Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Eliminate mistakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

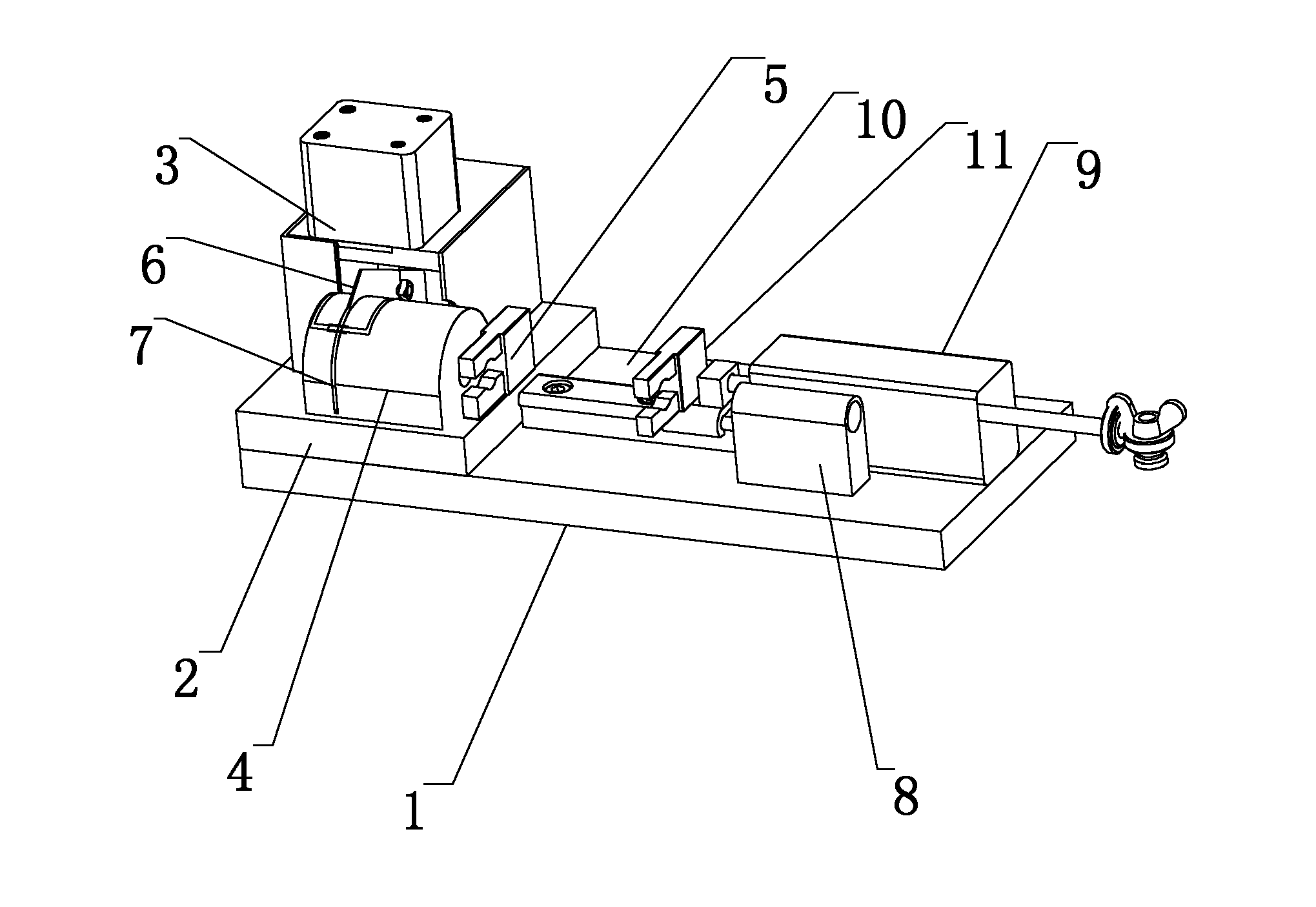

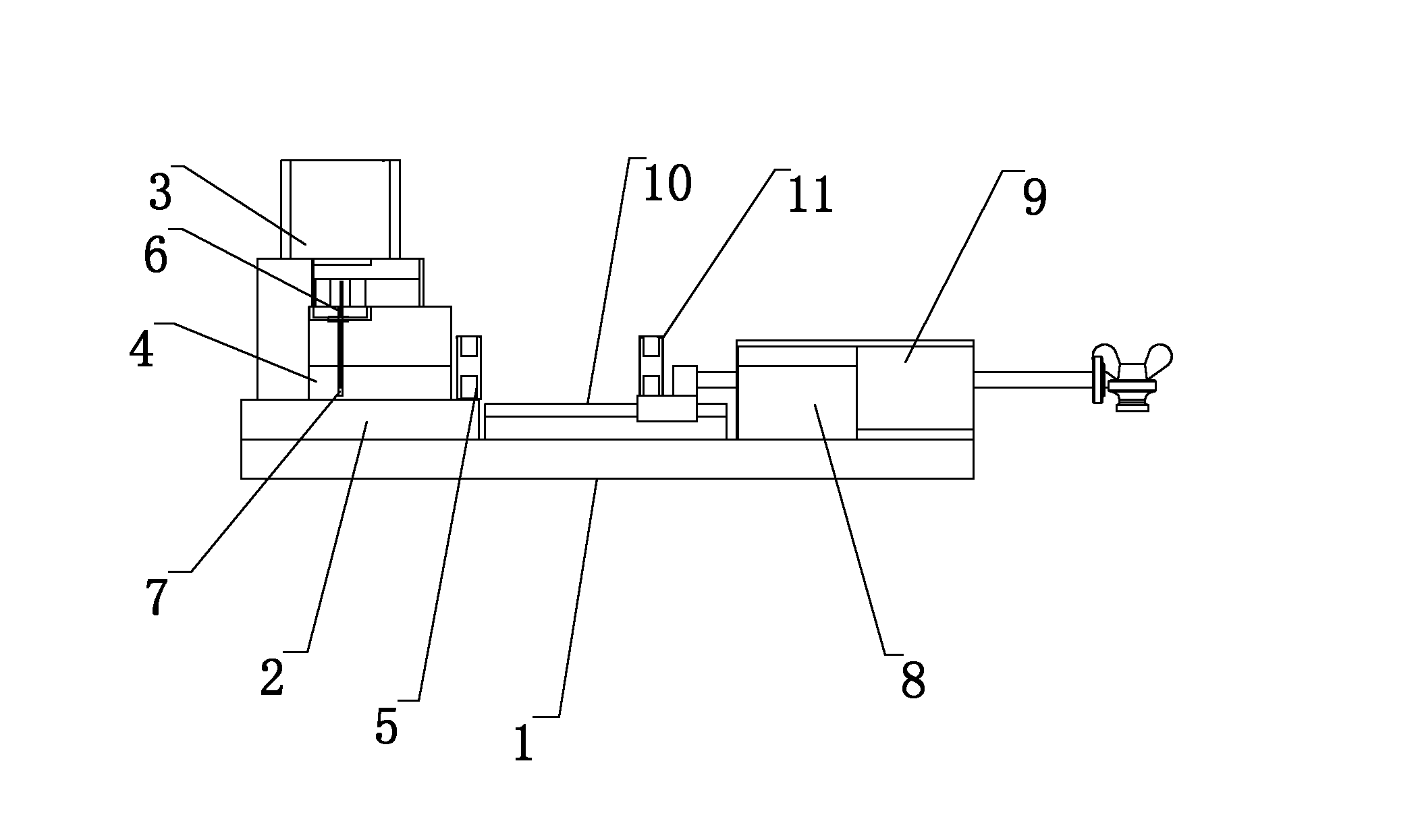

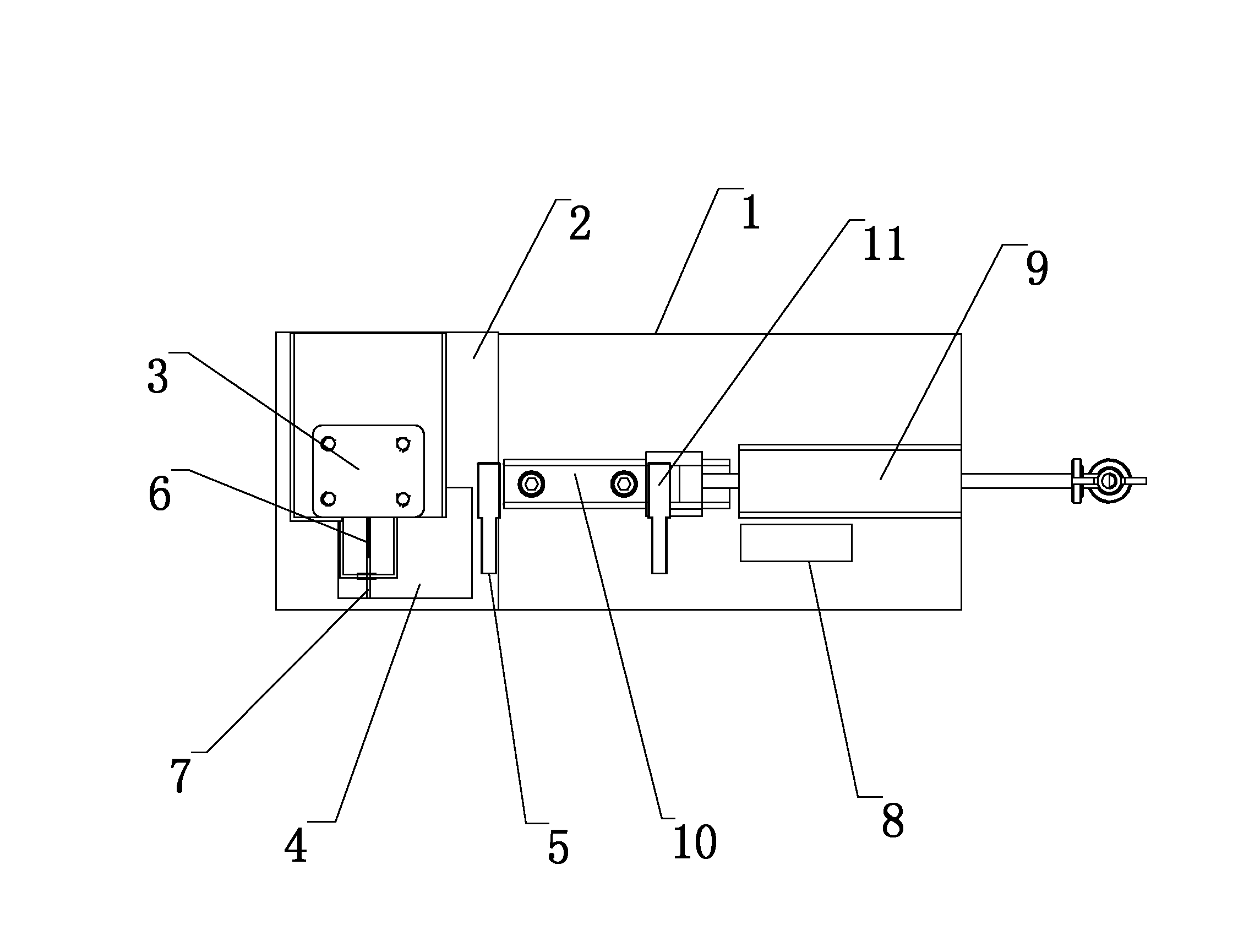

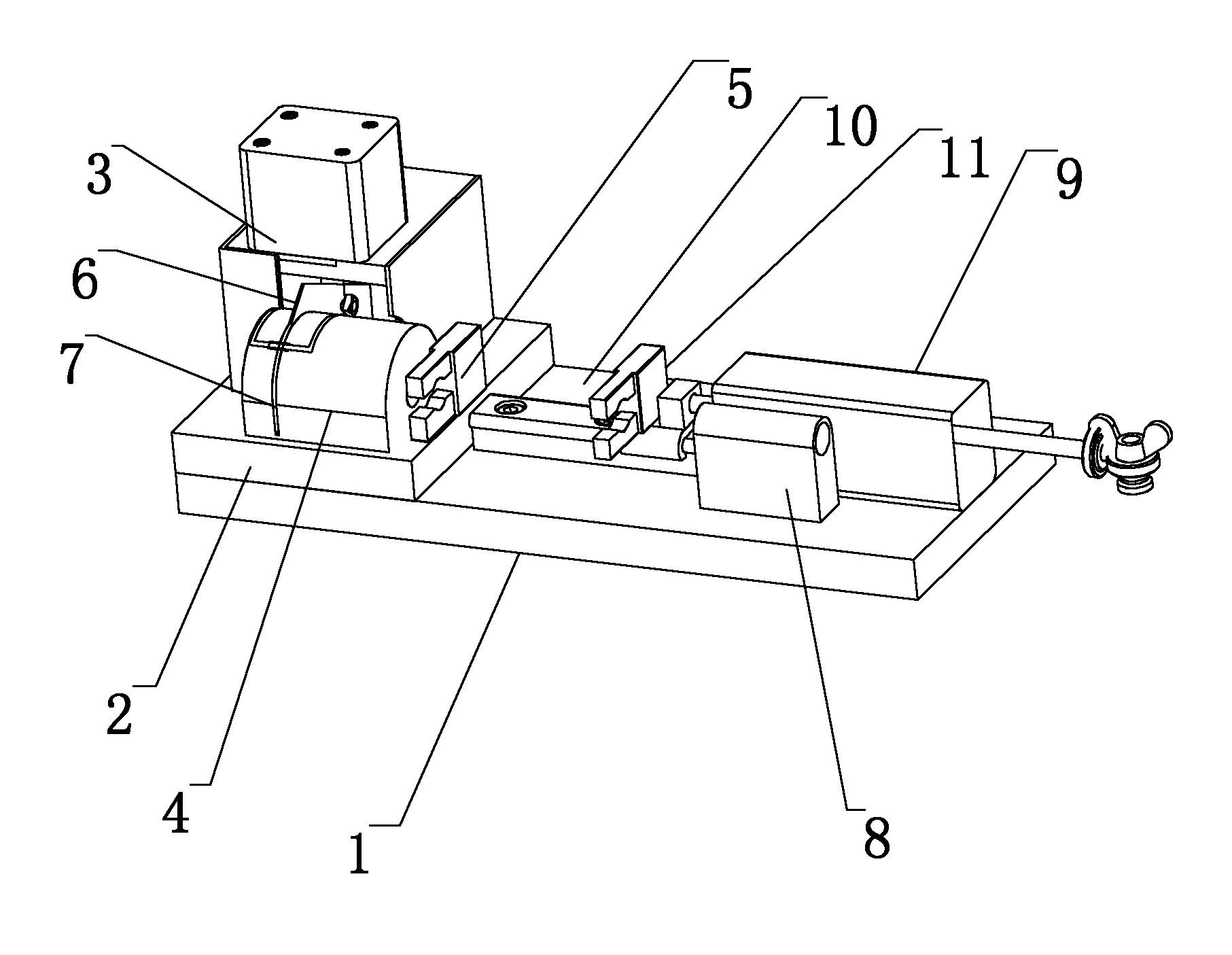

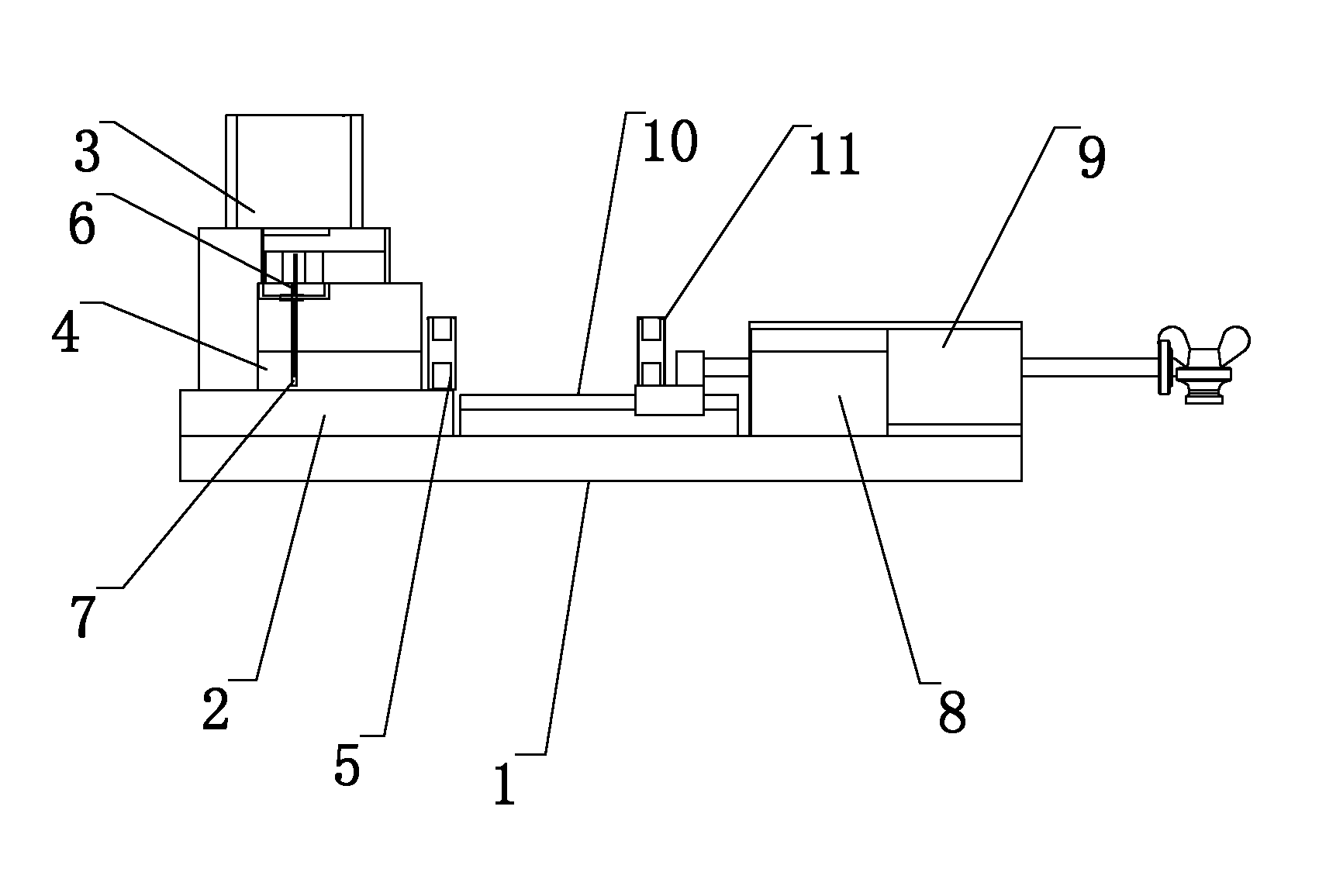

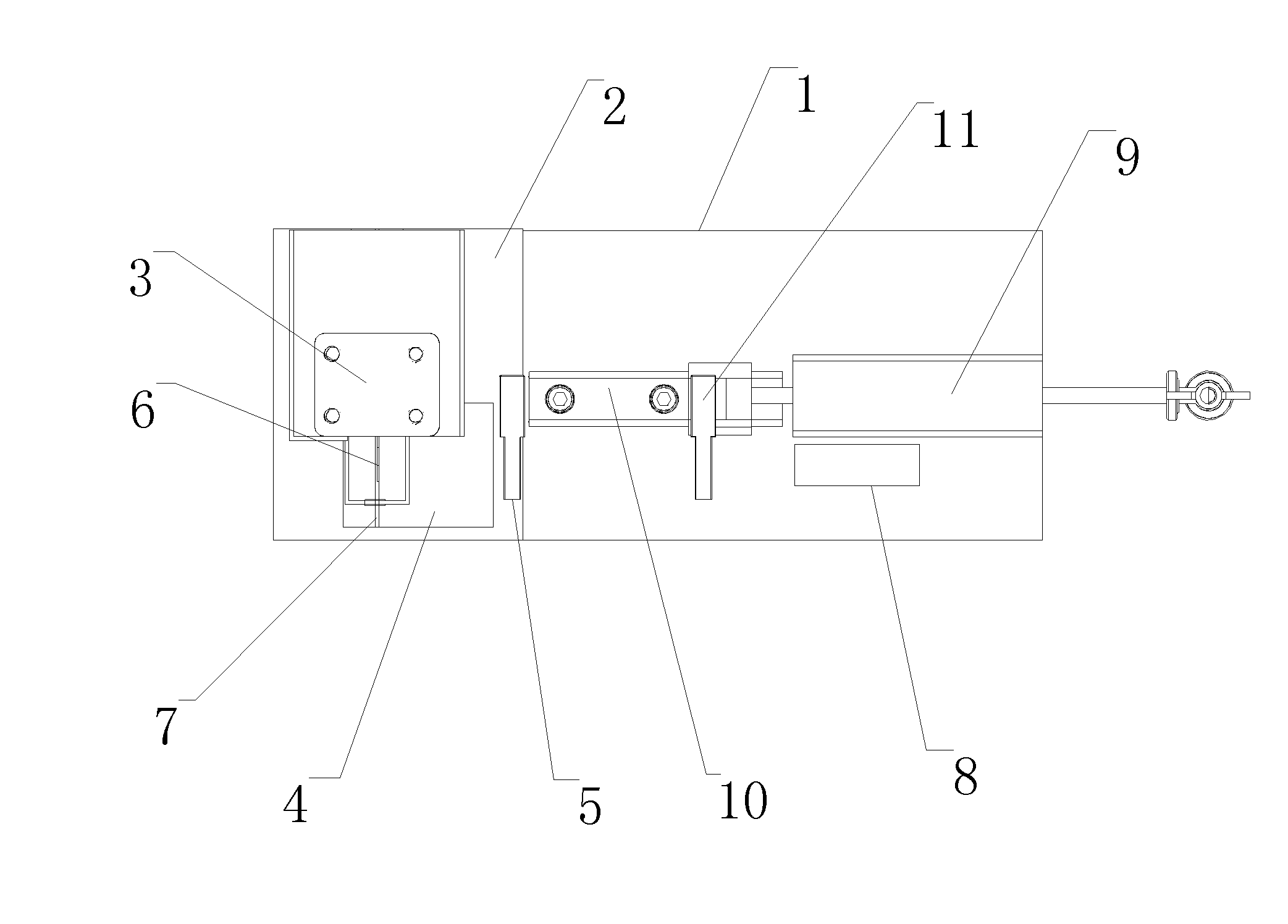

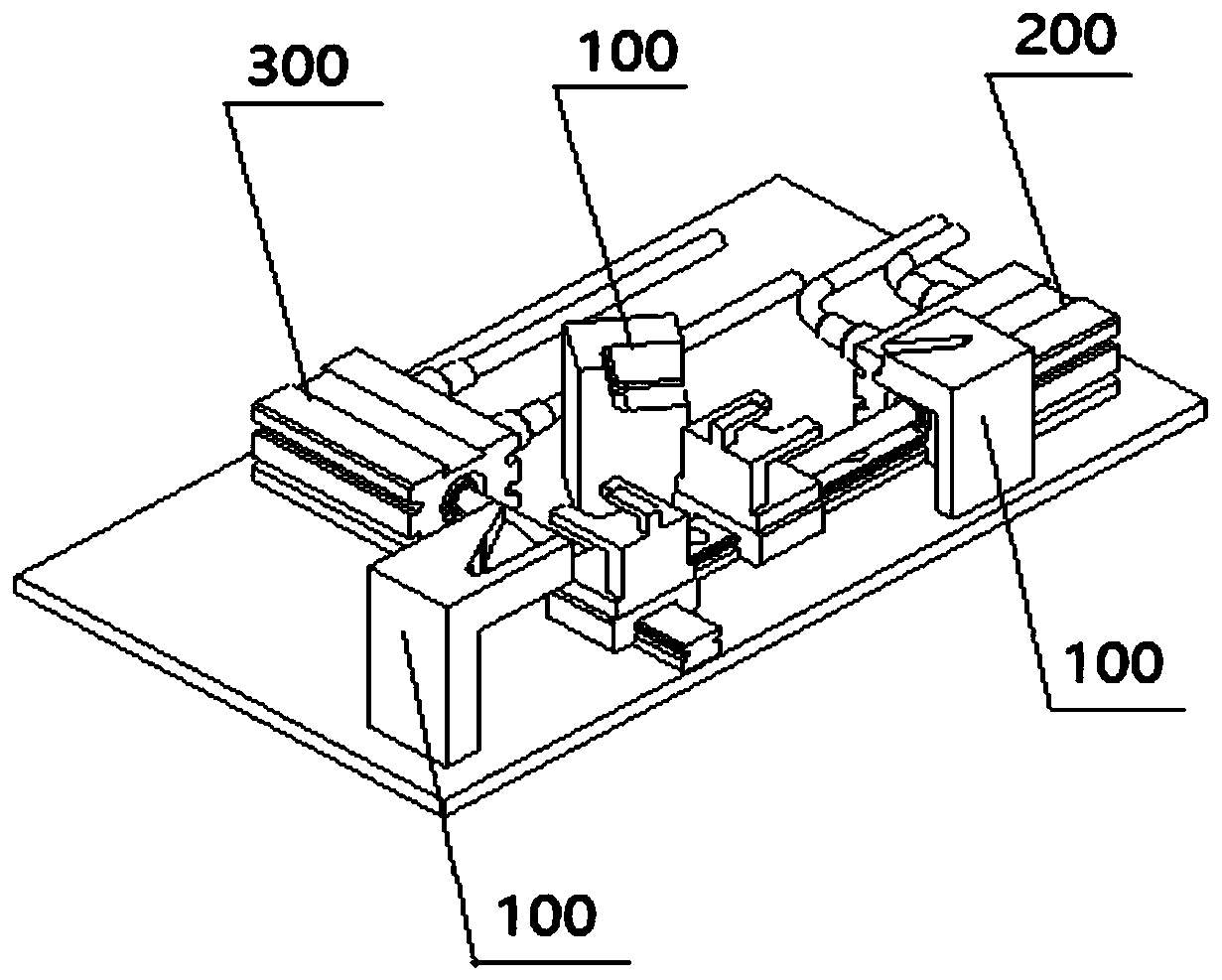

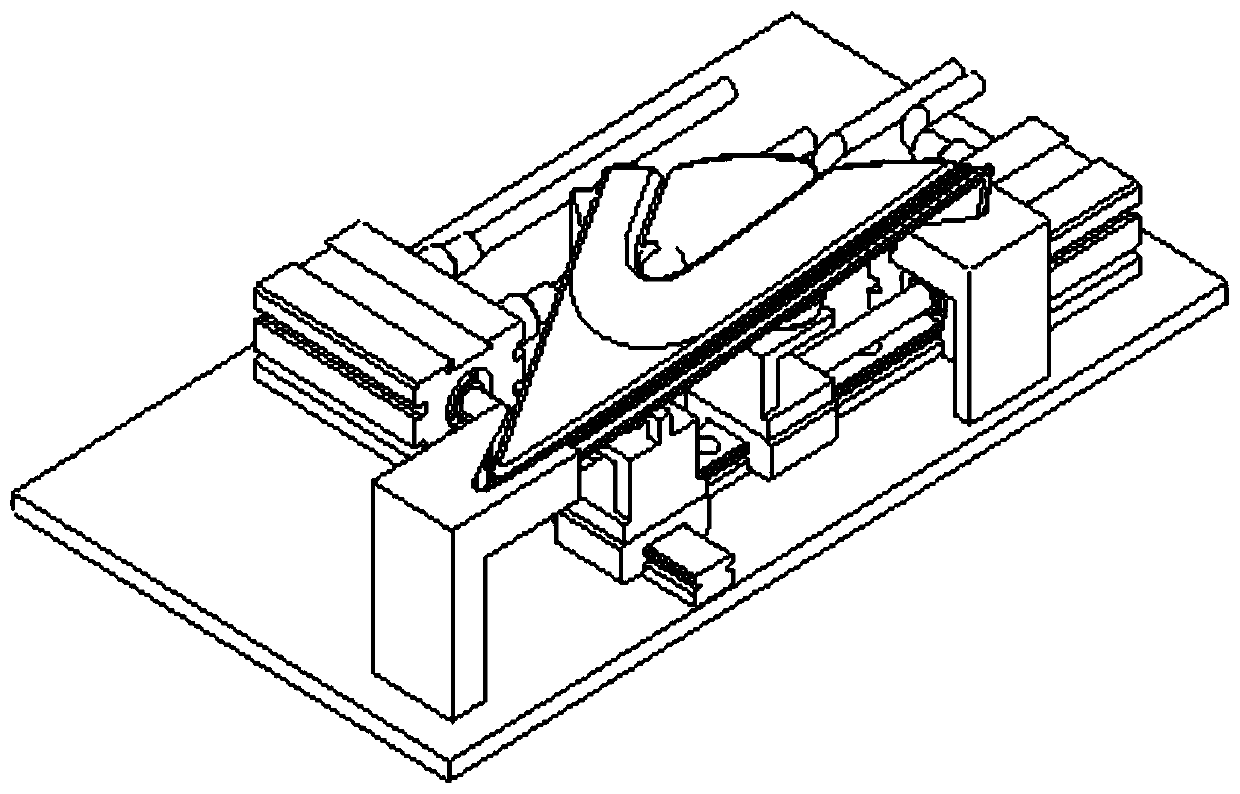

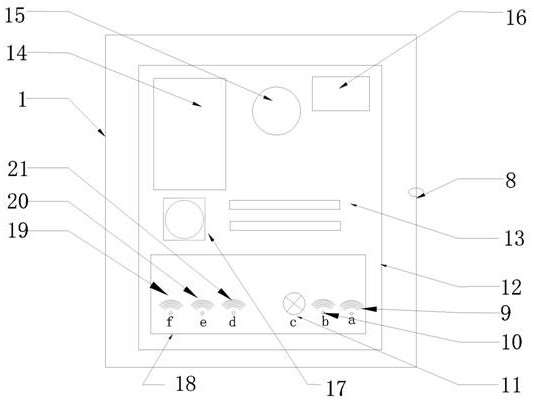

Corrugated pipe cut-off machine

ActiveCN102601443AShort tripReduce labor intensityTube shearing machinesShearing machine accessoriesDouble-timeSemi automatic

The invention relates to a corrugated pipe cut-off machine, which comprises a base. A boss is arranged at one end of the base, a cut-off cylinder and a first guide pipe are disposed on the boss, a second clamping cylinder is arranged on one side of the first guide pipe, a cutter is connected onto the cut-off cylinder and matches with a groove on the first guide pipe, a second guide pipe and an adjustable cylinder are arranged at the other end of the base, a linear guide track is disposed between the adjustable cylinder and the cut-off cylinder, and a first clamping cylinder is arranged on the linear guide track. The corrugated pipe cut-off machine has the advantages that electric elements including the four cylinders, a double-time setting relay, a counter, an electromagnetic valve and the like are integrated, and functions of an automatic corrugated pipe feeding device are realized by means of linkage of the cut-off cylinder, the adjustable cylinder and the two clamping cylinders. In addition, strokes of the cylinders are short, the running speed is fast, labor intensity of staffs is greatly reduced, semi-automatic pipe cutting operation is realized, cost investment is low, production efficiency is high, consumed working hours per capita can be reduced, and potential safety hazards caused by operational fatigue are eliminated.

