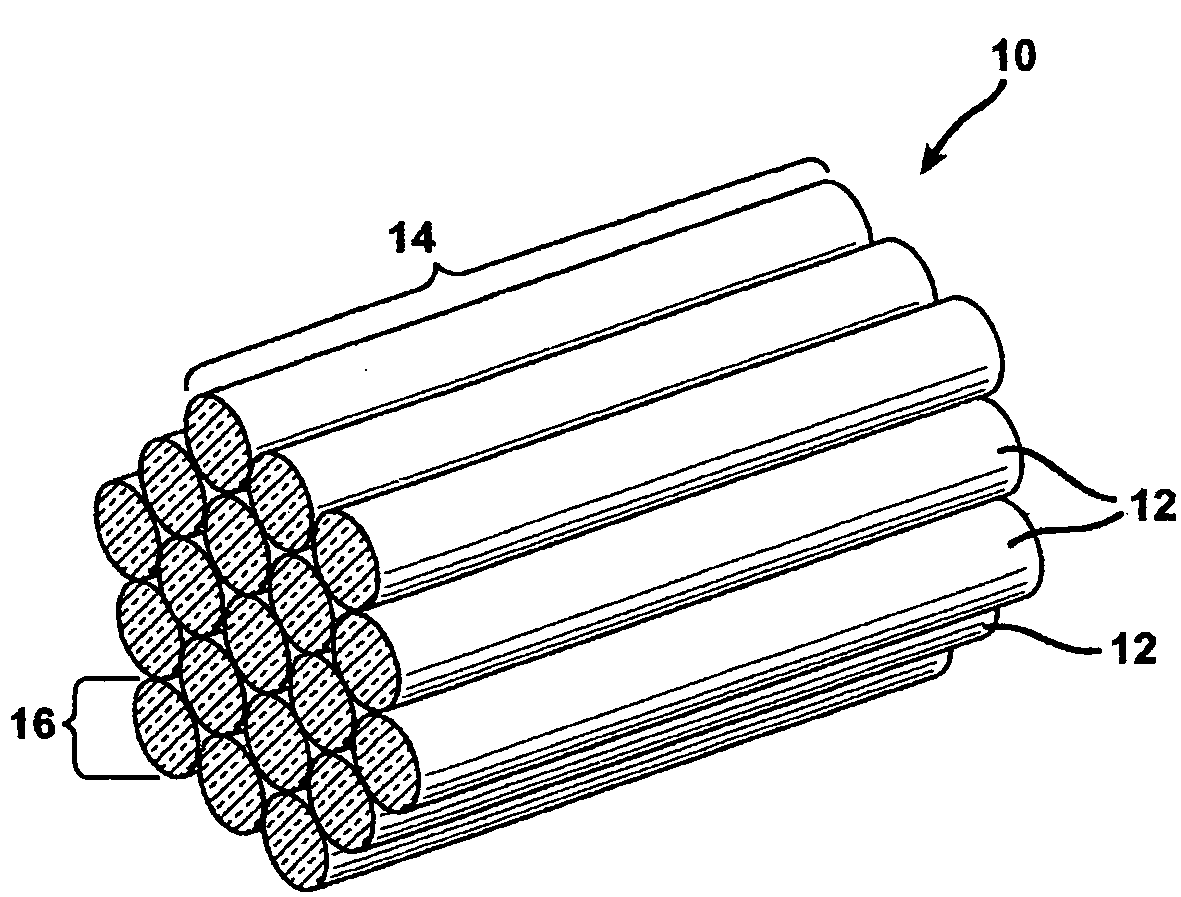

Fibers treated with polymerization compounds and fiber reinforced composites made therefrom

InactiveUS20110045275A1Group 4/14 element organic compoundsMolecular sieve catalystsFiber-reinforced compositePolymer chemistry

Methods of making fiber reinforced composite articles are described. The methods may include treating fibers with a sizing composition that includes a polymerization compound, and introducing the treated fibers to a pre-polymerized composition. The combination of the treated fibers and pre-polymerized composition may then undergo a temperature adjustment to a polymerization temperature at which the pre-polymerized composition polymerizes into a plastic around the fibers to form the fiber-reinforced composite article. Techniques for introducing the treated fibers to the pre-polymerized composition may include pultrusion, filament winding, reactive injection molding (RIM), structural reactive injection molding (SRIM), resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM), long fiber injection (LFI), sheet molding compound (SMC) molding, bulk molding compound (BMC) molding, a spray-up application, and / or a hand lay-up application, among other techniques.

Owner:TADEPALLI RAJAPPA +3

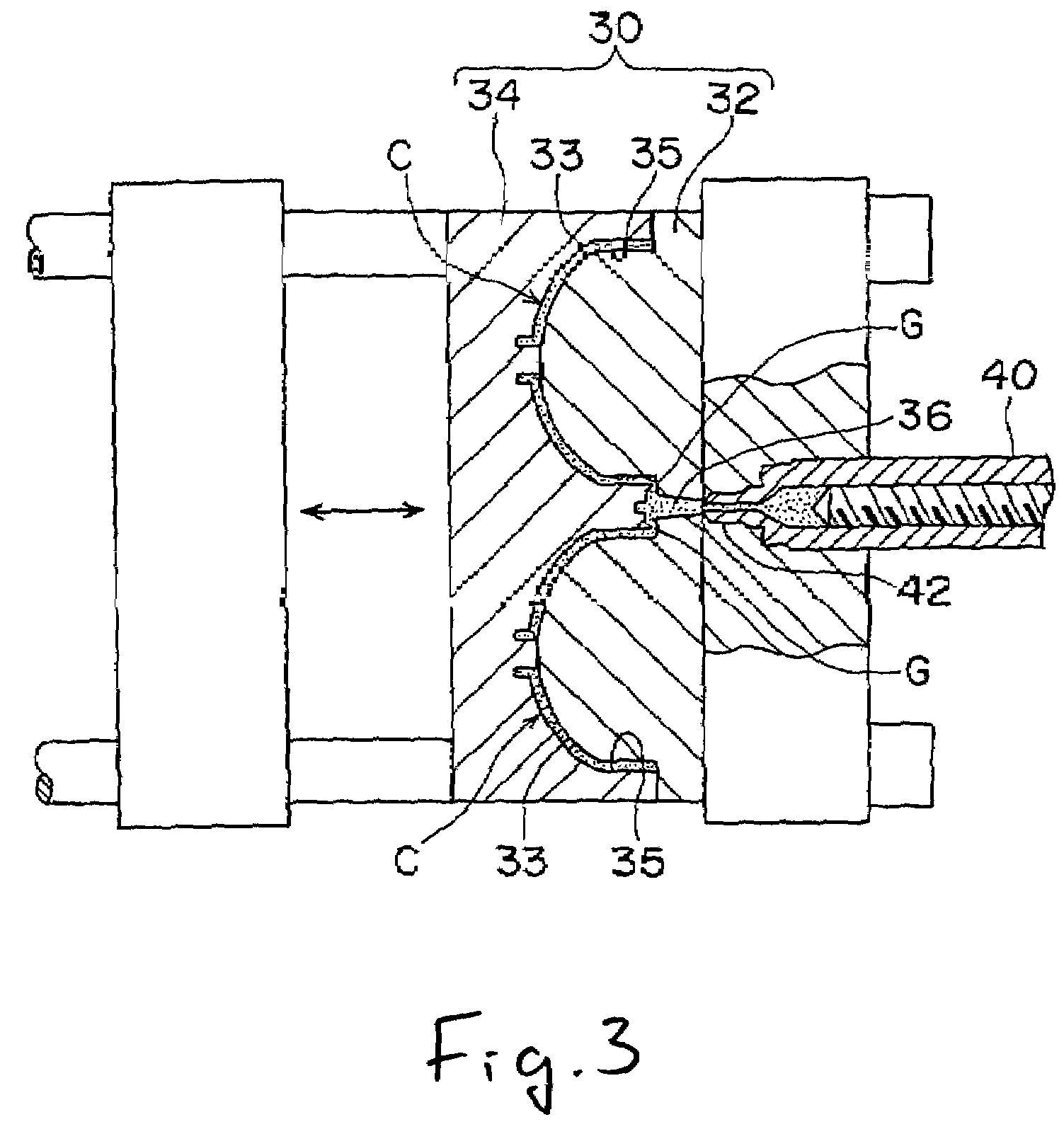

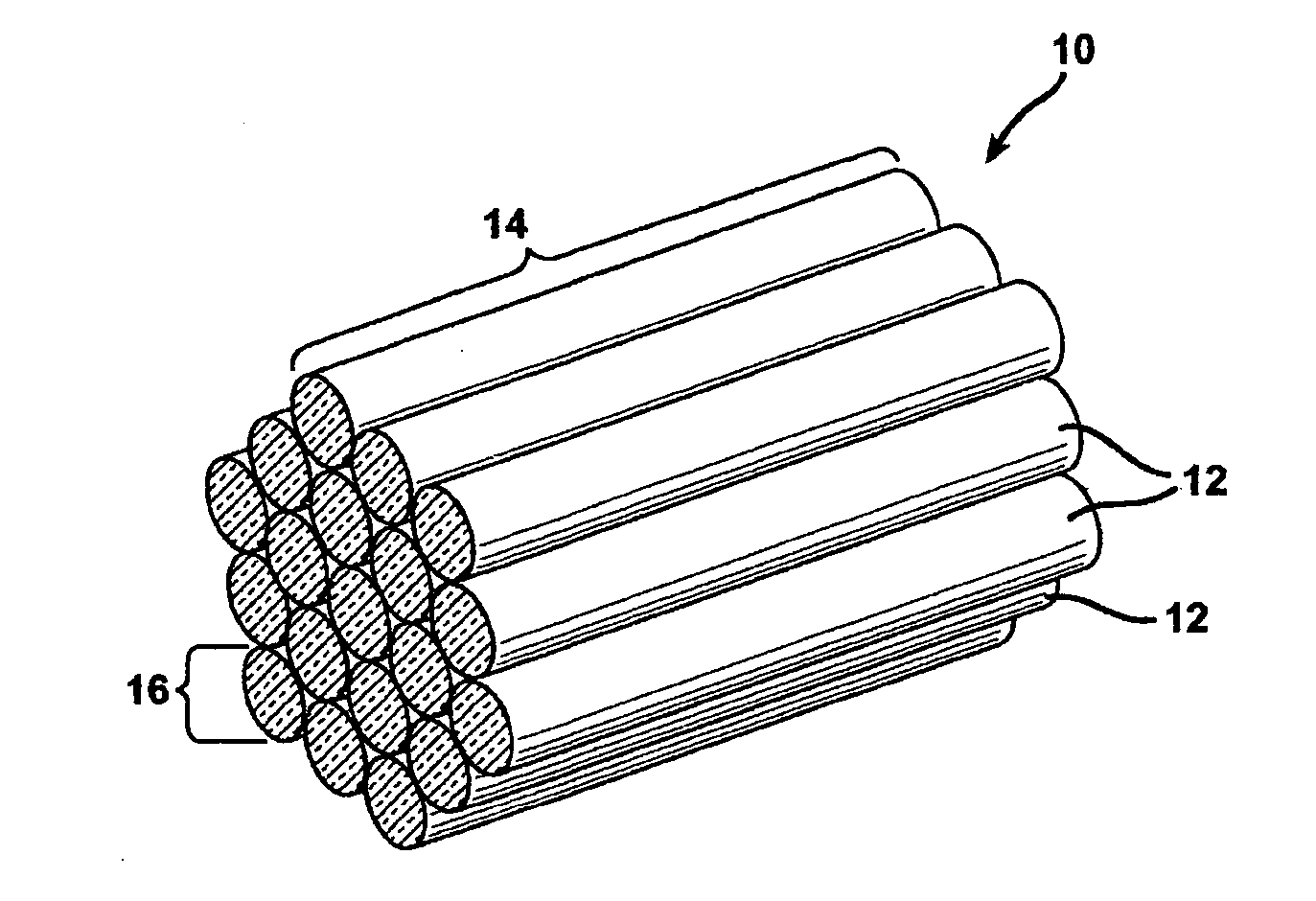

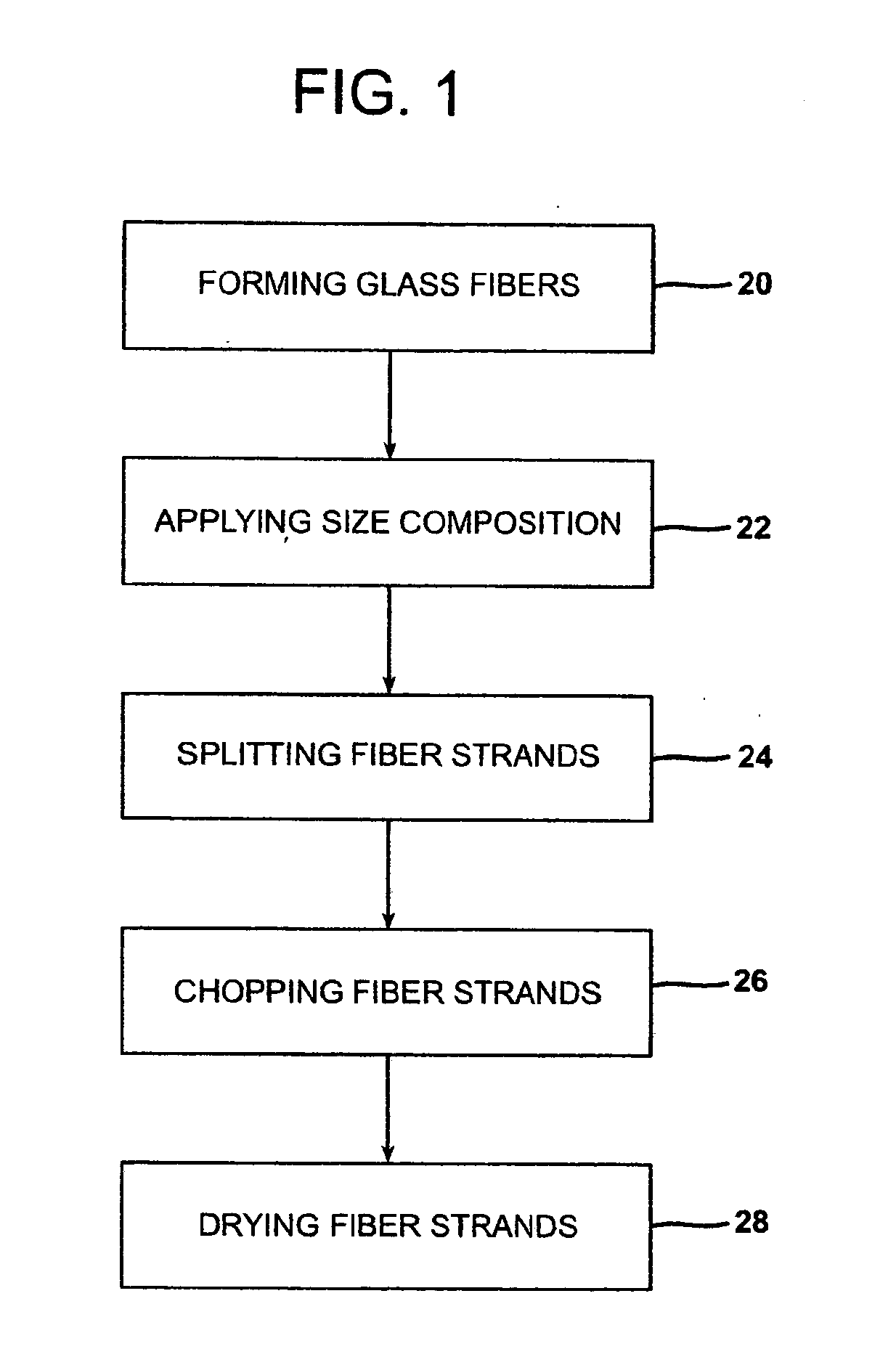

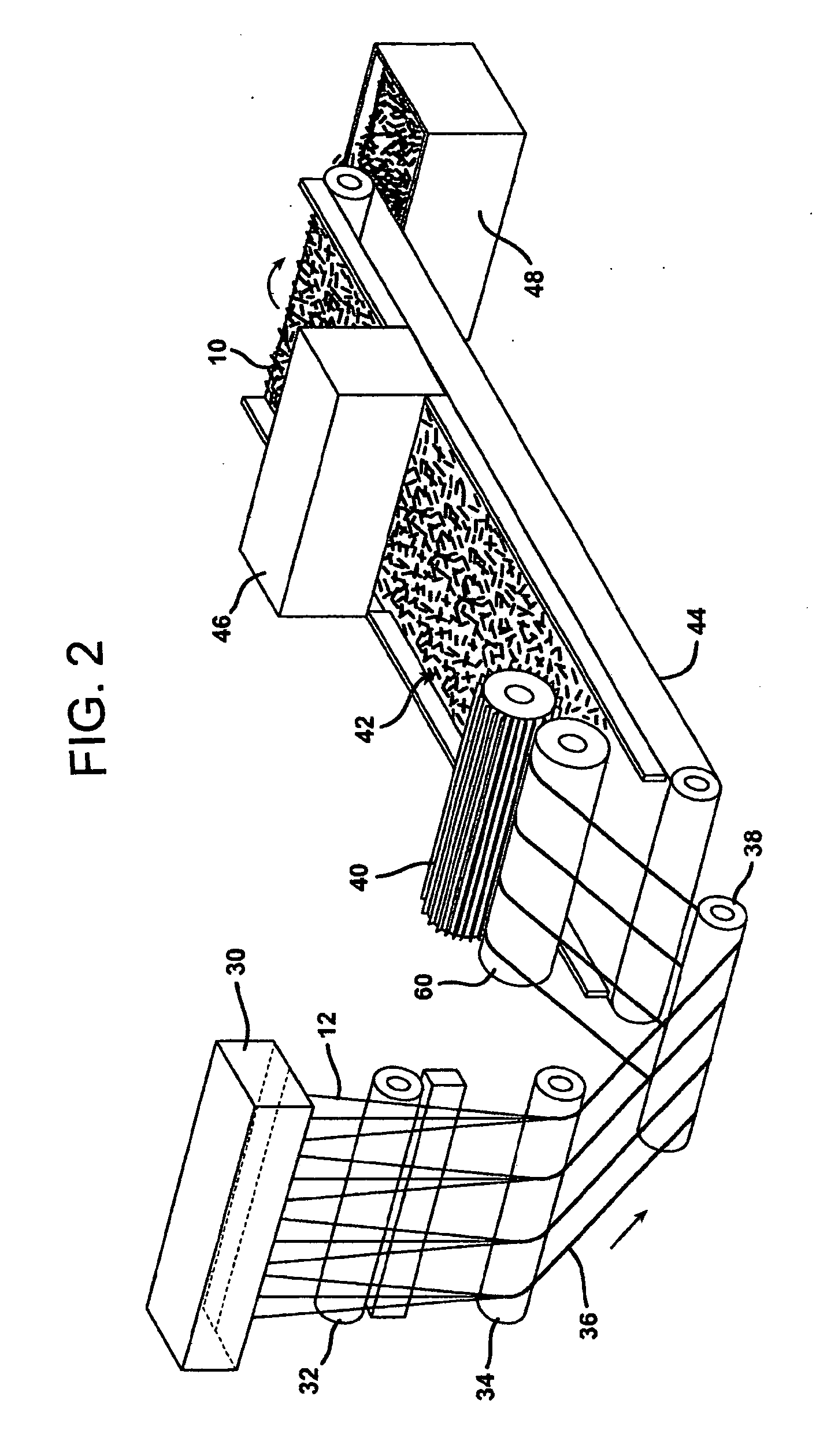

Sizing composition for glass fibers

InactiveUS20080160281A1Improve productivityReduce manufacturing costGlass making apparatusGlass/slag layered productsProduction rateGlass fiber

