Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Narrow residence time distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

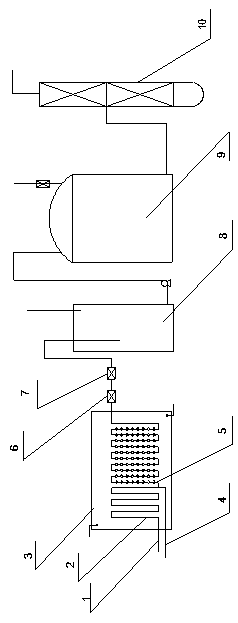

Reaction device for preparing low-carbon olefin by employing methyl alcohol and/or dimethyl ether

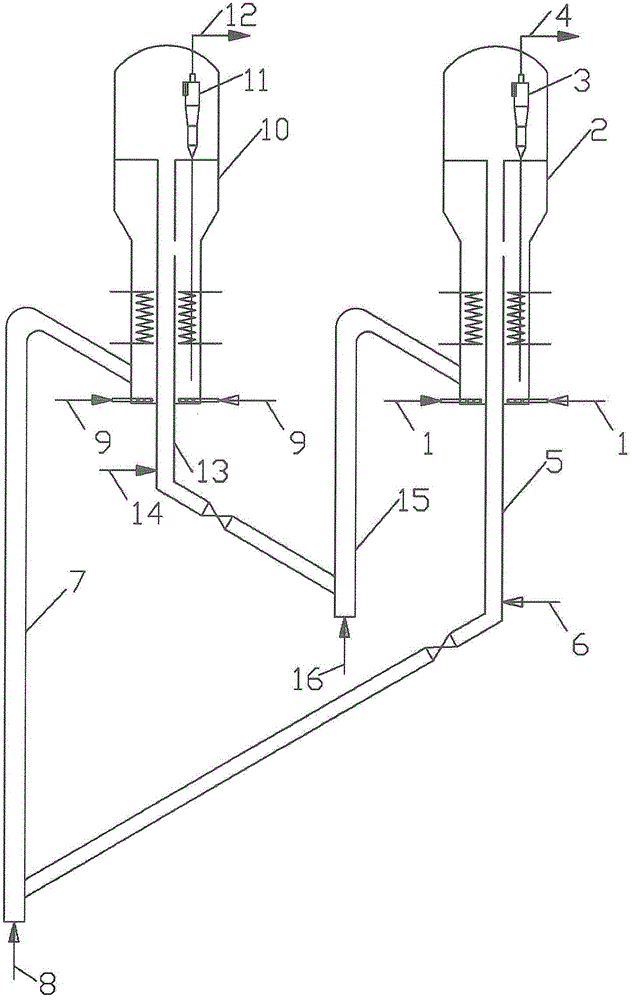

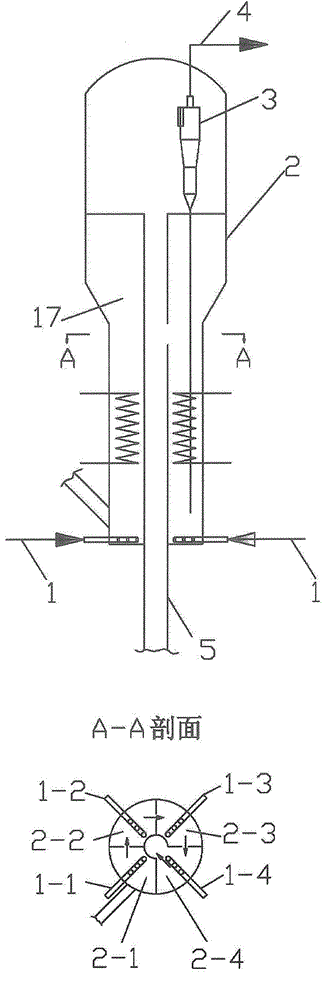

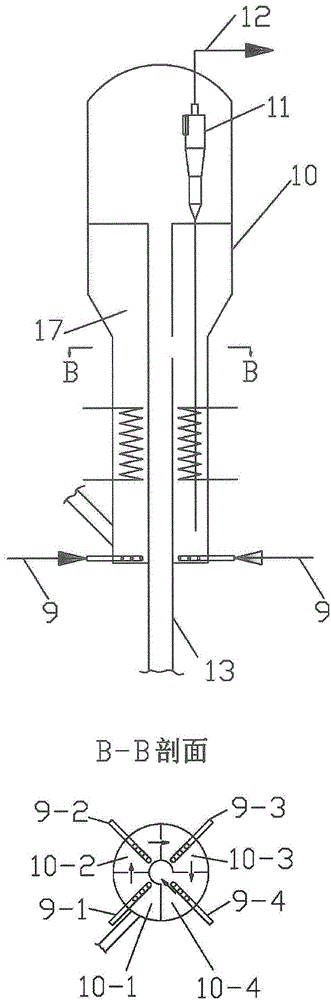

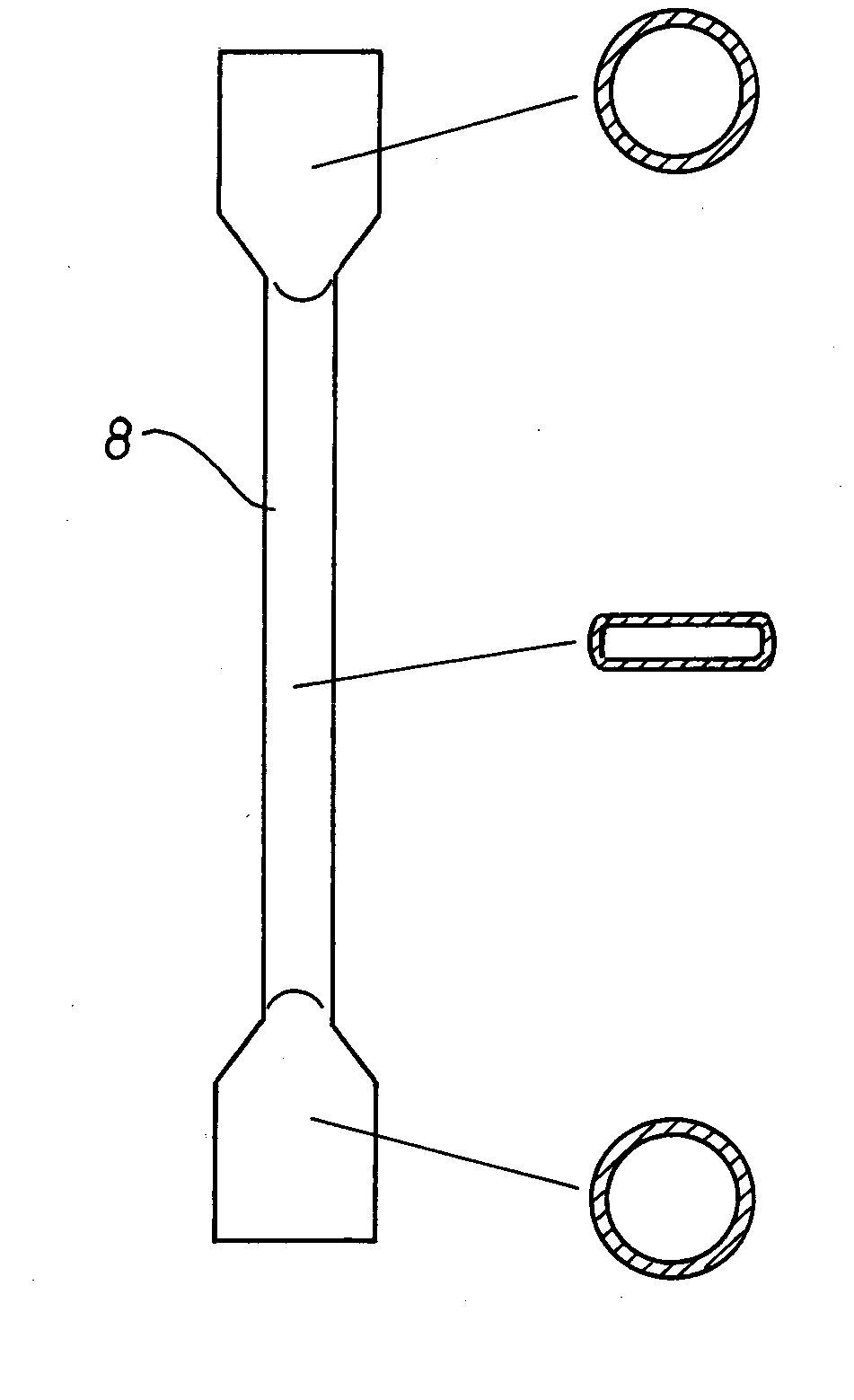

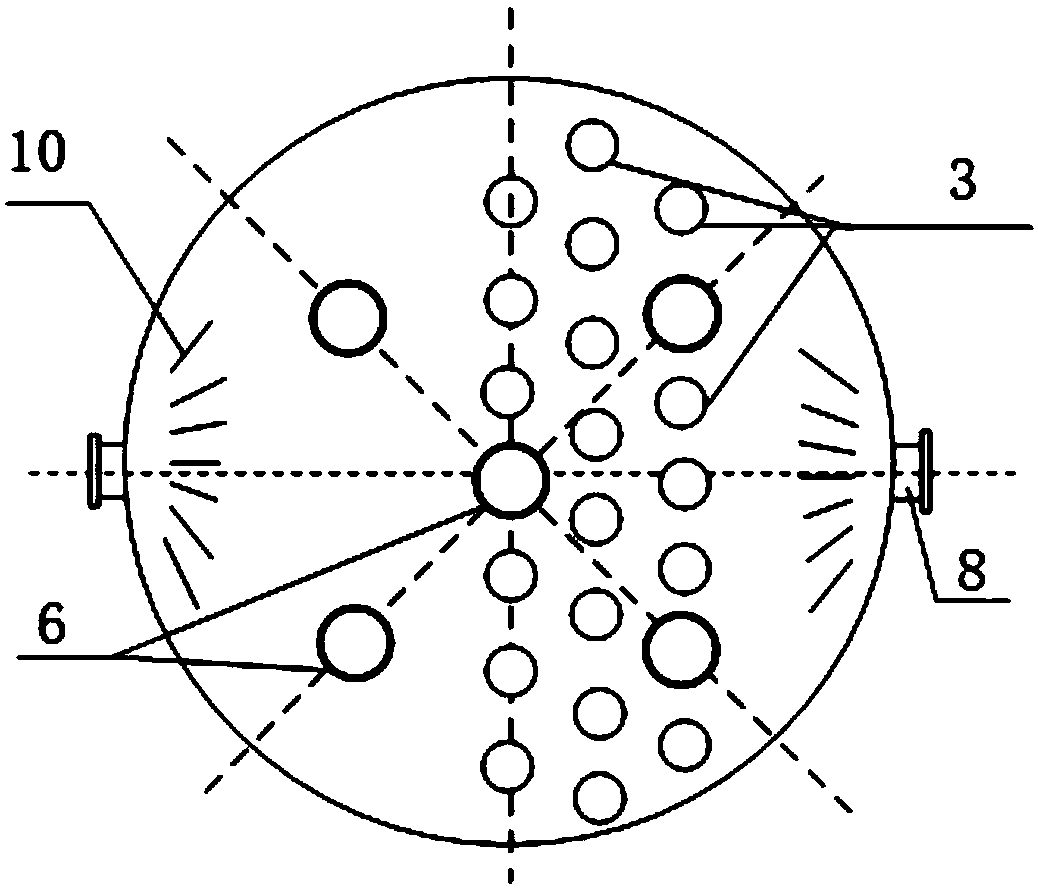

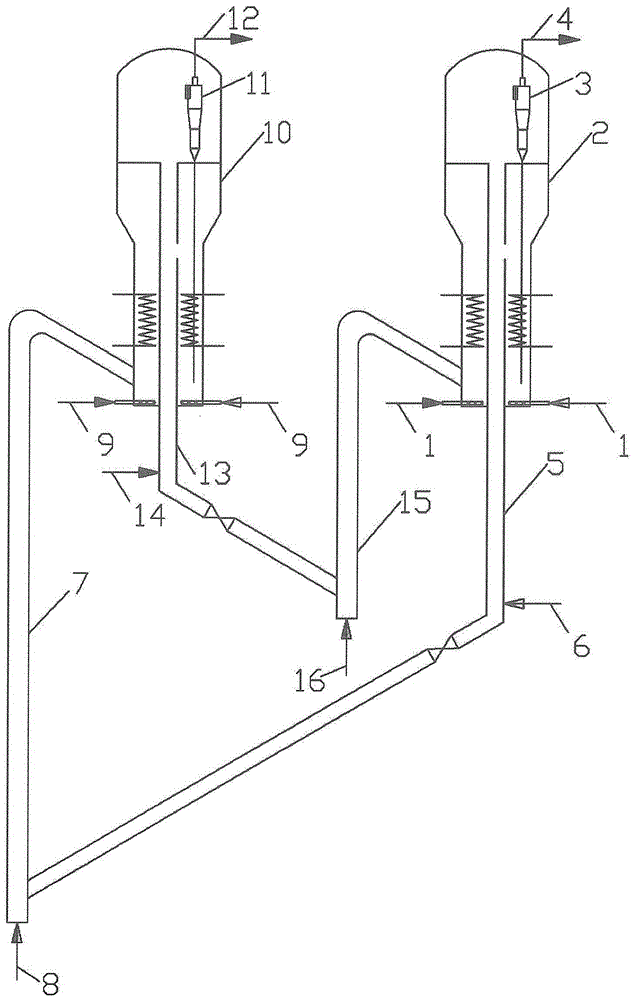

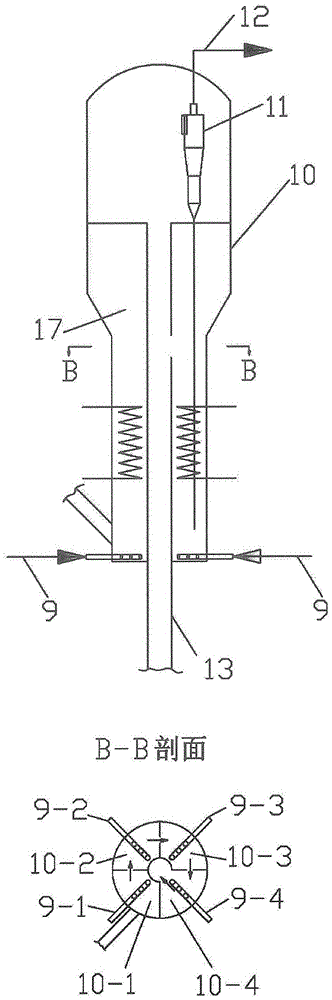

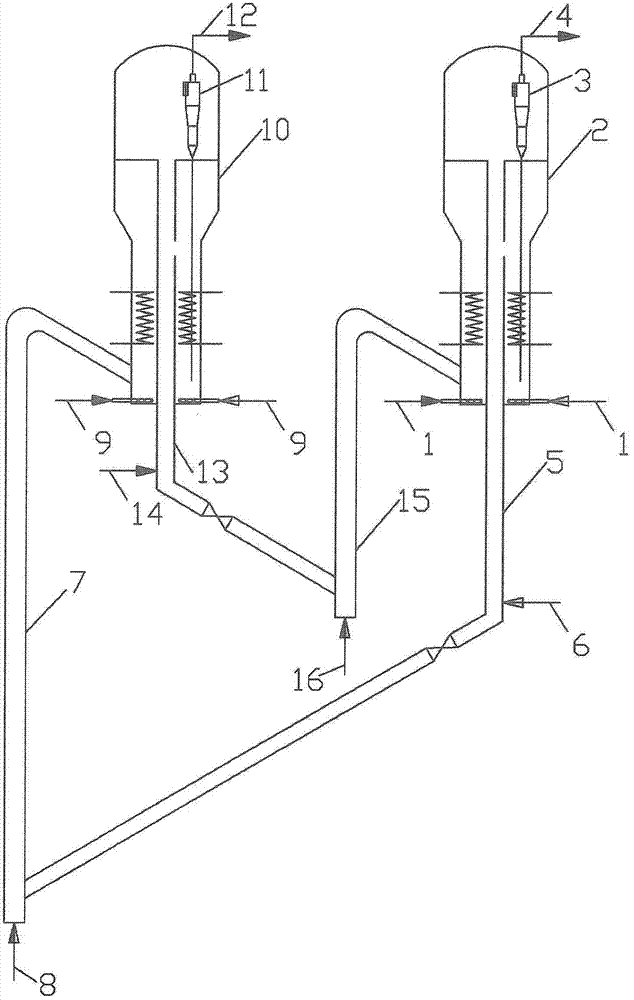

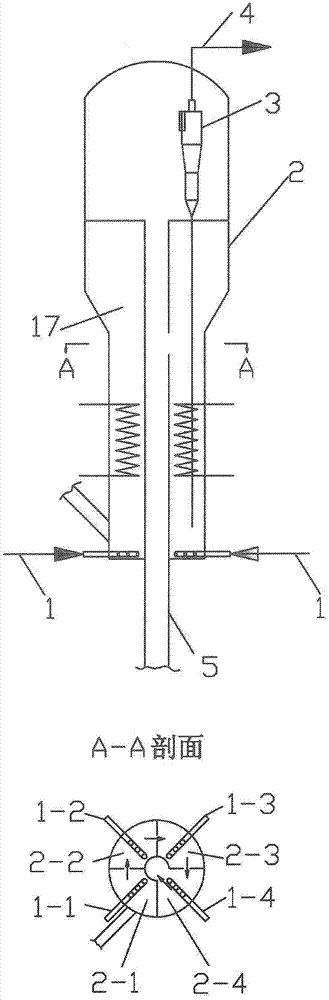

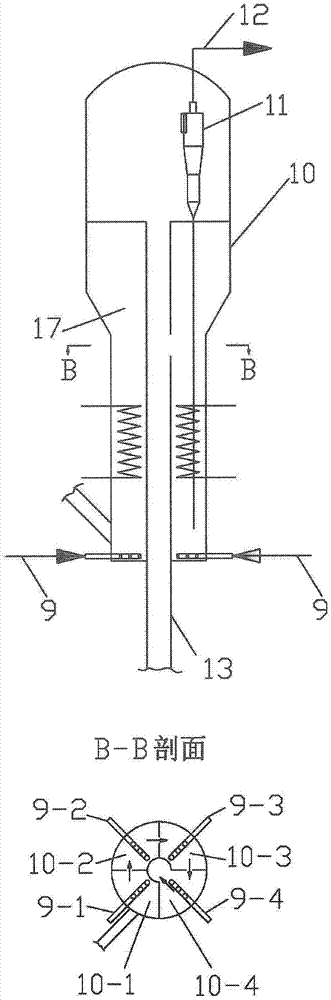

ActiveCN104672045AIncrease bed densityReduce wearHydrocarbon from oxygen organic compoundsEthylene productionAlcoholFluidized bed

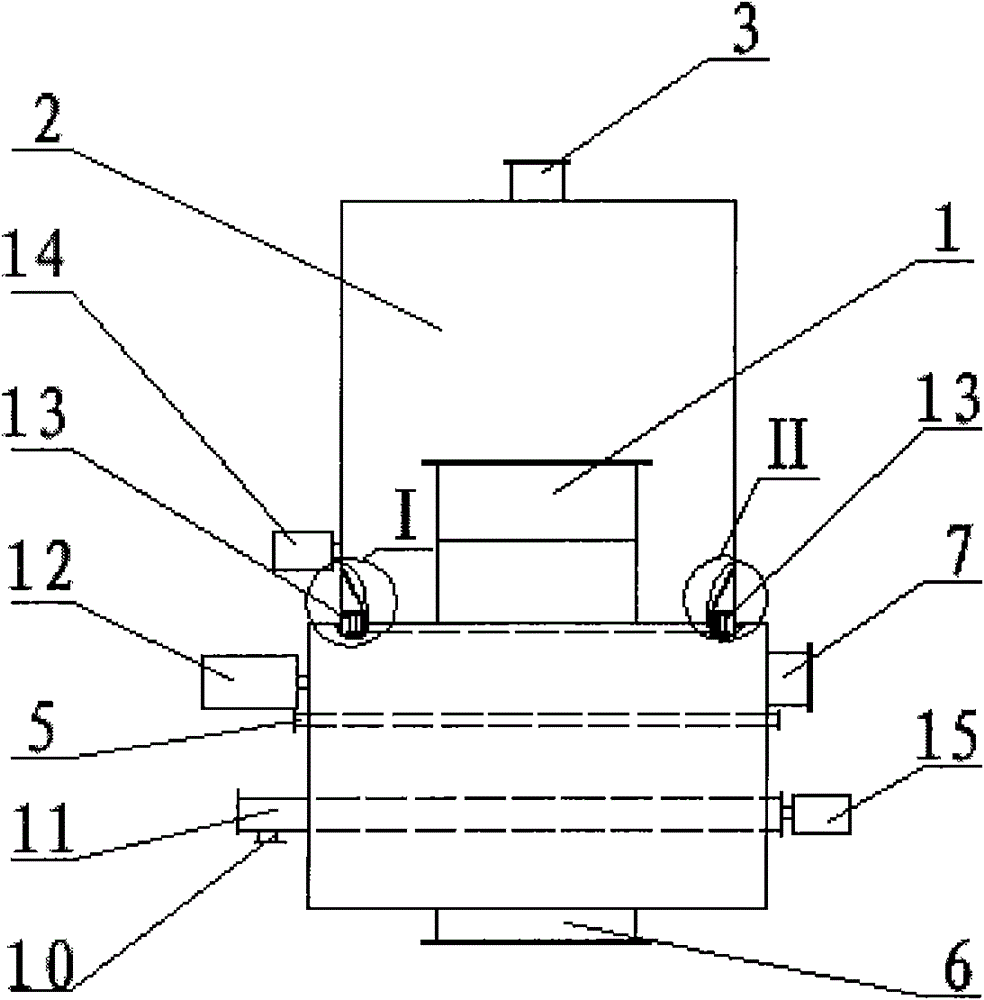

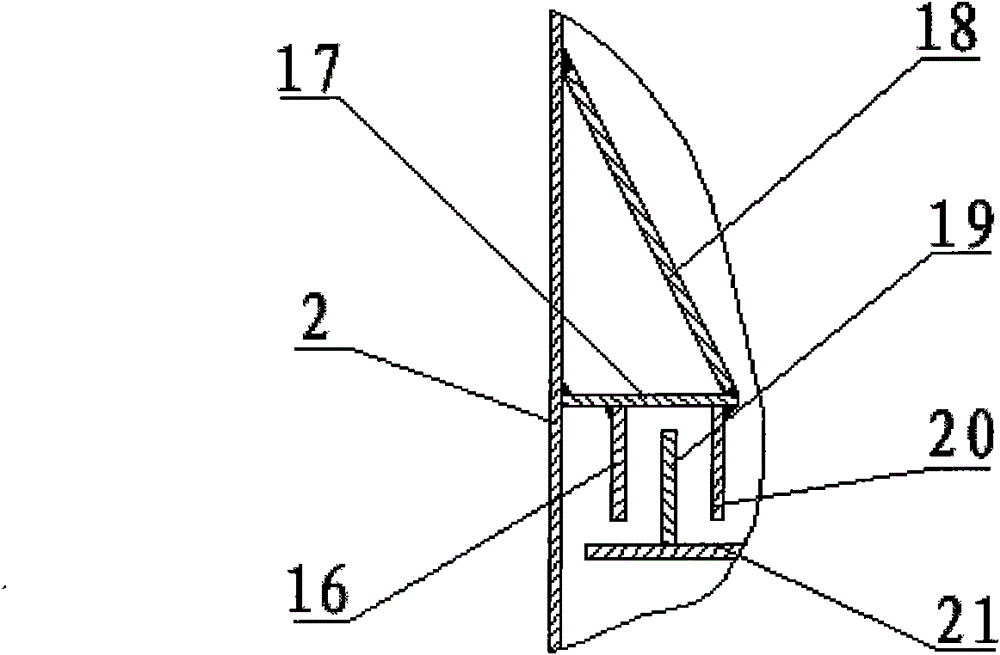

The invention relates to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether, in particular to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether. The reaction device mainly comprises a dense-phase fluidized bed reactor (2), a cyclone separator (3), a stripper (5), a lift pipe (7), a dense-phase fluidized bed regenerator (10), a cyclone separator (11), a stripper (13) and a lift pipe (15), wherein the dense-phase fluidized bed reactor (2) is partitioned into n (n is greater than or equal to 2) secondary reaction zones by material flow controllers (17); and the dense-phase fluidized bed regenerator (10) is partitioned into m (m is greater than or equal to 2) secondary regeneration zones by the material flow controllers (17). By virtue of the reaction device, the problems in the prior art that carbon deposit distribution of a catalyst is uneven and low-carbon olefin selectivity is relatively low are solved.