Owner:TIANJIN GREAT WALL LEAN AUTOMOTIVE PARTS CO LTD

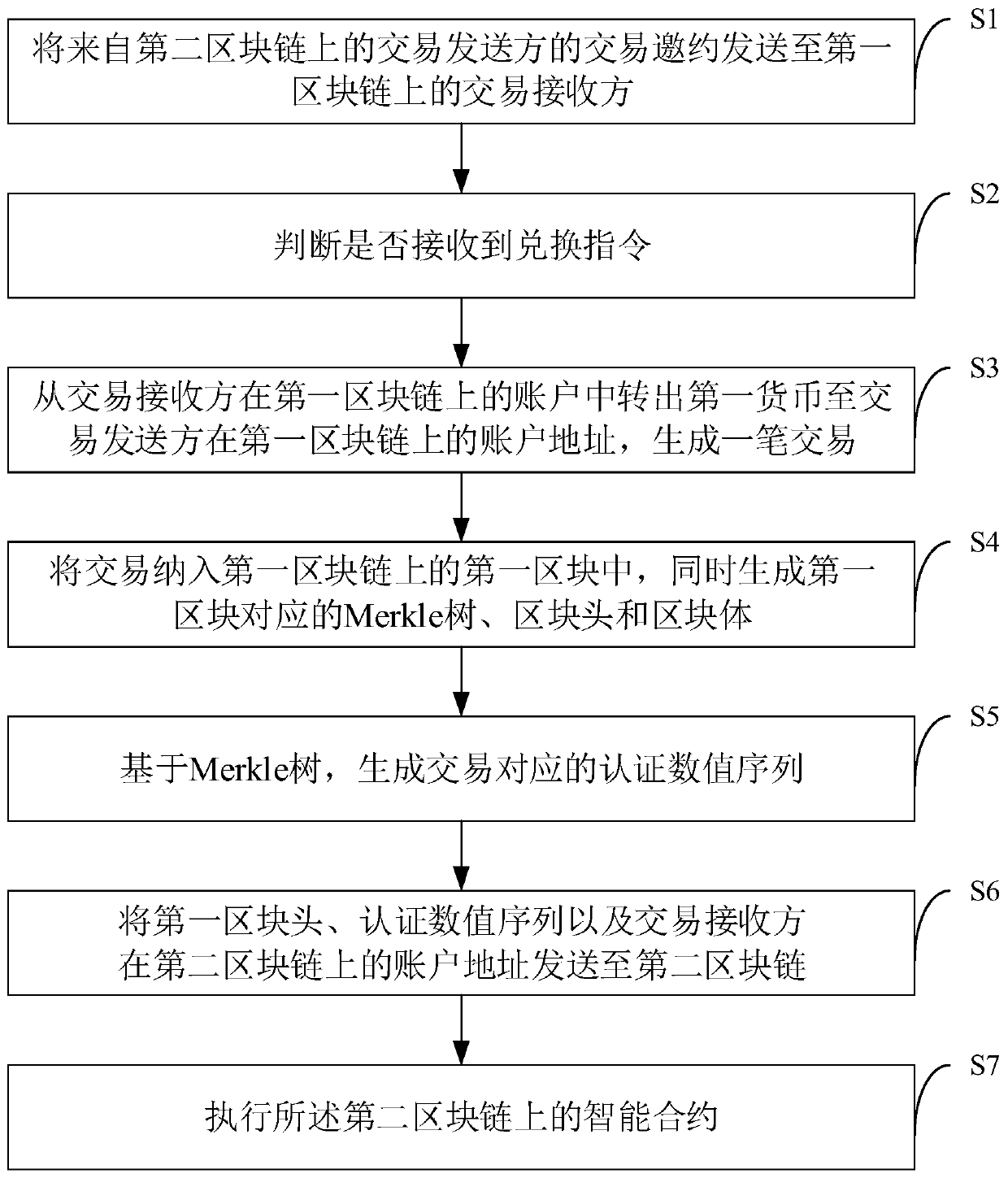

Cross-chain digital currency exchange method and device, computer system and storage medium

PendingCN109886661ASimple Payment VerificationGuarantee fairnessPayment protocolsPayment circuitsDigital currencyComputerized system

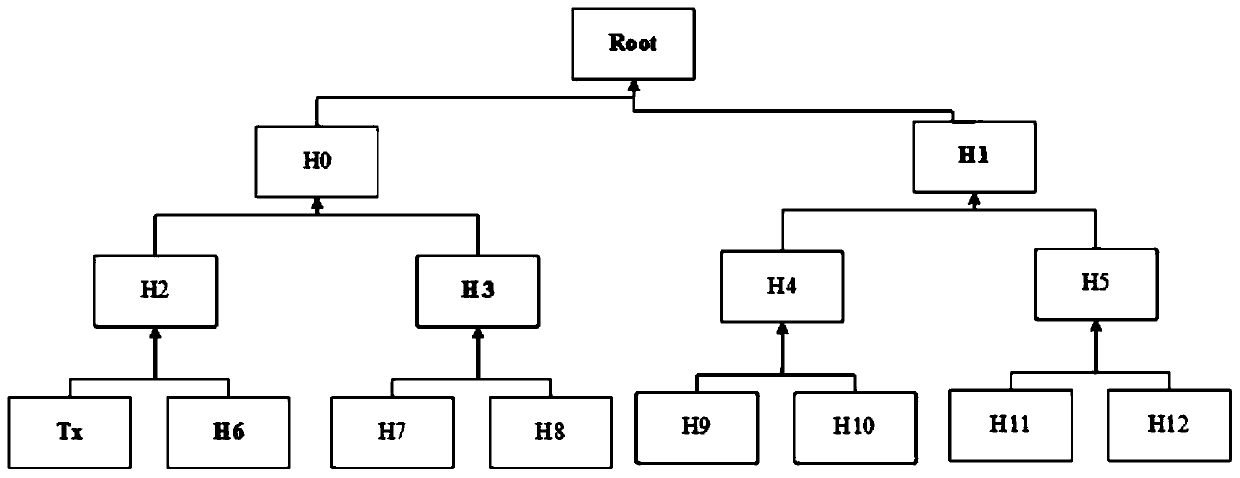

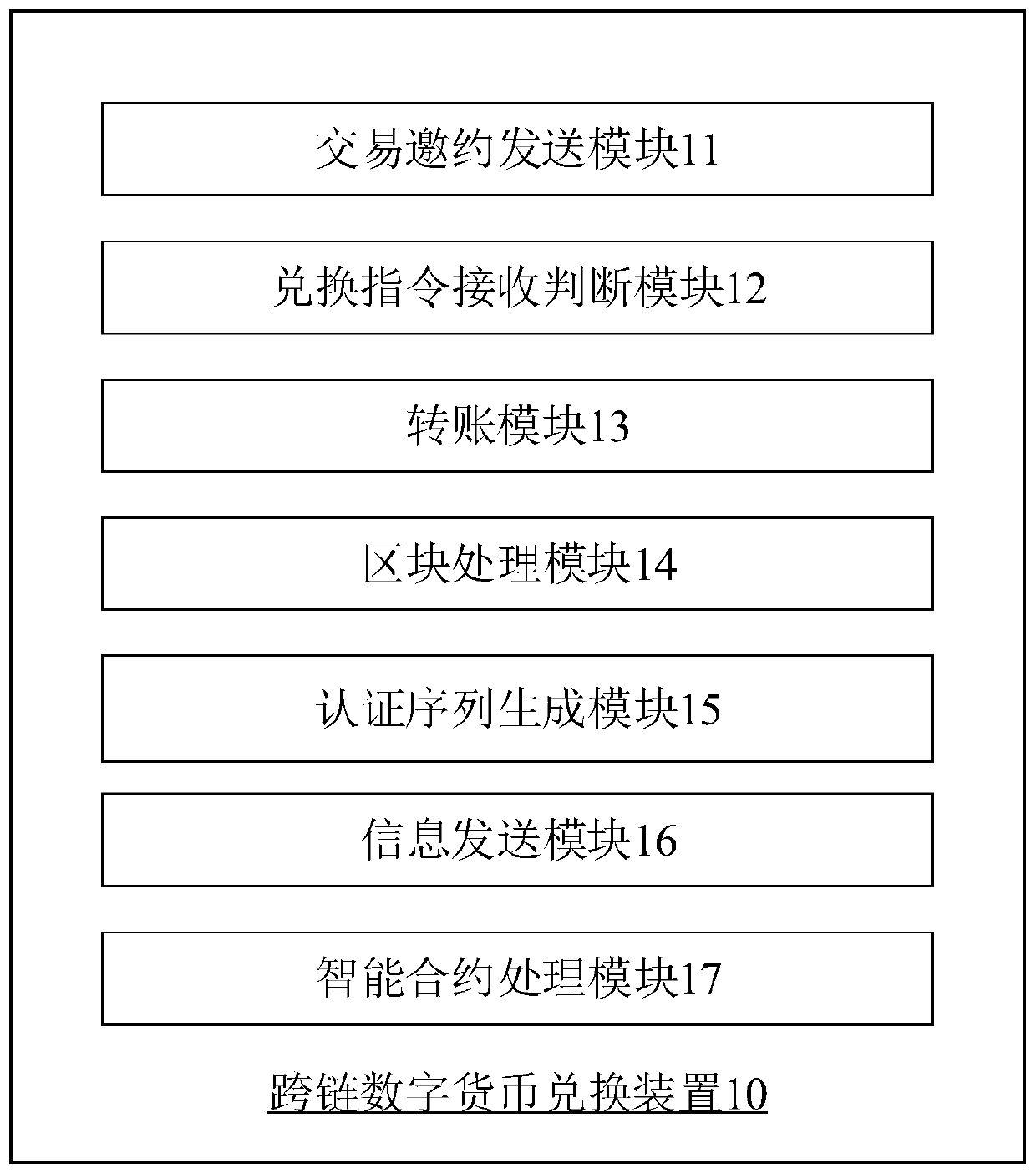

The invention provides a cross-chain digital currency exchange method and device, a computer system and a storage system. The method comprises the steps of sending a transaction invitation from a transaction sender on a second block chain to a transaction receiver on a first block chain; judging whether an exchange instruction is received or not; transferring the exchanged number of first currencies from the account of the transaction receiver on the first block chain to the account address of the transaction sender on the first block chain to generate a transaction; incorporating the transaction into a first block on a first block chain; generating an authentication value sequence corresponding to the transaction; sending the first block head of the block, the authentication value sequence and the account address of the transaction receiver on the second block chain to the second block chain; and executing the smart contract on the second block chain to verify the transaction, and ifthe verification is passed, transferring the second currency from the account of the transaction sender on the second block chain to the account address of the transaction receiver on the second blockchain. According to the invention, the monopoly operation of a centralized transaction station is eliminated.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

