Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "No need to invest" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of halogen-free flame-retardant thermoplastic polyurethane elastomer sheath material and its preparation and application

InactiveCN102295835ANo need to investWide extrusion processing temperatureInsulated cablesInsulated conductorsHalogenThermoplastic polyurethane

The invention discloses a zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material and a preparation method thereof. The zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material is prepared from the following raw material components in parts by weight: 50-80 parts of polyurethane, 10-30 parts of zero-halogen flame retardant, 10-20 parts of zero-halogen smoke suppressant, 5-20 parts of processing modifier, 0.2+ / -0.05 part of processing auxiliary agent, 0.2+ / -0.05 part of antioxidant and 0.2+ / -0.05 part of ultraviolet resistant. Compared with the prior art, the zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material prepared by the invention has the advantages of wider processing temperature range, ultrahigh physical and mechanical properties and flame retardant property of UL-94 and V-0 level.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

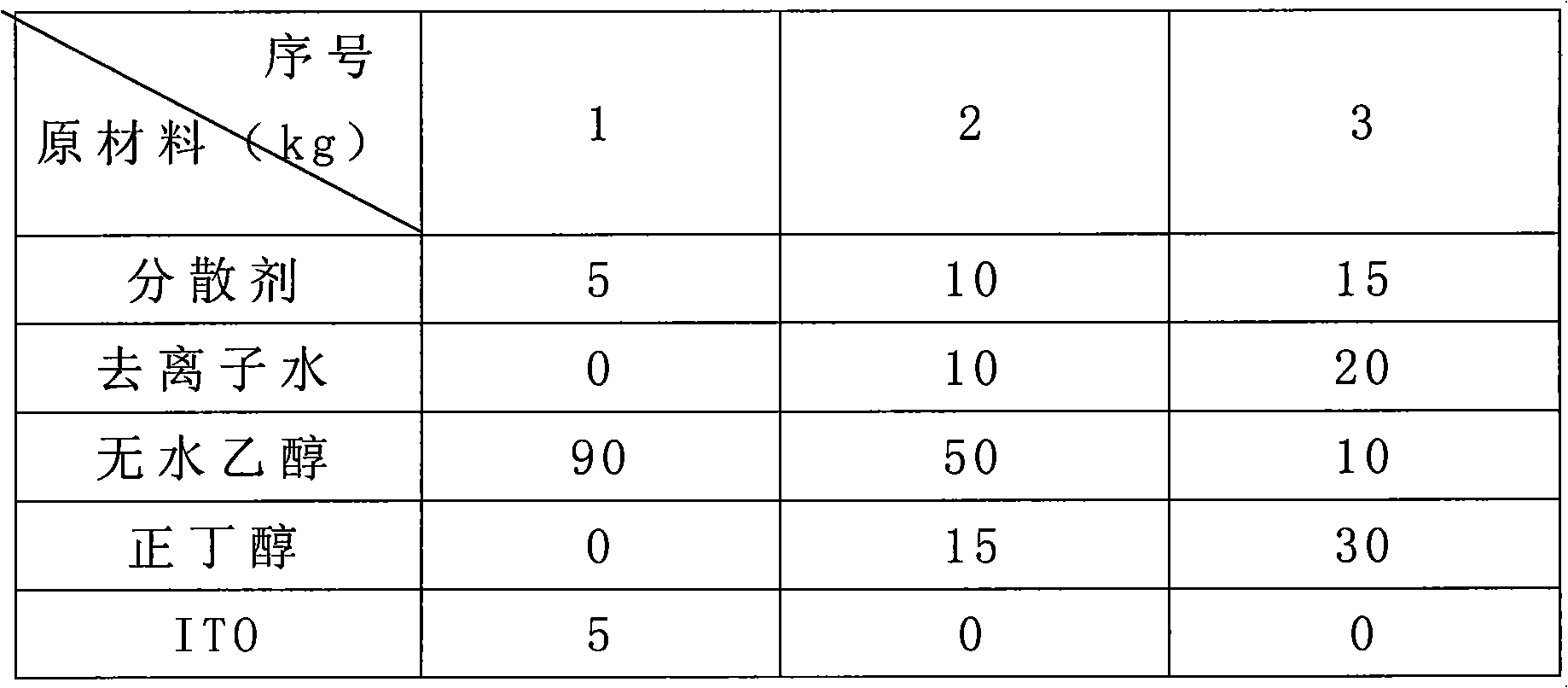

Insulating mould coating, laminated glass intermediate film, heat-protecting glass and laminated glass thereof

The invention relates to an insulating mould coating, a laminated glass intermediate film, a piece of heat-protecting glass and a piece of laminated glass thereof. The transparent insulating mould coating is prepared by dissolving a thermal plastic macromolecule resin into a solvent, then adding a nanometer material body sizing agent and other auxiliary agents and stirring the mixture evenly. Theinsulating mould coating can be coated on glass and transparent resin film materials, and has very strong bonding strength, and refraction coefficients similar to that of the glass and the laminated glass intermediate film; and the insulating laminated glass prepared by using the insulating mould coating has the characteristics of high visible light transmittance, infrared ray shielding, heat insulation, ultraviolet ageing resistance and the like. The insulating mould coating is simple to prepare, needs no large-scale equipment, and is favorable for popularization.

Owner:HUNAN MASHI NANOMETER NEW MATERIAL

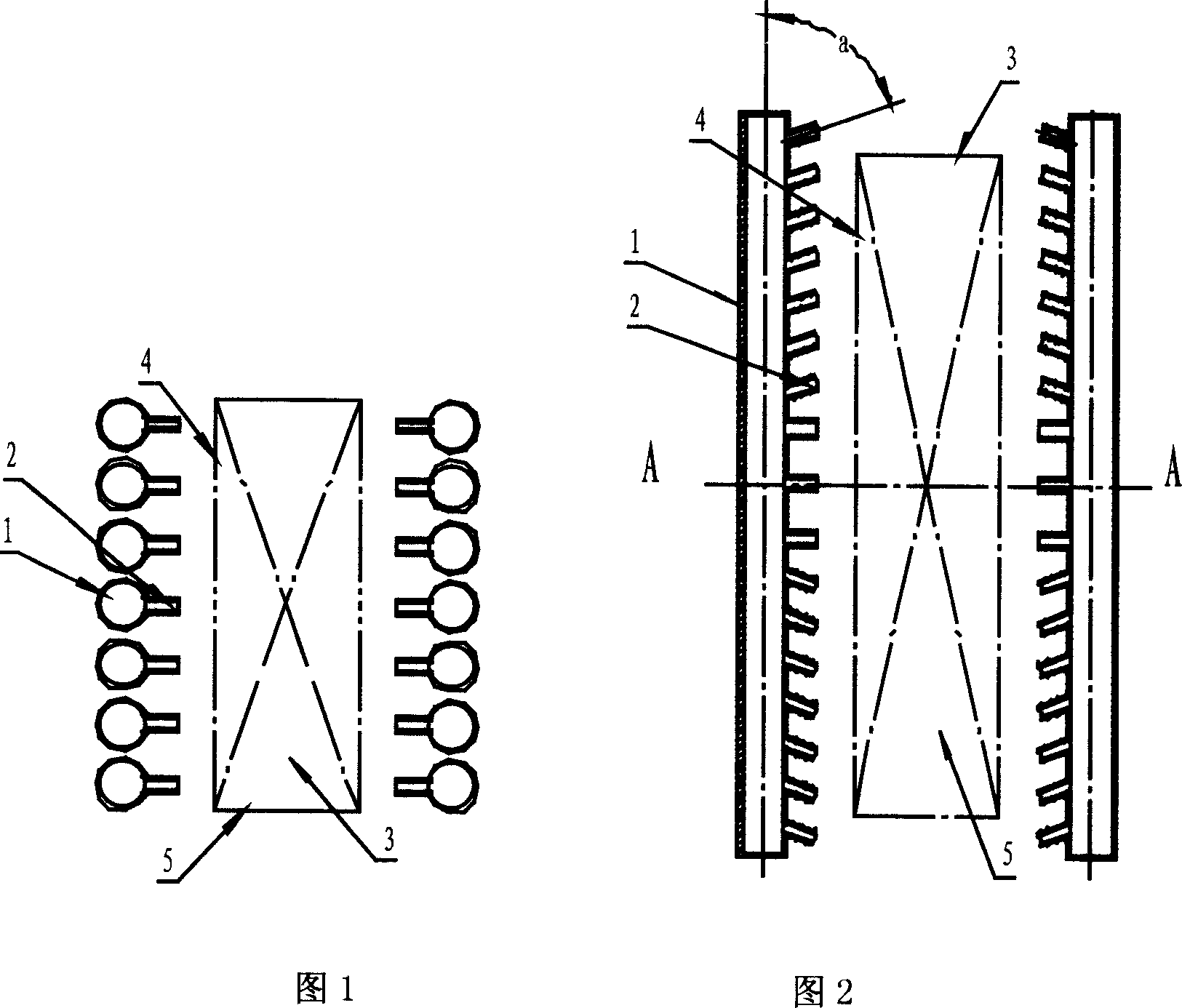

Method for preventing end-face spray quenching cracking of quenching piece by changing spray angle

InactiveCN101012491AReduce cooling intensityIncrease cooling intensityFurnace typesHeat treatment process controlDielectricQuenching

The invention discloses an end-face spray quenching crack-preventing method of quenching piece through changing spraying angle in the heat disposal domain of metal material, which is characterized by the following: placing quenching piece in the quenching equipment with pipe; making quenching piece with lateral and end faces; setting lateral face as rapid freezing face only; paralleling lateral face and pipe; setting the end face of quenching piece perpendicular to pipe; flowing quenching dielectric through pipe; displaying angle a (0-90 deg) for pipe and lateral face of quenching piece; fitting for cooling lateral face of quenching piece; avoiding crack effectively.

Owner:SHANGHAI JIAO TONG UNIV

Carbon fiber sandwich gauge framework and manufacturing method thereof

The invention relates to a carbon fiber sandwich gauge framework and its manufacturing method. The gauge framework is composed of an internal foam core and a carbon fiber plate wrapped on the internal foam core. According to a carbon fiber sandwich gauge, the gauge is designed to a sandwich structure with internal foam and outside carbon fiber plate so as to further reduce weight of the gauge. Meanwhile, a foam block is cut into a preform according to product requirements, and then the cut carbon fiber plate is pasted onto the preform. By full utilization of the characteristic that foam has good machinability and is convenient for processing, foam can be rapidly and simply processed into various shapes, thus satisfying different structural shapes. Technological requirements are very low; investment in large-scale equipment is not required; and the technological design is very flexible.

Owner:东莞市海旭新材料技术有限公司

Environment-friendly ultraviolet light resistant and high-temperature resistant paint for outer walls of buildings

InactiveCN103482905AGood liquidityExcellent anti-mildew and anti-corrosion propertiesSolventPolyaspartic acid

Environment-friendly ultraviolet light resistant and high-temperature resistant paint for outer walls of buildings comprises A compositions, B compositions and a C composition, wherein the A compositions comprise the following substances in parts by weight: 25-35 parts of polyaspartic acid ester resin, 20 parts of an aromatics mixed solvent, 8-10 parts of nano-scale ceramic powder, 2-4 parts of mica powder, 10-18 parts of diacetone alcohol, 3-8 parts of ethylene glycol monobutyl ether, 7-11 parts of a cellulose thickener solution with the mass percent of 2%, 1.0-1.4 parts of a polyphosphate dispersing agent solution with the mass percent of 10%, 1-3 parts of an emulgator, 0.1-0.3 part of sodium hydroxide, 30-50 parts of ethyl alcohol, 70-100 parts of deionized water, 140-180 parts of titanium dioxide; the B compositions comprise the following substances in parts by weight: 3-5 parts of a paint curing agent, 0.02-1 part of an initiator, 1 part of a dispersing agent, 0.6 part of a flatting agent, 0.3 part of an antifoaming agent, 0.3 part of a defoaming agent, 25 parts of a modified ammonia curing agent, 2-4 parts of tetrachloroisophthalonitrile, 3-5 parts of a dry film antiseptic; the C composition is an environment-friendly color mixed-phase inorganic pigment.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

