Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "No rework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

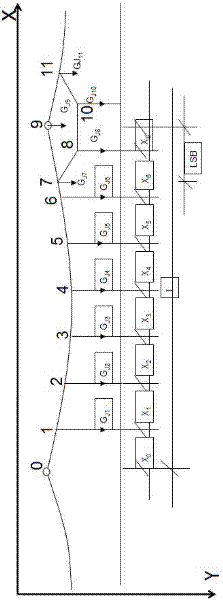

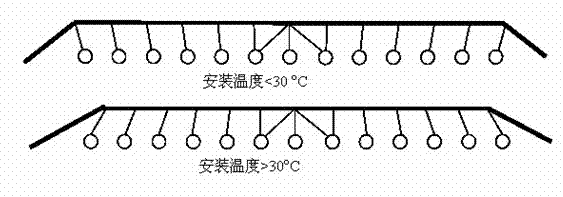

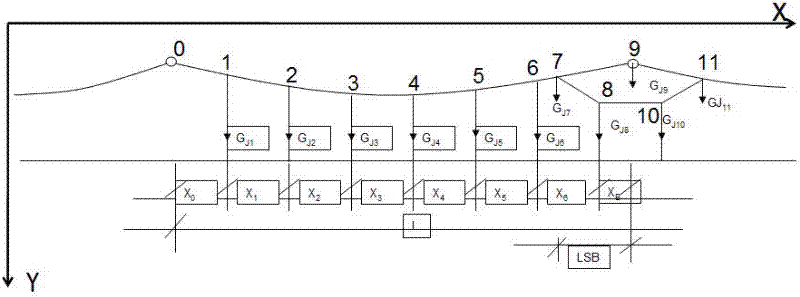

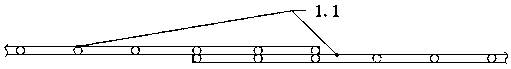

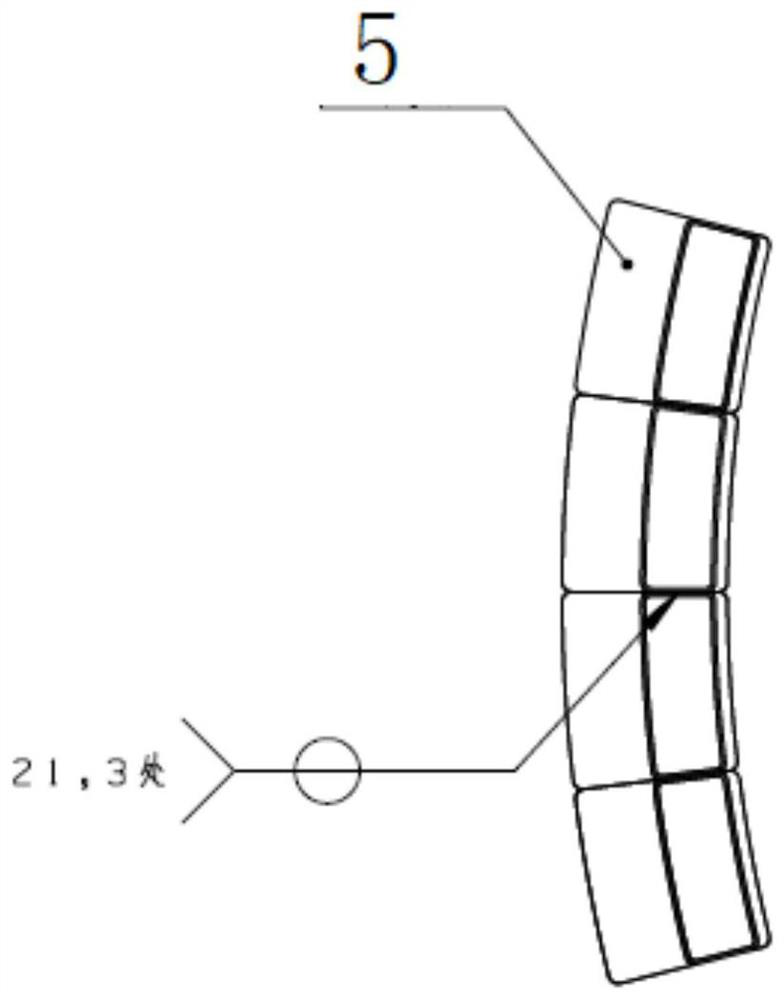

Full-compensation elastic chain hanging construction method for high-speed rail contact network

InactiveCN102381212AGuaranteed accuracyGuaranteed installation qualityTrolley linesContact networkArchitectural engineering

A full-compensation elastic chain hanging construction method for high-speed rail contact network, which comprises a construction preparing process, a construction measuring process, a software calculating process, a precasting process for sling and dropper, a mounting adjusting process for sling and dropper, and an ending process; each process is equipped with uniform and high-quality construction standards, and is assisted by modern construction meanses for satisfying with technical requirements for construction of high-speed rail contact network of 350 km / h; the software calculating process especially can obtain more accurate pre-stowage data of dropper length via a brand new calculating method finding form based on sling net, and then improve elastic chain hanging construction accuracy for high-speed rail contact net of 350 km / h. So the construction method does not only benefit for improving accuracy of sling and droppser calculation, and the construction method but also has high-quality construction standards and modern construction meanses, and is capable of improving quality and speed of construction of high-speed rail contact net of 350 km / h.

Owner:中铁建电气化局集团南方工程有限公司

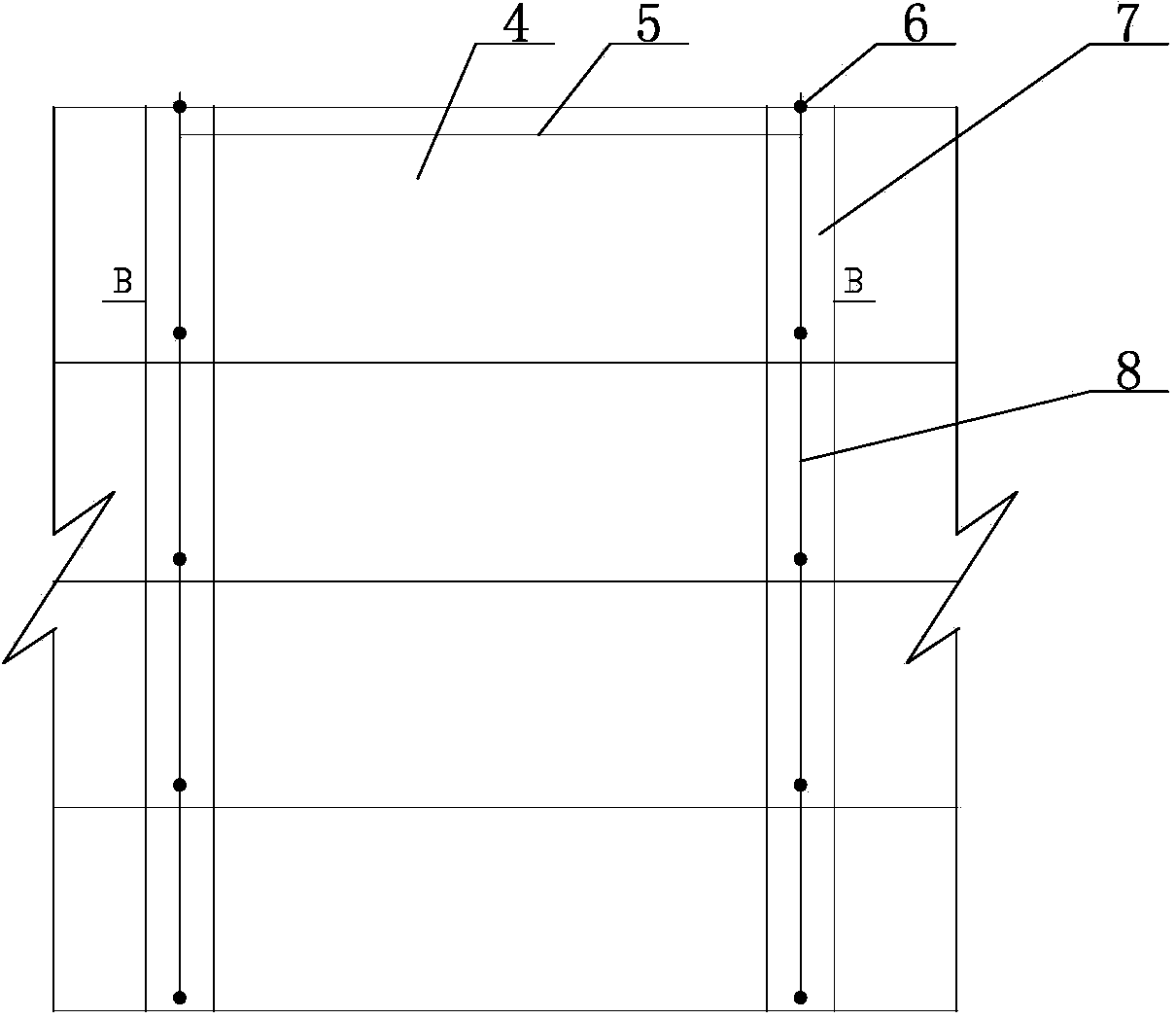

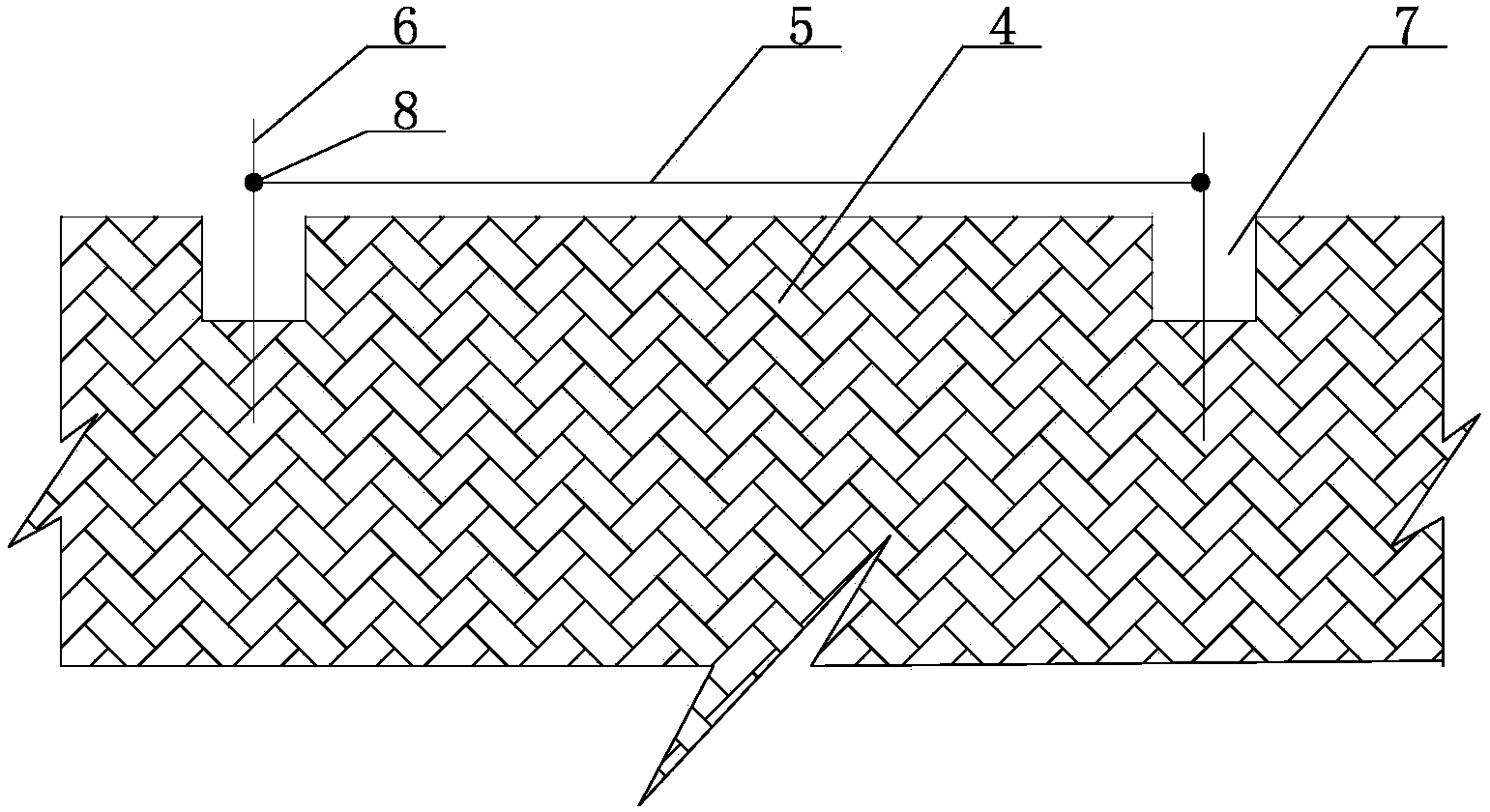

Garage abrasion-proof concrete pavement terrace crack control method

The invention relates to a terrace construction method, in particular to method for controlling a crack of a garage abrasion-resistant concrete pavement terrace. The method comprises the following: a step of layout of isolation joints, which is to arrange the ground isolation joints along the axial line of a building without spanning the center line, to arrange an isolation joint at a distance of 200 millimeters from the wall along the direction of the wall, to arrange a closed quadrangular isolation joint on a position of a structural column at a distance of 200 millimeters from four sides of the column, and to cut off the isolation joints when the isolation joints along the axial line encounter dilatation joints of the foot of the wall or the column without the necessity of cutting the isolation joints to the foot of the column or the wall; a step of cutting construction, which is to snap a line on the ground according to the isolation joint layout designed in advance and then to cut the isolation joints along the snapline by a street cutter with a joint cutting depth 50 millimeters; and a step of caulking, which is to use a high-pressure air pump to blow and wash along the joints and wash clean plastering float in the joints after the isolation joints are cut, and then to use flexible sealing materials to compactly and evenly fill up the isolation joints. The method not only improves the construction speed of the whole ground but also achieves the aim of effective control of ground cracks; and even a small number of cracks exist, the cracks are generated in an isolated lattice, thereby large-area repair can not be caused.