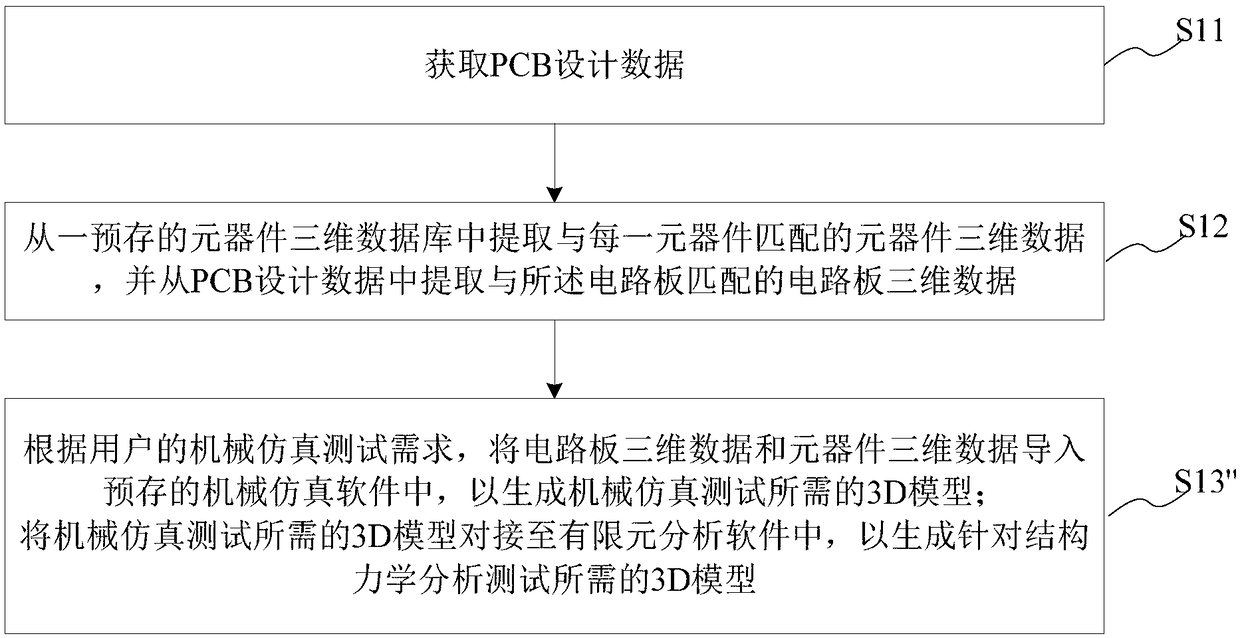

3D simulation data generation method and system, computer storage medium and device

InactiveCN109446600AEliminate mistakesShorten the timeSpecial data processing applications3D modellingSimulation3d simulation

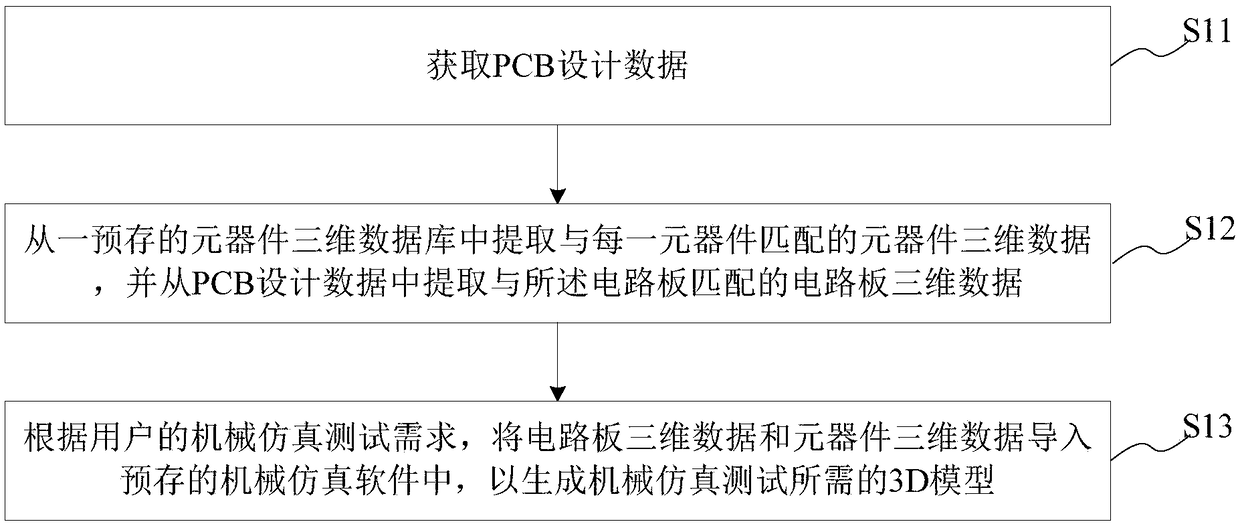

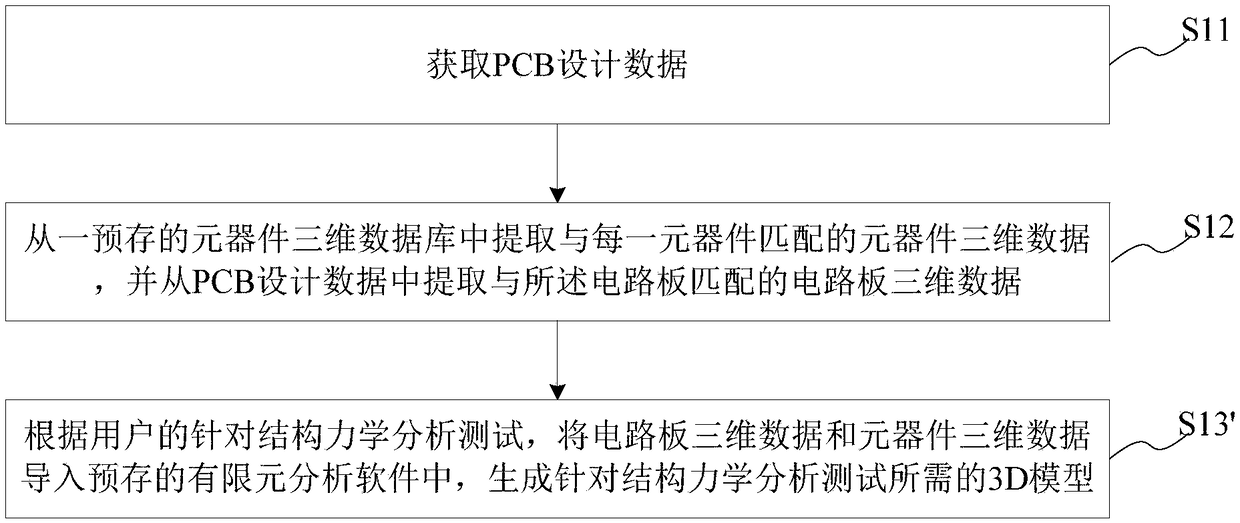

The invention provides a 3D simulation data generation method and system, a computer storage medium and a device. The generation method comprises the following steps of obtaining the PCB design data;extracting three-dimensional data of components from a pre-stored three-dimensional database of components and extracting three-dimensional data of circuit board; according to the test requirements ofusers, importing the 3D data of circuit board and components into the pre-stored mechanical simulation software to generate the 3D model for mechanical simulation test; or importing the three-dimensional data of circuit board and components into the pre-stored finite element analysis software to generate the three-dimensional model needed for structural mechanics analysis and testing; or dockingthe 3D model needed for mechanical simulation test into the finite element analysis software to generate the 3D model needed for structural mechanics analysis test. The invention can eliminate a lot of repetitive work, replace the manual work with automation, reduce the working difficulty, and realize the fast conversion of PCB design data to simulation software.

Owner:VAYO SHANGHAI TECH

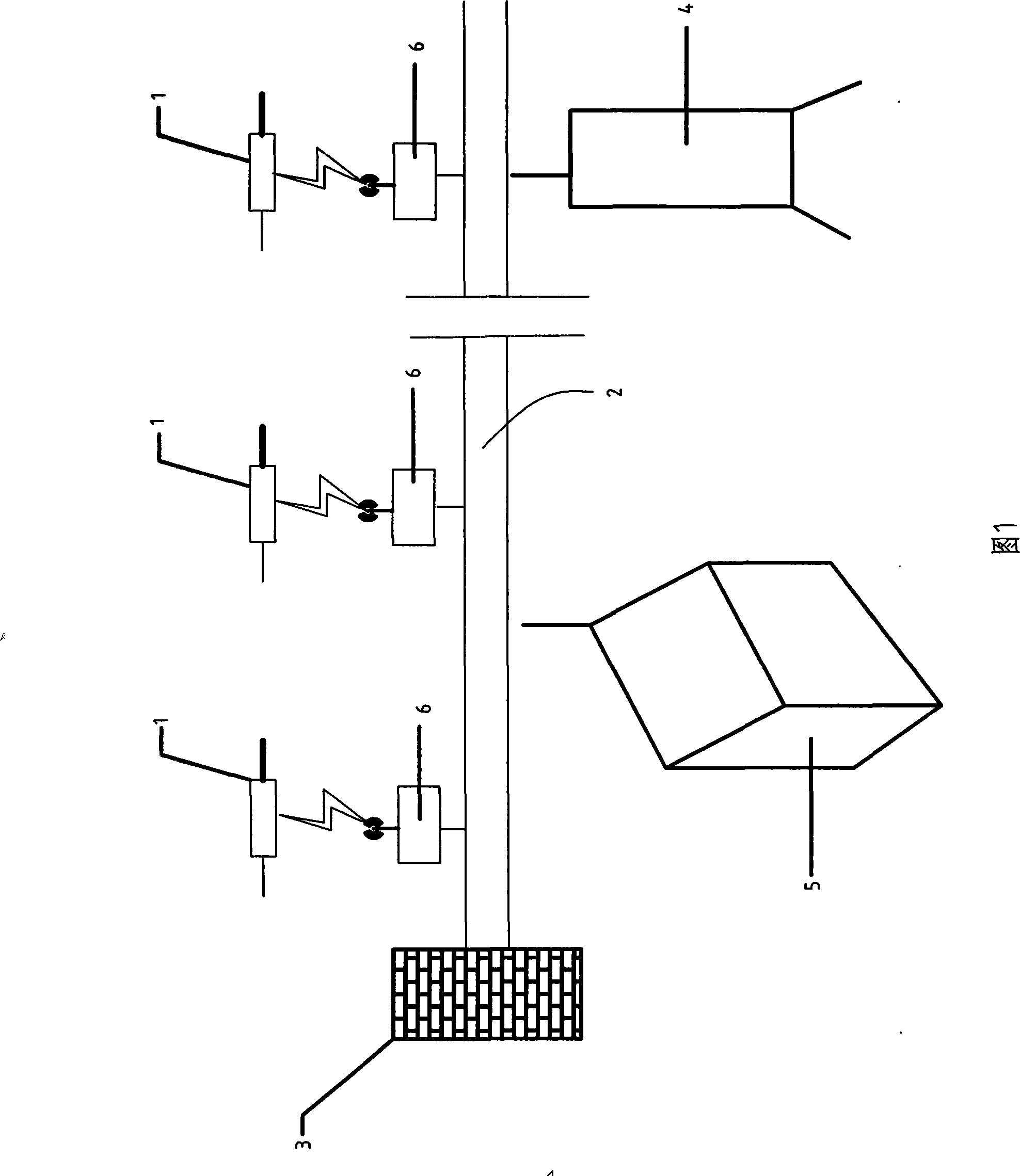

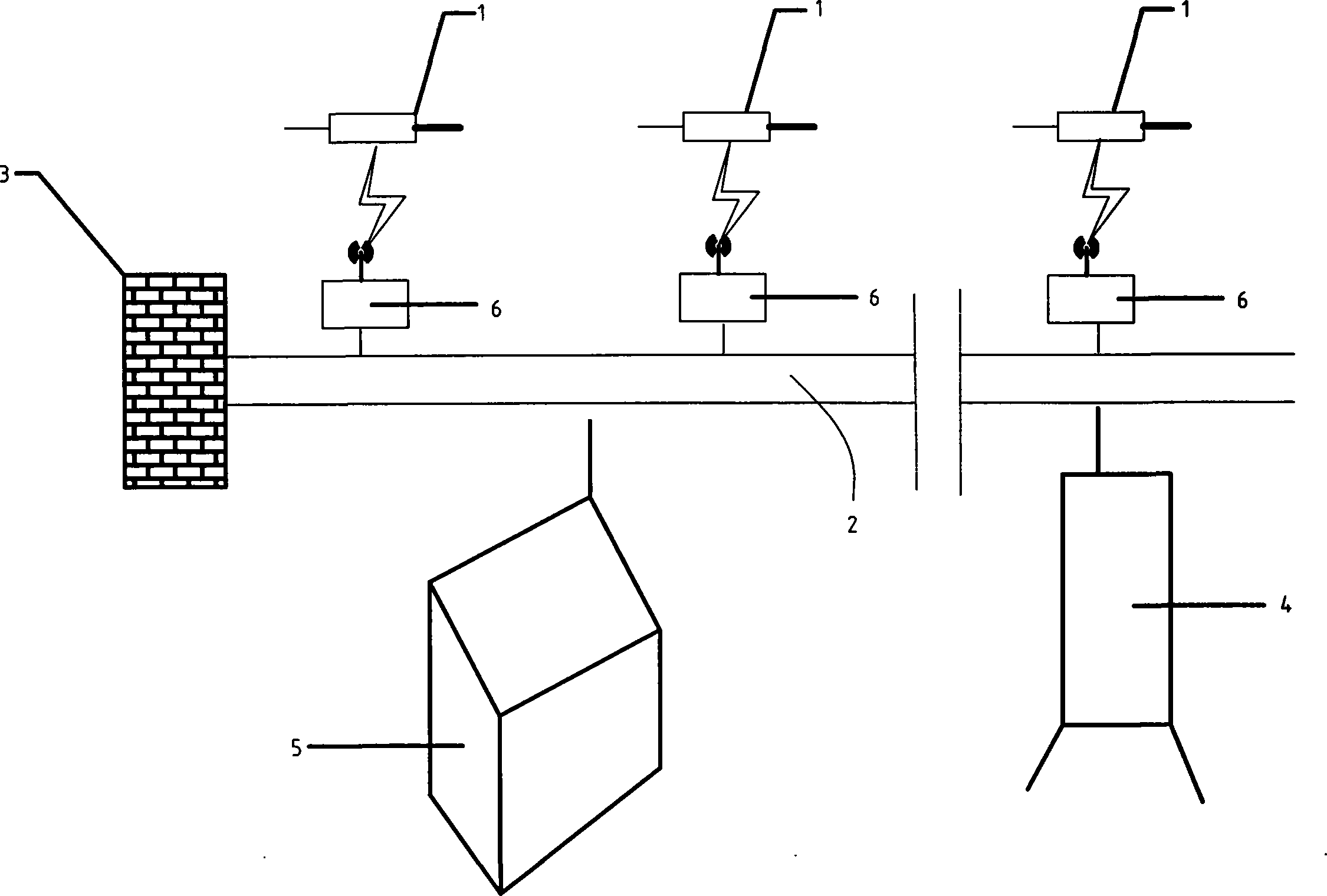

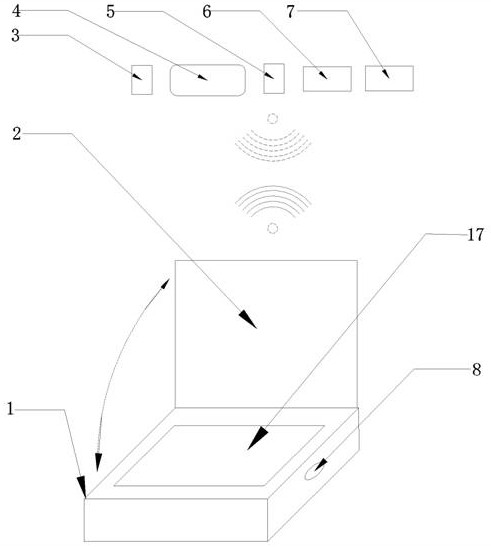

Wireless tool control system and method for vehicle assembly and fabrication technique

InactiveCN101470441AImplement security authenticationIncrease the difficulty of malicious damageTotal factory controlProgramme total factory controlQuality controlData processing

Disclosed are a wireless tool control system for automobile assembling and manufacturing techniques and a method thereof, which realize self-adaptive safety certification, working data tracking, preventing and collecting errors in the producing process of all wireless tools on the automobile assembling and manufacturing line, and realize real-time control, data process and working record storage simultaneously. The wireless tool control system comprises at least one wireless tool, an Ethernet network of the automobile manufacture production line, an enterprise firewall embedded in the Ethernet network of the automobile manufacture production line, and a production line monitor center which is connected with the Ethernet network of the automobile manufacture production line and is provided with a human-machine interface, wherein a control system of the wireless tool is provided with a quality control servo unit, the quality control servo unit is provided with a data storage system, the data storage system is provided with a quality data base, the control system of the wireless tool is equipped with at least one Ethernet serial server and is embedded with a safety certification system, and the safety certification system allocates one identification certificate for each wireless tool, and each identification certificate is different from each other.