Owner:中科催化新技术(大连)股份有限公司

Process and apparatus for removing volatile substances from highly viscous media

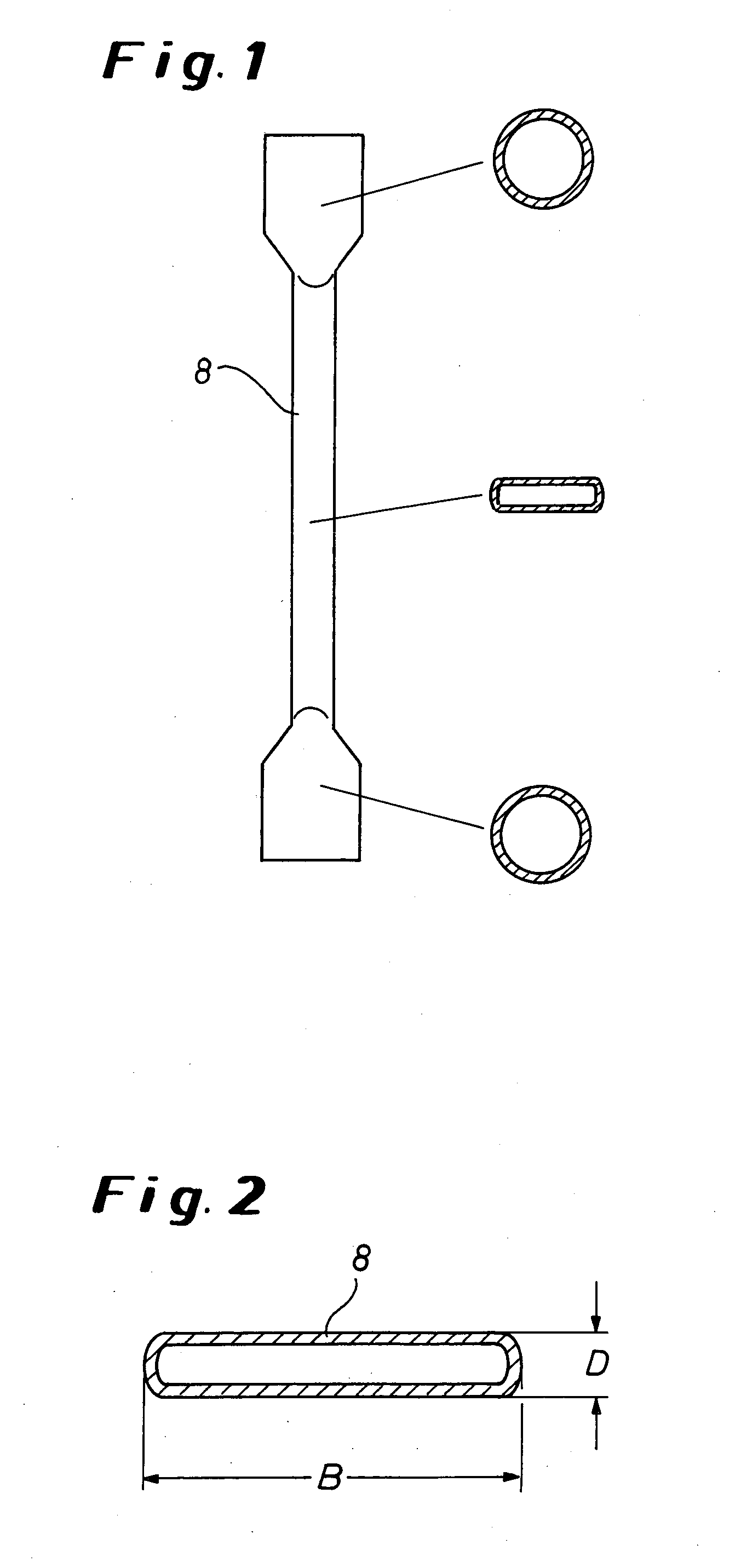

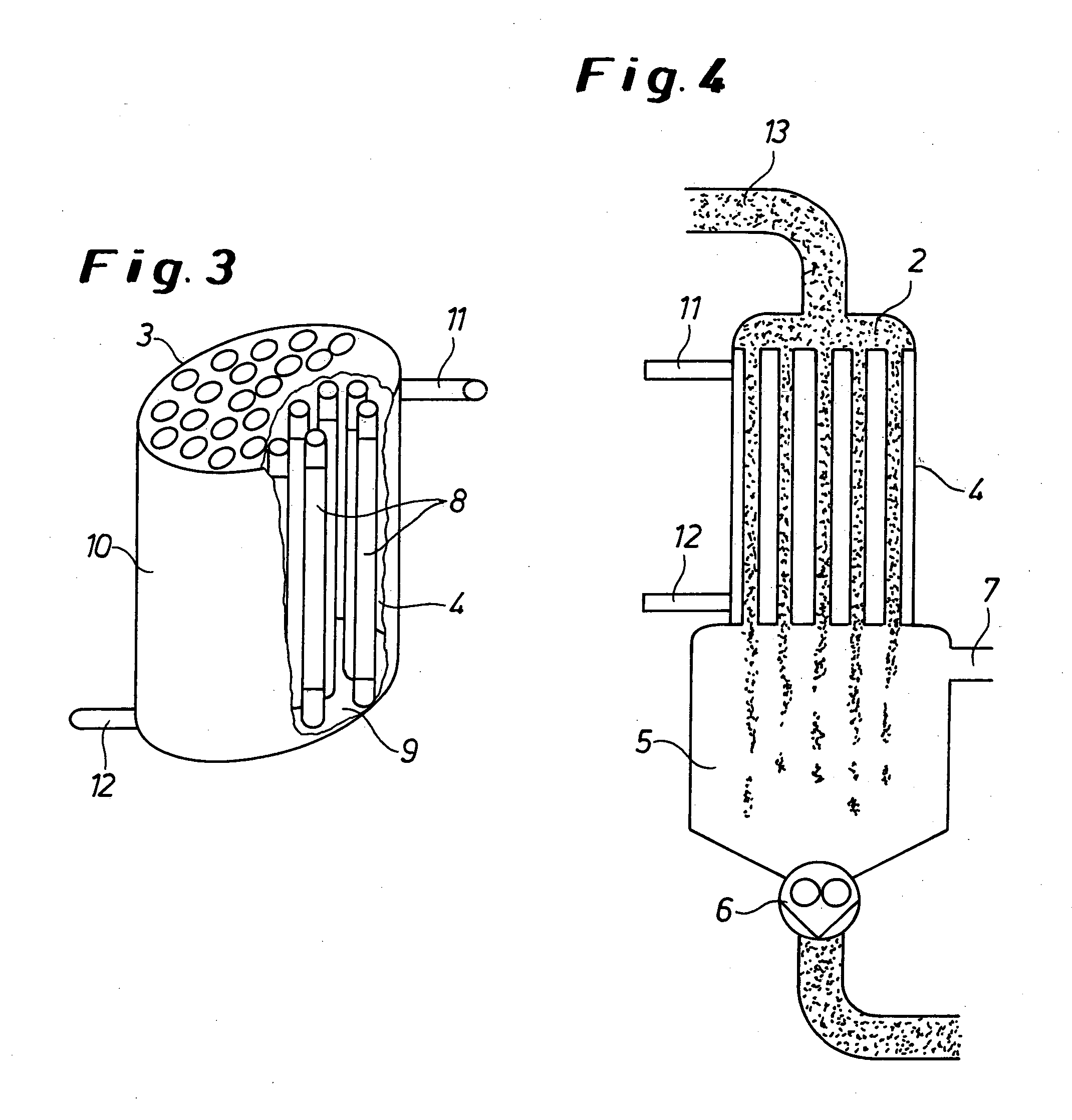

InactiveUS20050092444A1Reduce heat loadNarrow residence time distributionDrying using combination processesEvaporation with vapour compressionProcess engineeringViscous medium

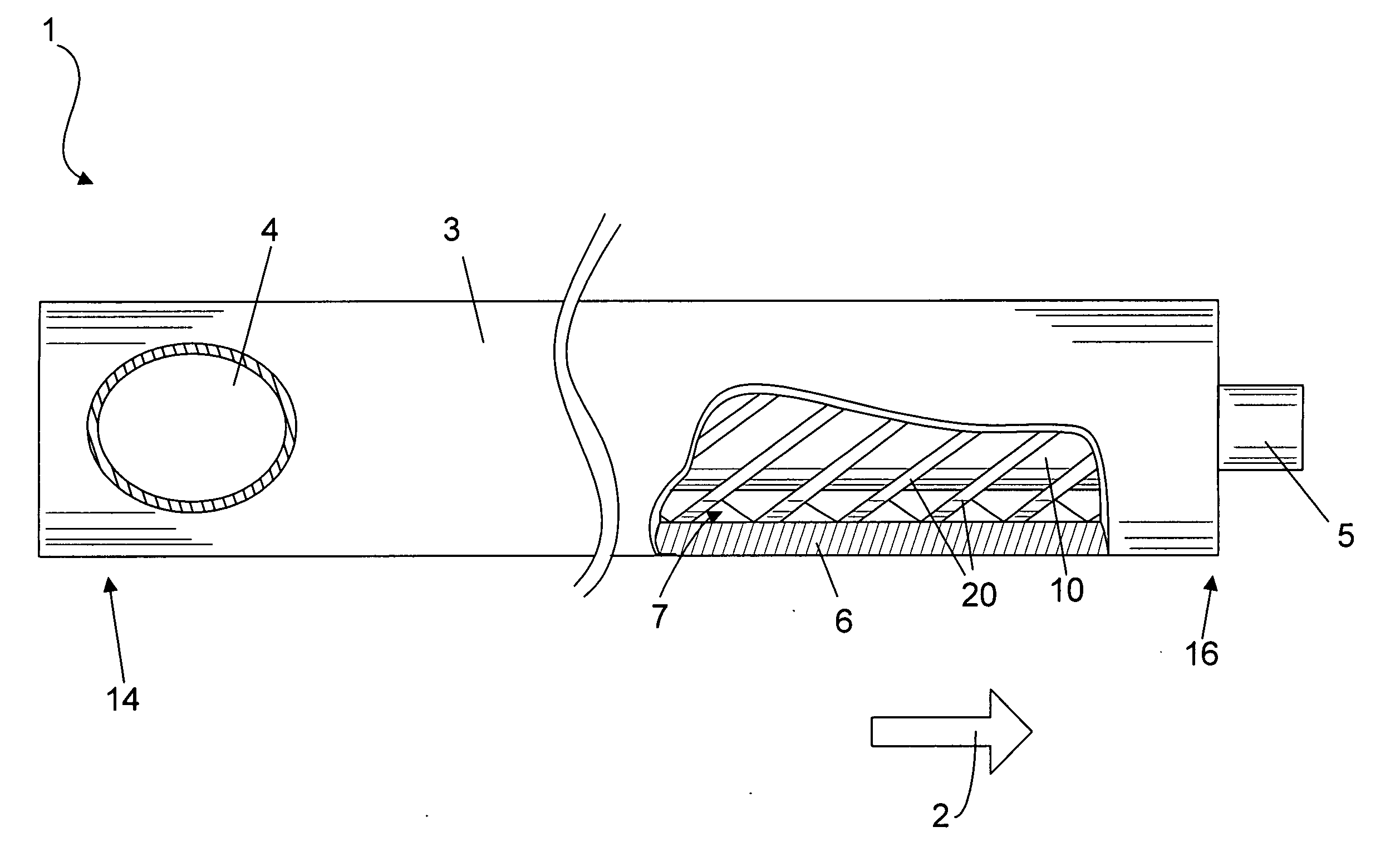

Evaporator apparatus (1) for the treatment of viscous media comprised of at least a feed chamber (2) having a perforated tray (3), a tube-bundle heat exchanger (4) connected thereto having perpendicularly arranged tubes (8) and a devolatilization chamber (5) connected thereto, a discharge unit (6) for the product and a vapor take-off (7) for removing volatile components, the tubes (8) of the heat exchanger (4) having a rectangular cross section over the greater part of their length.

Owner:BAYER TECH SERVICES GMBH

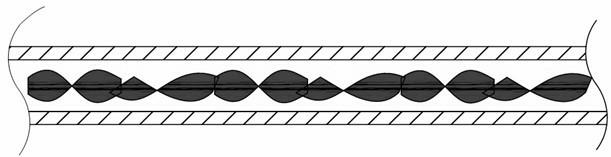

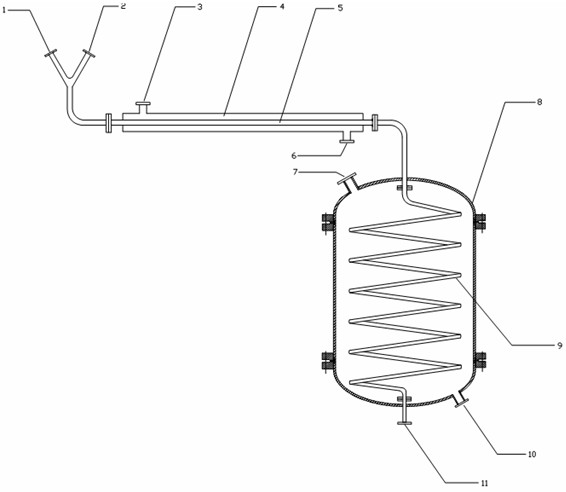

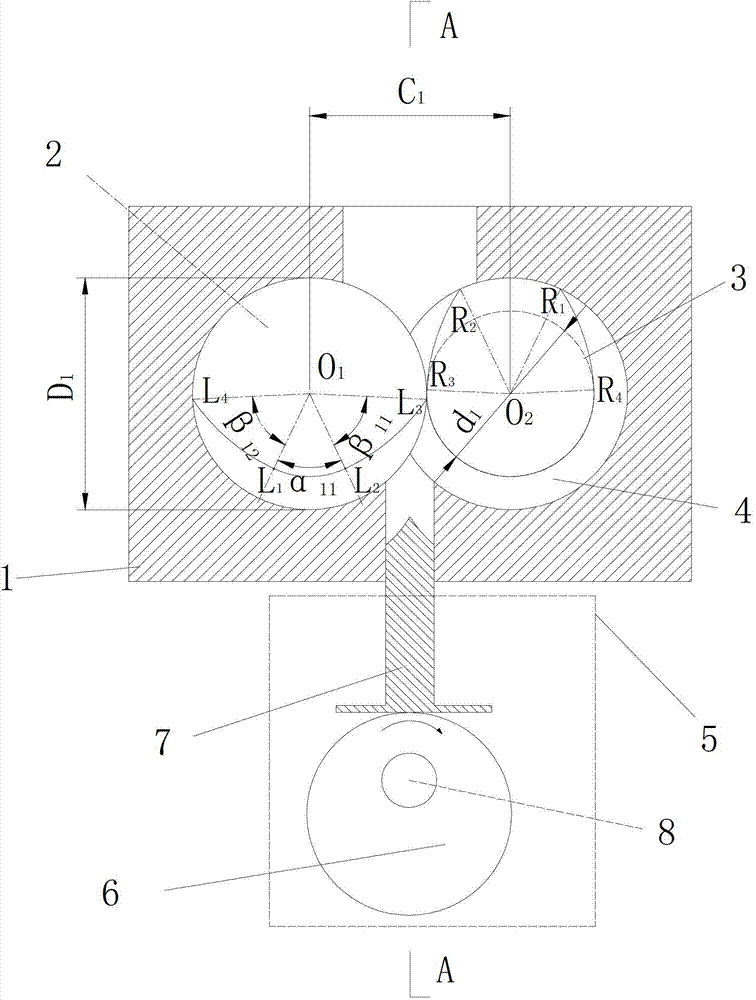

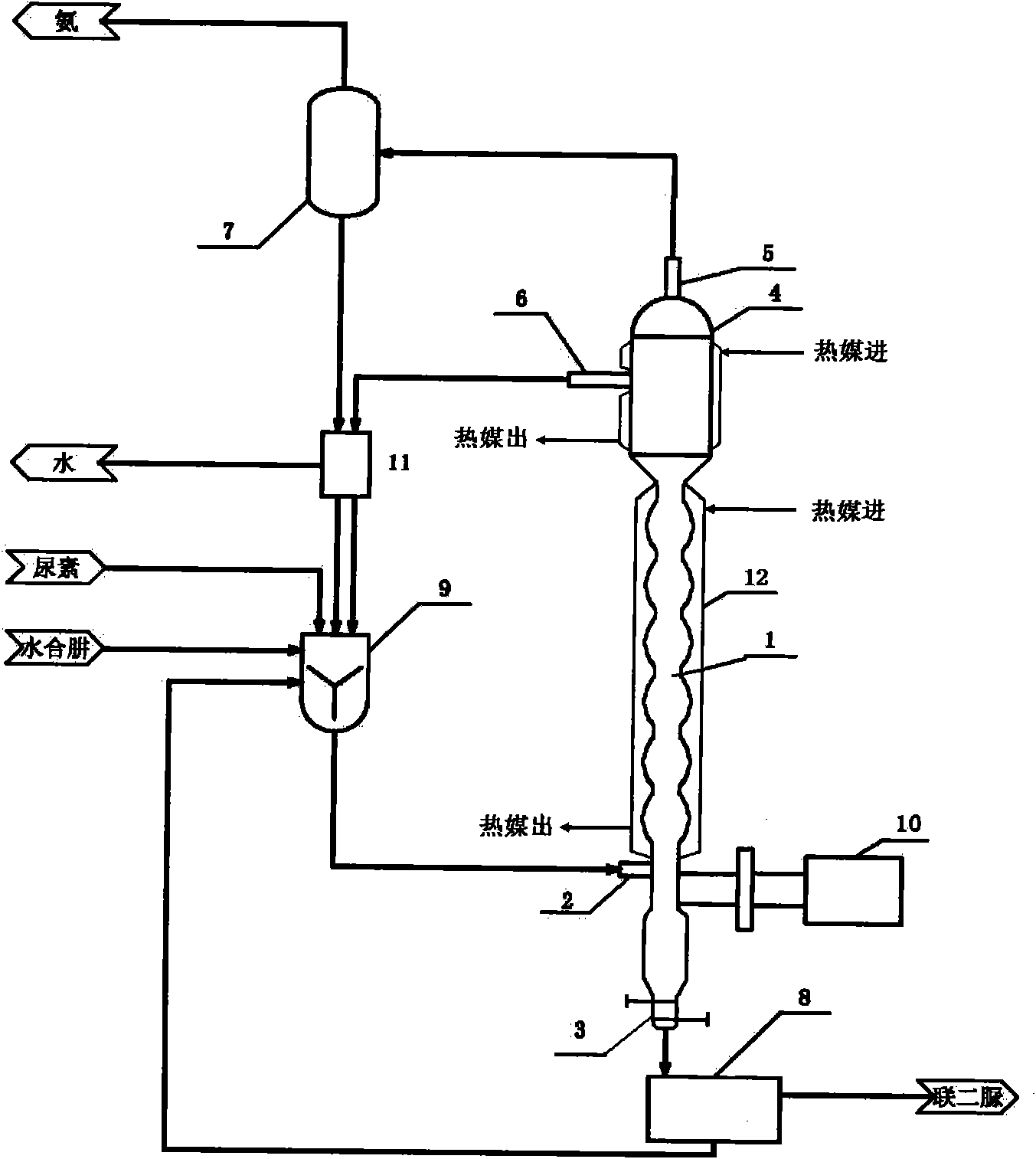

Pipe reactor with static mixing device

InactiveCN102553512AEasy to processImprove the mixing effectFlow mixersChemical/physical/physico-chemical stationary reactorsHeat carrierProcess engineering

The invention discloses a pipe reactor with a static mixing device. The pipe reactor with the static mixing device comprises a Y-shaped fluid feed port, a static mixing device, and a pipe reacting device, wherein the Y-shaped fluid feed port is provided with a fluid inlet A and a fluid inlet B, and the static mixing device comprises a jacket and an SK-type static mixer; a jacketed inlet and a jacket outlet are arranged on the jacket, and the pipe reacting device comprises a reacting device shell and a pipe reactor; a heat carrier inlet and a heat carrier outlet are arranged on the reacting device shell, and one end of the SK-type static mixer is connected with the Y-shaped fluid feed port; and the other end of the SK-type static mixer is connected with the pipe reactor. According to the pipe reactor with the static mixing device, two streams of fluids have a good mixing effect at a low flow and a flow rate, the mixing and the reaction process of the two streams of fluids are carried out at different temperatures, and part of raw material is avoided being pre-reacted, so that the mixing and the reaction process of the two streams of fluids are safer and more stable. The pipe reactor with the static mixing device is suitable for the mixing reaction process of the two streams of fluids at a low flow and a flow rate.