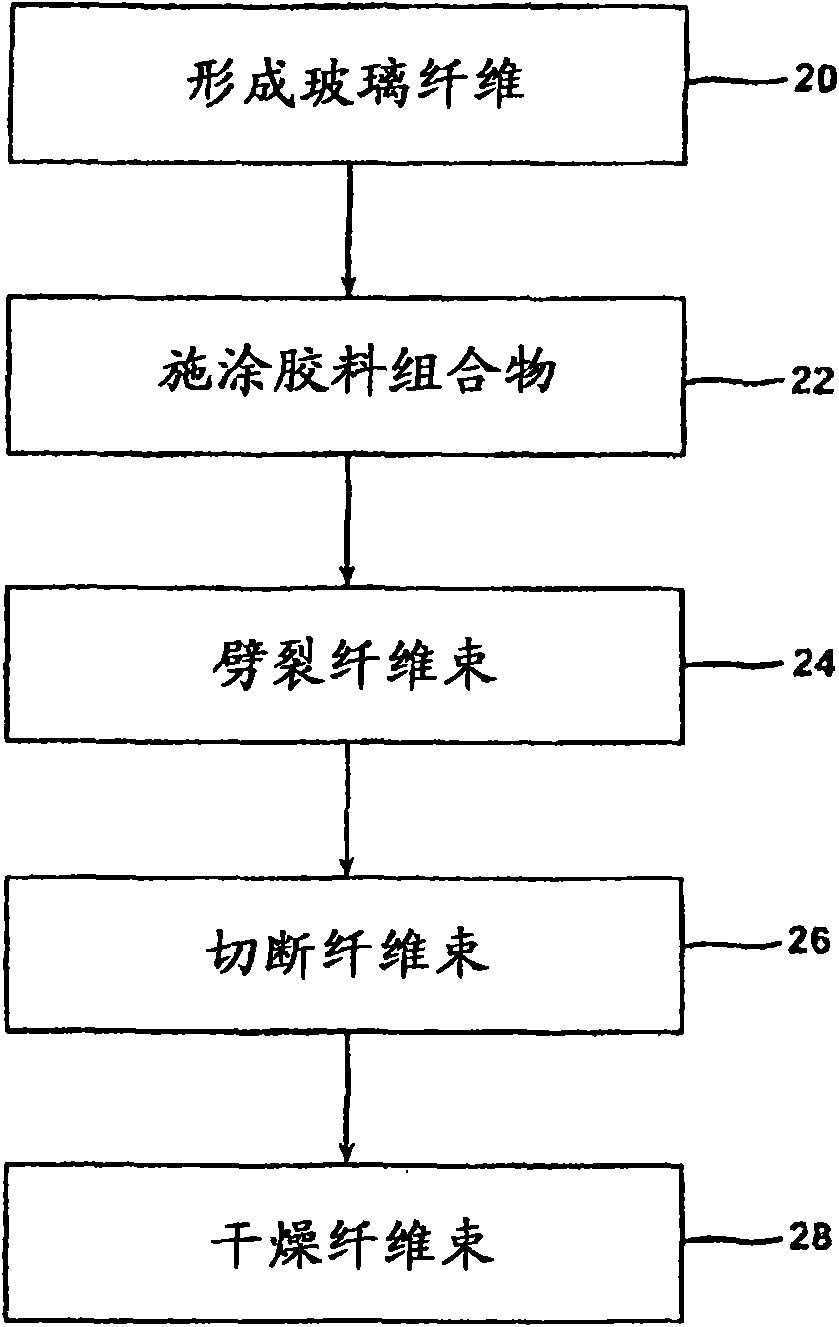

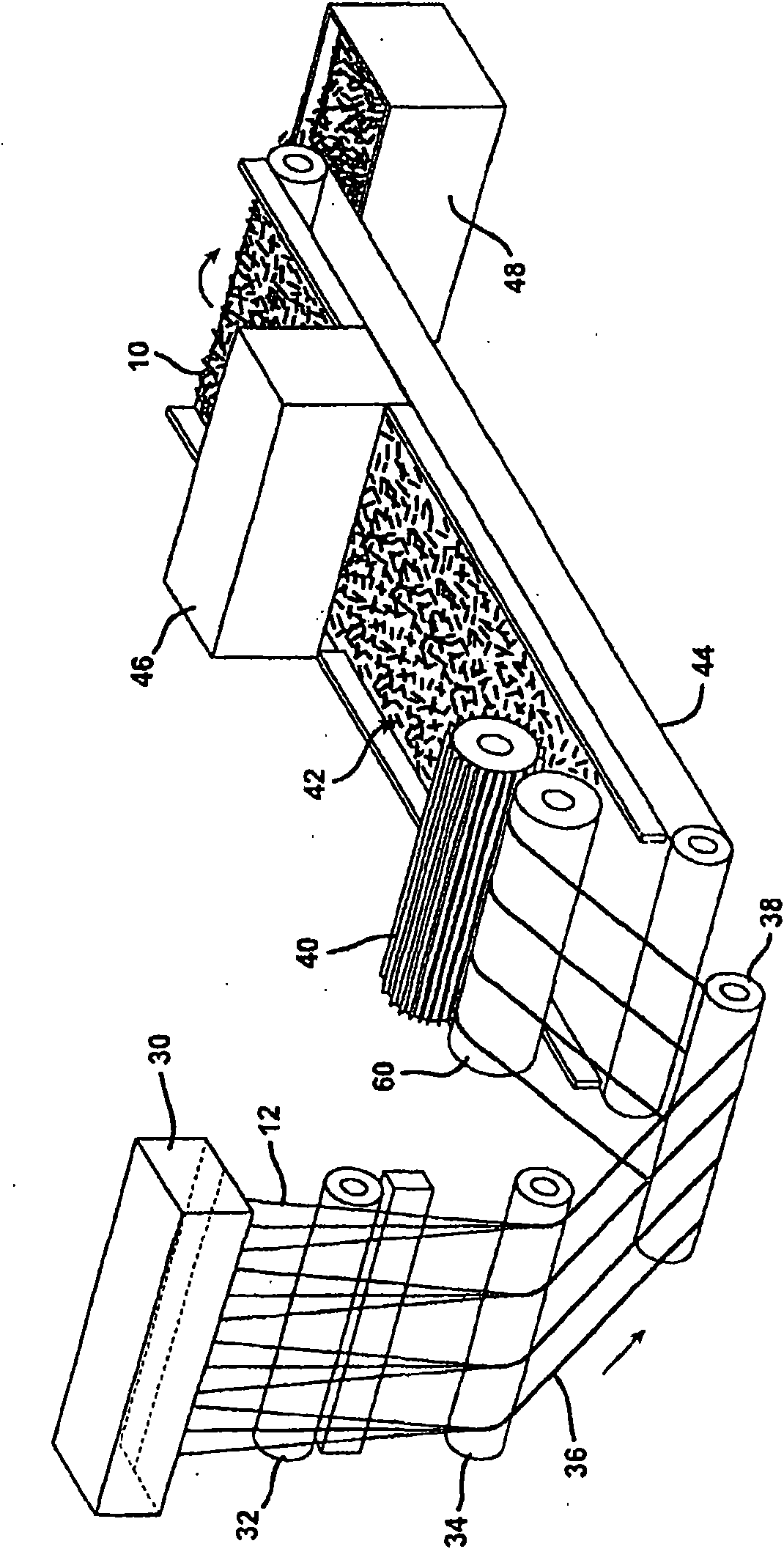

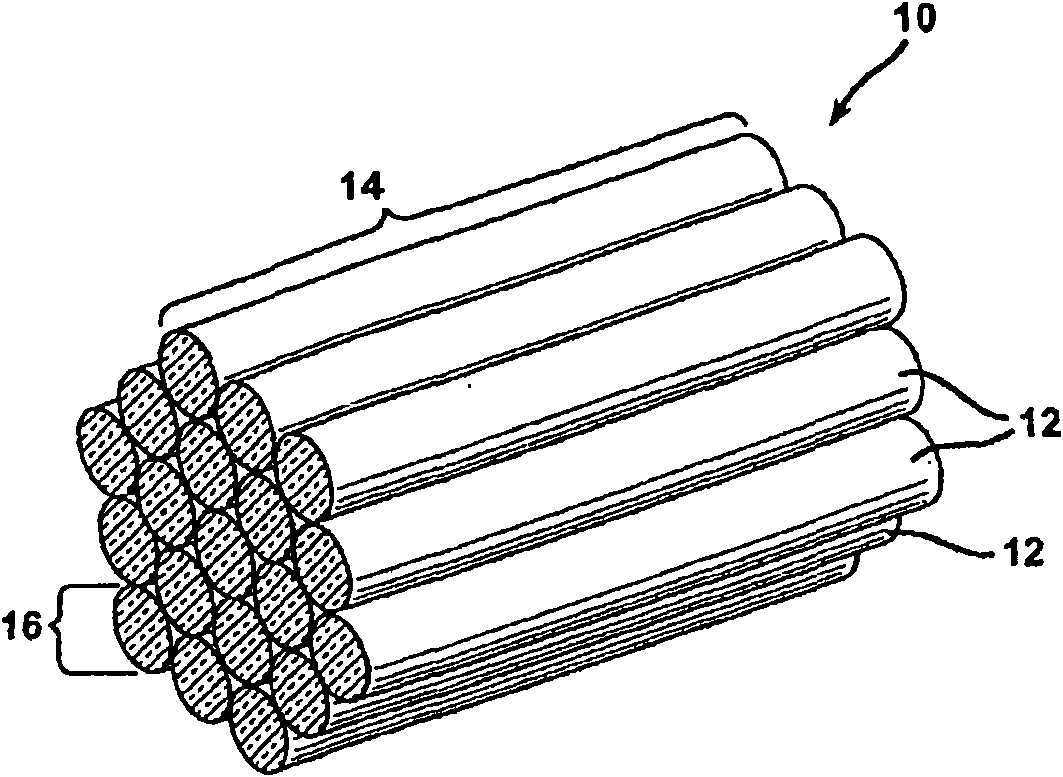

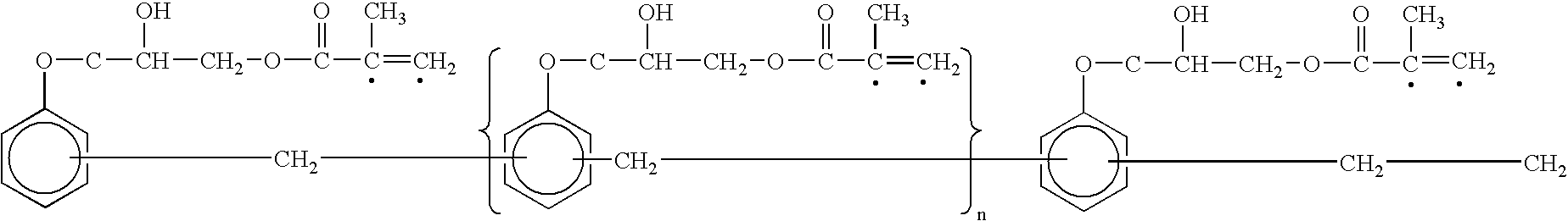

A sizing composition that permits in-line chopping and drying of reinforcement fibers for reinforcing thermoset resins is provided. The size composition includes at least one coupling agent and one or more blocked polyurethane film forming agents. The blocking agent preferably de-blocks at a temperature that permits simultaneous or nearly simultaneous de-blocking and curing of the polyurethane film former. The sized fiber strands may be chopped to form chopped strand segments and dried in a fluidized bed oven, such as a Cratec® drying oven, in-line. The chopped fiber strands may then be used in a bulk molding compound and molded into a reinforced composite article. Chopping the glass fibers in-line lowers the manufacturing costs for products produced from the sized fiber bundles. Further, because the reinforcement fibers can be chopped and dried at a much faster rate with the inventive size composition compared to conventional off-line chopping processes, productivity is increased.

Owner:OCV INTELLECTUAL CAPITAL LLC

Carbon fiber and glass fiber hybrid-reinforced sheet moulding compound and manufacturing technology thereof

The invention provides a carbon fiber and glass fiber hybrid-reinforced sheet moulding compound and is characterized in that the sheet moulding compound mainly comprises resin paste I, resin paste II and thickening agent; the manufacturing technology of the sheet moulding compound comprises the following steps: the preparation of the resin paste I, the resin paste II and the thickening agent; the mixing of the resin paste I and the thickening agent and that of the resin paste II and the thickening agent; and impregnation: the resin paste I and chopped carbon fiber, and the resin paste II and chopped glass fiber are impregnated on an SMC (Sheet Molding Compound) machine set respectively, the impregnated chopped glass fiber is uniformly placed on the impregnated chopped carbon fiber, and then the impregnated chopped glass fiber and the impregnated chopped carbon fiber are composited by pressure through a compacting machine to manufacture a carbon fiber and glass fiber hybrid sheet material which is wound or packaged in a box through the compacting machine and then is subject to slaking treatment; and after the slaking treatment, the carbon fiber and glass fiber hybrid sheet material is made into a finished sheet moulding compound product through mould pressing. The sheet moulding compound has a low cost and a low manufacturing cost, can meet requirements for utilization, is suitable for industrial production and is simple and applicable.

Owner:青岛威奥时代智能装备有限公司

Formulations comprising isosorbide-modified unsaturated polyester resins and low profile additives which produce low shrinkage matrices

InactiveUS20110040004A1High strengthAlkaline-earth metal silicatesFibre treatmentPolymer scienceFiber-reinforced composite

Formulations comprising an isosorbide-modified unsaturated polyester comprising maleic acid, fumaric acid, itaconic acid or maleic anhydride and isosorbide and one or more low profile additives. The formulations exhibit better shrink control in molding compound formulations with standard low profile additives than their non-isosorbide-modified analogues. These isosorbide-modified unsaturated polyester resins may be applied in molding compounds like sheet molding compounds or bulk molding compounds and may be components of fiber reinforced composites or other composite materials.

Owner:INEOS COMPOSITES IP LLC

Sizing composition for glass fibers

InactiveCN101641303AKeep dryImprove productivityCoatingsThin material handlingProduction rateGlass fiber

A sizing composition that permits in-line chopping and drying of reinforcement fibers for reinforcing thermoset resins is provided. The size composition includes at least one coupling agent and one ormore blocked polyurethane film forming agents. The blocking agent preferably de-blocks at a temperature that permits simultaneous or nearly simultaneous de-blocking and curing of the polyurethane film former. The sized fiber strands may be chopped to form chopped strand segments and dried in a fluidized bed oven, such as a Cratec(R) drying oven, in-line. The chopped fiber strands may then be usedin a bulk molding compound and molded into a reinforced composite article. Chopping the glass fibers in-line lowers the manufacturing costs for products produced from the sized fiber bundles. Further, because the reinforcement fibers can be chopped and dried at a much faster rate with the inventive size composition compared to conventional off-line chopping processes, productivity is increased.

Owner:OCV INTELLECTUAL CAPITAL LLC

Global mold plastic, preparing method and uses thereof

The invention provides a bulk moulding compound (BMC) and a preparation method thereof. The material is solidified at certain speed in an injection mould, prevents surface deficiencies, such as ripples, pinholes, pockmarks, scorching, etc., does not reduce the production capability because of too long solidifying time, so the obtained BMC material can be adaptive to all kinds of injection moulds. The invention also provides an automobile lamp reflector substrate processed by such bulk moulding compound and a processing method thereof. The obtained reflector substrate not only has excellent heat resistance and mechanical strength, but also can form a neat and smooth reflective mirror without ripples and other surface deficiencies on the surface through aluminum evaporation plating. Even if the temperature of the mould is as low as 150 DEG C to 160 DEG C, satisfying effect can still be obtained.

Owner:HASCO VISION TECHNOLOGY CO LTD

Preparation of fuel cell composite bipolar plate

ActiveUS7090793B2Improve thermal stabilityImprove mechanical propertiesNon-metal conductorsConductive materialPolymer electrolytesFuel cells

A composite bipolar plate of polymer electrolyte membrane fuel cells (PEMFC) is prepared as follows: a) preparing a bulk molding compound (BMC) material containing a vinyl ester resin and a graphite powder, the graphite powder content of BMC material ranging from 60 wt % to 80 wt %, based on the compounded mixture; b) molding the BMC material from step a) to form a bipolar plate having a desired shape at 80–200° C. and 500–4000 psi, wherein the graphite powder is of 40 mesh–80 mesh.

Owner:IND TECH RES INST +1

Method of manufacturing composite wood golf club head with metal face

A method of manufacturing a composite golf club head with a metal face includes the following steps. 1. Arrange two die and a mold plunger. 2. Combine the dies to form a mold cavity, which bottom is installed with a metal bottom board. 3. Put a bulk molding compound (B.M.C.) into the mold cavity. 4. Move the mold plunger into the mold cavity to compress the B.M.C. 5. Solidify the compressed bulk molding compound, and then separate the dies and the mold plunger to get a composite main body of the golf club head. The main body thus obtained has a main casing with a top opening. 6. Mount a composite top casing to the main casing to cover the top opening. Mount a metal front casing to a front side of the main casing to form the face.