Owner:广州信邦智能装备股份有限公司

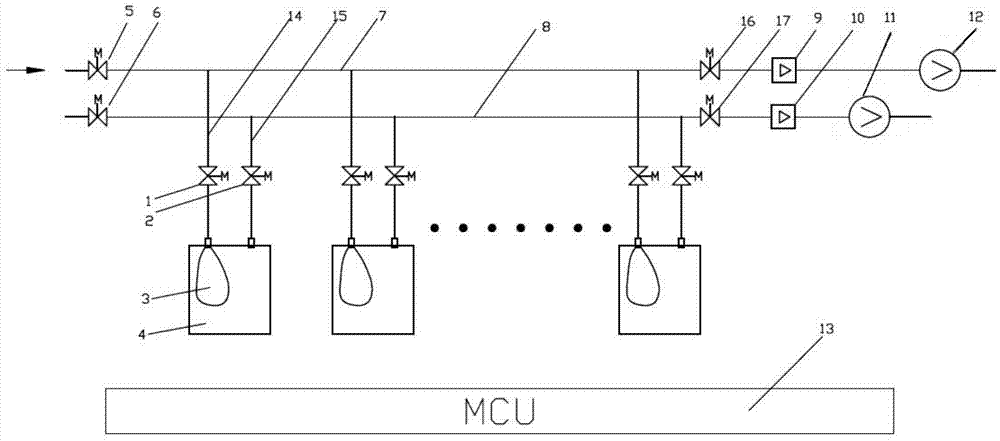

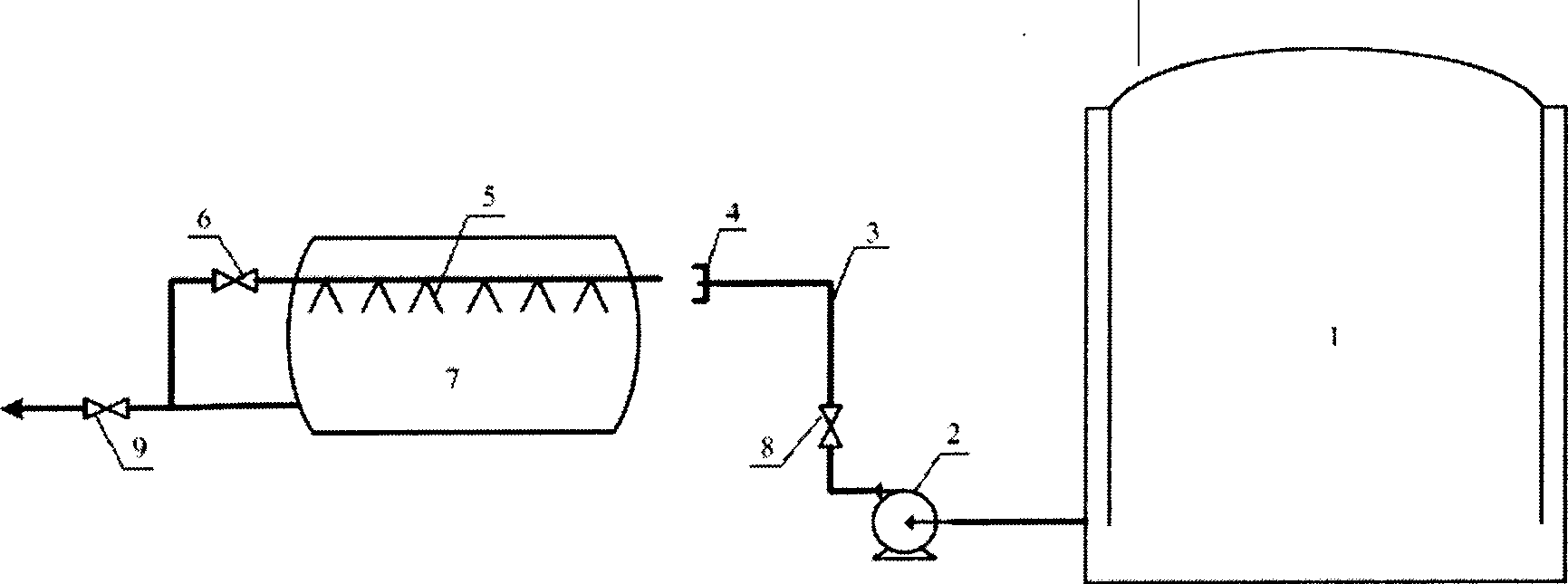

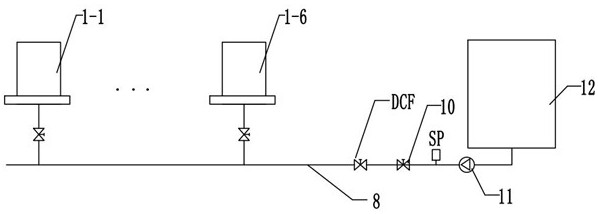

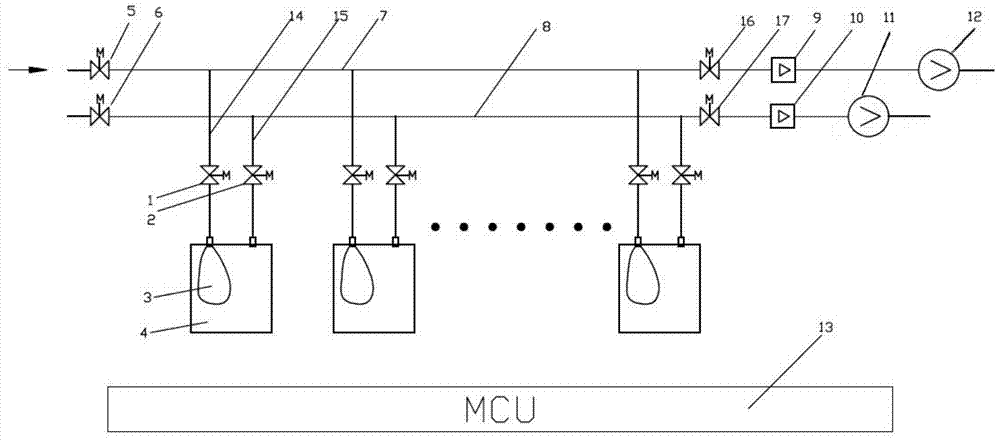

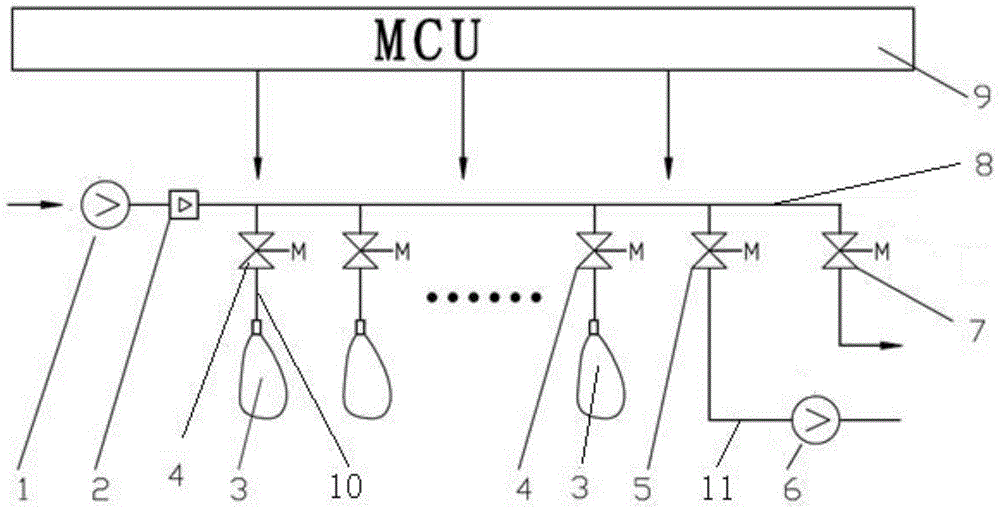

Non-contact type full-automatic gas sample retention device

ActiveCN104764632AImprove accuracyIncrease productivityWithdrawing sample devicesControl engineeringAir pump

The invention discloses a non-contact type full-automatic gas sample retention device. The non-contact type full-automatic gas sample retention device comprises a sampling pipe which is sequentially provided with a sample gas valve, an evacuation flowmeter and an air pumping pump, wherein a plurality of gas bags are connected to the sampling pipe between the sample gas valve and the evacuation flowmeter via sample gas branch pipes, and a communicating valve is arranged on each sample gas branch pipe; the non-contact type full-automatic gas sample retention device further comprises an air pipeline which is sequentially provided with an air valve, a sampling flowmeter and a sampling gas pump, a plurality of vacuum boxes which are in one-to-one correspondence with the gas bags are connected to the air pipeline between the air valve and the sampling flowmeter via evacuation branch pipes, each gas bag is hermetically arranged in the corresponding vacuum box, and a bleeder valve is arranged on each evacuation branch pipe; and the non-contact type full-automatic gas sample retention device further comprises a controller which is electrically connected with the various flowmeters, the valves and the gas pumps. The device can be used for not only realizing automatic precise sample retention of gas, improving the production efficiency and saving the labor cost, but also isolating artificial contact by the design of the non-contact type gas bags, facilitating the installation of a gas heating device and simultaneously improving the production safety; and furthermore, the device can ensure that gas has no pollution and no loss during the whole process.

Owner:苏州聚阳环保科技股份有限公司

Overfilling preventing device for fuel gas cylinder of automobile using liquefied natural gas as fuel

InactiveCN1789781ASimple structureGuaranteed uptimePipeline systemsContainer filling under pressureGas cylinderTar

This invention relates to liquefied natural gas automobile tube over casting resistant device in the liquefied natural gas application technique field. The device comprises LHG storage tar, low temperature pump, vacuum isolation heating tube, rapid connector, fuel gas tube, gas saving valve and spray device. This invention uses the spray device fixed on the fuel gas tube to make the LNG sprayed out by smoke to realize the condensing by vapor and voltage reducing and LNG adding to ensure the fuel gas tube maintained with enough expansion space to prevent over adding.

Owner:SHANGHAI JIAO TONG UNIV

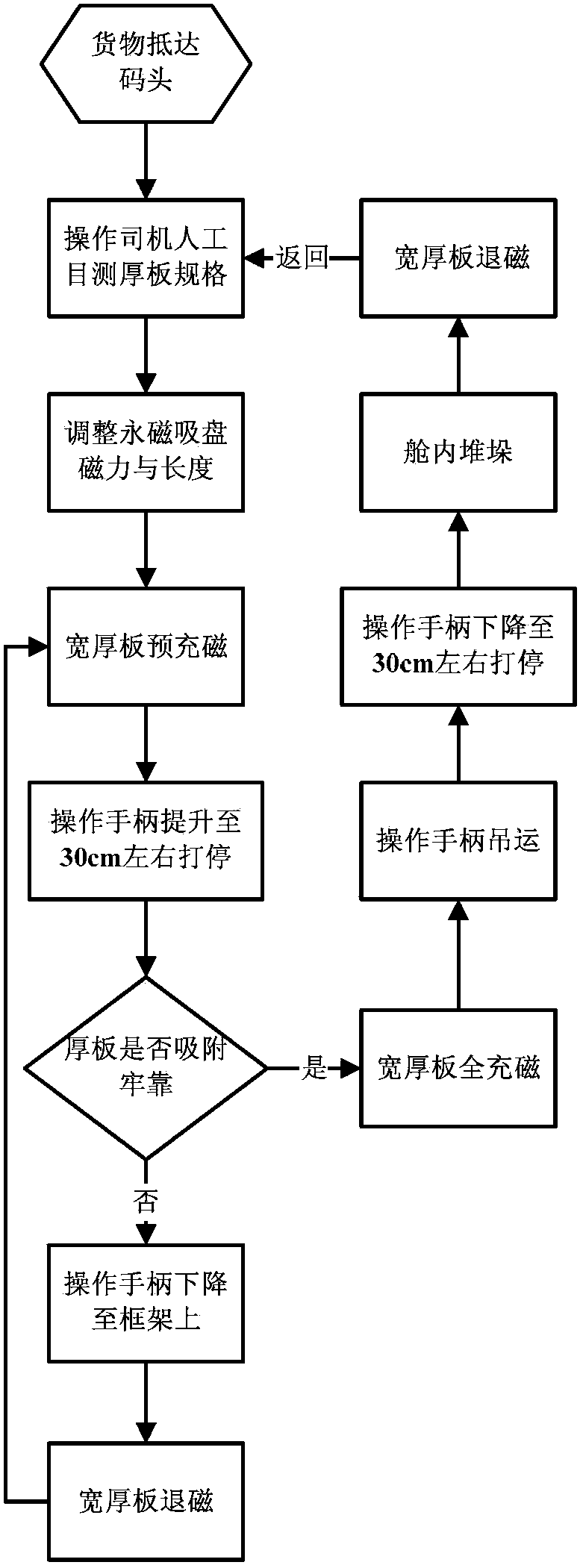

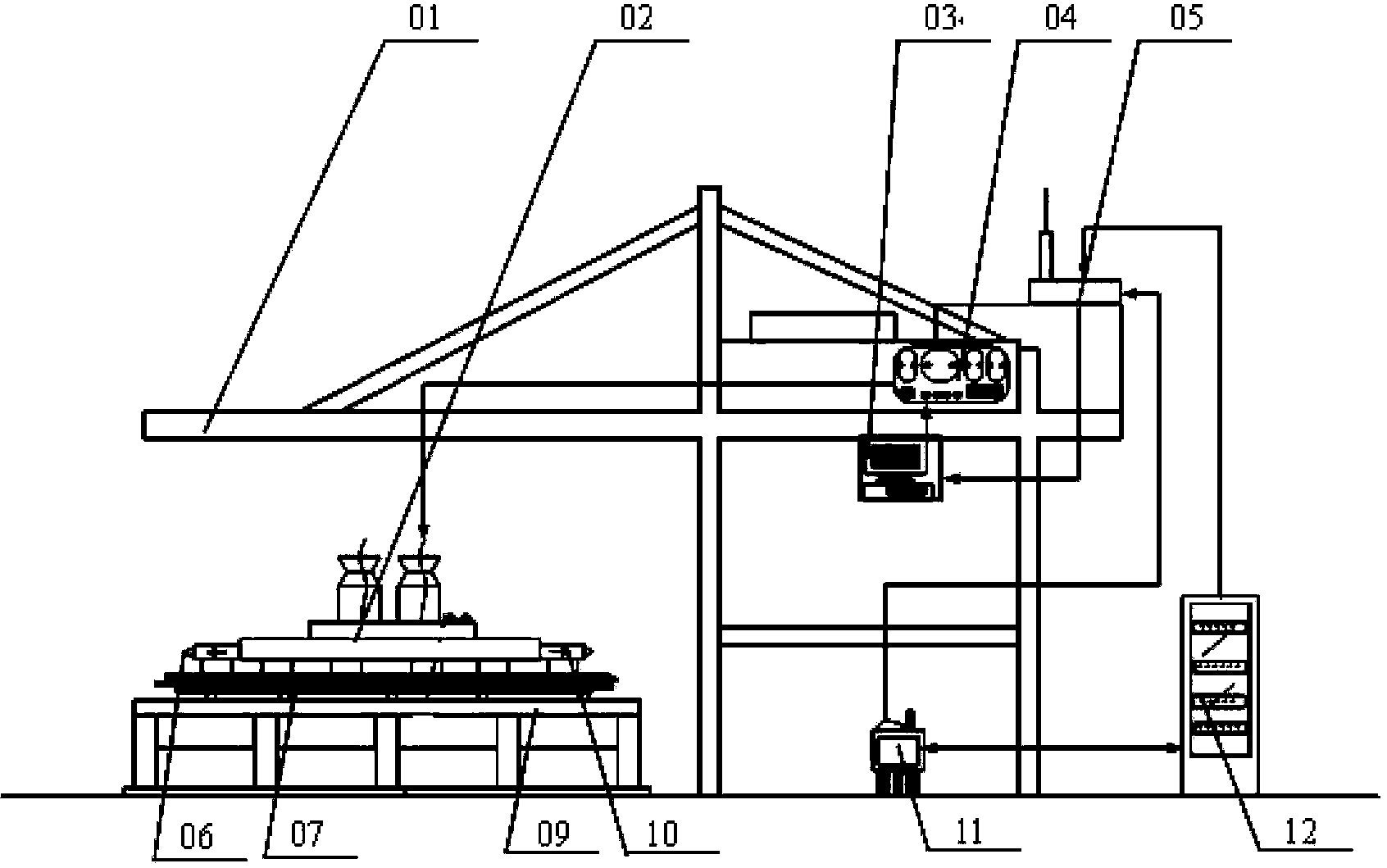

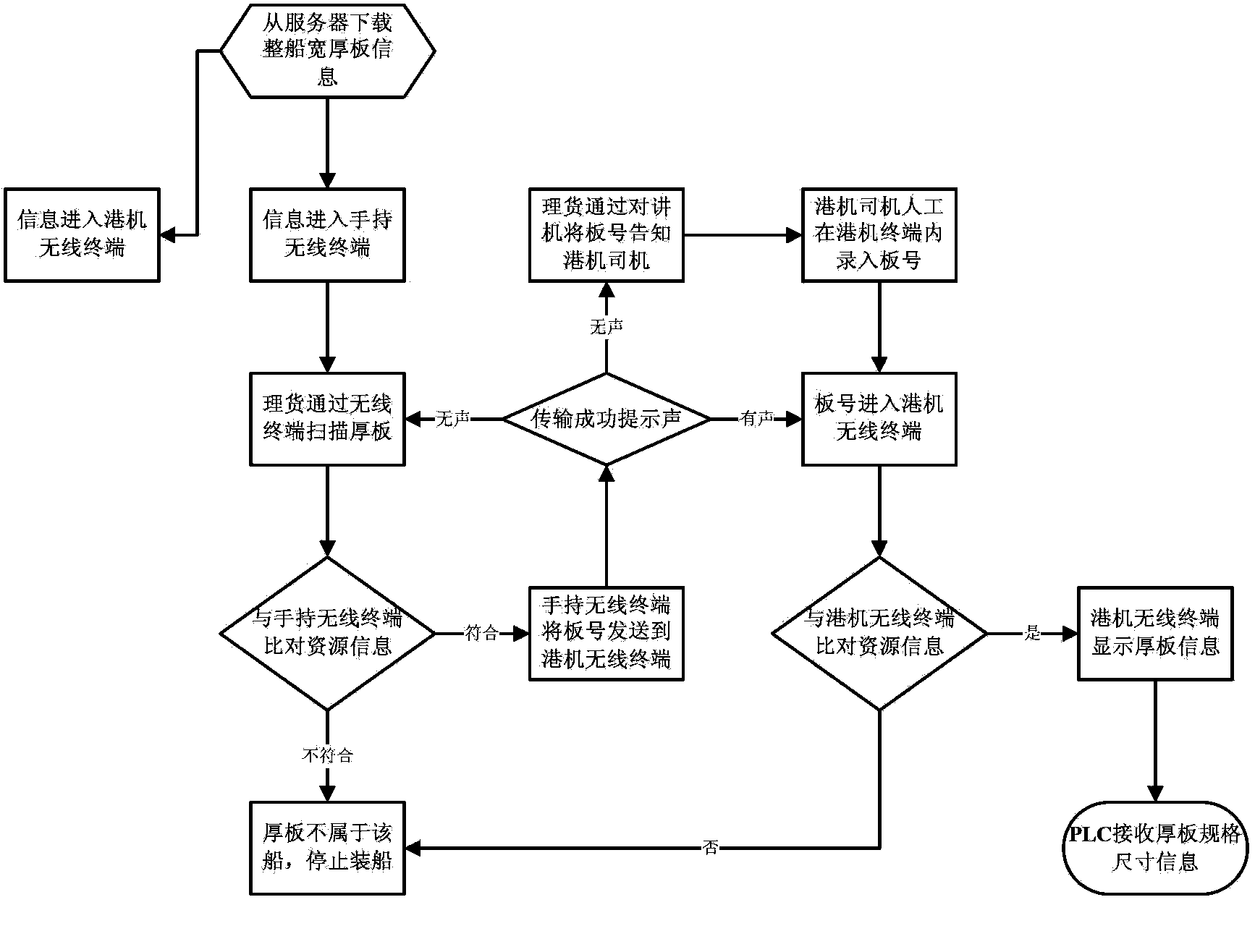

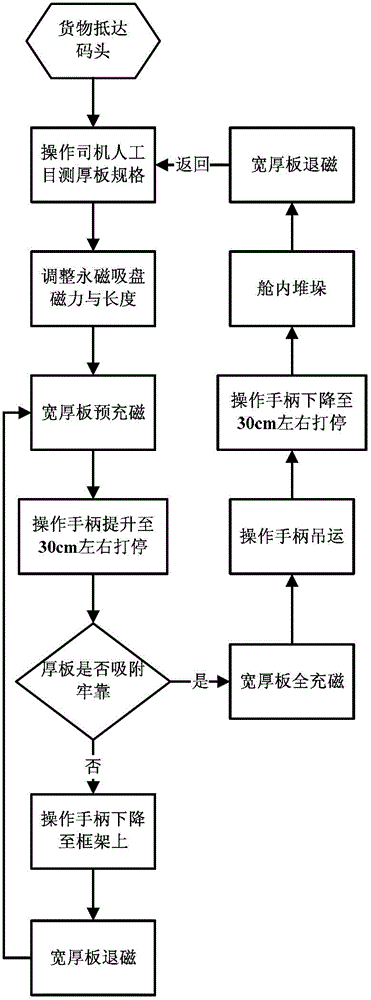

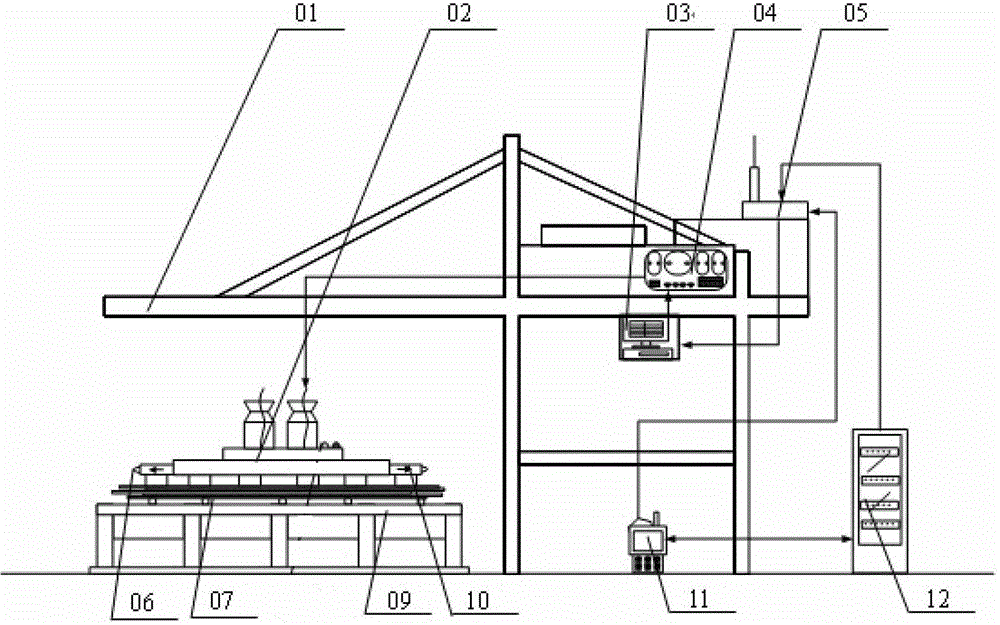

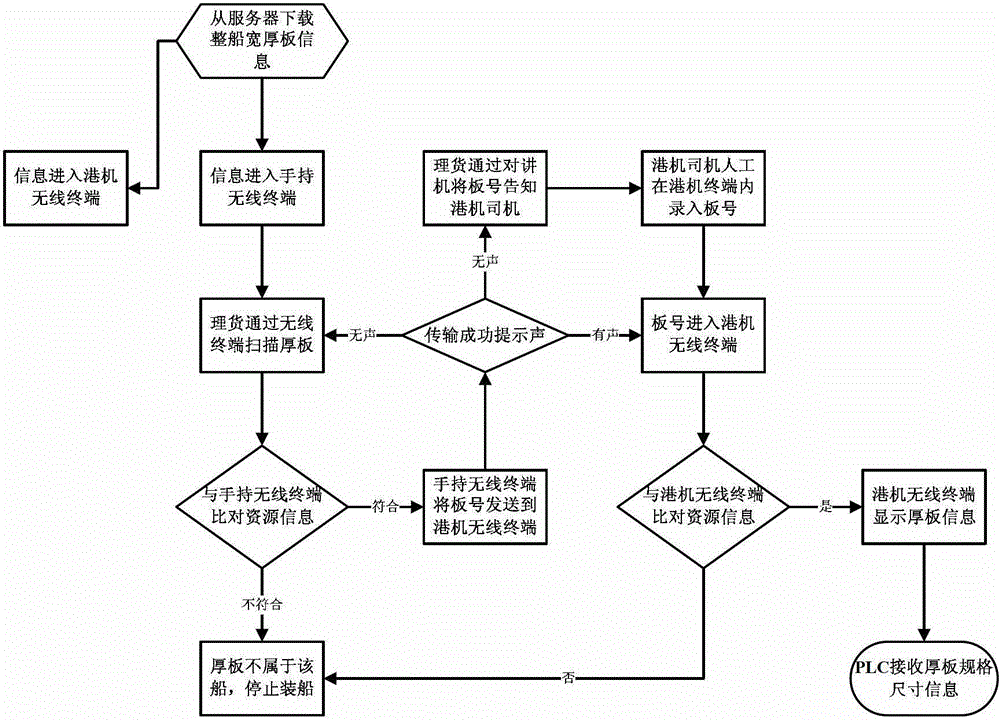

Shipping system and method for wide and thick plates

The invention discloses a shipping system for wide and thick plates. The system comprises: a sling used for hoisting and swinging wide and thick plates, wherein a permanent magnetic chuck is arranged on the sling and is provided with a chuck expansion device which adjusts expansion of the permanent magnetic chuck according to the length of the wide and thick plates; bar codes arranged on the wide and thick plates, wherein the bar codes are used for identification of identity and specification information of the wide and thick plates; a server in which the identity and specification information of the wide and thick plates is stored; a hand-held wireless terminal, wherein a bar code reader is arranged on the hand-held wireless terminal, and the hand-held wireless terminal is connected with the server; a port machinery wireless terminal which is connected with the hand-held wireless terminal through a wireless signal receiving and converting device; and a PLC which is connected with the port machinery wireless terminal, the sling and the permanent magnetic chuck and receives information sent by the port machinery wireless terminal to control hoisting and swinging motion of the sling and adsorption motion of the permanent magnetic chuck. Accordingly, the invention further discloses a shipping method for the wide and thick plates.

