Drainage pipe connector with gas purification function for underground engineering construction

A technology for gas purification and underground engineering, applied in the field of underground engineering, can solve problems such as air pollution, and achieve the effect of improving purification effect, reducing space occupation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

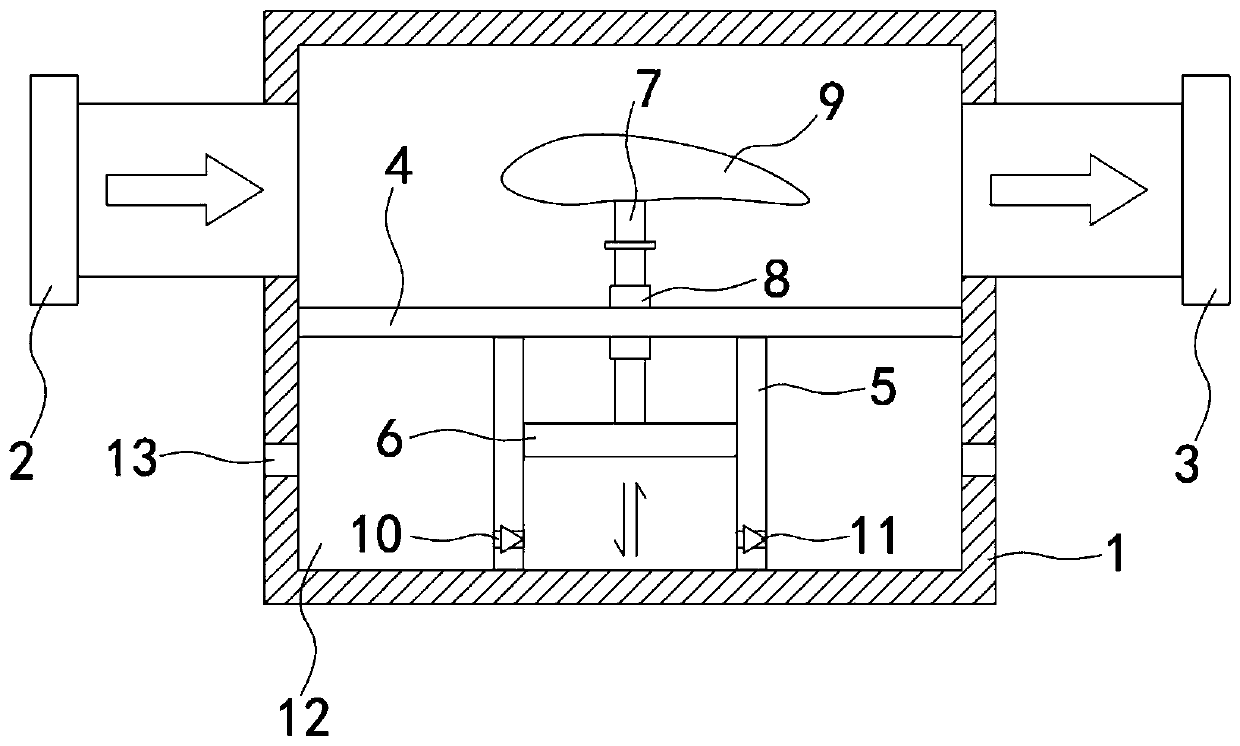

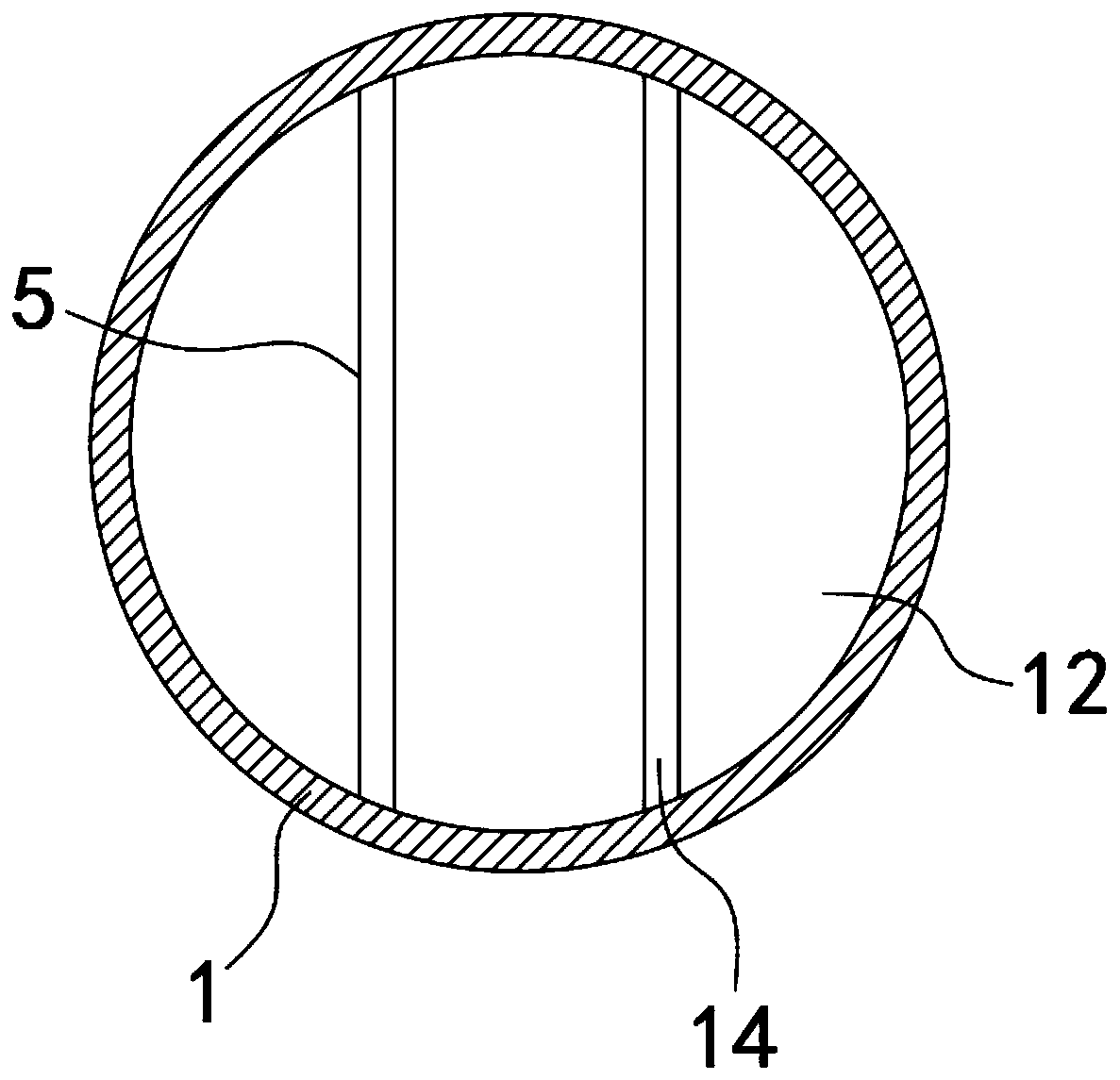

[0023] Such as Figure 1-2 As shown, a drainage pipe joint with gas purification function for underground engineering construction includes a purification box 1, the two ends of the purification box 1 are respectively connected with a water inlet pipe 2 and a drainage pipe 3, and the interior of the purification box 1 is sealed and connected with a horizontally arranged Partition 4, the underside of the partition 4 is provided with a pumping part 5, the pumping part 5 is slidingly and sealed connected with a pumping plate 6, the upper end of the pumping plate 6 is fixedly connected with a connecting rod 7, and the parting plate 4 is penetrated and fixed A casing 8 is connected.

[0024] The upper end of the connecting rod 7 runs through the casing 8 and is fixedly connected with the wing flow plate 9. The upstream surface of the wing flow plate 9 is set facing the water inlet pipe 2. When the water flow flows from the water inlet pipe 2 to the drain pipe 3, it will directly ac...