Owner:CHEN ARCHER C C

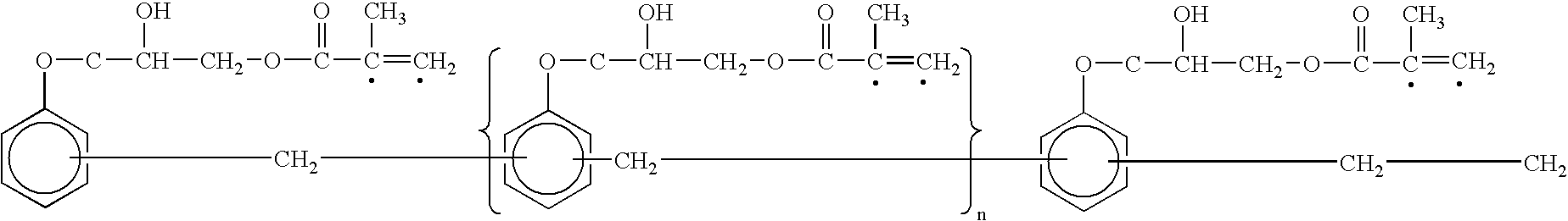

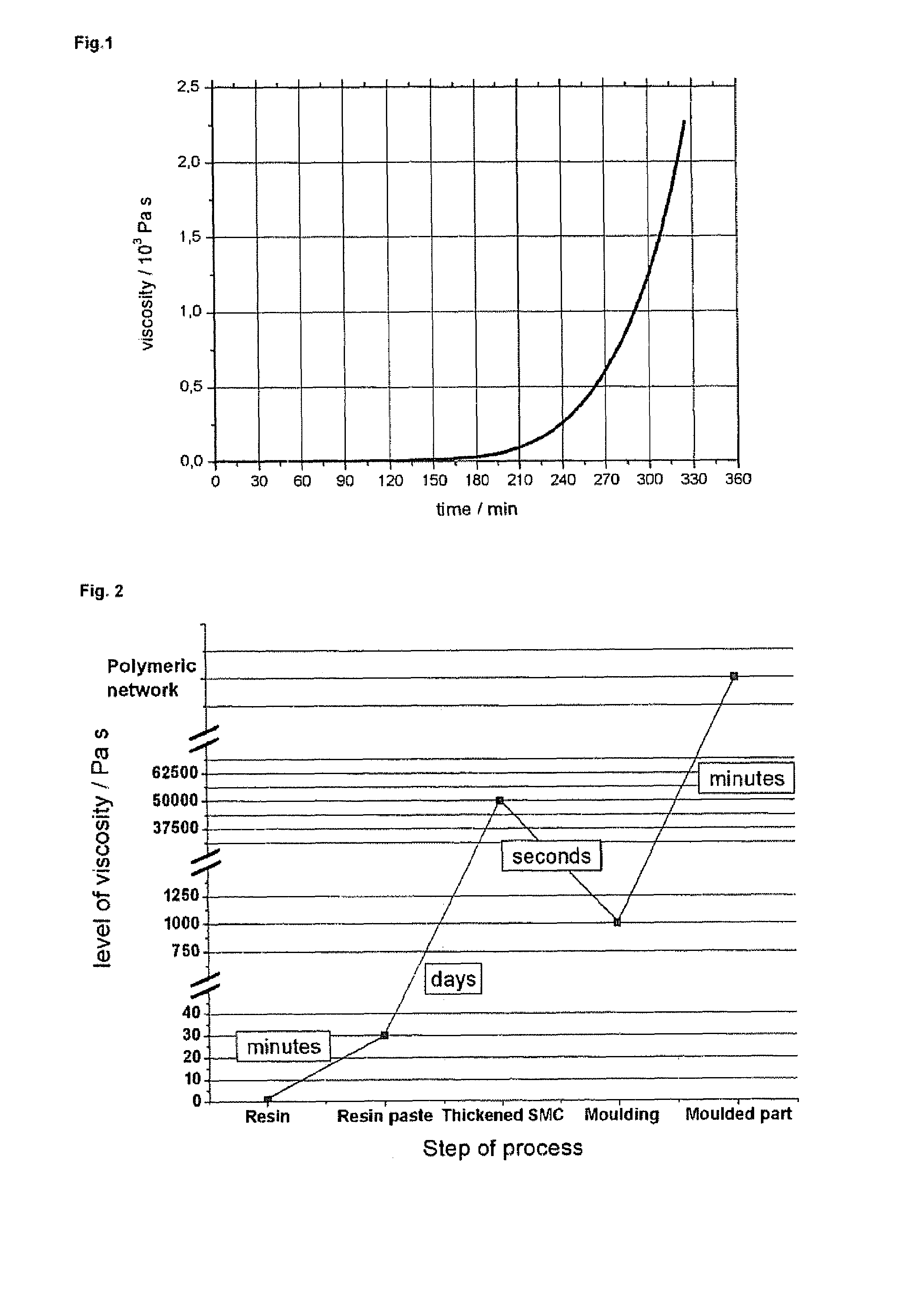

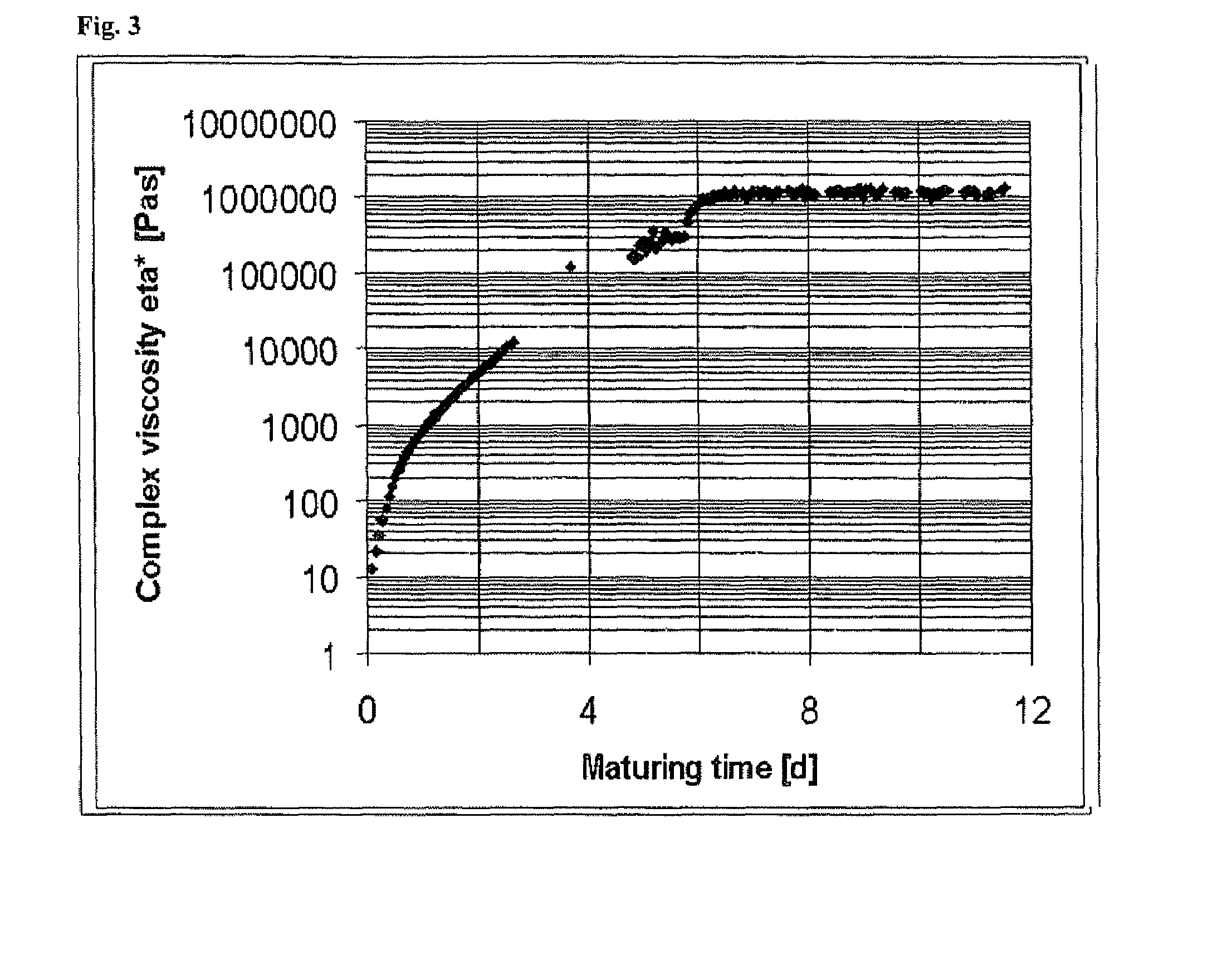

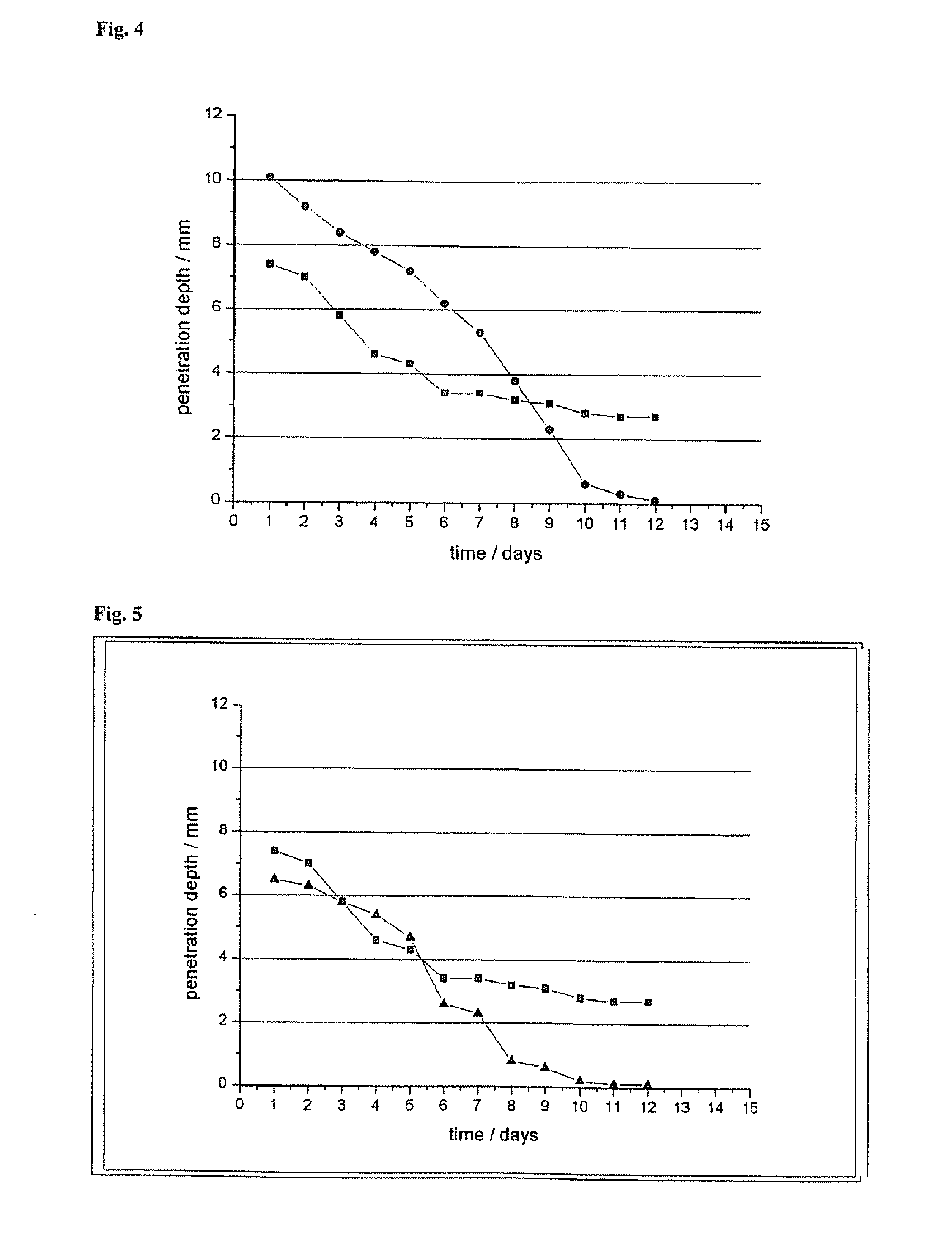

Sheet molding compounds (SMC), thick molding compounds (TMC), and bulk molding compounds (BMC) comprising thermosetting resins based on renewable resources

ActiveUS8241739B2Shorten cycle timeMedium material priceSynthetic resin layered productsThin material handlingRenewable resourceBulk moulding compound

The object of the invention is a new Sheet Molding Compound (SMC), Thick Molding Compound (TMC), or Bulk Molding Compound (BMC) comprising at thermosetting resin on the basis of renewable resources with which molded parts can be produced in a molding process at elevated temperature and pressure said process being suitable to produce molded parts in an industrial process.