Owner:ZHEJIANG UNIV

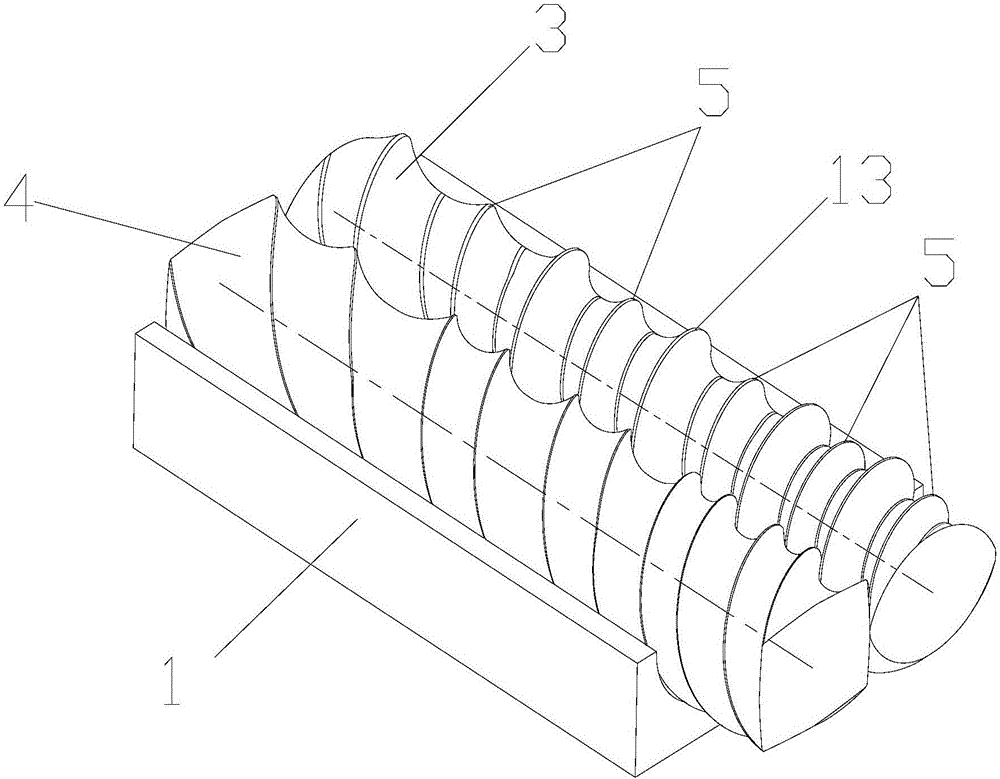

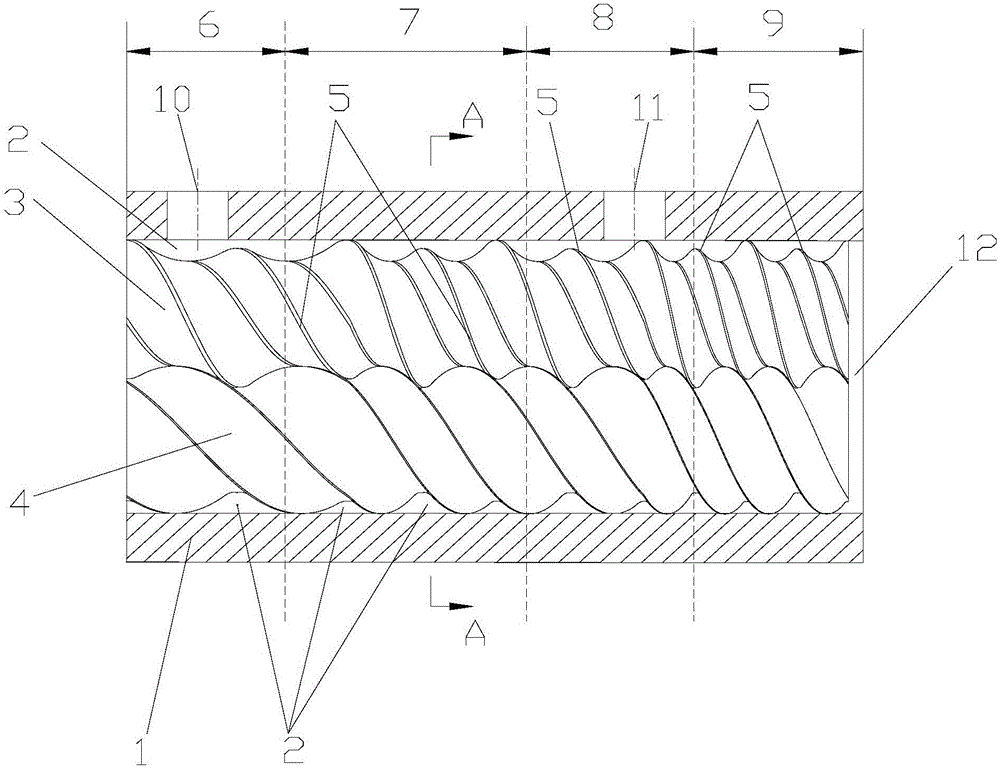

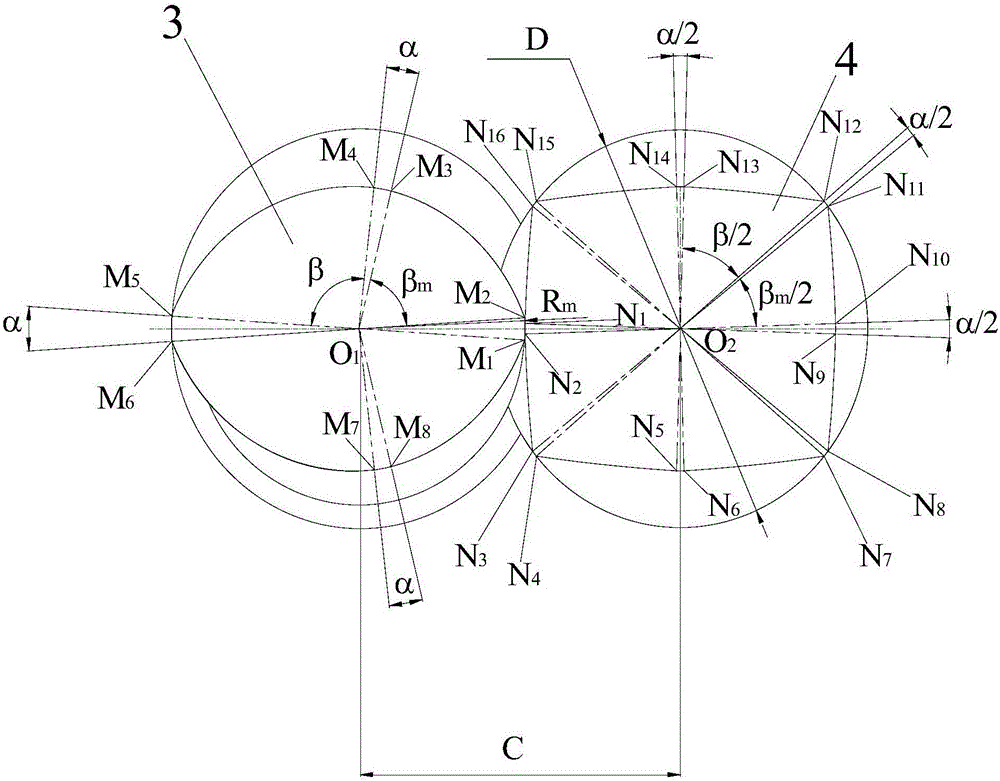

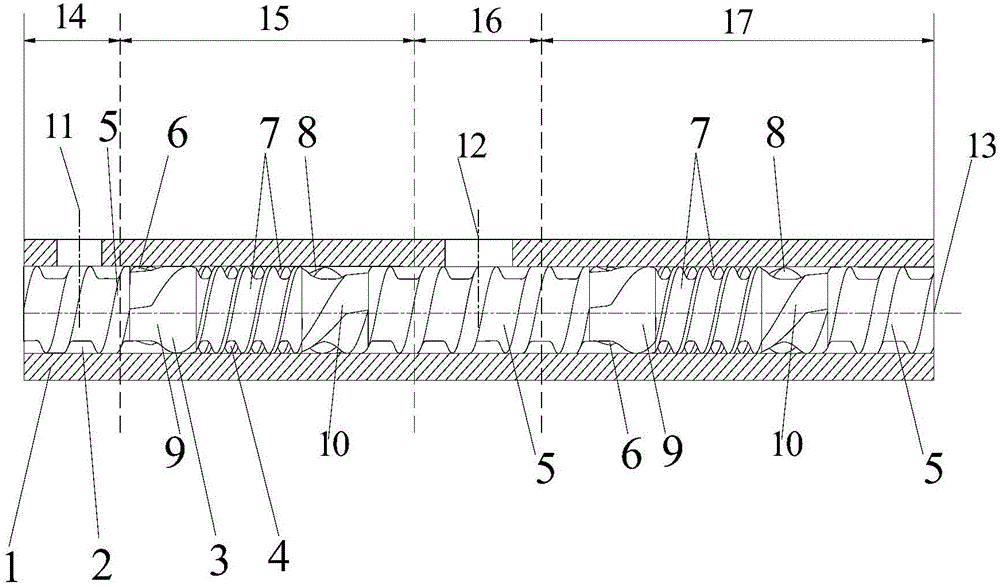

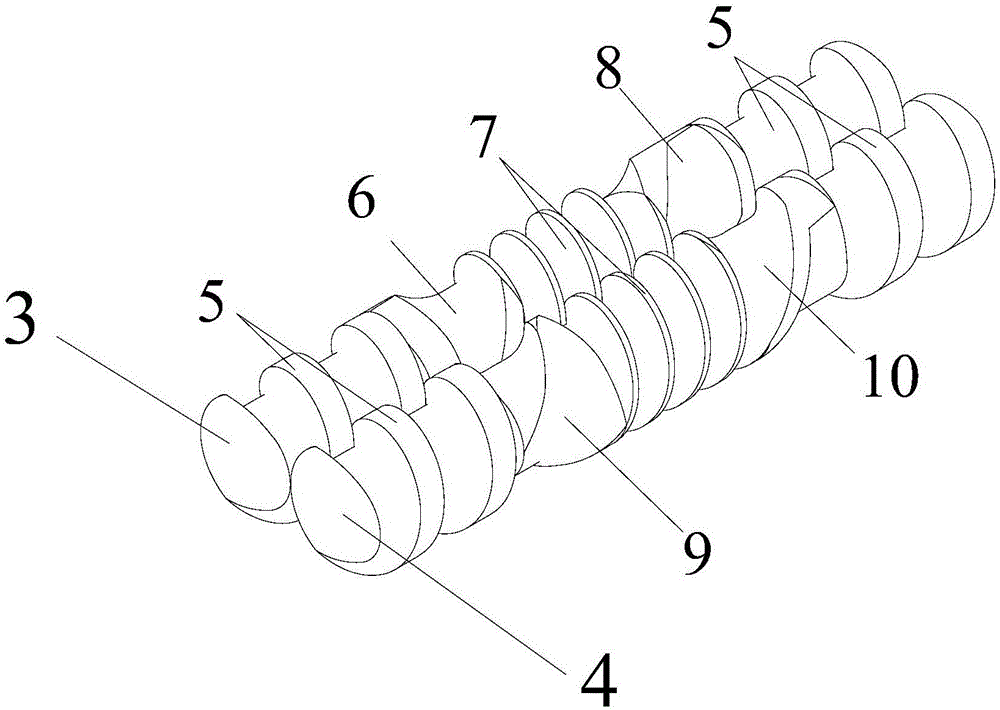

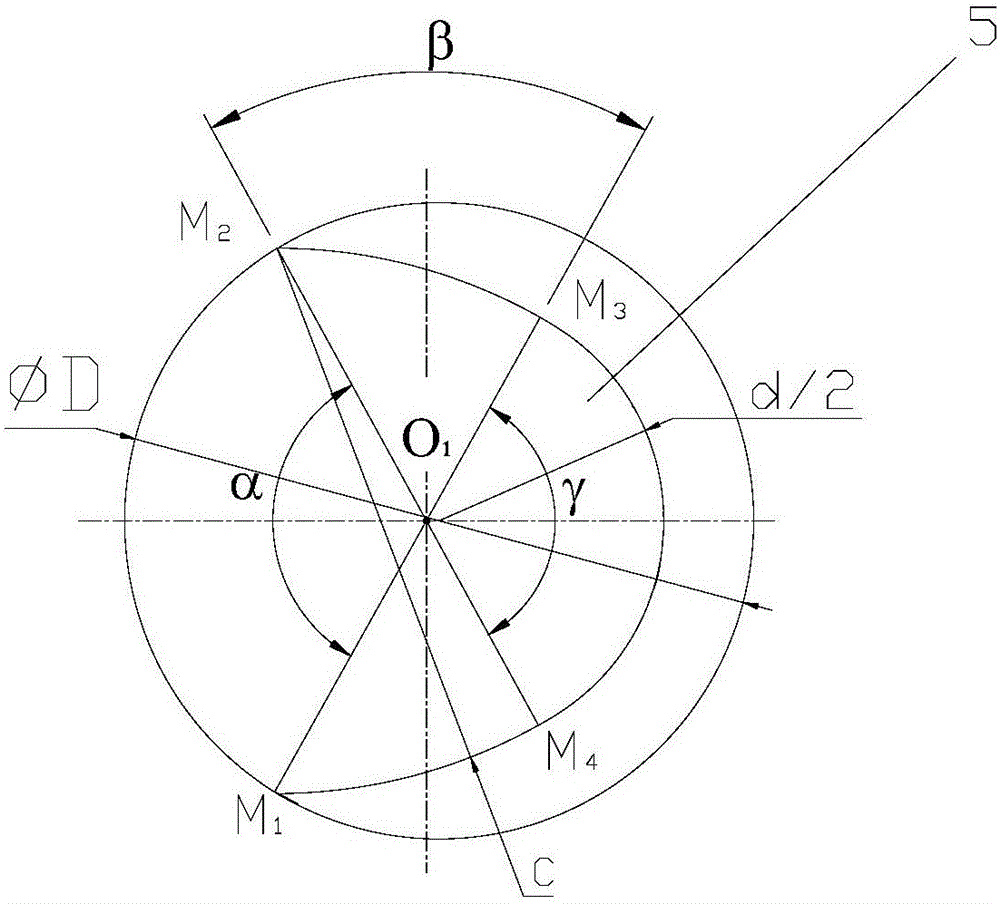

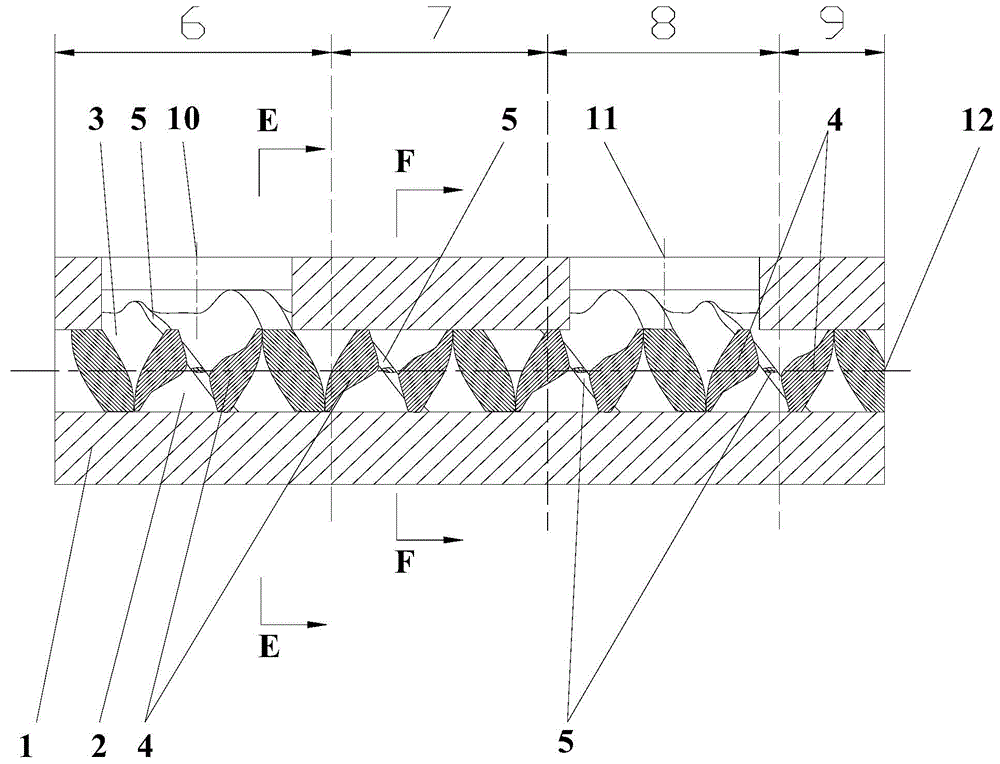

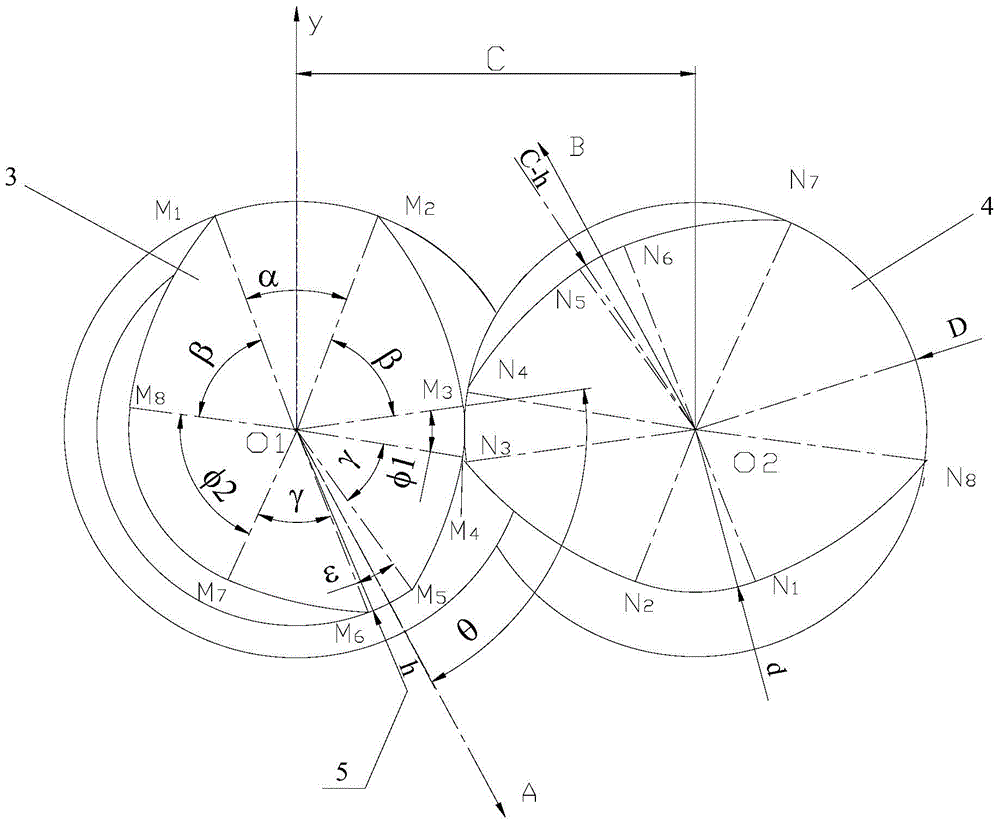

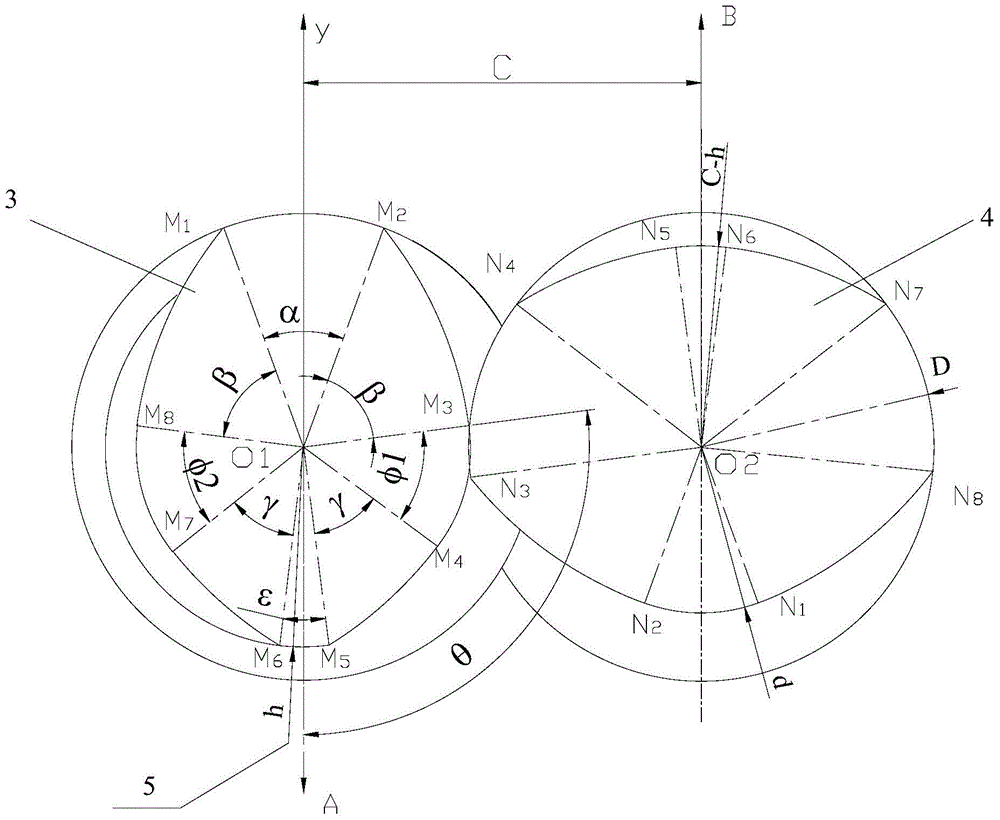

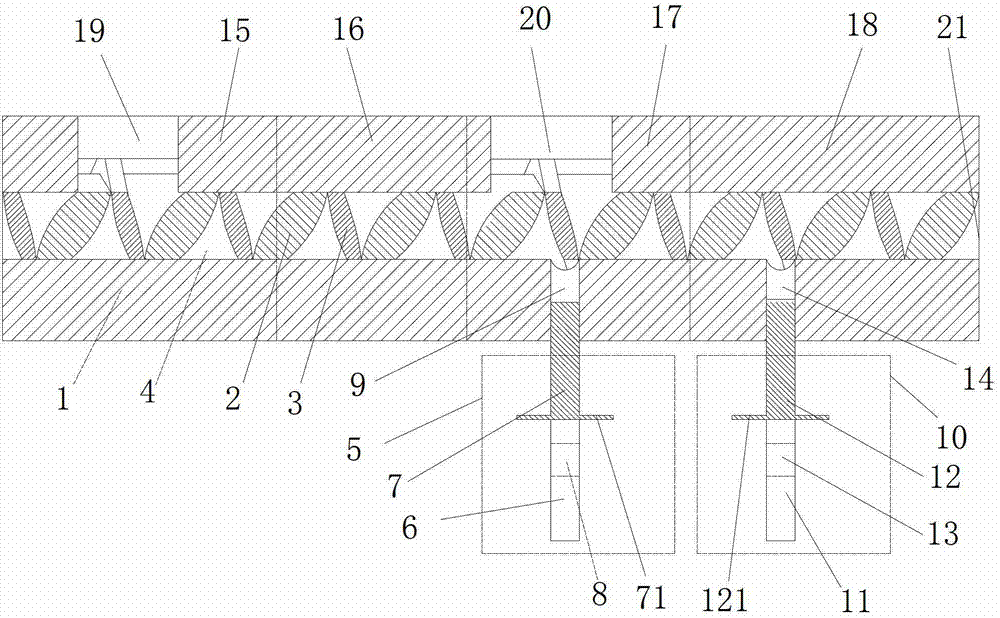

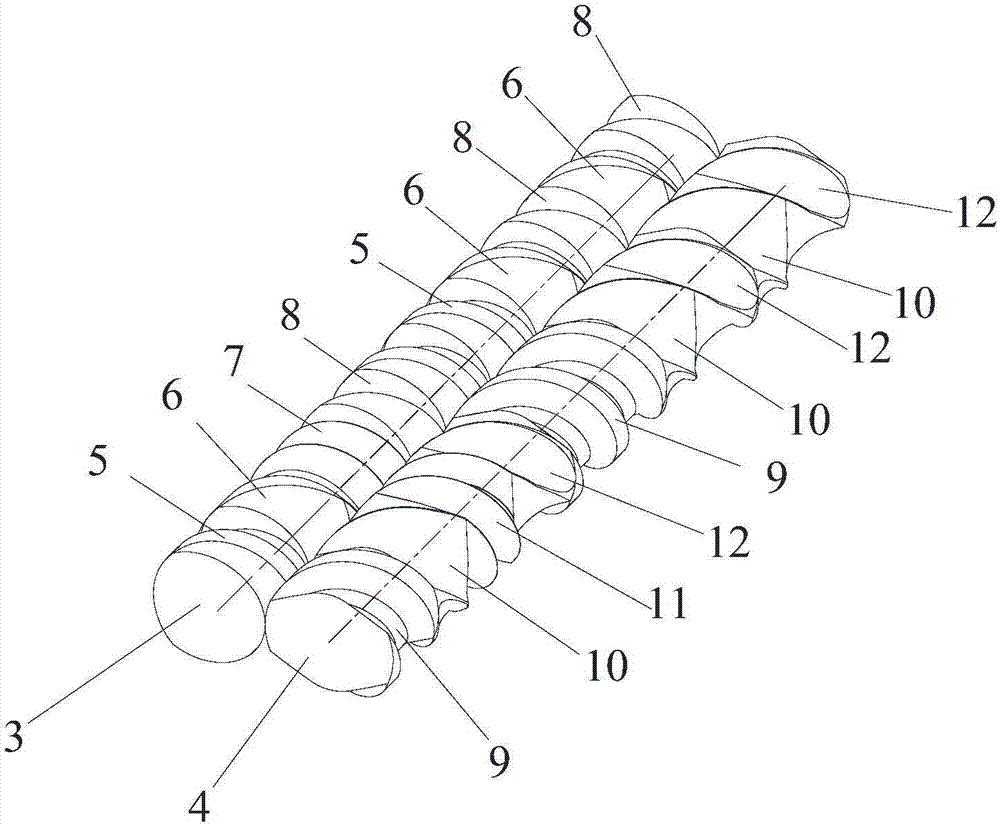

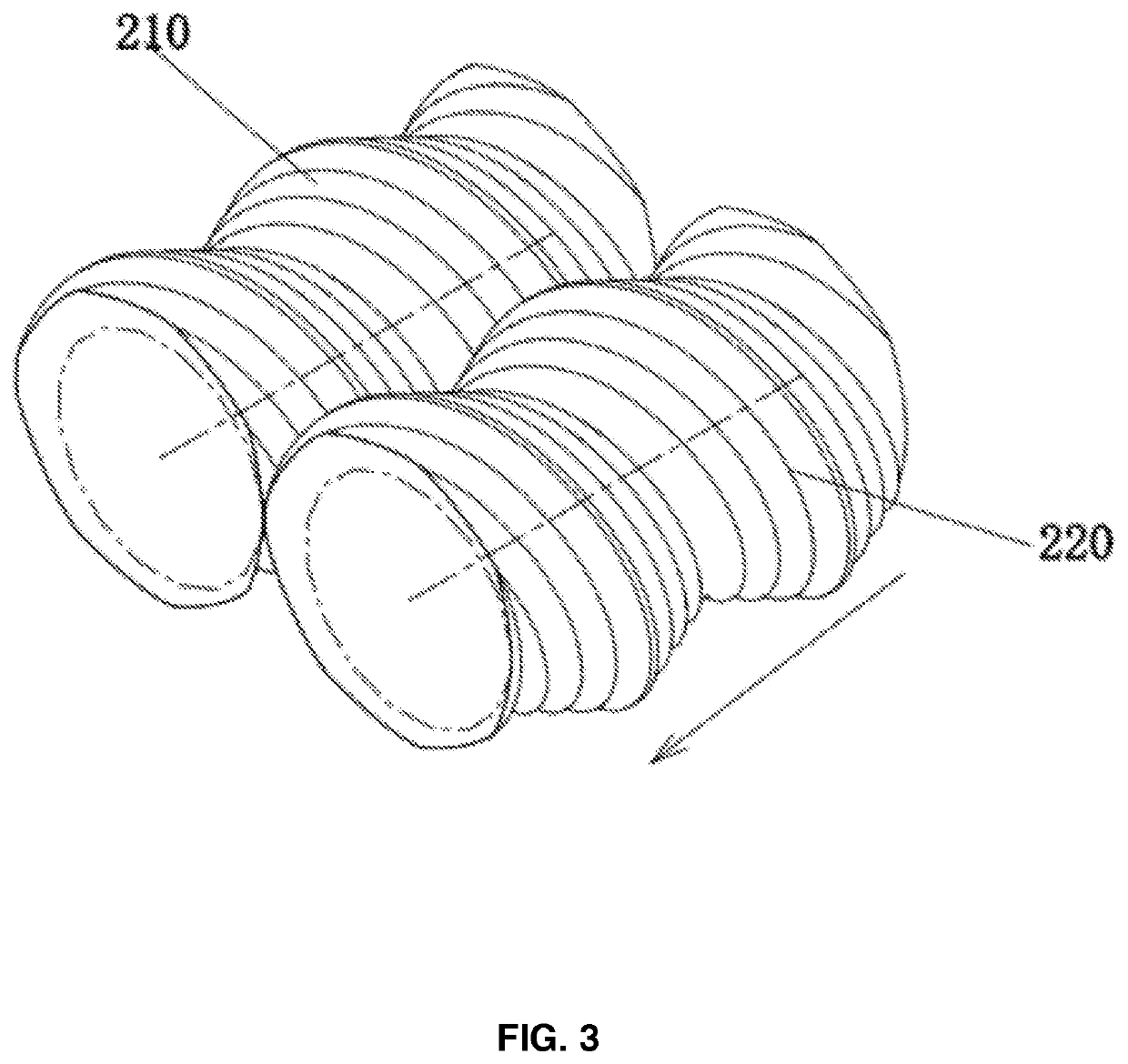

Embedded type short-screw-flight same-direction asymmetric multi-screw extruder and machining method thereof