Owner:MCC JINGTANG CONSTR

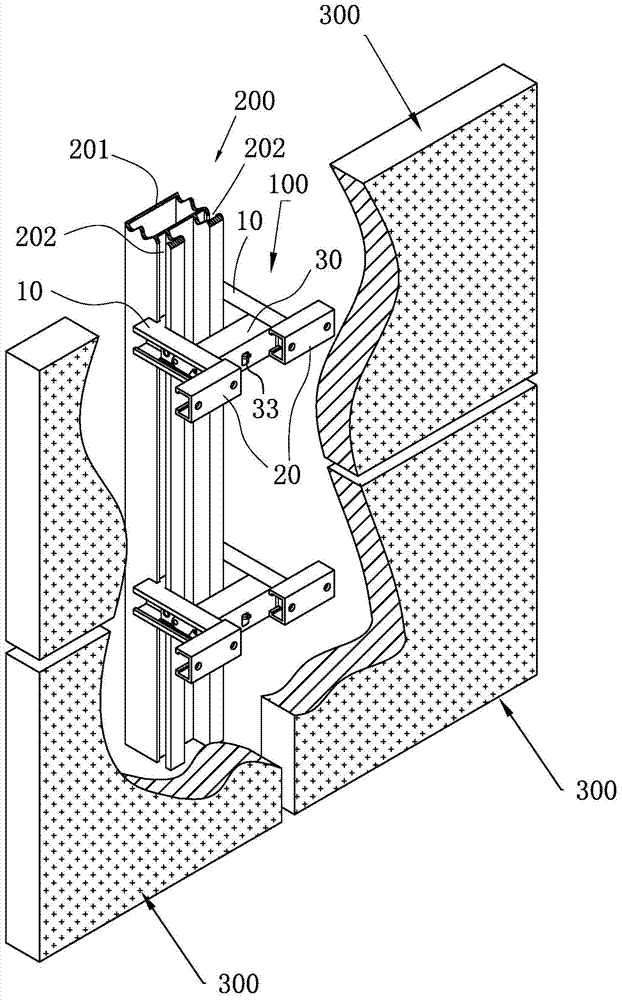

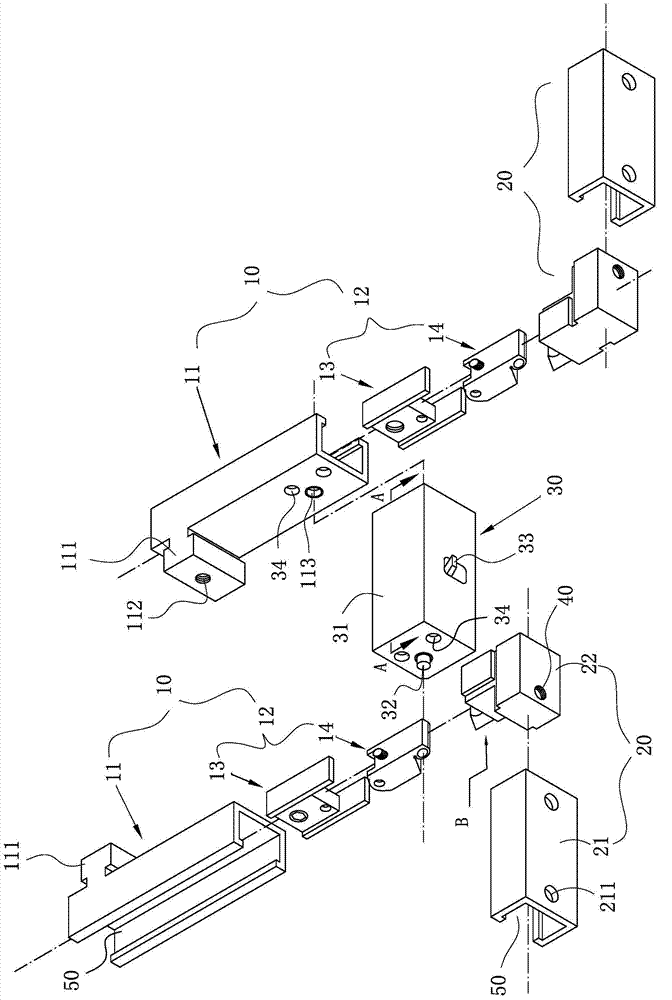

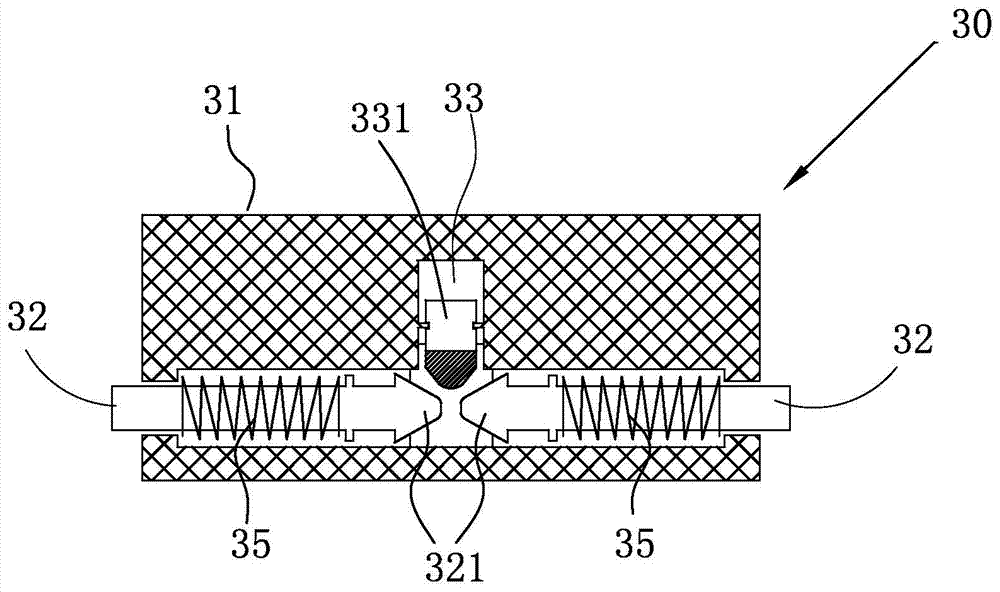

Mounting system of decoration panel, connecting component and mounting method of decoration panel

The invention discloses a mounting system of a decoration panel, a connecting component and a mounting method of the decoration panel. According to mounting system of the decoration panel, the connecting component and the mounting method of the decoration panel, the decoration panel can be mounted and dismantled rapidly through locking and unlocking and can be replaced freely at any time. The mounting system of the decoration panel comprises a stand column, the decoration panel and the connecting component which fixes the decoration panel on the stand column, wherein the connecting component comprises a longitudinal fastening assembly and a horizontal fastening assembly, the longitudinal fastening assembly is connected to the lateral side of the stand column in a detachable mode and can reciprocate vertically on the lateral side of the stand column, the horizontal fastening assembly is connected with the decoration panel in a detachable mode, and the longitudinal fastening assembly is connected with the horizontal fastening assembly in a fast assembling and disassembling mode through a locking mechanism. According to the mounting system of the decoration panel, the connecting component and the mounting method of the decoration panel, horizontal keels and a basic cushion board are not needed, the decoration panel mounting method which is novel, accurate, reliable, efficient, high in quality, standard and industrialized is provided, and the decoration panel can be replaced and updated freely and conveniently at any time by an owner or a user or decoration panels which are the same as the decoration panel which is mounted on the wall can be mounted according to the requirements of the owner or the user for the decoration panel after the decoration panel is mounted or when the decoration panel is in use. The mounting system of the decoration panel, the connecting component and the mounting method of the decoration panel are suitable for public decoration and home decoration, the mounting speed is high, cost is low, and needed labor is little.

Owner:深圳广田高科新材料有限公司

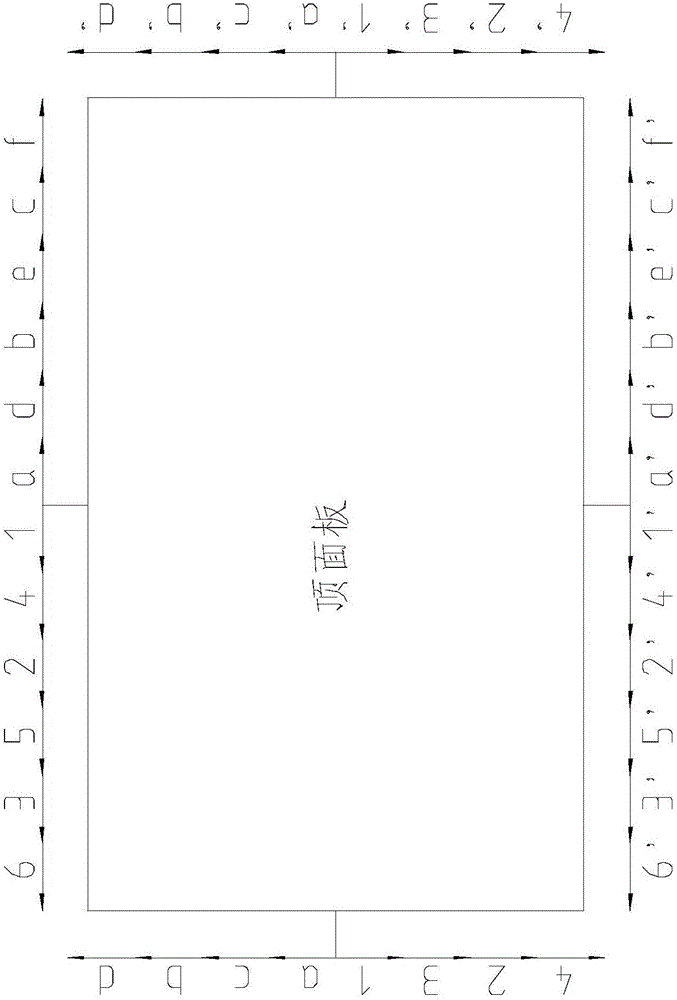

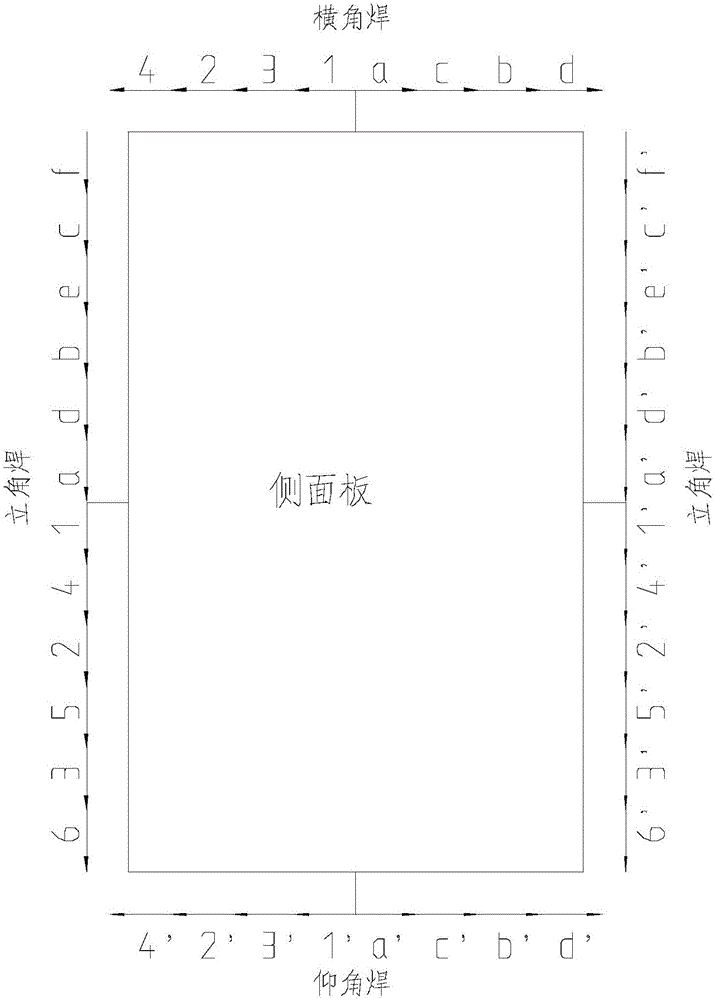

Chemical module panel laying and welding method

ActiveCN106141471AReduce welding distortionUniform weld patternWelding apparatusQuality by DesignChemical engineering

The invention discloses a chemical module panel laying and welding method. The chemical module panel laying and welding method comprises the following steps of (A) dividing a frame of a chemical module into sub planes; (B) splicing, shaping and blasting sand to subpanels; (C) preparing before the panels are laid; (D) laying the panels: laying the top panel, the bottom panel and the side panel; (E) welding the panels: welding the top panel, the bottom panel and the side panel; and (F) inspecting and accepting the whole chemical module. According to the panel laying and welding method, the bottlenecks of unstable quality and difficulty in meeting design quality requirements in the prior art are overcome, the module panel welded by using the panel laying and welding method has the advantages of attractive appearance, no irregularity and stable laying and welding quality, and the panel laying and welding method has a wide popularization vale in the field of chemical module panel laying and welding construction.

Owner:江苏利柏特股份有限公司

Rudder position adjusting and measuring clamp and method

The invention provides a rudder position adjusting and measuring clamp and method. The clamp comprises a position pointer, clamping lug pieces and an elastic compressing device, wherein the position pointer is of a symmetrical structure; the outer contour projection of the position pointer is the same as that of the lower portion of an airplane rudder; the end of the position pointer is provided with a sharp point perpendicular to the horizontal datum of the clamp; the clamping lug pieces are symmetrically distributed on the two sides of the position pointer; the attachment surfaces are consistent with the appearance airplane wing surfaces. The clamp has wide portability and can almost be applied to adjustment and measurement of rudder systems of various airplanes.

Owner:XI'AN AIRCRAFT INTERNATIONAL

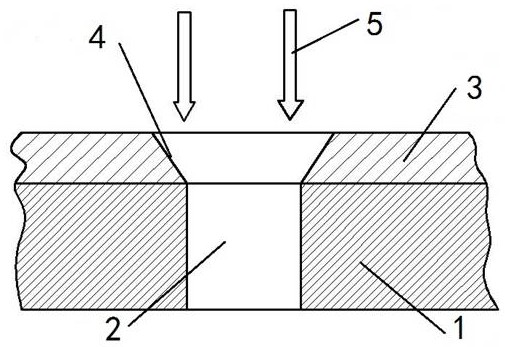

Method for welding steel plates

The invention provides a method for welding steel plates, comprising the following steps: firstly, pre-embedding an angle iron frame in a concrete base; then, welding each steel plate with the angle iron frame; and finally, connecting two adjacent steel plates in a butt welding manner. The steel plates welded by adopting the method have firm welding and reliable quality, the phenomenon of weld failure without repairing is sovled and the steel plate surfaces are protected from hollowness, thereby ensuring that production of enterprises can operate normally.