Owner:POLYNT +1

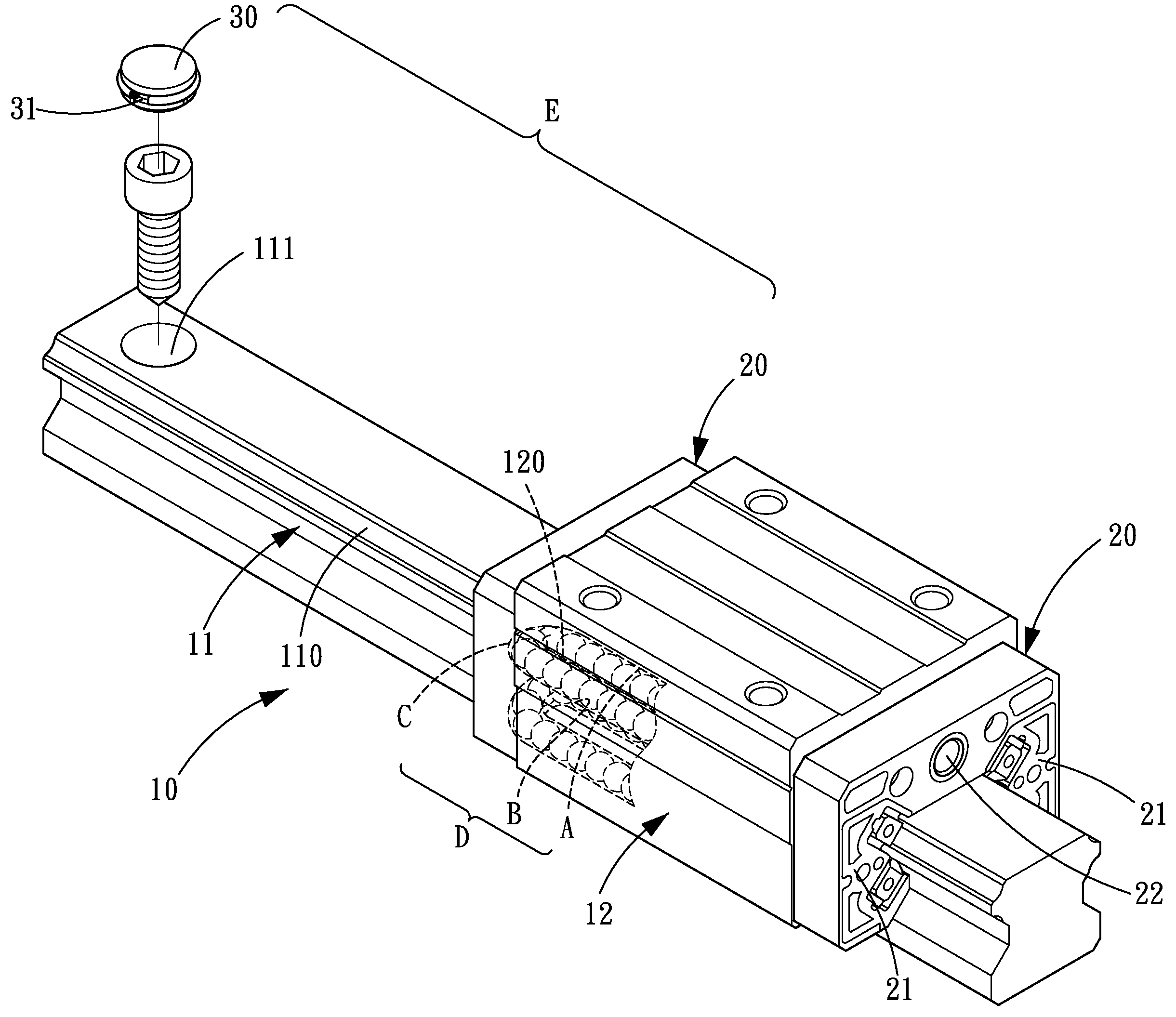

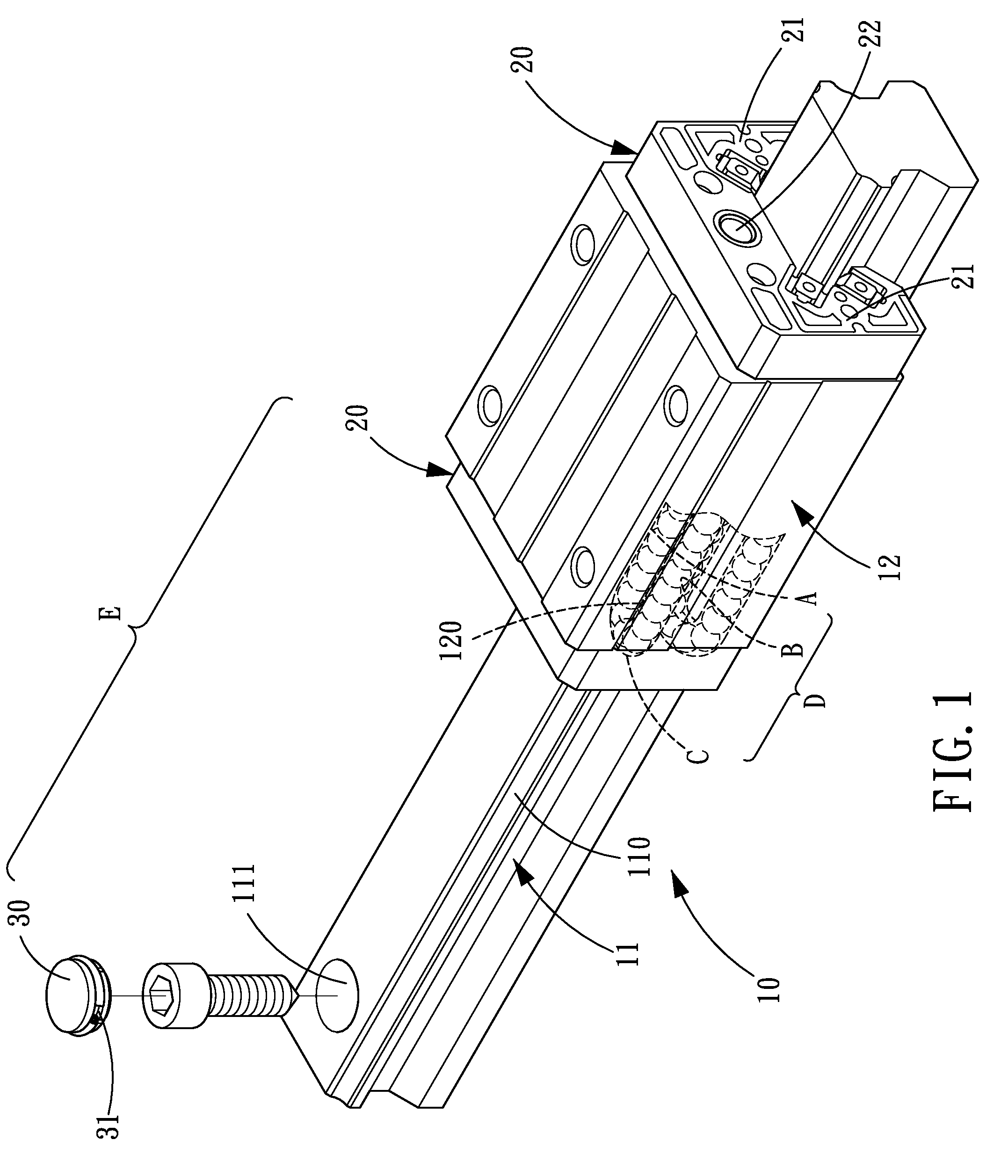

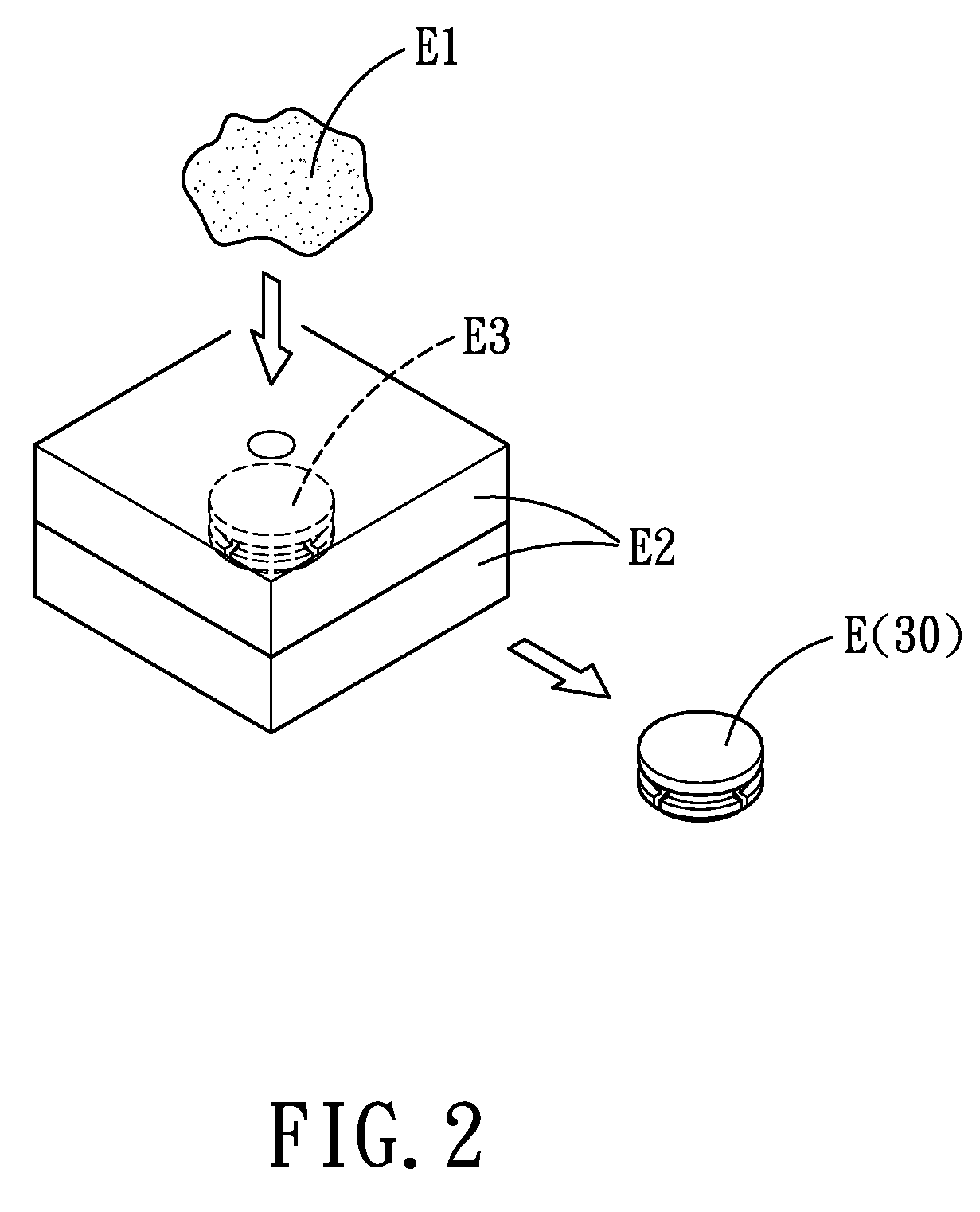

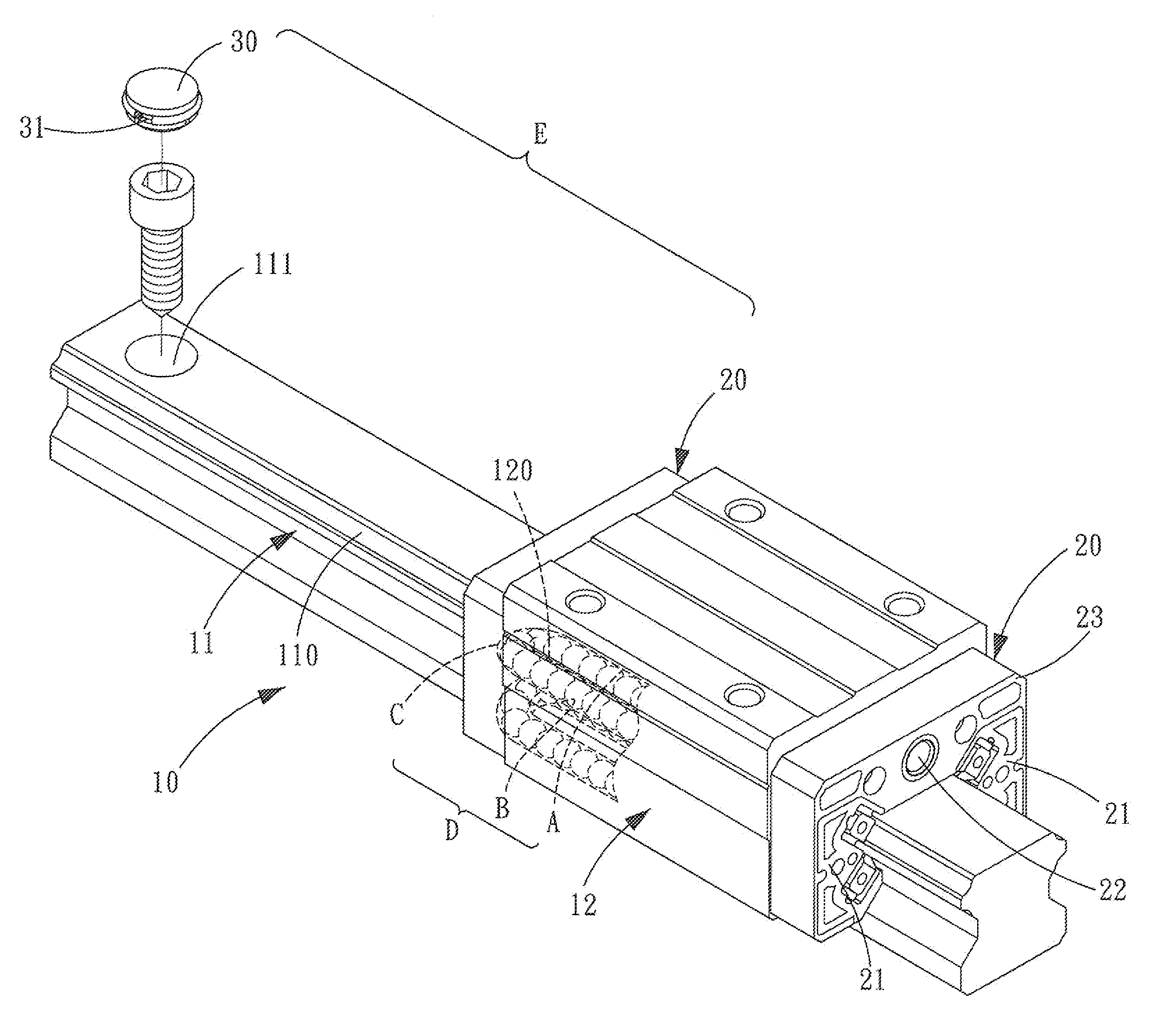

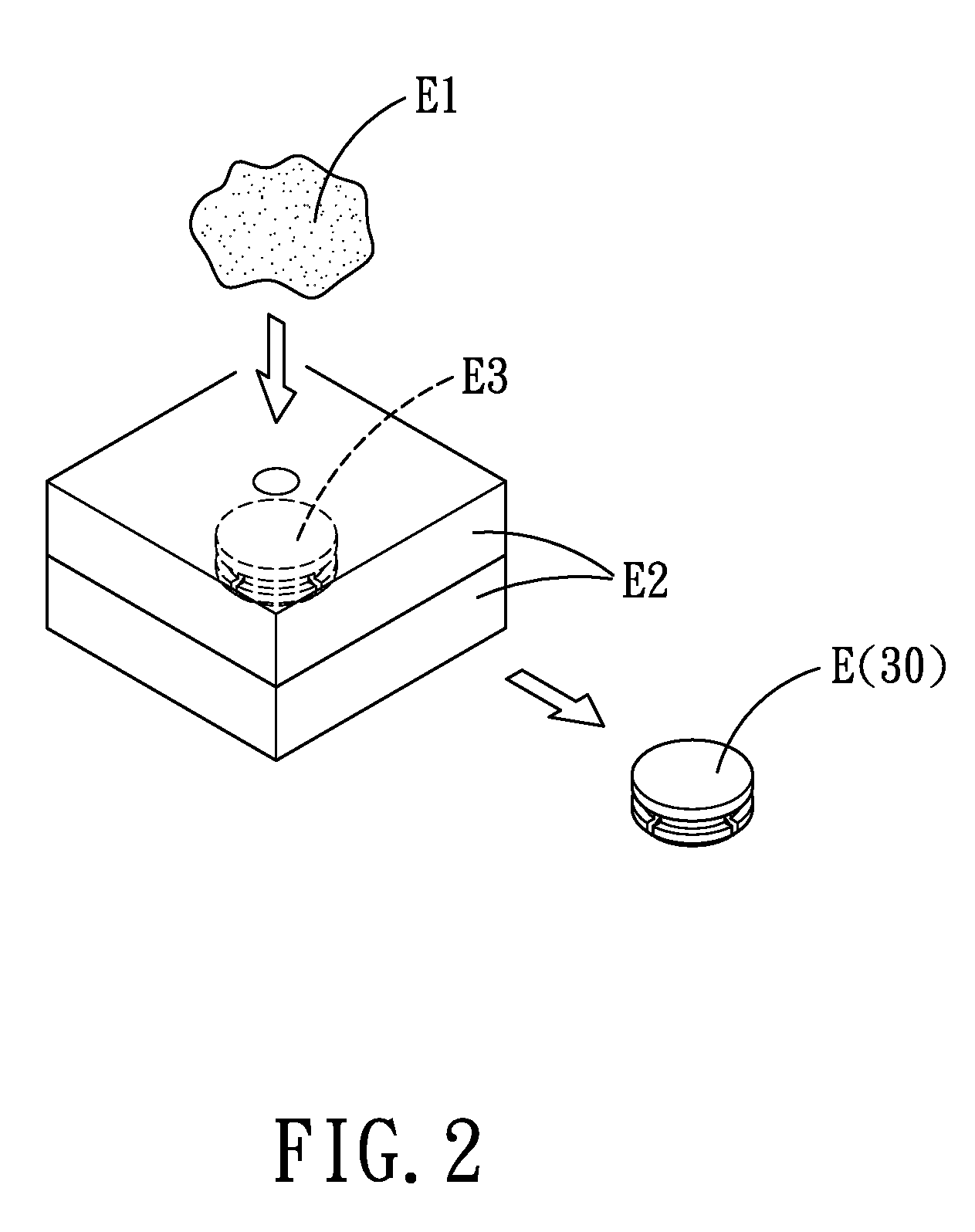

Component for Linear Guideway and Method for making the same

ActiveUS20100183252A1Fast formingShorten production timeLinear bearingsNutsPlastic injection moldingEngineering

A component for linear guideway and method for making the same, wherein the component is an end cap or a bolt cover which is made by bulk molding compound which is injected into a mold and formed into the desired shape by thermal setting. The component can be an assembly made up of a plurality of members, namely, an inserting member which is provided for passage of rolling elements can be formed simultaneously when the component is molded by plastic injection molding. The inserting member is formed by: injecting metal powder into a first mold and forming into an inserting member with acceptable rigidity and precision; putting the inserting member into a second mold and bulk molding compound; then the die material is formed into the desired component by thermal setting directly on the inserting member.

Owner:HIWIN TECH

Golf club head

InactiveUS20130331203A1Easy to hitEasy to closeGolf clubsRacket sportsBulk moulding compoundGolf club

A hollow golf club head includes a face portion, a sole portion, a side portion, a crown portion, and a hozel portion. A main portion of the crown portion is made of a fiber reinforced resin. The fiber reinforced resin portion includes a bulk molding compound (BMC) molded body. At least the face portion, a leading edge of the crown portion continuous with the face portion, and a center portion of the sole portion in a toe-heel direction are made of a metal. Alternatively to this configuration, the face portion may be provided with a metal faceplate, a portion subsequent to the face portion may include a BMC molded body, and a rear portion of the crown portion may include a molded laminate of prepreg sheets. The height of center of gravity may be 24 mm or less.

Owner:BRIDGESTONE SPORTS

Component for linear guideway and method for making the same

ActiveUS8328422B2Fast formingShorten production timeLinear bearingsNutsPlastic injection moldingEngineering

A component for linear guideway and method for making the same, wherein the component is an end cap or a bolt cover which is made by bulk molding compound which is injected into a mold and formed into the desired shape by thermal setting. The component can be an assembly made up of a plurality of members, namely, an inserting member which is provided for passage of rolling elements can be formed simultaneously when the component is molded by plastic injection molding. The inserting member is formed by: injecting metal powder into a first mold and forming into an inserting member with acceptable rigidity and precision; putting the inserting member into a second mold and bulk molding compound; then the die material is formed into the desired component by thermal setting directly on the inserting member.

Owner:HIWIN TECH

Sheet molding compounds (SMC), thick molding compounds (TMC), and bulk molding compounds (BMC) comprising thermosetting resins based on renewable resources

ActiveUS20100041802A1Shorten cycle timeMedium material priceGroup 4/14 element organic compoundsWood working apparatusShell moldingRenewable resource

The object of the invention is a new Sheet Molding Compound (SMC), Thick Molding Compound (TMC), or Bulk Molding Compound (BMC) comprising at thermosetting resin on the basis of renewable resources with which molded parts can be produced in a molding process at elevated temperature and pressure said process being suitable to produce molded parts in an industrial process

Owner:POLYNT +1

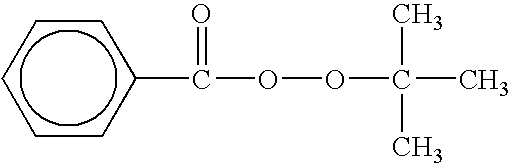

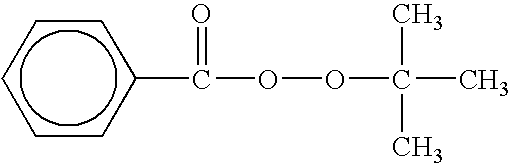

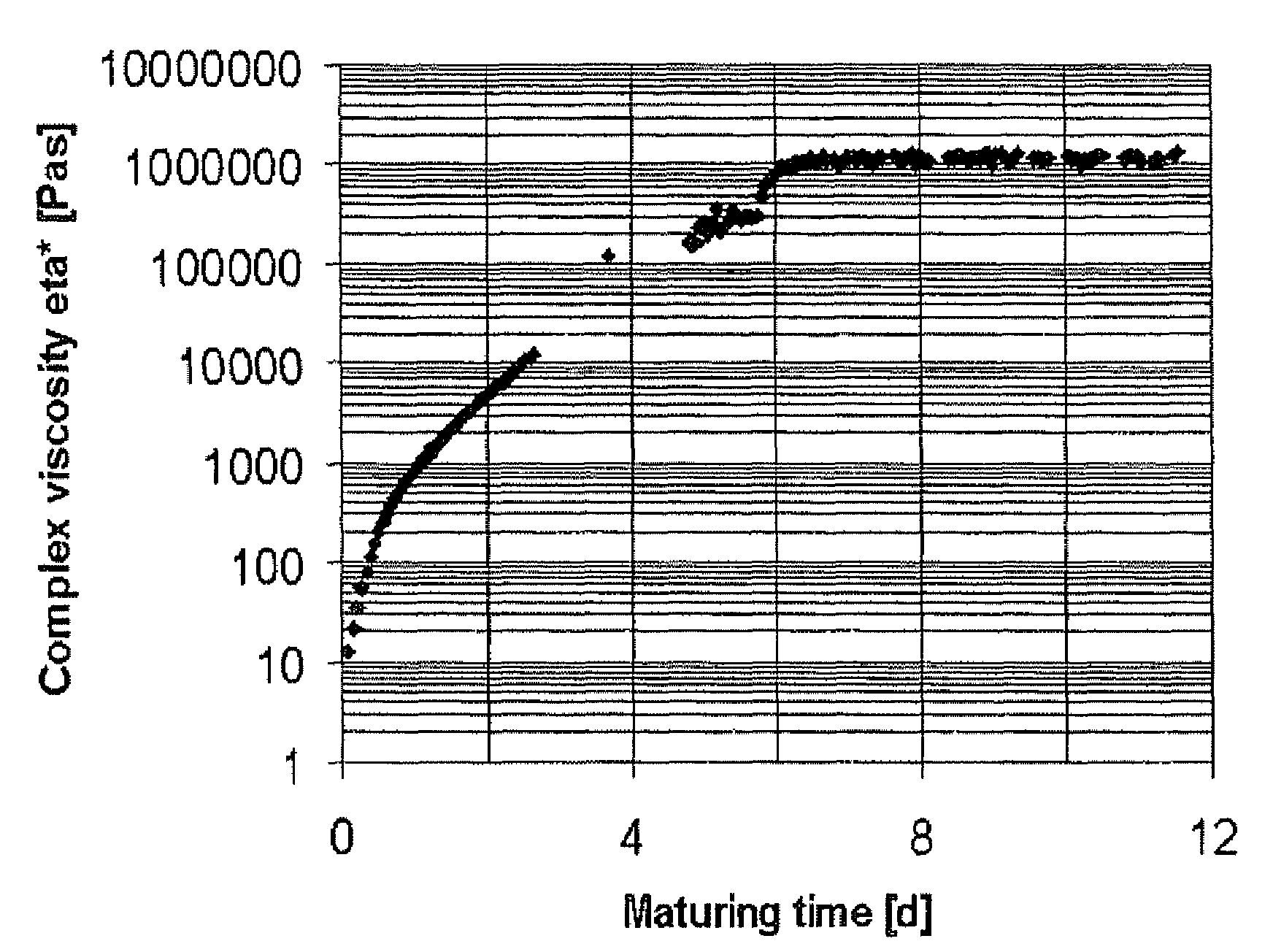

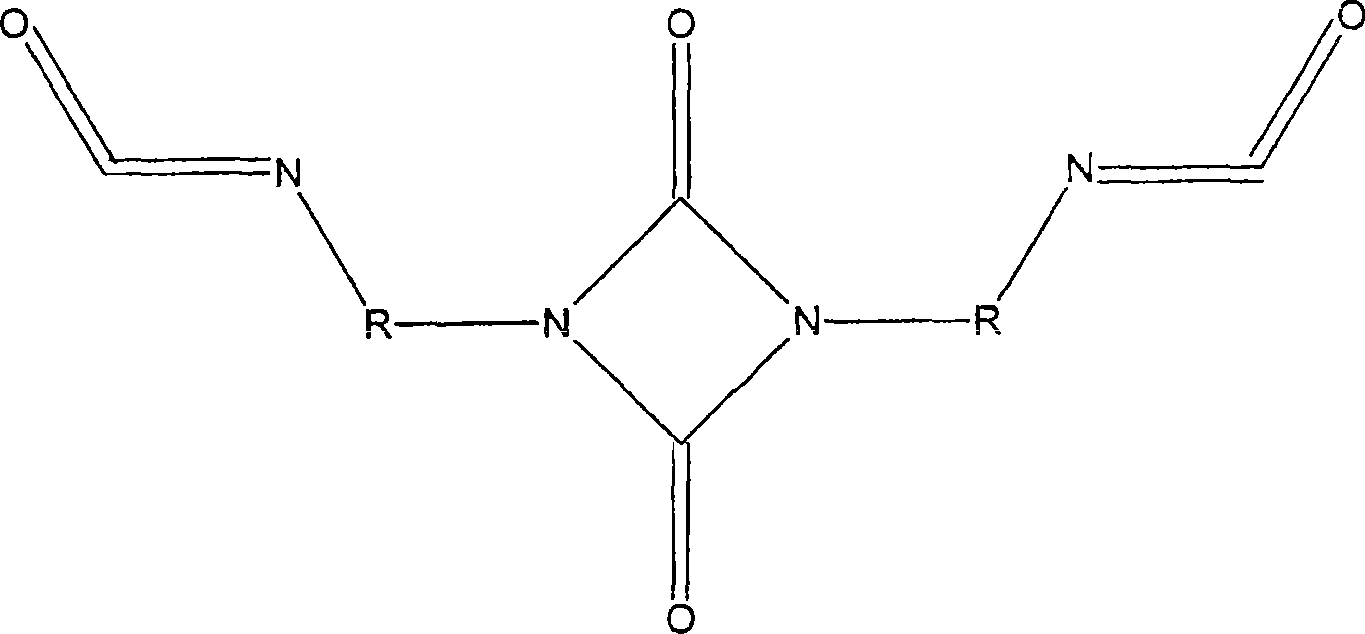

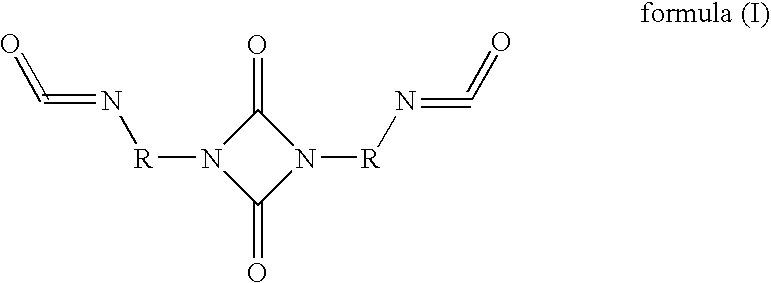

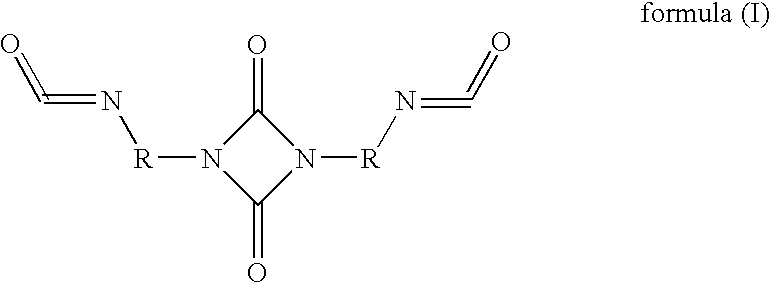

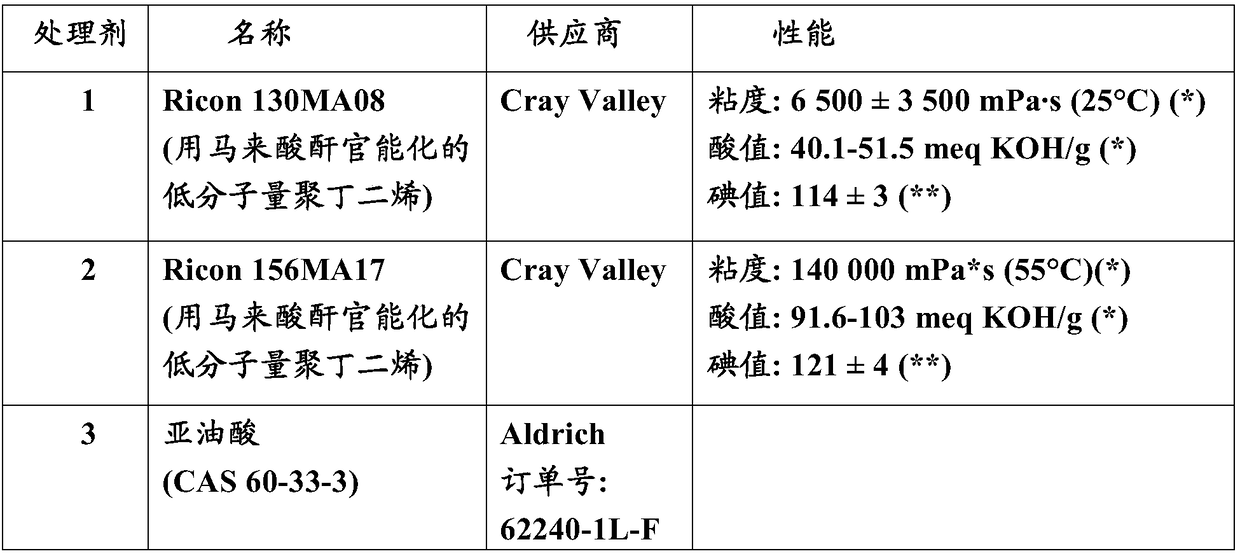

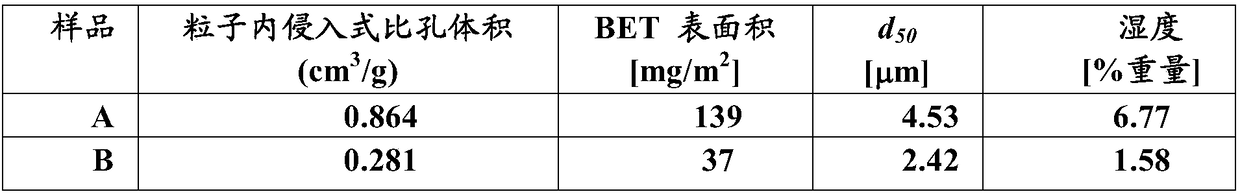

Polyester resin compositions with reduced emission of volatile organic compounds

Thermally curate resin composition, having shrink-controlled properties and being suitable for use in sheet moulding compounds and bulk moulding compounds (SMCs and BMCs) comprising, inter alia (a)an unsaturated polyester; (b) an alkenyl aromatic monomer; (c) a low profile additive; (d) a peroxide initiator; (e) a thickening agent; (f) fibrous reinforcement material; and optionally one or more components selected from the group of (g) mould release agents; (h) wetting and viscosity reducing agents; and (i) fillers, wherein the composition also comprises a uret dione diisocyanate, in an amount of at least 0,2-1,0% by weight relative to the total weight of components (a), (b) and (c) of the resin composition. The resin compositions according to the invention in particular have a low emission of volatile organic compounds (VOC). More particularly, the resin compositions have excellent Class A properties. The present invention also relates to low profile additives (LPAs) wherein a uret dione diisocyanate is chemically attached through one or both of its reactive side-chain isocyanate groups to one or more of the OH-, NH2-, or COOH- groups of a component already having LPA properties. Finally, the present invention relates to low-VOC products and parts produced from the SMCs and BMCs according to the invention.

