Method for repairing transverse threaded holes of bogie of passenger train

A technology of a railway passenger car and a repair method, which is applied in the field of rail transit equipment repair, can solve the problems of low success rate of one repair, many rework times, low efficiency, etc., and achieves convenient alignment and tapping, high repair efficiency, and high quality of plugging welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

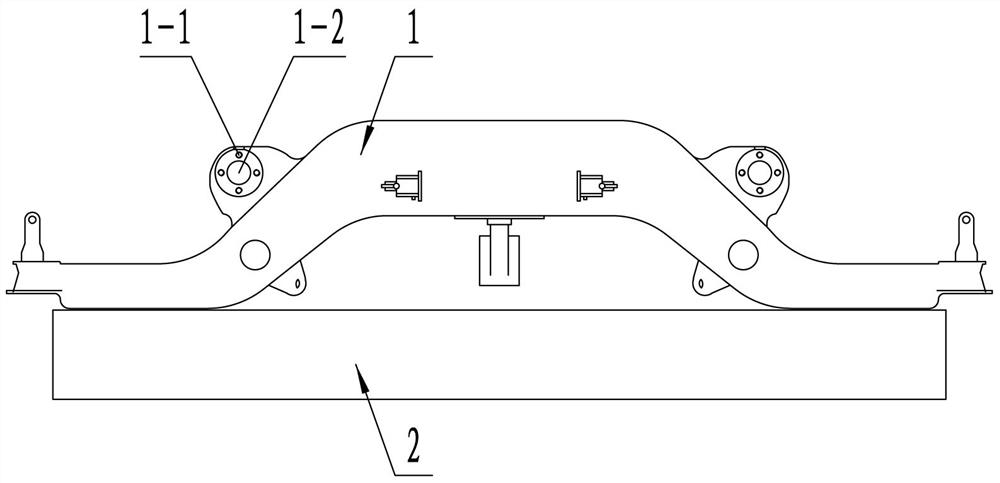

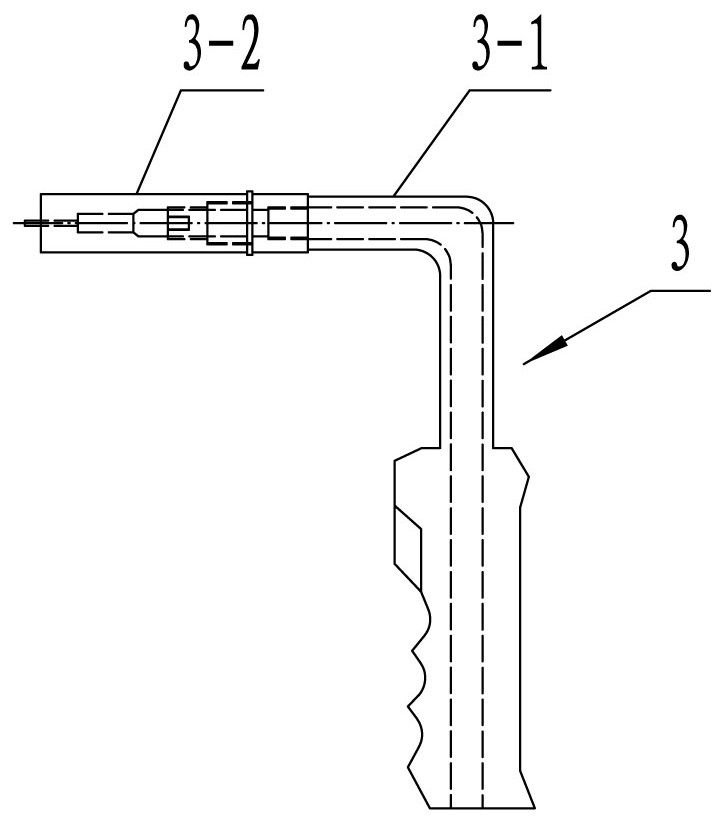

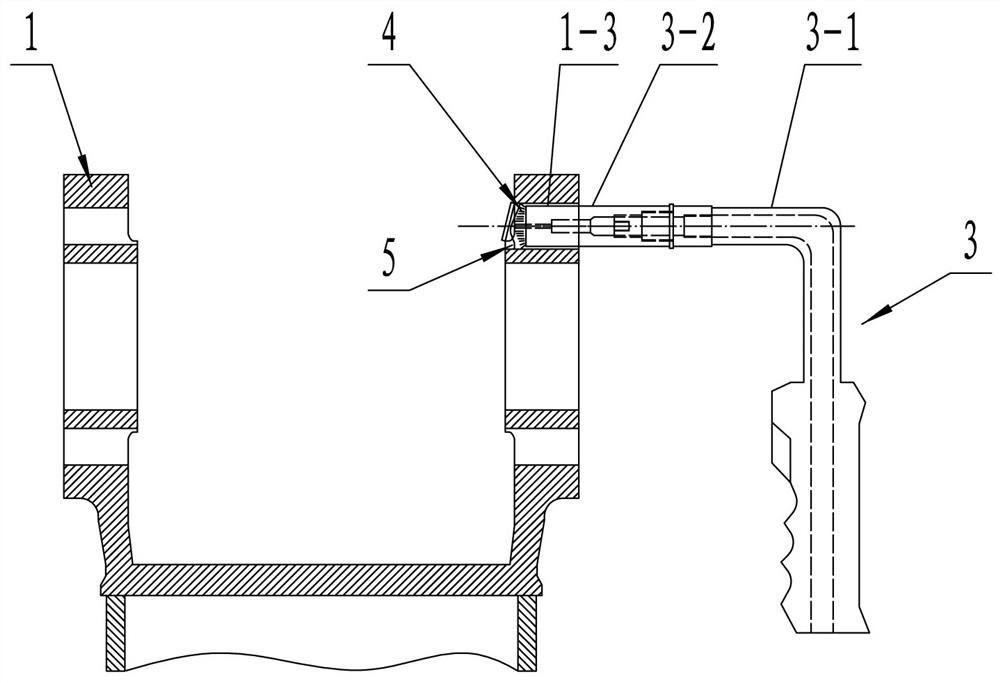

[0030] Such as figure 2 , Figure 4 with Figure 7 As shown, the method for repairing the transverse threaded hole of the railway passenger car bogie uses a special welding torch 3, a drilling positioning tool 6, a universal rocker drill and a universal tapping machine 7 installed on a trolley 8, and a universal tapping machine 7 in the repair process. Radial drill and universal tapping machine 7 are commercially available products. Such as figure 2 As shown, the bending degree of the wire feeding guide 3-1 of the special welding torch 3 is 90°, and the wire feeding guide 3-1 is covered with a coaxial protective cover 3-2. Figure 4 with Figure 5 The shown drilling positioning tool 6 includes a positioning shaft 6-3 and a positioning plate 6-1 connected to one end of the positioning shaft 6-3. The positioning plate 6-1 is provided with a positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com