Precision high-efficiency tubing sizing sleeve

A sizing sleeve and high-efficiency technology, which is applied in the field of pipe sizing sleeves, can solve problems such as difficulty in forming precise dimensions, affecting the appearance quality of pipes, and slow cooling speed of sizing sleeves, so as to achieve stable and reliable cooling and sizing systems. High-speed and high-precision pipe production, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

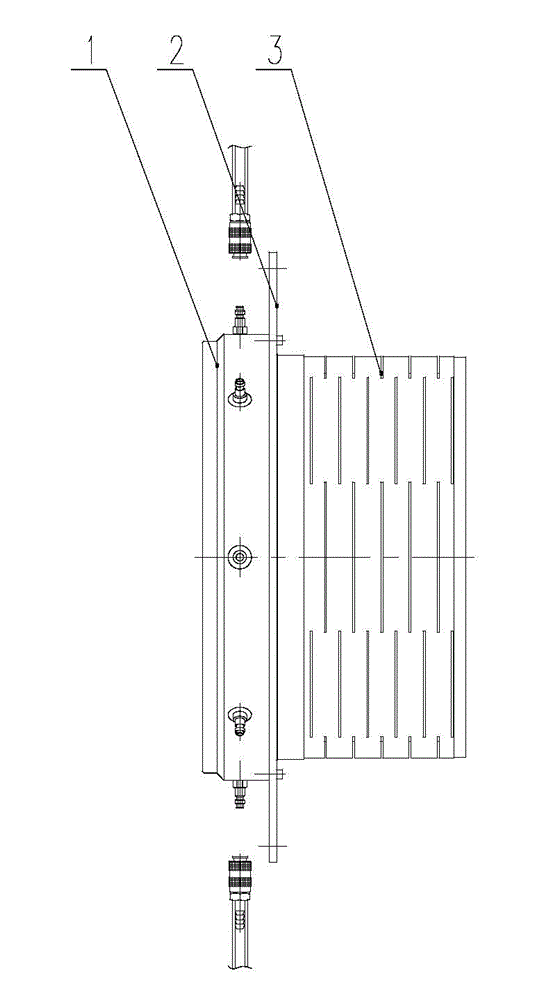

[0023] A precise and efficient pipe sizing sleeve, its structure is as follows Figure 1-2 As shown, it includes a water distribution seat 1, a sizing sleeve 3 and a flange 2 connecting the water distribution seat 1 and the sizing sleeve 3. The water distribution seat 1 is provided with a water inlet joint 6 and a drainage joint 5, which are used for the entry and exit of cooling water. The cooling water enters the water distribution seat 1 through the water inlet joint 6, and an annular water ring is formed in the water distribution seat. The sleeve 3 is a single-walled metal pipe. The inner side of the pipe wall of the front section is provided with spiral grooves and densely covered with through holes, and the pipe wall of the rear section is provided with straight grooves. When in use, a water inlet valve 7 is also provided at the water inlet joint 6 to control the intake of cooling water, and a water outlet valve 4 is also provided at the water outlet joint 5 to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com