Owner:DSM IP ASSETS BV

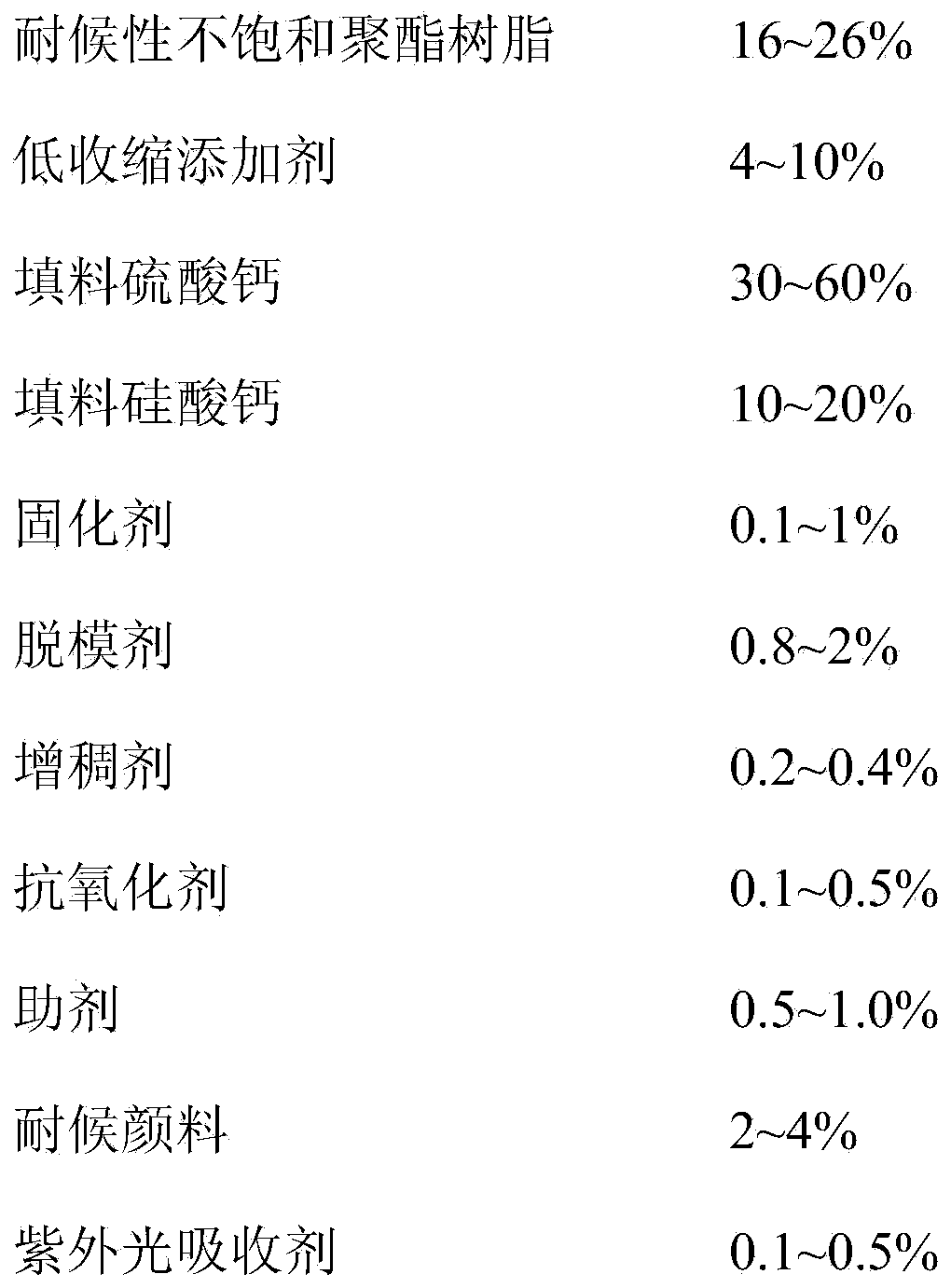

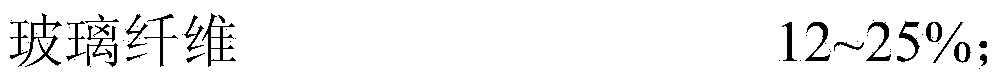

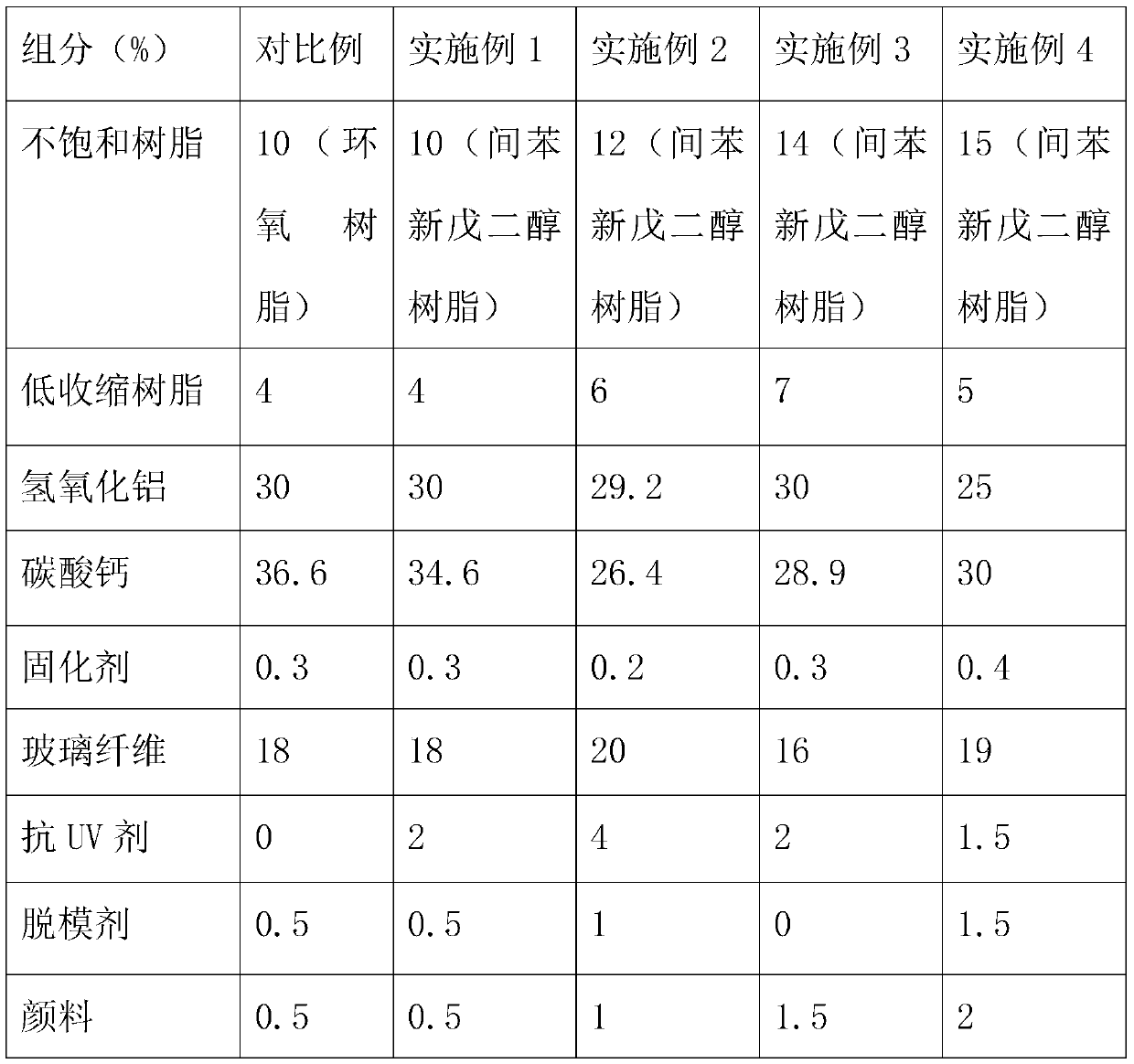

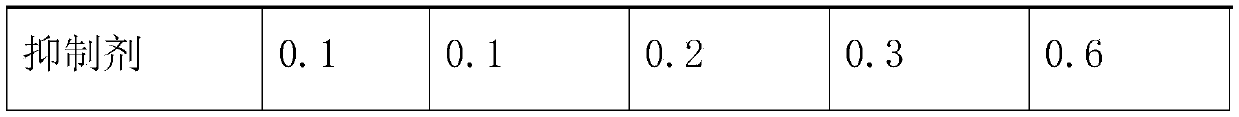

BMC (Bulk Moulding Compound) material with weather resistance and preparation method of BMC material

InactiveCN103724959AGood acid and alkali resistanceExcellent resistance to UV oxidationCalcium silicateAntioxidant

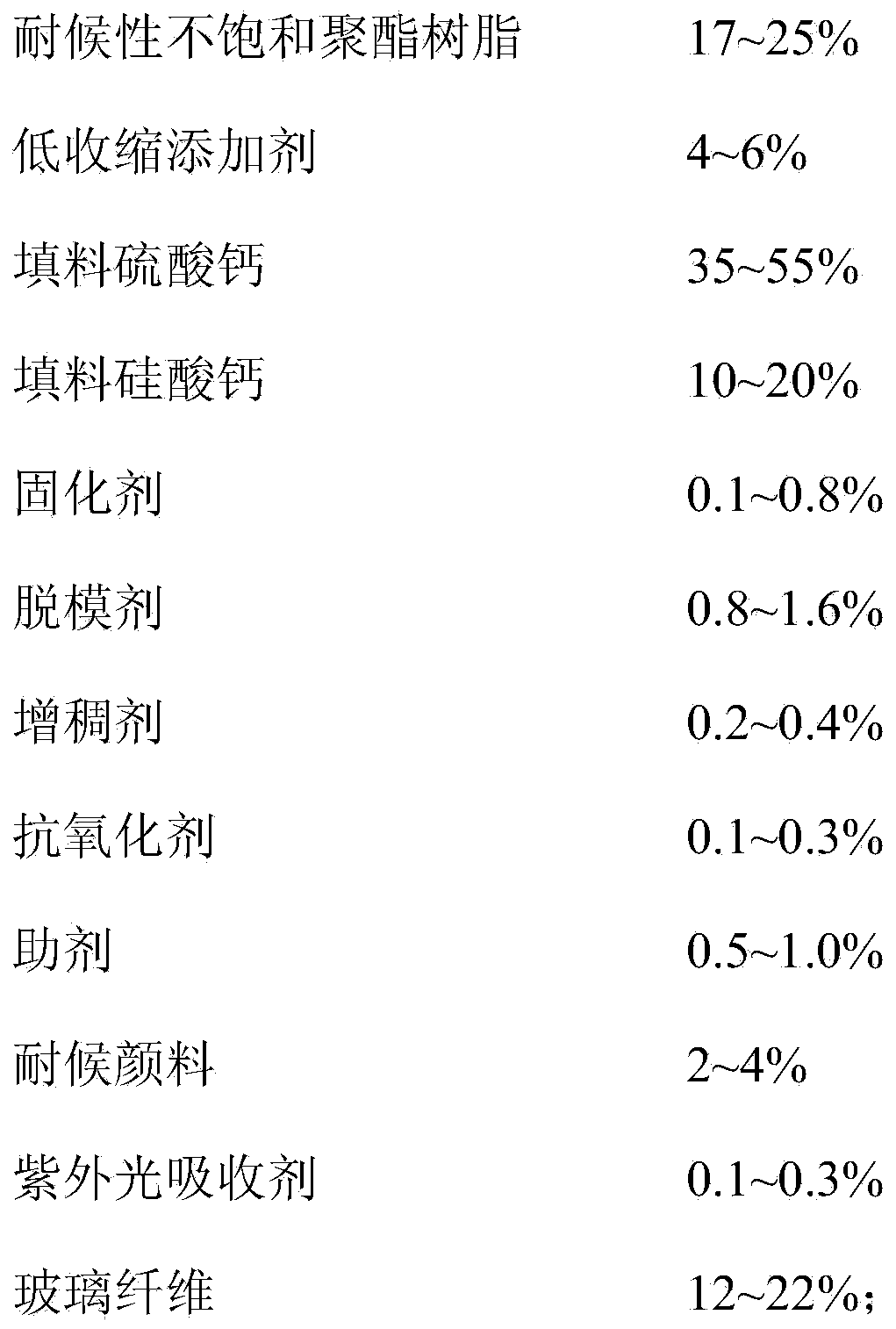

The invention discloses a BMC (Bulk Moulding Compound) material with weather resistance. The BMC material is prepared from the following main raw materials in percent by weight in the terms of the weight of the BMC material: 16-26 percent of weather-resisting unsaturated polyester resin, 4-10 percent of low-shrinkage additive, 30-60 percent of filler calcium sulfate, 10-20 percent of filler calcium silicate, 0.1-1 percent of curing agent, 0.8-2 percent of releasing agent, 0.2-0.4 percent of thickening agent, 0.1-0.5 percent of antioxidant, 0.5-1.0 percent of assistant, 2-4 percent of weather-resisting pigment, 0.1-0.5 percent of ultraviolet absorber and 12-25 percent of glass fiber, wherein the sum of the percents by weight of all raw materials of the BMC is 100 percent. The BMC material has excellent acid and alkali resistance, ultraviolet light oxidation resistance, hydrolysis resistance, high-low temperature resistance, and weather resistance.

Owner:无锡新宏泰电器科技股份有限公司

Composite substrate for counter electrode of dye-sensitized solar cell

ActiveUS20100154871A1Good dimensional stabilityImprove mechanical propertiesMaterial nanotechnologyElectrolytic capacitorsComposite substrateVinyl ester

A substrate for counter electrode of dye-sensitized solar cell is made of a composite material, which is prepared by: a) compounding vinyl ester and graphite powder to form bulk molding compound (BMC) material, the graphite powder content ranging from 60 wt % to 95 wt % based on the total weight of the graphite powder and vinyl ester, wherein 0.01-10 wt % of an electrically conductive filler, based on the weight of the vinyl ester resin, is optionally added during the compounding; b) molding the BMC material from step a) to form a substrate for the counter electrode having a desired shaped at 80-200° C. and 500-4000 psi.

Owner:NATIONAL TSING HUA UNIVERSITY

Graphite-based composite bipolar plate for fuel cell and preparation method thereof

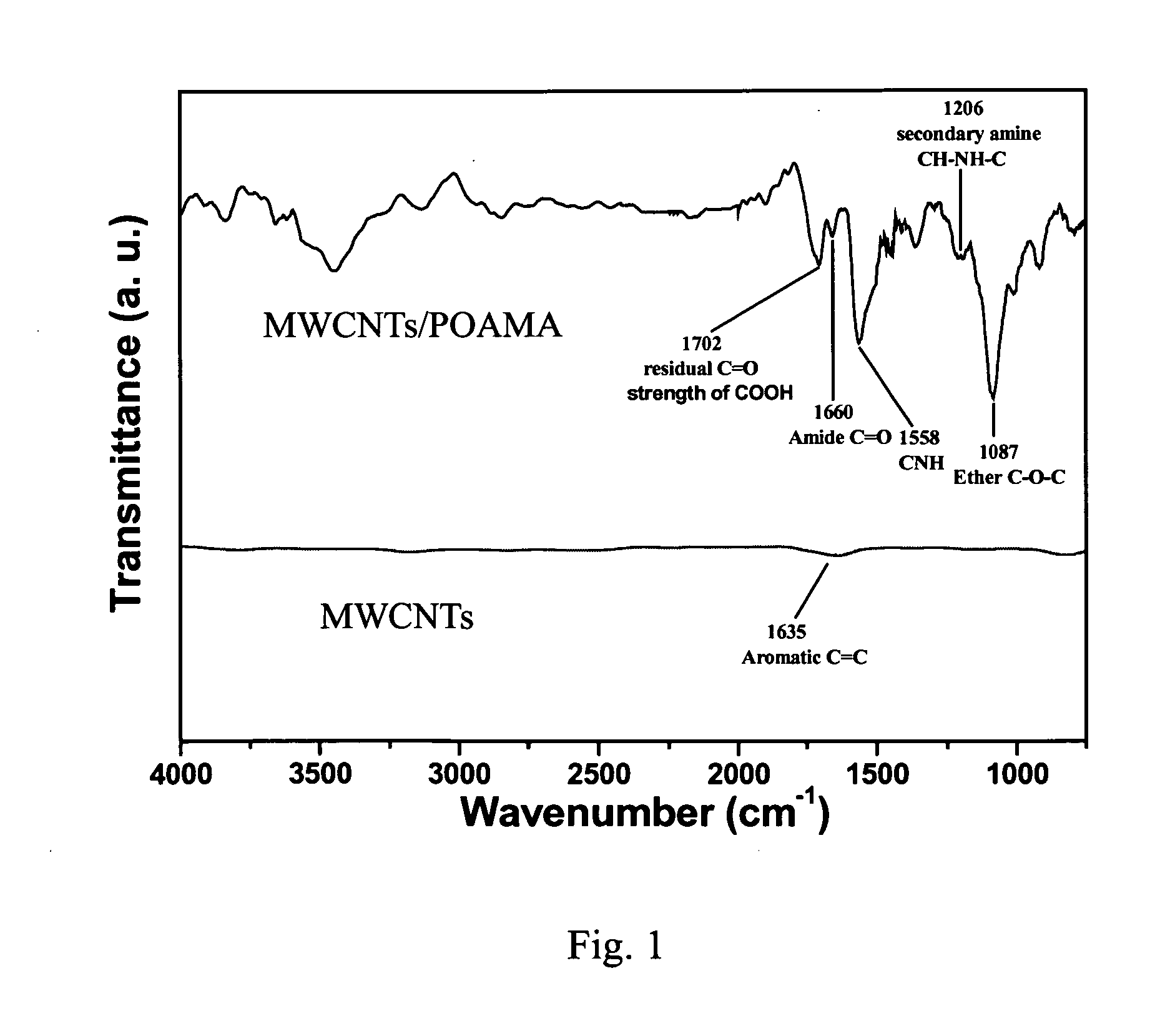

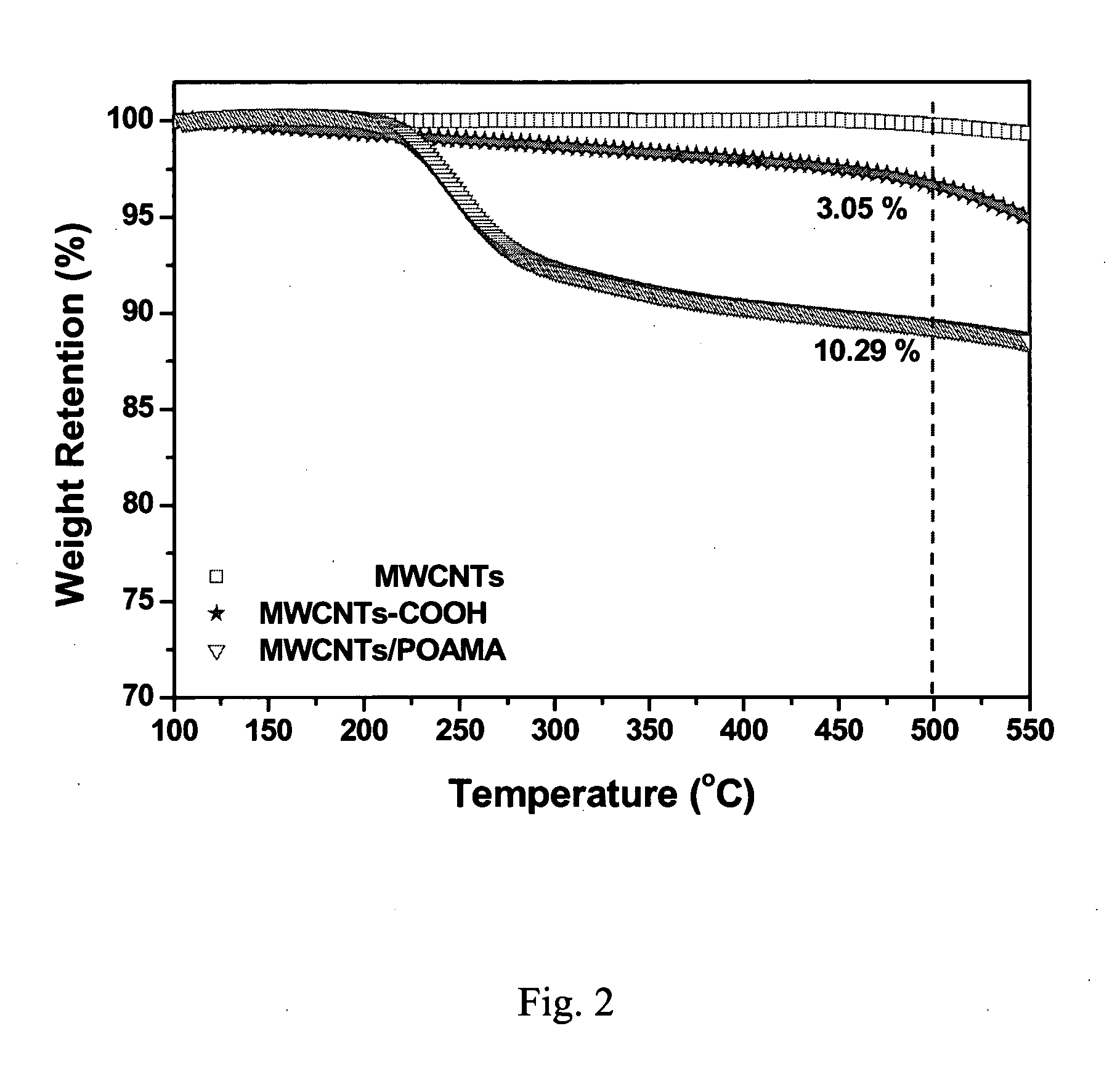

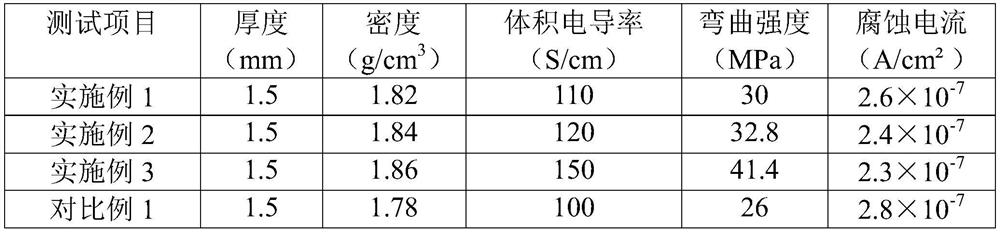

InactiveCN113097521AImprove mechanical propertiesIncreasing the thicknessFuel cellsFuel cellsModified carbon