ActiveCN106476242AImprove delivery efficiencyAvoid unstable product qualityHomoclinic orbitEngineering

The invention discloses an embedded type short-screw-flight same-direction asymmetric multi-screw extruder and a machining method thereof. A screw mechanism in the extruder comprises a first screw and a second screw which are engaged with each other. The first screw is of a single-start thread structure, and the second screw is of a four-start thread structure. Embedded type short screw flights used as auxiliary screw flights are arranged in screw channel passageways each formed between two adjacent main screw flights in the first screw. The height of the auxiliary screw flights is smaller than or equal to the height of the main screw flights. According to the machining method of the embedded type short-screw-flight same-direction asymmetric multi-screw extruder, material conveying is achieved under the common effect of the axial positive displacement conveying force of the screw mechanism and the friction force between the first screw and the second screw. By means of the homoclinic orbit flow disturbance which is introduced through the embedded type short screw flights and shaped like the Arabic number '8', the whole-journey chaotic mixing in the screw channel passageways, the one-to-two topological chaotic effect formed by a passageway composed of the first screw and the second screw, the periodic compression and expansion effect generated by the passageways of the screw mechanism and the differential-speed rotation effect of the two screws are triggered, and the materials are sufficiently mixed, molten, mixed and plastified.

Owner:GUANGDONG IND TECHN COLLEGE

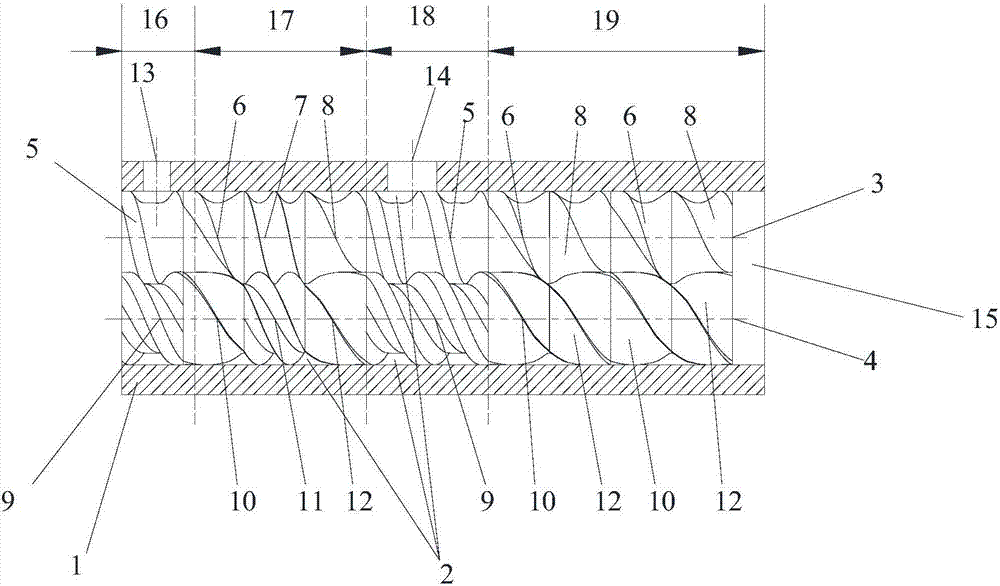

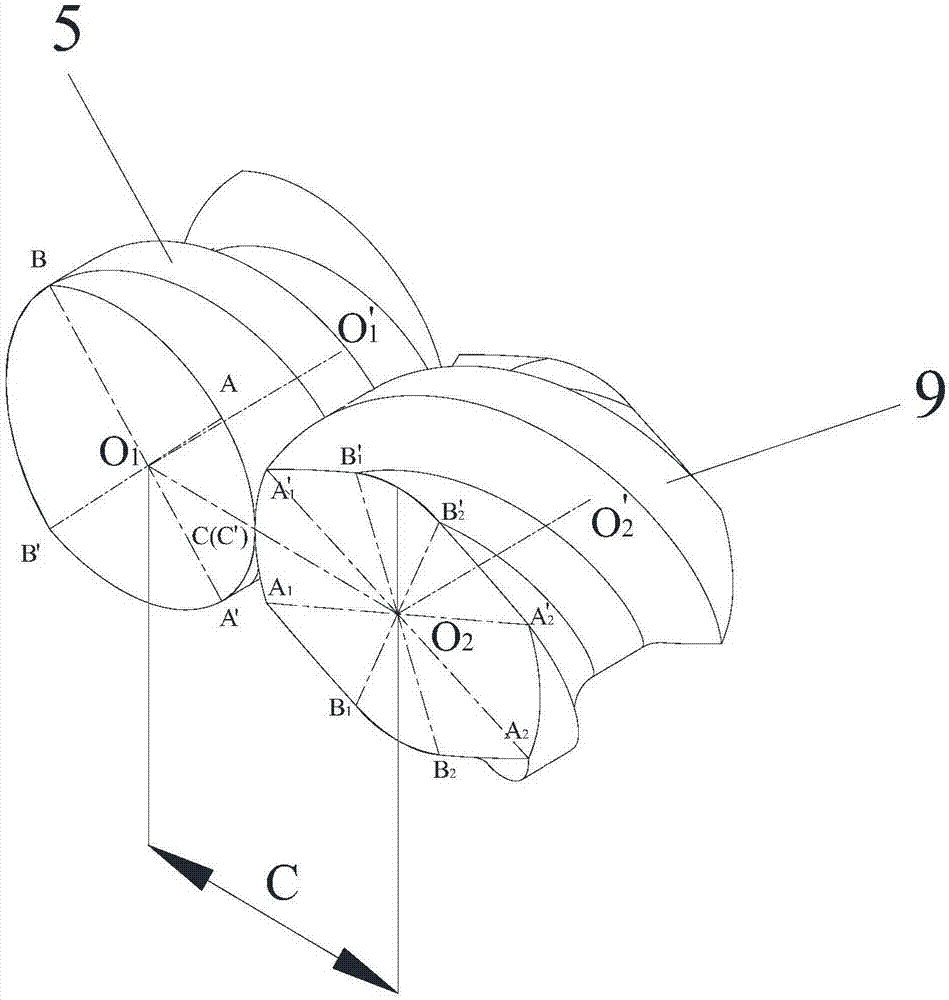

Homodromous self-cleaning double-screw extrusion machine with number of starts gradually changing and with whole-process self-cleaning function and machining method thereof

The invention discloses a homodromous self-cleaning double-screw extrusion machine with the number of starts gradually changing and with a whole-process self-cleaning function and a machining method thereof. A screw assembly of the extrusion machine comprises a first screw and a second screw, wherein the first screw and the second screw rotate at equal speed and in the same direction and are kept engaged. The first screw comprises a first single-start thread element, a first transitional element, a multi-start thread element, a second transitional element and a second single-start thread element which are connected in sequence. The second screw comprises a first single-start thread element, a third transitional element, a multi-start thread element, a fourth transitional element and a second single-start thread element which are connected in sequence. The machining method includes the steps that materials are conveyed through rotation of the first screw and the second screw, and constituents in the materials are promoted to be mixed through a structure of gradually changing numbers of starts of threads; a runner expands, contracts and expands again in sequence, so that the materials are divided, combined and divided again in the runner for chaotic mixing; self-cleaning is achieved through mutual wiping of the first screw and the second screw.

Owner:GUANGDONG IND TECHN COLLEGE

Same-direction self-cleaned twin-screw extruder with baffle plates and processing method thereof

ActiveCN104527025AImprove delivery efficiencyAvoid unstable product qualityTransportation and packagingRotary stirring mixersFistEngineering