Owner:QINGDAO INSTALLATION & CONSTR +1

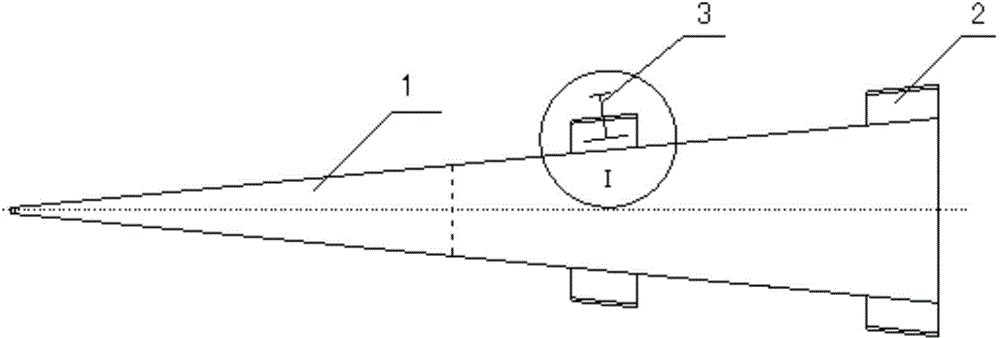

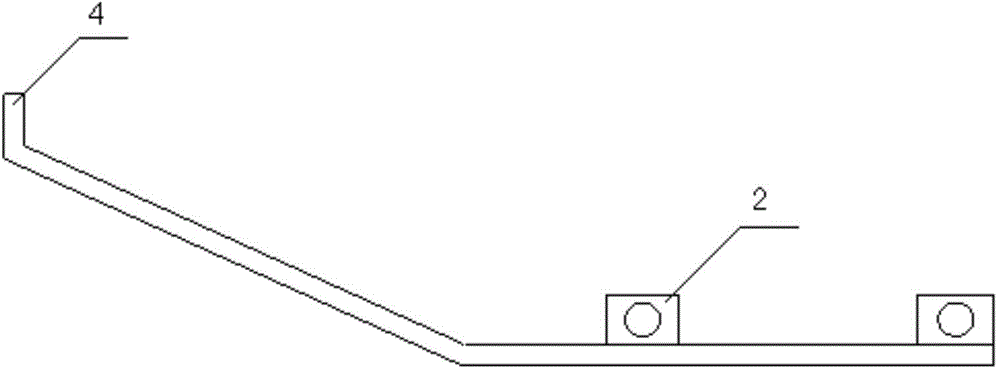

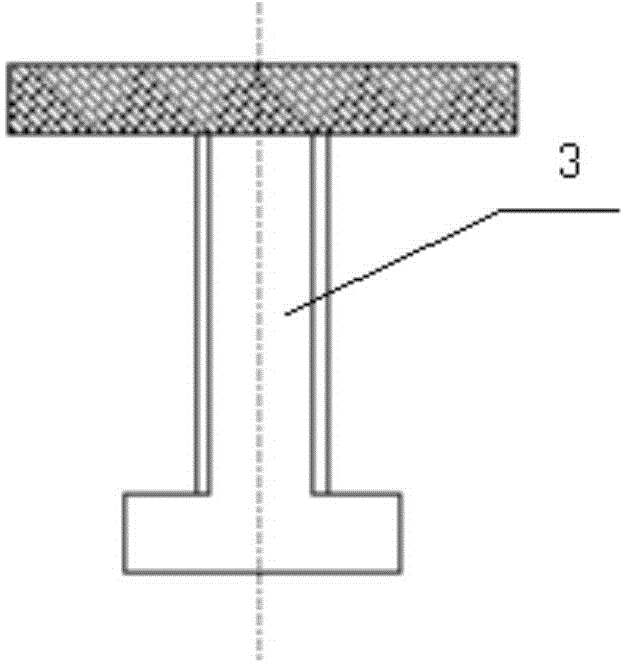

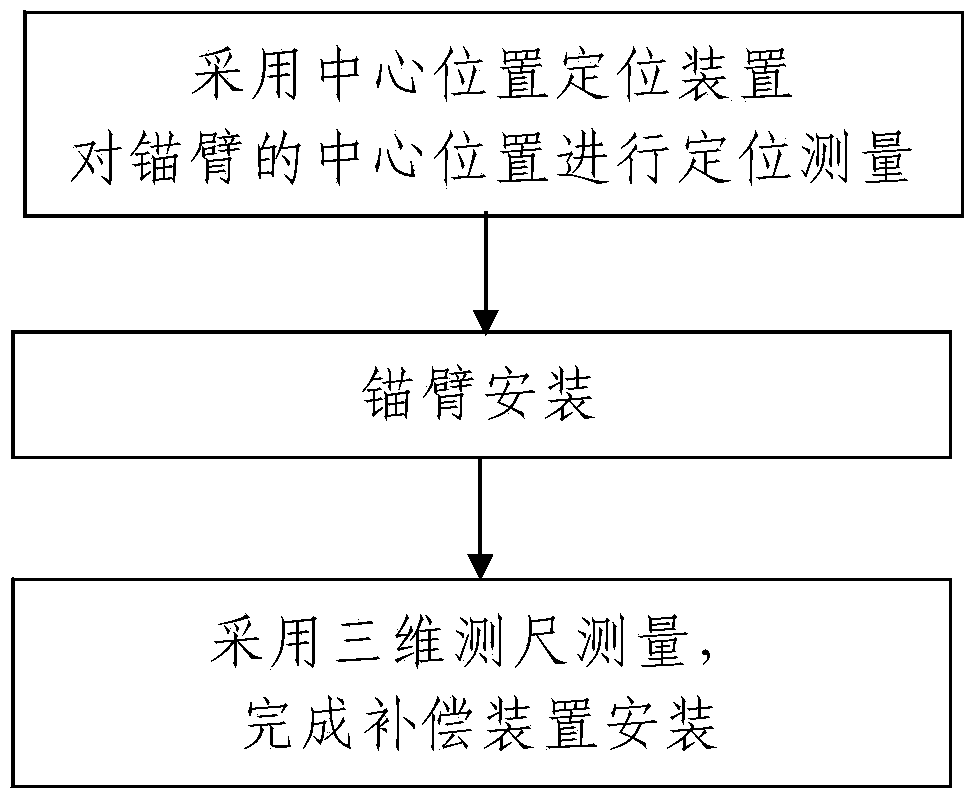

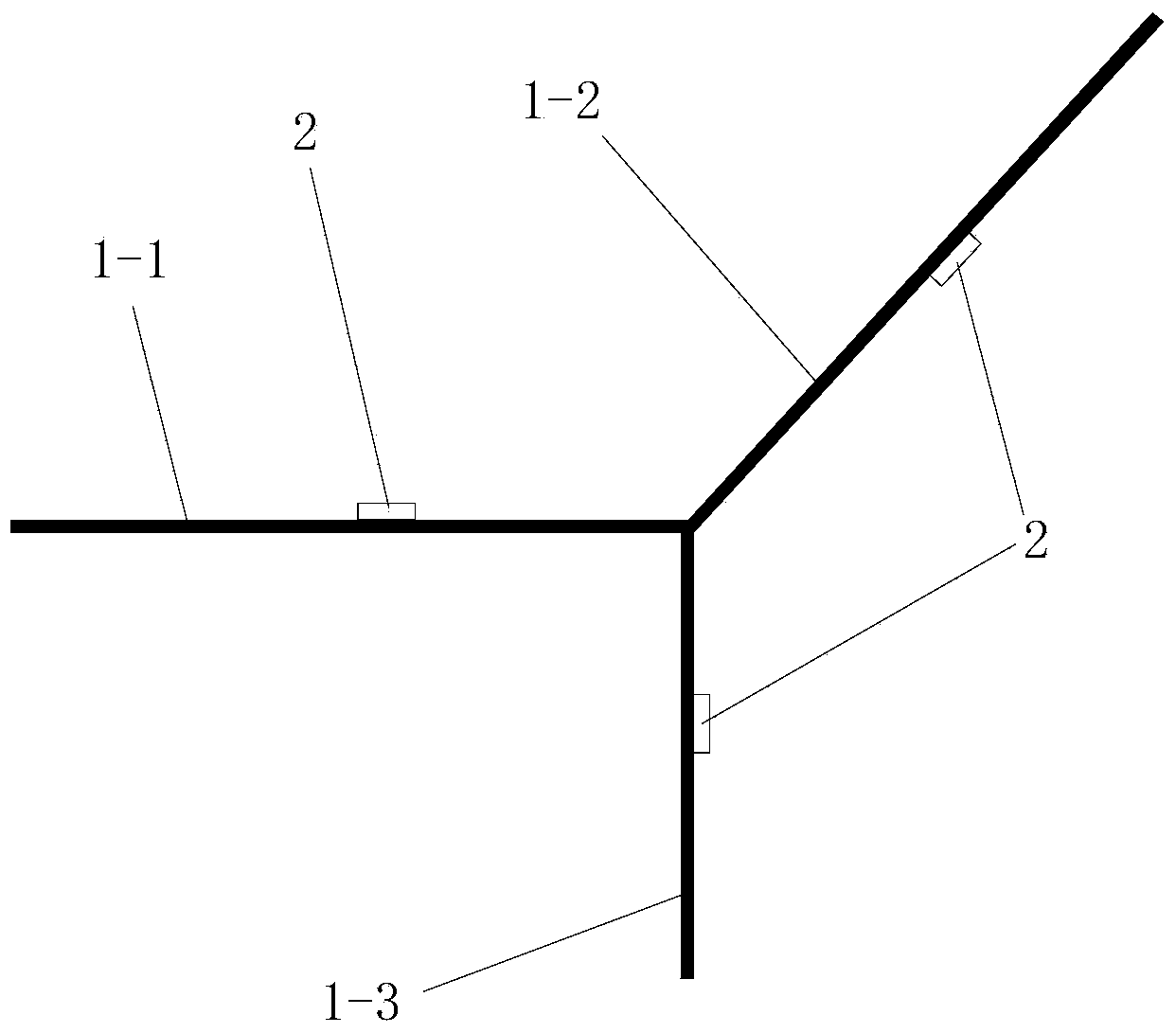

Anchor mooring construction surveying method for contact network in tunnel

ActiveCN103983256ASimple structureReasonable designSurveying instrumentsIncline measurementObservational errorContact network

The invention discloses an anchor mooring construction surveying method for a contact network in a tunnel. The contact network to be constructed is divided into a plurality of anchoring sections, wherein an anchoring section joint is arranged between two adjacent anchoring sections, and comprises an anchor mooring device, the anchor mooring device comprises a supporting device, a contact suspending device and a compensating device, and the supporting device is an anchoring arm fixed on the wall of the tunnel. An anchor mooring device is installed by adopting the following steps: installing the supporting device, namely, installing the anchoring arm of the currently installed anchor mooring device; and 2, installing the compensating device, namely, when the compensating device is installed, performing surveying and positioning by adopting a three-dimensional surveying rule, wherein the compensating device is installed by adopting the following processes, namely installing a front side pulley, laying the three-dimensional surveying rule, positioning a guide pulley and installing a compensating rope and a compensating pulley. The anchor mooring construction surveying method is simple, reasonable in design, relatively low in input cost, convenient to realize, good in use effect, and capable of solving the problems of inconvenience in use and operation, large workload, relatively high measurement difficulty, relatively large measurement errors, and the like in a conventional measurement method.

Owner:中铁二十局集团电气化工程有限公司

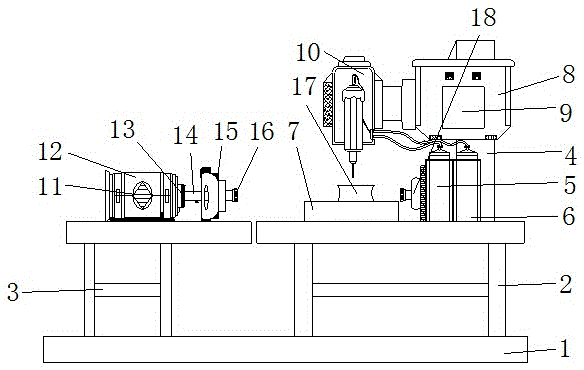

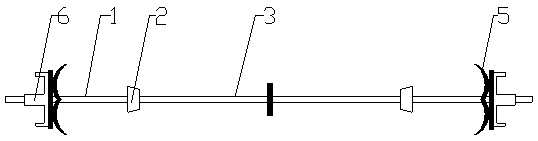

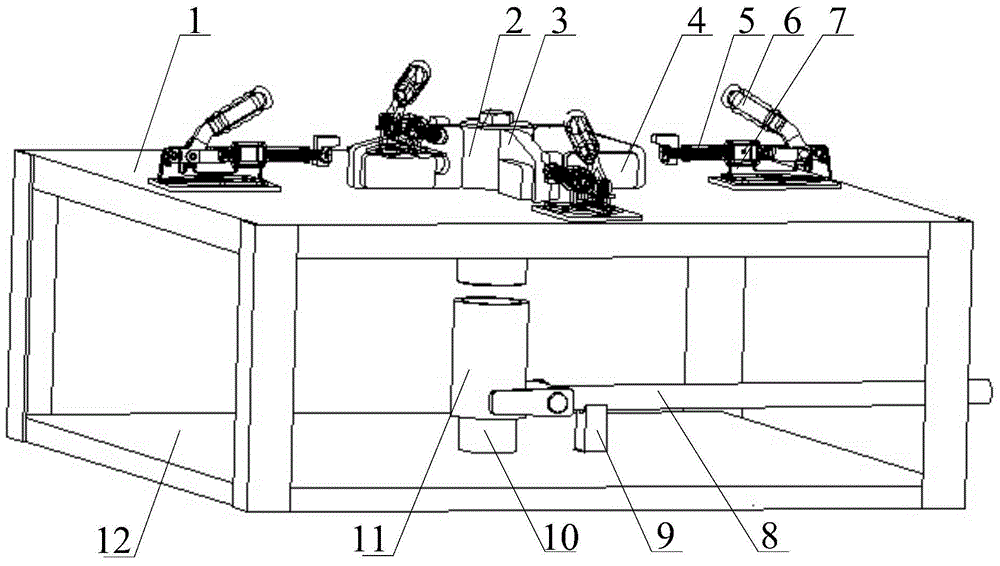

Steel pipe welding equipment

InactiveCN105414701APracticalImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWork quality

The invention discloses steel pipe welding equipment which comprises a machine base, a welding table, a feeding table and a welding joint. The welding table and the feeding table are arranged at the top of the machine base. The welding joint is arranged on the left side of a vertical frame. A heater is arranged at the top of a lifting barrel. One end of the right side of a motor is connected with one end of the left side of a rotary shaft through a speed regulator. The steel pipe welding equipment is high in practicality and work efficiency, convenient to operate, high in maneuverability and precision, good in automation performance, firm in welding, free of errors and reworking and good in work quality. The equipment is provided with the feeding table, the feeding table is provided with the rotary shaft and a steel pipe clamp, a welding clamp and a steel pipe fixing arm are arranged on the welding table so that the problem that assistance of multiple persons is needed during use in existing procedures can be effectively solved, the effect is improved, and labor force is saved.