The invention belongs to the technical field of fuel cells, and particularly relates to a graphite-based composite bipolar plate for a fuel cell and a preparation method of the graphite-based composite bipolar plate. The preparation method of the graphite-based composite bipolar plate comprises the following steps: (a) mixing prepared thermosetting resin slurry and graphite powder to form a blocky molding compound, and adding modified carbon nanotubes accounting for 0.1%-10% of the total weight of the graphite powder and the thermosetting resin slurry in the mixing process; and (b) carrying out mold pressing on the blocky molding compound obtained in the step (a) at 50-300 DEG C and 5-35 MPa for 0.5-5 min to obtain the graphite-based composite bipolar plate for the fuel cell. The carboxylation reaction modified carbon nanotubes are used in the preparation of the graphite-based composite bipolar plate, and the prepared graphite-based composite bipolar plate has the advantages of high conductivity, high corrosion resistance, excellent mechanical properties, ultra-thin thickness, excellent dimensional stability, high thermal stability and the like; and the volume power density and the safety of the fuel cell can be improved.

Owner:江苏中氢氢电科技有限公司

Polyester Resin Compositions With Reduced Emission Of Volatile Organic Compounds

Thermally curate resin composition, having shrink-controlled properties and being suitable for use in sheet moulding compounds and bulk moulding compounds (SMCs and BMCs) comprising, inter alia (a) an unsaturated polyester; (b) an alkenyl aromatic monomer; (c) a low profile additive; (d) a peroxide initiator; (e) a thickening agent; (f) fibrous reinforcement material; and optionally one or more components selected from the group of (g) mould release agents; (h) wetting and viscosity reducing agents; and (i) fillers, wherein the composition also comprises a uret dione diisocyanate, in an amount of at least 0.2-1.0% by weight relative to the total weight of components (a), (b) and (c) of the resin composition. The resin compositions according to the invention in particular have a low emission of volatile organic compounds (VOC). More particularly, the resin compositions have excellent Class A properties. The present invention also relates to low profile additives (LPAs) wherein a uret dione diisocyanate is chemically attached through one or both of its reactive side-chain isocyanate groups to one or more of the OH—, NH2—, or COOH— groups of a component already having LPA properties. Finally, the present invention relates to low-VOC products and parts produced from the SMCs and BMCs according to the invention.

Owner:DSM IP ASSETS BV

Wet surface treatment of surface-modified calcium carbonate

The present invention relates to a process for the surface treatment of a surface-modified calcium carbonate, a surface-treated calcium carbonate obtained by the process as well as the use of the surface-treated calcium carbonate in a polymer composition, in paper making, paper coatings, agricultural applications, paints, adhesives, sealants, construction applications, pharma applications and / or cosmetic applications, or for cross-linking of rubber, in sheet moulding compounds, in bulk moulding compounds, in cross-linkable polyolefin system formulations, preferably for pipes and cables, in cross-linkable polyvinyl chloride, in unsaturated polyesters and in alkyd resins, and the use of the surface-treated calcium carbonate and a curing agent for crosslinking of cross-linkable compounds.

Owner:OMYA INT AG

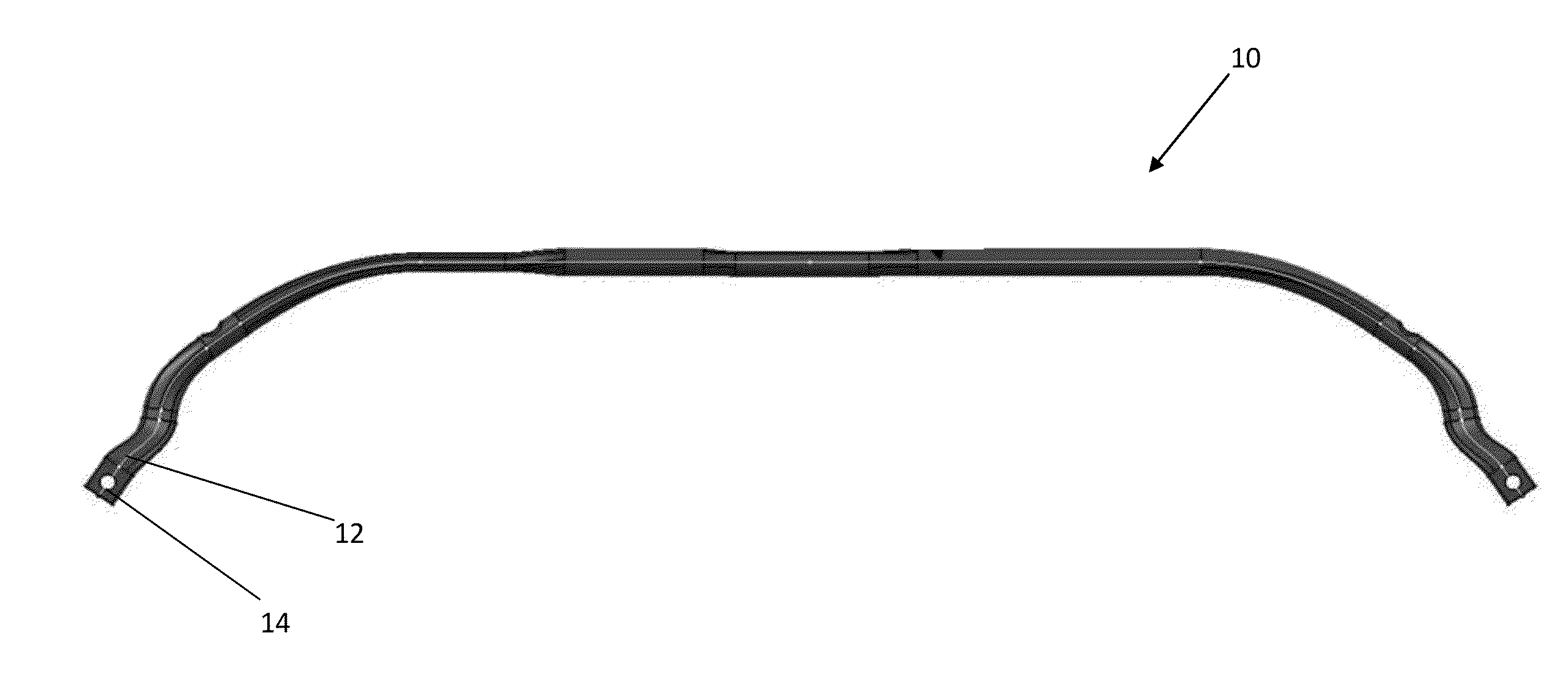

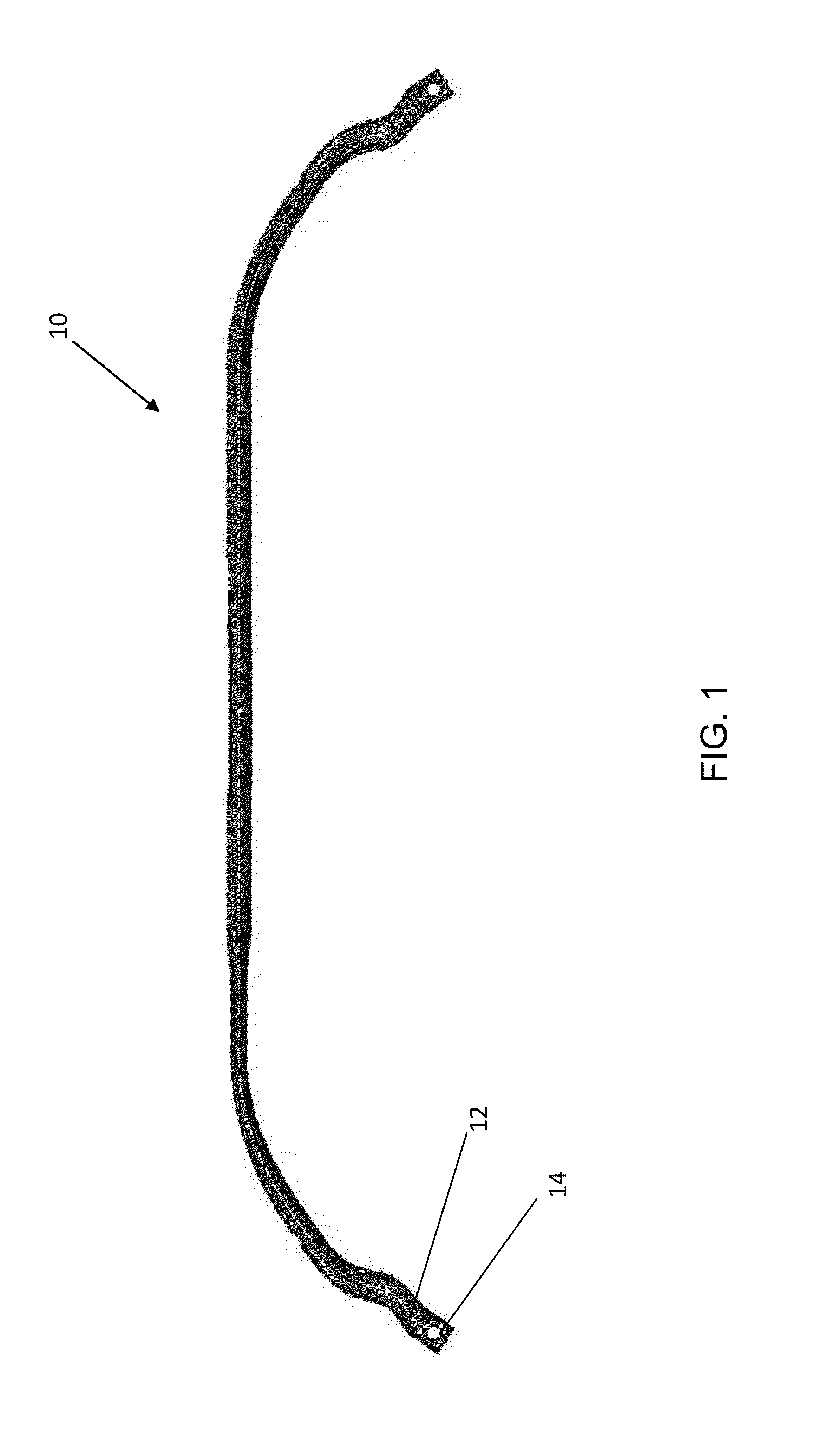

Hydro-form bonded bolster

A vehicle front end load bearing bolster is provided with improved structural performance and a lower component weight, while also minimizing material, tooling, and production costs. The front end assembly is formed with a hydro-formed cross car reinforcement tube secured or bonded with mechanical fasteners and room temperature adhesive to a bolster, thereby improving stress distribution and increasing cross car system stiffness. The bonded hydro-form tube / bolster assembly provides increased torsion stiffness and dimensional stability to the vehicle frame. The hydro-formed cross car reinforcement tube have flattened terminal ends with apertures for integrated attachment to a bolster. The hydro-formed cross car reinforcement tube is formed of aluminum, brass, carbon, steel, stainless steel, copper and high strength alloys. The bolster is formed of high strength plastics and composites including sheet molding compounds (SMC), bulk molding compounds (BMC), and thermoplastic compounds such as glass mat thermoplastic (GMT) and direct long fiber thermoplastic (DLFT).