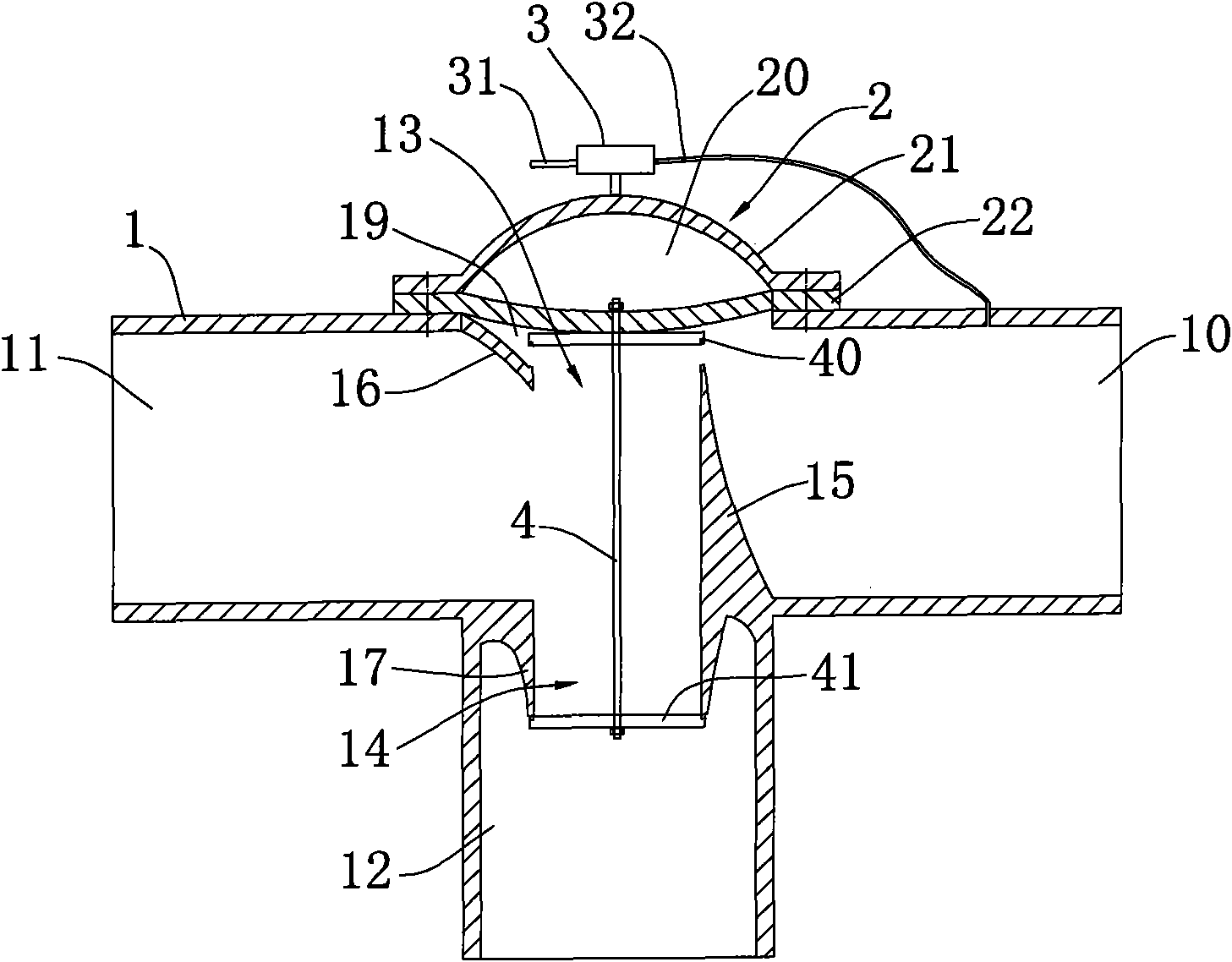

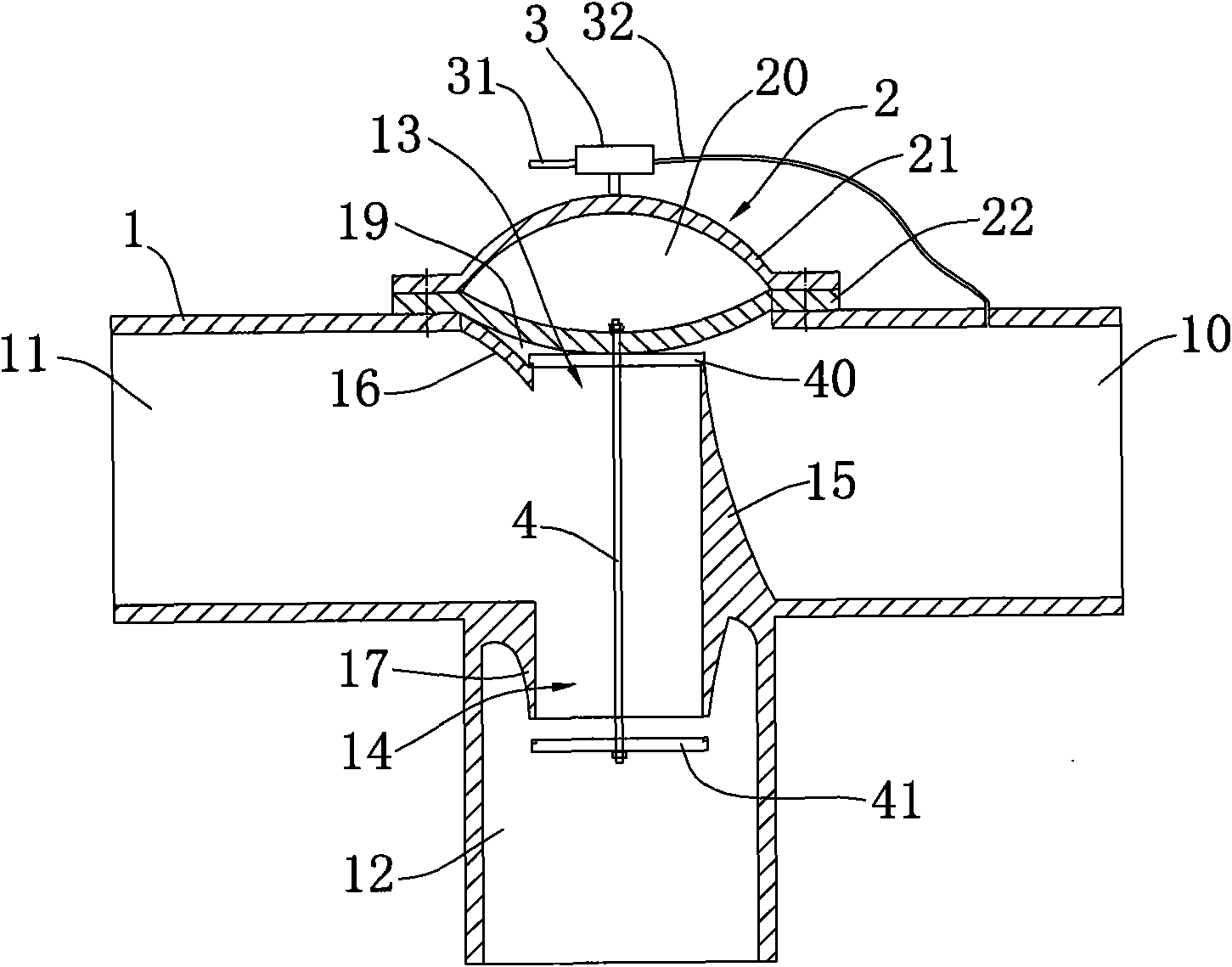

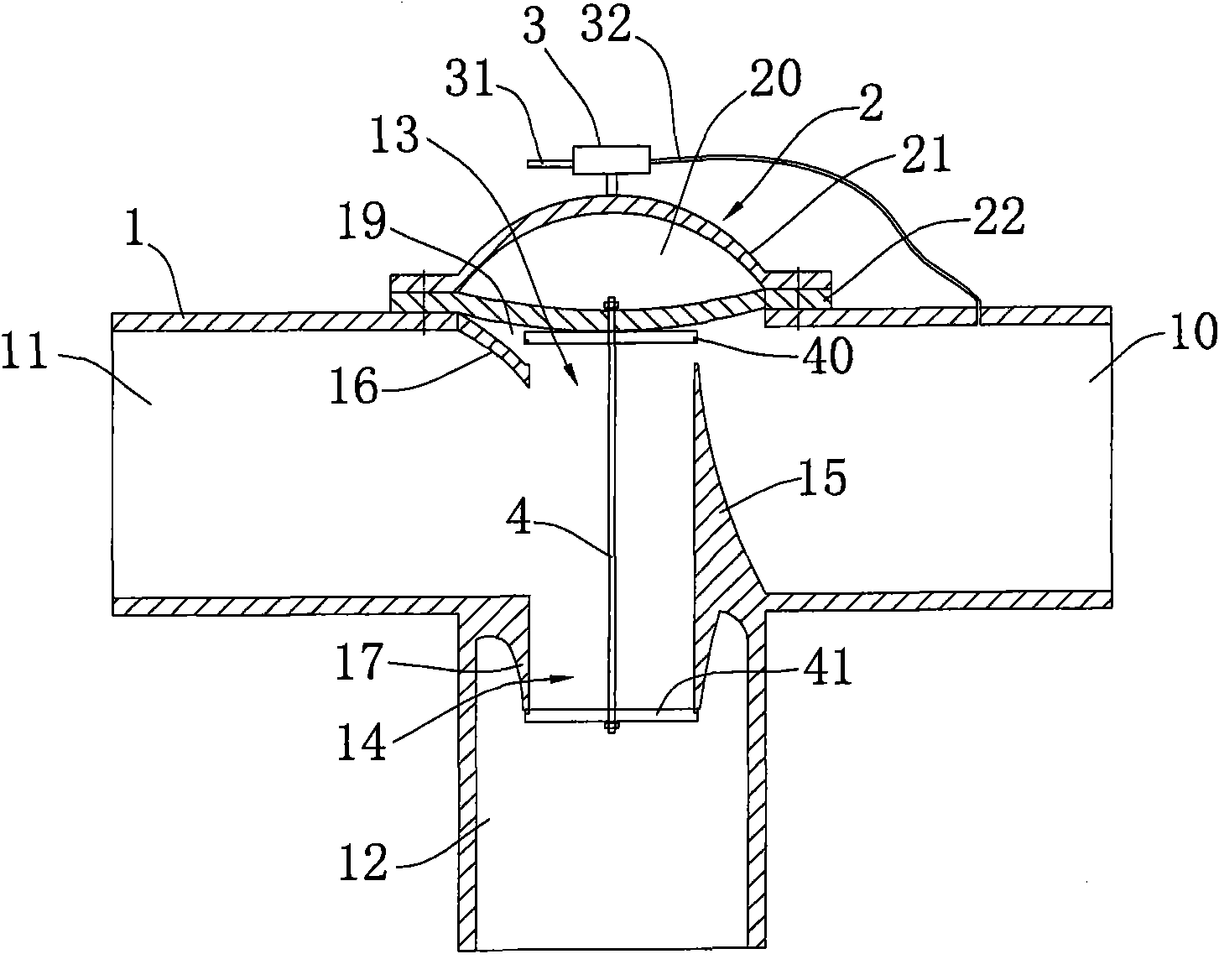

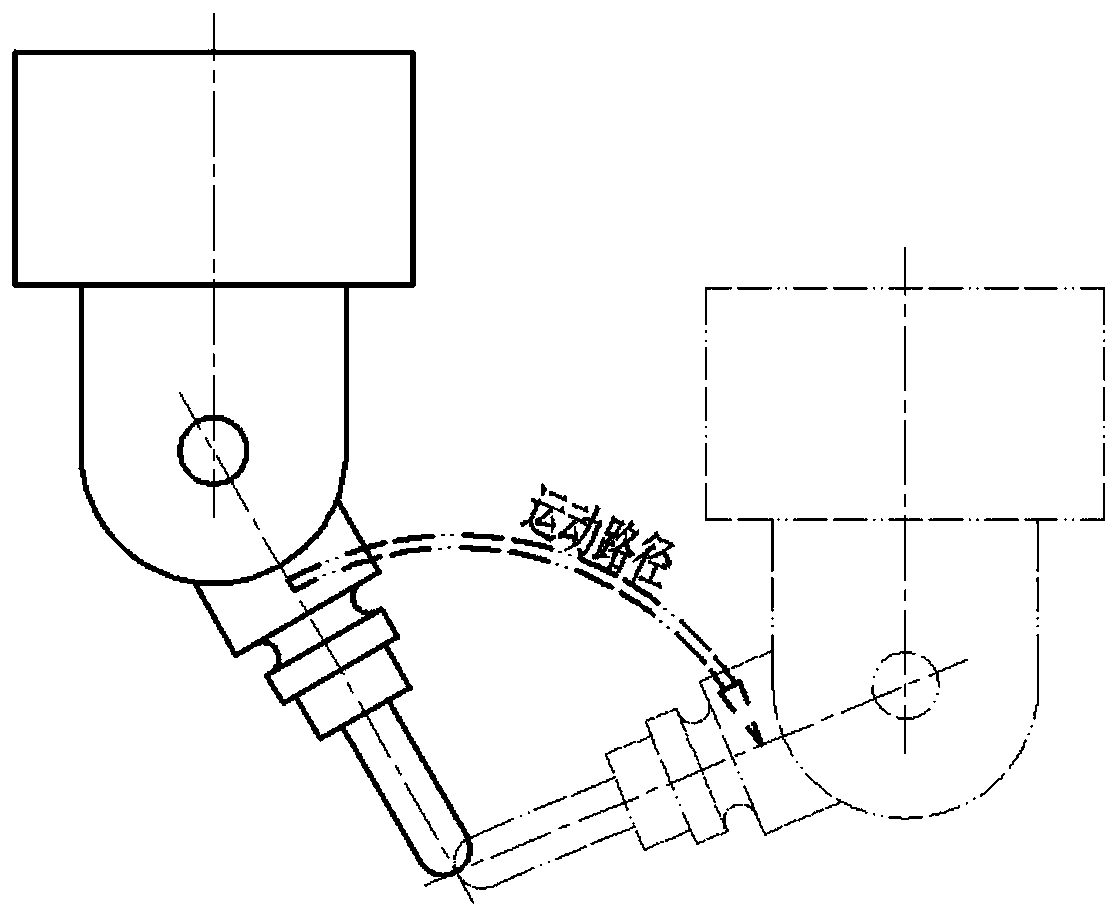

Liquid flushing type multi-channel switching channel valve assembly

InactiveCN101956862AImprove filtering effectAchieve backwashOperating means/releasing devices for valvesMultiple way valvesInternal pressurePressure controlled ventilation

The invention discloses a liquid flushing type multi-channel switching channel valve assembly, which comprises a valve body. A water inlet cavity, a water outlet cavity and a water drain cavity are formed in the valve body; a flow guide part I for communicating the water inlet cavity with the water outlet cavity, a flow guide part II for communicating the water outlet cavity with the water drain cavity, and a valve core assembly for controlling the alternate switching on and switching off of the flow guide part I and the flow guide part II are arranged at the junction of the water inlet cavity, the water outlet cavity and the water drain cavity; an elastic cavity which is connected with the valve core assembly and a pressure control mechanism for regulating the internal pressure of the elastic cavity are also arranged on the valve body; and due to the regulation of the pressure control mechanism, the elastic cavity expands and contracts to drive the valve core assembly to slide between the flow guide part I and the flow guide part II in a reciprocating mode, so that the alternate switching on and switching off of the flow guide part I and the flow guide part II is realized. Channel switching is finished in a pressure regulation mode, but pressure change is realized by controlling an electromagnetic valve; and the liquid flushing type multi-channel switching channel valve assembly has the advantages of simple structure, convenient control, no investment in equipment such as an air source and the like, and low manufacturing cost.