Owner:WUXI CHENYUAN CONSTR EQUIP

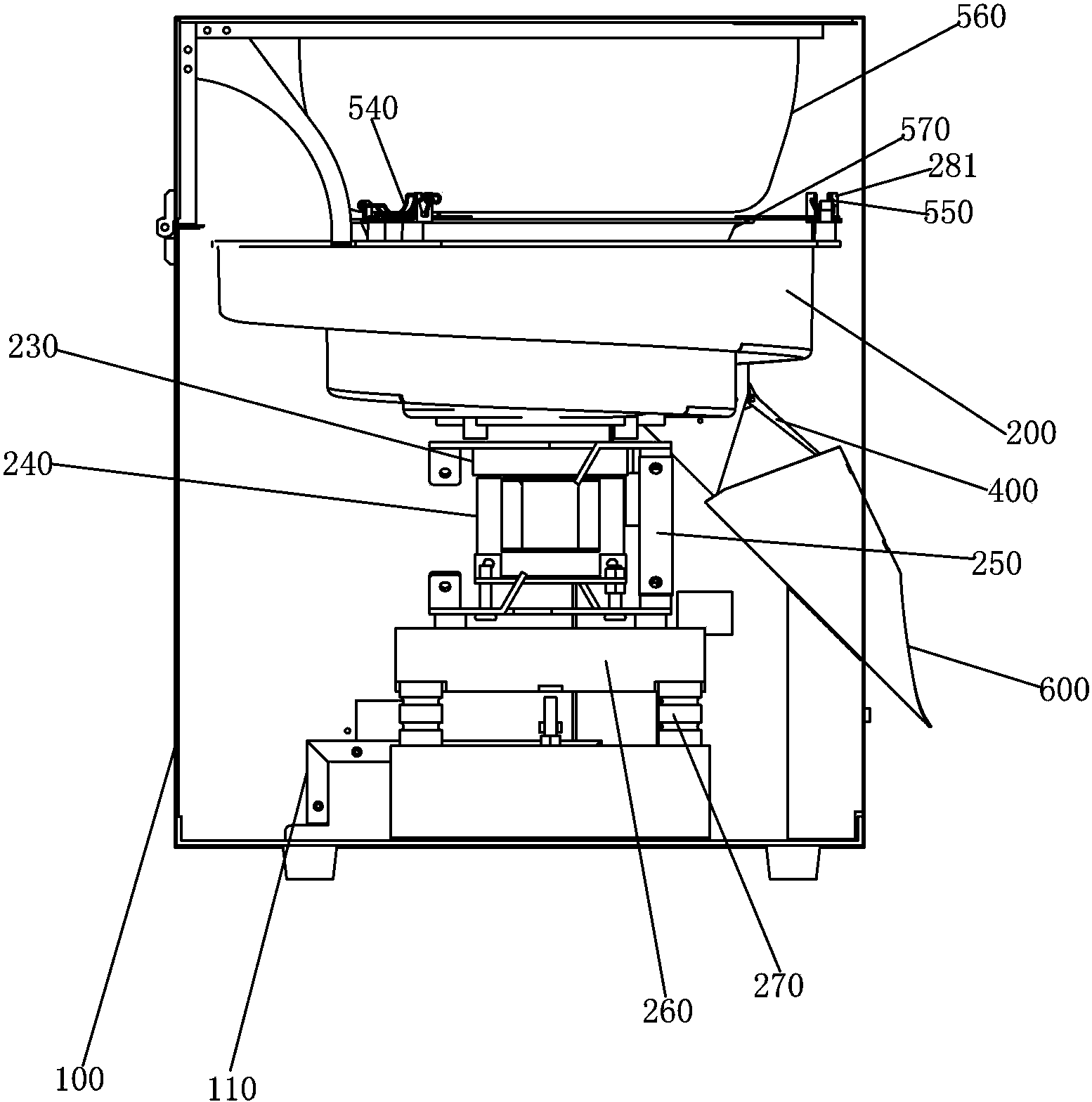

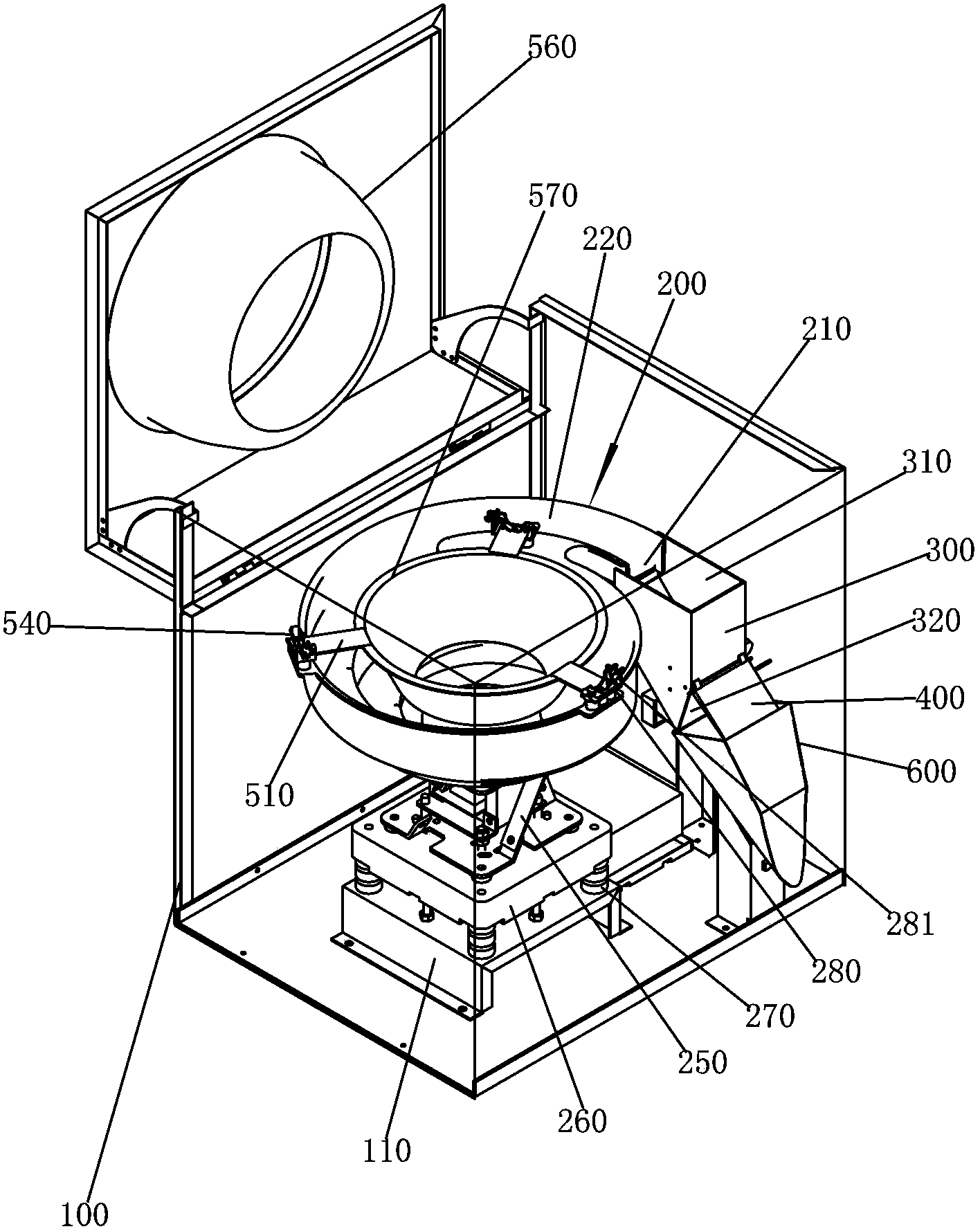

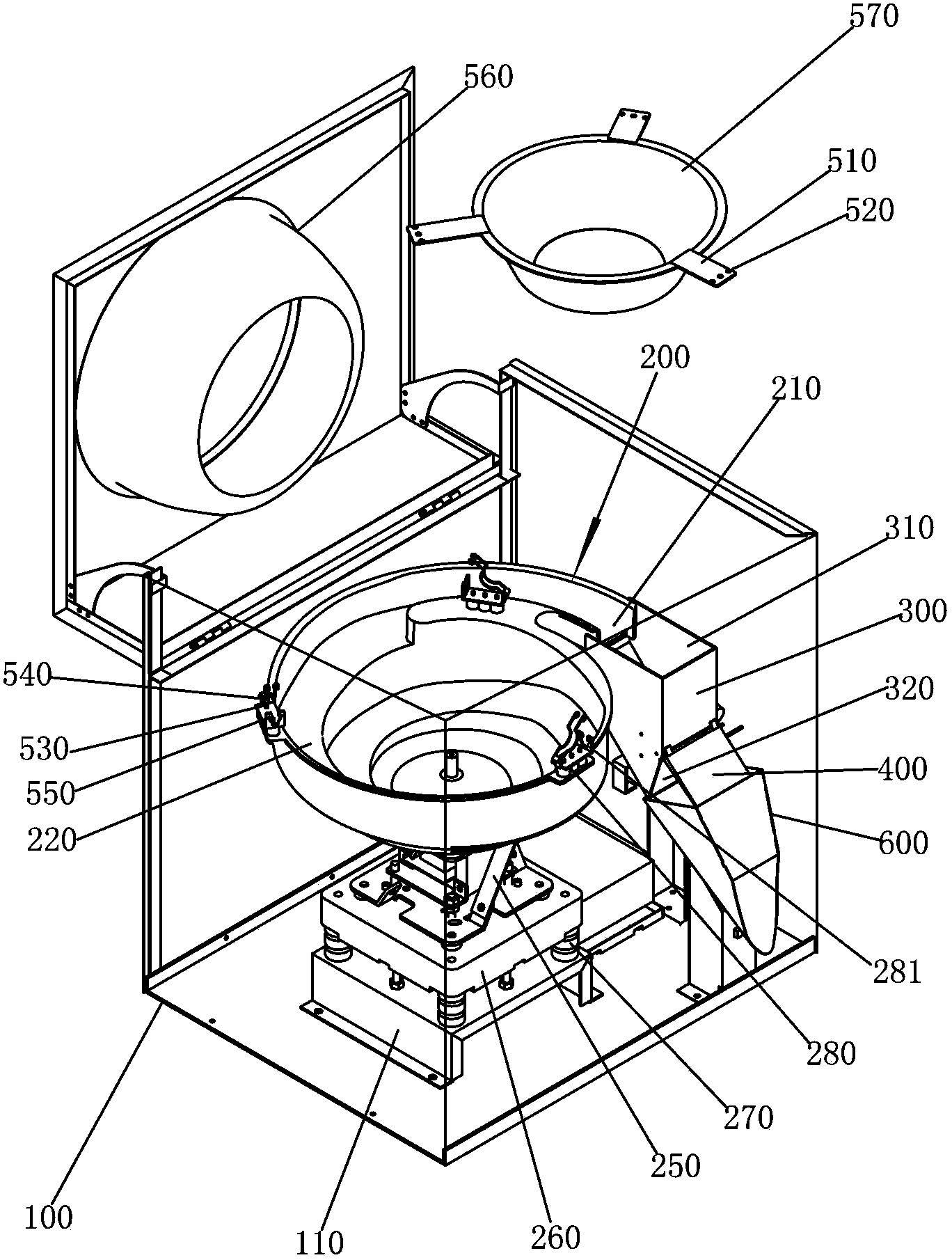

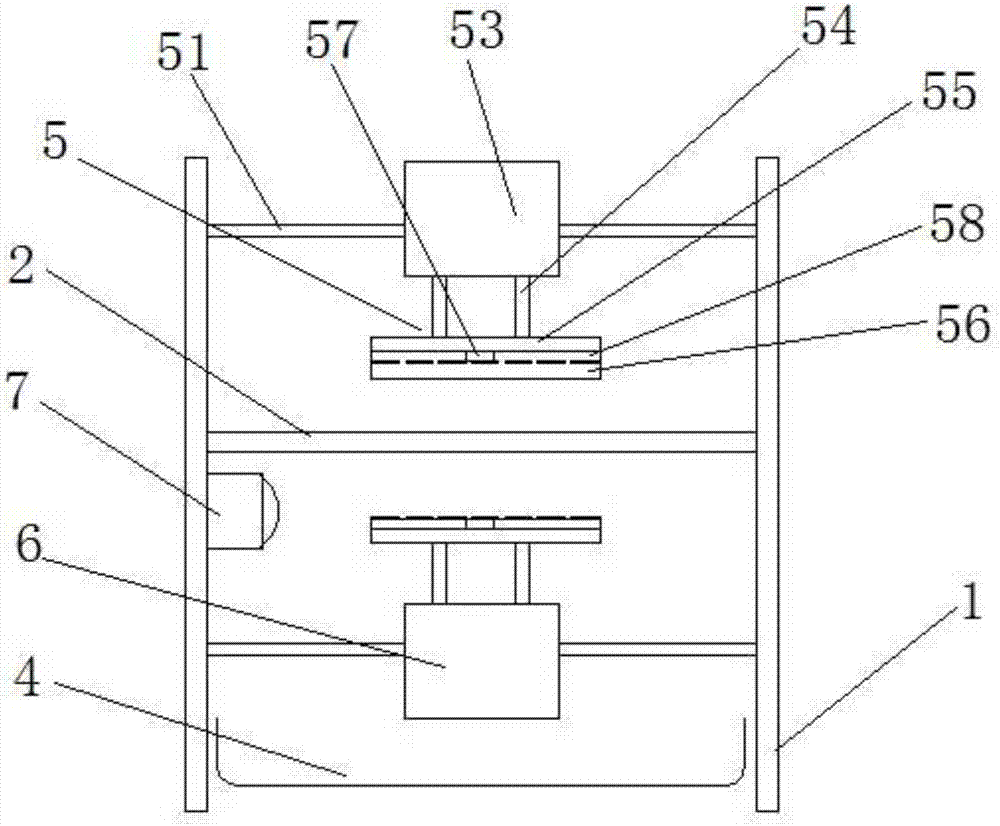

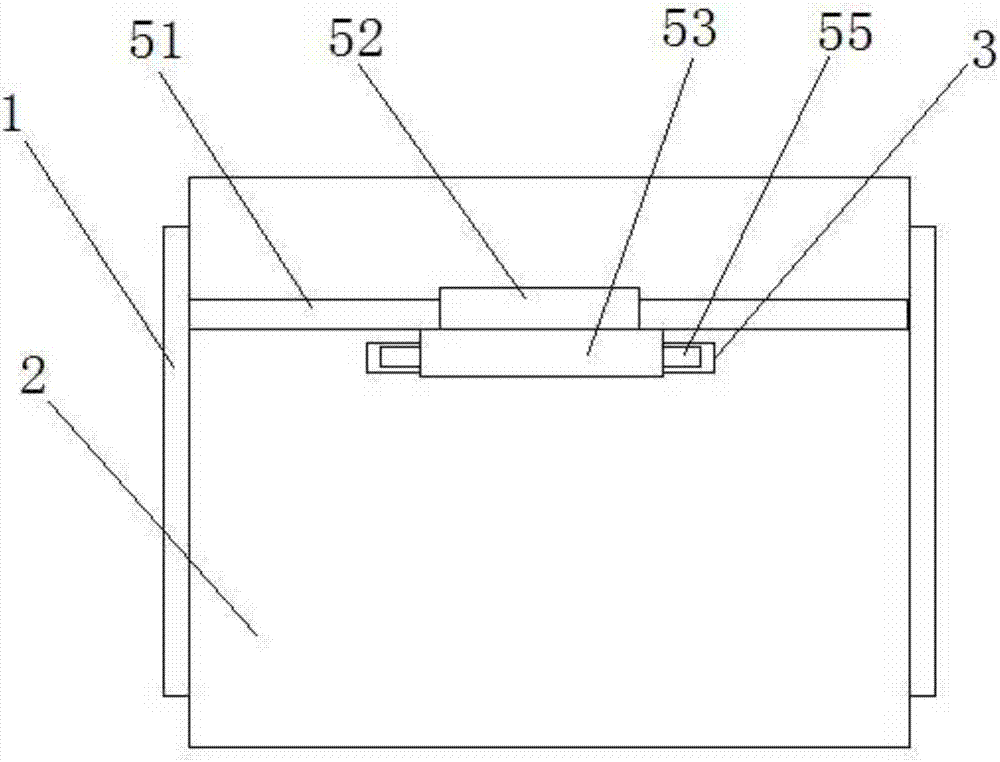

Material sub-packaging machine

InactiveCN104118584AAvoid accumulationPrevent the hassle of accumulationSolid materialPush pullEngineering

The invention discloses a material sub-packaging machine. The material sub-packaging machine comprises a rack, a vibrating mechanism, a weighing mechanism, a baffle turn-over mechanism, a material storage hopper and a buffering hopper. The vibrating mechanism is connected in the rack and comprises a vibration driving unit and a vibrating disk, and a discharging port is formed in the vibrating disk. The weighing mechanism is connected in the rack and comprises a weighing hopper with an inlet and an outlet, and the inlet of the weighing hopper corresponds to the discharging port. The baffle turn-over mechanism is connected in the rack and comprises a push-pull electromagnet and a baffle in transmission connection with the push-pull electromagnet, and the baffle is rotationally connected to the outlet of the weighing hopper. The material storage hopper is connected to the rack and located above the vibrating disk. The buffering hopper is detachably connected to the vibrating disk and located between the material storage hopper and the vibrating disk. More materials can be placed in the material storage hopper, because the buffering hopper is arranged, the material sub-packaging machine can be fully automatic, materials can be fed into the material storage hopper continuously, the trouble for attending the material storage hopper manually to prevent material accumulation is saved, and the production efficiency is greatly improved.

Owner:CHENGFENG COMP EQUIP

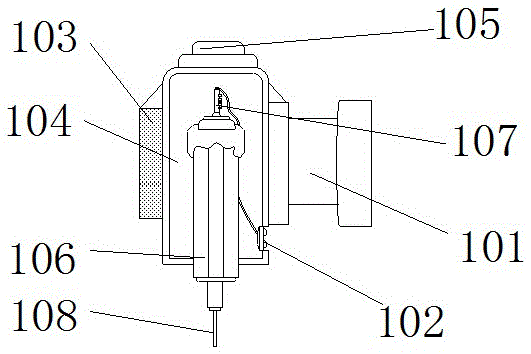

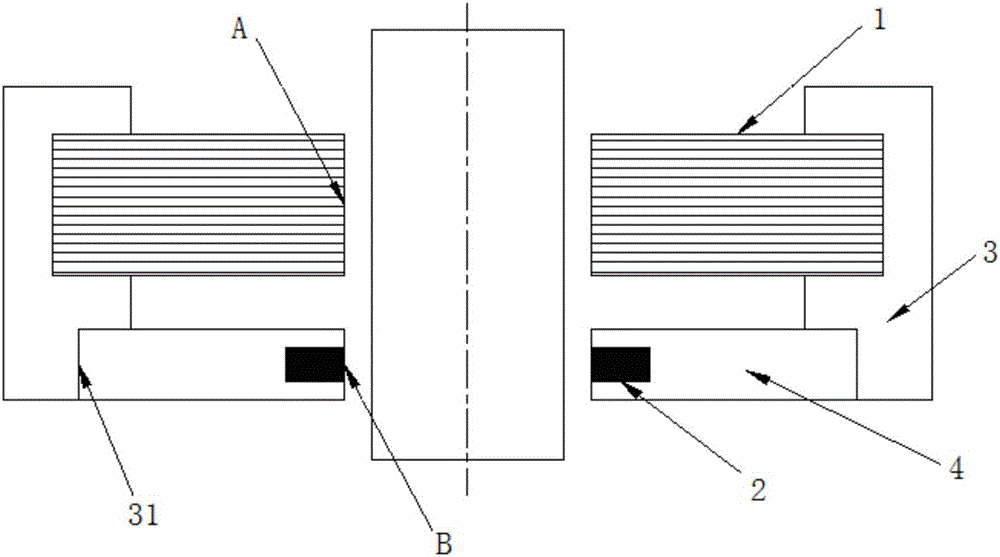

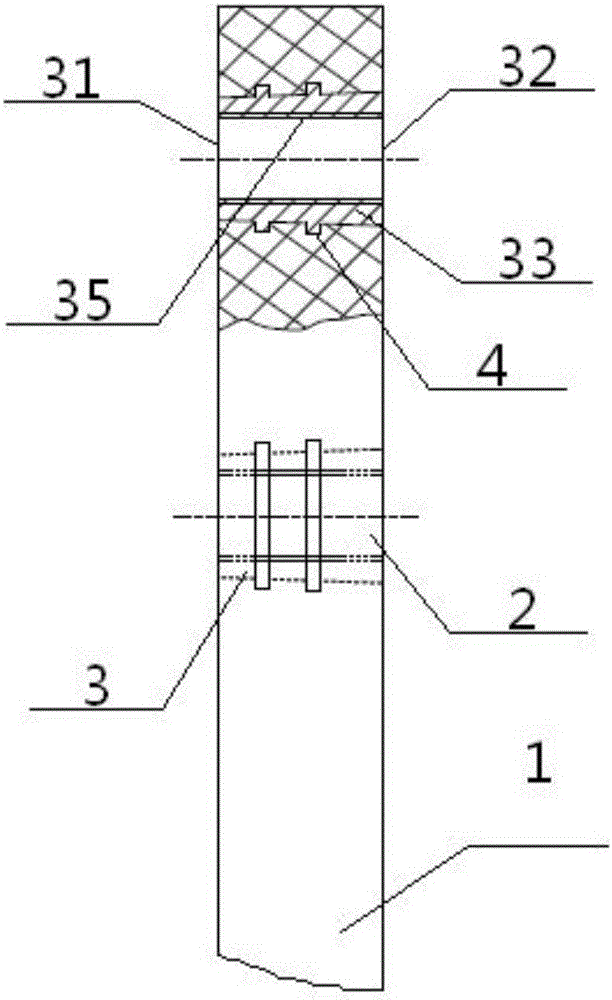

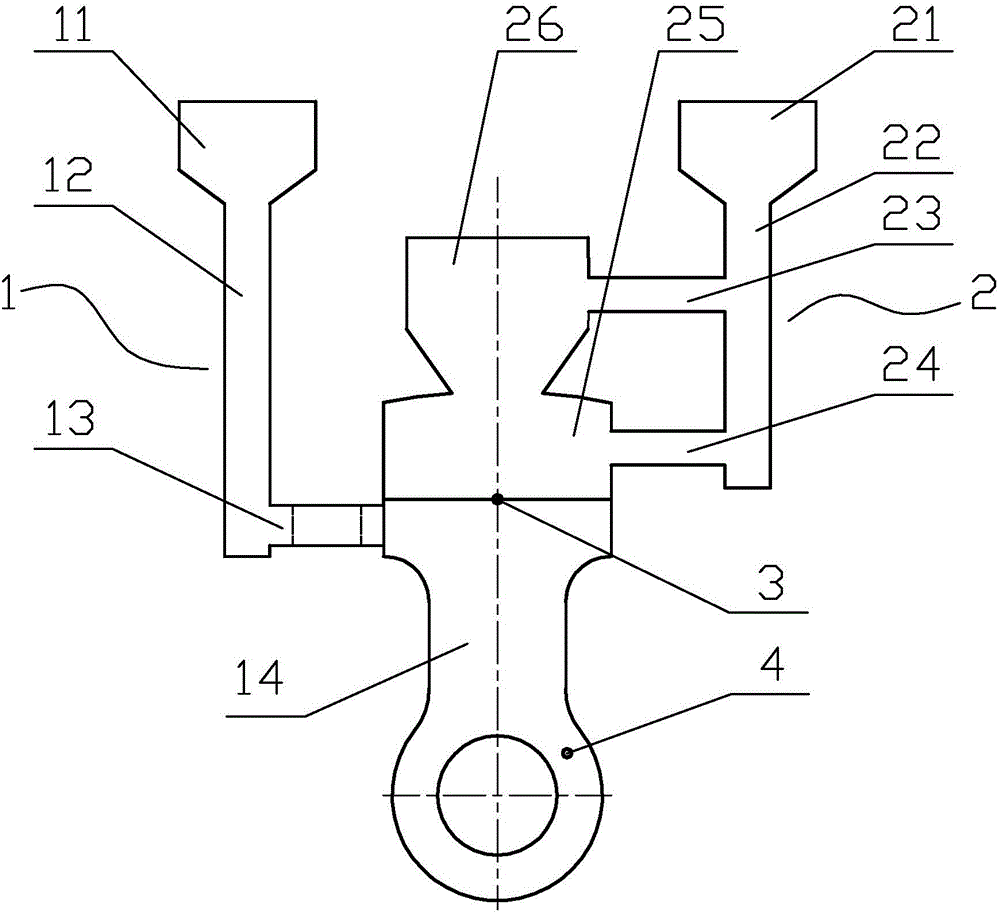

Radial magnetic bearing and sensor bracket split structure

InactiveCN106402158ASimplify control proceduresReduce control errorBearing assemblyShaft assemblySensor holderEngineering

