Environment-friendly water-based imitating electrosilvering coating and preparation method thereof

A kind of imitation electroplating, environment-friendly technology, applied in the direction of coating, etc., can solve the problems of high VOC, low solid content, etc., and achieve the effect of improving water resistance, strong metal feeling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

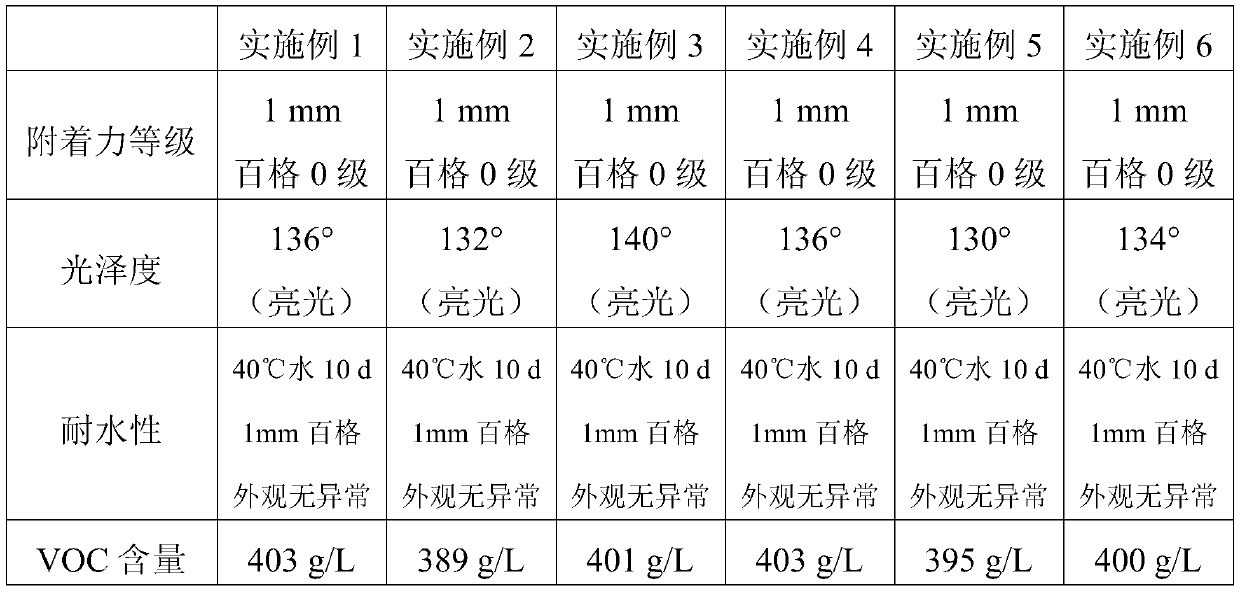

Examples

Embodiment 1

[0036] A preparation method of an environment-friendly water-based imitation electroplating silver coating, comprising the following steps:

[0037] (1) Soak 4 parts of L56161 water-based aluminum-silver paste in 4 parts of film-forming aid dipropylene glycol methyl ether (DPM), stir evenly to make a semi-finished product of aluminum-silver paste, and put it aside for later use; wherein the stirring speed is 1000rpm;

[0038] (2) Then add 60 parts of water-based acrylic emulsion, 2 parts of BYK-333 high-efficiency silicone dispersant, 2 parts of BYK-420 anti-settling agent, and 2 parts of RHEOLATE 299 thickener. Put into semi-finished product of aluminum silver paste, 0.5 part of pH adjuster dimethyl ethanolamine (DMEA); Wherein, the rotating speed of middle and low speed stirring is 800rpm, and the stirring speed of inputting while stirring is 600rpm;

[0039] (3) Add 25.5 parts of deionized water and disperse for 5-15 minutes to obtain a stable and environmentally friendly wat...

Embodiment 2

[0041] A preparation method of an environment-friendly water-based imitation electroplating silver coating, comprising the following steps:

[0042] (1) Soak 5 parts of L56161 water-based aluminum-silver paste in 8 parts of film-forming aids dipropylene glycol methyl ether (DPM), stir evenly to make a semi-finished aluminum-silver paste, and put it aside for later use; wherein the stirring speed is 1000rpm;

[0043] (2) Add 70 parts of water-based acrylic emulsion, 4 parts of BYK-333 high-efficiency silicone dispersant, 5 parts of BYK-420 anti-settling agent, and 3 parts of RHEOLATE 299 thickener. Put into semi-finished product of aluminum silver paste, 1 part of pH adjuster dimethyl ethanolamine (DMEA); Wherein, the rotating speed of middle and low speed stirring is 800rpm, and the stirring speed of inputting while stirring is 600rpm;

[0044] (3) Add 4 parts of deionized water and disperse for 5-15 minutes to obtain a stable and environmentally friendly water-based imitation...

Embodiment 3

[0046] A preparation method of an environment-friendly water-based imitation electroplating silver coating, comprising the following steps:

[0047] (1) Soak 4 parts of L56161 water-based aluminum-silver paste in 6 parts of film-forming aid dipropylene glycol methyl ether (DPM), stir evenly to make a semi-finished product of aluminum-silver paste, and put it aside for later use; wherein the stirring speed is 1000rpm;

[0048] (2) Add 65 parts of water-based acrylic emulsion, 3 parts of BYK-333 high-efficiency silicone dispersant, 3 parts of BYK-420 anti-settling agent, and 2 parts of RHEOLATE 299 thickener. Put into the semi-finished product of aluminum silver paste, 0.8 part of pH adjuster dimethyl ethanolamine (DMEA); Wherein, the rotating speed of middle and low speed stirring is 800rpm, and the stirring speed of inputting while stirring is 600rpm;

[0049] (3) Add 16.2 parts of deionized water and disperse for 5-15 minutes to obtain a stable and environmentally friendly wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com