Owner:GUANGDONG IND TECHN COLLEGE

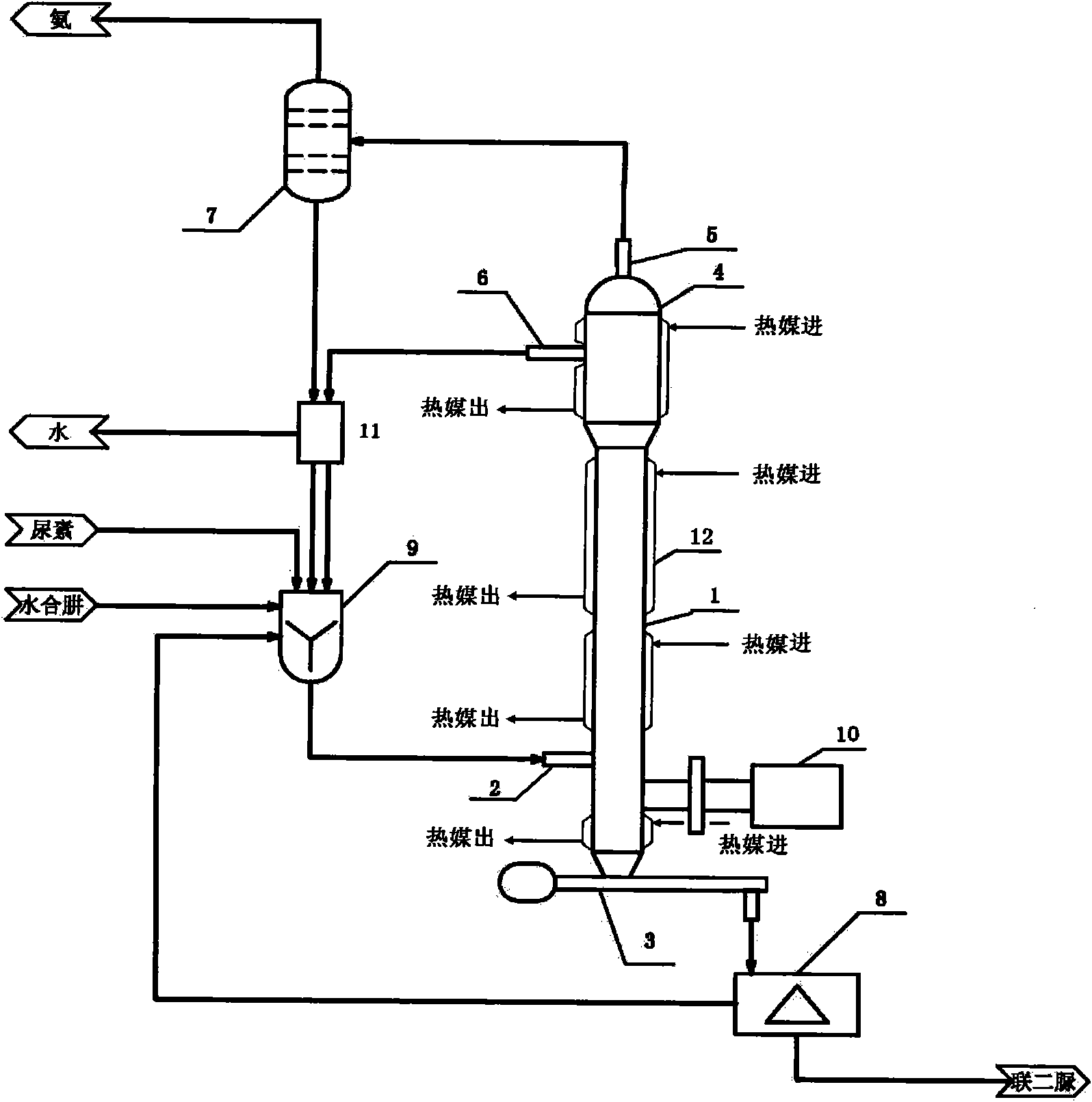

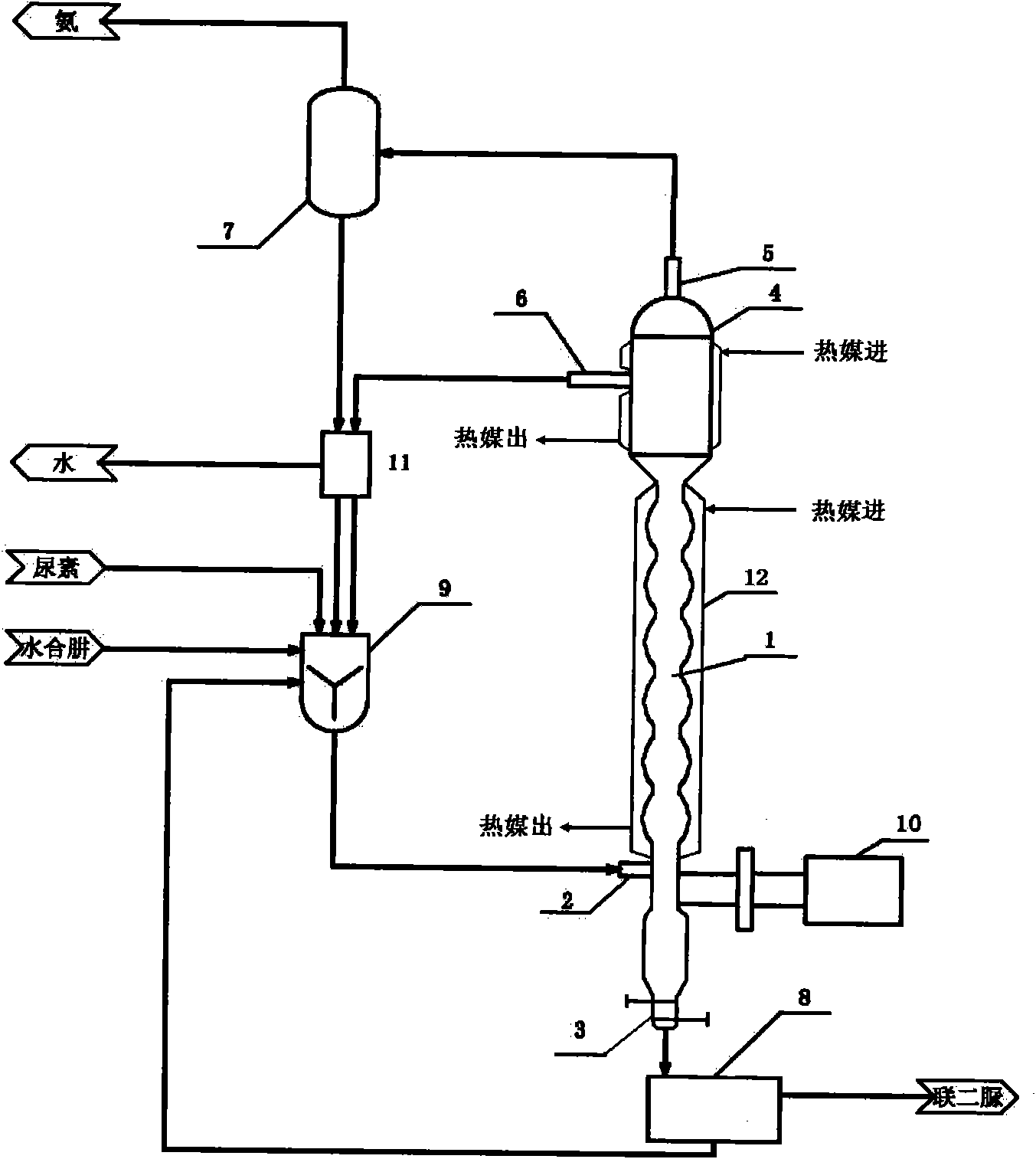

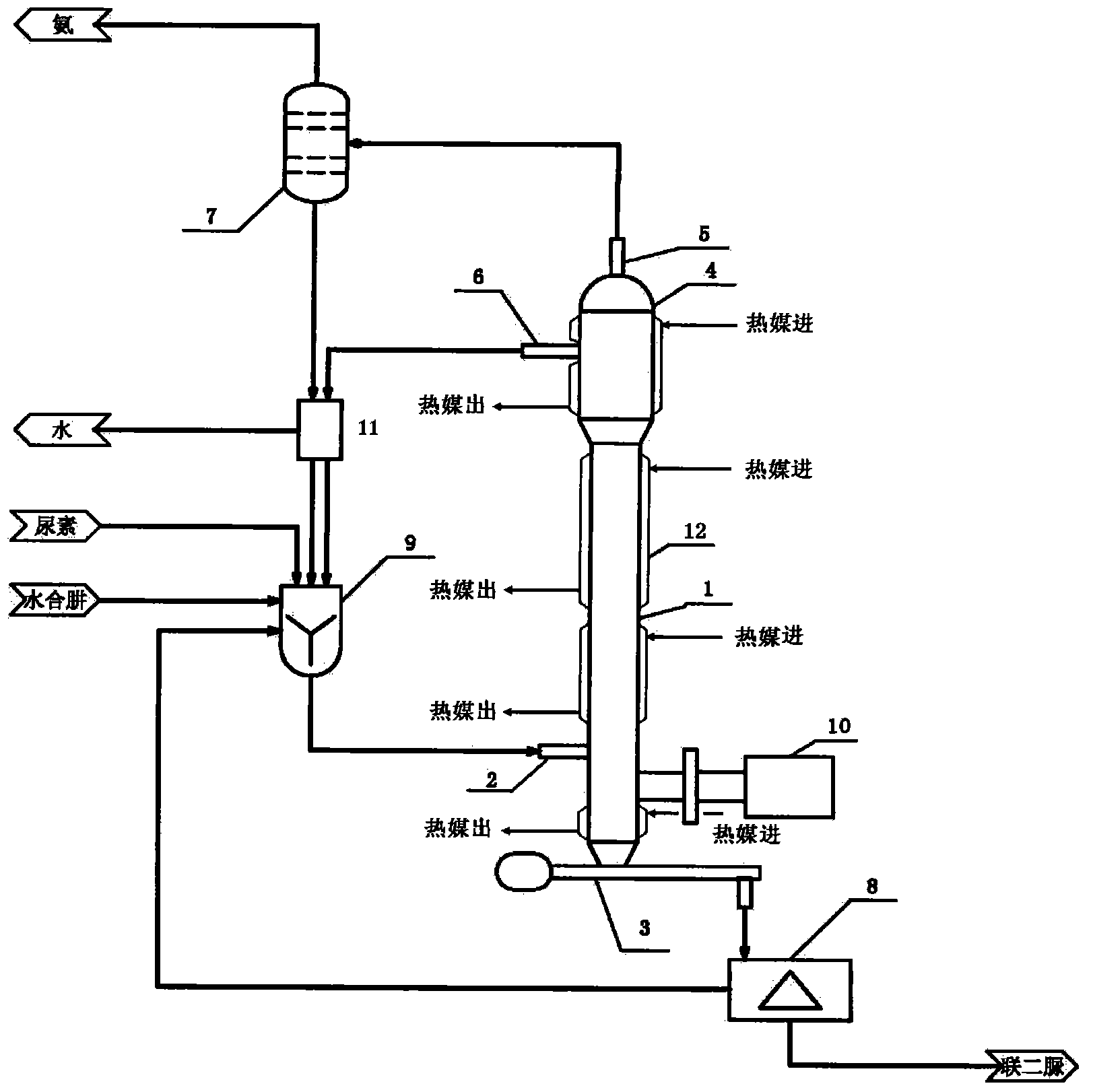

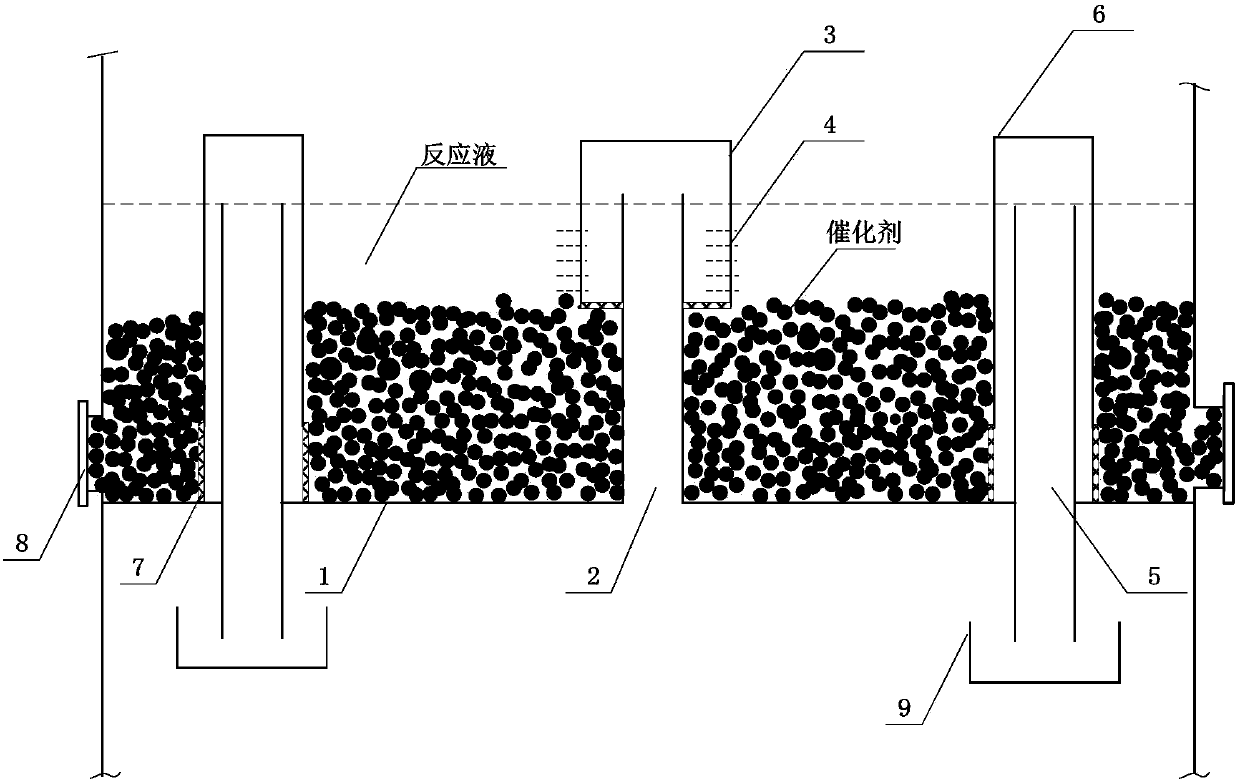

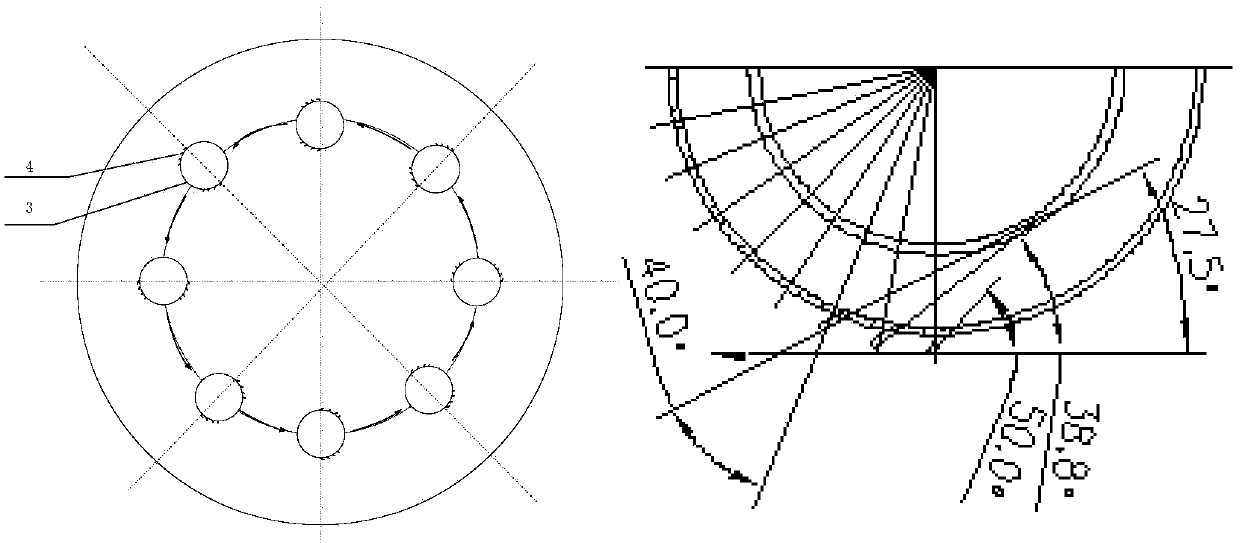

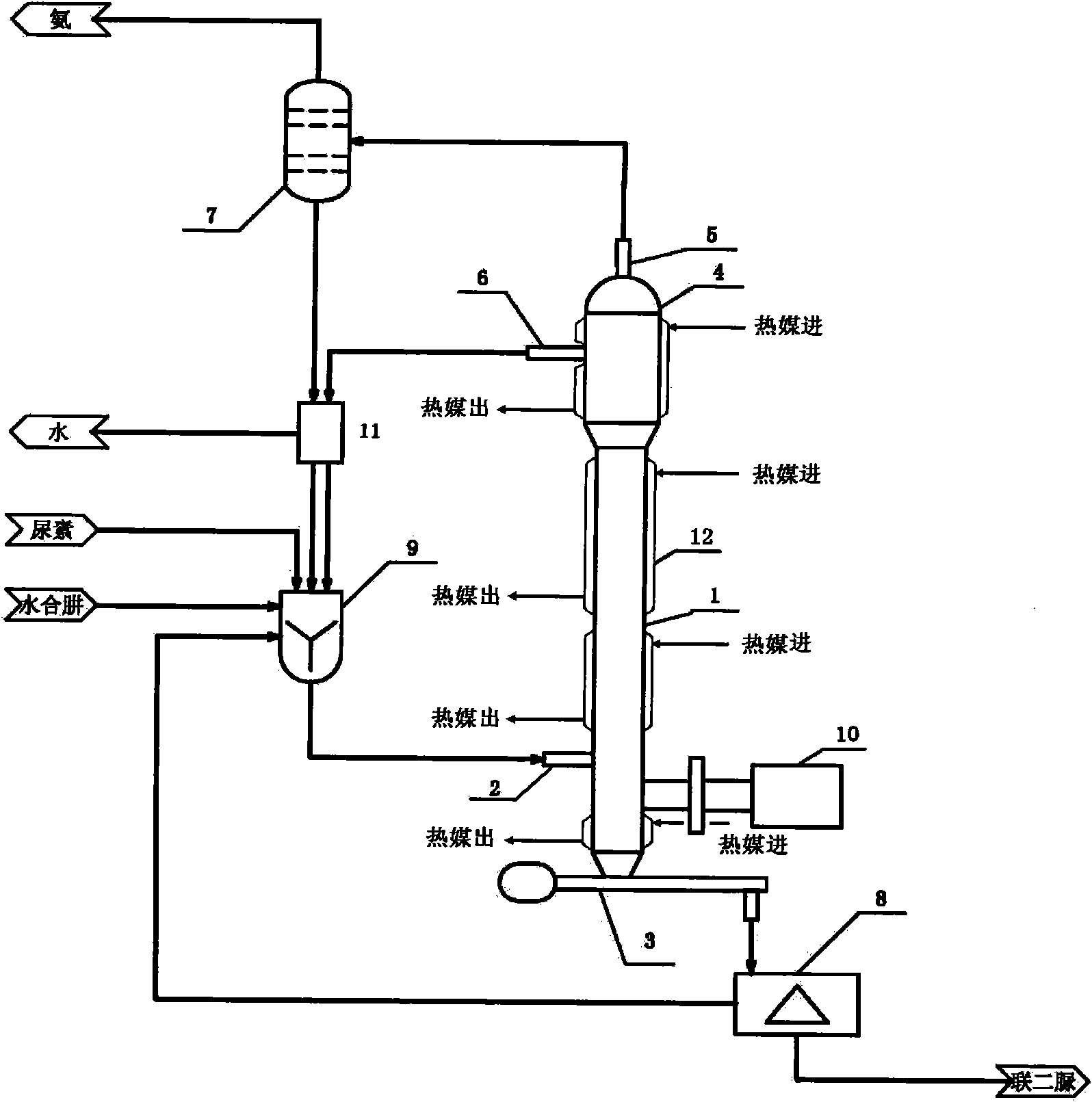

Continuous production method and continuous production device for synthesizing biruea

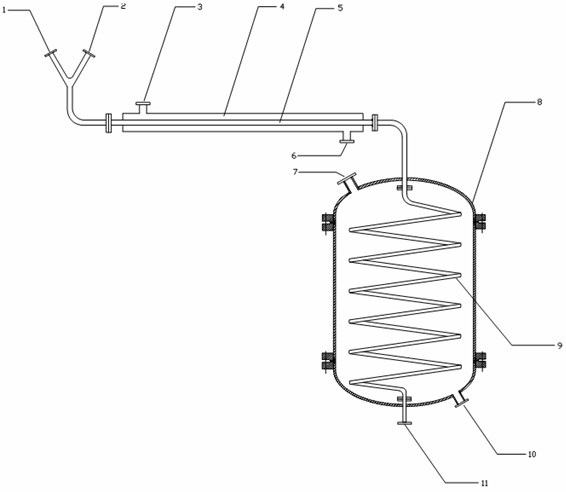

ActiveCN101967114ANarrow residence time distributionWith selective suspensionUrea derivatives preparationOrganic compound preparationReaction rateOscillating flow

The invention discloses a continuous production method for synthesizing biruea, comprising the following steps of: (1) continuously adding hydrazine hydrate and a urea solution into the middle lower part of an oscillating flow tubular reaction crystallizer to react and generate biruea grains; (2) along with the processes of reaction and crystallization, gradually increasing the grain diameter of the biruea grains, settling the biruea grains at the bottom of the reaction crystallizer, continuously discharging the biruea grains settled at the bottom of the reaction crystallizer, separating solids and liquid and cleaning to obtain the biruea; and (3) continuously discharging mother liquid with unconverted reactants from the upper part of the reaction crystallizer and continuously dischargingammonia as a by-product from the top of the reaction crystallizer. The invention also discloses the oscillating flow tubular reaction crystallizer which is used for implementing the production method. The continuous production method is suitable for alkaline condensation technology, increases an average reaction rate, has high production capacity of unit reactor volume and can control the grain diameter of the biruea to separate subsequently and reduce purification cost.

Owner:ZHEJIANG ENG DESIGN +2

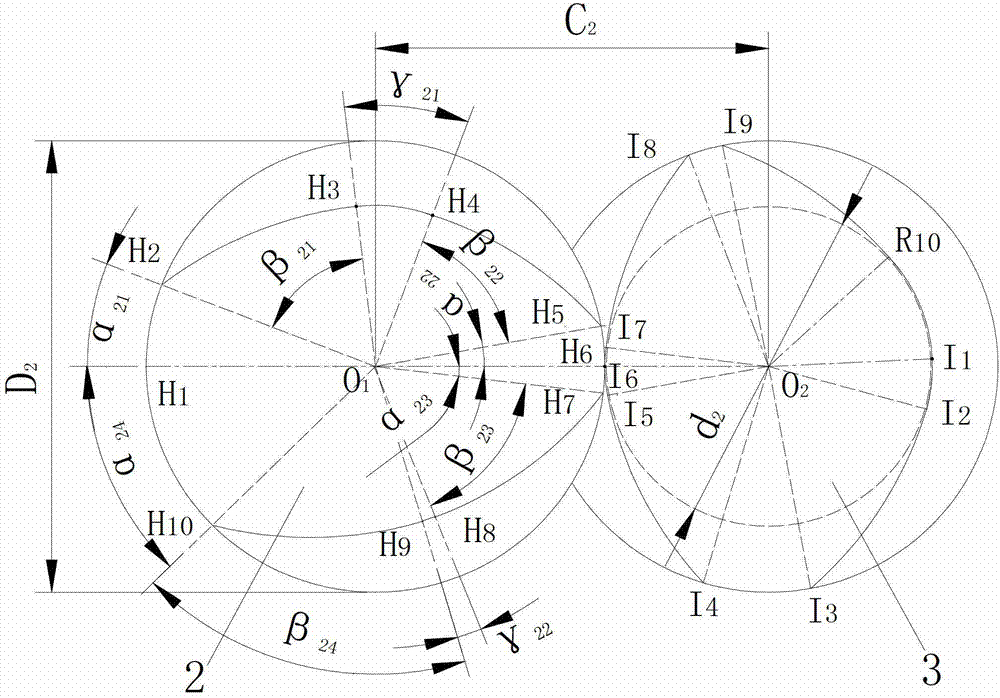

Homodromous self-cleaning double-screw extruder with stretching function and processing method thereof

ActiveCN103112193AImprove delivery efficiencyImprove extrusion outputShaping pressCompression actionEngineering

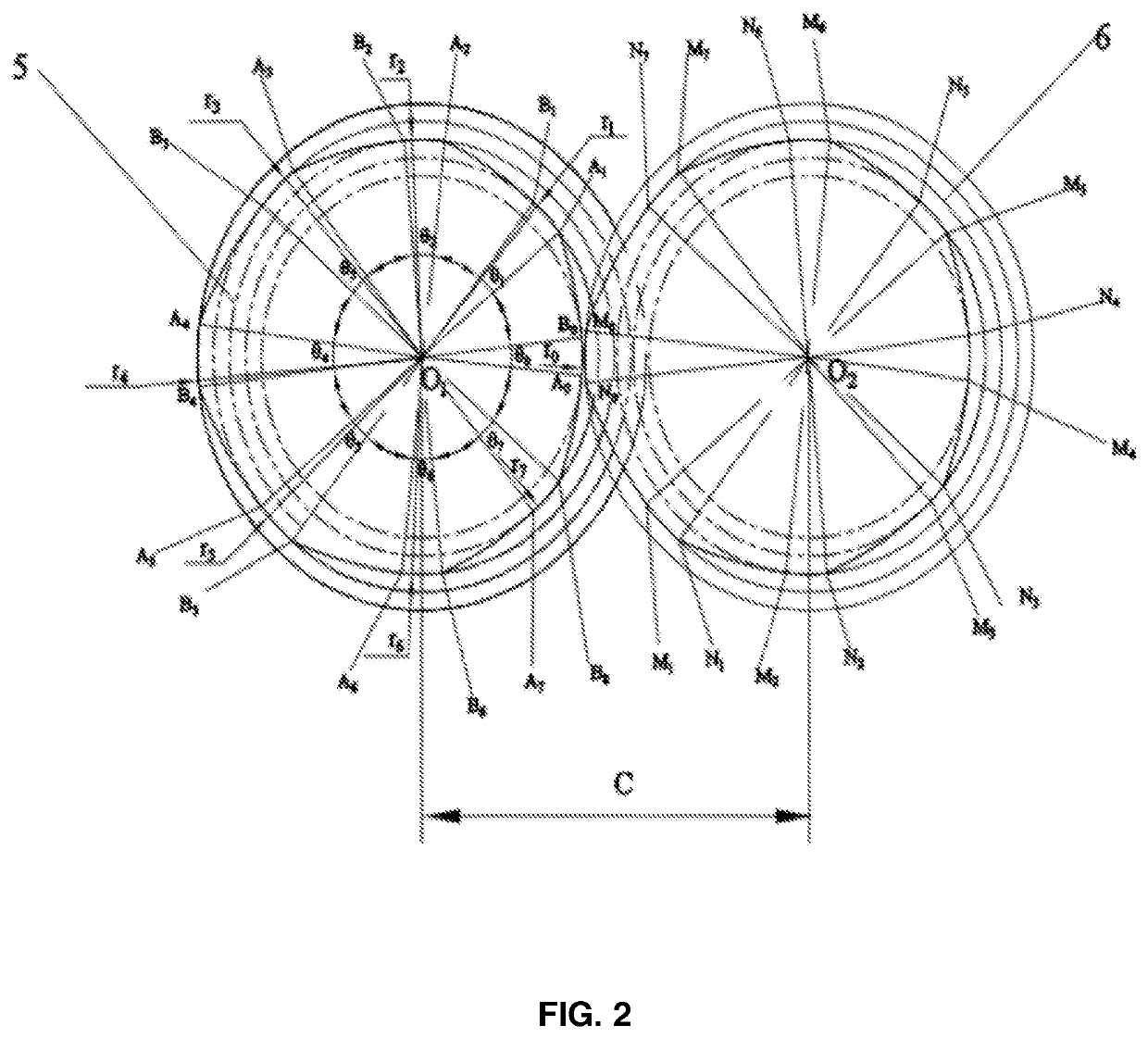

The invention discloses a homodromous self-cleaning double-screw extruder with a stretching function. The homodromous self-cleaning double-screw extruder with the stretching function comprises a machine barrel, a first screw and a second screw. The cross section of the first screw and the cross section of the second screw are both formed by multiple sections of circular arcs which are unequal in radius of curvature, and the cross section of the first screw and the cross section of the second screw are different in shape. The invention further provides a processing method of the homodromous self-cleaning double-screw extruder with the stretching function. According to the homodromous self-cleaning double-screw extruder with the stretching function and the processing method of the homodromous self-cleaning double-screw extruder with the stretching function, when the first screw and the second screw which are different in cross-section shape rotate in an identical direction, periodical change happens to a cross-section shape of a flow passage, so that a compression action and a squeezing action are applied on materials in the flow passage, a flowing space of the materials is compressed and expanded in a periodical mode, and therefore a chaotic mixing effect is generated, a mixing and heat transfer process is strengthened, a thermal and mechanical process which is plasticized is largely shortened, energy consumption is low, an energy-saving and consumption-reducing effect is notable.

Owner:GUANGDONG IND TECHN COLLEGE

Co-rotating differential multi-screw extruding machine with gradually changing type thread number and machining method thereof

InactiveCN107031015AFacilitate interface updatesIncrease the exhaust areaDifferential equationEngineering

The invention discloses a co-rotating differential multi-screw extruding machine with the gradually changing type thread number and a machining method thereof. A first threaded rod in the extruding machine comprises two single-start thread elements, three single-start-gradually-changed-to-double-start transition thread elements, a double-start thread element and three double-start-gradually-changed-to-single-start transition thread elements; and a second threaded rod comprises two double-start thread elements, three double-start-gradually-changed-to-four-start transition thread elements, a four-start thread element and three four-start-gradually-changed-to-double-start transition thread elements. According to the machining method, a threaded rod mechanism achieves five enhancement mixing mechanisms by adopting the structure of the threaded rod mechanism, and conducts all-sided enhancement mixing on materials.

Owner:徐百平

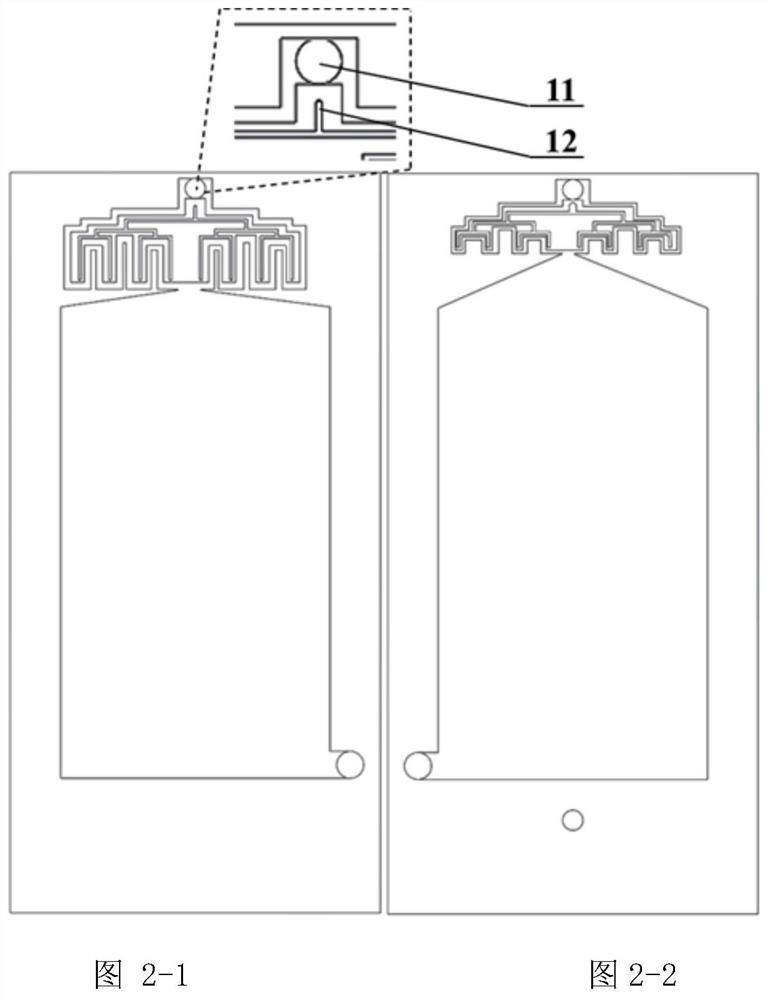

Chip type structure catalysis multiphase microreactor

InactiveCN113058521AImprove efficiencyLarge specific surface areaChemical/physical/physico-chemical microreactorsPetrochemicalHomogeneous catalysis

The invention relates to a chip type structure catalysis multiphase microreactor which comprises a microreaction chip and a structure catalyst and comprises a gas-liquid two-phase reactant distributor, a multiphase catalysis reaction chamber, heat exchange channels on two sides of the catalysis reaction chamber and heat exchange channels on two sides of the gas-liquid two-phase reactant distributor; and gas-liquid or liquid-liquid is uniformly distributed to an inlet of a catalyst with a high-precision structure at the rear end by utilizing a dendritic distribution form and T-shaped shear mixing, and flowing heat exchange areas are respectively arranged on the upper side and the lower side of the catalytic reaction chamber. By optimizing the structural design of the reactor, the reactor has the advantages of excellent mass transfer and heat transfer characteristics, controllable reactant retention time, narrow retention time distribution, personalized design of a catalyst structure according to a reaction system, easiness in amplification and the like, and solves the bottleneck problem that a homogeneous catalyst or a fine powder catalyst is difficult to separate from a product; and the chip type structure catalysis multiphase microreactor is widely applicable to petrochemical, chemical, pharmaceutical, environmental protection, food and other fields.

