Concentric installation process and mounting and dismounting assisting concentric device for inner bore of woodworking tool

An installation process and inner hole technology, used in wood processing appliances, manufacturing tools, rotary cutting tools, etc., can solve problems such as poor concentricity, large machine vibration, locking of tools and mechanical shafts, etc., to save grinding time, Long service life and consistent concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

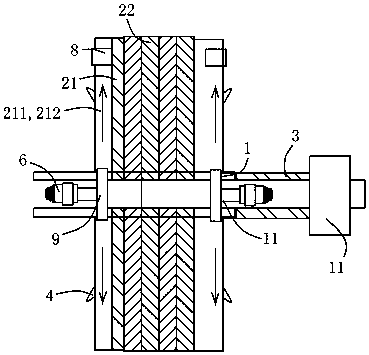

[0031] Such as figure 1 As shown, the concentric installation process of the inner hole of the woodworking tool is used to install the tool shaft 1 with the inner hole 11, and at least four blades 2 concentrically installed outside the tool shaft 1 in turn, so that all the blades 2 after the installation are completed. Can be concentric with the inner hole 11 of the tool shaft.

[0032] In a specific operation process, the blade 2 is set to include two end blades 21, and at least two sandwich blades 22 between the two end blades, the thickness of the end blade 21 is set to be m, and the sandwich blade 22 The thickness of n is n, and the thickness of each end blade 21 is guaranteed to be greater than the thickness of any sandwich blade 22 when the tool is installed, i.e. m>n. The main purpose of this design is to drive the sandwich blades synchronously with the help of the gravity of the two end blades during inflatable installation. Generally speaking, the best implementation...

Embodiment 2

[0035] See details figure 2 As shown, a better embodiment is that each flexible pressure equalizing air pipe 212 is located at the outer edge of the end blade with an electromagnetic deflation valve 5, and the electromagnetic deflation valve 5 and the inflation nozzle 6 are connected to the inflation device 7 to realize inflation. And deflate; when the inflation nozzle is inflated, the gas entering the flexible pressure equalizing air pipe flows from the center position of the end blade to both sides respectively, so that the flexible pressure equalizing air pipe expands rapidly, thereby adjusting the two end blades and clamped on it The inner sandwich blade is concentric. The use of the electromagnetic deflation valve 5 is mainly to realize automatic pressure relief (i.e. deflation) after the pressure equalizing air pipe is used up, so that it is convenient to inflate directly to the center when it is used next time, so as to improve work efficiency.

Embodiment 3

[0037] The difference from Embodiments 1 and 2 is that each flexible pressure equalizing air pipe 212 is provided with at least one pair of counterweight structures 4 at a symmetrical position near the outer edge of the end blade, and the counterweight structure is such that the center of gravity faces toward the outer edge of the end blade. Inclined conical structure or polygonal pyramid structure, the use of these conical structures or polygonal pyramid structures, on the one hand, is to assist the inflation of the uniform pressure trachea, and on the other hand, to provide heavier equal pressure pressure and improve the concentric effect .

[0038] A preferred embodiment is that at the bottom of any one of the flexible pressure equalizing air pipes 212, use an adhesive to bond it in its corresponding inflation groove 211, or define the expansion channel of the flexible pressure equalizing air pipe 212 through an annular clamp, and the annular The length of the hoop is not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com