Owner:TEIJIN AUTOMOTIVE TECH INC

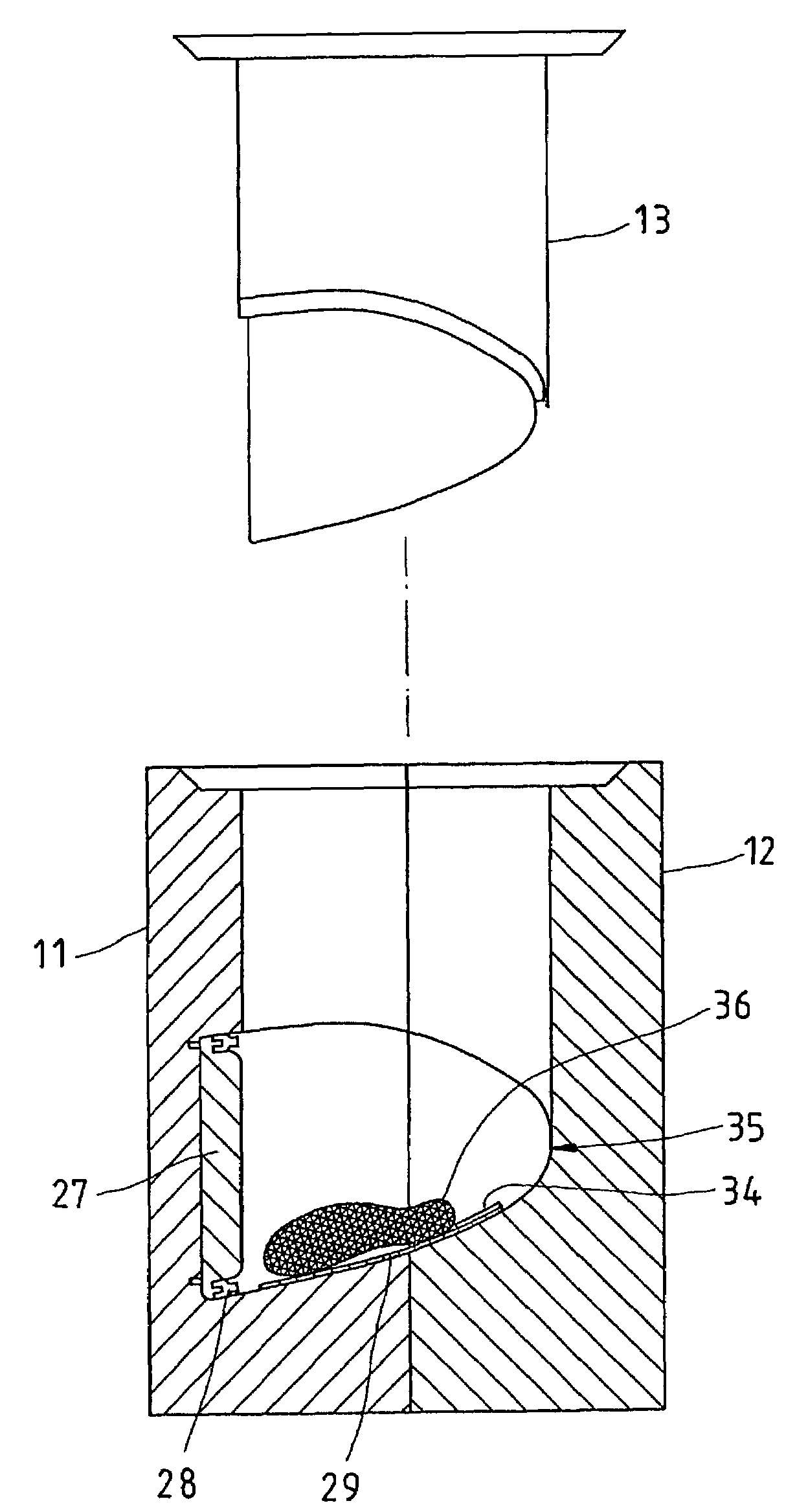

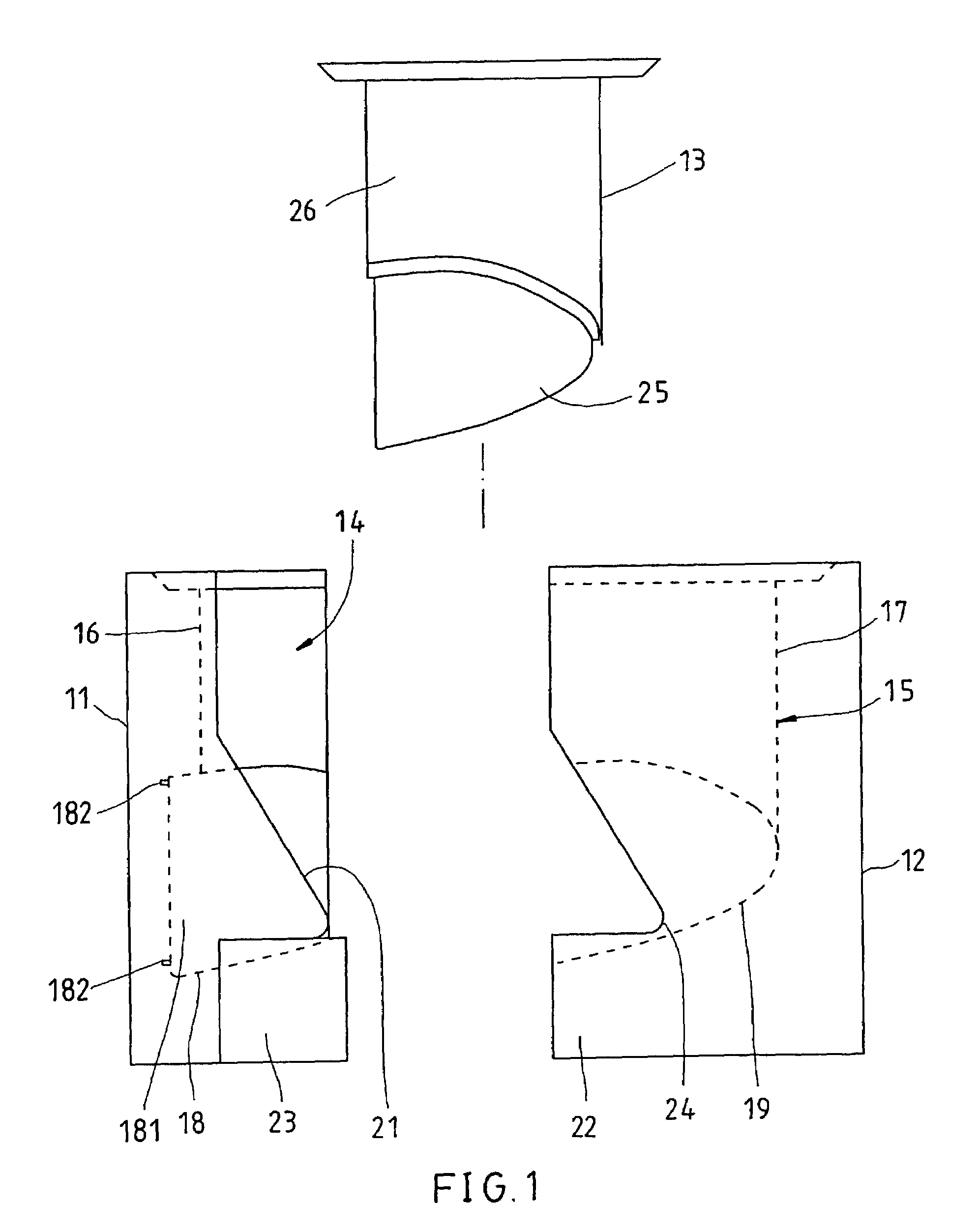

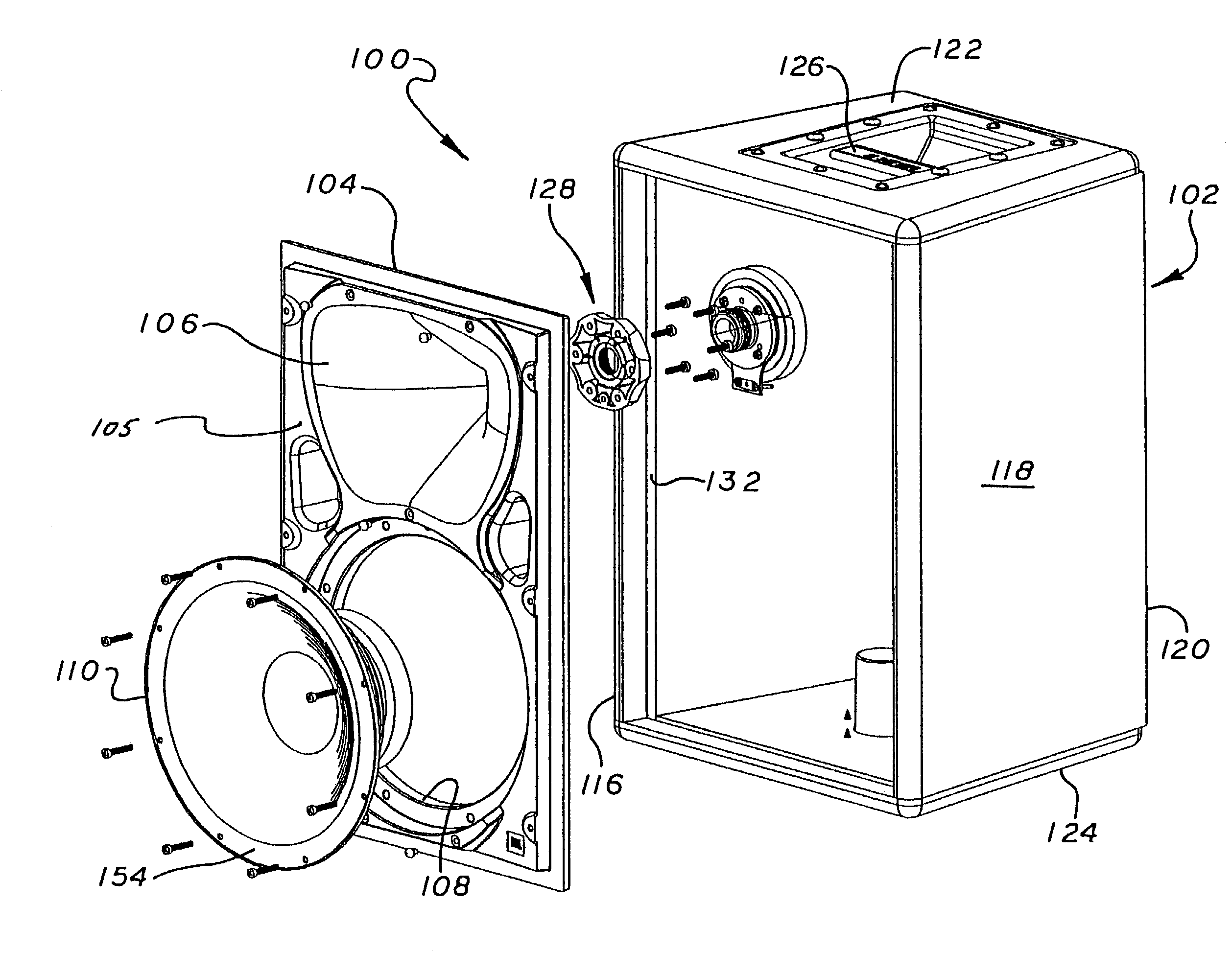

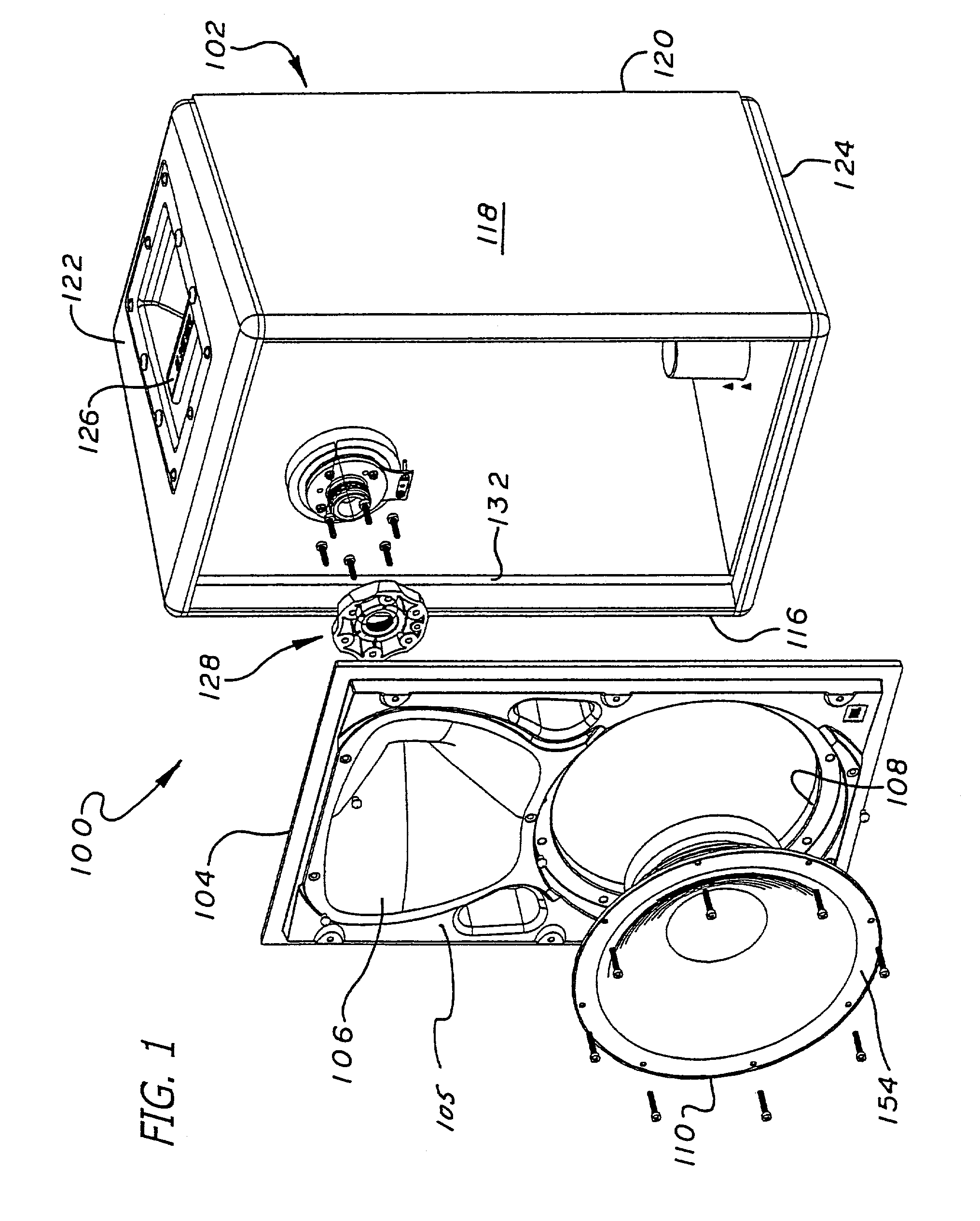

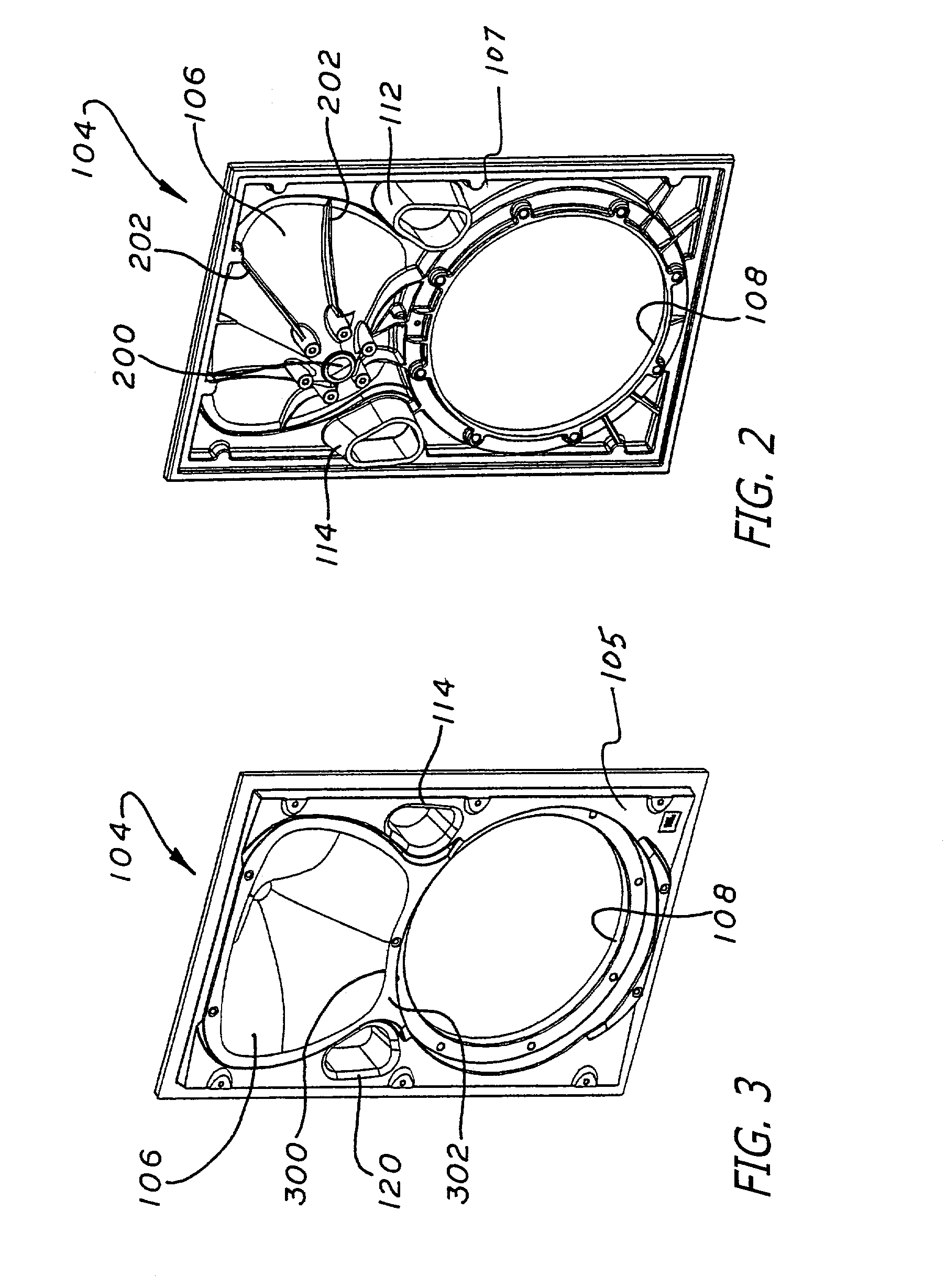

Thermoset composite material baffle for loudspeaker

InactiveUS7013019B2MiniaturizationHigh strengthLoudspeaker transducer fixingFrequency/directions obtaining arrangementsTransducerHigh intensity

This invention provides a baffle formed from a thermoset composite material such as Bulk Molding Compound (BMC), Thick Molding Compound (TMC), or Sheet Molding Compound (SMC). Due to the physical properties of BMCs, TMCs, and SMCs, the baffle may be molded to minimize the propagation of vibrational energy and resonant mode behavior while providing high strength and rigidity. The baffle may also be formed so transducer mounts, ports and wave-guides may be molded into the baffle shape.

Owner:HARMAN INT IND INC

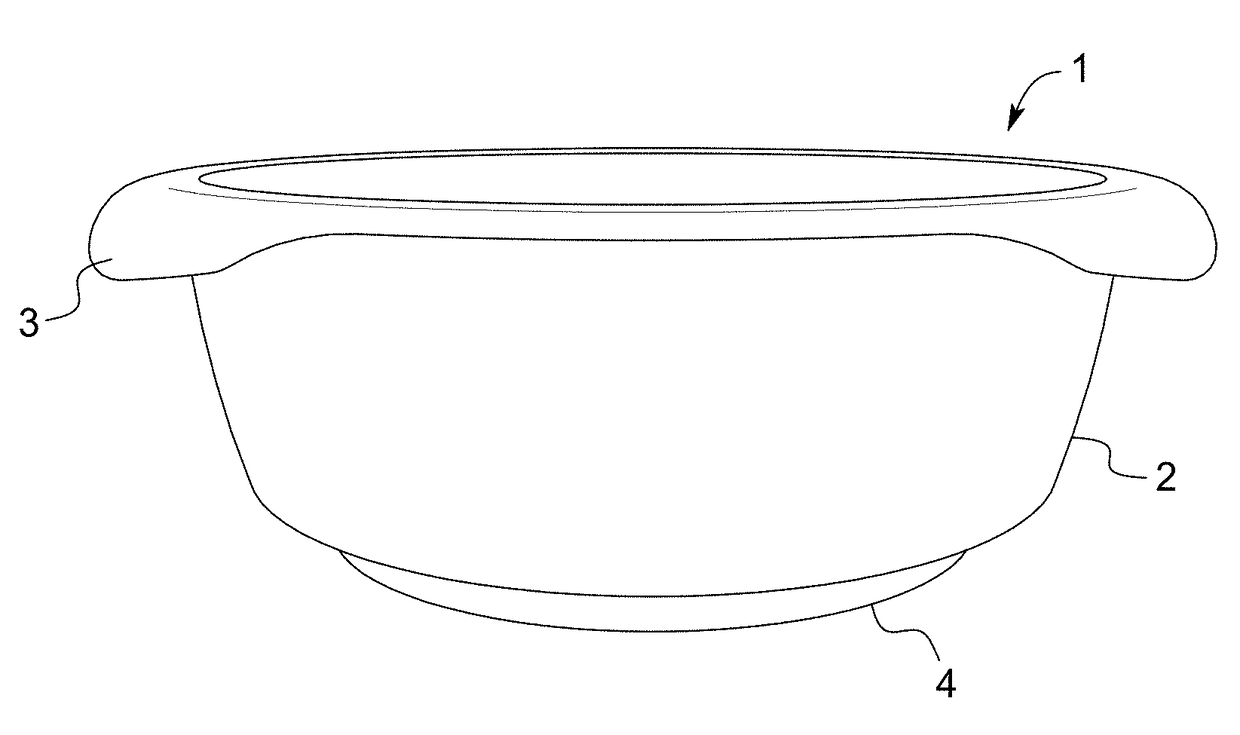

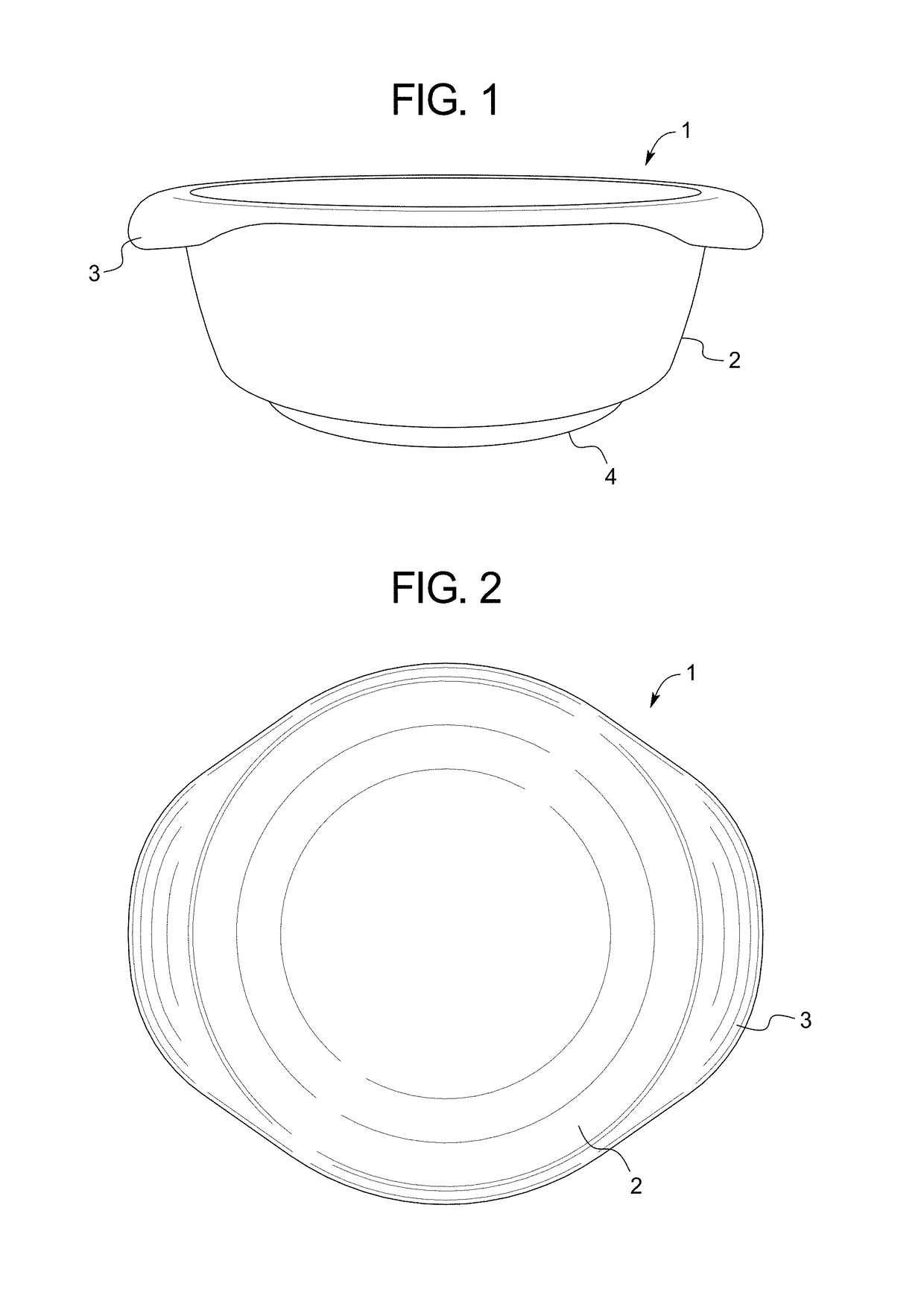

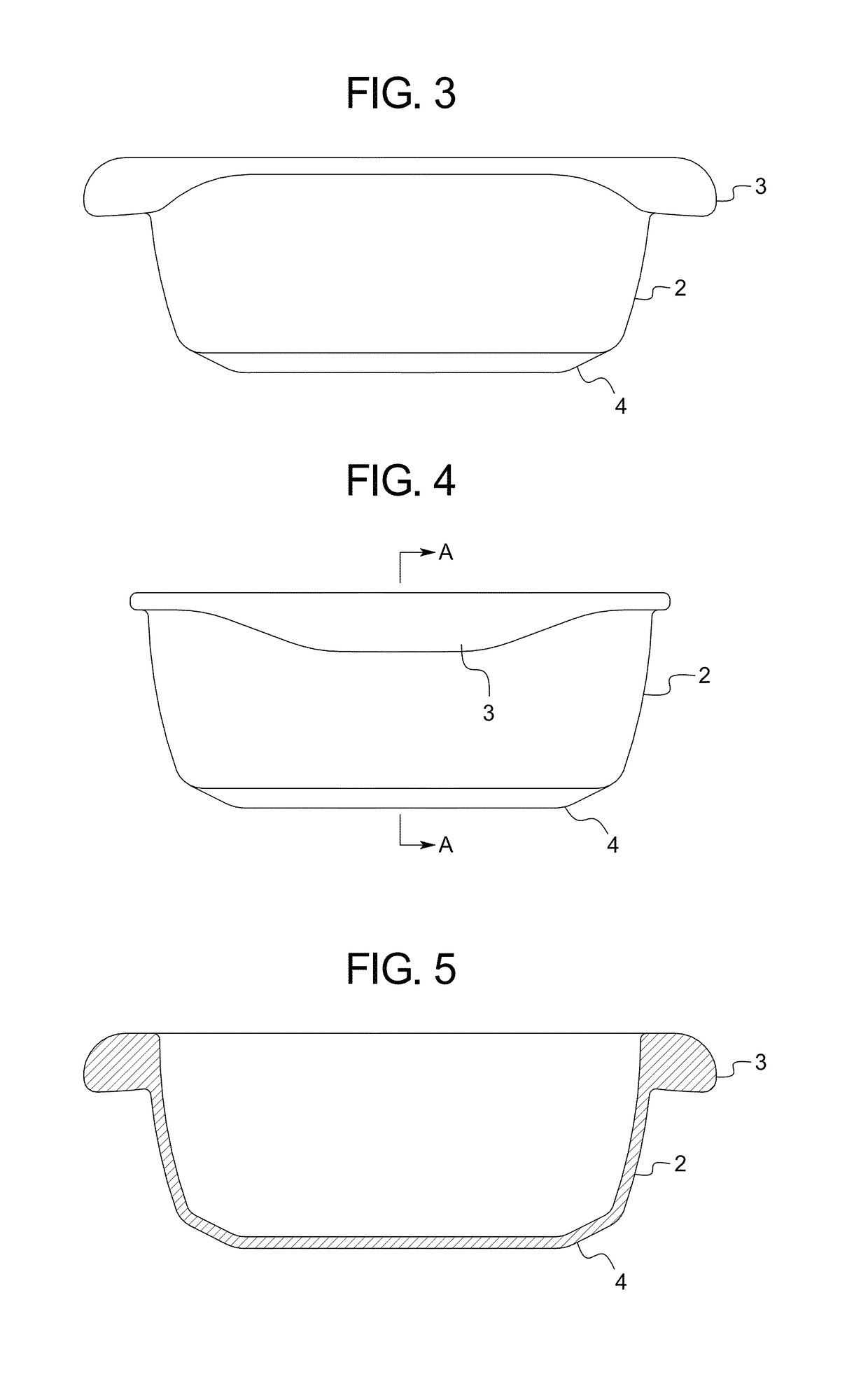

Bulk molding compound-based pet bowl

A bowl includes a body portion. The body portion is formed from a material comprising a bulk molding compound. The bulk molding compound includes a polyester resin, glass fiber and calcium carbonate. A method for forming a bowl includes providing a composition comprising a bulk molding compound, providing the composition in a cavity of a mold including a male die member and a female die member, and compressing the male die member and the female die member under heat to form a molded material. The bulk molding compound includes a polyester resin, glass fiber and calcium carbonate.

