Solder resist hole plugging method for BMU printed circuit board

A technology for printed circuit boards and plug holes, which is applied in the fields of printed circuit, printed circuit, and printed circuit manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention, but this does not constitute a limitation to the protection scope of the present invention.

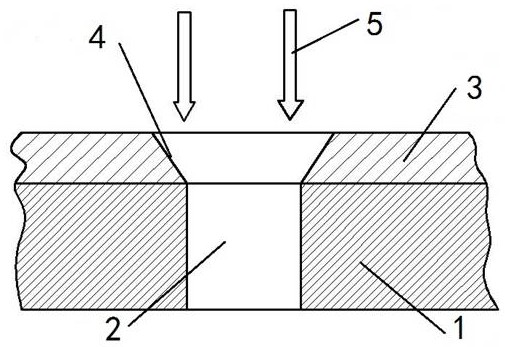

[0044] see figure 1 , The present embodiment provides a BMU printed circuit board 1 solder resist plugging method, comprising the following steps:

[0045] S1. Targeting: Target holes are made on the BMU printed circuit board 1; in actual operation, the target holes can be made on the BMU printed circuit board 1 by a shooting machine, and the significance of the target holes is that the BMU printed circuit board 1 usually consists of many layers of plates Stacking and pressing together requires target holes for alignment, so that the alignment accuracy can meet the production needs, otherwise the misalignment between layers will lead to open circuits and affect reliabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com