Owner:BAOSHAN IRON & STEEL CO LTD

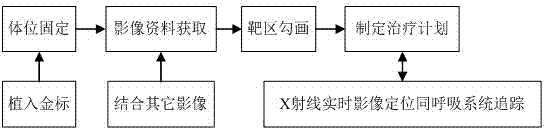

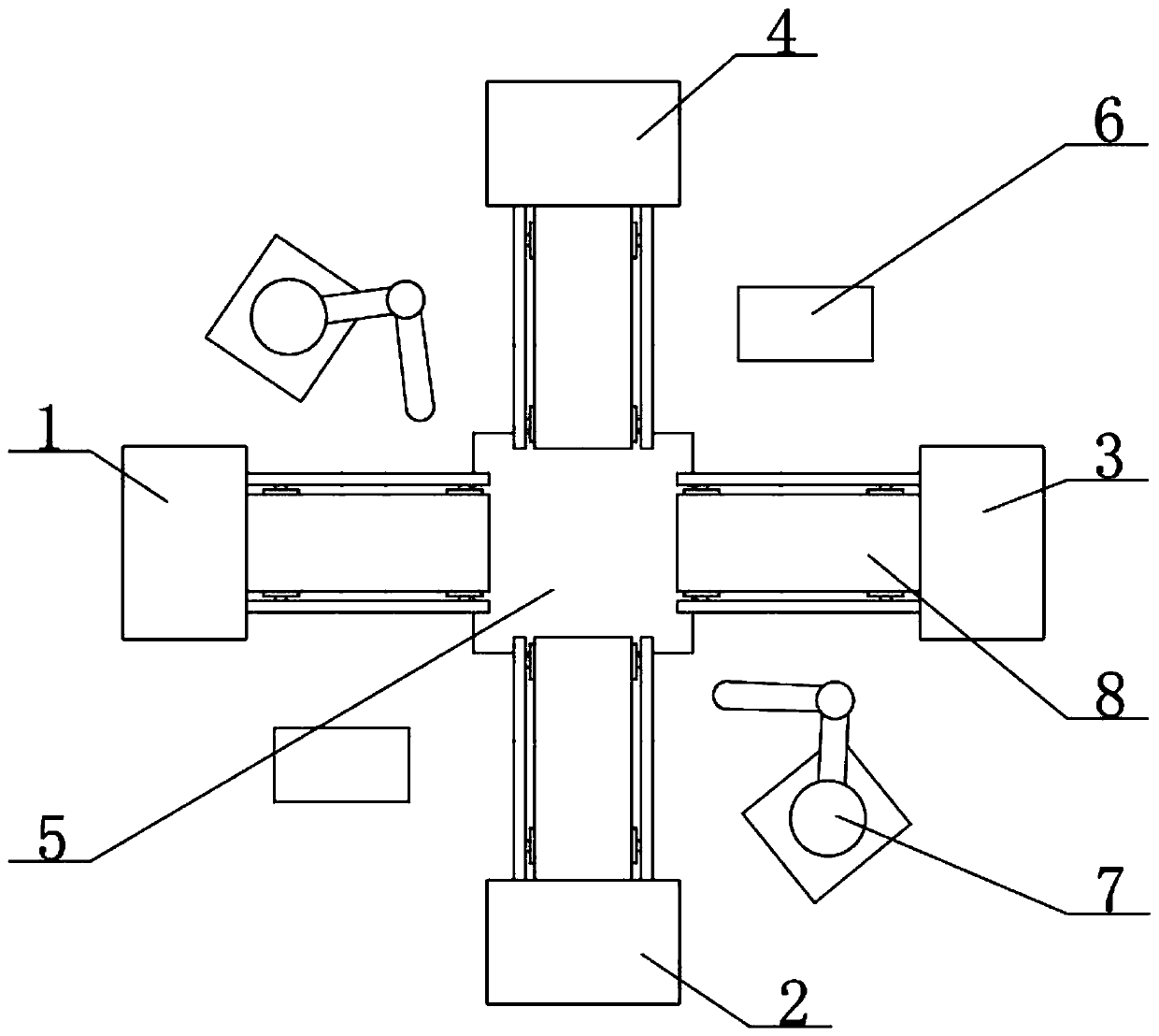

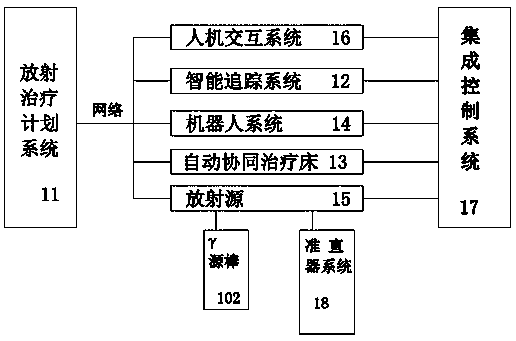

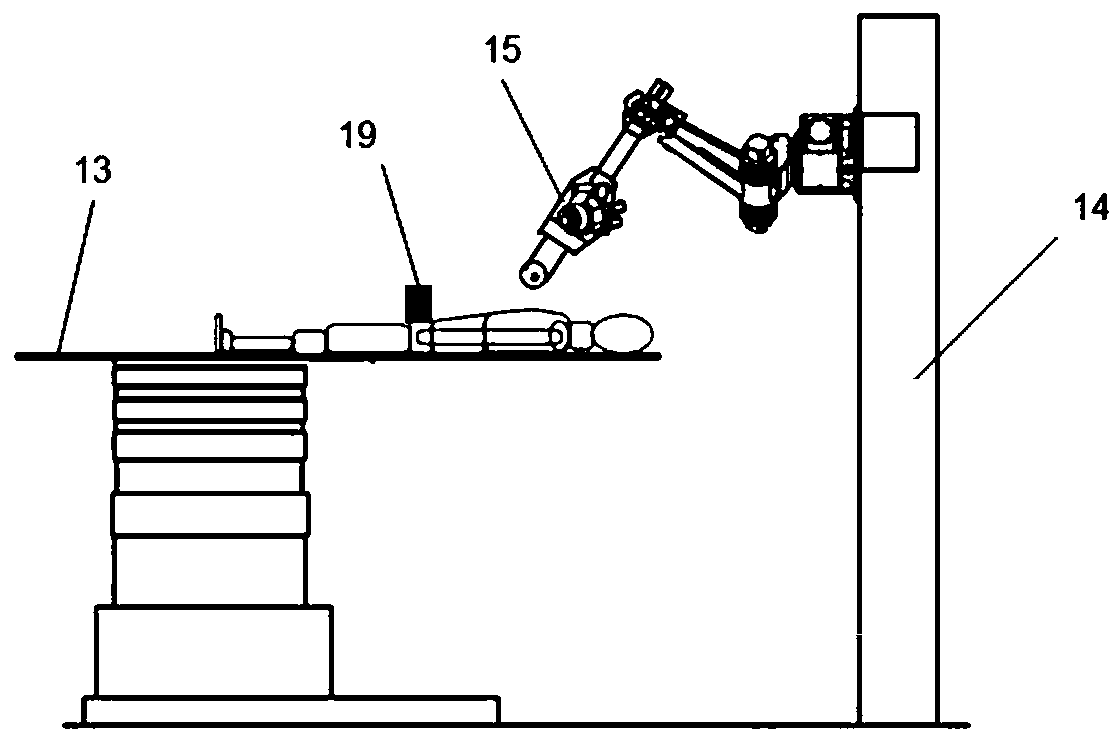

Cancer therapy system based on cyber knife

The invention provides a cancer therapy system based on a cyber knife. The cancer therapy system comprises a robot projection system, a real-time image tracking and positioning system, an infrared synchronous breath tracking system, an automated therapy bed and an intelligent therapy plan system. The robot projection system comprises a mechanical arm and a linear accelerator, the real-time image tracking and positioning system comprises two thousand volts X-ray infrared cameras and corresponding non-crystal digital video detectors; the infrared synchronous breath tracking system is composed of three infrared cameras installed on a ceiling and three infrared diode generators fixed on a breath tracking waistcoat; the automatic therapy bed is designed based on a PID adjustment controller and can freely adjust for five degrees of freedom; the intelligent therapy plan system is used for providing comprehensive therapy design and therapy scheme. The therapy system can achieve accurate positioning of a movable cancer, and reduces harm to human healthy organs while improving therapy accuracy.

Owner:HUBEI UNIV OF TECH

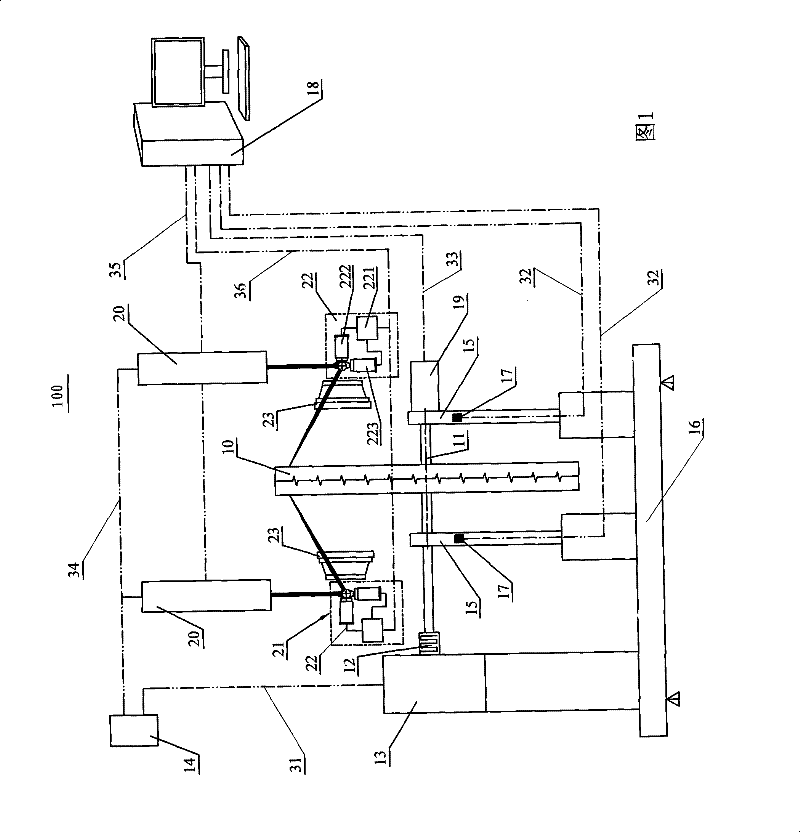

Large-scale production process for galvanic pile of MWGW-level electrolytic cell

InactiveCN111468943AHigh precisionGood repeatabilityAssembly machinesMetal working apparatusProduction lineThermodynamics

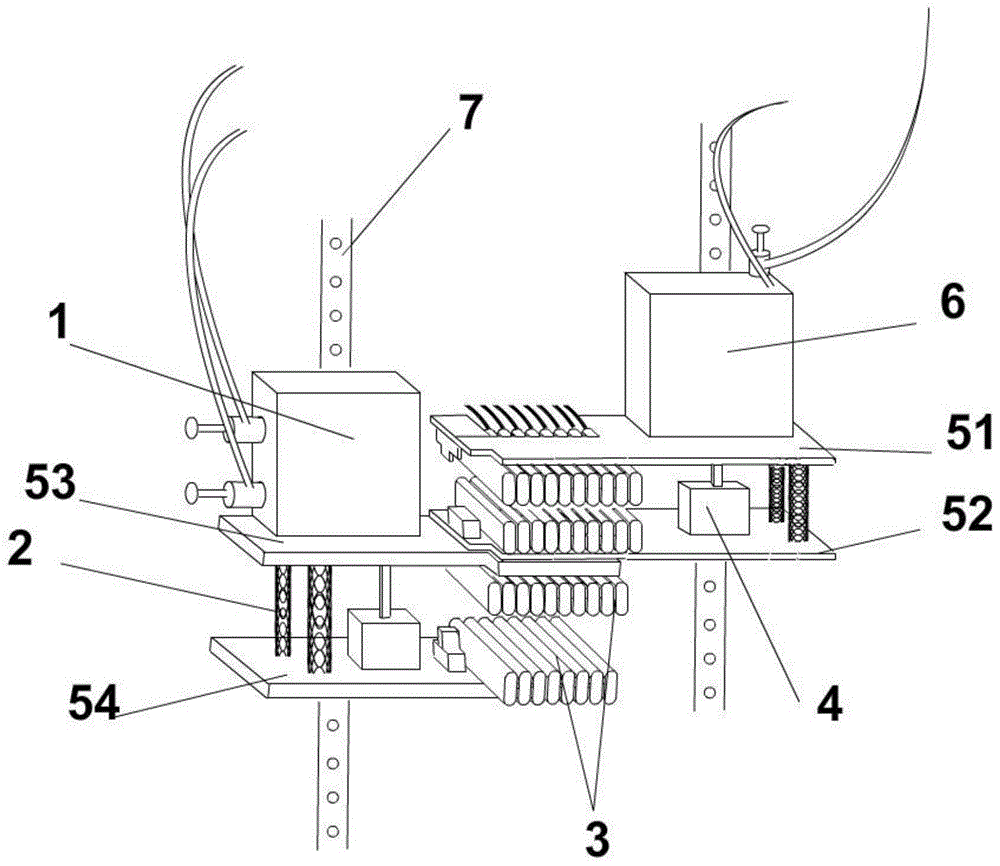

The invention relates to a large-scale production process for a galvanic pile of an MWGW-level electrolytic cell. The large-scale production process comprises field inspection and management equipment, a mechanical arm and belt conveyors, wherein ends of the belt conveyors are connected to an automatic gravity induction assembly platform; the belt conveyor which is positioned at the left side of the automatic gravity induction assembly platform communicates with a polar plate feeding hole; the belt conveyor which is positioned at the lower side of the automatic gravity induction assembly platform communicates with a sealing material feeding hole; the belt conveyor which is positioned at the right side of the automatic gravity induction assembly platform communicates with a nickel net feeding hole; and the belt conveyor which is positioned at the upper side of the automatic gravity induction assembly platform communicates with a diaphragm feeding hole. All assembly processes are automatically accomplished by a mechanical system, so that assembly is quick, the yield is high and finished product precision is high. The large-scale production process is very suitable for volume production of the large-unit-area galvanic pile, reduces a rejection rate according to field inspection; and a mechanical production line eliminates human errors or mistakes.

Owner:李海明

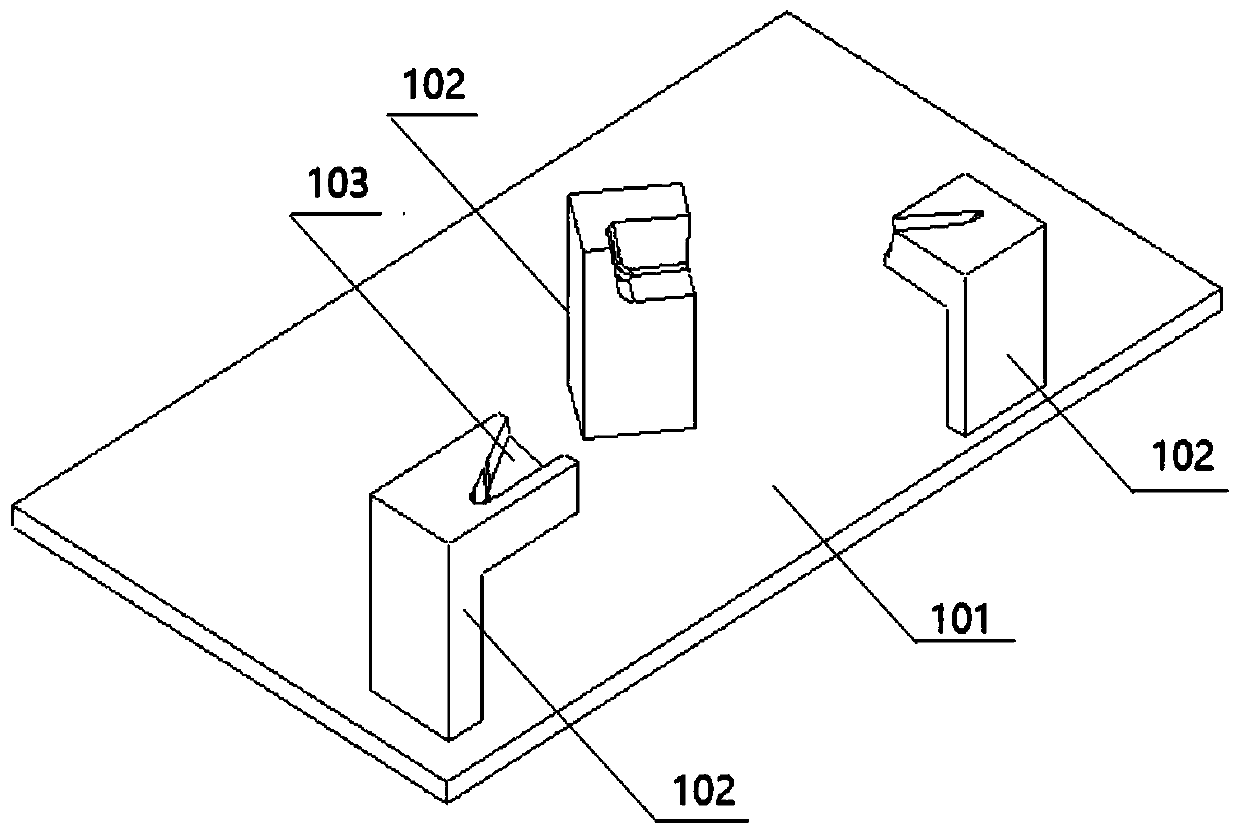

Automatic breaker clamp

InactiveCN104440648ASo as not to damageAccurate pressingWork holdersMeasurement instrument housingEngineeringCircuit breaker

An automatic breaker clamp comprises an air cylinder a, an air cylinder b, springs, a pressing sheet, mechanical arms, a sliding table a, a sliding table b, a sliding table c, a sliding table d and a track. The track is fixed in a groove of a monitor station. One side of the sliding table a and one side of the sliding table b are fixed to the track. One side of the sliding table c and one side of the sliding table d are reversely arranged on the track. The air cylinder a is horizontally arranged at the front upper end of the sliding table c and connected with the mechanical arm fixed on the sliding table d through a connection shaft. The springs are connected between the sliding tables. The air cylinder b is horizontally arranged at the tail upper end of the sliding table a and connected with the mechanical arm fixed on the sliding table b through a connection shaft. The air cylinders, the sliding tables, the mechanical arms and the track are all made of steel. The automatic breaker clamp is different from an existing purely manual or semiautomatic device, and the springs play a buffer role and can protect the components against damage. The automatic detection clamp is a full-automatic detection device, positioning is more accurate, efficiency is higher, errors caused by manual operation are avoided, and manpower resources are saved at the same time.

Owner:TIANJIN CLP HUALI ELECTRICAL SCI & TECH GROUP

Wireless tool control system and method for vehicle assembly and fabrication technique

InactiveCN101470441BImplement security authenticationIncrease the difficultyTotal factory controlProgramme total factory controlHuman–machine interfaceCar manufacturing

Disclosed are a wireless tool control system for automobile assembling and manufacturing techniques and a method thereof, which realize self-adaptive safety certification, working data tracking, preventing and collecting errors in the producing process of all wireless tools on the automobile assembling and manufacturing line, and realize real-time control, data process and working record storage simultaneously. The wireless tool control system comprises at least one wireless tool, an Ethernet network of the automobile manufacture production line, an enterprise firewall embedded in the Ethernet network of the automobile manufacture production line, and a production line monitor center which is connected with the Ethernet network of the automobile manufacture production line and is providedwith a human-machine interface, wherein a control system of the wireless tool is provided with a quality control servo unit, the quality control servo unit is provided with a data storage system, thedata storage system is provided with a quality data base, the control system of the wireless tool is equipped with at least one Ethernet serial server and is embedded with a safety certification system, and the safety certification system allocates one identification certificate for each wireless tool, and each identification certificate is different from each other.

