Sizing composition for glass fibers

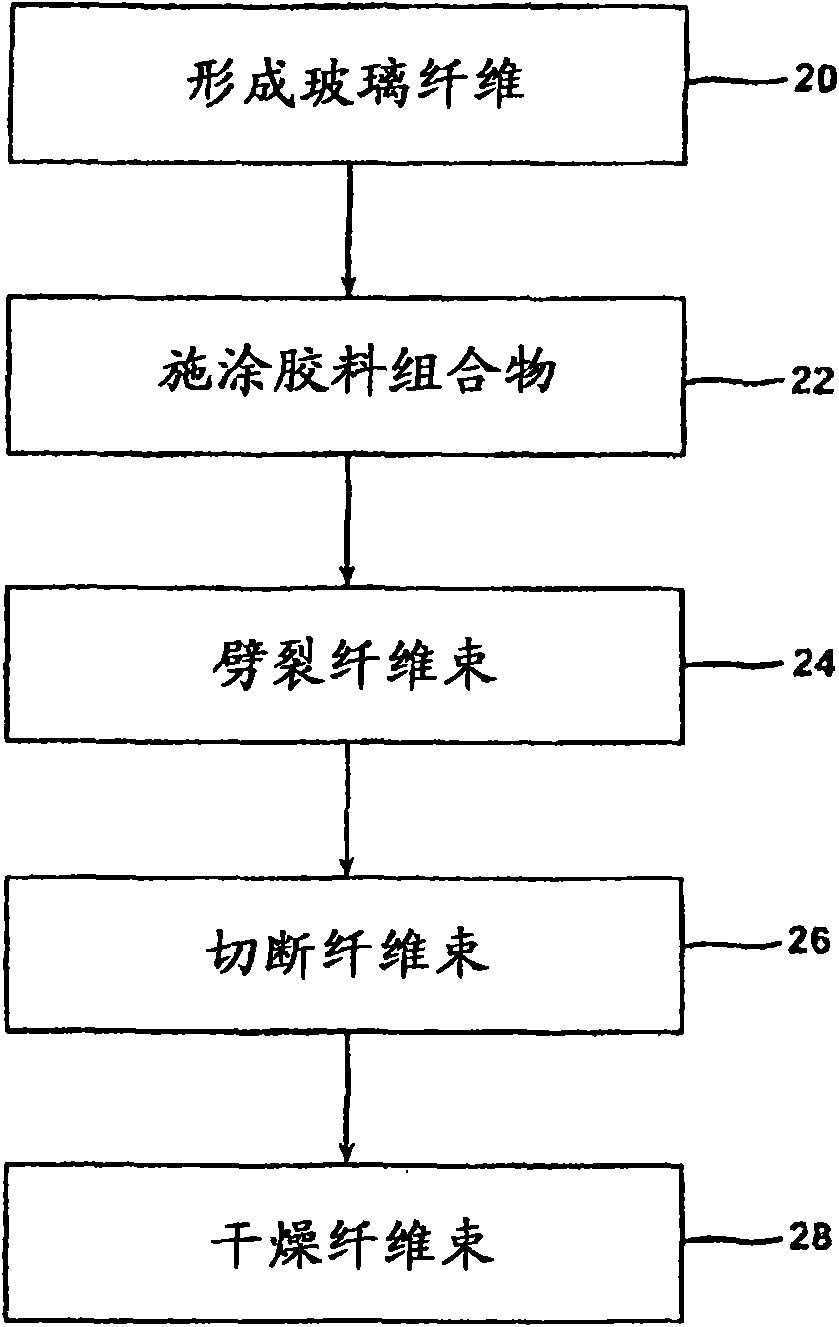

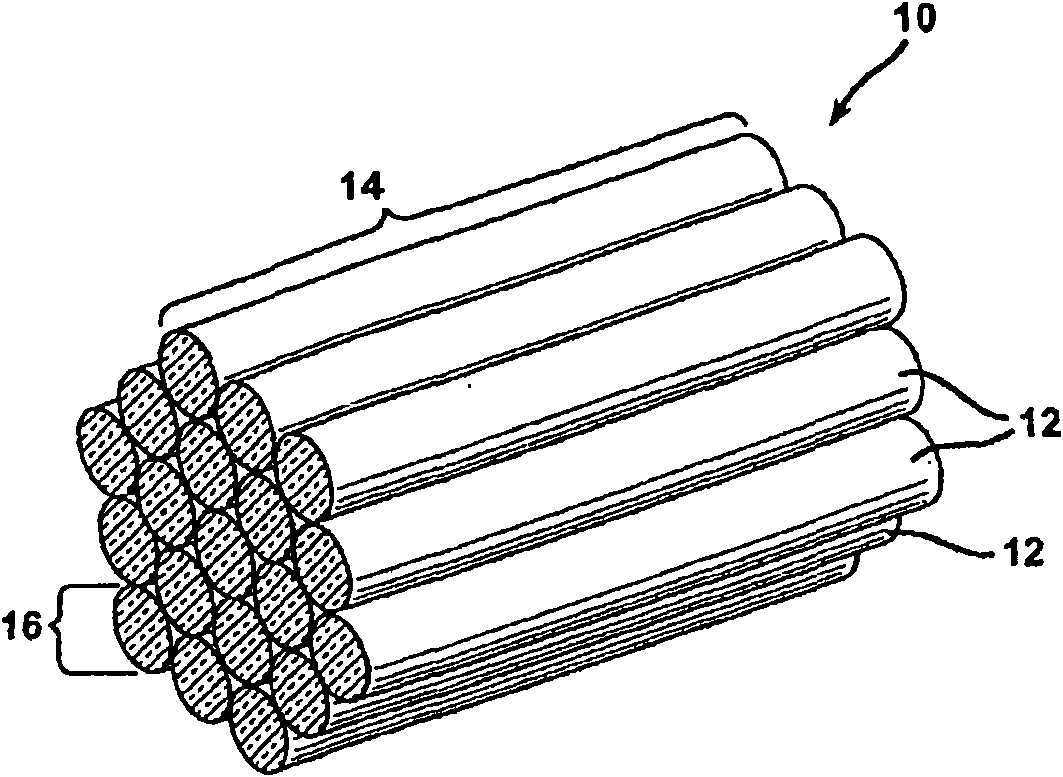

一种玻璃纤维、短切玻璃纤维的技术,应用在施胶组合物领域,能够解决离线法耗时等问题,达到劳动强度小、生产率提高、制造成本和制造时间降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Injection Molded Composite Parts Using the Size Composition of the Invention

[0060] The sizing formulations shown in Table 2 were prepared in buckets as outlined below. To prepare the size composition, 90% water and silane coupling agent were added to a bucket to form a mixture. The mixture is then stirred for a period of time to hydrolyze the silane. After hydrolysis of the silane, a film former is added to the mixture with stirring to form a size composition. The size composition was then diluted with the remaining water to achieve a target mixed solids of 6.0% mixed solids.

[0061] Table 2

[0062] Sizing composition of the present invention

[0063] Components of the compound composition

[0064] (a) γ-Aminopropyltrimethoxysilane (General Electric)

[0065] (b) Isocyanate-terminated polyurethane film-forming dispersion (Chemtura)