Owner:DOSKOCIL MFG

Formulations comprising isosorbide-modified unsaturated polyester resins and low profile additives which produce low shrinkage matrices

Owner:INEOS COMPOSITES IP LLC

UV-resistant BMC material used outdoors and preparation method of material

The invention provides a UV-resistant bulk moulding compound (BMC) material used outdoors. The material comprises resin, aluminum hydroxide, calcium carbonate, a curing agent, glass fibers and an anti-UV agent, wherein the resin is unsaturated resin and low-shrinkage resin, and the anti-UV agent is a benzoic acid anti-UV agent or a benzotriazole anti-UV agent. The invention also provides a preparation method of the ultraviolet-resistant BMC material used outdoors. According to the method provided by the invention, after analysis comparison and screening tests of current anti-UV agents, the benzoic acid or benzotriazole anti-UV agent is added into a current common BMC material, so that the BMC material has good compatibility with the unsaturated resin and can be colored, and the propertiesand forming of the material are not affected; and the product has a high-efficiency light stability effect, and the characteristics of no toxicity, non-flammable performance, non-explosive performance, corrosion resistance and good storage performance.

Owner:绍兴金创意塑化电器有限公司

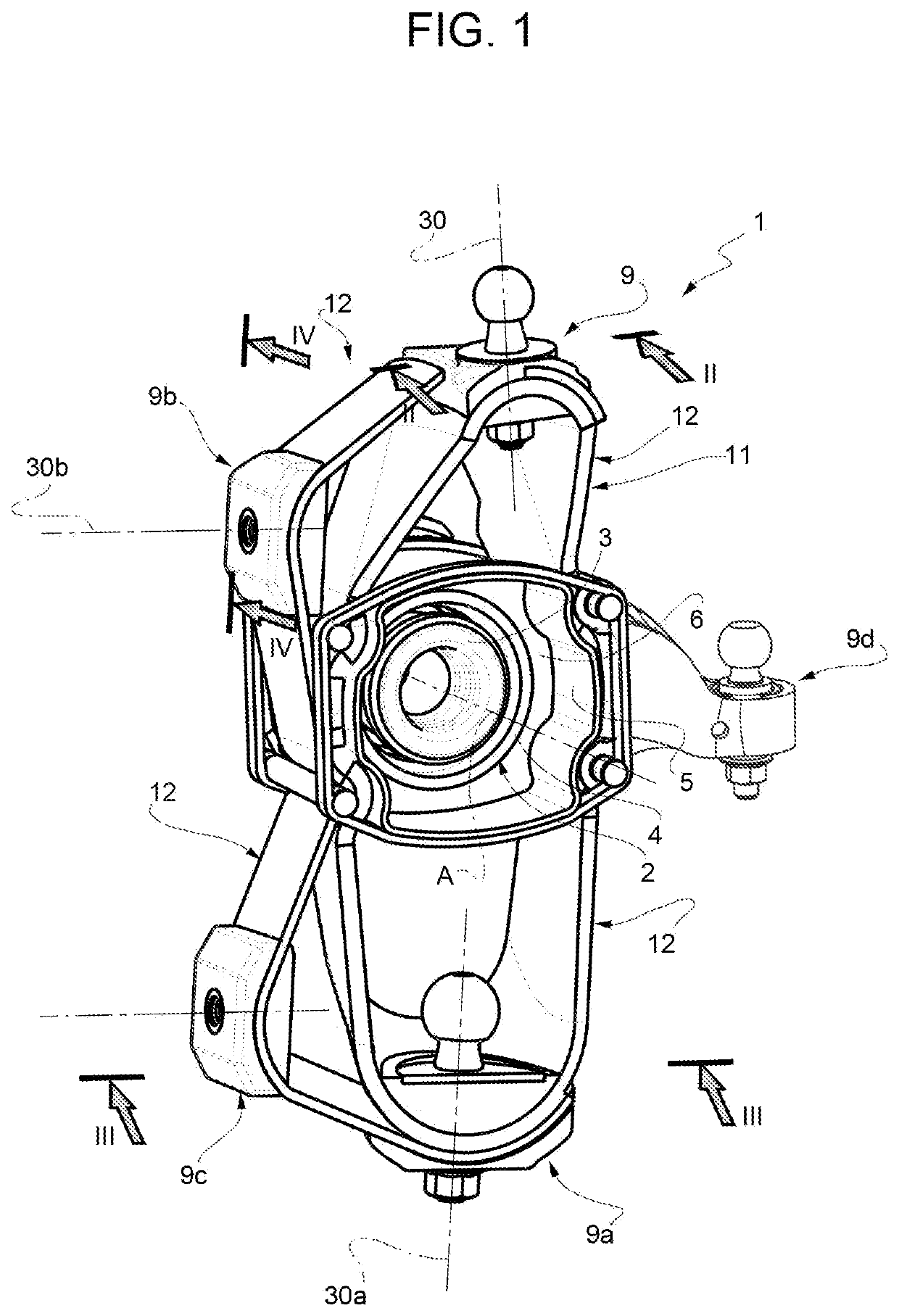

Attachment interface for connecting a vehicle composite component

ActiveUS20200049202A1Easy transferImproved force transmissionYielding couplingSteering linkagesThermoplasticMechanical engineering

An attachment interface is provided for connecting a vehicle composite component having a plate portion that is made of a fiber reinforced polymer and has a passage extending in a through manner along an axis. The attachment interface provides a metal attachment device, which includes an inner portion engaging the passage and an outer portion defining a connection point suitable to be connected to another vehicle element. The plate portion is axially sandwiched between two layers made of a fiber reinforced polymer composite material selected from the group consisting of BMC (Bulk Molding Compound), LFT (Long Fiber Thermoplastic) and DLFT (Direct Long Fiber Thermoplastic).

Owner:AB SKF +1

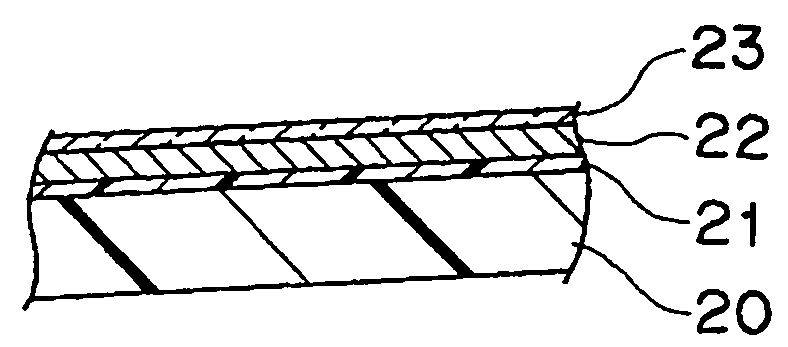

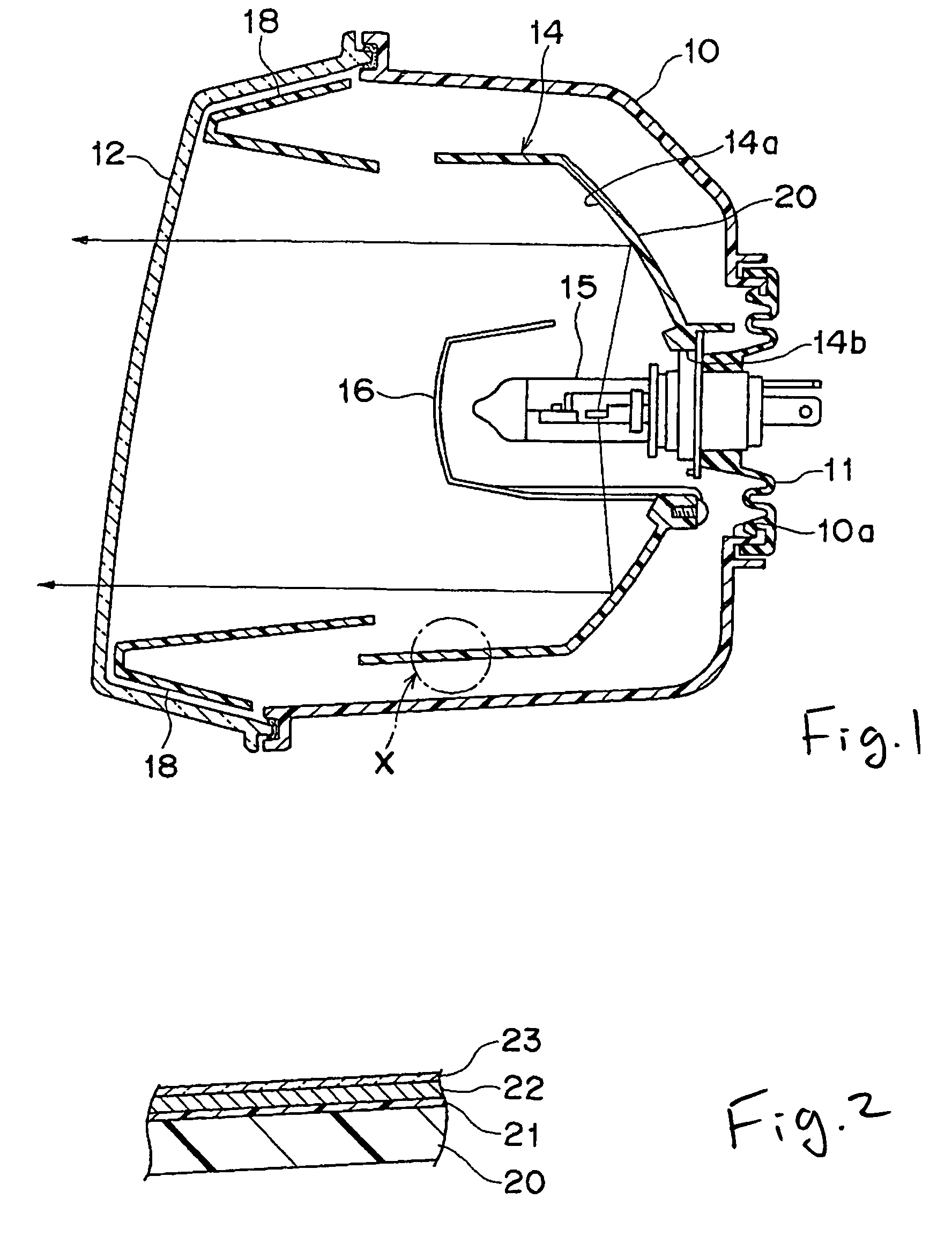

Lamp reflector including bulk molding compound

InactiveUS7210823B2Improve rigidityReleasability is reducedMirrorsOptical articlesGlass fiberCompound a

Owner:KOITO MFG CO LTD

Sizing composition for glass fibers

InactiveUS20110305904A1Improve productivityLow costPolyurea/polyurethane coatingsGlass/slag layered productsProduction rateGlass fiber

Owner:OCV INTELLECTUAL CAPITAL LLC

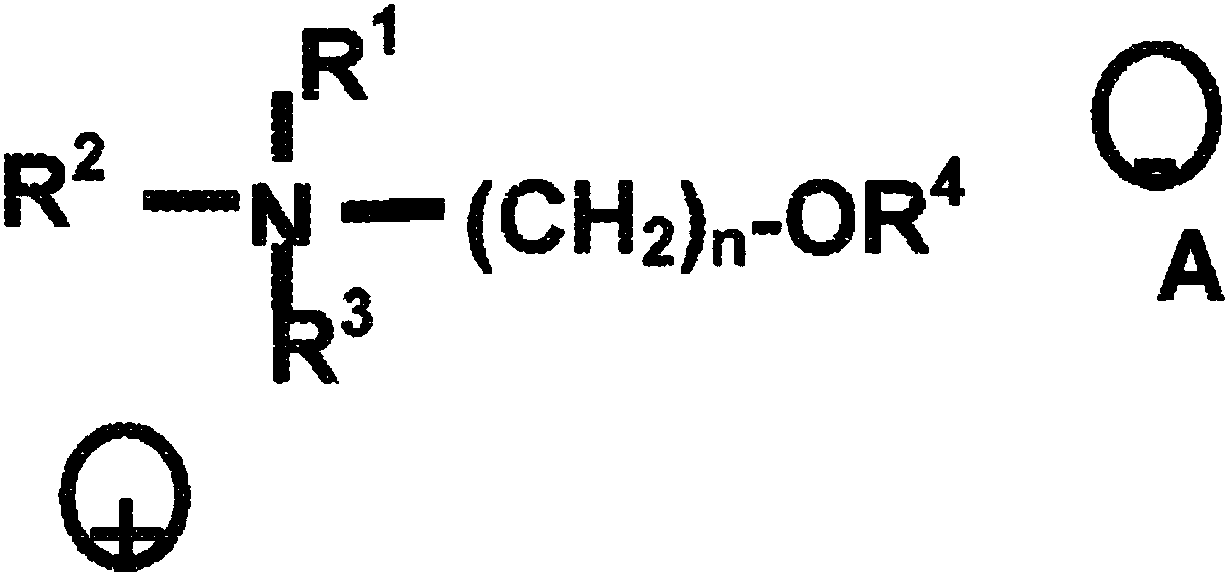

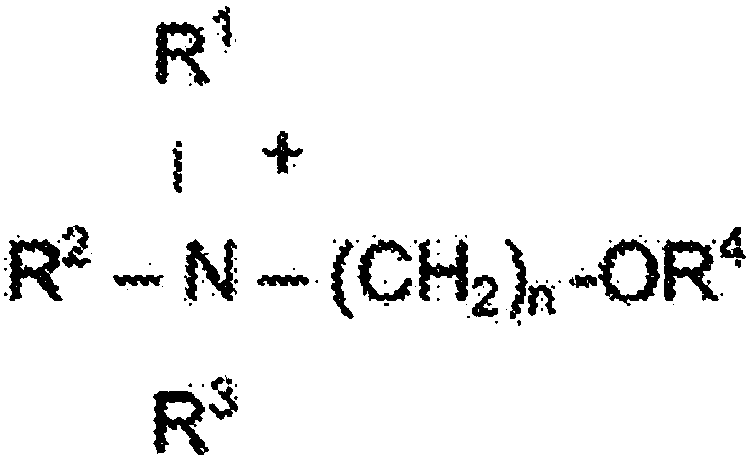

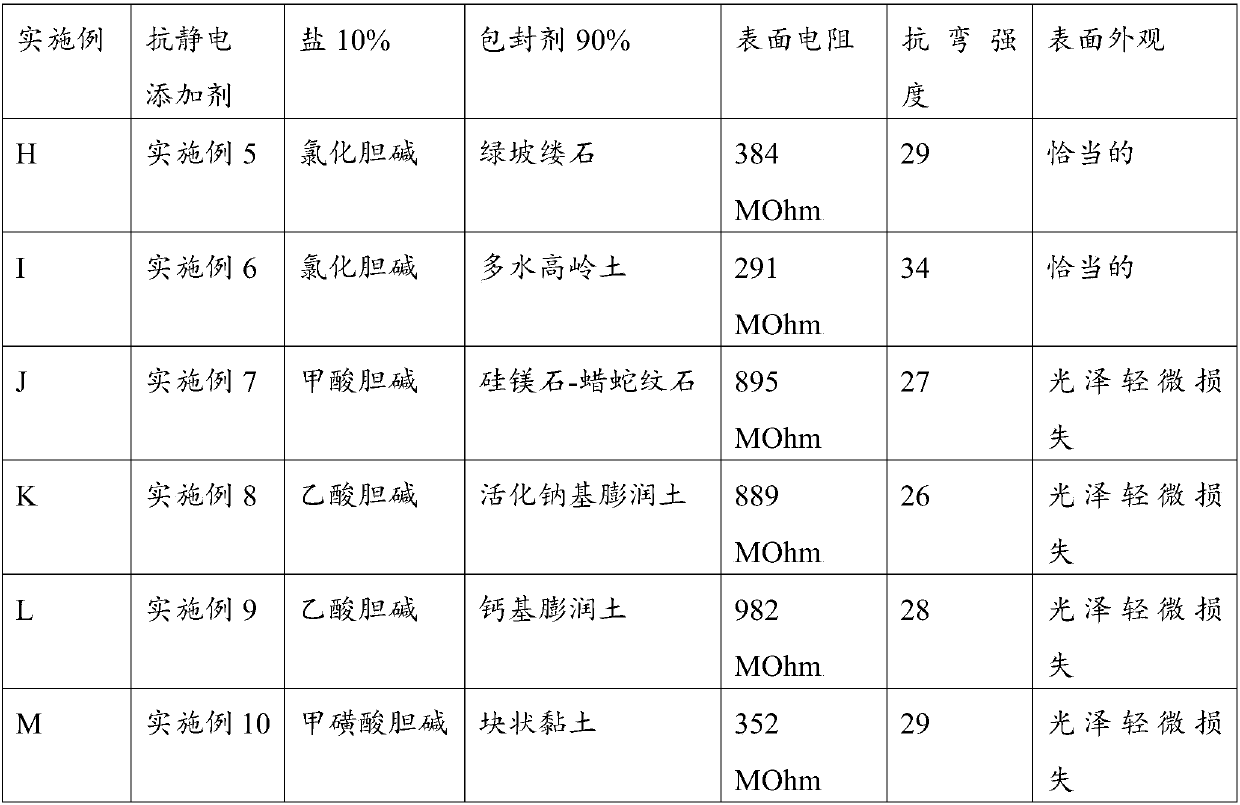

Anti-static bicomponent formulation for unsaturated polyester resins and epoxy vinyl ester resins

The invention relates to a novel formulation based on two components, which, when added to items produced with epoxy vinyl ester or unsaturated polyester resin, provides same with electric charge dissipation and / or antistatic characteristics, maintaining the mechanical characteristics thereof and the possibility of dyeing the material in all of the possible colour ranges. The formulation has a first component which is an active substance which is an ionic salt that allows ion mobility, the cation being a compound based on the (R4)N,N,N-trialkyl-alkyl-ol-ammonium species, as it is or derivatised on the OH group, and a system that supports said active substance. This additive or formulation added to epoxy vinyl ester or unsaturated polyester resin can be used in the production of agglomerated stone, gel coat, sheet moulding composite or bulk moulding composite.

Owner:AVANZARE INNOVACION TECHCA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com