Owner:NANJING CIGU TECH CORP LTD

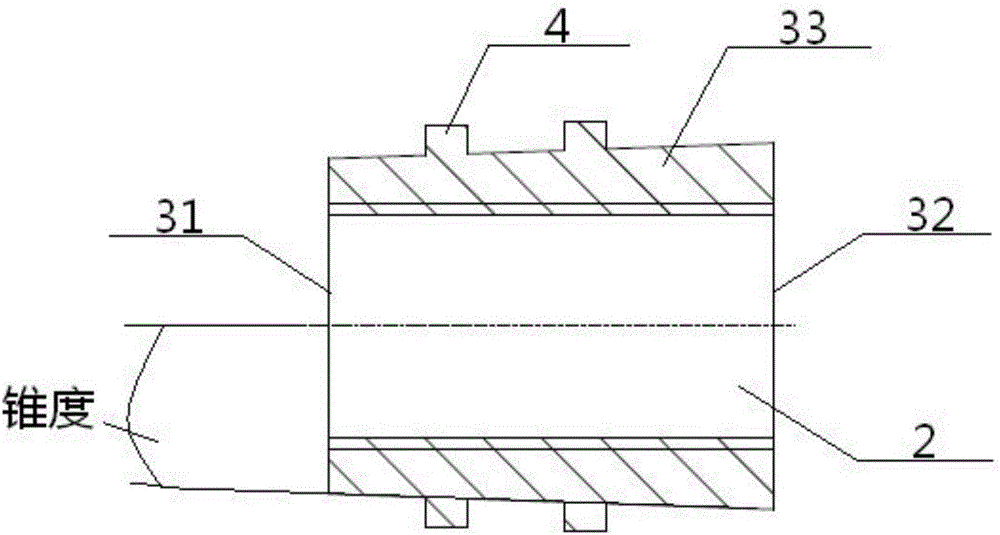

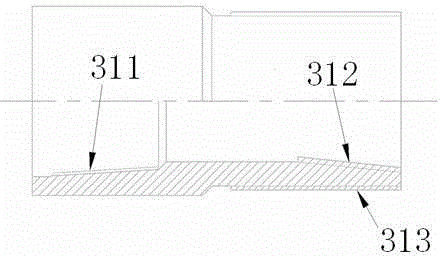

Automobile plastic lateral baffle

ActiveCN106476555AAvoid breakingNo reworkLeaf springsResilient suspensionsVehicle frameThreaded insert

The invention relates to an automobile plastic lateral baffle which comprises a plastic main body and a metal threaded insert part embedded into the plastic main body, wherein the metal threaded insert part has a hollow conical circular platform structure and comprises a narrow platform surface, a wide platform surface and a conical platform part located between the narrow platform surface and the wide platform surface; the narrow platform surface is parallel and level with the inner side wall of the plastic main body; the wide platform surface is parallel and level with the outer side wall of the plastic main body; the conical platform part has a hollow structure; a thread is formed on the inner wall of the conical platform part so as to form a thread hole; and at least two annular bulges are arranged on the outer wall of the conical platform so as to fixedly connect with the interior of the plastic main body. According to the design, the connecting thread is higher in durability and assembling efficiency, the clinging of the lateral baffle and the frame is benefited, and the combining firmness of the metal threaded insert part and the plastic main body is promoted.

Owner:DONGFENG COMML VEHICLE CO LTD

Side slope gradient control method in deep foundation pit excavation process

The invention belongs to the technical field of building deep foundation pits, and particularly relates to a side slope gradient control method in a deep foundation pit excavation process. The side slope gradient control method is characterized by including the steps: 1) deep foundation pit positioning and paying off; 2) deep foundation pit hierarchical excavation; 3) standard side slope groove construction; 4) piling horizontal reinforcement piles; 5) side slope gradient standard steel wire hanging; 6) slope repairing horizontal steel wire hanging; 7) precise slope repairing; 8) deep foundation pit timbering. By means of the construction process, including hierarchical excavation, hierarchical slope repairing and hierarchical timbering, matched with deep foundation pit timbering design conditions, the side slope gradient and integral stability of the foundation can meet design requirements; steel wires are tensioned on the side slope to serve as slope repairing control lines and approximately insusceptible to wind force, and whether the side slope gradient at any position of the slope face is accurate or not can be detected; a slope gradient detection ruler is used for detecting construction standard slope gradient grooves, a slope repairing control method of hanging slope repairing horizontal steel wires is adopted, and consequently large-area slope repairing operations on a same excavation level can be conducted, and high slope repairing efficiency is achieved.

Owner:SHANDONG GOLDENCITY CONSTR

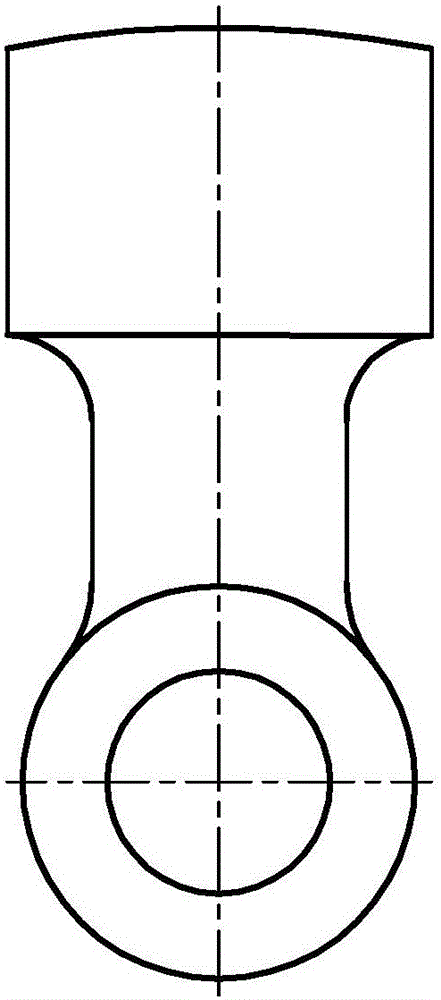

Lost-foam-casting bimetal hammerhead pouring system

ActiveCN105750498AImprove feeding effectIncrease temperatureFoundry mouldsFoundry coresEngineeringStructural engineering

The invention discloses a lost-foam-casting bimetal hammerhead pouring system, and relates to a pouring system.The lost-foam-casting bimetal hammerhead pouring system comprises a first pouring system body for pouring of a material of a hammer handle part and a second pouring system body for pouring of a material of a hammerhead part.The first pouring system body comprises a first pouring cup, a first vertical pouring channel, a first transverse pouring channel and a hammer handle cavity; the second pouring system body comprises a second pouring cup, a second vertical pouring channel, a second upper transverse pouring channel, a second lower transverse pouring channel, a hammer head cavity and a feeding head.According to the second pouring system body, the double-pouring-opening structure and the high-position feeding head structure are adopted, high-hardness-material liquid metal enters the hammer head cavity from the second lower transverse pouring channel firstly along the second vertical pouring channel, and then enters the feeding head from the second upper transverse pouring channel; as the newly-entering liquid metal is high in temperature, the temperature of the feeding head can be effectively increased, the feeding effect can be greatly improved accordingly, and the casting defects can be avoided.The product further has the advantages of being high in impact-resistant strength, excellent in appearance quality, stable in performance, long in service life and the like, and the customer satisfaction degree can be greatly increased.

Owner:柳州桂滨铸造有限公司

Waste clearing device for carton in punching process

The invention discloses a carton punching and waste removal device, which comprises a vertical plate, a support plate, a punching gap, a collection box, a first waste removal mechanism and a second waste removal mechanism, and a support is provided in the middle of the two vertical plates The support plate is provided with punching gaps, and the support plate is provided with a first waste removal mechanism and a second waste removal mechanism on both sides, and a collection box is arranged under the second waste removal mechanism. By improving the waste stripping device used in the prior art, the second stripping mechanism is arranged symmetrically on the lower part of the support plate, which can cooperate with the first stripping mechanism to remove the waste paper at the opening. The strip is clamped between the two pressure plates, and driven by the piston rod, it is taken out of the area of the support plate, and the waste paper strips on the pressure plate are blown away by the fan to complete waste removal and collection. The invention has the advantages of simple structure, convenient use, good waste removal effect, high work efficiency, thorough waste removal and no need for rework.

Owner:天津王朝包装印刷制品有限公司

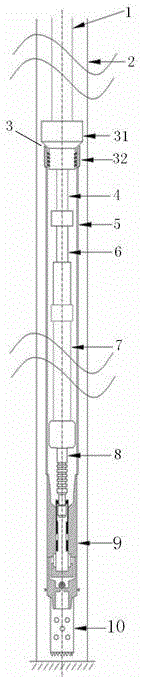

Secondary well cementing technique and secondary well cementing device by liner pipe

ActiveCN104879089AReasonable structural designImprove reliabilityDrilling rodsWell/borehole valve arrangementsWell cementingPipe

The invention discloses a secondary well cementing technique and a secondary well cementing device by a liner pipe. The secondary well cementing device mainly comprises a conveying pipe string, an inner string and an outer string, wherein the conveying string mainly comprises an upper release sub body and a lower release sub body which are in screwed connection with a tubing I, the inner string mainly comprises a tubing nipple, a tubing length compensator, a tubing II and an inserting pipe which are in screwed connection with the upper release sub body sequentially, and the outer string mainly comprises the liner pipe, an inserting pipe well cementing valve and a zigzag screen pipe which are in screwed connection with the lower release sub body sequentially. The secondary well cementing technique adopting the secondary well cementing device includes the steps of determining a well cementing segment, placing the outer string and the inner string in the well cementing segment, performing pumping injection, boosting, using workover fluid for washing a well bore, injecting cement for well cementation, backwashing a well and the like. The secondary well cementing device has the advantages of reasonable structural design, wide application range, high reliability, high sealability, simple technology and capabilities of guaranteeing well cementing quality, substantially improving operation efficiency and substantially reducing construction cost.

Owner:中国石油化工股份有限公司华东油气分公司泰州采油厂

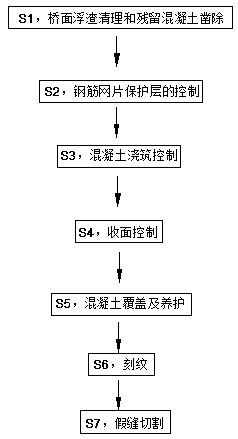

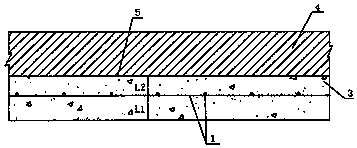

Bridge deck pavement surface crack control method

InactiveCN111576253AImprove construction qualityGuaranteed flatnessBridge erection/assemblyBridge strengtheningSurface finishArchitectural engineering

The invention belongs to the technical field of highway bridge deck pavement construction, particularly relates to a bridge deck pavement surface crack control method, and solves problems that bridgeconstruction quality is seriously influenced, construction cost is increased and construction efficiency is reduced due to pavement layer surface cracking caused by defects of a traditional bridge deck pavement construction process. The invention comprises a claim 1 and the like. The method comprises the following steps that S1, bridge deck scum is removed, and residual concrete is chiseled away;S2, a reinforcing mesh protective layer is controlled; S3, concrete pouring control is performed; S4, surface finishing control is performed; S5, concrete covering and curing are performed; S6, linesare carved; and S7, false seam cutting is performed. Cracks generated on the pavement surface are effectively controlled, rework is not needed, the bridge construction quality is improved, the construction cost is greatly reduced, and the construction efficiency is improved; and flatness and overall appearance quality of bridge deck pavement are also ensured.

Owner:CHINA RAILWAY SIXTH GROUP

Inner wall whitewash-free coating construction method

The invention relates to the field of building construction, and specifically relates to an inner wall whitewash-free coating construction method. The method is characterized by comprising the following steps: step 1, coating an adhesive on the surface of an inner wall; step 2, paving fiberglass mesh on the surface of the inner wall; step 3, hanging corner wall protectors on internal corners and external corners of the inner wall; step 4, coating the adhesive on the surface of an inner wall, wherein the adhesive in the step 1 and step 4 is formed by mixing a colloidal mixture of a construction glue and putty powders with water according to weight ratio of 1:4, and thickness of the coating does not exceed 6 mm. The construction method is simple and convenient to apply. Compared with a conventional inner wall painting method, the method is simple and efficient.

Owner:CHINA MCC20 GRP CORP

Solder resist hole plugging method for BMU printed circuit board

ActiveCN111988920AThe steps are well designedEasy inflowPrinted circuit aspectsPrinted circuit manufactureAcid etchingSolder mask

The invention discloses a solder resist hole plugging method for a BMU printed circuit board. The solder resist hole plugging method comprises the following steps of: S1, target shooting; S2, edges and fillets milling; S3, acid etching for copper reduction; S4, board grinding; S5, selective plating, so that an annular slope is formed in the region, close to the hole position, of the hole needing solder mask hole plugging; S6, sequentially subjecting a BMU printed circuit board to drilling, copper deposition, board electroplating, line pretreatment, film pressing, exposure, development, detection, pattern electroplating, alkaline etching and AOI; and S7, sequentially carrying out solder mask hole plugging, surface oil printing, pre-baking, exposure and development on the BMU printed circuitboard. The solder resist hole plugging method is reasonable in step design, the steps S3, S4 and S5 are added, and an annular slope is formed in the region, close to the step S3, S4 and S5, of the hole site needing solder mask hole plugging, so that the plumpness of the plugged hole is improved, ink rising is avoided, and yellowing of the via hole is avoided.

Owner:TEAN ELECTRONICS DA YA BAY CO LTD

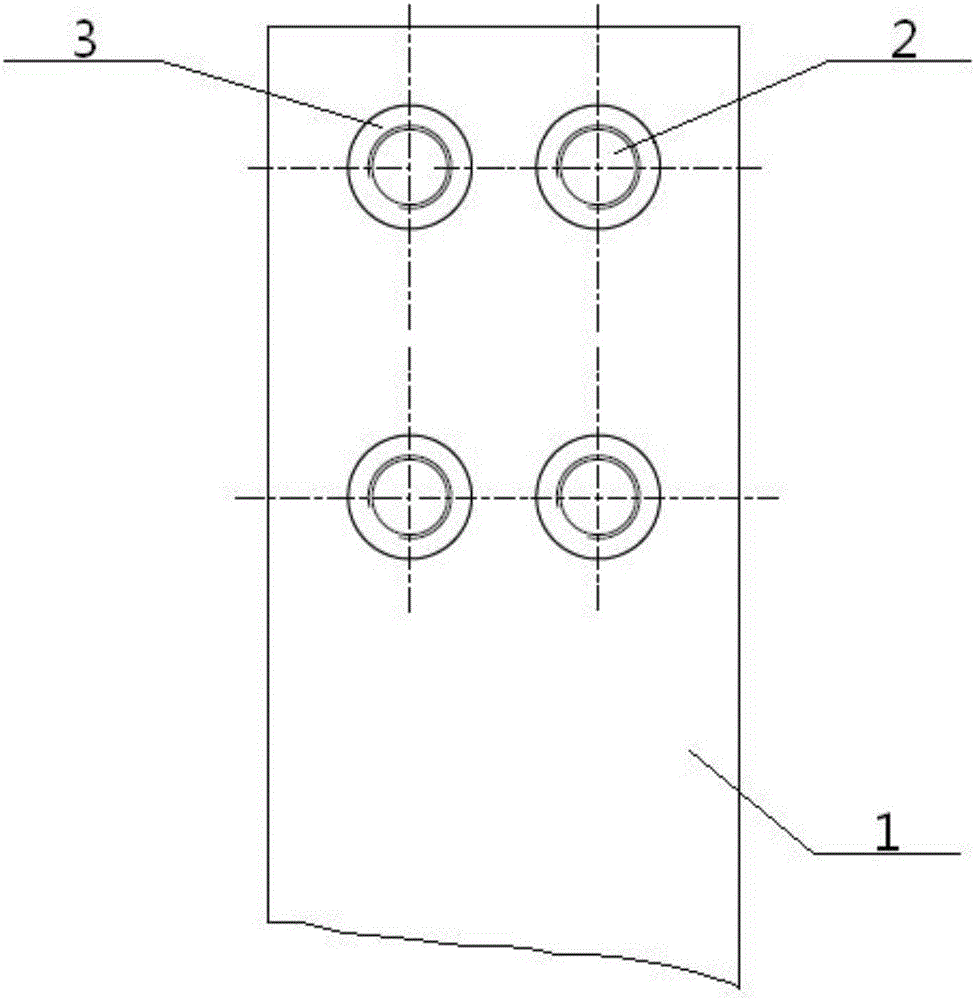

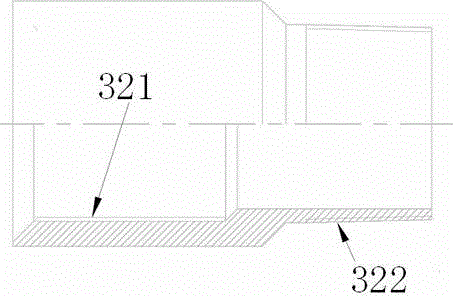

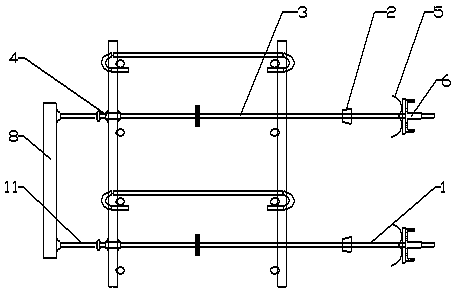

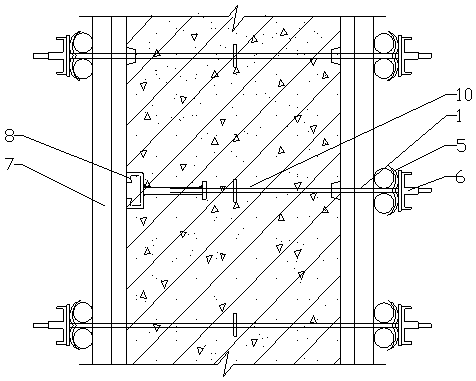

Lateral embedding installing method for C-type Haffen groove of concrete structure

ActiveCN109826441AFit tightlySo as not to damageArtificial islandsAuxillary members of forms/shuttering/falseworksArchitectural engineeringRebar

The invention relates to the field of construction of municipal engineering, and particularly discloses a lateral embedding installing method for a C-type Haffen groove of a concrete structure. The method comprises the following steps of 1, preparing a half section of water stopping screw; 2, welding and assembling an inner-supporting Haffen groove; 3, fixing the inner-supporting Haffen groove andrebars; 4, installing a template. The Haffen groove is easy to install and definite in stress, a rebar net restrains but not limit the groove and needs but not depend on the groove, the influence ofthe rebars on the groove is eliminated, the groove and the template are fitted tightly, the template is not damaged, after installation is finished, the template is firm and stable, the phenomenon ofreworking does not exist, the construction cost is reduced, the installing quality and appearance quality are greatly improved, and the method can be widely applied to embedded channel installing construction.