Owner:浙江晶泉水处理设备有限公司

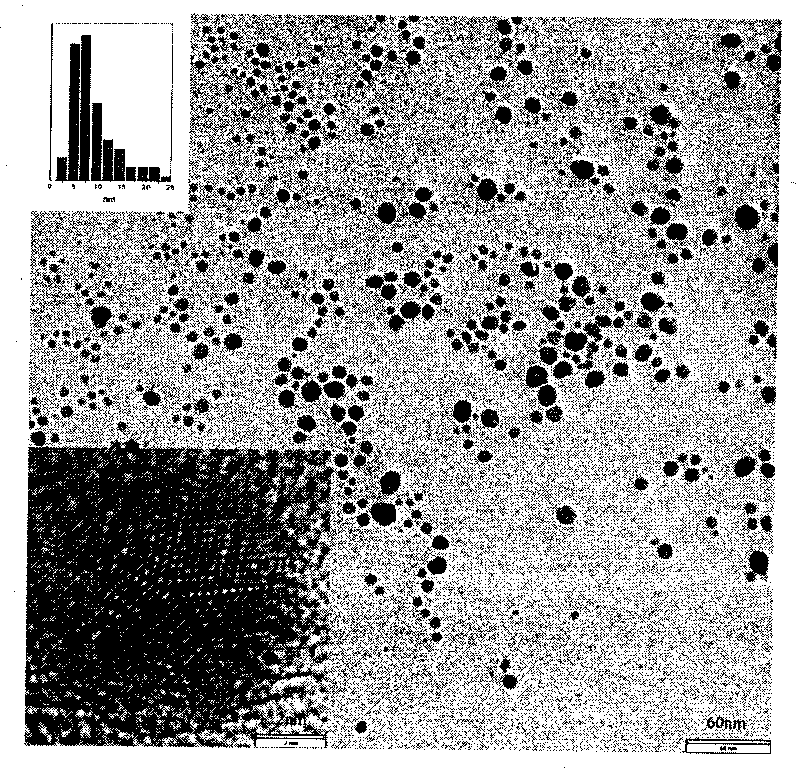

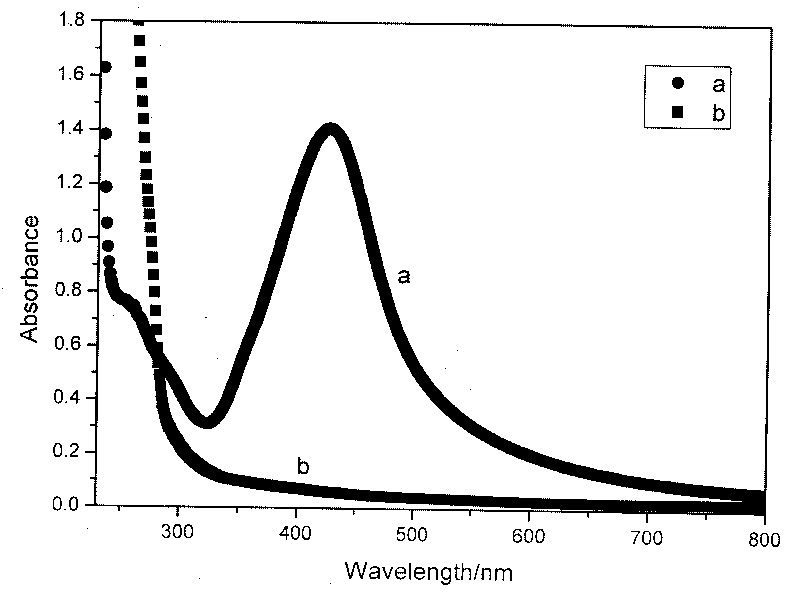

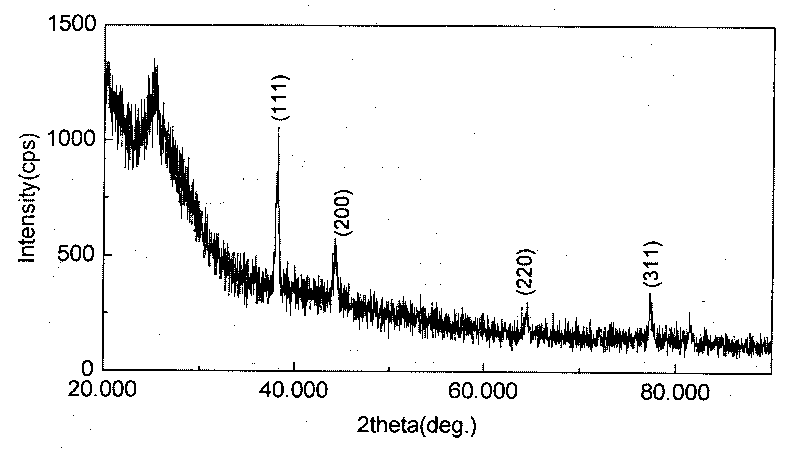

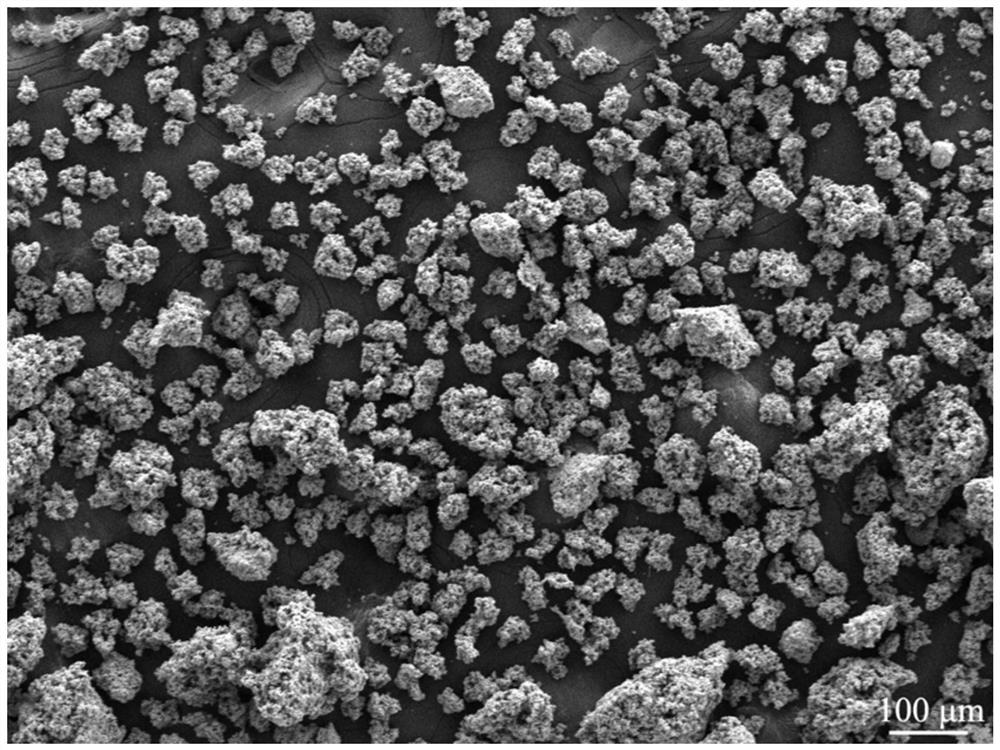

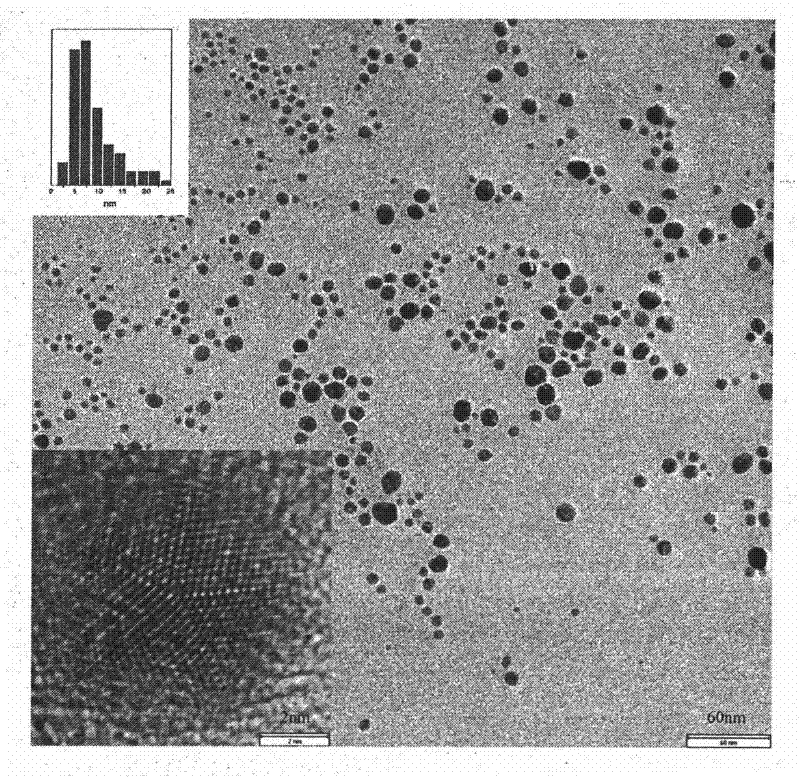

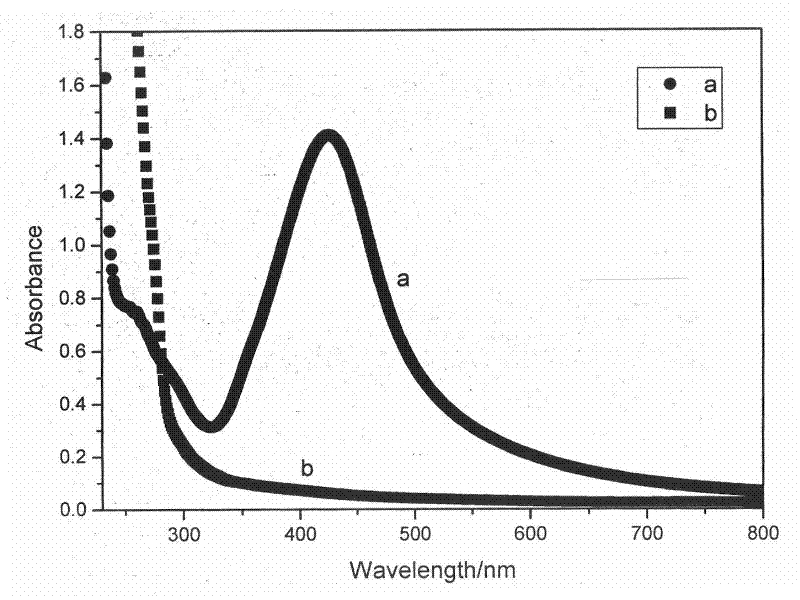

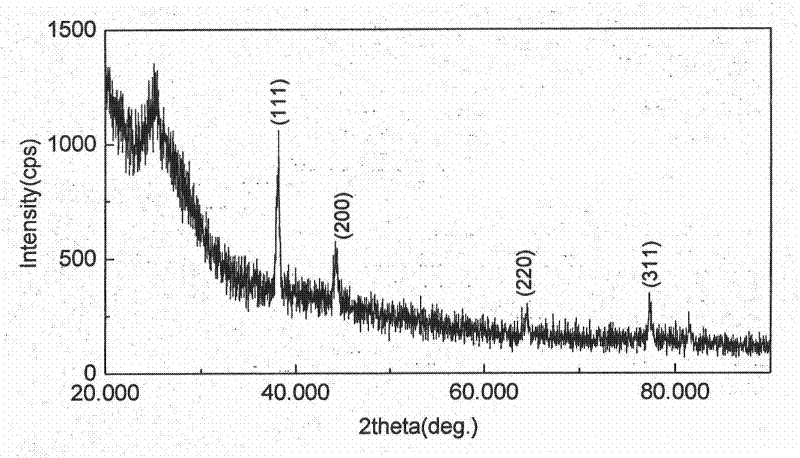

Preparation method of nano silver solution and polyaniline/ silver nanocomposite

The invention discloses a preparation method of nano silver solution and polyaniline / silver nanocomposite, belonging to the field of nanometer preparation and polymer inorganic matter nanocomposite. Linear alkyl benzene sulphonic acid is used as protective agent; silver oxide colloid generated by sodium hydroxide and silver nitrate serves as a precursor; aniline reduces the silver oxide colloid to prepare nano silver solution. In the preparation method of polyaniline / silver nanocomposite, the nano silver solution prepared by the above steps is directly adopted; the preparation method simplifies the fussy steps for removing the protective agent and reducing agent and saves material and energy compared with other in-situ oxidation styles; nano silver particles have favourable composite effect with generated polyaniline matrix; the whole preparation process is carried out at constant temperature and pressure; the adopted solvent is deionized water, and the preparation process is simple, needs fewer devices and has low comprehensive cost.

Owner:BEIHANG UNIV

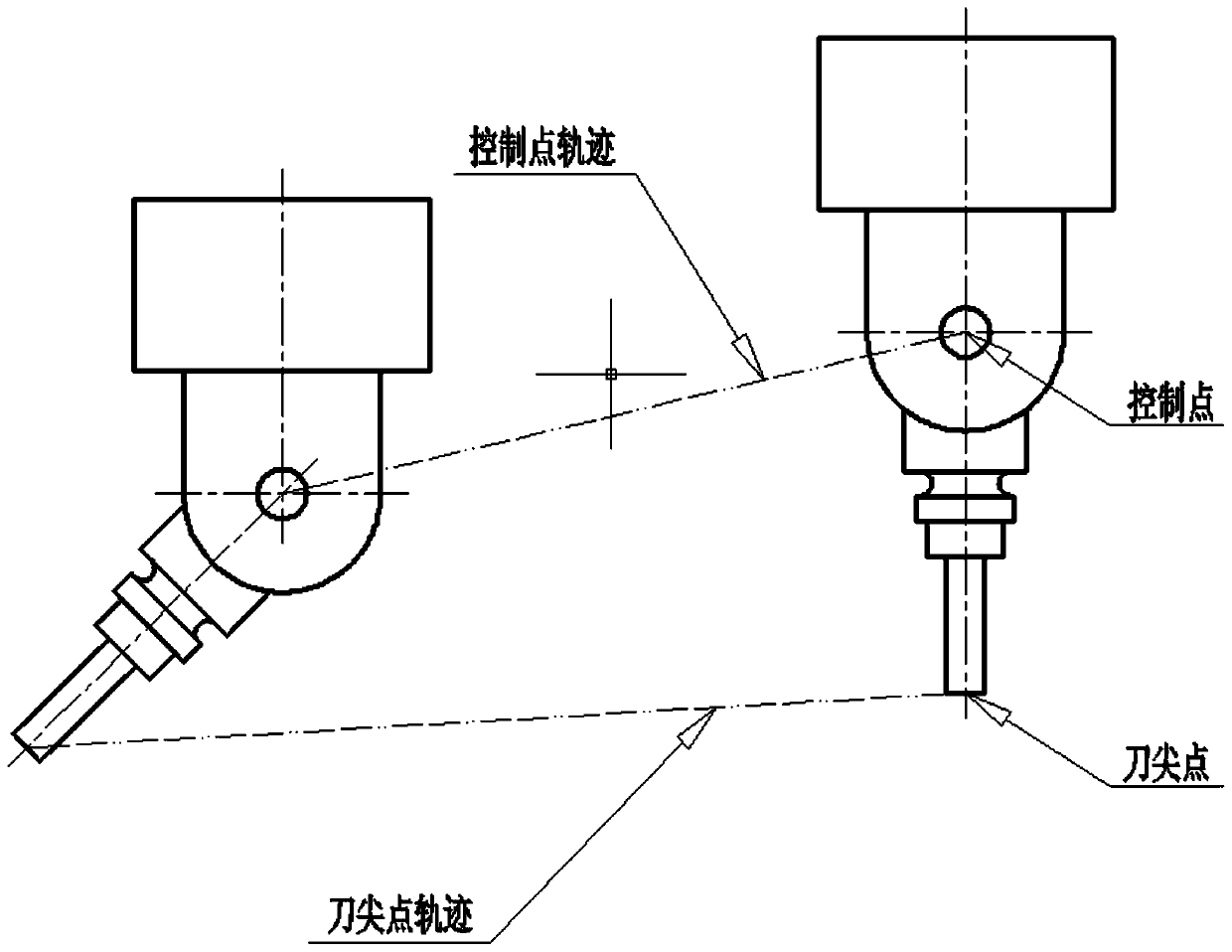

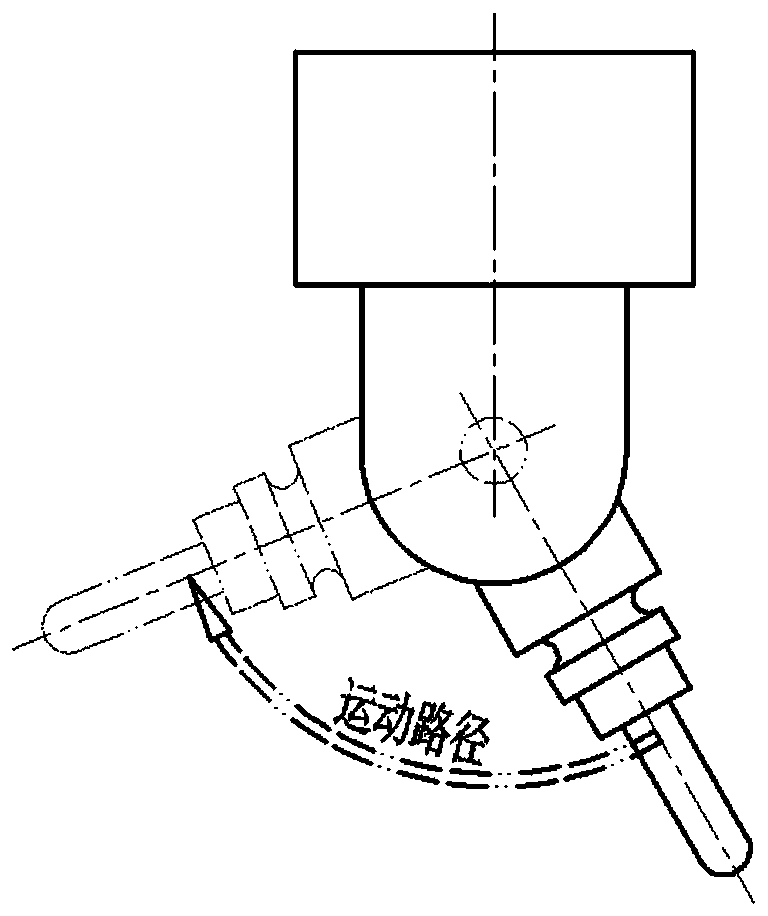

Method for achieving rotated tool center point function in four-shaft horizontal processing center by macroprogram

ActiveCN110412939ANo need to investLow costComputer controlSimulator controlComputer scienceNumerical control system

The invention belongs to the technical field of numerical control processing, and particularly relates to a technical method for achieving a rotated tool center point function in a four-shaft horizontal processing center by a macroprogram. A required microprogram is compiled by employing a corresponding system variable according to a Siemens840Ds1 numerical control system platform, the displacement deviation of each point in an automatic compensation numerical control program is achieved by calling the microprogram, so that the rotated tool center point (RTCP) function is achieved on the four-shaft horizontal processing center.

Owner:SHENYANG LIHANGFA PETROCHEM MACHINERY EQUIP MFG CO LTD

Skin care cream with skin beautifying function and preparation method thereof

InactiveCN103040693AEasy to makeNutrition in placeCosmetic preparationsToilet preparationsBenzimidazoleMethyl formate

The invention belongs to the technical field of cosmetics and relates to a skin care cream with a skin beautifying function. The skin care cream is characterized by consisting of a component A, a component B and a component C according to a mass ratio of (80-170):(110-260):1, wherein the component A comprises glycerol, sweet almond oil, albolene, glycerol monostearate, cera alba, vitamin E, vitamin A, vitamin F and vitamin B5; the component B comprises aloe vera gel, titanium dioxide, aluminum magnesium silicate, deionized water, isooctyl p-dimethylamino benzoate, benzimidazole methyl carbamate and methyl paraben; and the component C is essence. The invention also discloses a method for producing the skin care cream. The skin care cream has the beneficial effects that the skin nutrition is met, so that the whitening performance of the skin is good, and the skin has high elasticity; and moreover, the skin care cream is easy to prepare and low in equipment investment.