Embodiment 2

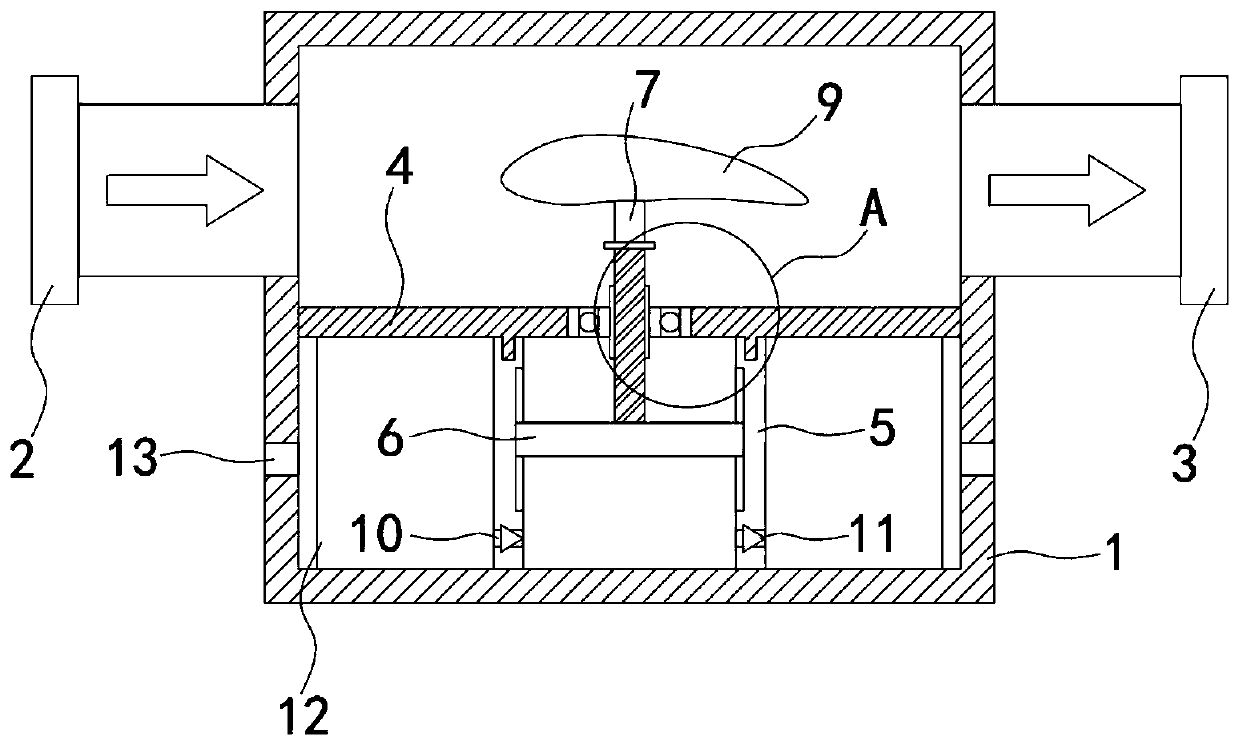

[0029] Such as Figure 3-5 As shown, the difference between this embodiment and Embodiment 1 is that the pumping part 5 includes a pumping cylinder 15, the lower end of the pumping cylinder 15 is fixedly connected with the inner side wall of the purification box 1, and the upper end of the pumping cylinder 15 rotates with the partition plate 4 Connection, specifically, the lower end of the dividing plate 4 is provided with an annular protrusion 19, and the upper end of the pump cylinder 15 is provided with an annular chute, the annular protrusion 19 is located in the annular chute and is connected with the annular chute for sealing and rotation, the pump air cylinder 15, The clapboard 4 and the purification box 1 together form a closed space. The lower end of the clapboard 4 is fixedly connected with a commutator cover 16, and the commutator cover 16 is provided with a diversion hole 17 correspondingly. Rotational connection, the casing 8 is provided with an internal thread, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com