Owner:JINAN URBAN CONSTR GRP

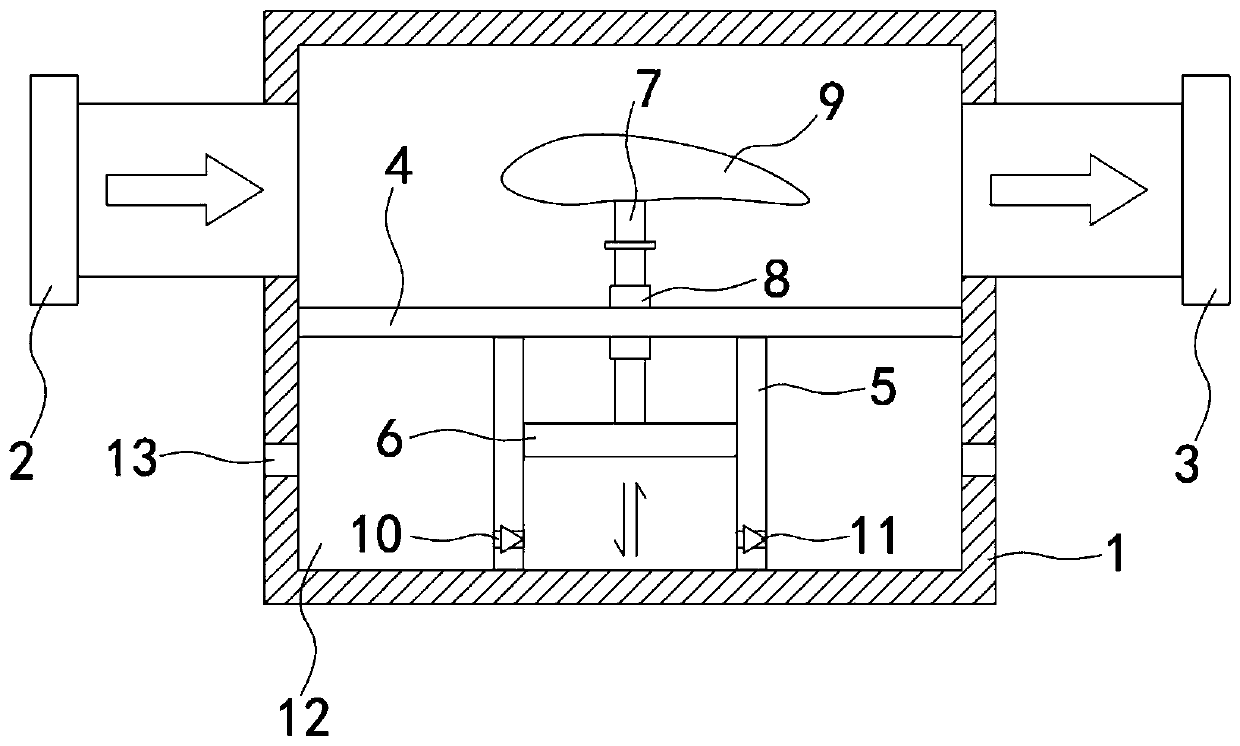

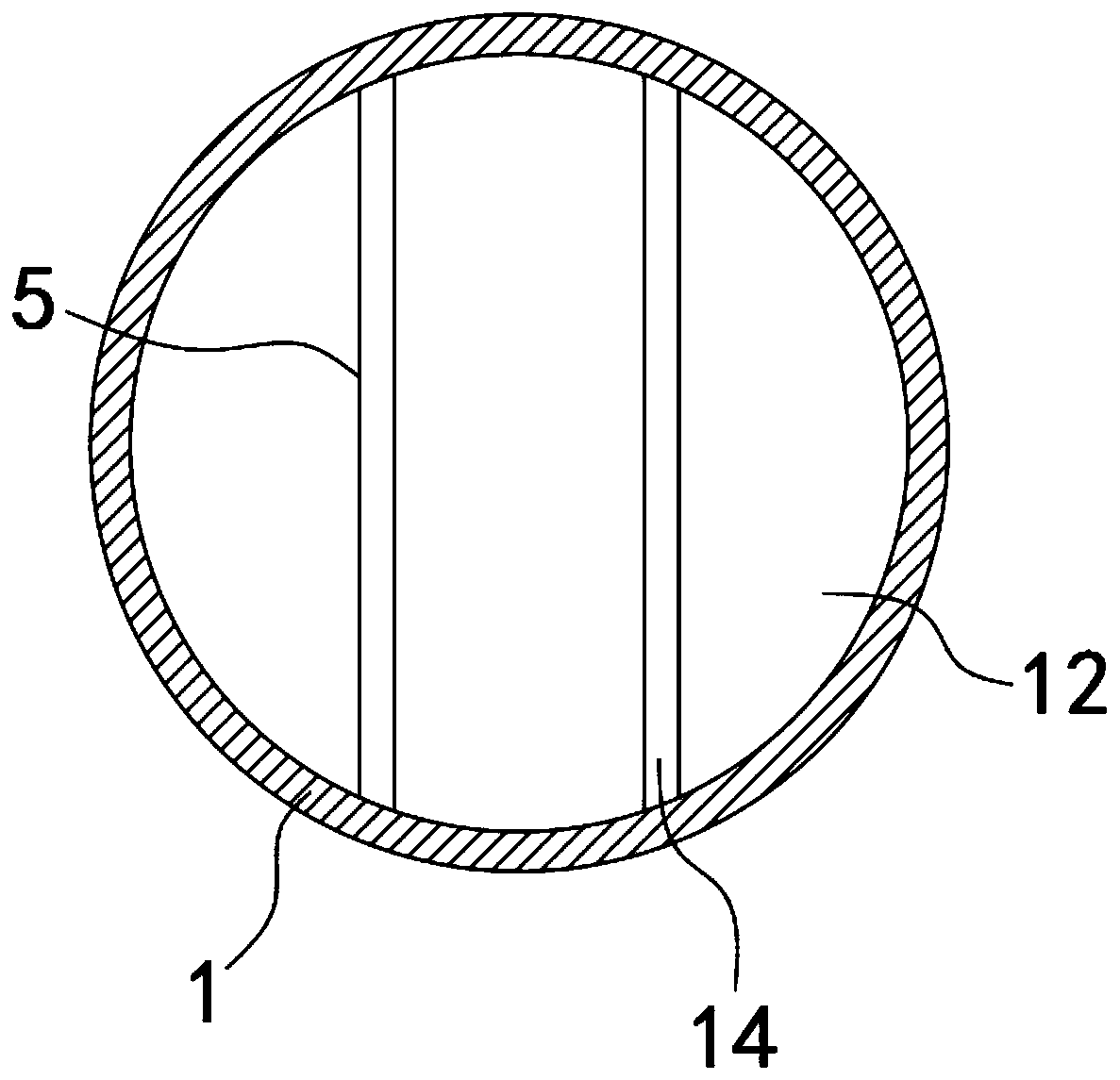

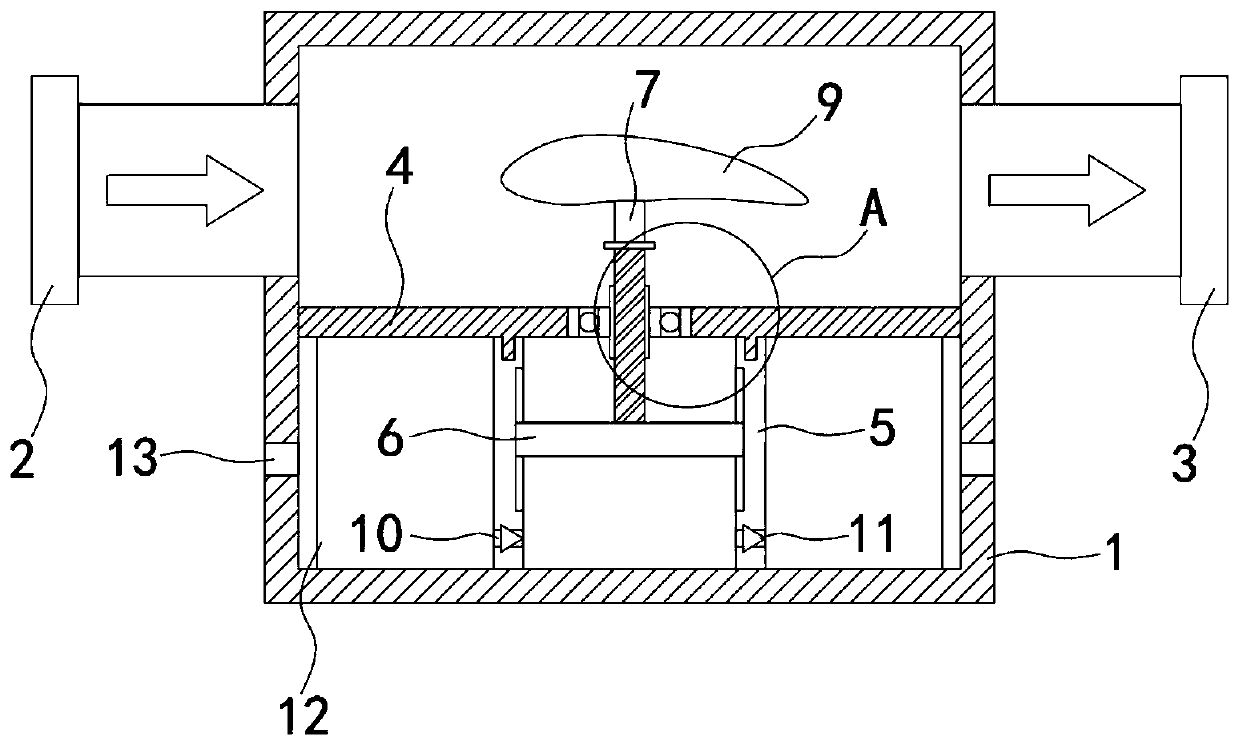

Drainage pipe connector with gas purification function for underground engineering construction

The invention belongs to the field of underground engineering and in particular relates to a drainage pipe connector with a gas purification function for underground engineering construction. The drainage pipe connector comprises a purification tank, wherein a water inlet pipe and a drainage pipe are respectively connected with both ends of the purification tank; a partition plate which is horizontally arranged is connected inside the purification tank in a sealed manner; a gas pump part is arranged on the lower side of the partition plate; a gas pump plate is connected inside the gas pump part in a sliding sealed manner; a connecting rod is fixedly connected with the upper end of the gas pump plate; a casing is fixedly connected with the partition plate in a penetration manner; the upperend of the connecting rod penetrates through the casing and is fixedly connected with a wing plate; the incident flow surface of the wing plate is arranged right aligned to the water inlet pipe; a one-way gas inlet and a one-way gas outlet are formed in the side wall of the gas pump part; and a purification cavity is formed between the gas pump part and the inner side wall of the purification tank. Due to arrangement of the wing plate, the wing plate can be driven to move up and down through variation of flowing speeds of water flows of a sewage pipe, so that an extra driving part does not need to be arranged, not only are energy conservation and environment protection better achieved, but also emission of heat can be reduced, and the arrangement difficulty of a gas purification device canbe also greatly reduced.

Owner:聊城市洛溪信息科技有限公司

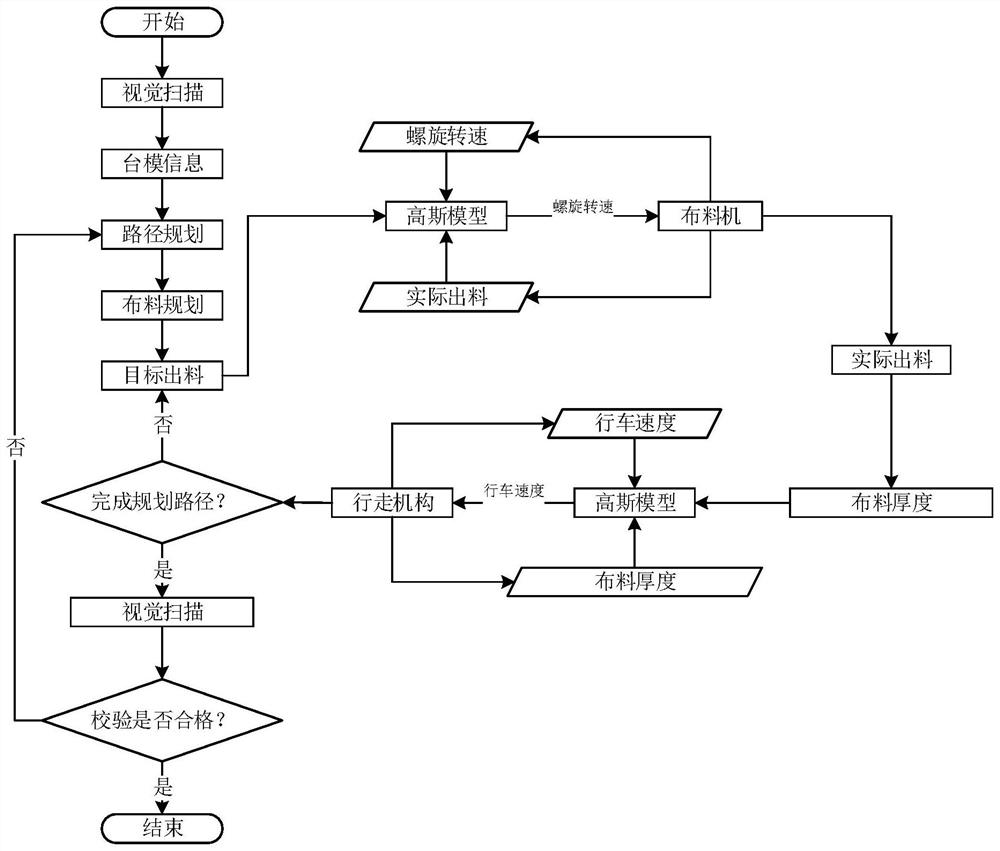

Concrete distribution control method and system

ActiveCN114147851AEasy to controlUniform clothFeeding arrangmentsAuxillary shaping apparatusDistribution controlStructural engineering

The invention provides a concrete distribution control method which comprises the following steps: acquiring mold data acquired by a visual system through scanning, and acquiring a preset model I, namely a relation model between the spiral rotating speed and the discharging amount of a concrete spreader, the second model is a relation model between the running speed of the concrete spreader at the specific spiral rotating speed and the spreading thickness or the spreading amount per unit area; material distribution path planning and discharge port opening and closing planning are automatically carried out according to mold data; carrying out material distribution control and blanking according to the model I and the model II; and collecting material distribution data in real time in the concrete material distribution control and blanking process, dynamically calibrating and updating the model I and / or the model II in real time according to the material distribution data, and circularly entering the step of carrying out material distribution control and blanking according to the model I and the model II until the material distribution is finished. By means of the method, concrete distribution can be accurately controlled, the obtained concrete member is even in distribution, secondary material supplementing and reworking are not needed, and manpower, material resources and financial resources can be remarkably saved.