Owner:广州暨大美塑生物科技有限公司

Epoxy resin coating for exterior wall of building

The invention belongs to the technical field of coatings, and particularly relates to an epoxy resin coating for an exterior wall of a building. The epoxy resin coating is characterized by comprising a component A, a component B and a component C in proportion of (900-1800):(30-50):1 in parts by weight, wherein the component A comprises the components in parts by weight as follows: 8-12 parts of epoxy resin, 12-18 parts of acetone, 3-8 parts of ethylene glycol monobutyl ether, 1-3 parts of commercial OP-10 emulsifier, 0.1-0.3 part of sodium hydroxide, 30-50 parts of ethanol, 70-100 parts of de-ionized water, 140-180 parts of titanium dioxide and 35-45 parts of lithopone; the component B comprises a paint curing agent and tetrachloroisophthalonitrile; and the component C is a pigment. The epoxy resin coating mainly has the beneficial effects that the fluidity is good, the anti-mildew and anticorrosive property is perfect, the coating drying and solidification speed is fast, the color harmonization is flexible, the fast construction is convenient, a preparation method is simple, the operation is easy, and a needed device is simple.

Owner:CHINA NUCLEAR IND HUATAI CONSTR

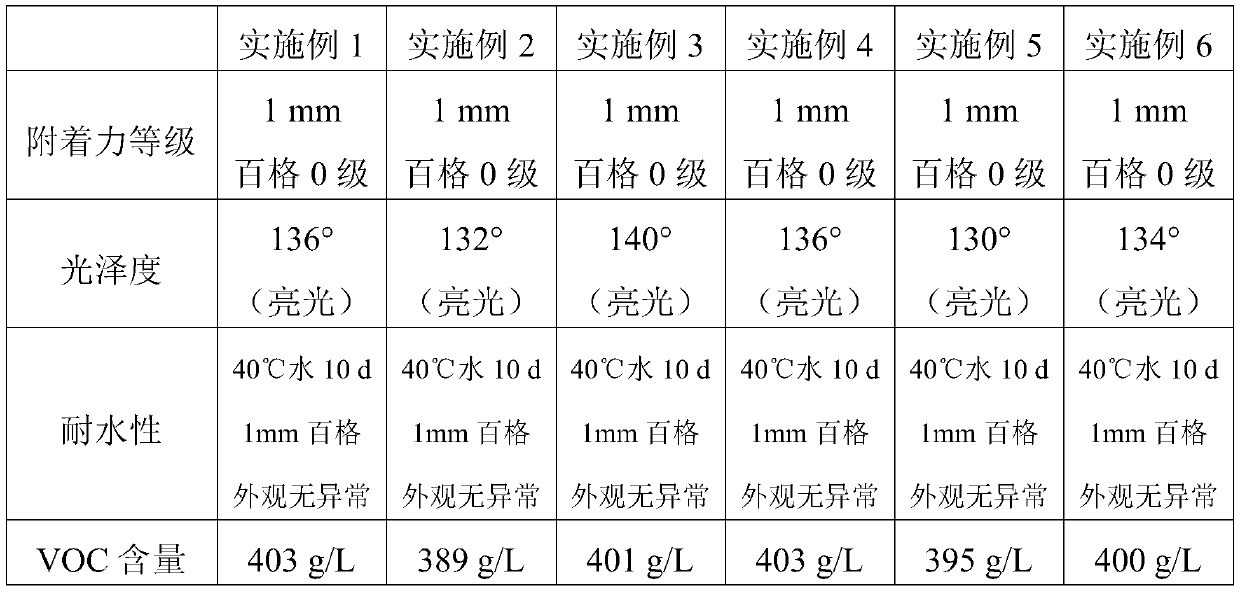

Environment-friendly water-based imitating electrosilvering coating and preparation method thereof

The invention relates to an environment-friendly water-based imitating electrosilvering coating. The coating is prepared from, by weight, 4 to 5 parts of a water-based aluminum paste, 4 to 8 parts ofa coalescing agent, 30 to 50 parts of resin, 3 to 5 parts of a dispersing agent, 3 to 5 parts of an anti-settling agent, 2 to 3 parts of a thickening agent, 0.5 to 1 part of a pH regulator and 30 to 40 parts of deionized water. The preparation method comprises the steps of stirring, standing and dispersing. Compared with coatings in the prior art, the coating of the invention has the advantages oflow cost, strong metal feeling, excellent adhesion to plastic parts, good water resistance, excellent film coating performance, reduction of VOC emission and the like.

Owner:DONGLAI COATING TECH SHANGHAI

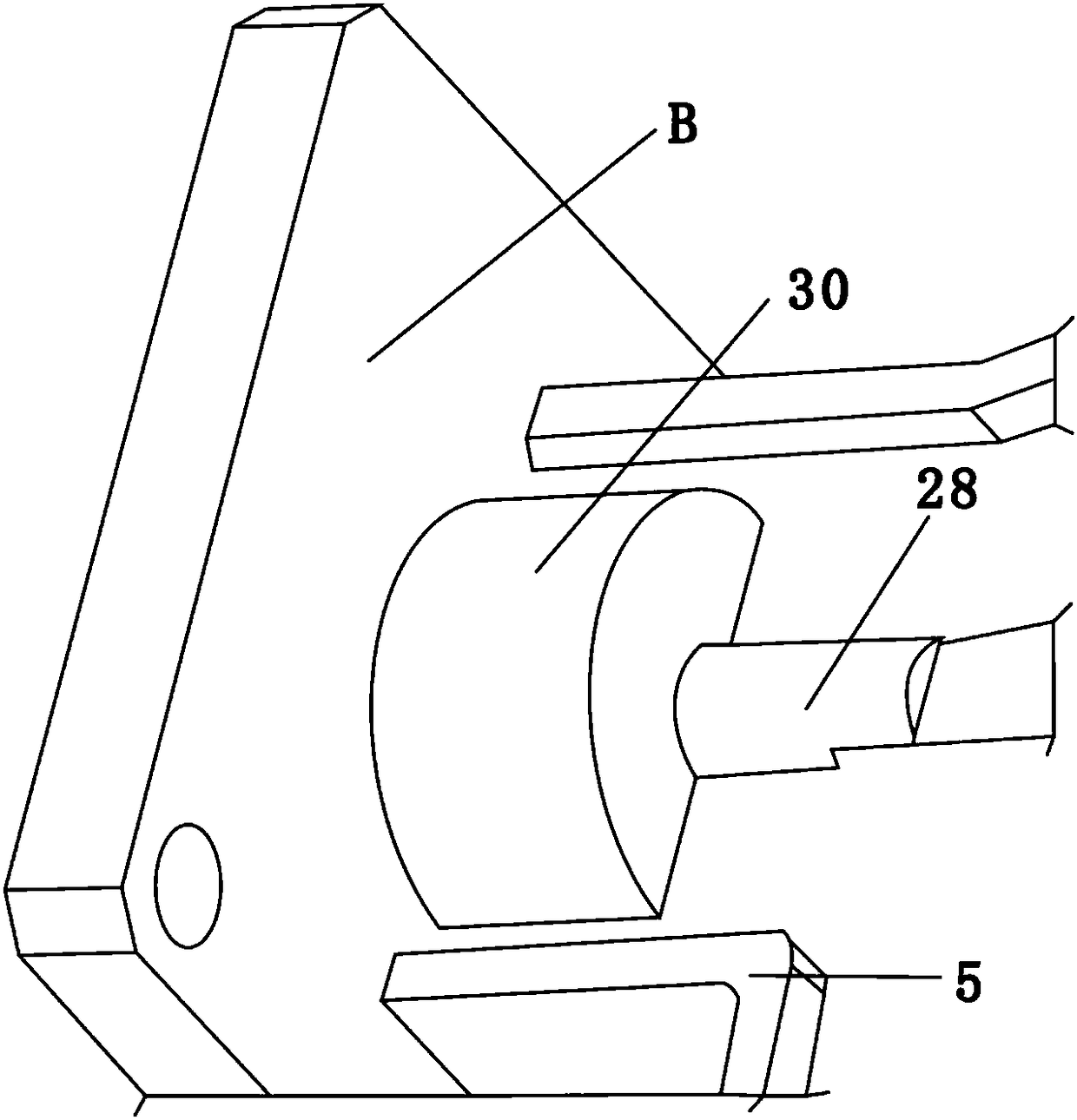

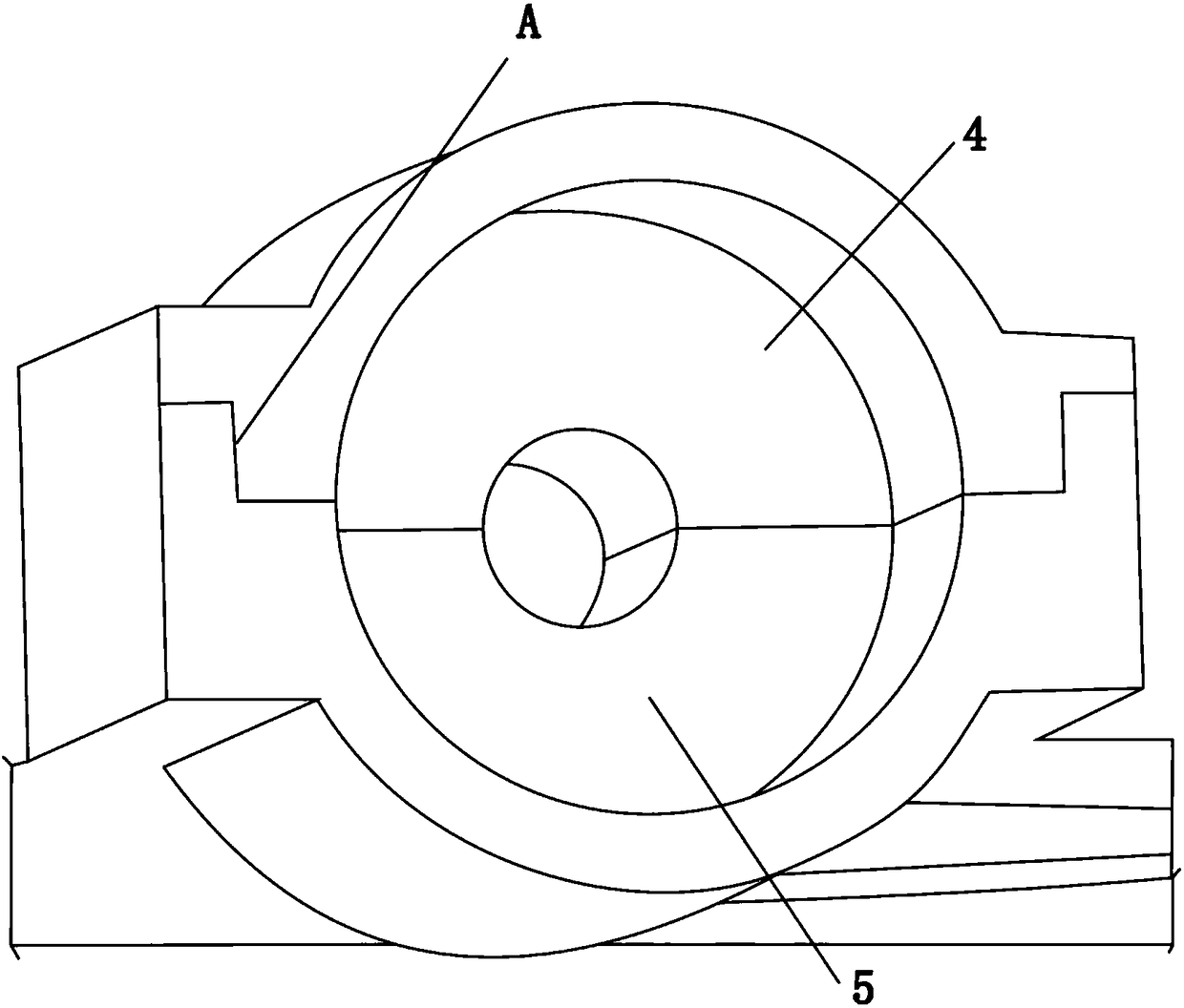

High-power circulator for L-waveband micro-discharge suppression of satellite

ActiveCN108521001AAvoid straight air gapsAvoid it happening againHigh level techniquesWaveguide type devicesElectrical conductorMicrowave

The invention discloses a high-power circulator for L-waveband micro-discharge suppression of a satellite, belonging to the technical field of microwave components and parts. The high-power circulatorcomprises a circulator main body and a connector connected with two ends of the connector main body, wherein the connector main body mainly comprises an upper cavity and a lower cavity which are mutually connected, an upper medium and a lower medium are respectively arranged in the upper cavity body and the lower cavity body, the inside of the connector is formed by the surrounding of the inner sides of the upper medium and the lower medium, substrates are arranged on the inner sides of the upper medium and the lower medium, and central conductors are arranged on the substrates; and a connector inner conductor and a connector medium are arranged in the connector, the central conductor is connected with the connector inner conductor, and the connector medium extends into the circulator andis staggered with the upper medium and the lower medium. According to the high-power circulator, the micro-discharge can be effectively suppressed, the structure and boundary dimension of a product are not limited, the high equipment input is not required, the process is simple, and the high-power circulator is suitable for popularization.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS

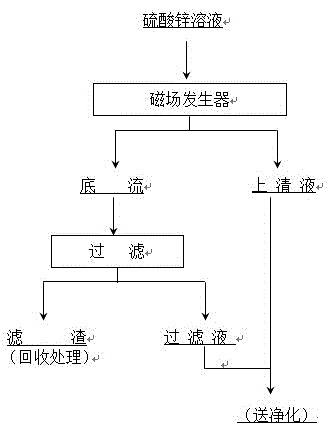

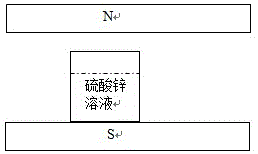

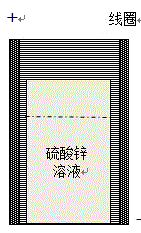

Purification method of germanium in zinc sulfate solution by using magnetic field

ActiveCN104988310AGood removal effectShort working hoursProcess efficiency improvementChemical industryElectromagnetics fields

The present invention relates to a purification method of germanium in zinc sulfate solution by using magnetic field and belongs to the field of metallurgical and chemical industry. This method comprises the following steps: 1) passing a neutral leaching zinc sulfate solution containing 0.08-2.0mg / L of germanium and with temperature of 60-90 DEG C and pH value of 4.5-5.4 from a wet zinc metallurgical process through a magnetic field generator; 2) keeping the zinc sulfate solution containing germanium in the magnetic field generator for 30-60 min; and 3) conducting liquid-solid separation on the zinc sulfate solution after magnetic field treatment. The germanium in zinc sulfate solution is charged colloid, and in the magnetic field, charged germanium colloid directionally move and agglomerate into large particulate matters, in order to achieve purification of germanium in the zinc sulfate solution. The magnetic field generator uses a permanent magnetic field or electromagnetic field, so that the germanium in zinc sulfate solution in the magnetic field can condense into large particulate matters. The method has the advantages of good germanium removal effect, short work time, no raw material investment, low production costs and low labor intensity.

Owner:云南驰宏国际锗业有限公司 +1

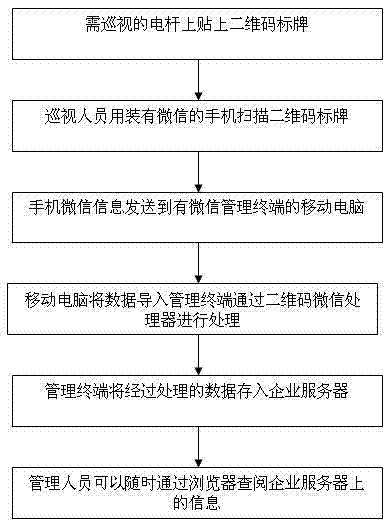

Transmission line inspection assessment method based on WeChat platform

InactiveCN106898964APracticalEasy to operateResourcesApparatus for overhead lines/cablesMobile deviceComputer science

The invention discloses a transmission line inspection assessment method based on a WeChat platform, which is characterized by comprising a two-dimensional code WeChat sign attached to each transmission line pole, a mobile device provided with WeChat software, a mobile computer provided with a WeChat management terminal, a two-dimensional code WeChat management terminal, an enterprise server, management software arranged in the enterprise server and a browser. Thus, inspection management on the transmission line can be effectively enhanced, inspection in place can be further promoted scientifically, concealment reporting and lie reporting for line inspection do not happen any more, the difficult problem that the line inspection efficiency is not assessed and managed for a long time can be solved, the line fault is reduced, and the management level is improved.

