Lost-foam-casting bimetal hammerhead pouring system

A lost foam casting and pouring system technology, applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of low impact strength of joint parts, difficult to quantify metal, easy to stick sand, etc., to improve impact strength , Improve the effect of feeding and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

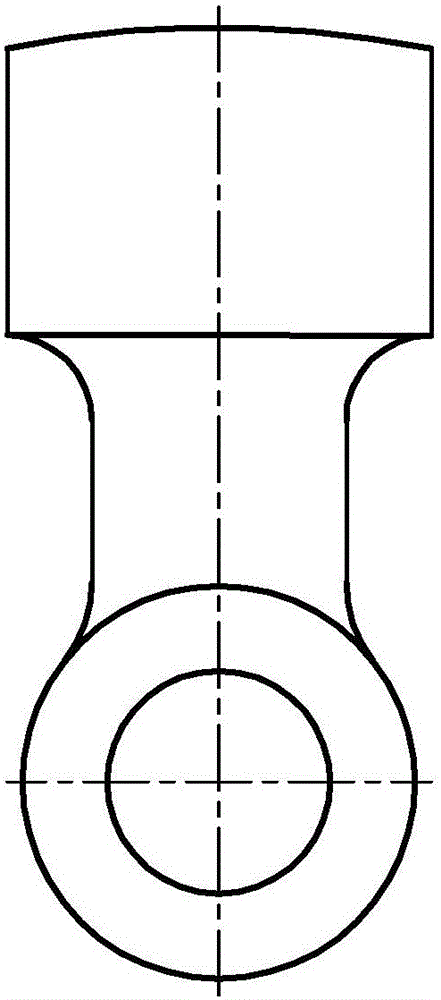

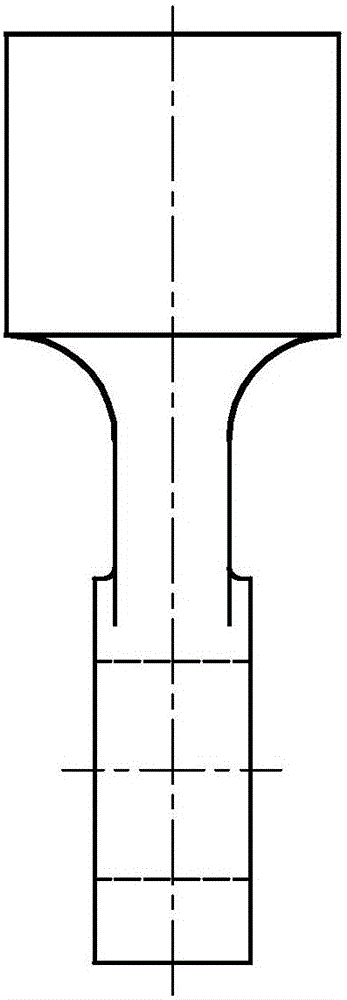

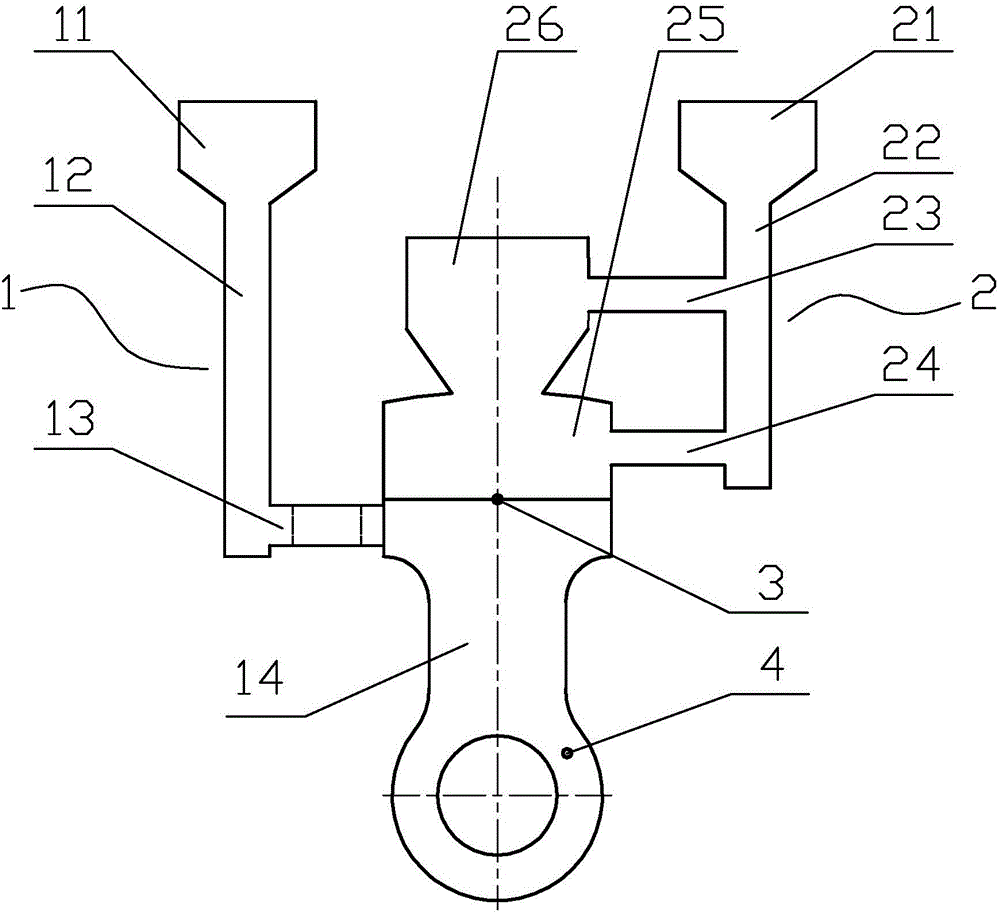

[0042] A gating system for bimetallic hammerheads in lost foam casting, including gating system I1 for pouring the material of the hammer handle, and gating system II2 for pouring the material of the hammerhead, wherein:

[0043] The pouring system I1 includes a sprue cup I11, a vertical sprue I12, a runner I13, and a hammer handle cavity 14. The sprue cup I11 is arranged on the top of the vertical sprue I12 and communicates with the vertical sprue I12, The runner I13 is arranged at the bottom of the vertical runner I12, and one end is connected to the vertical runner I12, and the other end is connected to the hammer handle cavity 14. The runner I13 is also provided with a block 131 for slag retention and backflow prevention.

[0044] The pouring system II2 includes sprue cup II21, vertical sprue II22, upper runner II23, lower runner II24, hammer head cavity 25, and feeding riser 26. The sprue cup II21 is set at The top of the vertical runner II22 is connected to the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com