Owner:广州信邦智能装备股份有限公司

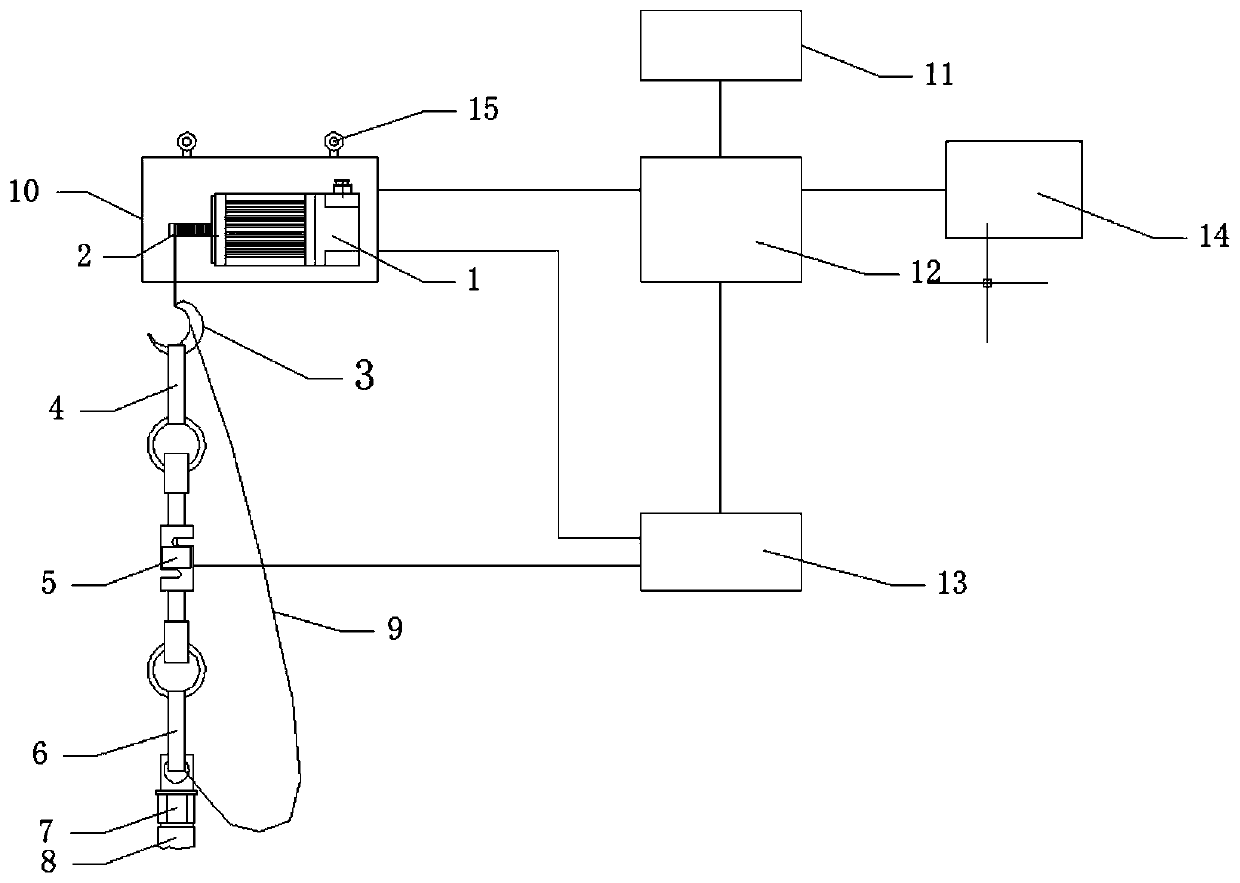

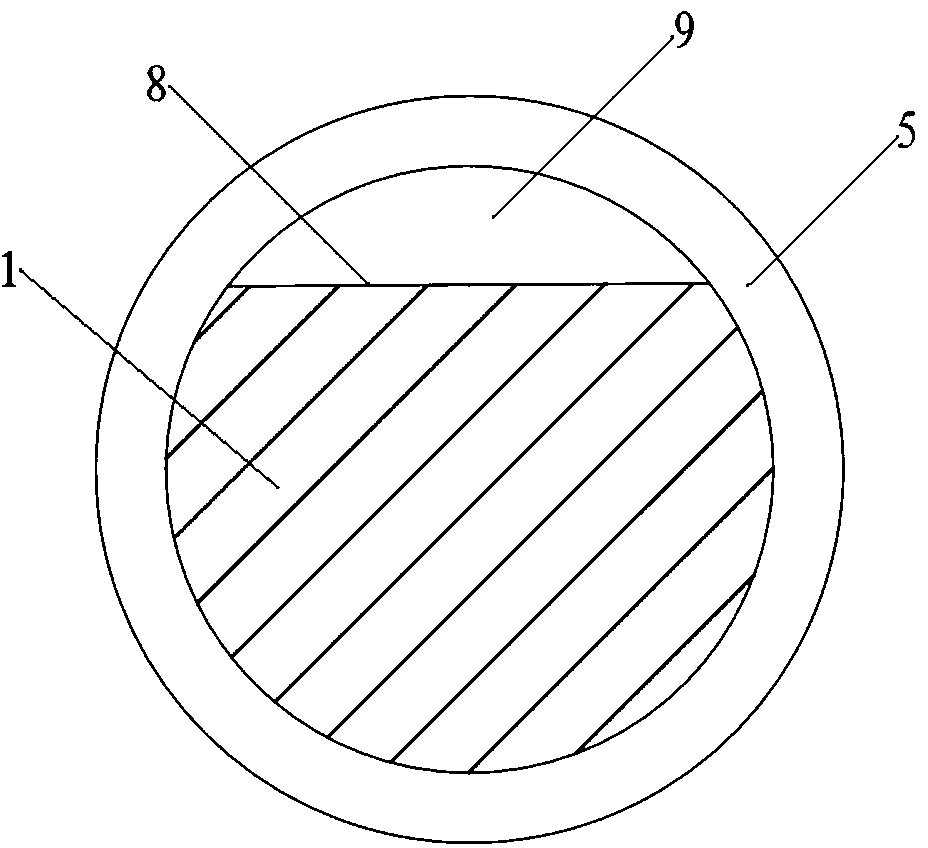

Friction force test device for reactor control rod driving mechanism

PendingCN111312416ASave human effortEliminate mistakesNuclear energy generationNuclear monitoringNuclear powerEngineering

The invention belongs to the technical field of nuclear power station reactor maintenance, and specifically relates to a friction force test device for a reactor control rod driving mechanism. The friction force test device comprises a servo motor, a steel cable, a lifting hook, annular lifting belts, an S-shaped tension sensor, a driving rod transportation tool, a driving rod and a driver, wherein the driver is hung below a cantilever crane through hanging lugs; the servo motor is arranged in the driver; the driving end of the servo motor is connected with the lifting hook through the steel cable; the S-shaped tension sensor is hung at the lower end of the lifting hook through a first annular lifting belt; the driving rod transportation tool is hung on the S-shaped tension sensor througha second annular lifting belt; and the driving rod is hung on the driving rod transportation tool. According to the invention, manpower is liberated; the working efficiency and reliability are improved; and the possibility of errors caused by human factors is eliminated.

Owner:JIANGSU NUCLEAR POWER CORP

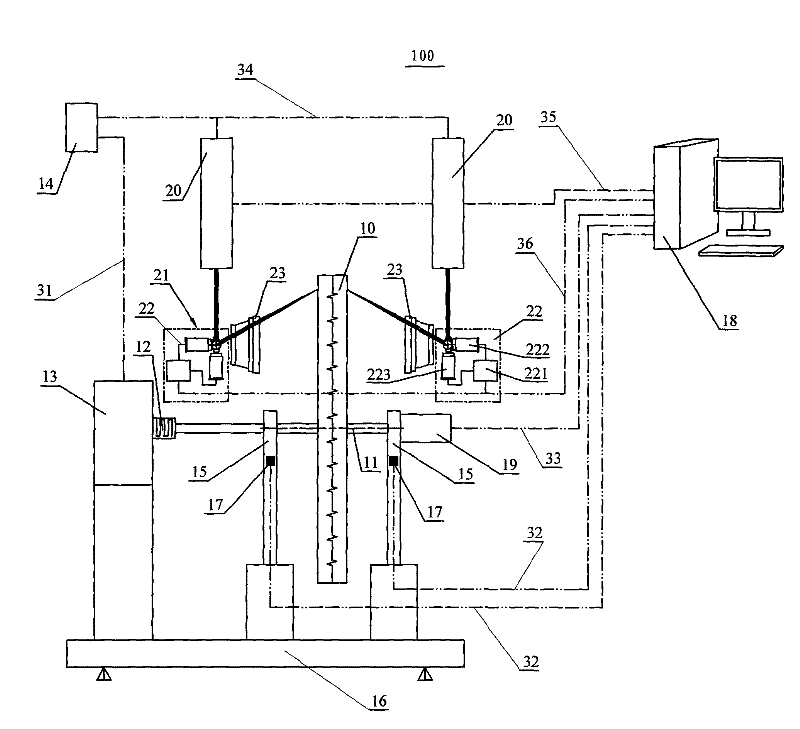

Laser dynamic balance adjustment method and device thereof

ActiveCN101629865BIncrease productivityImprove reliabilityStatic/dynamic balance measurementLaser beam welding apparatusTime delaysHigh energy

Owner:HANS LASER TECH IND GRP CO LTD

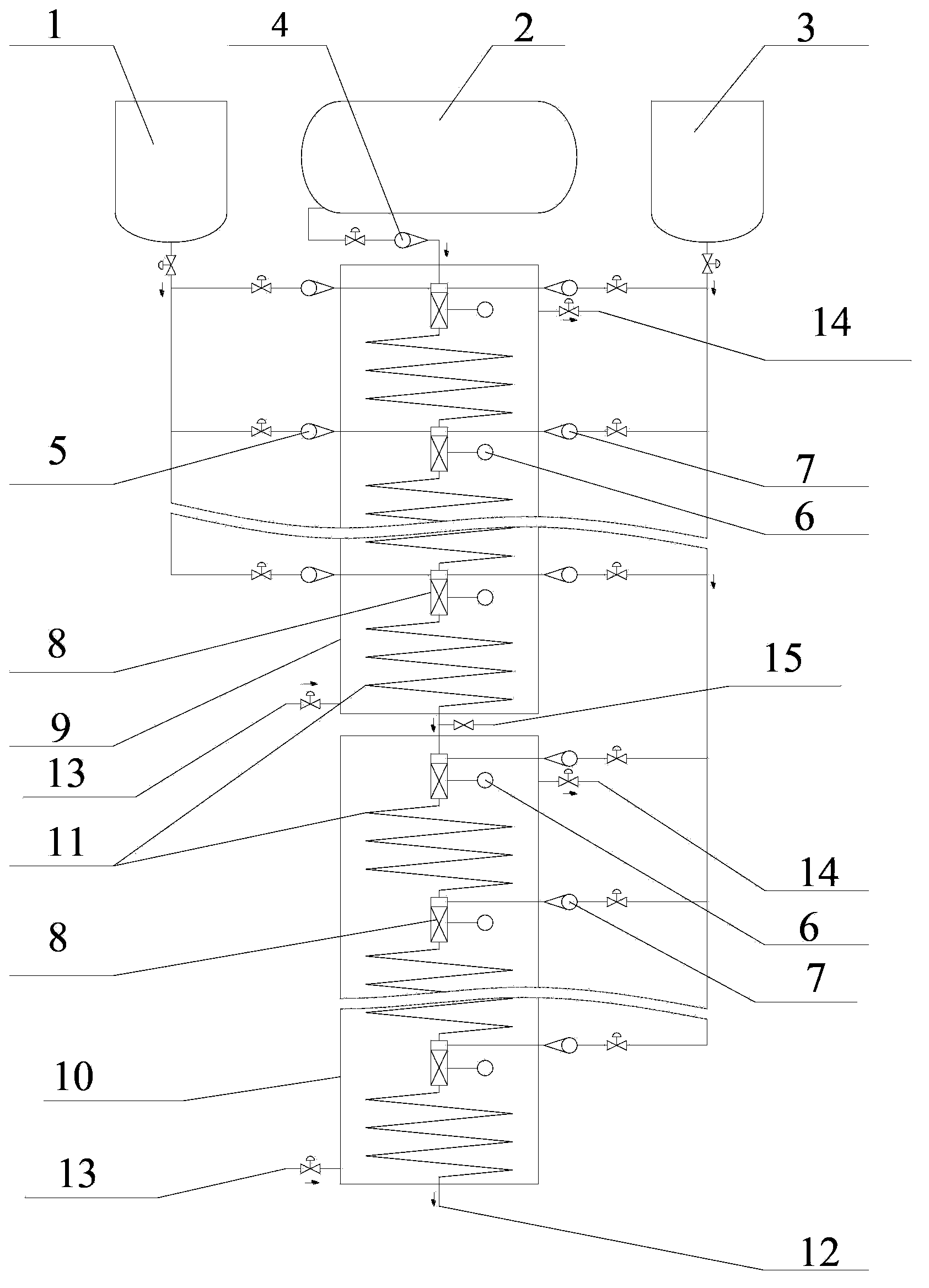

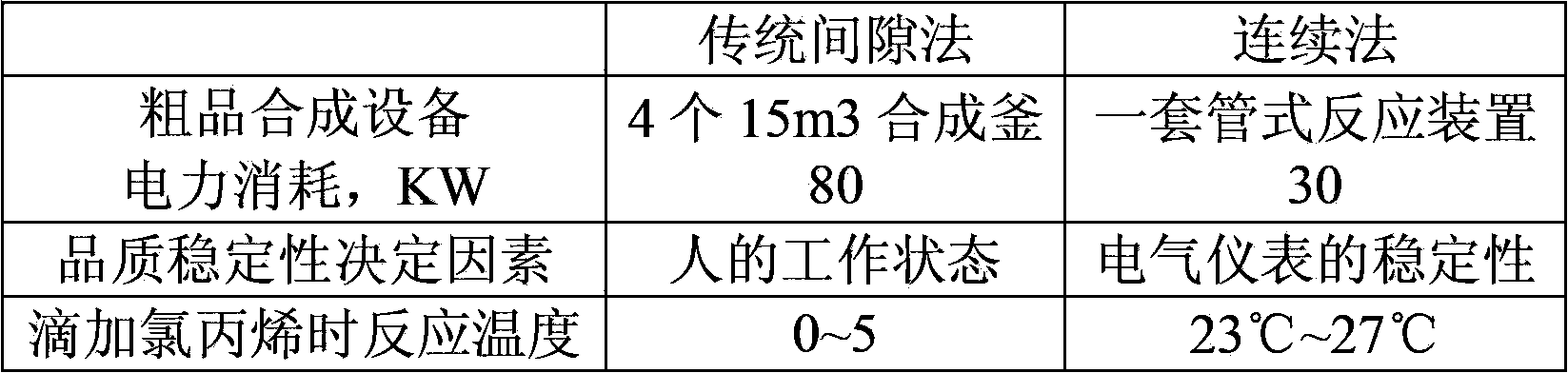

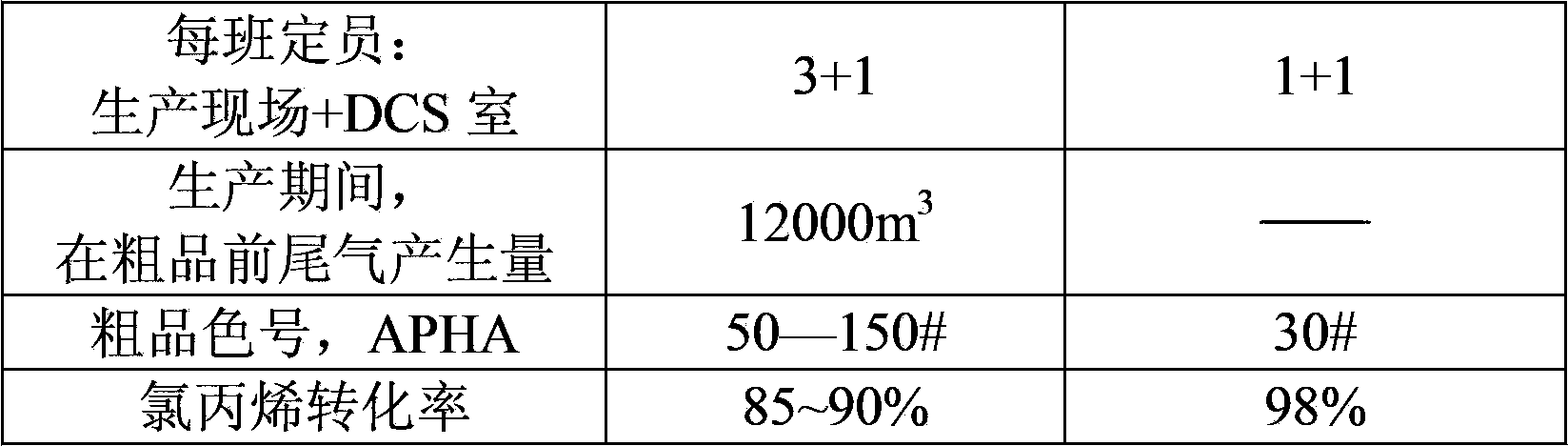

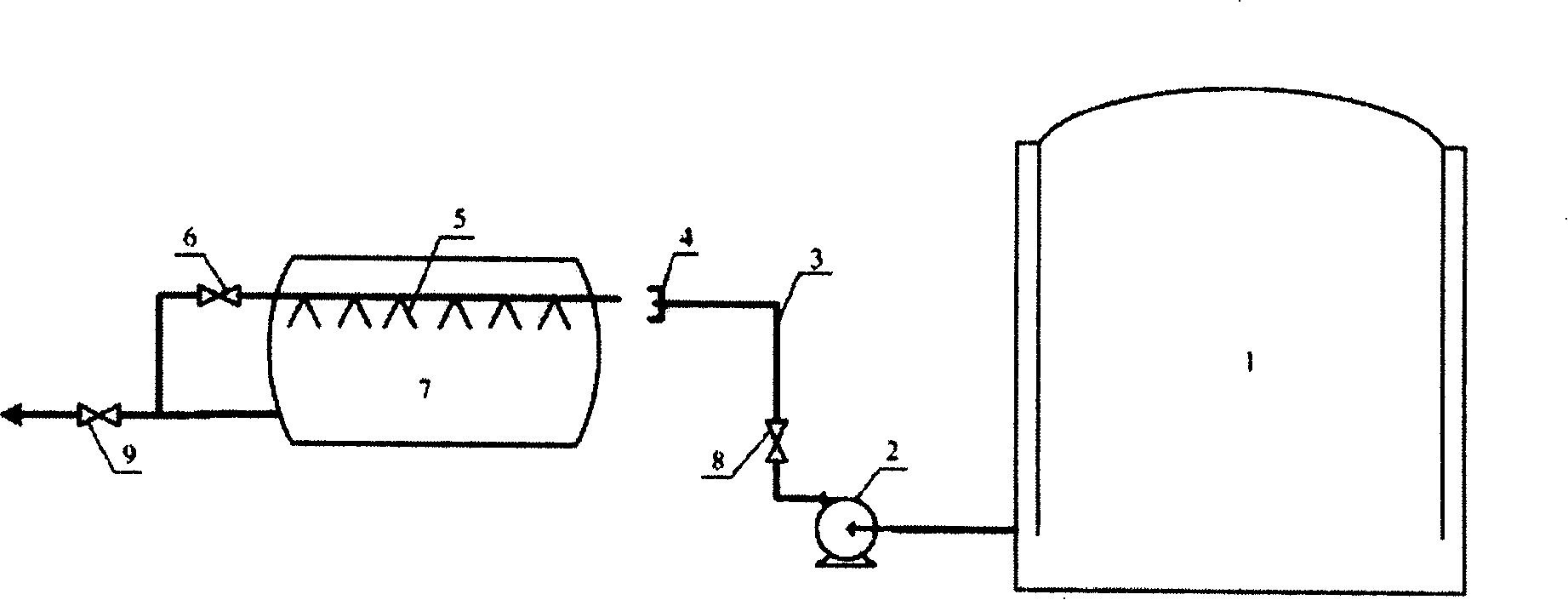

Preparation method of dimethyldiallylammonium chloride

ActiveCN102924285BDarken the colorNo emptying problemsOrganic compound preparationAmino compound preparationAutomatic controlDistributed control system

The invention discloses a preparation method of dimethyldiallylammonium chloride, which comprises the following steps: in a continuous pipeline type reactor, keeping the temperature at 15-35 DEG C, reacting a dimethylamine water solution having a flow rate of u kg / h and chloropropene having a flow rate of 1.27-1.54u / n kg / h until the free amine concentration is lower than 3.8*10<-4> mol / g, wherein the pH value is controlled at 7.0-12.0 in the reaction process; then, regulating the reaction temperature to 35-60 DEG C, controlling the pH value of the reaction solution at 8.5-12.0, and further reacting until the free amine concentration is 5.1*10<-5> mol / g; and after the reaction is finished, further performing post treatment, and purifying to obtain dimethyldiallylammonium chloride. According to the invention, a continuous method is used, so that no evacuation problem exists, and nitrogen gas gap substitution is not required; through the on-line control on the pH value, the dropwise adding amount of the liquid alkali is controlled, thereby maximally relieving the hydrolysis of the chloropropene, improving the product yield and reducing the production of three wastes; and due to continuous production, all operating parameters are constant, and a DCS (distributed control system) can be used to perform full-automatic control. Thus, the error and deviation caused by artificial operation can be eliminated, and the product quality is more stable.