Owner:ZHEJIANG KE CHANG ELECTRONICS

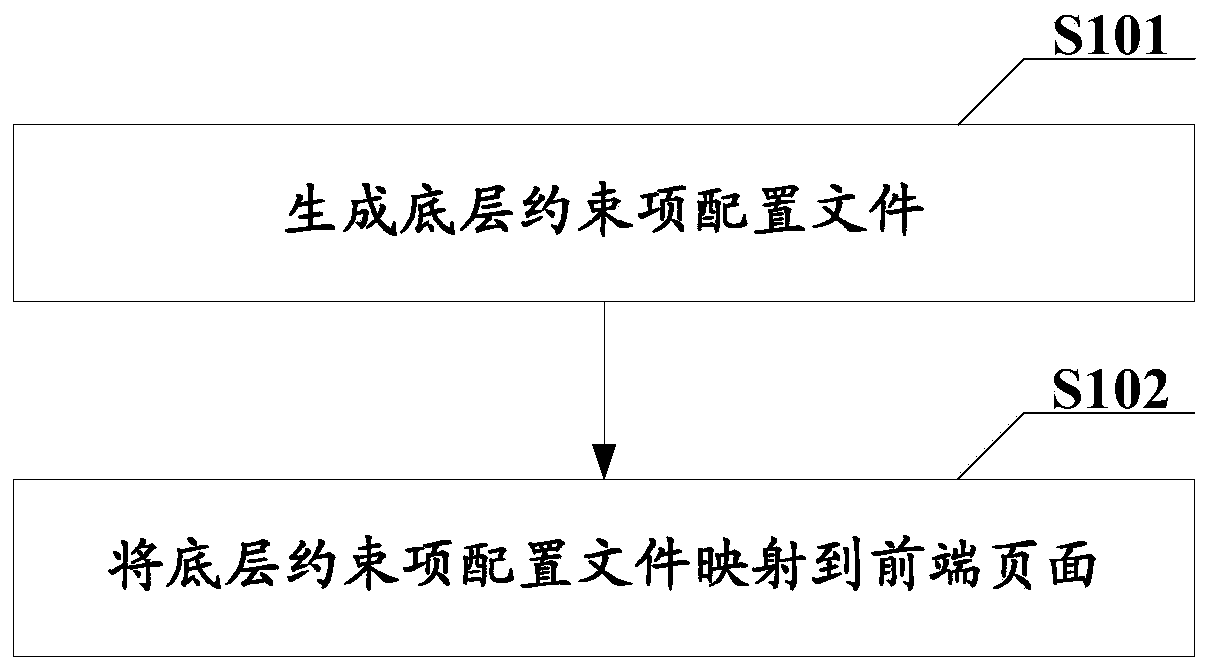

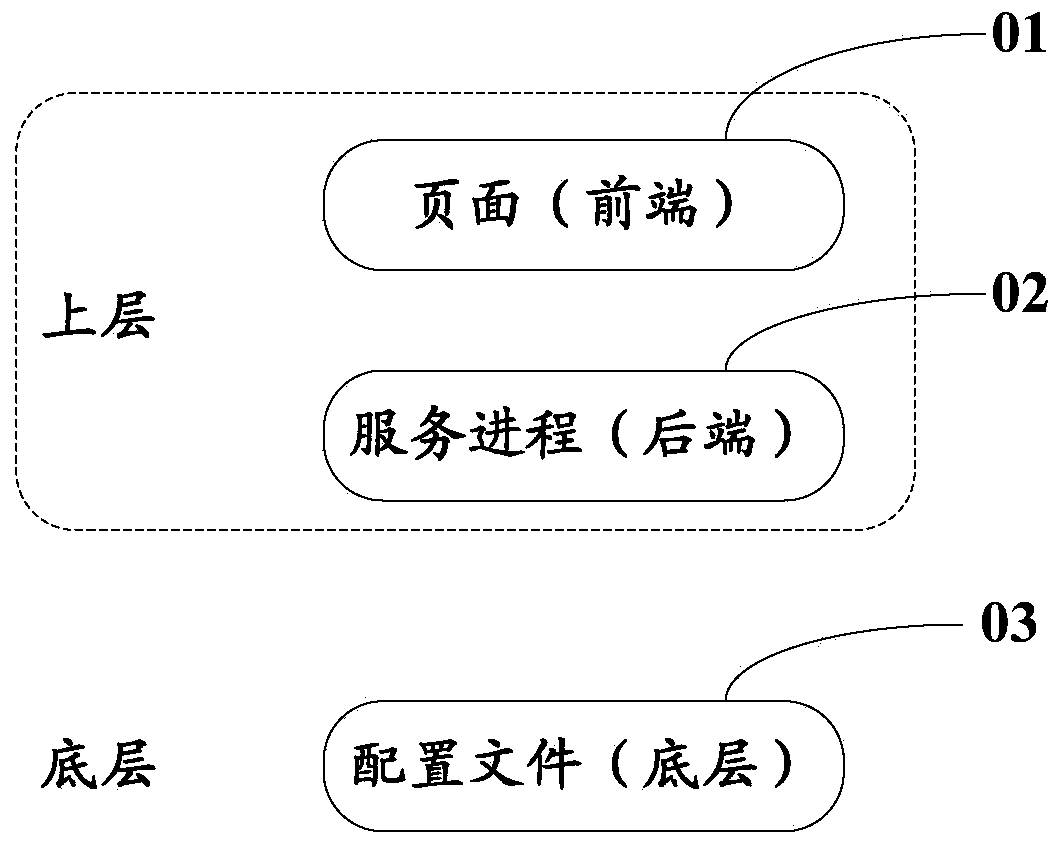

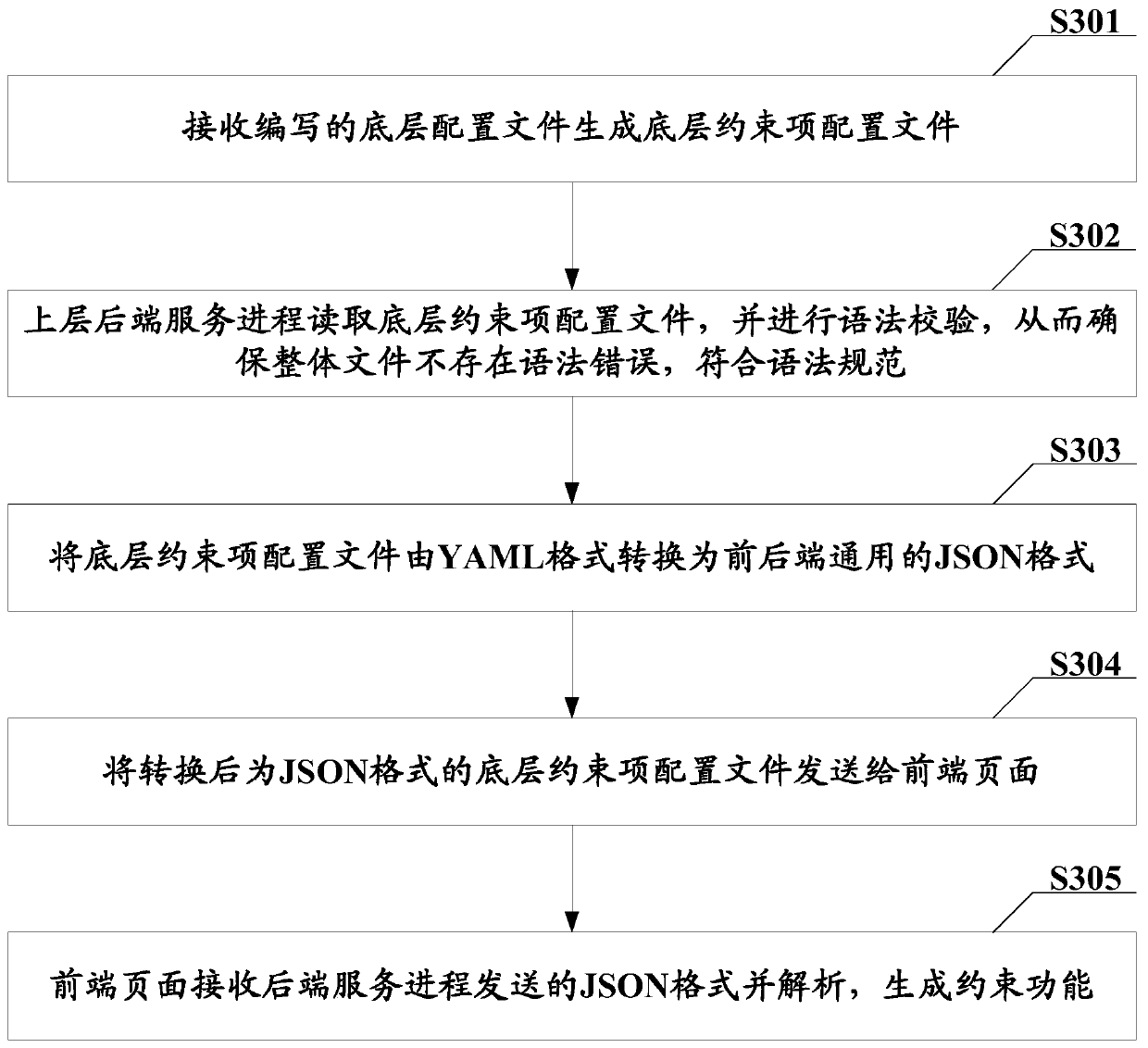

Constraint configuration method and device and electronic equipment

InactiveCN109918119APrecise positioningImprove experienceVersion controlTransmissionElectric equipmentDatabase

The embodiment of the invention provides a constraint configuration method and device and electronic equipment, and the method comprises the steps: generating a bottom constraint item configuration file in which constraint conditions are recorded, and mapping the bottom constraint item configuration file to a front-end page, thereby enabling the front-end page to be associated with the bottom constraint item configuration file. Therefore, when the front-end page is managed and controlled, management and control can be carried out according to constraint conditions in the bottom-layer constraint item configuration file, that is, the front-end page has a constraint function corresponding to the bottom-layer constraint item configuration file. Through the implementation process, the constraint condition can be configured only by writing the constraint condition into the form of the bottom constraint item configuration file and mapping the bottom constraint item configuration file to the front-end page, the whole process is very simple, meanwhile, the investment of front-end personnel and rear-end personnel is not needed, and the labor cost is reduced.

Owner:WUXI CHINAC DATA TECH SERVICE

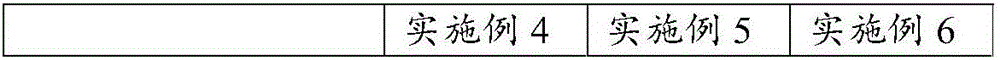

Hot melt adhesive used for pipeline anticorrosion, preparation method thereof, and thermal shrinkable sleeve

InactiveCN106520021AImprove performanceLow surface treatment requirementsNon-macromolecular adhesive additivesBituminous material adhesivesAsphalt masticHot-melt adhesive

The invention relates to a hot melt adhesive used for pipeline anticorrosion, a preparation method thereof, and a thermal shrinkable sleeve. The hot melt adhesive used for pipeline anticorrosion is mainly formed through mixing, by weight, 30-80% of asphalt mastic, 15-50% of thermoplastic resin, 5-40% of tackifying resin, 0-5.0% of an antioxidant and 0-20% of a filler. The problems of poor high-and-low-temperature application range and poor low-temperature performances are solved, and the hot melt adhesive has good low temperature resistance, good high temperature adhesion, good seal performance and good anticorrosion effect.

Owner:NITTO QINGDAO TECH RES INST CO LTD

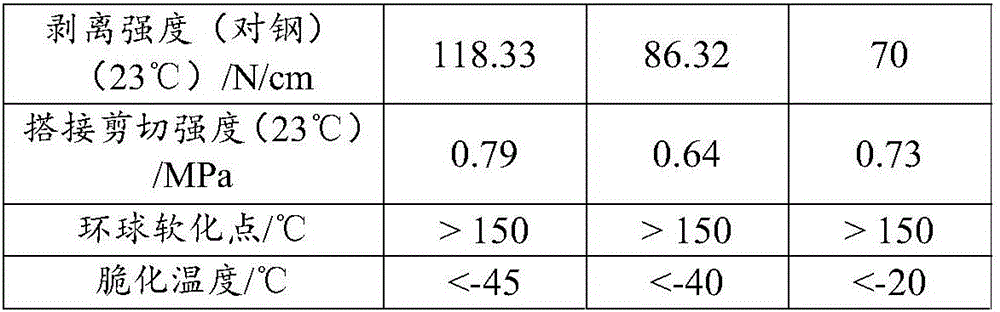

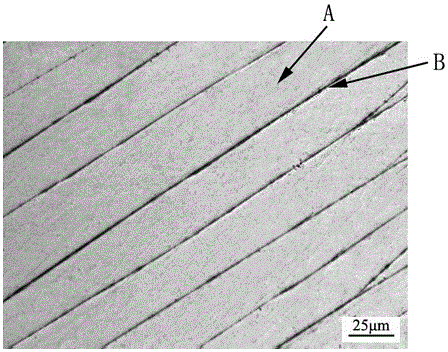

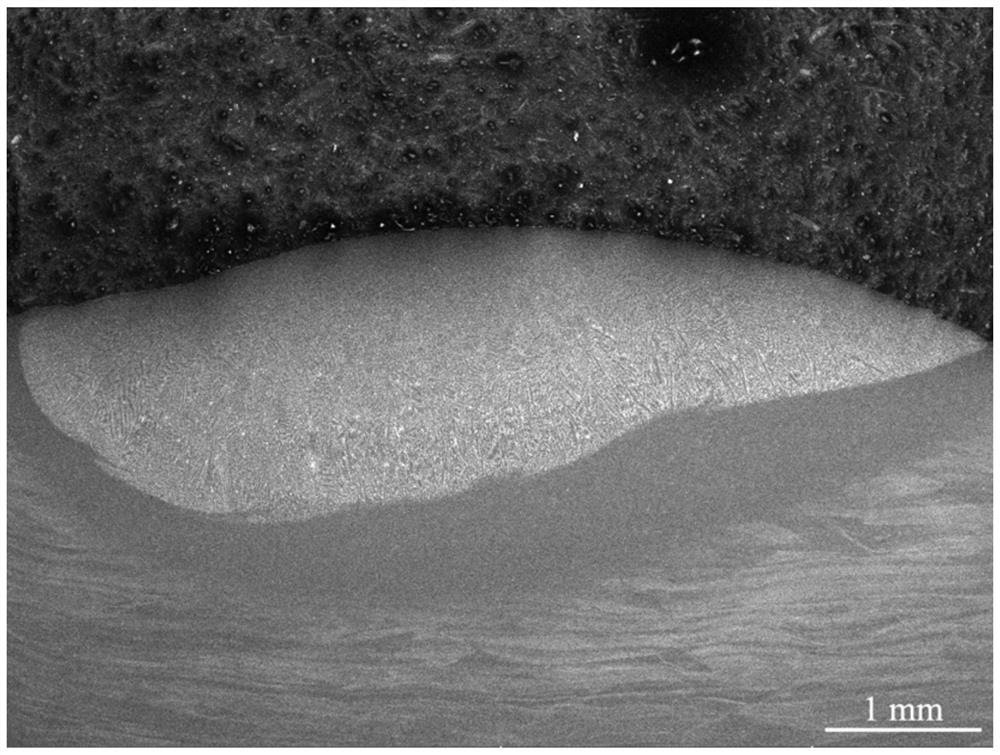

A method for observing shear bands in zirconium-based amorphous alloys

InactiveCN103983499BClear shear band morphologyClear shapePreparing sample for investigationMicro structureMicroscopic scale

The invention discloses a method for observing inner shearing zone of zirconium base amorphous alloy, and belongs to the technical field of metal material micro-structure observation. The method is characterized by comprising the following steps: (1) carrying out plastic deformation on zirconium base amorphous alloy through rolling; (2) carrying out step-by-step grinding on the plastically-deformed zirconium base amorphous alloy test-piece to obtain at least one observation surface; (3) carrying out mechanical polishing on the observation surface of the test-piece; (4) etching the polished observation surface of the test-piece; (5) observing the morphology of the inner shearing zone of the test-piece through an optical microscope. The observation method overcomes the shortages of conventional methods that directly use a scanning electron microscope to observe a test-piece surface or use a transmission electron microscope to observe the test-piece interior, is capable of clearly observing the morphology and distributions of shearing zones in deformed zirconium base amorphous alloy, is easy and practicable, and does not need special equipment.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Skin care cream with skin beautifying function and preparation method thereof

InactiveCN103040693BNo need to investEasy to makeCosmetic preparationsToilet preparationsP-dimethylaminobenzoic acidMethyl carbamate

The invention belongs to the technical field of cosmetics and relates to a skin care cream with a skin beautifying function. The skin care cream is characterized by consisting of a component A, a component B and a component C according to a mass ratio of (80-170):(110-260):1, wherein the component A comprises glycerol, sweet almond oil, albolene, glycerol monostearate, cera alba, vitamin E, vitamin A, vitamin F and vitamin B5; the component B comprises aloe vera gel, titanium dioxide, aluminum magnesium silicate, deionized water, isooctyl p-dimethylamino benzoate, benzimidazole methyl carbamate and methyl paraben; and the component C is essence. The invention also discloses a method for producing the skin care cream. The skin care cream has the beneficial effects that the skin nutrition is met, so that the whitening performance of the skin is good, and the skin has high elasticity; and moreover, the skin care cream is easy to prepare and low in equipment investment.

