Purification method of germanium in zinc sulfate solution by using magnetic field

A technology of zinc sulfate solution and magnetic field, which is applied in metallurgy and chemical industry, can solve the problems of high production cost, high consumption of zinc powder, long working time, etc., and achieve the effect of low production cost, short working time and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

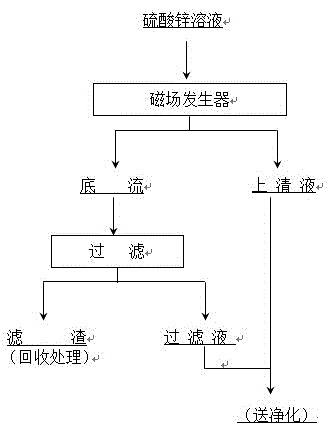

Method used

Image

Examples

Embodiment 1

[0025] The neutral leaching pH of the roasted ore is 4.5, and the 500ml zinc sulfate solution with a germanium content of 0.08mg / L is statically placed in a permanent magnetic field strength of 15T for 30 minutes, and the supernatant Ge is measured to be 0.062mg / L.

Embodiment 2

[0027] A 500ml zinc sulfate solution with a neutral leaching pH of 5.0 and a germanium content of 0.46mg / L of the roasted ore was placed in a permanent magnetic field of 300T for a holding time of 50 minutes, and the supernatant Ge was measured to be 0.07mg / L.

Embodiment 3

[0029] The neutral leaching pH of the roasted ore is 5.4, and the 500ml zinc sulfate solution with a germanium content of 1.65mg / L is statically placed in a permanent magnetic field strength of 800T for 60 minutes, and the supernatant Ge is measured at 0.064mg / L.

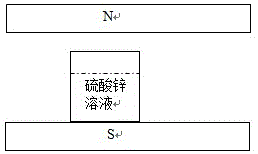

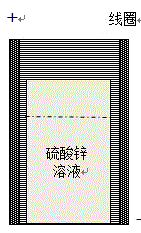

[0030] In the present invention, germanium is a charged colloid in the zinc sulfate solution. Under the action of a magnetic field, the charged germanium colloid moves in a directional direction and condenses into large particles, thereby realizing the purification of germanium in the zinc sulfate solution. The magnetic field generator of the present invention The magnetic field used is a permanent magnetic field or an electromagnetic field. The germanium in the zinc sulfate solution can be condensed into large particles under the action of the magnetic field, which has a good removal effect on germanium, short operation time, no need to input raw materials, low production cost, and labor intensity small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com