Assembly welding method for ring-shaped thin-walled sheet metal part of gas turbine and welding electrode

A gas turbine and welding method technology, which is applied to the assembly of complex structures in a narrow space on annular sheet metal welding assemblies, and the field of special welding electrodes, which can solve problems such as assembly of complex structures, optimize the processing process, reduce the deformation of parts, and reduce rework. Effects of Repair Situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical conception and implementation of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0041] In this embodiment, a special welding electrode and assembly and welding methods for the narrow space and complex structure on the annular sheet metal welding assembly are designed:

[0042] (1) Design basis: According to the actual space structure of the parts and the design and processing requirements, a set of resistance spot welding electrode devices was independently designed and manufactured, and the assembly process was reasonably arranged according to the electrodes;

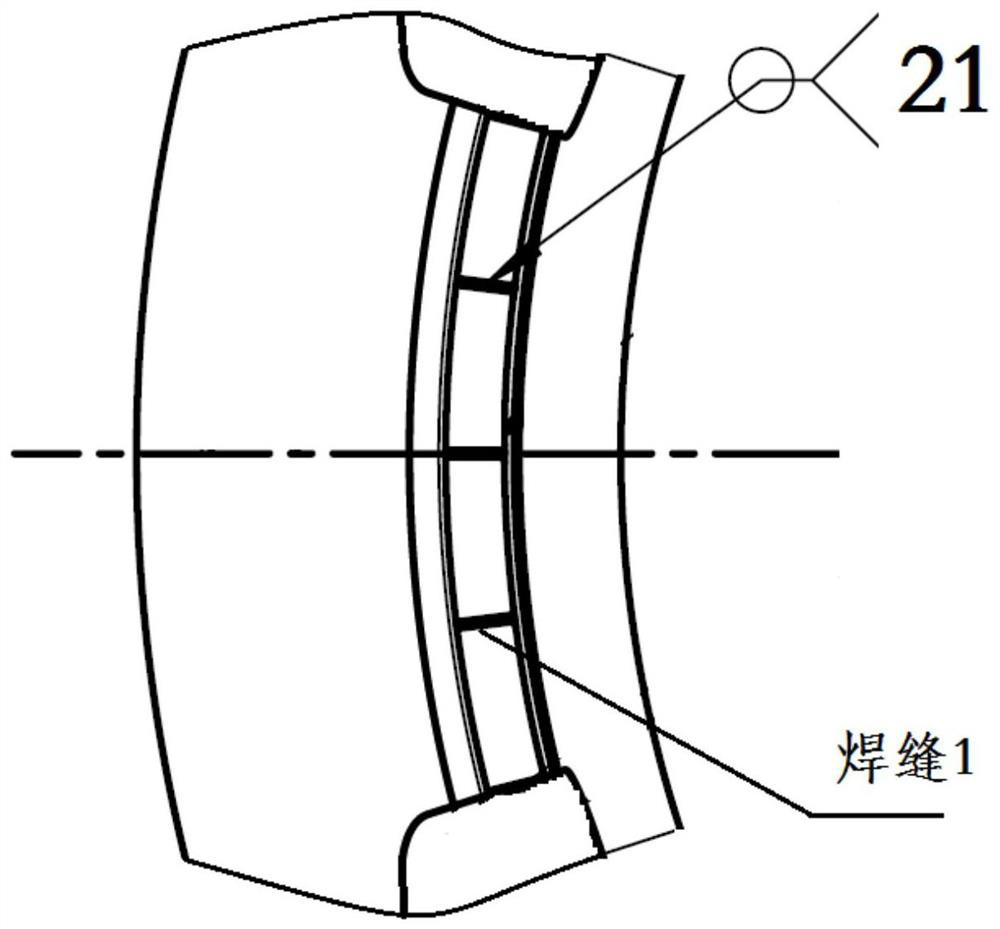

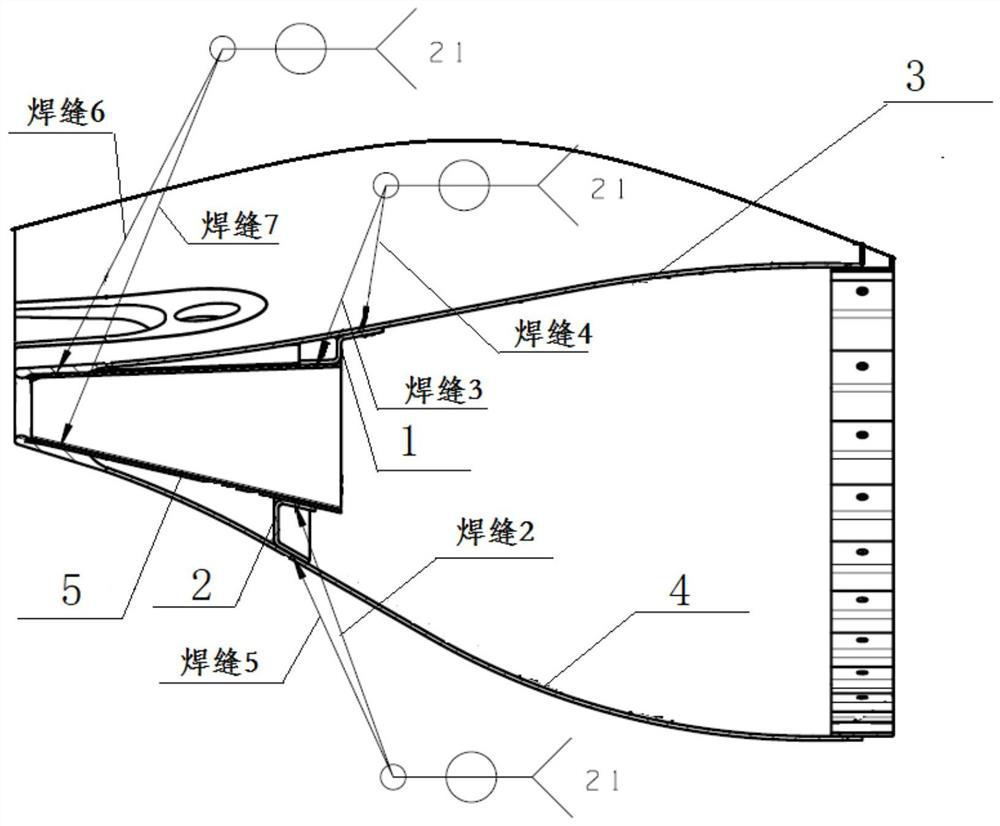

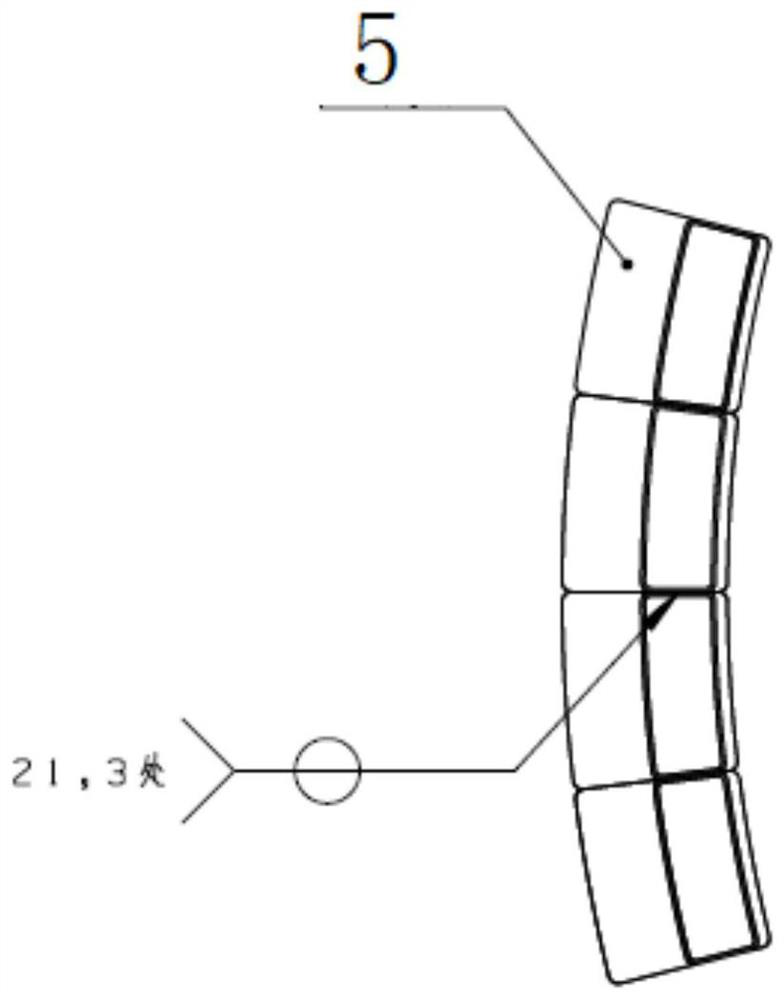

[0043] (2) Technical solution: According to figure 1 , figure 2 As shown, combined with the actual space size and welding method, with a set of special resistance spot welding welding electrode device independently designed and manufactured, it can meet the requirements of welding seam 1, welding seam 2, welding seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com