Owner:广州暨大美塑生物科技有限公司

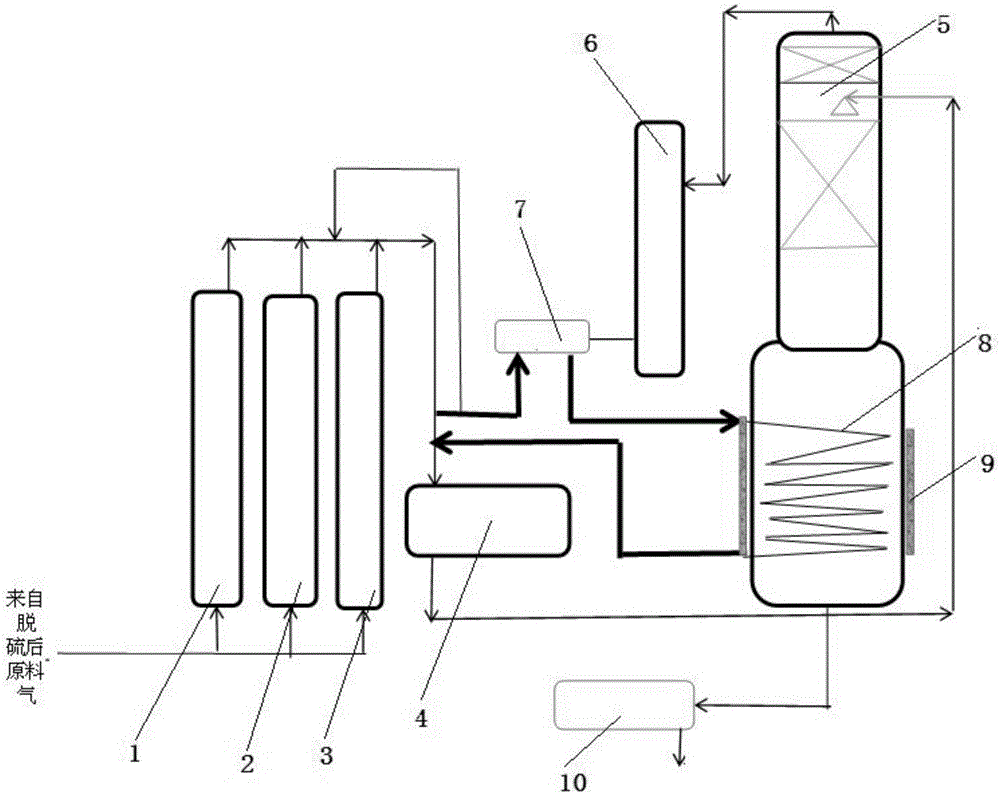

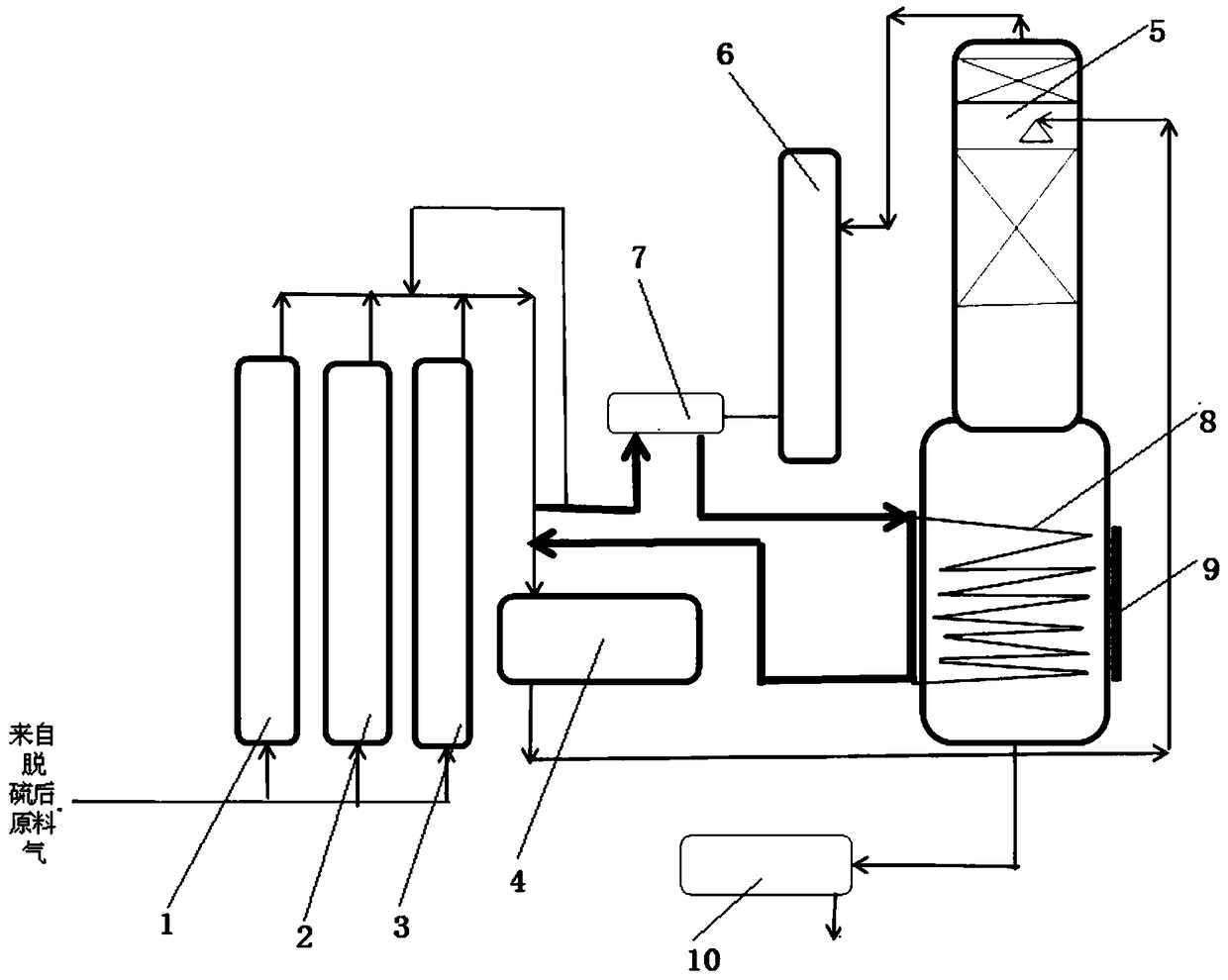

Efficient and energy-saving system for rectifying and purifying carbon dioxide

ActiveCN106348298AConvenient and quick escapeWill not affect yieldCarbon compoundsChemical industryNitrogenProcess engineering

The invention discloses an efficient and energy-saving system for rectifying and purifying carbon dioxide, and belongs to the technical field of chemical engineering equipment. According to a carbon dioxide rectifying and purifying process, the system comprises a drying adsorption tower, a liquefier and a purifying tower which are connected in sequence, and further comprises a renewable electric heater and a heat exchanger, wherein the renewable electric heater is connected with a noncondensable gas discharging pipe at the top of the purifying tower; a high-temperature renewable gas pipe of the renewable electric heater and a gas outlet pipe of the drying adsorption tower are respectively connected with the heat exchanger; an outlet of the heat exchanger is connected with a heating coiled pipe at the bottom of the purifying tower; a gas outlet of the heating coiled pipe is connected with a gas inlet of the liquefier. The carbon dioxide rectifying and purifying system simplifies a de-hydrocarbon procedure, i.e. three sets of equipment for de-hydrocarbon are all eliminated; hydrocarbon impurities and nonconcensable gas such as nitrogen and oxygen are removed together in the purifying tower; meanwhile, inside and outside of a liquid phase part of the purifying tower are indirectly heated, so that the carbon dioxide purifying efficiency is improved.

Owner:LANZHOU YULONG GAS

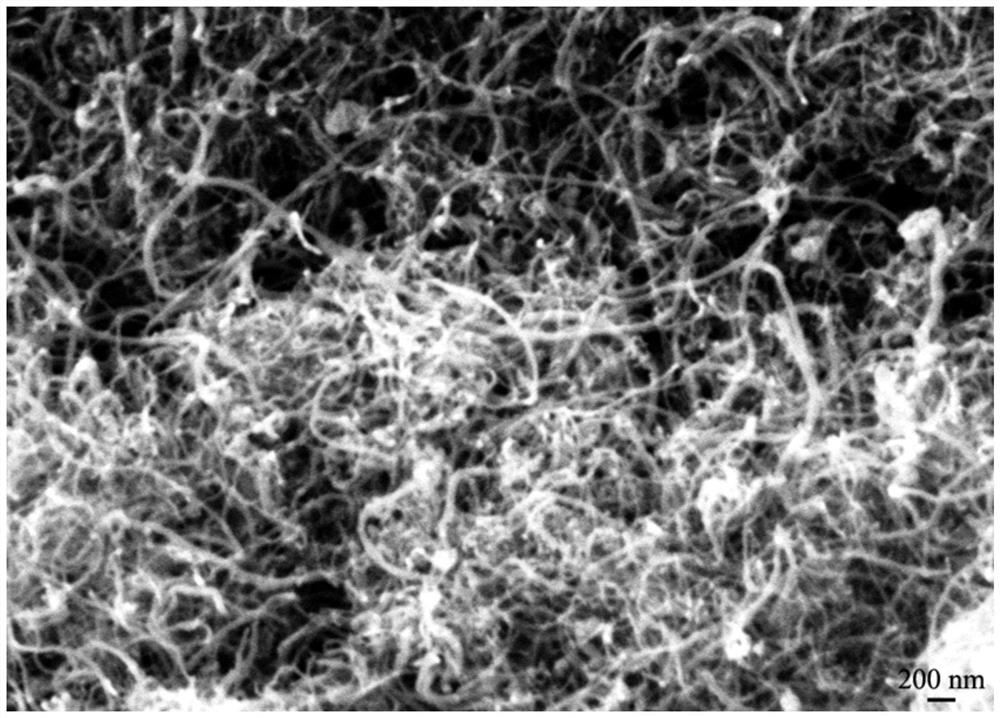

Method for manufacturing Cu-based alloy cladding layer by adopting infrared laser

ActiveCN113560567ATightly boundImprove liquidityLiquid/solution decomposition chemical coatingChemical platingMetallurgy

The invention relates to a method for manufacturing a Cu-based alloy cladding layer by adopting infrared laser. The method comprises the following steps that chemical copper plating treatment is performed on the surface of a nano reinforced material serving as a deposition substrate, and then the material is chemically plated with a metal layer with high infrared absorptivity to obtain multi-layer-coated Cu-based alloy powder; a common infrared laser is used as a heat source, and a coaxial powder feeding laser cladding technology is adopted for the multi-layer-coated Cu-based alloy powder, so that the Cu-based alloy cladding layer is prepared. According to the technical scheme, the Cu-based alloy cladding layer is processed and manufactured on the surface of a metal component by adopting infrared laser.

Owner:JINHUA VOCATIONAL TECH COLLEGE

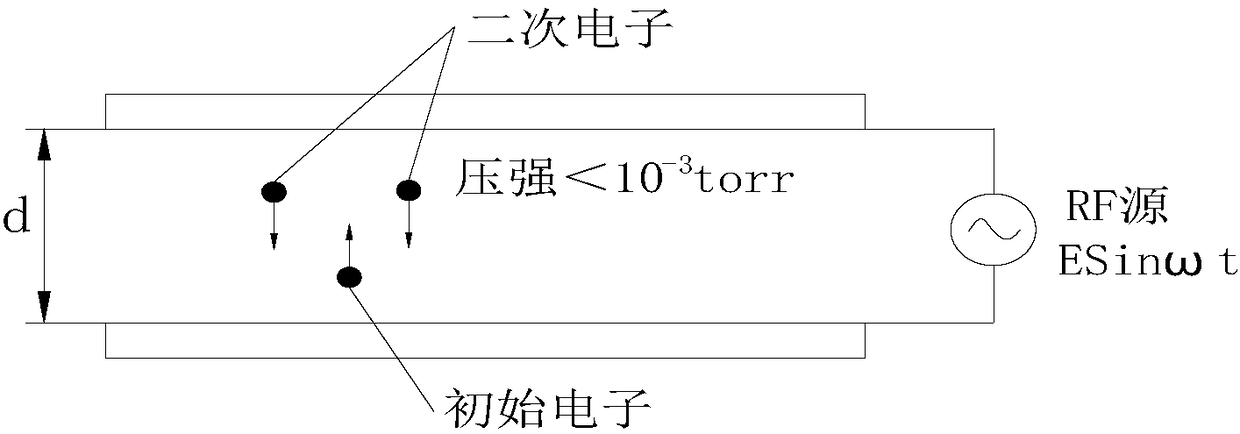

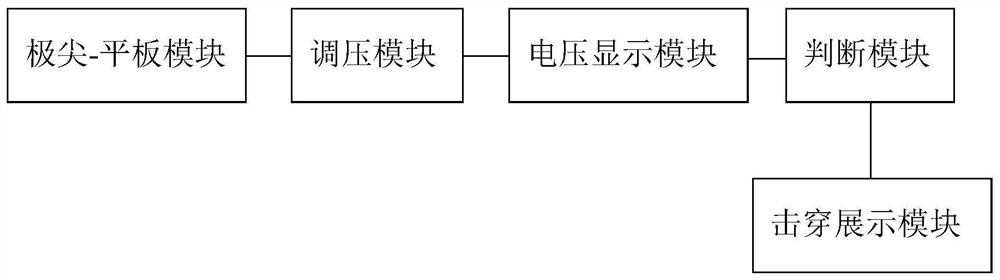

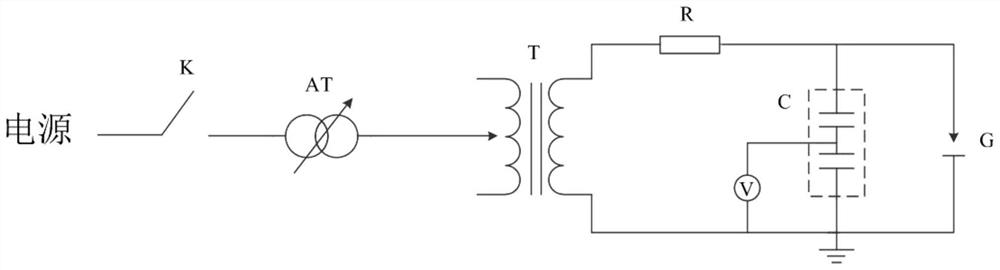

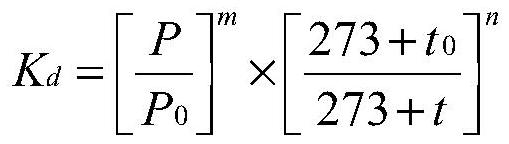

A virtual experiment system and method for simulating non-uniform electric field breakdown voltage

ActiveCN111077418BNo need to investLow costEducational modelsTesting using acoustic measurementsVoltage regulationMechanical engineering

The invention discloses a virtual experiment system and method for simulating non-uniform electric field breakdown voltage. The system includes a tip-flat panel module, a voltage module and a breakdown display module. The voltage module includes a PC module and a voltage regulation module , a judging module and a display module. The method includes the following steps: 1. Construct a corresponding two-dimensional relationship table and input it into the system for calling at any time during system operation; 2. Initialize the system, run the Jijian-flat module to generate a virtual electric field; 3. Run The voltage regulation module gradually increases the voltage; 4. The operating voltage module; 5. The operating judgment module; 6. The operating breakdown display module displays the virtual breakdown process. The invention does not need to invest in physical high voltage and its supporting equipment, and is economical; the remote experiment is flexible enough, which can not only ensure the safety of the experiment, but also get rid of the restrictions of the experimental site, the high voltage level of the physical equipment, and the insulation requirements.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of nano silver solution and polyaniline/ silver nanocomposite

The invention discloses a preparation method of nano silver solution and polyaniline / silver nanocomposite, belonging to the field of nanometer preparation and polymer inorganic matter nanocomposite. Linear alkyl benzene sulphonic acid is used as protective agent; silver oxide colloid generated by sodium hydroxide and silver nitrate serves as a precursor; aniline reduces the silver oxide colloid to prepare nano silver solution. In the preparation method of polyaniline / silver nanocomposite, the nano silver solution prepared by the above steps is directly adopted; the preparation method simplifies the fussy steps for removing the protective agent and reducing agent and saves material and energy compared with other in-situ oxidation styles; nano silver particles have favourable composite effect with generated polyaniline matrix; the whole preparation process is carried out at constant temperature and pressure; the adopted solvent is deionized water, and the preparation process is simple, needs fewer devices and has low comprehensive cost.