Owner:筑友智造建设科技集团有限公司

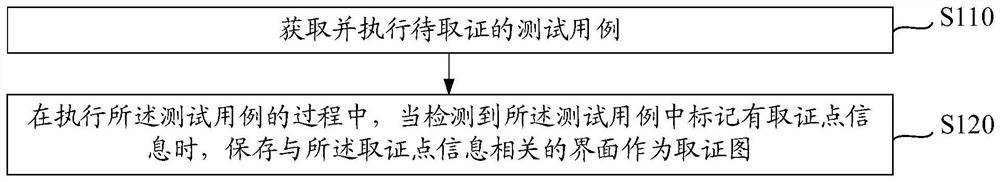

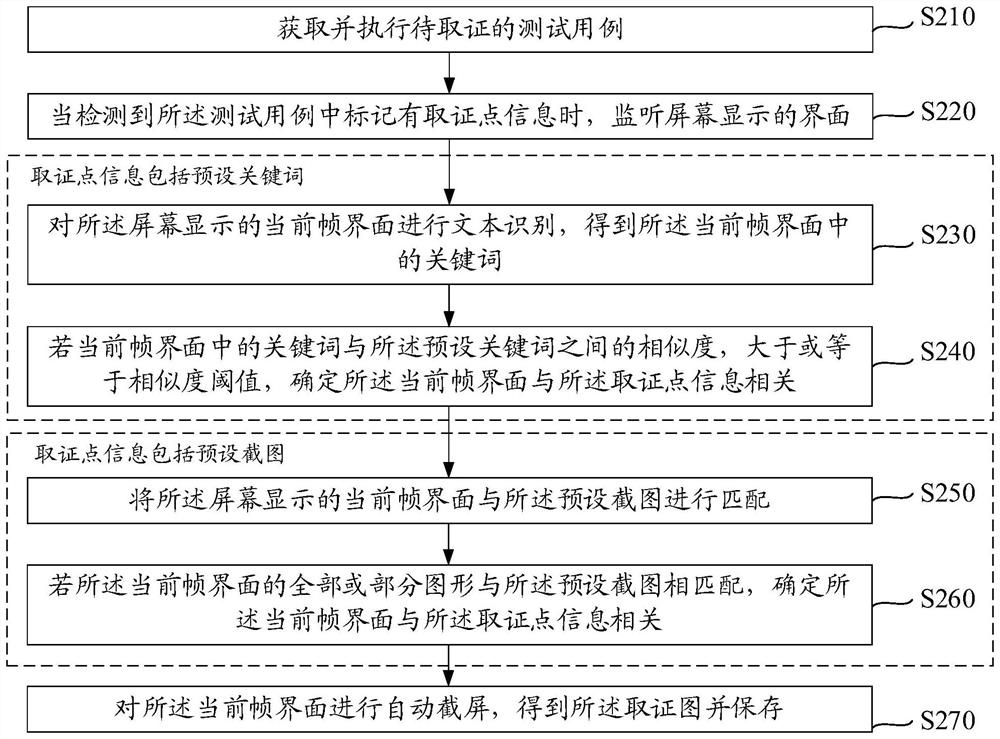

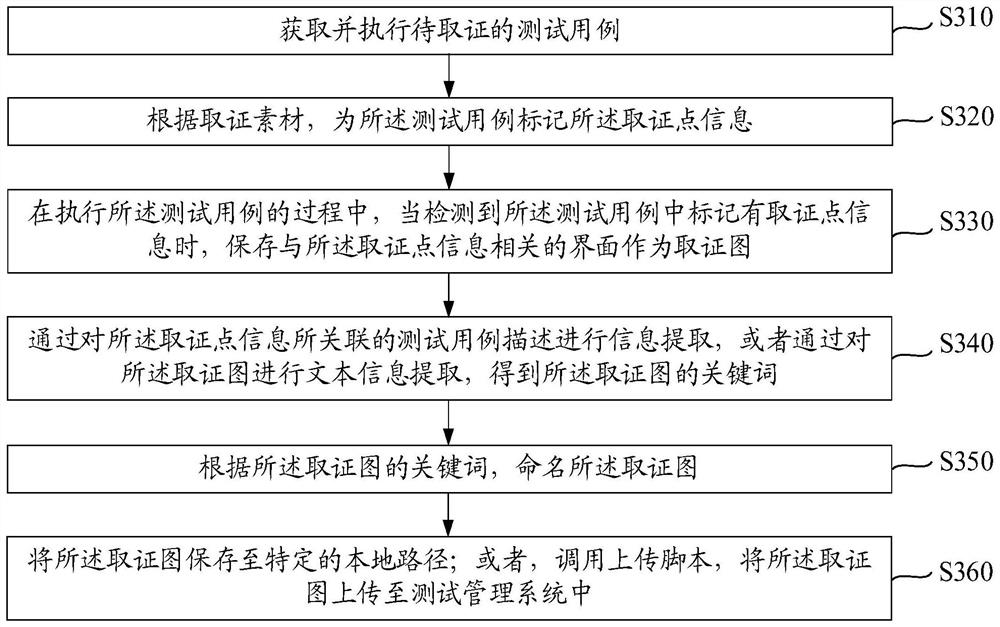

Test evidence obtaining method and device, equipment and storage medium

PendingCN113806208AAutomated testing and forensicsNo human intervention requiredInterprogram communicationSoftware testing/debuggingReliability engineeringComputer engineering

The invention discloses a test evidence obtaining method. The method comprises the steps of obtaining and executing a test case to be subjected to evidence obtaining; and in the process of executing the test case, when it is detected that evidence obtaining point information is marked in the test case, storing an interface related to the evidence obtaining point information as an evidence obtaining graph. In this way, full-automatic screenshot is achieved, manual intervention is not needed, reworking is avoided, efficiency is greatly improved, and human input is reduced. The invention further provides a test evidence obtaining device, equipment and a storage medium.

Owner:CHINA MOBILE SUZHOU SOFTWARE TECH CO LTD +1

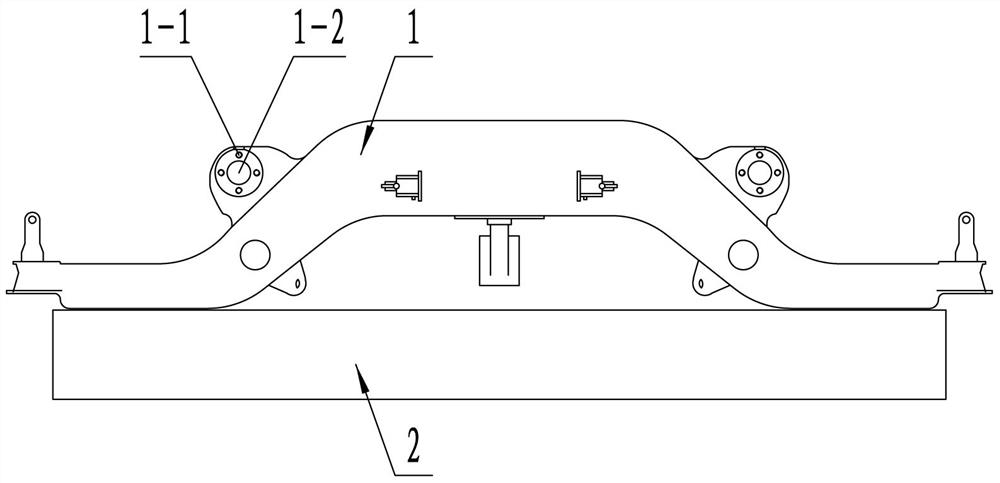

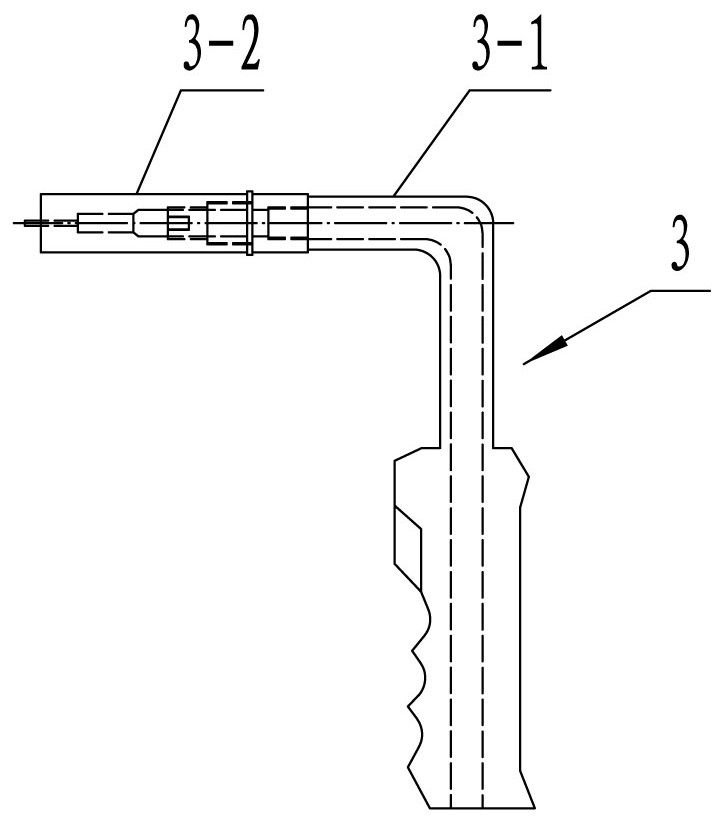

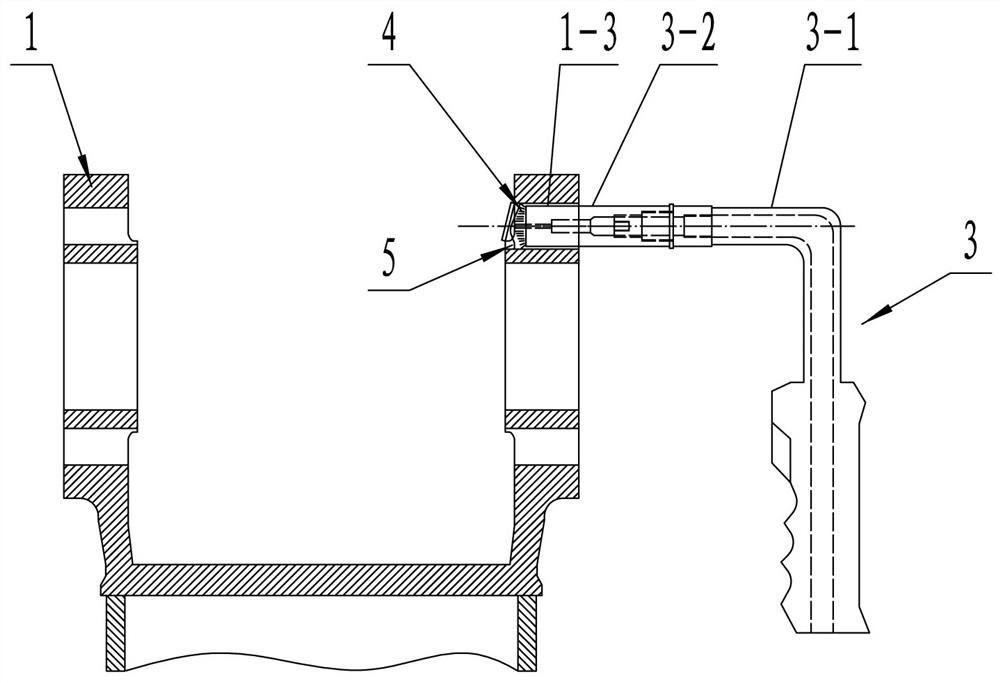

Method for repairing transverse threaded holes of bogie of passenger train

ActiveCN112846635AImprove repair efficiencyHigh precisionVehicle dissasembly recoveryBogieShielding gas

The invention discloses a method for repairing transverse threaded holes of a bogie of a passenger train, and relates to the technical field of rail transit equipment repairing. The method comprises the steps of 1, detecting, 2 broaching, 3 blocking the holes, 4 drilling bottom holes, 5 tapping and 6 inspecting. In the step 1, the bogie is placed on a maintenance platform, the threaded holes in the bogie are transversely arranged, and whether each threaded hole is damaged or not is detected; in the step 2, a universal radial drill is used for broaching the damaged threaded holes; in the step 3, the damaged threaded holes are subjected to plugging welding through a special welding gun, the center line of a protective sleeve of the special welding gun is kept parallel to the center line of each expansion hole in the plugging welding process, and a welding bead is covered with protective gas; in the step 4, a corresponding drilling positioning tool is selected and installed according to the positions of the damaged threaded holes, and the universal radial drill is used for drilling the bottom holes in hole blocking parts; and in the step 5, a universal tapping machine installed on a trolley is used for tapping the bottom holes. According to the method, the problems that existing railway carriage bogie threaded hole repairing is low in efficiency, low in precision, high in reworking frequency and low in one-time repairing success rate are solved.

Owner:柳州机车车辆有限公司

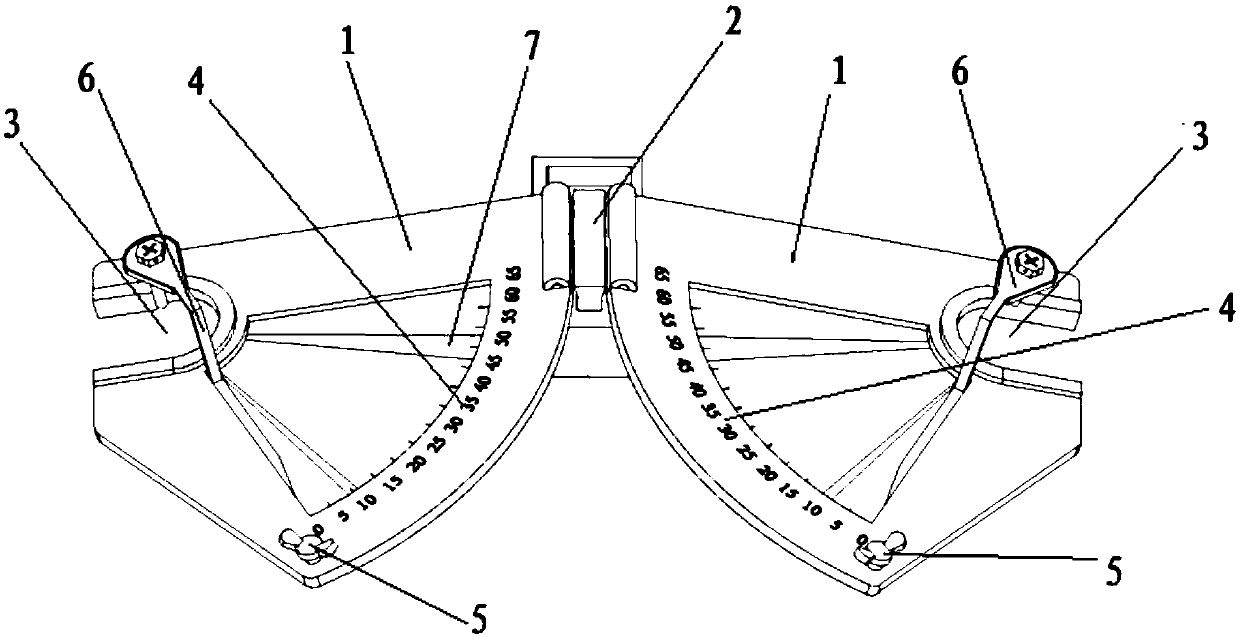

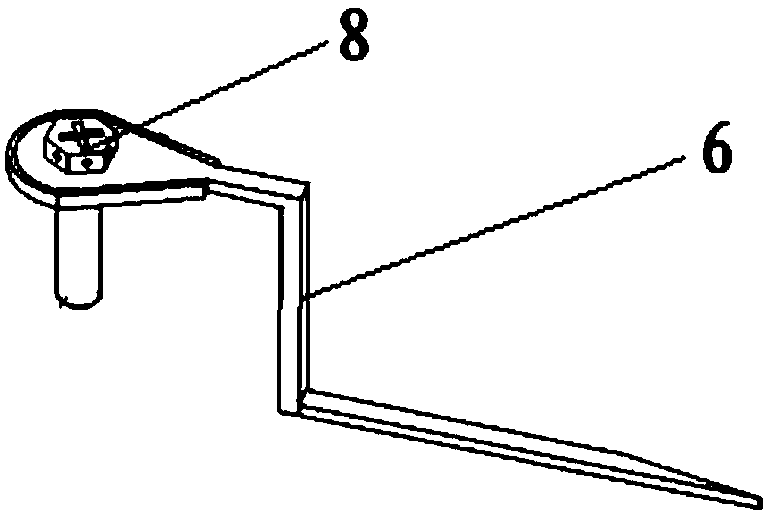

Measurement method and measurement device for rotation angles of aircraft windshield wipers

PendingCN109606733AAct as a support pointImprove measurement efficiencyAircraft components testingMeasurement deviceEngineering

The invention discloses a measurement method and a measurement device for rotation angles of aircraft windshield wipers. The measurement device comprises two symmetrical fan-shaped dials and a supporting locating pin subassembly; a U-shaped opening is disposed in a central position of each of the fan-shaped dials; an angle marked line is disposed at a distal end of each of the fan-shaped dials; each of the fan-shaped dials is provided with a pointer; the U-shaped openings of the two sector-shaped dials are respectively clamped in rotating shaft protection walls of the aircraft windshield wipers; the two symmetrical fan-shaped dials are connected into a whole through the supporting locating pin subassembly; the pointers are respectively fixed on rotating shafts of the two windshield wipers,so that the front ends of the pointers respectively point to zero-degree marked line positions of the fan-shaped dials; the aircraft windshield wipers are started to drive the pointers to rotate so as to implement measurement for the rotation angles of the aircraft windshield wipers.