Owner:EAST CHINA UNIV OF SCI & TECH

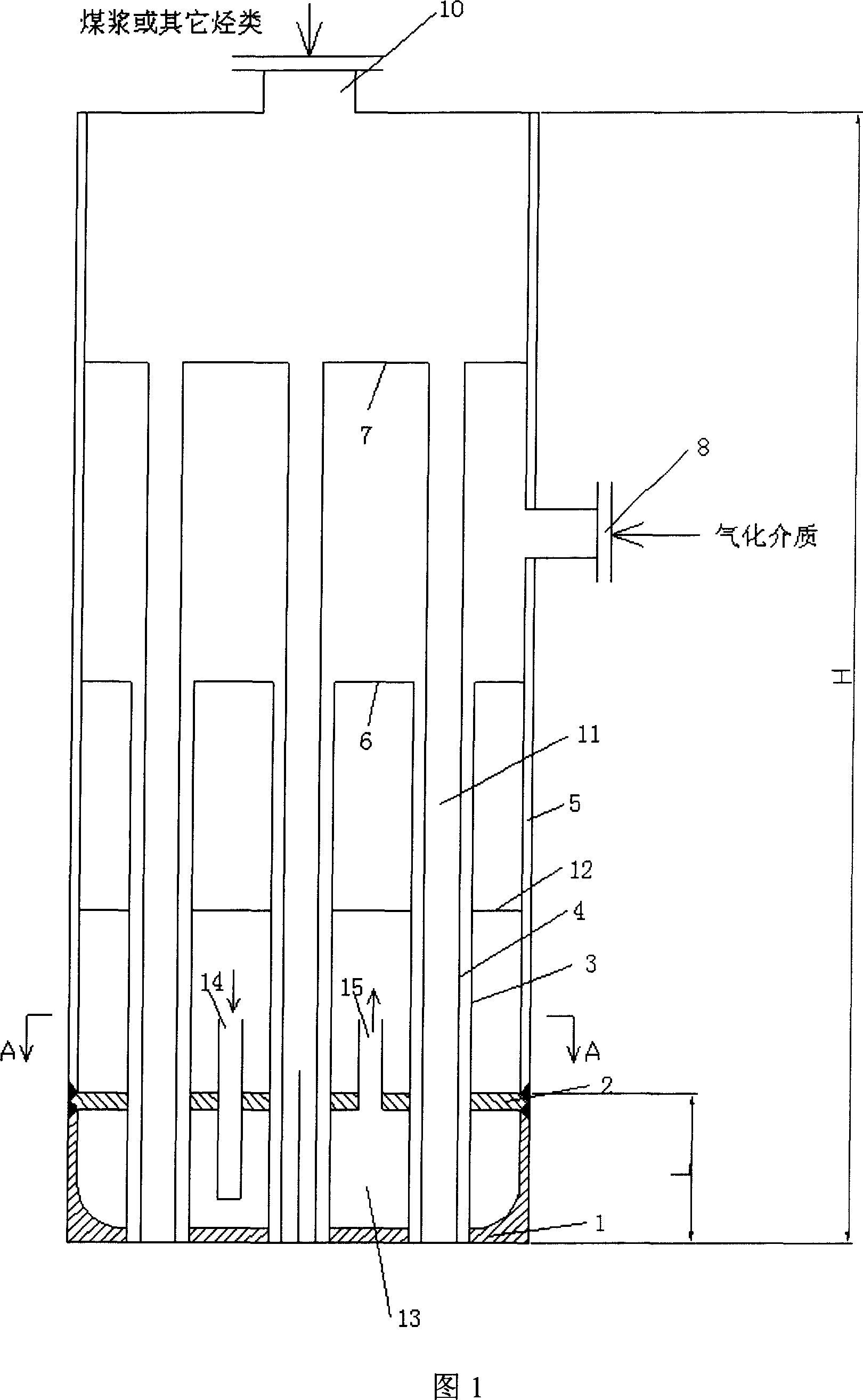

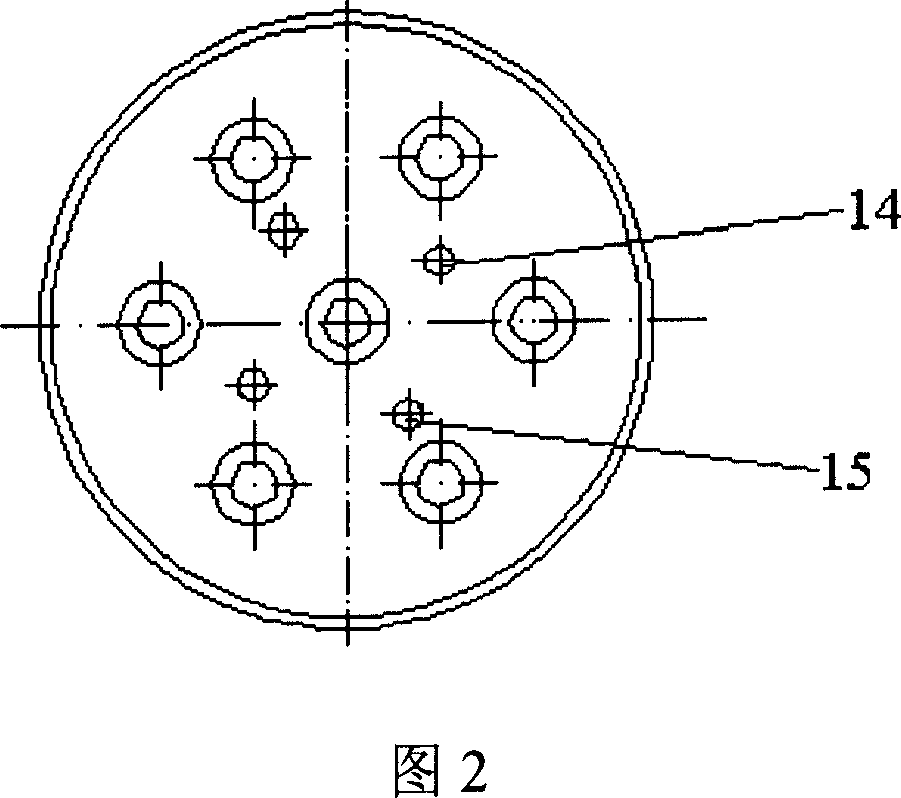

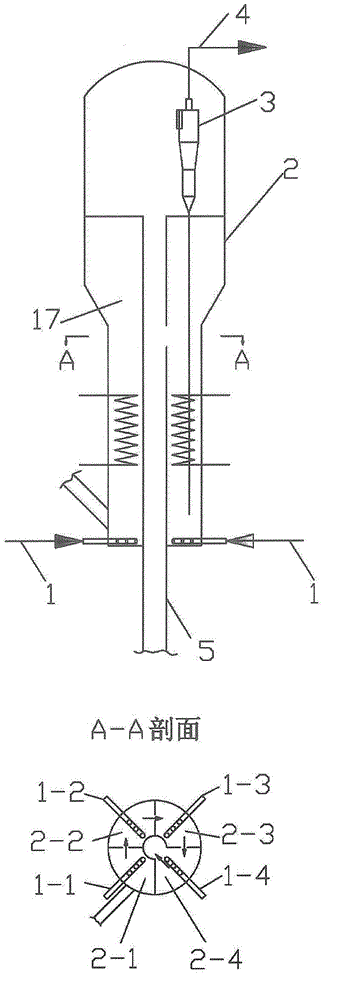

Beaming type gasification or combustion nozzle and its industrial use

InactiveCN1928431AExtended service lifeReasonable structureFluidized bed combustionCombustion using liquid and pulverulent fuelCombustionFire brick

The invention discloses a beaming gasifying or burner nozzle and the application in industry. It comprises shell (5) and N nozzles (11) set in shell (5), which comprises outer tube (3), inner tube (4) set in outer tube, lower tube plate (6), upper tube plate (7) and cooling room (13). Compared with conventional nozzle with concentric tubes (such as two-way, three-way and multiple way nozzle), it can protect anti-fire brick on the middle and lower part of gasifying boiler and prolong the service life because the flame is short and rectangle; improve conversion ratio of carbon because Residence time is scattered narrowly; and improve the service life of nozzle because of rational structure.

Owner:EAST CHINA UNIV OF SCI & TECH

Screw extruder and extruder screw for improved heat transfer

InactiveUS20050236734A1Increase heatWell mixedDough homogenizationFrozen sweetsEngineeringMechanical engineering

Owner:RAUWENDAAL EXTRUSION ENG

Two step process for chemically recycling plastic waste

ActiveUS20220290053A1Increase temperatureEasy to separateCatalytic crackingMolecular sieve catalystsFluidized bedChemical recovery

A two-step process that includes a pyrolytic first step carried out in a mechanically or gravitationally impelled reactor and a catalytic fluid bed second step that upgrades the resulting vapor, for the conversion of waste plastics, polymers, and other waste materials to useful chemical and fuel products such as paraffins, olefins, and aromatics such as BTX is described.

Owner:R PLUS JAPAN LTD

Device and method for continuously isomerizing epoxide

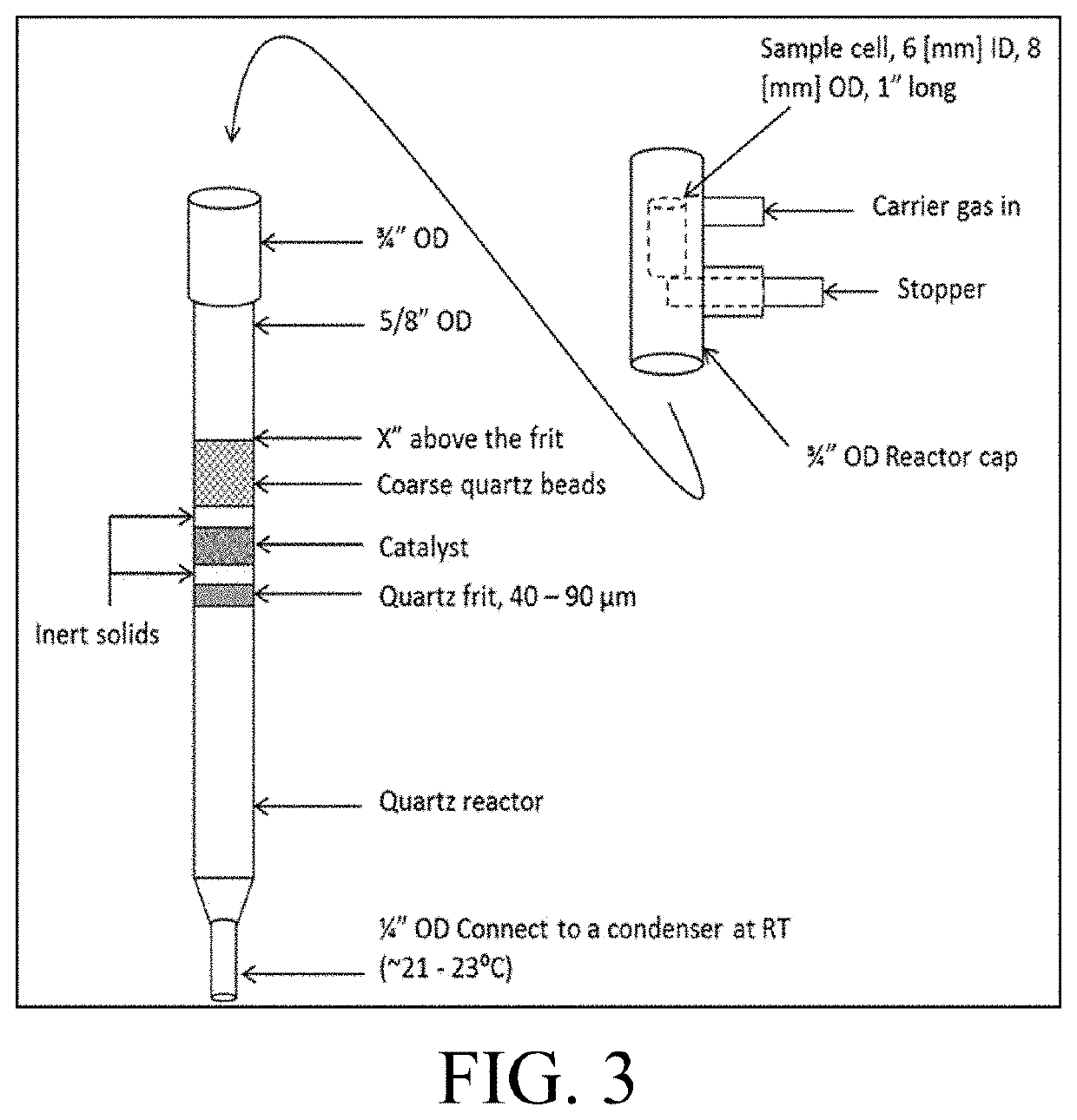

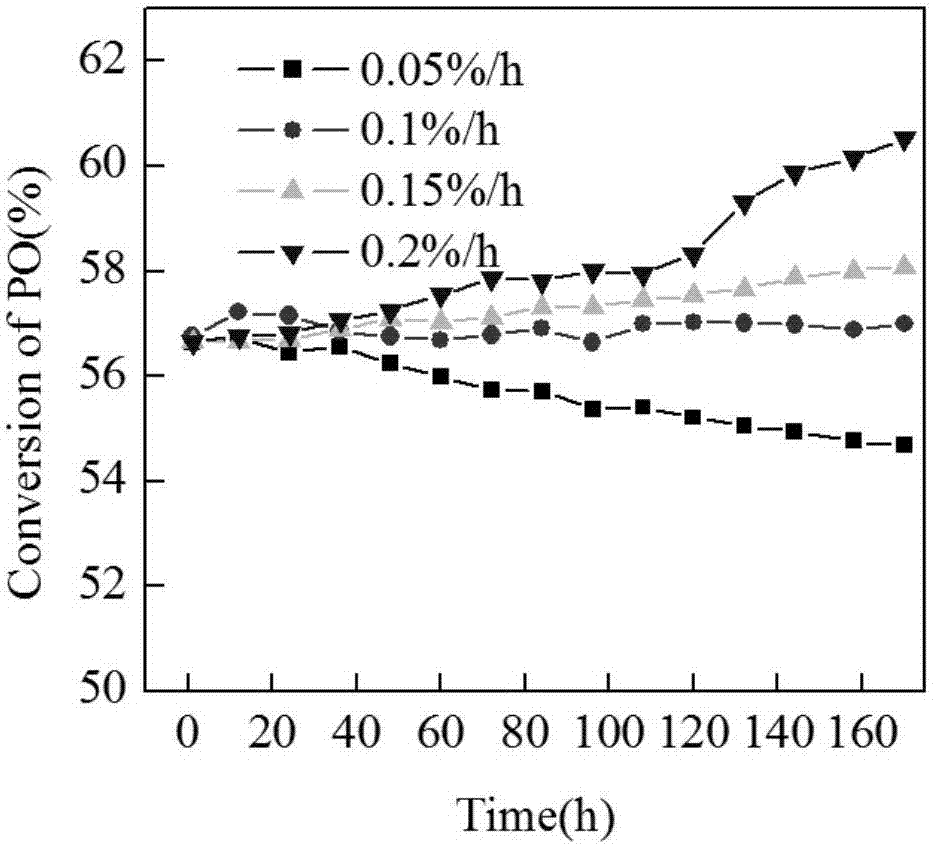

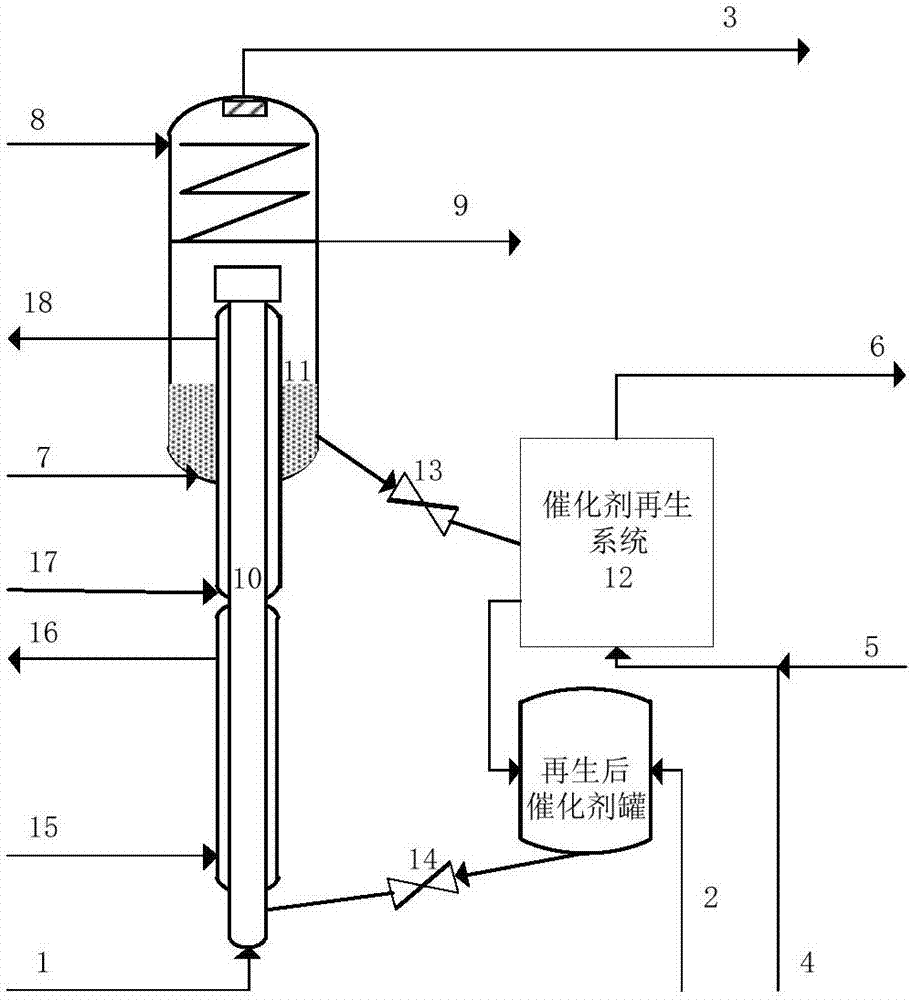

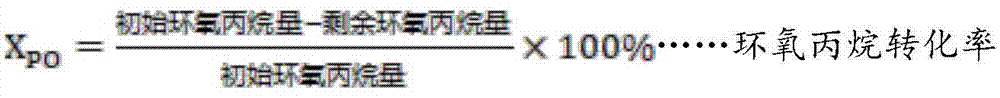

ActiveCN107879899APrecise control of reaction temperatureImprove reliabilityPreparation by isomerisationPhysical/chemical process catalystsIsomerizationFluidized bed

The invention relates to a device and a method for continuously isomerizing epoxide, which can be used for continuous isomerizing preparation of corresponding allyl alcohol products from epoxide. Themethod comprises steps as follows: reaction raw materials and carrier gas are preheated to certain temperature, the raw materials are contacted with a regenerated catalyst and a newly supplemented catalyst in a fluidized state in a fluidized bed reactor at a certain air speed, an isomerization reaction is performed under certain pressure, reaction gas and a carbon deposit catalyst are obtained through separation in a settler, wherein reaction gas rises and enters a product separation system via a reaction liquid pipeline at the top of the settler, the carbon deposit catalyst enters a regenerator for regeneration, and the regenerated catalyst returns to a lifting pipe reactor via a regenerated catalyst pipeline. The process has the characteristics of high atom economy, product yield and selectivity and no pollution and is notably superior to a current slurry bed process.

Owner:WANHUA CHEM GRP CO LTD

Continuous synthesis method and device of amion-2,2,6,6-tetramentylniperidine

PendingCN110317162ASmall footprintSmall footprint, safety hazardOrganic chemistryDistillationHydrogenation reaction

The invention relates to a continuous synthesis method of amion-2,2,6,6-tetramentylniperidine. The method includes the following steps that triacetylamine is used as a raw material, a catalyst is added, and ammonia gas is introduced for reaction at a first channel 2 of a microchannel for 5-300 seconds at the temperature of 50-150 DEG C and the pressure of 0.3-3 Mpa; hydrogen is introduced at a second channel 2 of the microchannel, the hydrogenation temperature is 50-150 DEG C, and hydrogenation lasts for 10-300 seconds at the pressure of 0.3-3 Mpa. After gas-liquid separation, the obtained reaction liquid enters a distillation tower for distillation to obtain the finished product. According to the technical scheme, a microchannel reactor is used for hydrogenation, the shortcomings of the prior art is overcome and a safer and more convenient production way is provided.

Owner:宿迁联盛科技股份有限公司

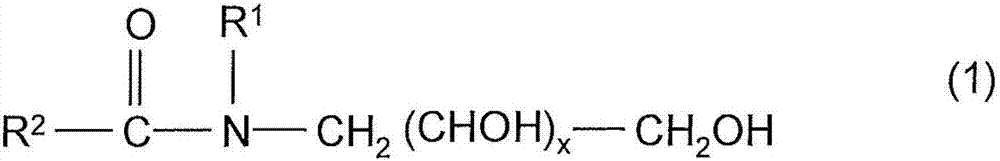

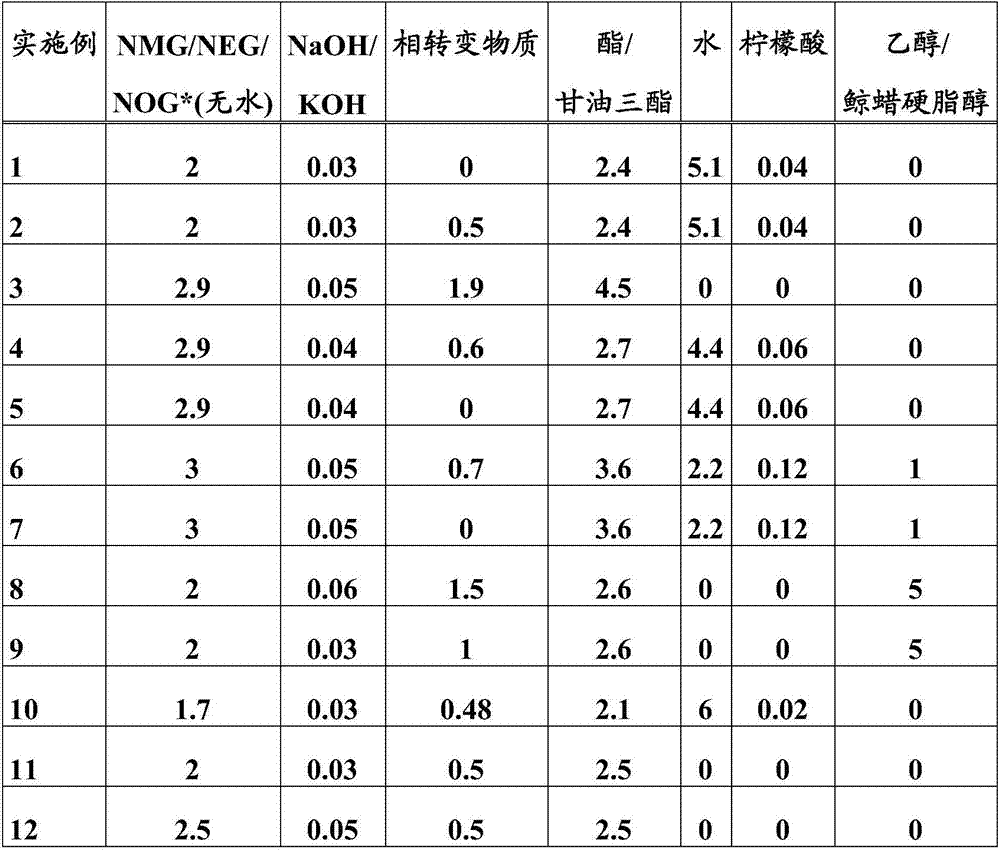

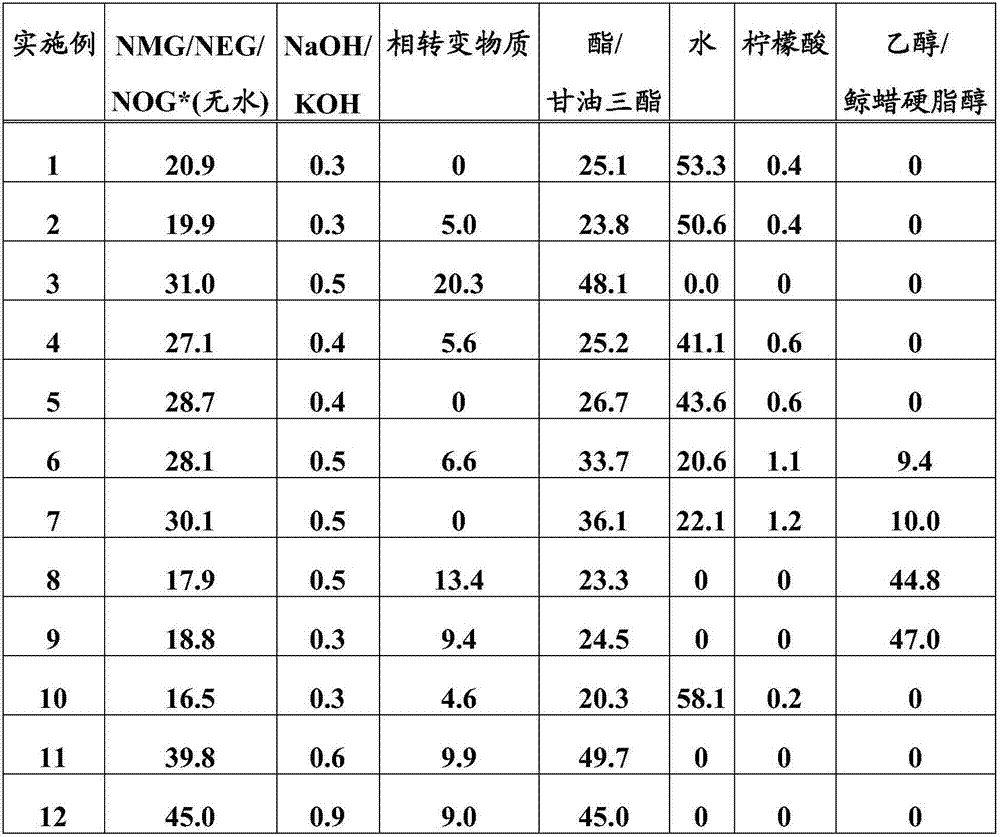

Continuous process for producing a tenside in a tube reactor

ActiveCN107001239ALarge capacityReduce stepsOrganic compound preparationCarboxylic acid amides preparationTG - TriglycerideFatty acid

The invention relates to a continuous method for producing a tenside, containing a compound of the formula (1), wherein R2 is a fatty acid alkyl residue and R1 is a linear or branched C1 to C12 hydrocarbon residue, and x is in the range from 1 to 15 by conversion of fatty acid alkyl esters or fatty acid triglycerides having an N-n-alkylized polyhydroxy compound in the presence of an alkali catalyst or a catalyst selected from hydroxides or alcoholates of the 2nd and 4th secondary group of the periodic system at a temperature in the range from 40 to 300 DEG C.