Owner:BEIHANG UNIV

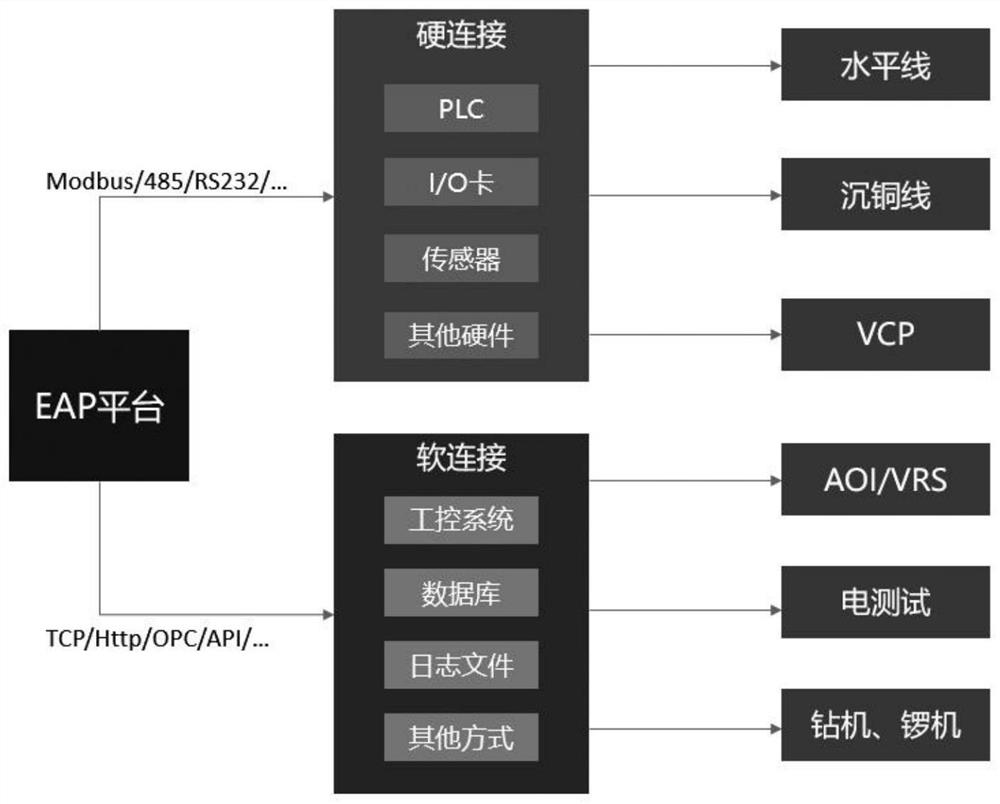

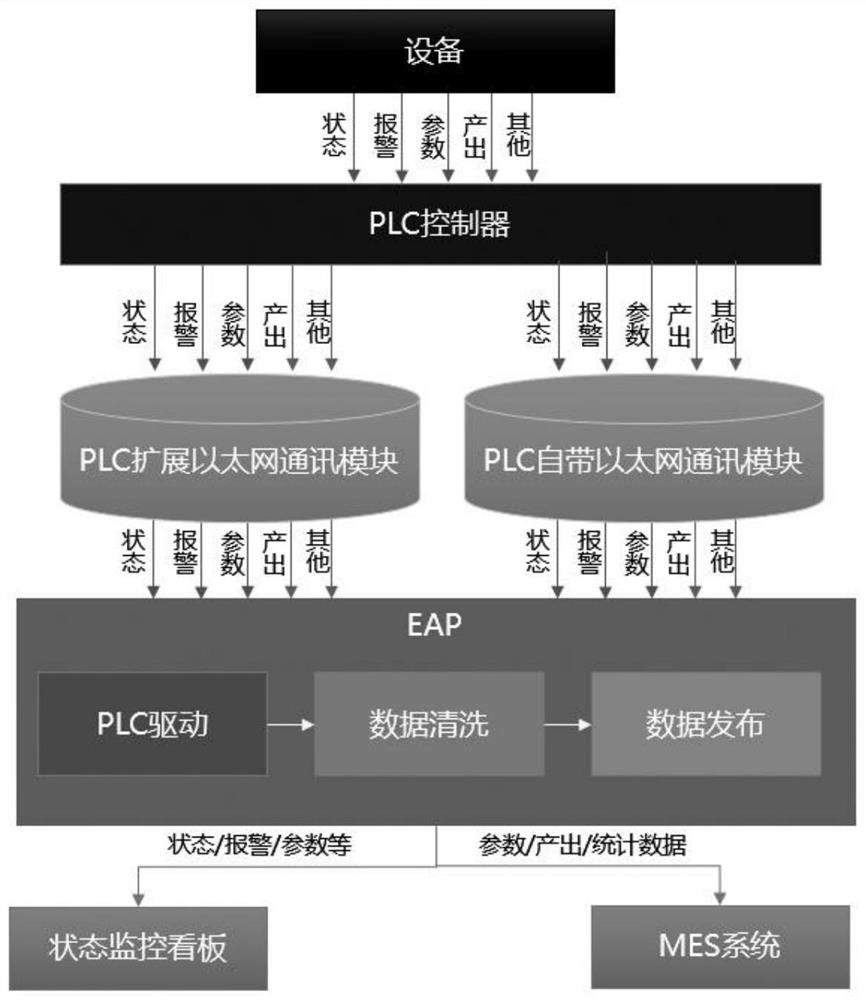

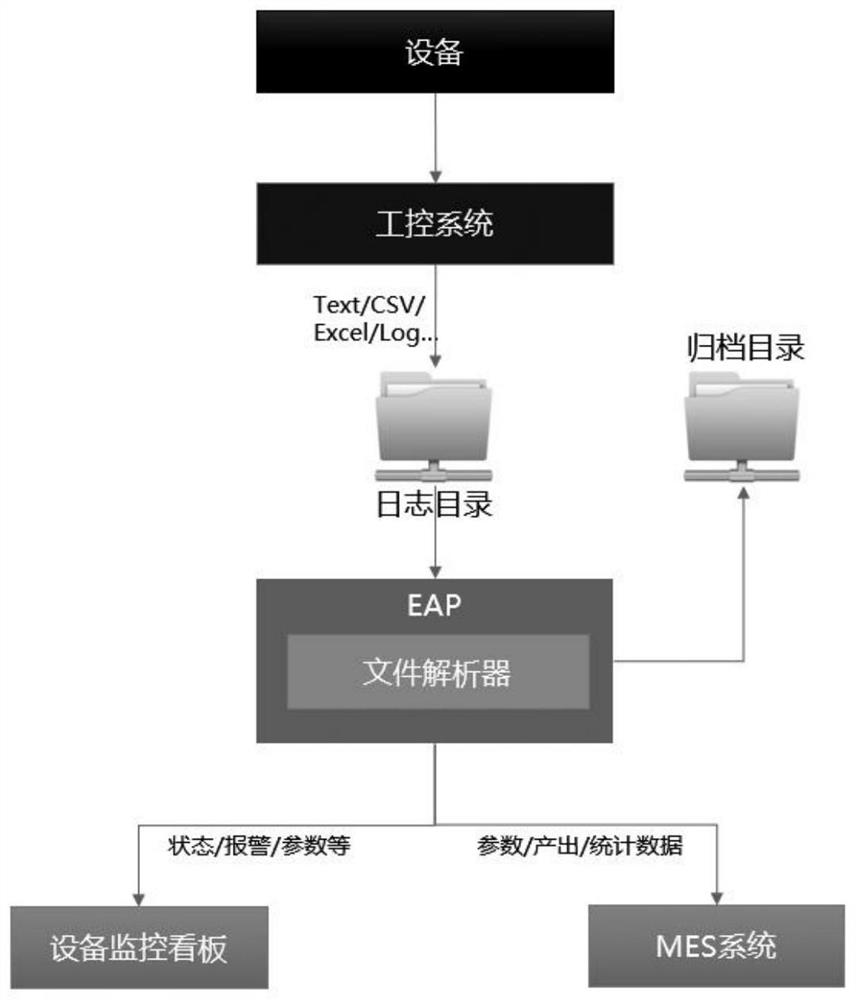

Online extensible Internet of Things platform based on circuit board production line

ActiveCN113608509ANo need to investImprove real-time performanceTotal factory controlProgramme total factory controlDrilling machinesBusiness enterprise

The invention relates to online extensible Internet of Things platform based on a circuit board production line. According to the online extensible Internet of Things platform based on the circuit board production line, an EAP platform carries out network connection on equipment of the production line through connection, and performs information exchange; the EAP platform is an enterprise management software platform; the connection modes comprise hard connection and flexible connection; and the circuit board production line comprises a horizontal line, a copper deposition line, a VCP, an AOI / VRS, an electrical test, a drilling machine and a milling machine. The Internet of Things platform shares data of the whole production line through the hard connection and flexible connection. With the online extensible Internet of Things the platform based on the circuit board production line adopted, the problems of online connection mode of production line equipment, PLC control and the like can be solved.

Owner:龙南骏亚精密电路有限公司

A high-efficiency energy-saving rectification and purification system for carbon dioxide

ActiveCN106348298BConvenient and quick escapeWill not affect yieldCarbon compoundsChemical industryDistillationNitrogen

The invention discloses an efficient and energy-saving system for rectifying and purifying carbon dioxide, and belongs to the technical field of chemical engineering equipment. According to a carbon dioxide rectifying and purifying process, the system comprises a drying adsorption tower, a liquefier and a purifying tower which are connected in sequence, and further comprises a renewable electric heater and a heat exchanger, wherein the renewable electric heater is connected with a noncondensable gas discharging pipe at the top of the purifying tower; a high-temperature renewable gas pipe of the renewable electric heater and a gas outlet pipe of the drying adsorption tower are respectively connected with the heat exchanger; an outlet of the heat exchanger is connected with a heating coiled pipe at the bottom of the purifying tower; a gas outlet of the heating coiled pipe is connected with a gas inlet of the liquefier. The carbon dioxide rectifying and purifying system simplifies a de-hydrocarbon procedure, i.e. three sets of equipment for de-hydrocarbon are all eliminated; hydrocarbon impurities and nonconcensable gas such as nitrogen and oxygen are removed together in the purifying tower; meanwhile, inside and outside of a liquid phase part of the purifying tower are indirectly heated, so that the carbon dioxide purifying efficiency is improved.

Owner:LANZHOU YULONG GAS

Environment-friendly ultraviolet light resistant and high-temperature resistant paint for outer walls of buildings

Environment-friendly ultraviolet light resistant and high-temperature resistant paint for outer walls of buildings comprises A compositions, B compositions and a C composition, wherein the A compositions comprise the following substances in parts by weight: 25-35 parts of polyaspartic acid ester resin, 20 parts of an aromatics mixed solvent, 8-10 parts of nano-scale ceramic powder, 2-4 parts of mica powder, 10-18 parts of diacetone alcohol, 3-8 parts of ethylene glycol monobutyl ether, 7-11 parts of a cellulose thickener solution with the mass percent of 2%, 1.0-1.4 parts of a polyphosphate dispersing agent solution with the mass percent of 10%, 1-3 parts of an emulgator, 0.1-0.3 part of sodium hydroxide, 30-50 parts of ethyl alcohol, 70-100 parts of deionized water, 140-180 parts of titanium dioxide; the B compositions comprise the following substances in parts by weight: 3-5 parts of a paint curing agent, 0.02-1 part of an initiator, 1 part of a dispersing agent, 0.6 part of a flatting agent, 0.3 part of an antifoaming agent, 0.3 part of a defoaming agent, 25 parts of a modified ammonia curing agent, 2-4 parts of tetrachloroisophthalonitrile, 3-5 parts of a dry film antiseptic; the C composition is an environment-friendly color mixed-phase inorganic pigment.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

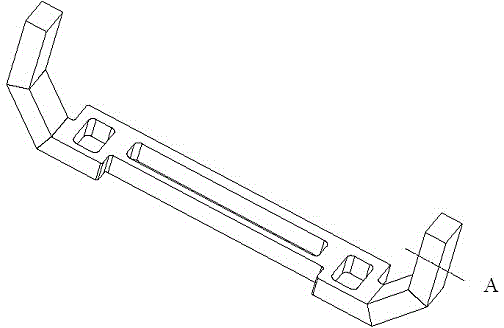

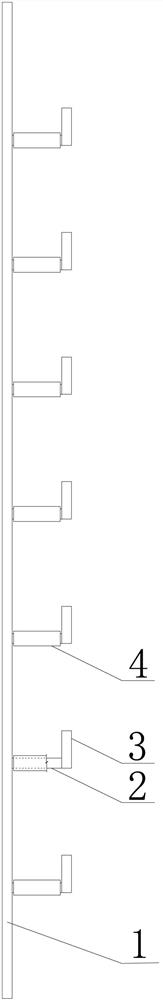

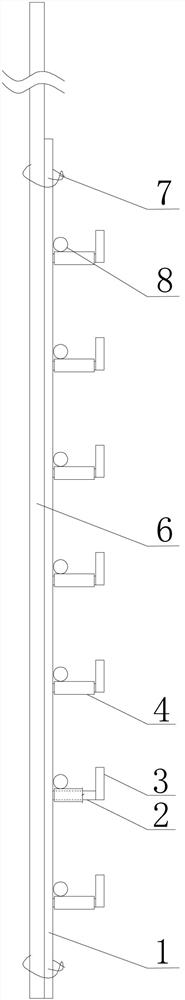

Shear wall horizontal rib installation positioning rod and construction method

PendingCN111636692AEasy to makeCost controlBuilding material handlingArchitectural engineeringShear wall

The invention provides a shear wall horizontal rib installation positioning rod and a construction method. The shear wall horizontal rib installation positioning rod comprises a main rod, wherein a plurality of positioning cross rods are welded and fixed to the side wall of the main rod at equal intervals in the height direction of the main rod, and a limiting vertical rod is vertically welded andfixed to the top of the tail end of each positioning cross rod; and the positioning cross rods are sleeved with rotating sleeves. The positioning rod can be used for auxiliary installation of a shearwall horizontal rib, the position precision and levelness of horizontal rib installation are guaranteed, meanwhile, the installation difficulty is effectively reduced, the installation of the horizontal rib can be completed by a single person, and the labor cost of operation is reduced.