Owner:XIAN AIRCRAFT IND GROUP

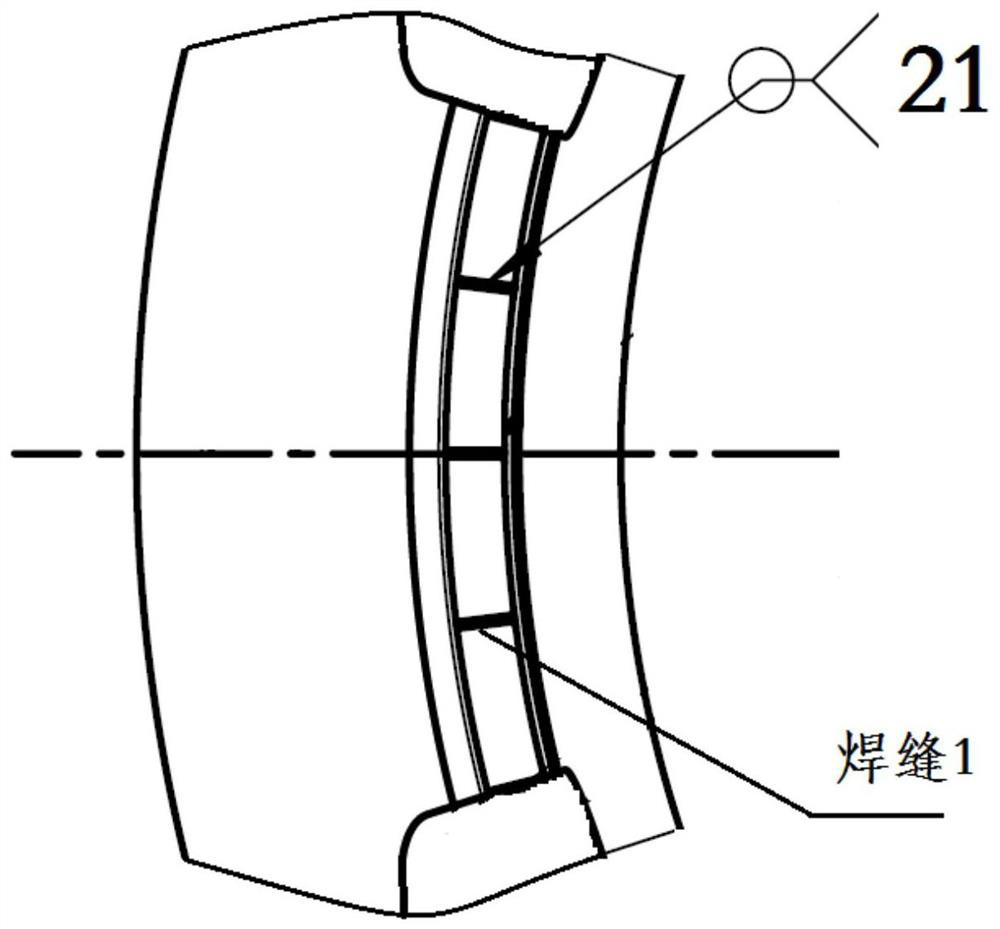

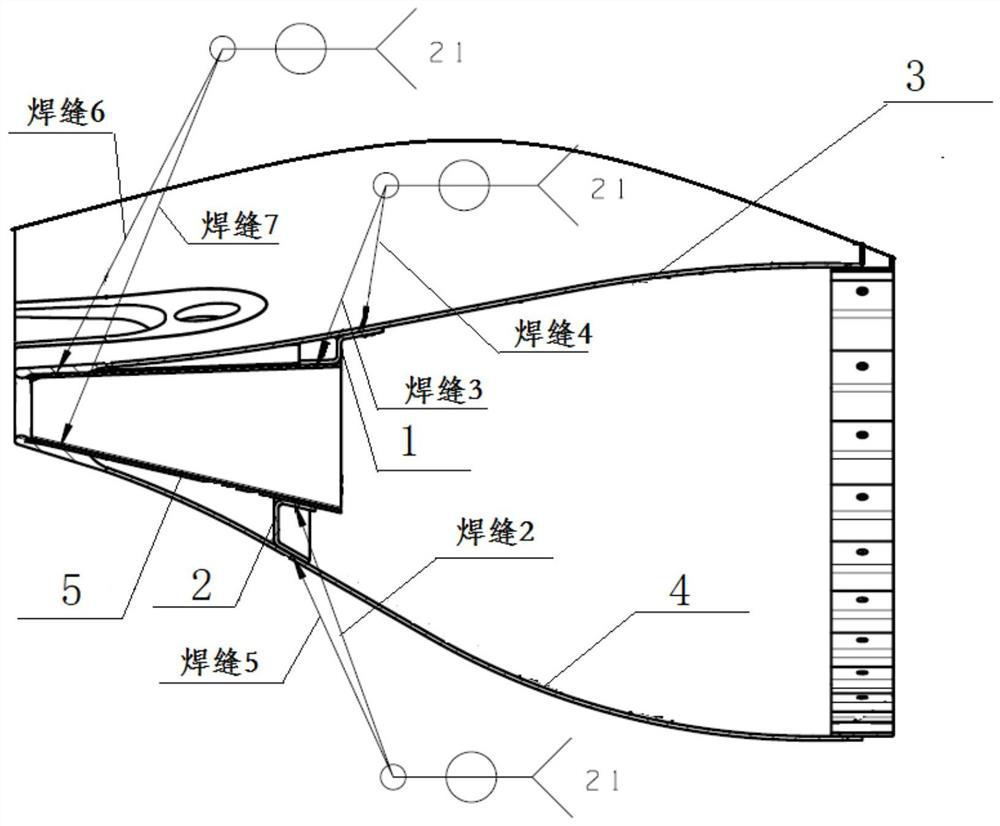

Assembly welding method for ring-shaped thin-walled sheet metal part of gas turbine and welding electrode

ActiveCN112091393AImprove accessibilitySimple structureResistance welding apparatusSpot weldingThin walled

The invention discloses an assembly welding method for a ring-shaped thin-walled sheet metal part of a gas turbine and a welding electrode. The welding electrode is divided into an upper electrode anda lower electrode of different shapes; during assembly welding, multiple pressure diffusing boxes are connected by spot-welding, are separately welded with a first reinforcing ring and a second reinforcing ring to define an integer; then, the pressure diffusing boxes, the first reinforcing ring and the second reinforcing ring are integrally arranged in a ring-shaped channel with inner and outer rings, the first reinforcing ring and the inner ring as well as the second reinforcing ring and the outer ring are separately welded to finally accomplish spot-welding connection of all pressure diffusing boxes, the inner ring and the outer ring. A welding sequence of the assembly welding method ensures welding among multiple assemblies without interference, and is stable in welding quality; and different welding electrodes are used for different welding positions to realize welding, in a narrow space, of a ring-shaped sheet metal assembly part.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Plastic surface hardening treatment method

The invention relates to the technical field of plastic products and discloses a plastic surface hardening treatment method.The method includes steps: cleaning a to-be-treated plastic part in deionized water at 50-60 DEG C for 15-20min, spraying and drying; filtering photocuring paint through a 600-1200-mesh screen, performing infrared drying for 20-25min at 60-65 DEG C, and performing cooling and leveling for 1-3min at the room temperature, wherein a spray coating pressure is 32-38kg / cm<2>; subjecting a formed coating to ultraviolet curing for 1-3min at 40-50 DEG C.By the plastic surface hardening treatment method, the problems of high cost and high paint waste in existing plastic surface hardening are solved.

Owner:广西柳州中嘉知识产权服务有限公司

Cleaning method for mushroom culture bottles

InactiveCN106583381AReduce manufacturing costLabor savingHollow article cleaningWater savingCleaning methods

The invention provides a cleaning method for mushroom culture bottles. In the cleaning method, the multiple culture bottles are loaded in a whole frame, bottle openings are arranged downwards, and rotation and water spraying cleaning is conducted through brushes with the radius larger than the inner diameter of the bottle openings. The cleaning method has the beneficial effects that cleaning can be conducted at any time, cleaning is thorough, reworking is not needed, the cleaning number is considerable, assembly line production is achieved, operation is simple, and water utilization and manual work are saved.

Owner:江苏东越生物技术发展股份有限公司

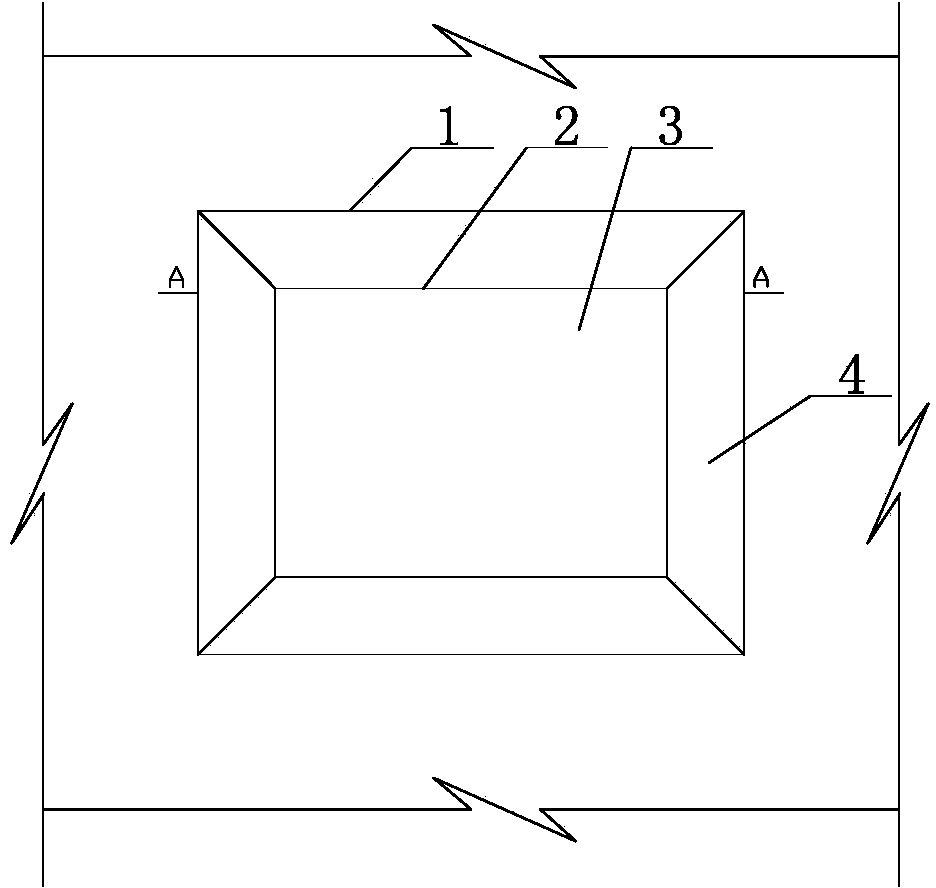

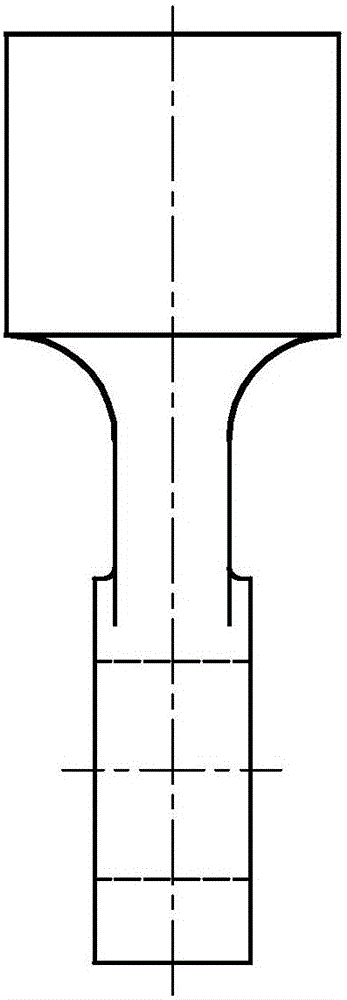

Installing and welding tool for installing and welding pressing mechanism

ActiveCN104526240AGuaranteed flatnessGuaranteed validityWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWelding

The invention discloses an installing and welding tool for an installing and welding pressing mechanism. The installing and welding tool comprises a base (12) and an installing and welding platform (1) installed at the upper portion of the base (12). The installing and welding platform (1) is provided with a through hole used for containing an inner thread sleeve (2) of the pressing mechanism, a step of the inner thread sleeve (2) is clamped on the upper surface of the installing and welding platform (1) through the through hole, limiting check blocks (4) used for clamping a pressing block (3) of the pressing mechanism are arranged on the upper surface in pairs, the paired limiting baffles (4) are arranged around the through hole, the center lines of the limiting check blocks (4) point at the through hole, and gaps used for performing welding are formed between the limiting check blocks (4) and the through hole. By means of the mode, operation is convenient, accurate positioning is easy, a whole inner four-claw material cover can effectively act, existing functions are guaranteed, unnecessary reworking cannot be caused, and meanwhile optimization of the manufacturing procedure and the achievement of batch production are facilitated.

Owner:ANHUI XINGMA SPECIAL PURPOSE VEHICLE

Hardening treatment method for surface of plastic

The invention discloses a hardening treatment method for a surface of a plastic and relates to the technical field of plastic products. The method comprises the following steps of putting a to-be-treated plastic part in deionized water at 50-60 DEG C to be cleaned for 15-20 min, spraying the plastic part and drying the plastic part; filtering photocuring paint with a 600-1200-mesh screen, whereinthe spraying pressure is 32-38 kg / cm<2>, drying the plastic part for 20-25 min with infrared rays at 60-65 DEG C, and carrying out cooling and leveling for 1-3 min at room temperature; and forming a coating by ultraviolet curing, wherein the curing temperature is 40-50 DEG C and the time is 1-3 min. The method solves the problems that much paint is wasted and the cost is high as the surface of theplastic is hardened in the prior art.

Owner:宁波晶牧太阳能科技有限公司

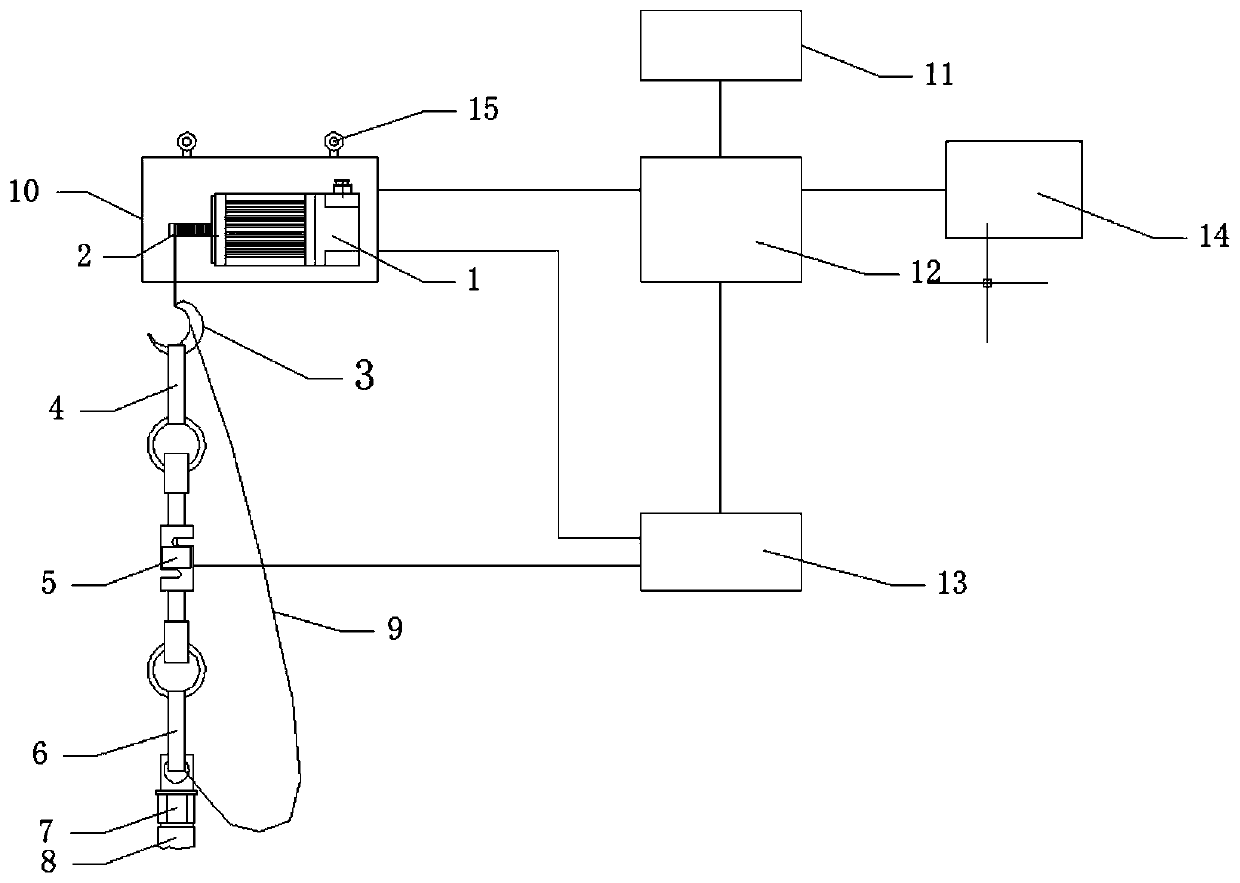

Friction force test device for reactor control rod driving mechanism

PendingCN111312416ASave human effortEliminate mistakesNuclear energy generationNuclear monitoringNuclear powerEngineering

The invention belongs to the technical field of nuclear power station reactor maintenance, and specifically relates to a friction force test device for a reactor control rod driving mechanism. The friction force test device comprises a servo motor, a steel cable, a lifting hook, annular lifting belts, an S-shaped tension sensor, a driving rod transportation tool, a driving rod and a driver, wherein the driver is hung below a cantilever crane through hanging lugs; the servo motor is arranged in the driver; the driving end of the servo motor is connected with the lifting hook through the steel cable; the S-shaped tension sensor is hung at the lower end of the lifting hook through a first annular lifting belt; the driving rod transportation tool is hung on the S-shaped tension sensor througha second annular lifting belt; and the driving rod is hung on the driving rod transportation tool. According to the invention, manpower is liberated; the working efficiency and reliability are improved; and the possibility of errors caused by human factors is eliminated.

Owner:JIANGSU NUCLEAR POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com