Concrete distribution control method and system

A control method and concrete technology, applied in manufacturing tools, auxiliary molding equipment, supply devices, etc., can solve the problem of not fully considering the problem of cloth thickness detection and control, and achieve the effect of saving manpower, material and financial resources, and uniform cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

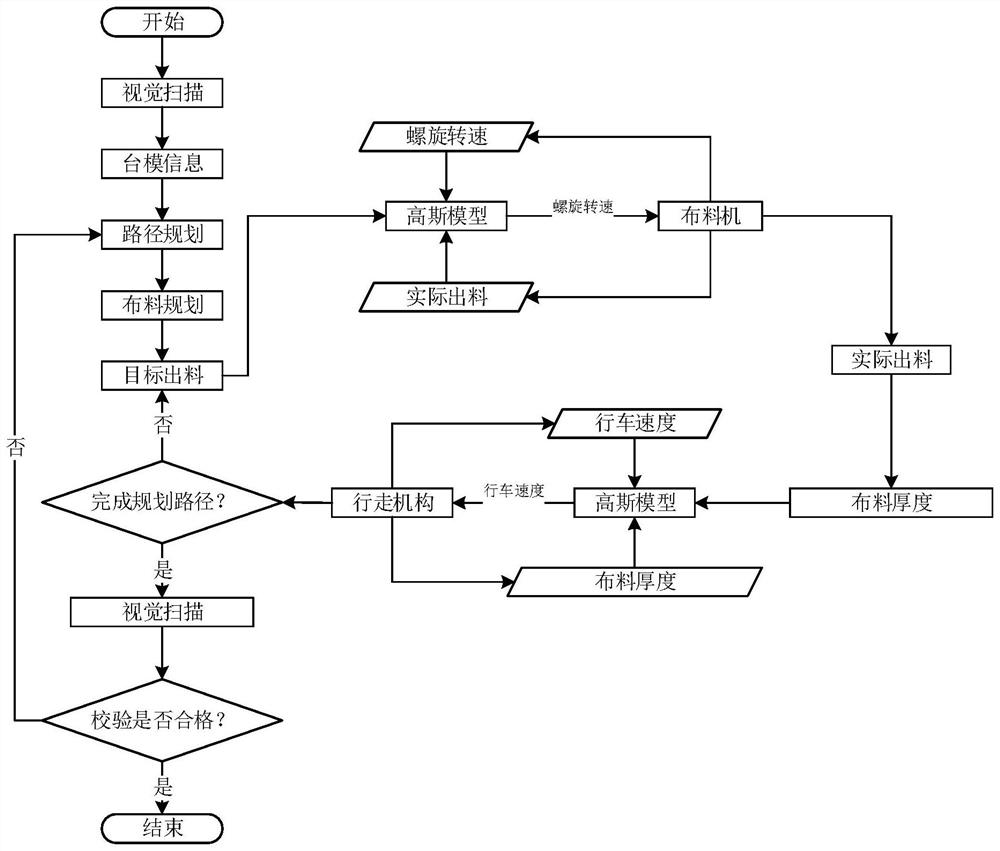

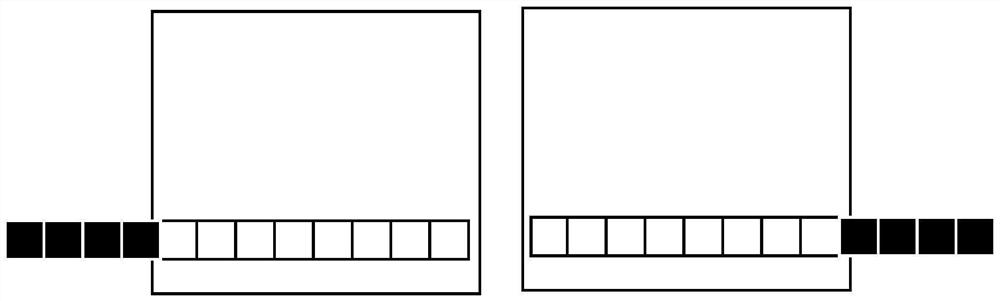

[0030] The invention proposes a concrete distribution control method, aiming at the real-time feedback control problem, firstly, model training is carried out based on the pre-collected data, secondly, the feedback control is realized based on the prediction based on the trained model, and finally, due to the hysteresis of the measured thickness, the hysteresis information and The data is added to the training data set for model calibration, so as to achieve the purpose of dynamic model update and better cloth planning.

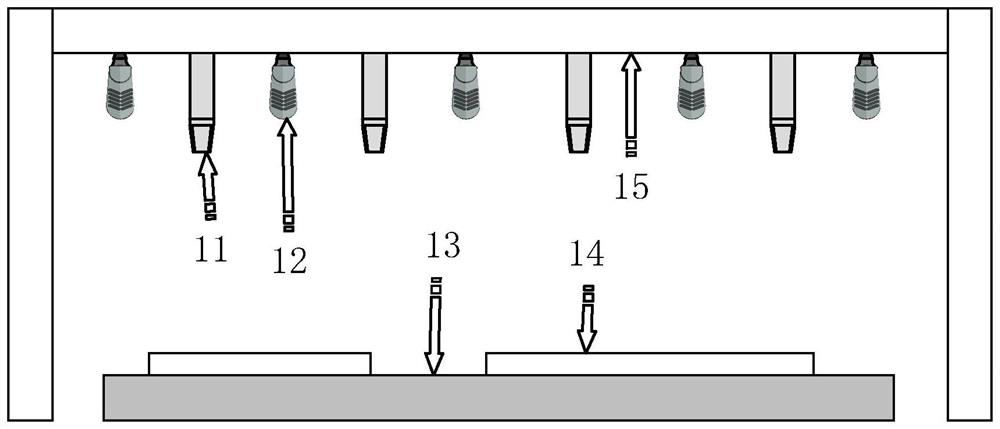

[0031] The present invention adopts the double Gauss model, the relationship model between the screw speed and the material output is model one, and the relationship model between the driving speed and the cloth thickness at a specific screw speed is the model two. Model 1 is mainly used to ensure the stability of the amount of material discharged. The key point of the present invention lies in model 2. Since the concrete is in a flowing state during the distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com