Owner:CHINA NUCLEAR IND 22ND CONSTR

A kind of forging method of high-purity niobium rod

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

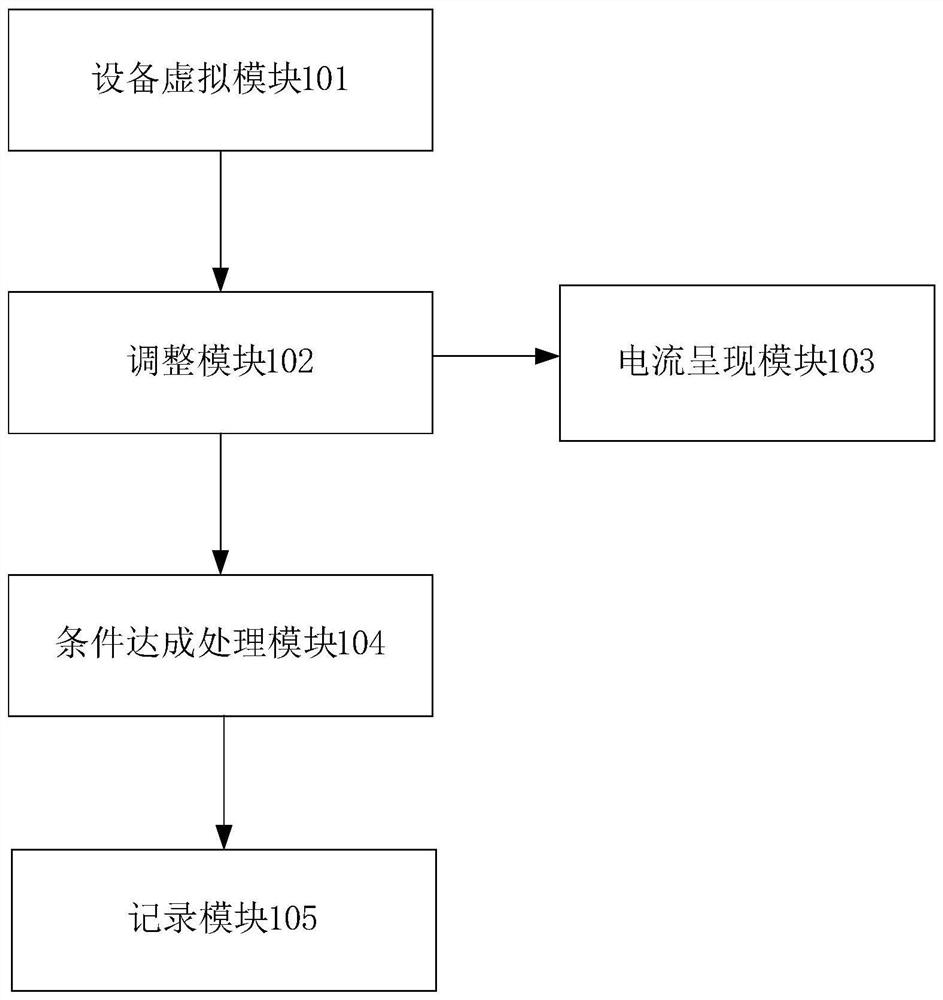

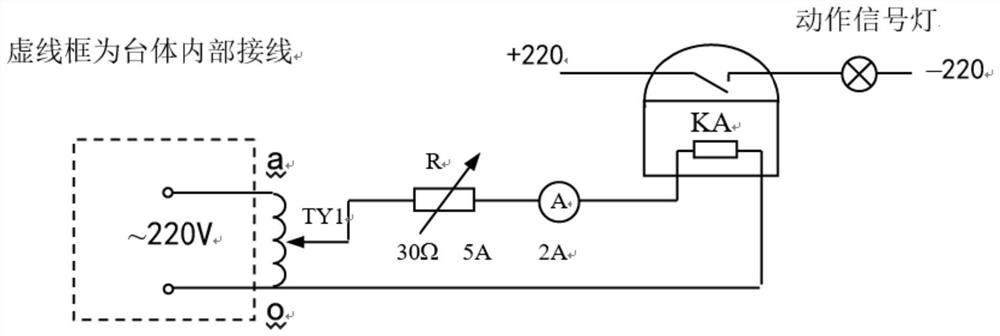

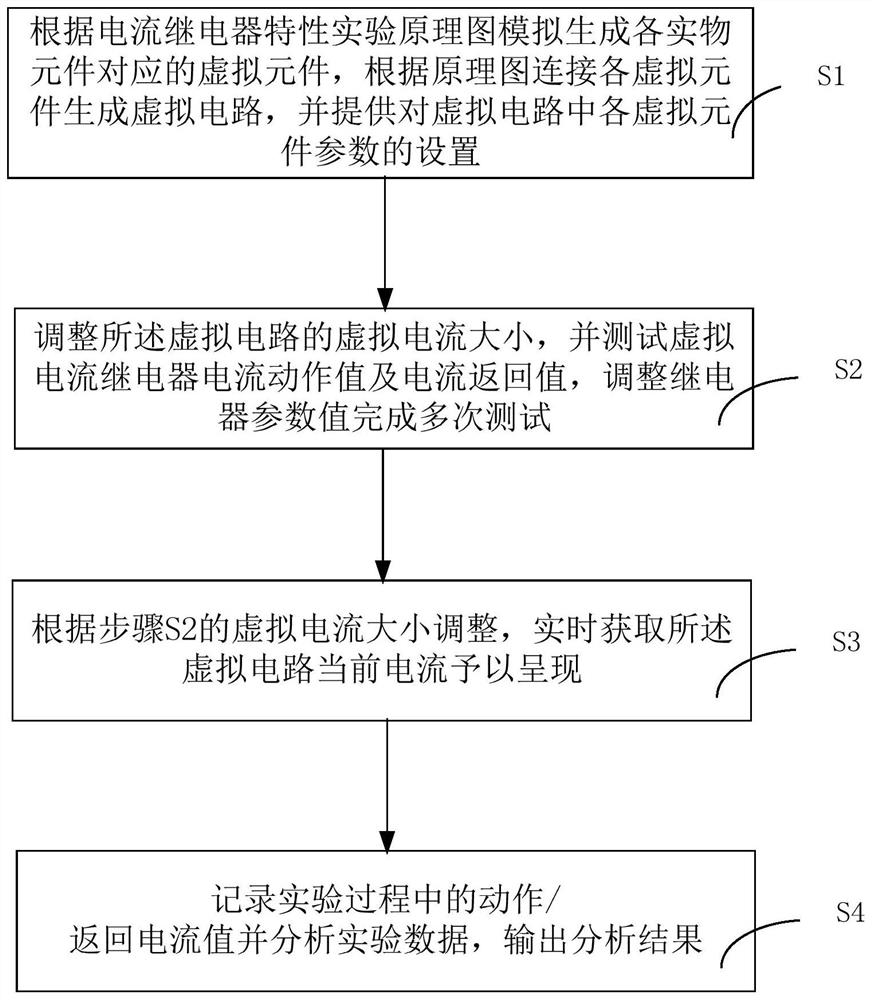

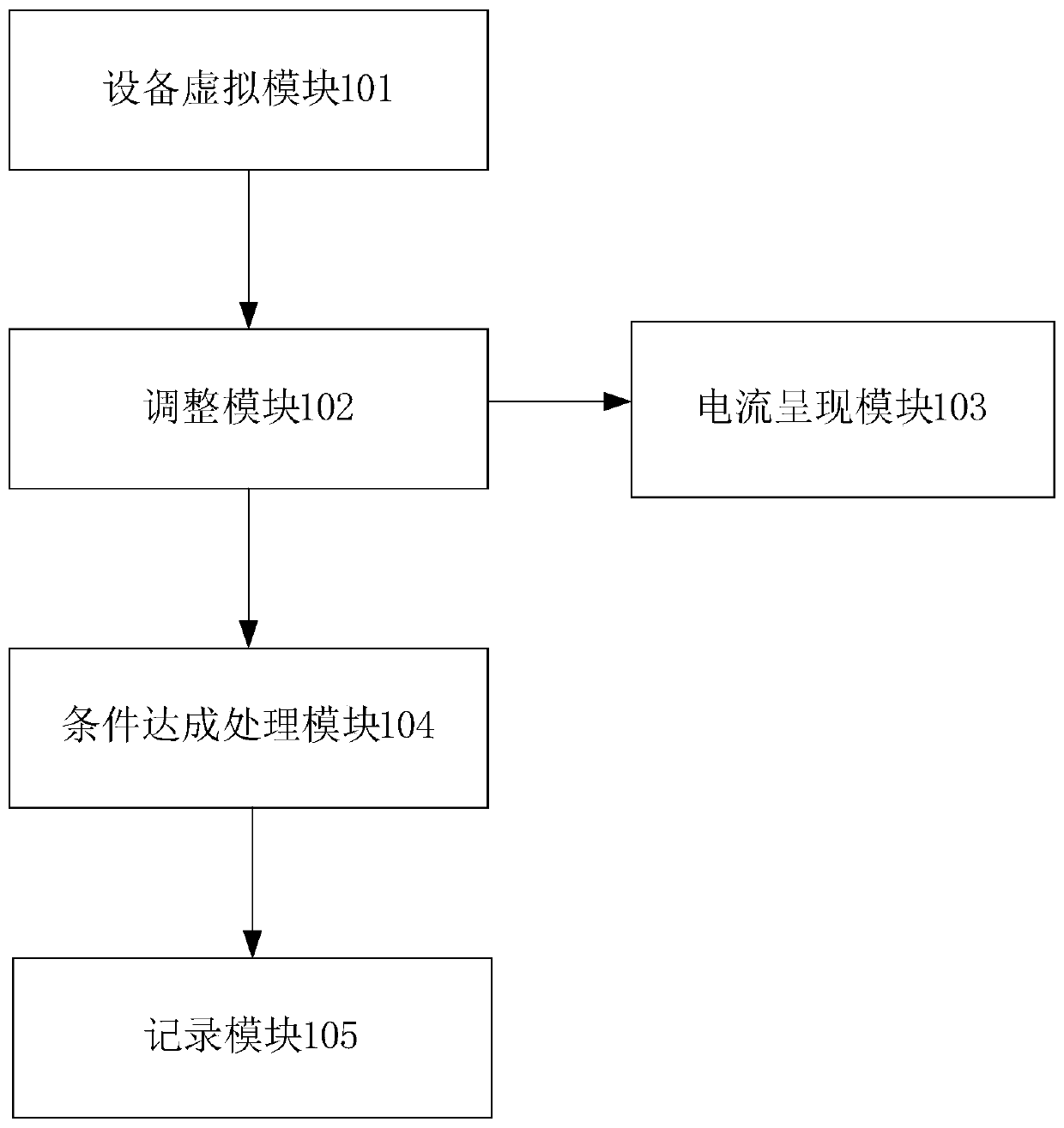

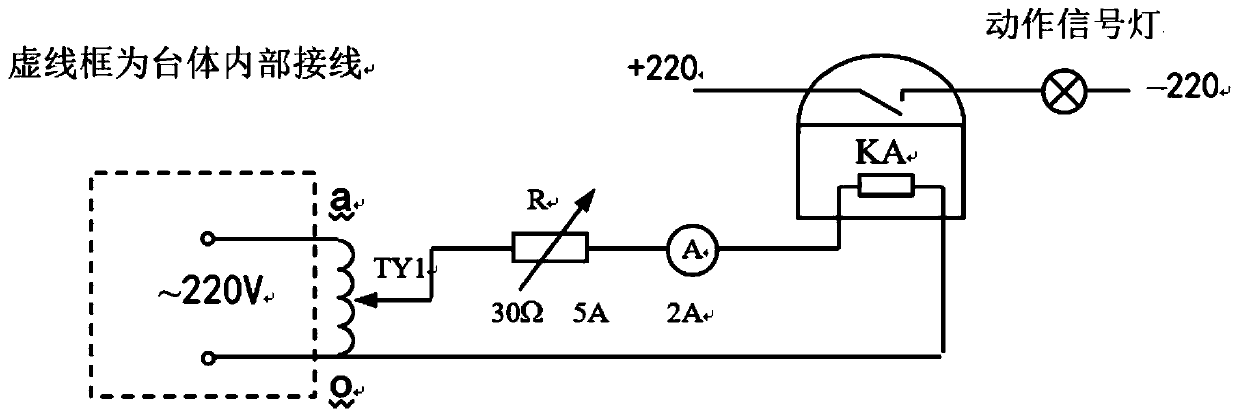

A system for virtual experiment of current relay characteristics and its realization method

ActiveCN111505498BComprehensive research impactAchieve high flexibilityCircuit interrupters testingProcessingElectric current flow

The invention discloses a system for virtual experiment of current relay characteristics and its realization method. The system comprises: a device virtual module, which simulates and generates virtual elements corresponding to each physical element according to the schematic diagram of the current relay characteristic experiment, and provides a reference for the virtual circuit. The setting of the parameters of each virtual component; the adjustment module is used to adjust the virtual current of the virtual circuit or the parameter value of the relay, and the start condition is reached; the processing module monitors the trigger condition of the virtual current to record the current action value and return value; Obtain the current current of the virtual circuit and present it; the condition fulfillment processing module monitors whether the trigger condition of the virtual current is fulfilled, judges that the current of the virtual circuit reaches the action value or return value, triggers the recording module, and at the same time executes the external performance of the real current relay action or return ; The recording module is used to record the action / return current value during the experiment and analyze the experimental data.

Owner:GUANGZHOU UNIVERSITY

System for current relay characteristic virtual experiment and implementation method thereof

ActiveCN111505498AComprehensive research impactAchieve high flexibilityCircuit interrupters testingPhysical elementProcessing

The invention discloses a system for a current relay characteristic virtual experiment and an implementation method thereof, and the system comprises an equipment virtual module which simulates and generates virtual elements corresponding to all physical elements according to a current relay characteristic experiment schematic diagram, and provides the setting of the parameters of all virtual elements in a virtual circuit; an adjusting module, used for adjusting the virtual current magnitude or the relay parameter value of the virtual circuit and starting the condition achieving processing module to monitor the virtual current triggering condition so as to record a current action value and a return value; a current presentation module, used for acquiring and presenting the current of the virtual circuit in real time; a condition achievement processing module, used for monitoring whether a virtual current triggering condition is achieved or not, triggering the recording module when judging that the current of the virtual circuit reaches an action value or a return value, and executing the external performance of action or return of the real current relay; and a recording module, used for recording the action / return current value in the experiment process and analyzing the experiment data.

Owner:GUANGZHOU UNIVERSITY

Method for forging high-purity niobium rods

The invention relates to a method for forging high-purity niobium rods. The method comprises the following steps that the outer circumference of a niobium ingot is subjected to turning, the turning size is based on the surface quality, steps are allowed to be included, and the steps are needed to be inclined and transitioned; and the niobium ingot is forged on a radial forging machine, the rollingreduction is 20-30mm, the pull-play speed is less than or equal to 1.5m / min, one-pull-play is carried out, reciprocating forging is forbidden, water pipe spraying cooling is started for a whole course, dynamic real-time temperature measurement is carried out, the process temperature and finishing temperature are less than and equal to 330 DEG C, if not, forging is stopped, billets are suspended away from forging equipment, underwater cooling is carried out for 15-20min, reciprocating jumping and moving up and down are carried out, the underwater penetration is greater than or equal to 0.5m, the billets after water cooling are continuous to be forged and formed on the radial forging machine, the rolling reduction is 5-10mm, the pull-play speed is less than or equal to 1.2m / min, one-pull-play is carried out, reciprocating forging is forbidden, water pipe spraying cooling is started for the whole course, after forging and forming, the billets are converted to a straightening machine forstraightening during lingering warmth, tiling, air cooling and material airing are carried out after straightening, and stacking is forbidden. According to the method for forging the high-purity niobium rods, no bluing and peeling phenomenon exists on the surface, the surface quality is improved, the yield is improved, and the manufacturing cost is reduced.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com