Owner:JIANGSU FEYMER TECH

Overfilling preventing device for fuel gas cylinder of automobile using liquefied natural gas as fuel

InactiveCN100392314CSimple structureGuaranteed uptimePipeline systemsContainer filling under pressureGas cylinderTar

This invention relates to liquefied natural gas automobile tube over casting resistant device in the liquefied natural gas application technique field. The device comprises LHG storage tar, low temperature pump, vacuum isolation heating tube, rapid connector, fuel gas tube, gas saving valve and spray device. This invention uses the spray device fixed on the fuel gas tube to make the LNG sprayed out by smoke to realize the condensing by vapor and voltage reducing and LNG adding to ensure the fuel gas tube maintained with enough expansion space to prevent over adding.

Owner:SHANGHAI JIAOTONG UNIV

A fully automatic testing device for impermeability of concrete samples

ActiveCN114112862BImplement automatic detectionEliminate mistakesPermeability/surface area analysisHigh pressure waterProcess engineering

Owner:HEBEI GUANGTONG ROAD & BRIDGE GRP

Non-contact automatic gas sample retention device

ActiveCN104764632BImprove accuracyIncrease productivityWithdrawing sample devicesElectricityEngineering

Owner:苏州聚阳环保科技股份有限公司

Shipping system and method for wide and thick plates

Owner:BAOSHAN IRON & STEEL CO LTD

A Numerical Control Machining Method of Multi-zero Parts

ActiveCN106406234BEliminate mistakesImprove efficiencyProgramme controlComputer controlNumerical controlProcess engineering

The invention relates to a numerical control machining method for parts with multiple zero points. Starting from the actual situation in the machining process of the parts, after recording the actual position of the reference hole on the machine tool, according to the theoretical position relationship of each point, calculate the position of each zero point on the machine tool. The actual coordinate value is obtained and input through programming language, which solves the problems of complicated calculation, too many input points and high human error rate in the prior art. The invention eliminates errors caused by artificial calculation and input of multiple zero points, and greatly improves processing efficiency and saves manufacturing time and labor cost due to the high efficiency of calculation and input of zero points.

Owner:HARBIN DONGAN ENGINE GRP

Corrugated pipe cut-off machine

ActiveCN102601443BShort tripReduce labor intensityTube shearing machinesShearing machine accessoriesDouble-timeSemi automatic

Owner:TIANJIN GREAT WALL LEAN AUTOMOTIVE PARTS CO LTD

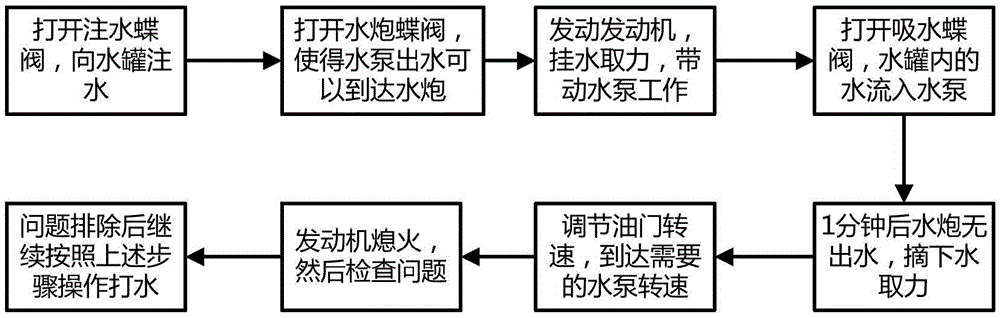

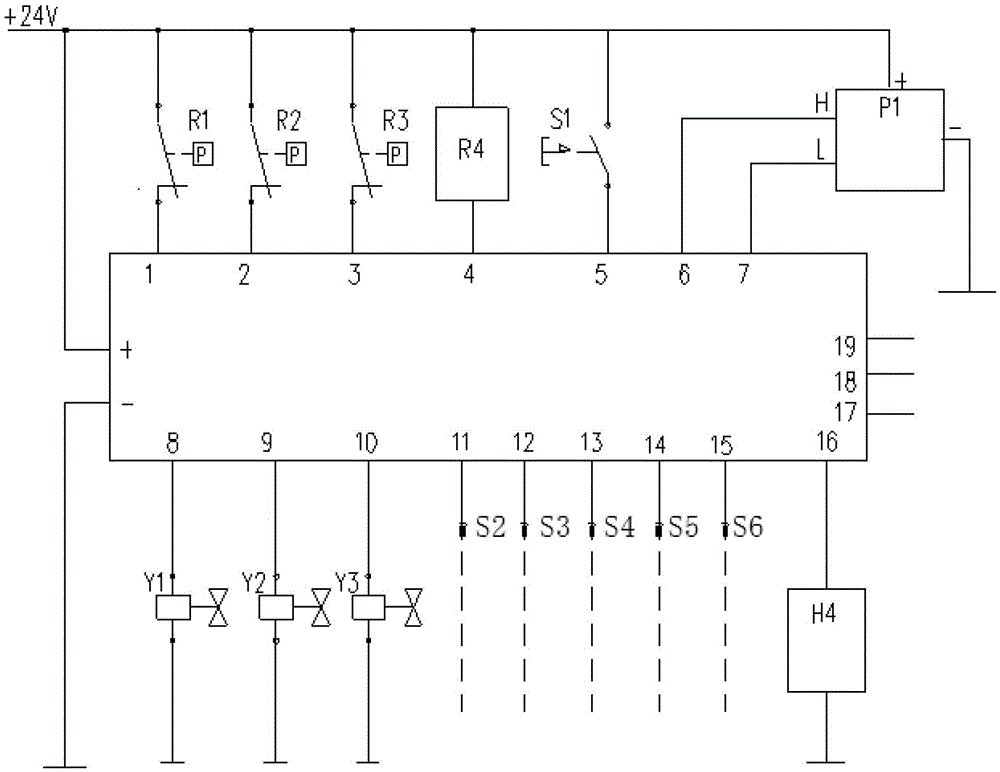

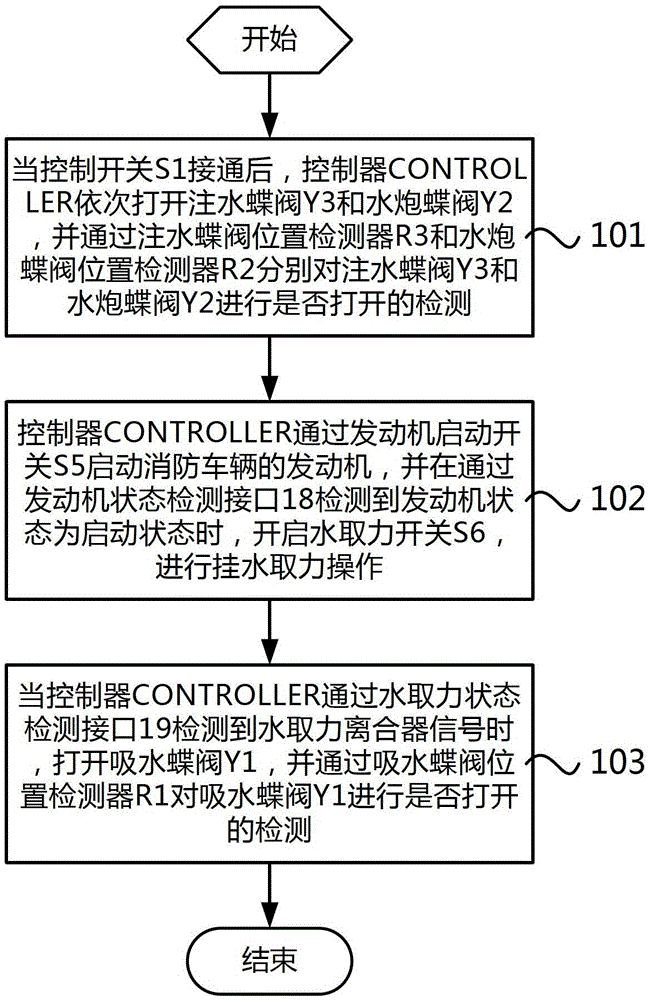

Firefighting operation control device and method

The invention relates to a fire-fighting operation control apparatus and a method. The apparatus comprises: a controller, a control switch, multiple butterfly valves, multiple corresponding butterfly-valve position detectors, a water pump throttle, an engine flame-out switch, an engine starting switch, a water force-taking switch and a water-pot liquid-level sensor; the control switch, the butterfly valves, the corresponding butterfly-valve position detectors, the water pump throttle, the engine flame-out switch, the engine starting switch, the water force-taking switch and the water-pot liquid-level sensor are all connected with the controller; and the control switch can be subjected to external control so that starting or stopping of work process of a fire-fighting operation are realized. According to the method, the controller is used to carry out centralized control on each element, the control switch is used to receive external control instructions, and the controller is used to automatically finish starting or stopping of work process of the fire-fighting operation according to a prescribed flow. Compared with a conventional fire-fighting water-fetching operation scheme, the apparatus and the method of the invention help to save a large amount of personnel operation, simplify operation process of firefighters, and eliminate faults caused by personnel operation of the firefighters.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

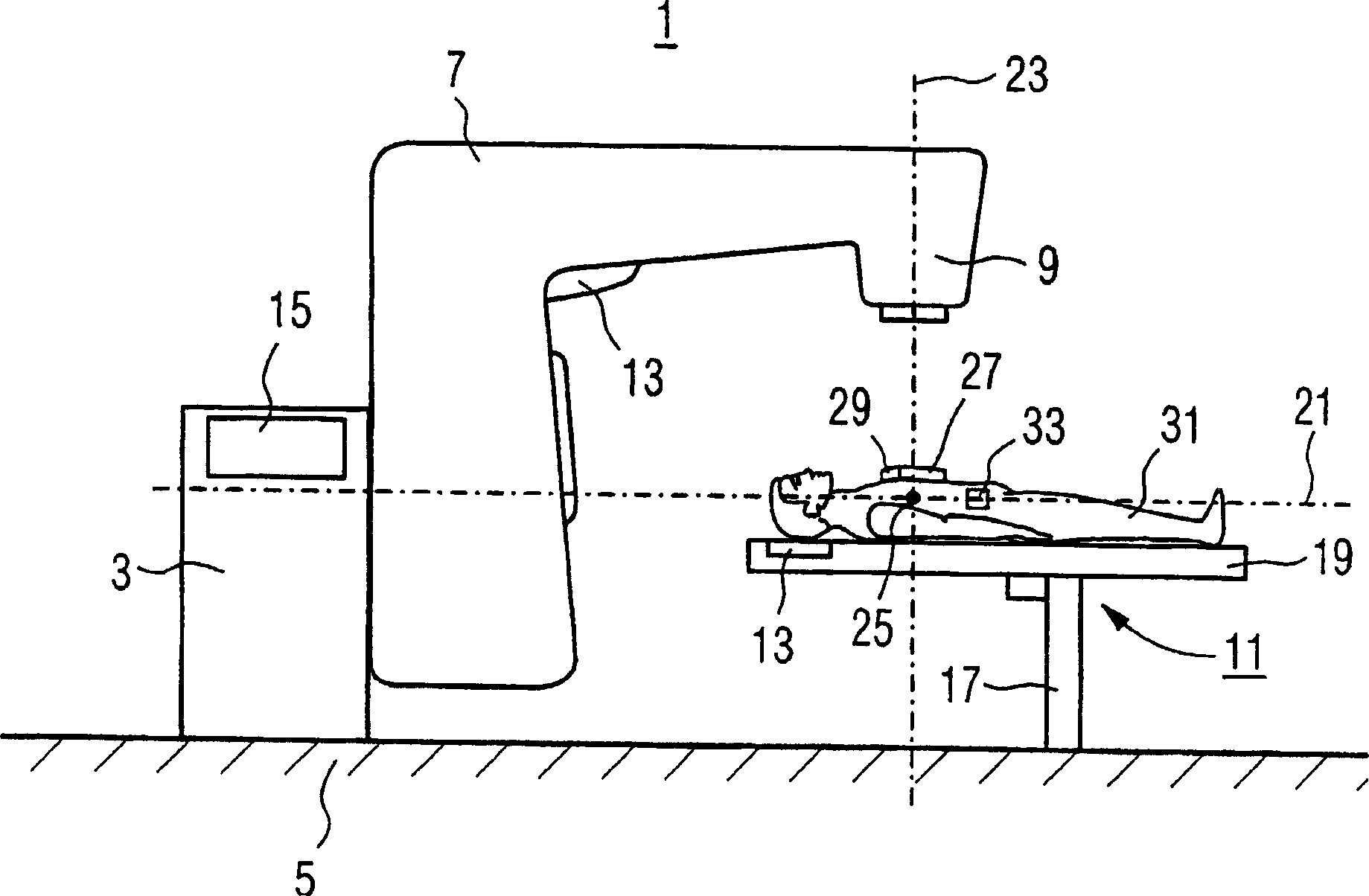

Identification device for medical equipment and patients

InactiveCN1806248AAutomatic recognitionEliminate mistakesElectrotherapyMemory record carrier reading problemsMedical equipmentEngineering

The invention relates to a device for identifying medical equipment and patients. Said device comprises a transponder-reading apparatus (13) and a control unit (15) that is connected thereto. The transponder-reading apparatus (13) is configured so as to be able to read out a patient transponder (33) and an equipment transponder that is mounted on a piece of medical equipment. The control unit (15) is configured so as to be able to pick up data which the transponder-reading apparatus (13) reads out of an equipment transponder as an input signal and generate an equipment identification signal according to said input signal while being able to pick up data which the transponder-reading apparatus (13) reads out of a patient transponder (33) as an input signal and generate a patient identification signal according to said input signal. The inventive device can be part of a radiation therapy system while the piece of medical equipment can be a radiation mask. Also disclosed is a system for identifying medical equipment, comprising a control unit (15), a transponder-reading apparatus (13) that is connected to the control unit (15), and an equipment transponder which is mounted on a piece of medical equipment.

Owner:SIEMENS AG

Triangular decoration plate buckle assembling device

PendingCN110757408AEasy to operateImprove installation efficiencyMetal-working hand toolsStructural engineeringHand operations

Owner:北京世东凌云科技有限公司

Product quantity and quality information simultaneous wireless intelligent terminal acquisition device

InactiveCN112132240AEasy to collectUnderstand the quantityParticular environment based servicesCo-operative working arrangementsComputer hardwareAcquisition apparatus

A product quality information wireless mobile terminal simultaneous acquisition device is provided with a wireless acquisition device which is arranged outside a body and used for wirelessly acquiringidentity card information of various workers, a work certificate information wireless scanner, an ID card information wireless acquisition device, a camera A used for wirelessly acquiring informationof products and code-pasted articles of various workers and work objects and integrates a 5G wireless function and an OCR function, and a camera B used for face recognition and integrates a 5G wireless function; personnel information of various workers for production, processing, transportation and the like, the number and quality of products and code pasting article information of working objects can be wirelessly and automatically collected at the same time. Simultaneous management of personnel information of various workers for production, processing, transportation and the like, and quantity and quality of products and code-pasted article information of working objects is facilitated.

Owner:大连晓达科技有限公司

Automatic gas sample retention device

Owner:苏州聚阳环保科技股份有限公司

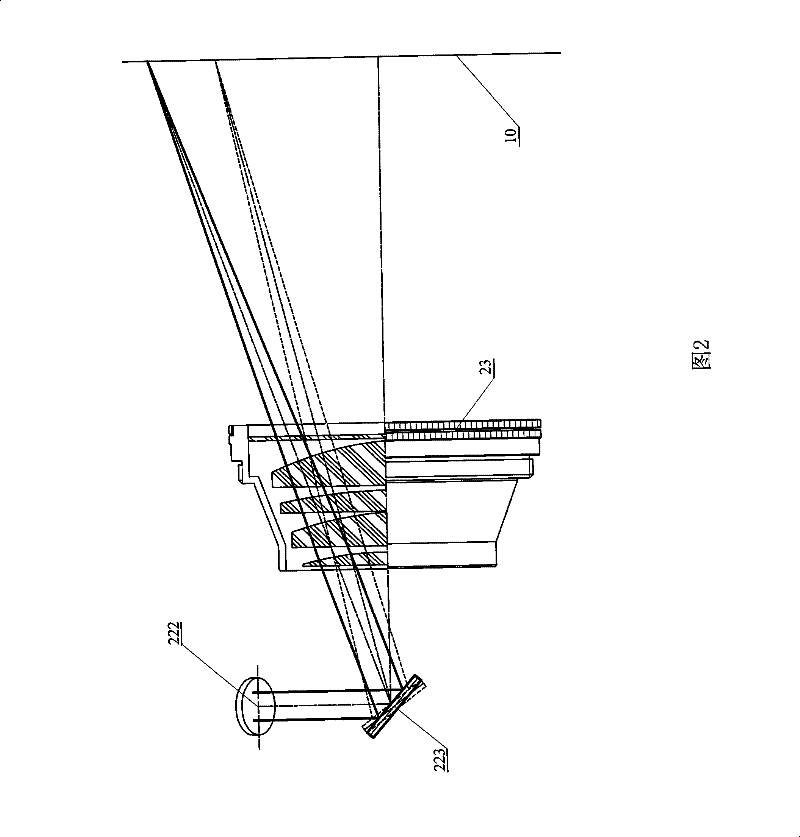

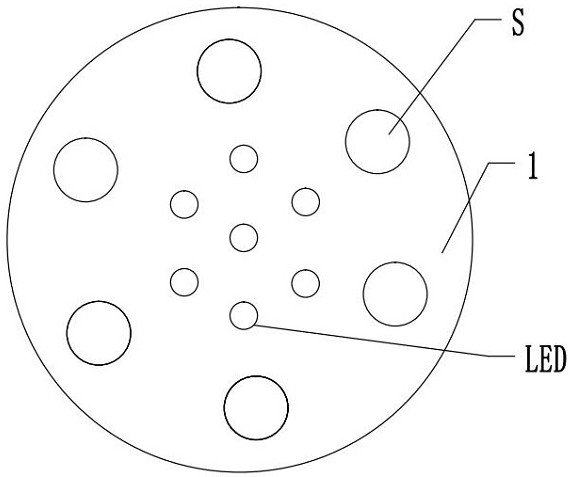

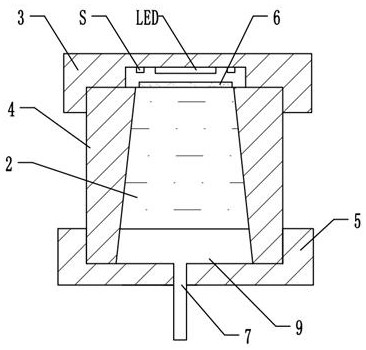

An intelligent projection system based on four-dimensional single-source gamma knife

ActiveCN109011209BPenumbra smallAccurate radiation doseX-ray/gamma-ray/particle-irradiation therapySurgical operationRadiation Dosages

The invention provides an intelligent projection system based on a four-dimensional single-source gamma knife. The system comprises a radiotherapy treatment planning system, an intelligent tracking system, an automatic collaborative treatment bed, a robot system, a radiation source, a human-computer interaction system and an integrated control system, the automatic collaborative treatment bed, therobot system, the intelligent tracking system, the radiation source and the human-computer interaction system are all connected with the integrated control system; the robot system is used for carrying out focus tracking and focusing irradiation on a patient bound on the automatic collaborative treatment bed, and the ray therapy beam emitted by a gamma source rod is subjected to non-isocentric intensity modulated and digital instant focus tracking laser focused four-dimensional radiotherapy plan projection through a gamma source rod and a collimator system, so that the focal point obtains several times of the radiation dose of the tissues and organs around the focal point, and the dose outside the target is reduced by a cliff type, the absorption dose of the focal tissues is accurate, thedose distribution is uniform, the focal tissue cells generate a radiation biological effect to occur necrosis, and a radiation treatment effect similar to surgical resection is generated.