Owner:CLARIANT INT LTD

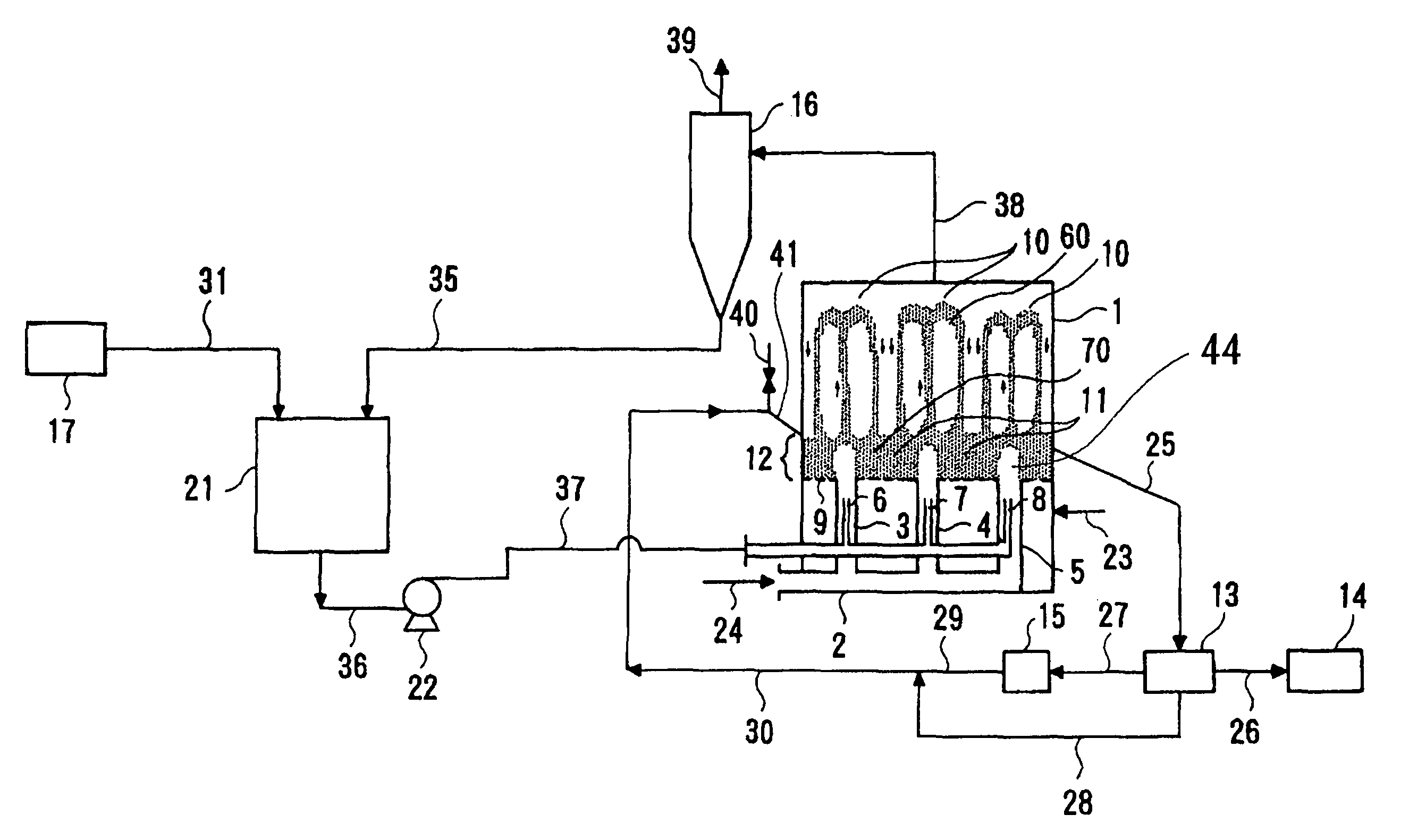

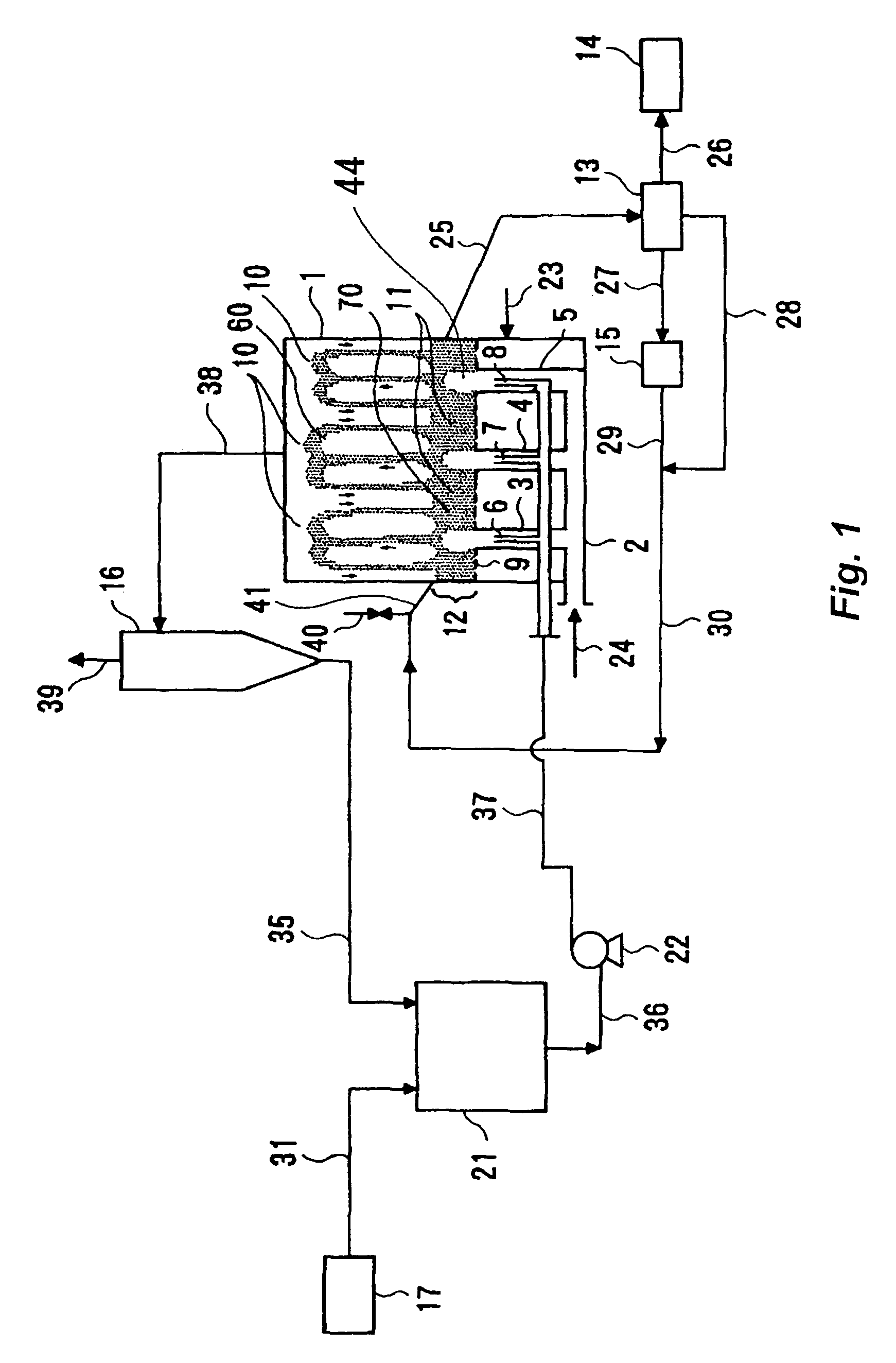

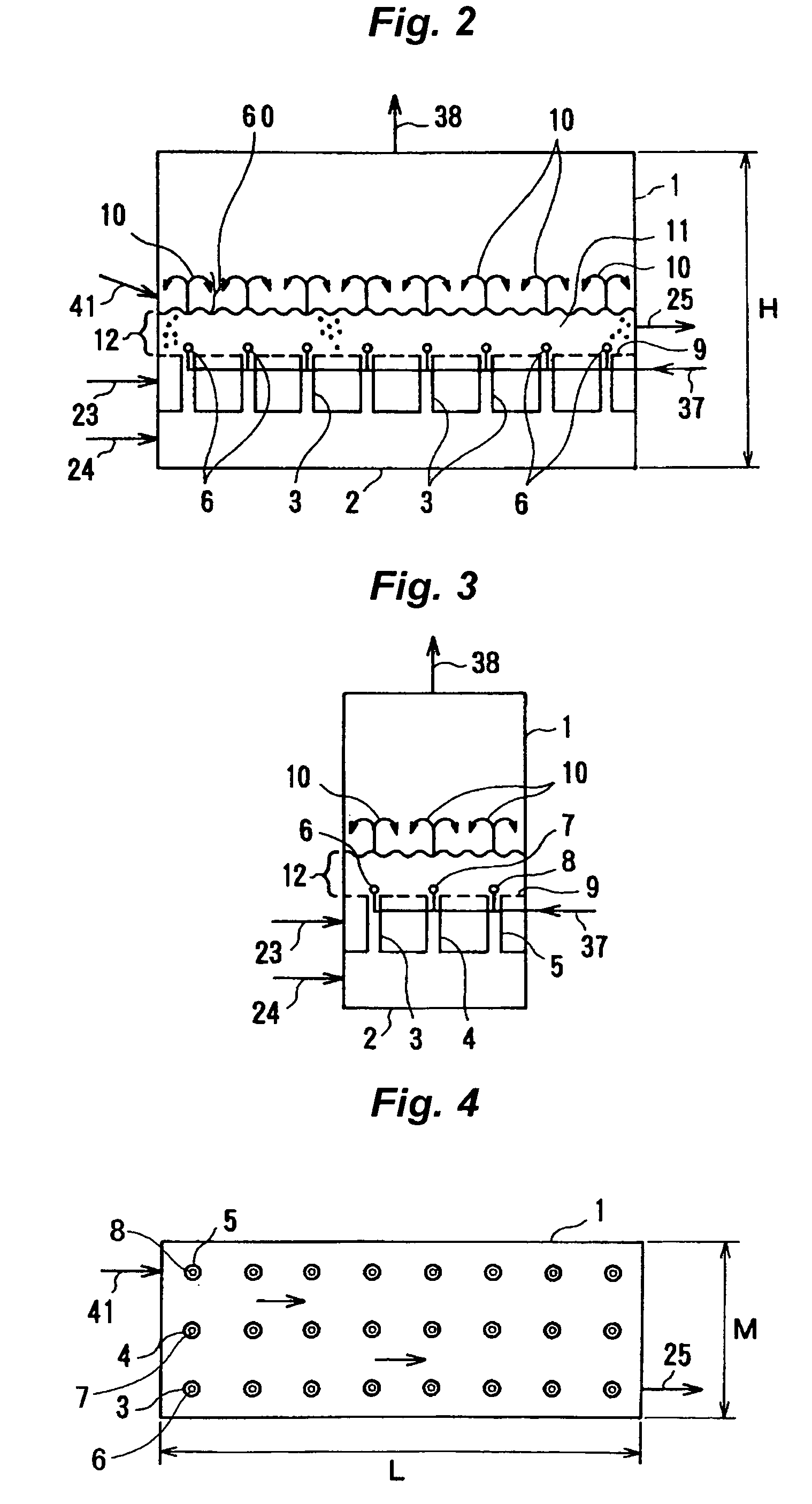

Method of granulation with a fluidized bed granulator

ActiveUS8197729B2Narrow residence time distributionReduce backmixingMaterial granulation and coatingBiocideFluidized bedSpray nozzle

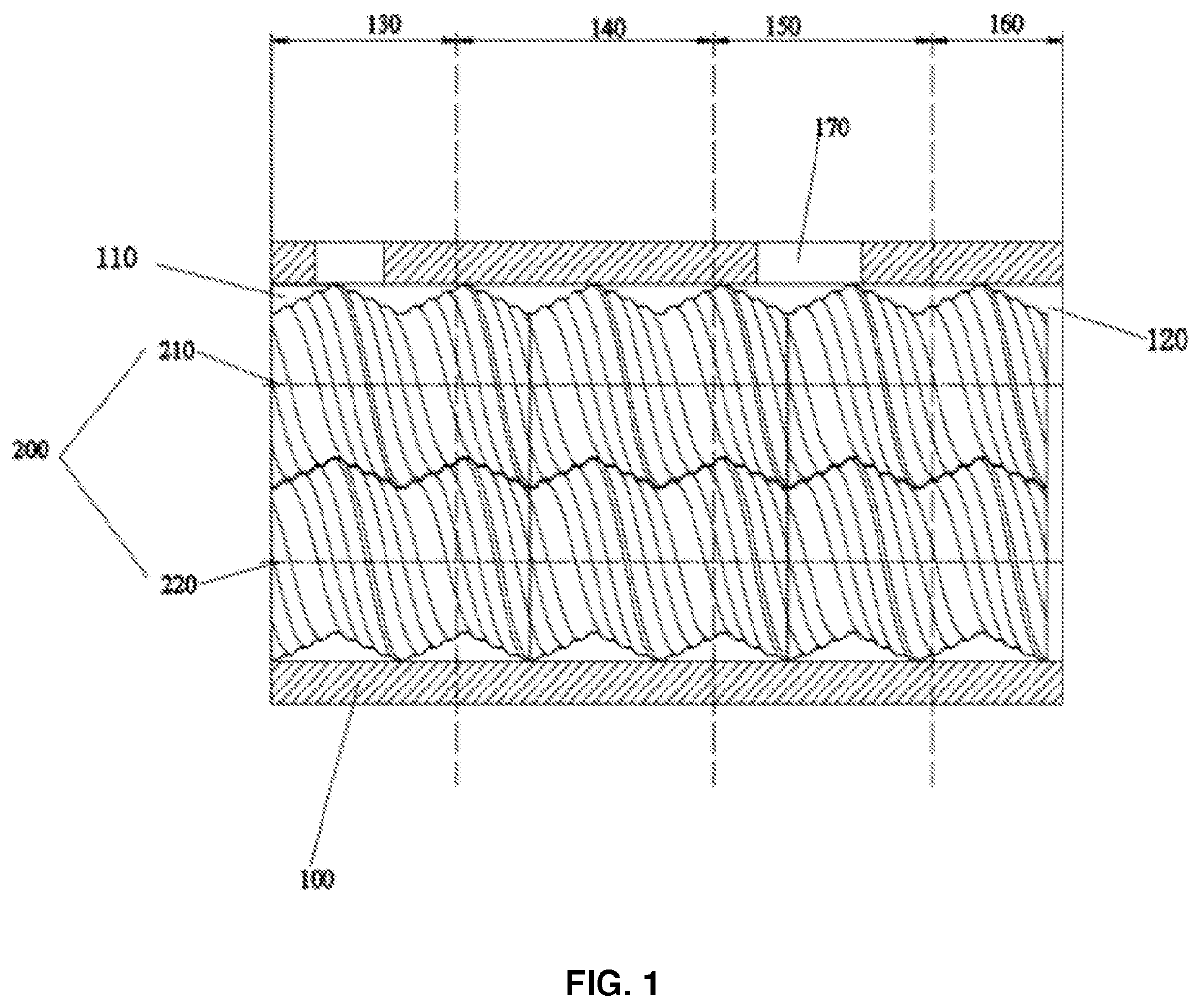

A granulator, having a granulation unit having a bottom floor with a perforated plate as its bottom part; an upper air-supplying pipe for supplying a fluidizing air to the bottom floor of the granulation unit; a lower air-supplying pipe; air-spouting pipes, each of which is branched from the lower air-supplying pipe, and has an opening in the bottom floor of the perforated plate, for jetting the air into the granulation unit; and spray nozzles for spraying a granulation raw material liquid, which each are provided in the center of an air outlet of the air-spouting pipe, or a granulator, having: the bottom floor; the air-supplying pipe; and spray nozzles for spraying a granulation raw material liquid each of which are provided in an opening in the bottom floor of the perforated plate, and use a high-pressure atomizing air as an auxiliary gas, wherein, in each granulator, the spray nozzles are provided in a triangular arrangement.

Owner:TOYO ENG CORP

Catalytic rectifying column plate allowing online replacement of catalyst

ActiveCN108043061AEasy loadingEasy to handleChemical industryHydrocarbon from oxygen organic compoundsEngineeringContact element

The invention discloses a catalytic rectifying column plate allowing online replacement of a catalyst. The catalytic rectifying column plate comprises a column tray, a plurality of gas-liquid contactelements and suspended downcomers arranged on the column tray, a suspended receiver tray arranged below the suspended downcomers, and a catalyst handling hole for handling a catalyst on the column tray. A free space formed by the suspended downcomers, the gas-liquid contact elements, the column tray and a column wall is a catalyst filling area; the catalyst is loosely packed in the catalyst filling area; each suspended downcomer comprises an inner downcomer passed through the column tray and an outer guide hood that covers the part, above the bottom of the column tray, of the inner downcomer.The catalytic rectifying column plate has no need for complex packaging of a catalyst; the catalyst is directly loosely packed on the column tray; the catalyst can be replaced online with no need forstopping equipment; the catalyst is distributed evenly; pressure drop of the column tray is low; rectifying efficiency is high. In addition, expensive catalyst packaging material and filling materialare omitted, and the cost can be significantly reduced.

Owner:WANHUA CHEM GRP CO LTD

A reaction device for producing light olefins from methanol and/or dimethyl ether

ActiveCN104672045BIncrease bed densityReduce wearHydrocarbon from oxygen organic compoundsEthylene productionAlcoholFluidized bed

The invention relates to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether, in particular to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether. The reaction device mainly comprises a dense-phase fluidized bed reactor (2), a cyclone separator (3), a stripper (5), a lift pipe (7), a dense-phase fluidized bed regenerator (10), a cyclone separator (11), a stripper (13) and a lift pipe (15), wherein the dense-phase fluidized bed reactor (2) is partitioned into n (n is greater than or equal to 2) secondary reaction zones by material flow controllers (17); and the dense-phase fluidized bed regenerator (10) is partitioned into m (m is greater than or equal to 2) secondary regeneration zones by the material flow controllers (17). By virtue of the reaction device, the problems in the prior art that carbon deposit distribution of a catalyst is uneven and low-carbon olefin selectivity is relatively low are solved.

Owner:中科催化新技术(大连)股份有限公司

A method for producing low-carbon olefins from oxygen-containing compounds and equipment used therefor

ActiveCN104672040BIncrease bed densityShorten speedHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedOxygen compound

The invention relates to a method for preparing light olefins from oxygen-containing compounds and equipment used therefor. More specifically, the present invention provides a method for producing low-carbon olefins from oxygen-containing compounds, using methanol and / or dimethyl ether as the main raw materials, using multi-stage (n≥2) dense-phase fluidized bed reactors and multi-stage ( m≥2) The catalyst regenerator solves the problems in the prior art that it is difficult to control the carbon deposition amount and uniformity of carbon content of the catalyst and the low selectivity of low-carbon olefins.

Owner:中科催化新技术(大连)股份有限公司

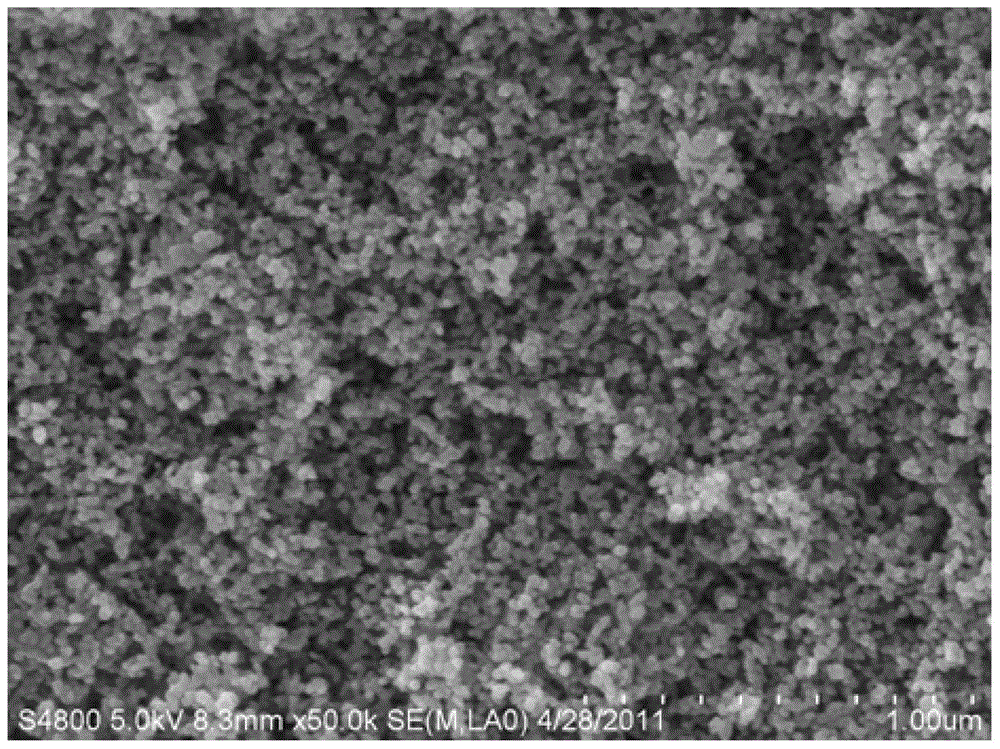

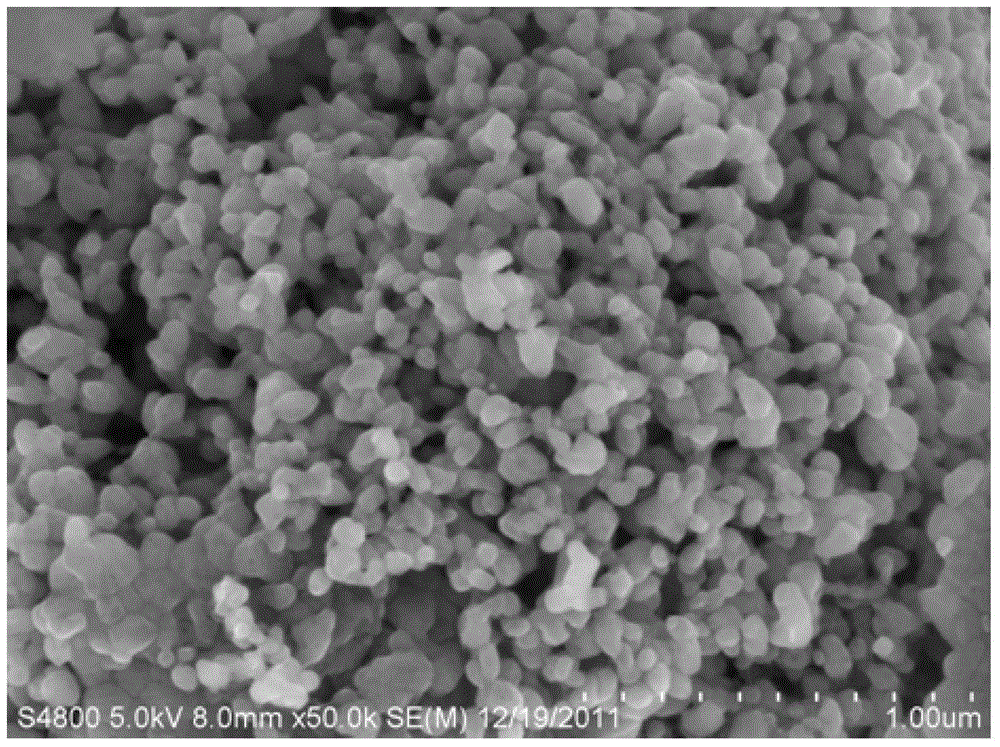

Micro-chemical preparation method of nano-iron phosphate and nano-iron phosphate

ActiveCN103259017BNarrow distributionParticle size distribution high speedMaterial nanotechnologyCell electrodesIron saltsPhosphate

The invention discloses a nano iron phosphate micro chemical preparation method and nano iron phosphate. The method comprises the following steps of: S1, respectively dissolving soluble iron salt and phosphate into deionized water according to a ratio that Fe: P=1:(0.8-1.2), wherein the concentrations of solutions are both 0.1-1mol / L, and the final volume parts of an iron salt solution and a phosphate solution are the same; S2, weighing and dissolving a surfactant which can theoretically generate 1wt.%-10wt.% of iron phosphate into the iron salt solution; S3, dropwise adding ammonia water into the phosphate solution, and regulating the pH to be 8-10; S4, regulating the rotation speed of a mechanical pump to be 10-300 rounds / minute, simultaneously adding the same flow of the iron salt solution and the phosphate solution into a microreactor of a micro chemical system to react for 10-60 minutes, and thus obtaining a turbid liquid; and S5, filtering and separating the turbid liquid, washing and drying at 70-90 DEG C so as to obtain spherical nano iron phosphate. The method can be used for preparing the nano iron phosphate with regular shape, good dispersibility, uniform size distribution and high reactivity.

