Closed space gas detection safety interlocking method

A confined space, gas detection technology, applied in building locks, measuring devices, program control, etc., can solve problems such as conditions that cannot reach absolute safety, misoperation, etc., to ensure life safety, ensure personnel safety, and improve practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

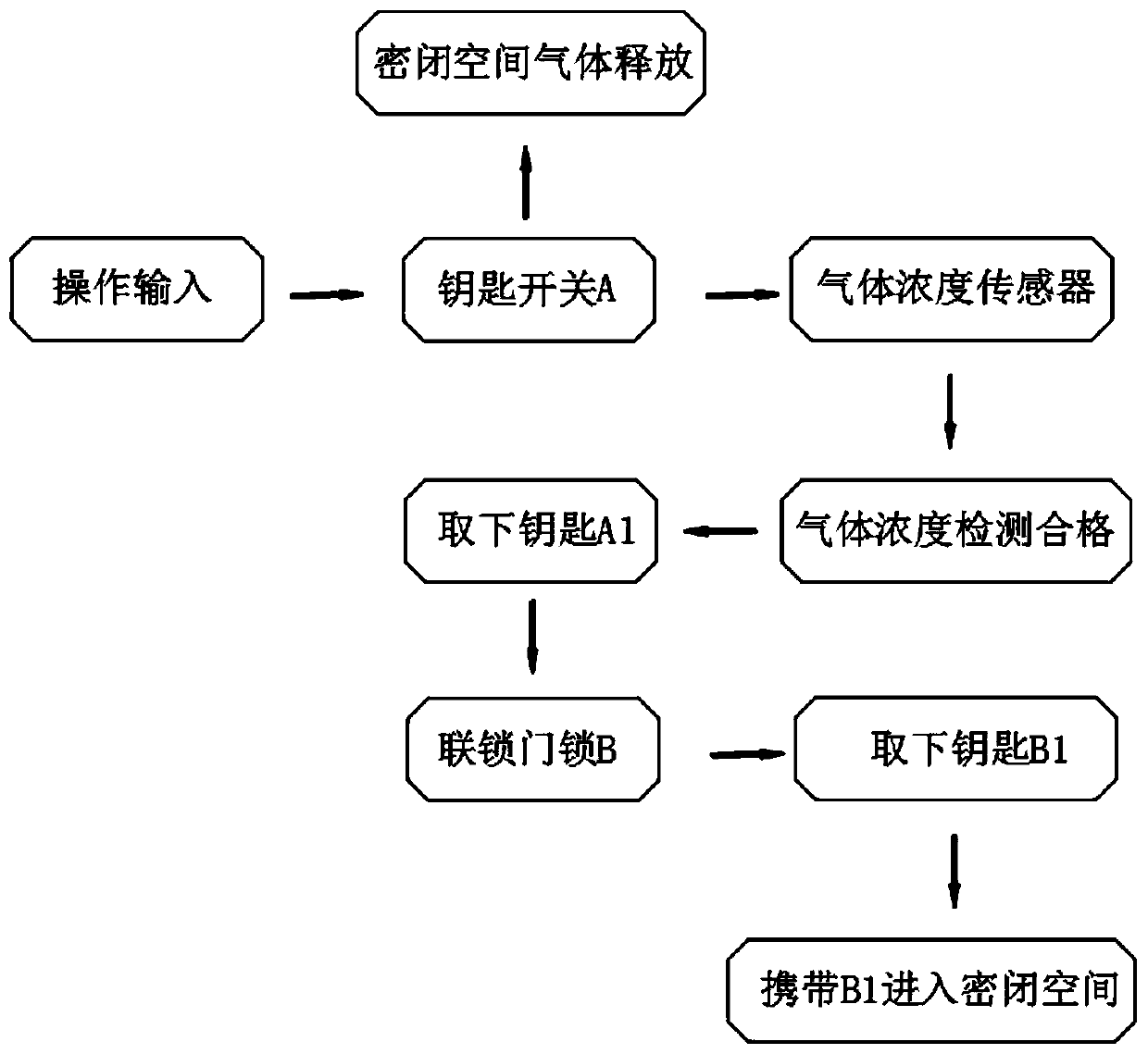

[0030] refer to figure 1 , a gas detection safety interlocking method in a confined space, comprising:

[0031] S1: Operation input, the worker operates the key switch A before entering the sealed space for maintenance;

[0032] S2: Seal the space under the control of the processor for the first release of gas;

[0033] S3: Under the control of the processor, the gas concentration sensor detects the concentration of toxic gases in the sealed space;

[0034] S4: The processor analyzes whether the toxic gas concentration is qualified, and the mechanical key A1 can be turned and removed only after the gas concentration is qualified;

[0035] S5: Under the control of the processor, after passing the gas concentration test, the sealed space is forcibly released for the second time;

[0036] S6: The worker carries the mechanical key A1 to the mechanical door lock B in the confined space, inserts it and turns the mechanical key A1 before turning the mechanical key B1 to open the d...

Embodiment 2

[0047] refer to figure 1 , a gas detection safety interlocking method in a confined space, the main difference between this embodiment and embodiment 1 is that the working hours of the first air pump and the second air pump are changed;

[0048] As a further solution of the present invention: S3 includes a gas concentration sensor and a display, the gas concentration sensor and the display are electrically connected, the gas concentration sensor and the display are electrically connected to the processor in S2 through a data line, and the first air pump works After 15-20 minutes, the gas concentration sensor detects the gas concentration in the sealed space, and the detected value is displayed on the display.

[0049] As a further solution of the present invention: the processor in S4 analyzes the value fed back by the gas concentration sensor, and compares it with the information in the database. If it is not within the safe range, the first air pump will continue to work. If...

Embodiment 3

[0055] refer to figure 1 , a gas detection safety interlocking method in a confined space, the main difference between this embodiment and Embodiment 1 and Embodiment 2 is that the working hours of the first air pump and the second air pump are changed;

[0056] As a further solution of the present invention: S3 includes a gas concentration sensor and a display, the gas concentration sensor and the display are electrically connected, the gas concentration sensor and the display are electrically connected to the processor in S2 through a data line, and the first air pump works After 20-25 minutes, the gas concentration sensor detects the gas concentration in the sealed space, and the detected value is displayed on the display.

[0057] As a further solution of the present invention: the processor in S4 analyzes the value fed back by the gas concentration sensor, and compares it with the information in the database. If it is not within the safe range, the first air pump will con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com