Owner:王全锋

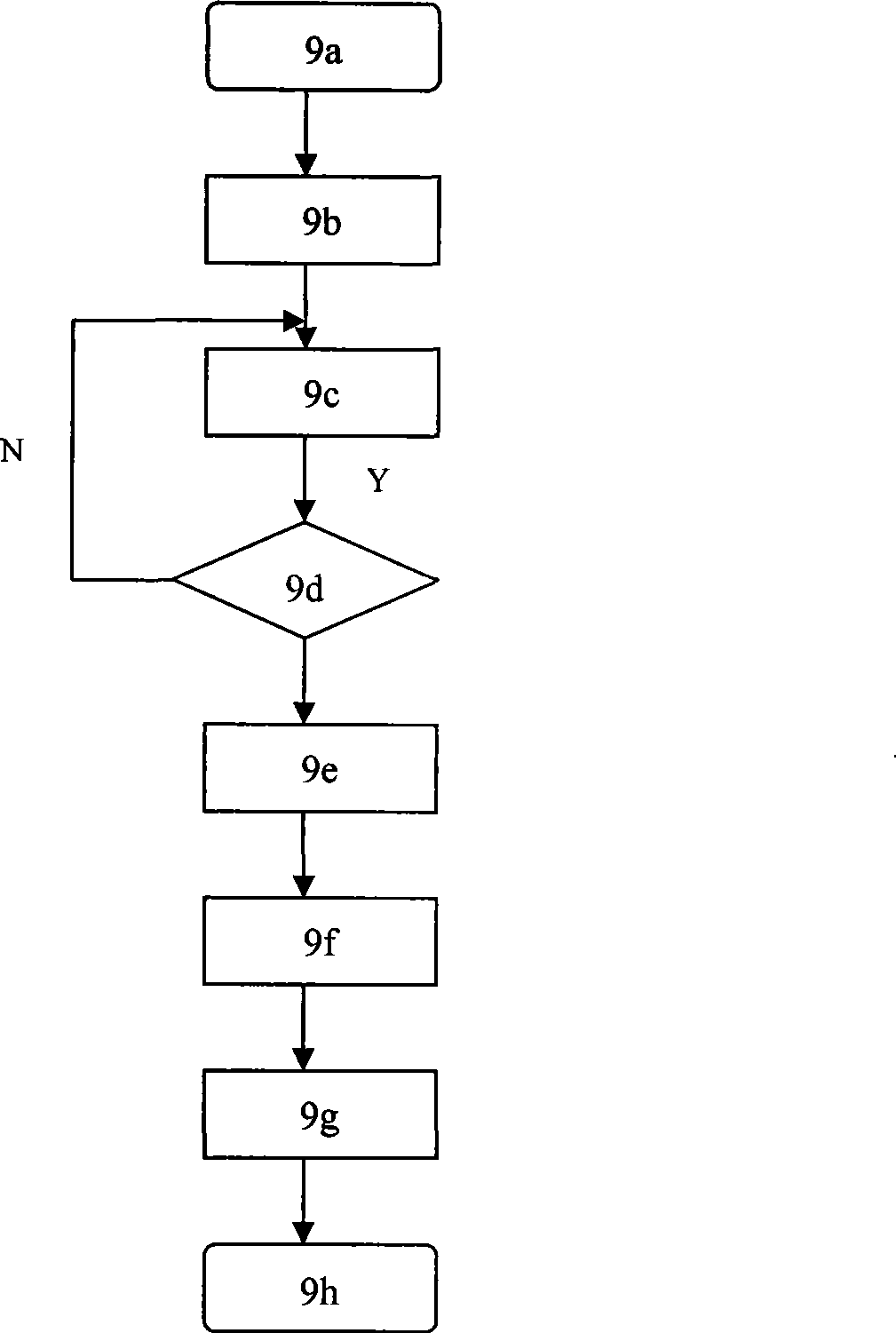

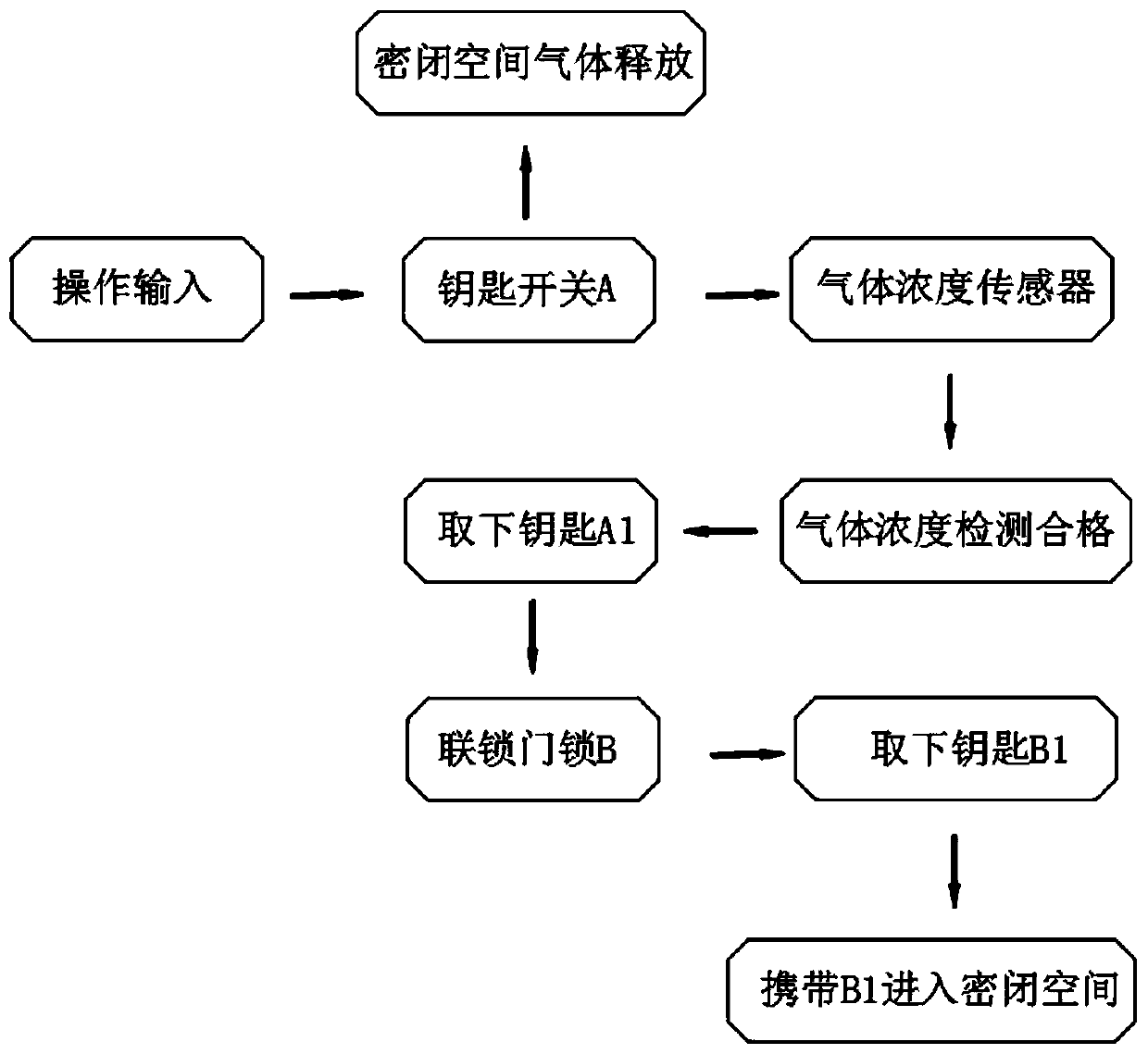

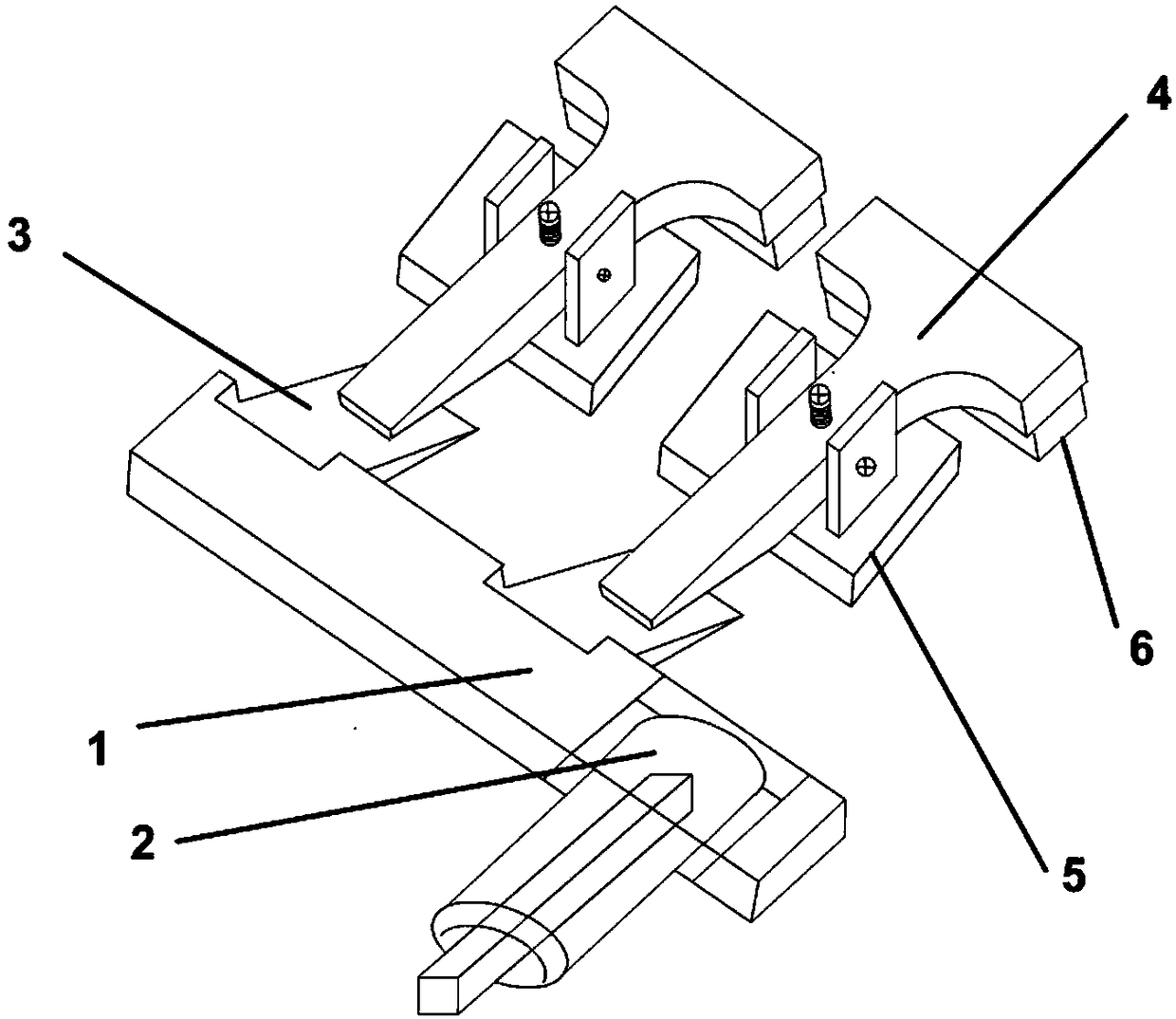

Closed space gas detection safety interlocking method

PendingCN110864002ANo misuseEliminate mistakesProgramme controlComputer controlToxic gasControl manner

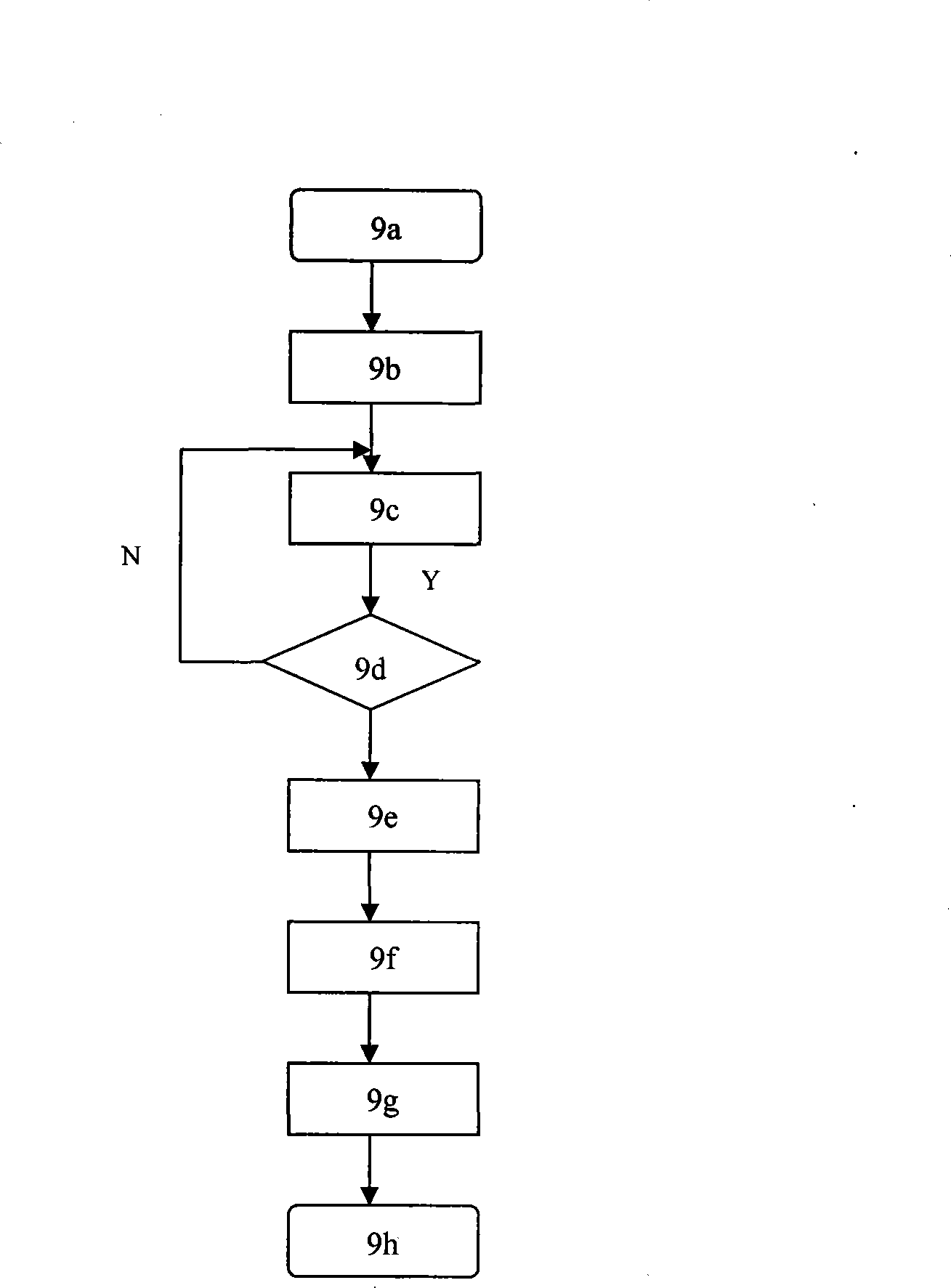

The invention discloses a closed space gas detection safety interlocking method. The method comprises the steps that (S1) the inputting is operated; and workers enter closed space to operate a key switch A before maintenance; (S2) under control by a processor, gas is released for the first time in the closed space; (S3) under control by the processor, a gas concentration sensor detects the concentration of poisonous gas in the closed space; (S4) the processor analyzes if the concentration of the poisonous gas is qualified; and after the concentration of the gas is qualified, a mechanical key A1 is rotationally taken down; and (S5) under control by the processor, after the concentration of the gas is qualified, the gas is forcedly released for the second time in the closed space. The methodadopts the mechanical safety interlocking control mode to guarantee no possibility of wrong operations, prevents the phenomenon of manual judgment faults, has the advantages of coerciveness and logicality compared with subjective judgment in traditional independent module detection and switching, and guarantees the people life safety.

Owner:青岛鼎信工业安全设备有限公司

Circuit breaker detection and compression device

InactiveCN108254680APrecise positioningAccurate detectionMeasurement instrument housingCircuit interrupters testingSemi automaticCompression device

Owner:天津意献科技有限公司

Data processing device for computer-aided organization of rail vehicle aerodynamic equipment

ActiveCN102915509A8Simplify the diagnostic processSmall sizeData processing applicationsSpecial data processing applicationsComputer moduleComputer-aided

The invention relates to a device for processing data of a pneumatic device of a single rail vehicle or a rail vehicle group which consists of a plurality of rail vehicles, wherein the pneumatic device is formed by a plurality of modules through computer-assisted organization. The device at least comprises a processor (6), a memory (8) and data which is stored in the memory (8) and represents a pneumatic device module directory; and the device is further provided with a configuration part (10) and a control part (16), wherein the configuration part (10) is used for selecting modules from the modules which are stored in the memory to organize a pneumatic device scheme; and the control part (16) is used for checking the compatibility of the modules which are selected through the configuration part and rejecting the scheme when the scheme which is organized by the selected modules and an allowable scheme are different, and otherwise, the scheme is allowed.

Owner:KNORR BREMSE BRAKE EQUIP SUZHOU CO LTD

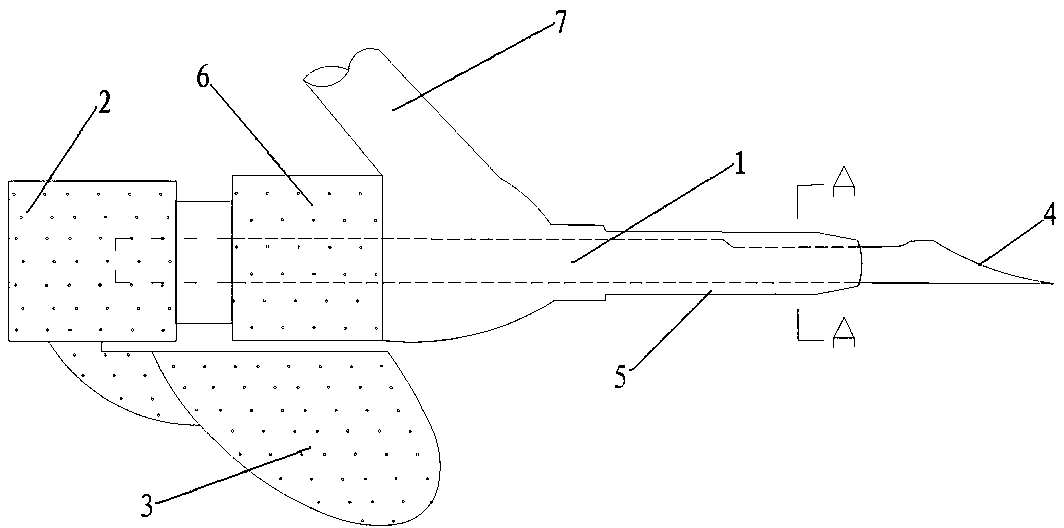

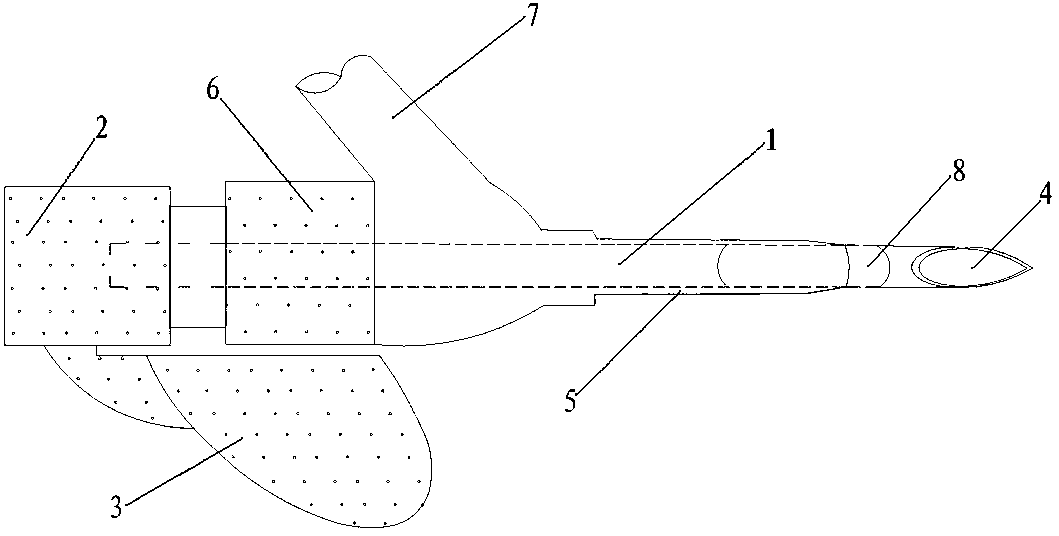

Venous indwelling needle

The invention provides a venous indwelling needle, belonging to a field of medical apparatus. The venous indwelling needle provided in the invention overcomes insufficiency of the puncture needle existing in the venous indwelling needle with a present structure, wherein the puncture needle can cut off human tissue, and causes blocking of a blood return hole and low strength of a needle rod. The venous indwelling needle provided in the invention comprises a puncture needle and a transfusion needle sleeved on the needle rod. of the puncture needle. Improvement provided in the invention is that the blood return hole composed of an axis hole and a side through hole on the puncture needle rod is canceled, thereby the whole puncture needle is solid; a section of axial direction flat section or axial direction groove is arranged on the needle rod on the narrowed port of the front end of the transfusion needle tubing, and a blood return through hole is formed between the narrowed port of the transfusion needle tubing and the axial direction flat section or the axial direction groove on the transfusion needle rod. The venous indwelling needle provided in the invention has the advantages that phenomenon of human tissue cutting does not exist in the puncture process because of non-existence of the blade formed on the inclined plane of the needle point. With the venous indwelling needle provided in the invention, no blood return or slow blood return due to blocking of the needle tubing of the puncture needle in the prior art are avoided so as to eliminate fault. t Excavation part of the cross section of the puncture needle rod is small for keeping out a blood return channel, and strength of the needle rod is strengthened. The venous indwelling needle provided in the invention has characteristics of bending resistance and flexural resistance, such that security of usage is improved.

Owner:刘佐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com