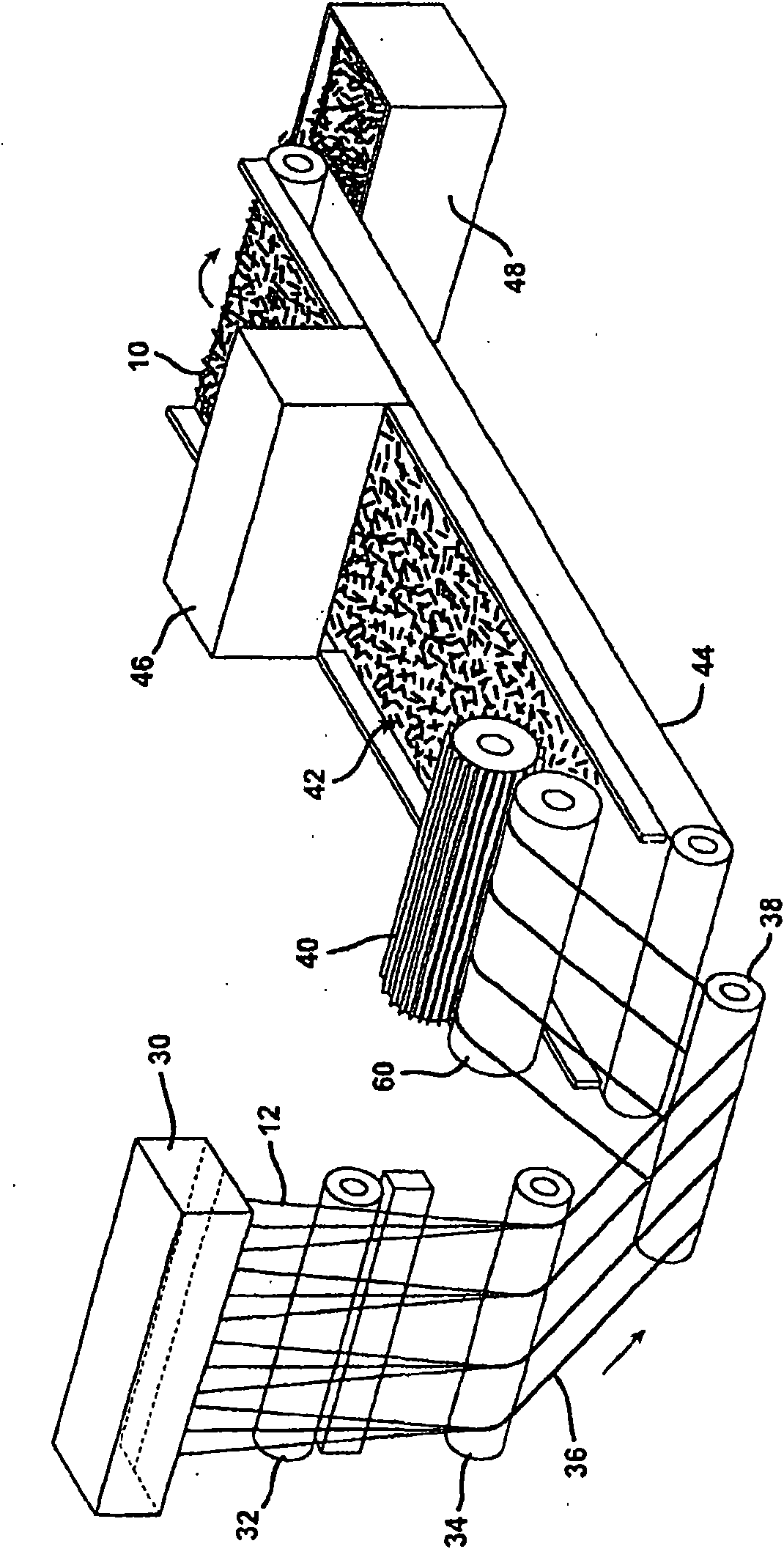

[0066] The size composition is applied to the E-glass by conventional means, such as the roller applicat...

Embodiment 2

[0071] Example 2: Compression-molded composite parts using the sizing composition of the invention

[0072] The sizing formulations shown in Table 4 were prepared in buckets following the outline instructions below. To prepare the size composition, 90% water and silane coupling agent were added to a bucket to form a mixture. The mixture is then stirred for a period of time to hydrolyze the silane. After hydrolysis of the silane, a film former is added to the mixture with stirring to form a size composition. The size composition was then diluted with the remaining water to achieve a target mixed solids of 6.0% mixed solids.

[0073] Table 4

[0074] Invented sizing composition

[0075] Components of the compound composition

[0076] (a) γ-Aminopropyltrimethoxysilane (General Electric)

[0077] (b) Isocyanate-terminated polyurethane film-forming dispersion (Chemtura)

[0078] The size composition is applied to the E-glass by conventional means, such as the roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com