Owner:深圳市毓丰新材料有限公司

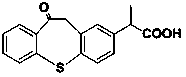

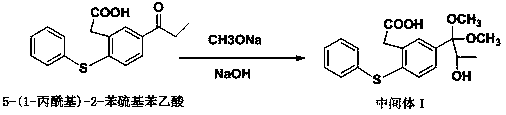

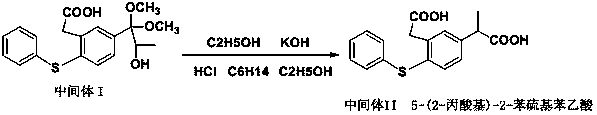

Applications of micro-channel reactor in zaltoprofen cyclization reaction, and zaltoprofen cyclization method

InactiveCN110407804ADiffusion distance is shortAvoid high viscosity, poor fluidity and other characteristicsOrganic chemistryChemical/physical/physico-chemical microreactorsDrugs synthesisReaction temperature

The invention belongs to the technical field of pharmaceutical synthesis, and specifically discloses a zaltoprofen cyclization method and applications of a micro-channel reactor in a zaltoprofen cyclization process. According to the present invention, cyclization is performed in a micro-channel reactor, and the uniformly stirred material is heated to a temperature of 60-70 DEG C before the material enters the micro-channel reactor, wherein the reaction temperature is 60-90 DEG C, the flow rate is controlled at 5-10 ml / min, the pressure drop is 6 bar, the material passing time is 5-10 s, and amass ratio of a zaltoprofen intermediate II 5-(2-propionyloxy)-2-phenylthiophenylacetic acid to polyphosphoric acid to phosphoric acid is 1:3-4:0.5. According to the present invention, by using the micro-channel reactor, the cyclization yield can be substantially increased, the reaction time can be shortened, the product quality can be stabilized, the post-treatment difficulty can be substantiallyreduced, and the pollution degree can be substantially improved.

Owner:河南后羿制药有限公司

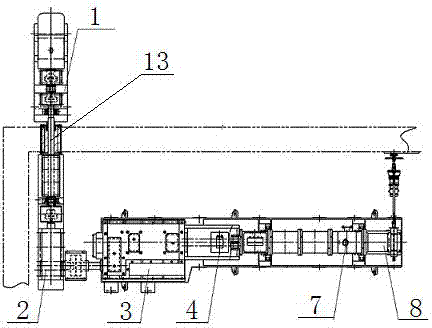

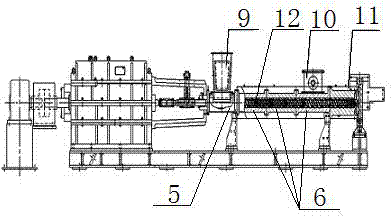

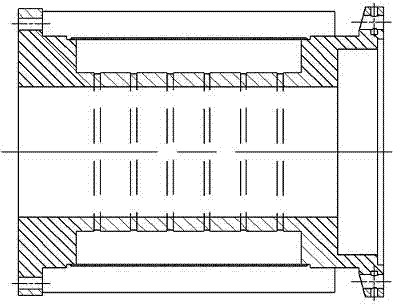

Gun propellant mixing and extruding device

The invention discloses a gun propellant mixing and extruding device, which comprises a motor, a conic reducer, a main reducing gear, a connecting device, a feeding machine barrel, a sealing machine barrel, a gas exhauster barrel and an explosion venting machine barrel, wherein the motor is connected with the conic reducer through a coupler and a wall penetration shaft; the conic reducer is connected with the main reducing gear through the coupler; the main reducing gear is connected with a connecting device; the connecting device is connected with the feeding machine barrel; the feeding machine barrel is connected with the sealing machine barrel; the sealing machine barrel is connected with the gas exhauster barrel; the gas exhauster barrel is connected with the explosion venting machine barrel; and the sealing machine barrel is internally provided with a co-rotating twin screw. With the adoption of the gun propellant mixing and extruding device, the intermittent mixing of a gun propellant extruder is changed into the continuous mixing, and the gun propellant extruder is in enclosed environment when in processing, thus greatly improving the production efficiency and the quality of products; and the gun propellant mixing and extruding device is good in self-cleaning property, so that residence time distribution range of materials in the gun propellant mixing and extruding device is narrower, and the mixing is uniform.

Owner:恒力石化股份有限公司

A Catalytic Rectification Tray with Online Catalyst Replacement

ActiveCN108043061BEvenly distributedSame flow distanceChemical industryHydrocarbon from oxygen organic compoundsPtru catalystElectrical and Electronics engineering

The invention discloses a catalytic rectification plate tower capable of replacing catalysts on-line, which comprises a tray, a plurality of gas-liquid contact elements arranged on the tray, a plurality of suspended downcomers, and a suspended The liquid receiving tray and the catalyst loading and unloading hole for loading and unloading the catalyst on the tray, the free space surrounded by the suspended downcomer, the gas-liquid contact element, the tray and the tower wall is the catalyst loading area, and the catalyst is scattered in the In the catalyst loading area, the suspended downcomer includes an inner downcomer passing through the tray and an outer guide cover covering the part of the inner downcomer above the bottom of the tray. The tray does not need to carry out complex packaging of the catalyst, but directly packs the catalyst in bulk on the tray, and the online catalyst replacement can be realized without stopping the device, the catalyst is evenly distributed, the tray pressure is reduced, and the rectification efficiency is high. At the same time, expensive catalyst packaging materials and fillers are omitted, and the cost can be significantly reduced.

Owner:WANHUA CHEM GRP CO LTD

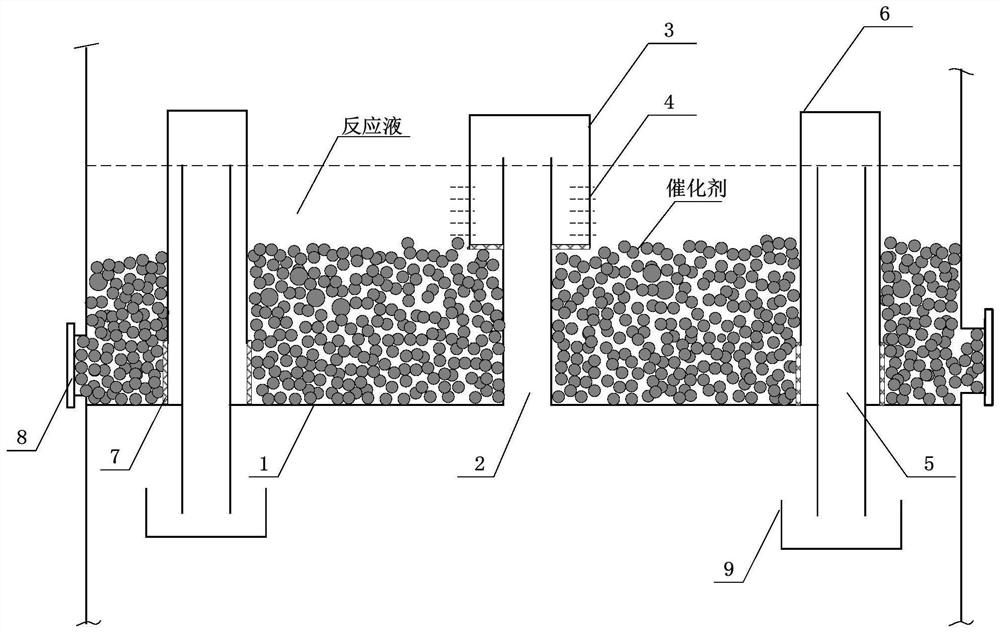

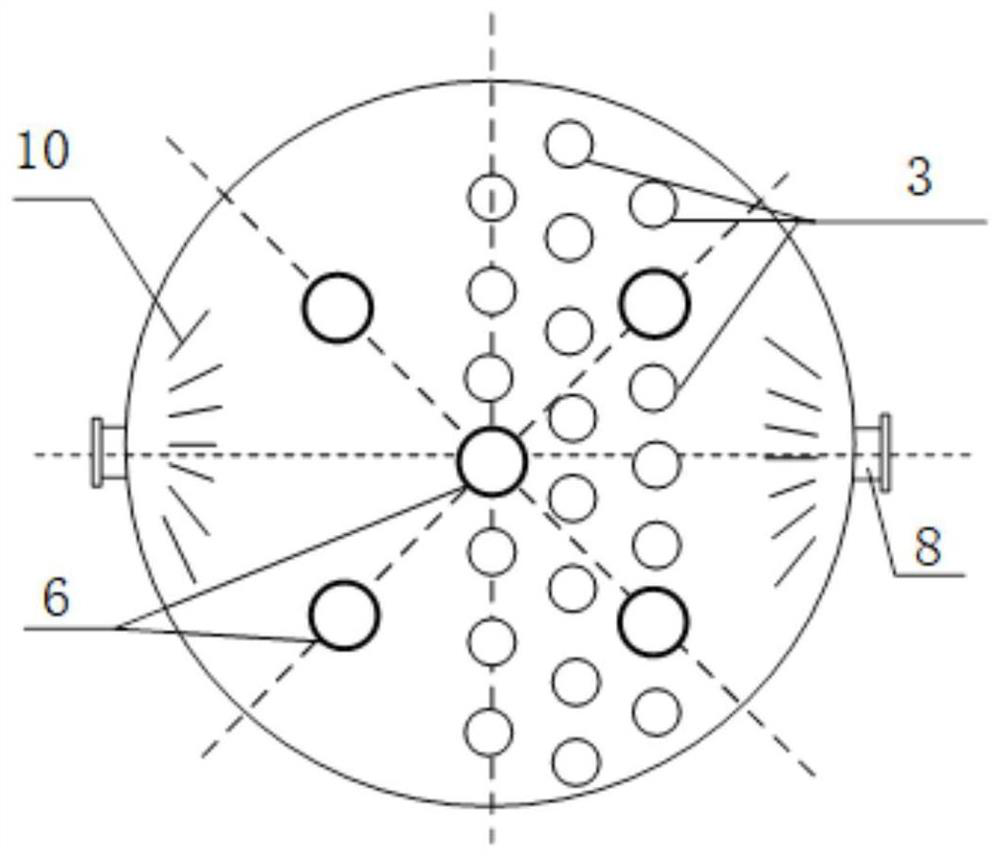

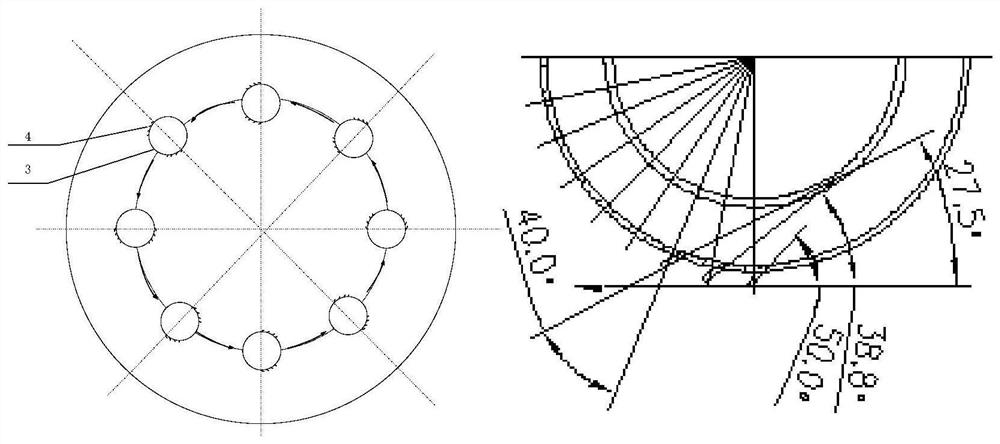

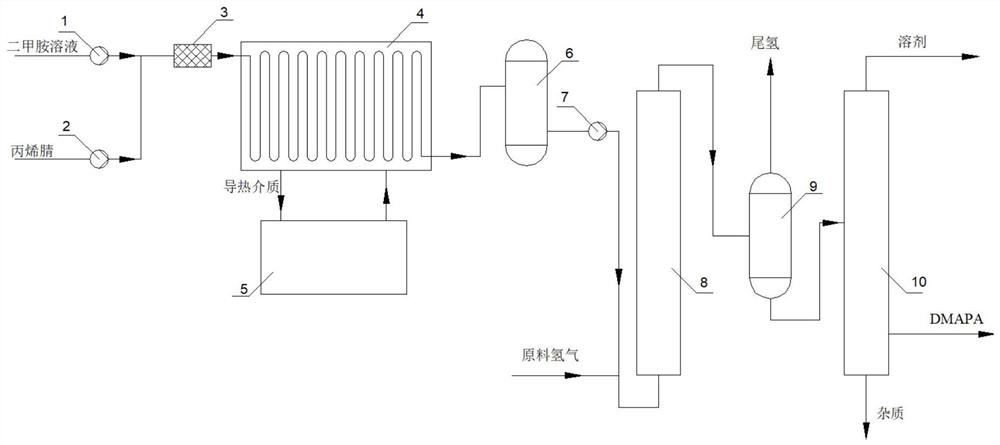

Preparation method of N, N-dimethyl-1, 3-propane diamine

PendingCN113620813AHigh mass and heat transfer efficiencyNarrow residence time distributionCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystHydrogenation reaction

The invention provides a preparation method of N, N-dimethyl-1, 3-propane diamine, which comprises the following steps: mixing acrylonitrile and a dimethylamine solution, injecting the mixture into a micro-channel reaction device for addition reaction, mixing the reaction liquid with hydrogen, preheating the mixture, feeding the preheated mixture into a continuous hydrogenation reactor filled with a Ni-based alloy hydrogenation catalyst, carrying out hydrogenation reaction and carrying out vacuum rectification separating to obtain the required product. According to the preparation method disclosed by the invention, the microchannel reactor has the advantages of continuity, high mass and heat transfer efficiency, narrow residence time distribution, no amplification effect and the like, so that the addition reaction of acrylonitrile and dimethylamine has the characteristics of high efficiency, high conversion rate and few byproducts; and the hydrogenation reaction is carried out under extremely mild reaction conditions by using the novel Ni-based alloy catalyst, and meanwhile, very high conversion rate and product selectivity are obtained, so that the whole reaction system has the advantages of continuous production, convenience in operation, high resource utilization rate and the like.

Owner:CHINA TIANCHEN ENG

Continuous production method and continuous production device for synthesizing biruea

ActiveCN101967114BNarrow residence time distributionWith selective suspensionUrea derivatives preparationOrganic compound preparationOscillating flowContinuous flow

Owner:ZHEJIANG ENG DESIGN +2

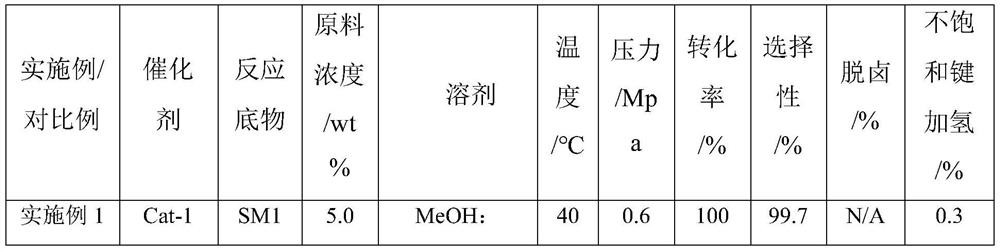

Method and catalyst for carrying out selective nitro reduction hydrogenation reaction by using micro-packed bed

PendingCN114773207AHigh selectivityIncrease contact areaCarboxylic acid nitrile preparationOrganic compound preparationActivated carbonPtru catalyst

The invention discloses a method for carrying out selective nitro reduction hydrogenation reaction by using a micro-packed bed and a catalyst. Comprising the following steps: (1) mixing a reaction substrate with a reaction solvent to prepare a raw material solution; (2) introducing the raw material liquid and hydrogen into a microreactor for reaction, wherein a reaction tube of the microreactor is filled with a modified catalyst; the modified catalyst comprises a catalyst active component, a catalyst auxiliary agent and a catalyst carrier; the catalyst active component is selected from one or more of Pd, Ru and Pt; the catalyst auxiliary agent is selected from one or more of Fe, Cu, Ni and Co; the catalyst carrier is activated carbon; and (3) carrying out gas-liquid separation and purification on a gas-liquid mixture obtained after the reaction is finished to obtain a reaction product. Through the combination of the micropacked bed and the modified catalyst, nitro reduction is realized with high selectivity, the selectivity can reach 99%, and the generation of by-products is effectively reduced.

Owner:PHARMABLOCK SCIENCES (NANJING) INC

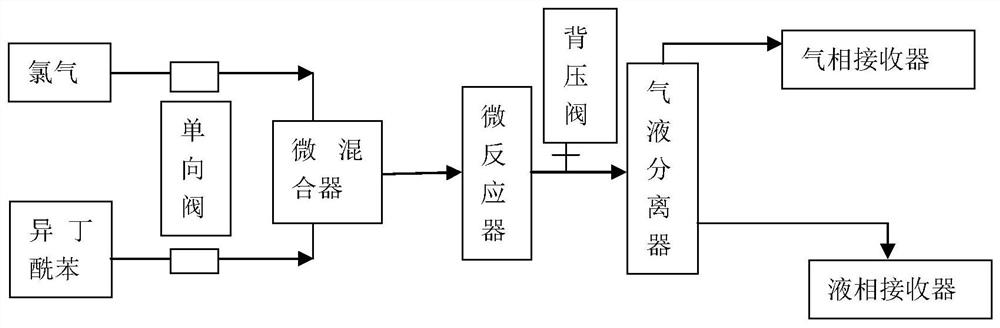

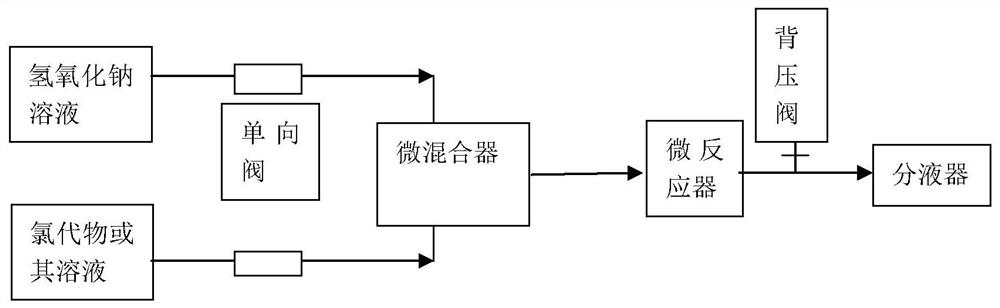

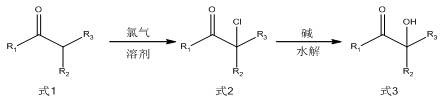

Method for preparing α-hydroxyketone photoinitiator in a microreactor

ActiveCN111056934BImprove operational safetyHigh selectivityOrganic compound preparationChemical/physical/physico-chemical microreactorsKetoneAlkaline hydrolysis

The invention relates to a method for preparing an α-hydroxy ketone photoinitiator in a microreactor. Isobutyrylbenzene is used as a raw material, and chlorine gas is introduced into it to obtain an intermediate chloroisobutyryl chloride, and the effect of the intermediate in an aqueous sodium hydroxide solution The α-hydroxy ketone photoinitiator is obtained by alkaline hydrolysis. The preparation method of the α-hydroxy ketone photoinitiator provided by the invention has high operational safety and high selectivity, small reaction volume, short reaction time, less corrosion to equipment, low energy consumption, green environmental protection, and is Process method suitable for industrial production.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

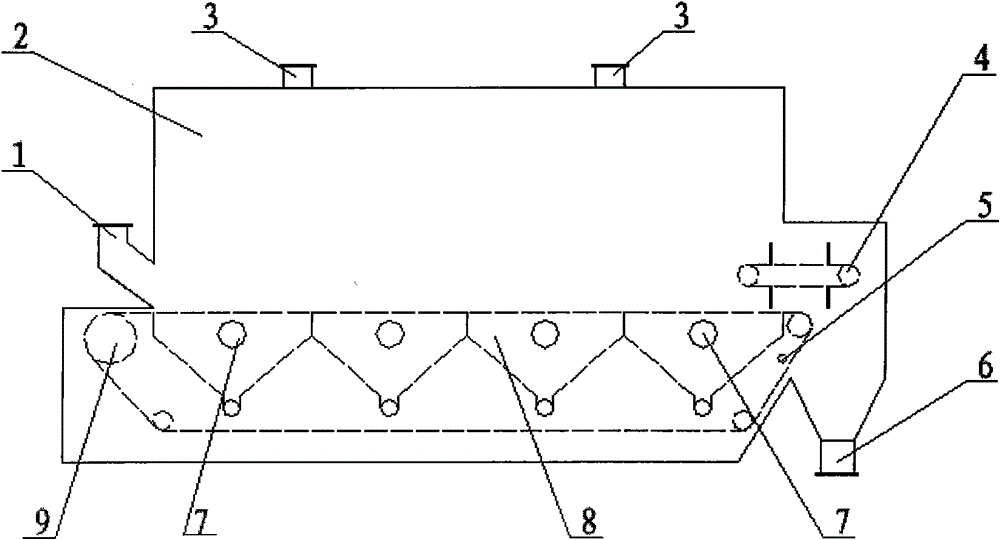

Mobile hot air distribution plate type fluidized bed dryer

ActiveCN102252501BNarrow residence time distributionThere is no problem that cannot be sorted outDrying solid materials with heatHearth type furnacesFluidized bed dryingSmall footprint

The invention discloses a mobile hot air distribution plate type fluidized bed dryer, and belongs to the technical field of drying equipment and engineering. The dryer is characterized by comprising a box body, a hot air distribution chamber, a mobile hot air distribution plate assembly, a mobile weir plate assembly, a material seal type hot air sealing structure, an air knife, a hot air inlet, awaste gas outlet, a wet material inlet, a product outlet and the like. A drying method using the drying equipment comprises the following steps of: adding a wet material onto a hot air distribution plate through the wet material inlet, performing fluidized drying on fine granules by means of hot air in a mobile hot air distribution plate type fluidized bed, drying coarse granules and the mobile hot air distribution plate together while moving, discharging the dried qualified product from the product outlet, and exhausting the waste gas from the waste gas outlet. The dryer has the advantages of simple structure, easiness in manufacture, small floor area, narrow material residence time distribution, uniform water content of the product, and safety and convenience in the operation process.

Owner:DALIAN UNIV OF TECH +1

Asymmetric co-rotating multi-screw extrusion device, extruder and processing method thereof

Disclosed is an asymmetric co-rotating multi-screw extrusion device, an extruder, and a processing method thereof. The barrel is provided with a feed port located at one end of the screw mechanism and a discharge port located at the other end of the screw mechanism, and the barrel comprises a conveying section, a melting section, an exhaust section, and a mixing extrusion section sequentially arranged from a side thereof where the feed port is located, wherein the exhaust section is provided with an exhaust hole. The screw mechanism comprises at least a first screw and a second screw arranged parallel to the first screw, wherein at least one of the first screw and the second screw has a cross-sectional profile comprising an arc forming a radial step between a root and a crest thereof, and the first screw and the second screw are asymmetrically inter-meshed and co-rotated at the same speed.

Owner:WUYI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com