Preparation method of N, N-dimethyl-1, 3-propane diamine

A technology of propylene diamine and dimethylamine, which is applied in the N field to achieve the effects of high efficiency, high conversion rate and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

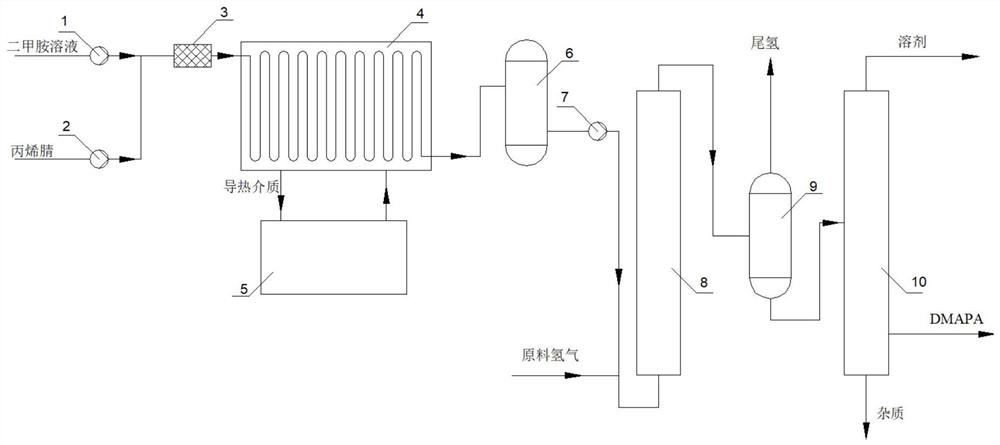

[0043] Among the present invention, the preparation method of N,N-dimethyl-1,3-propanediamine comprises the following steps:

[0044] (1) After mixing acrylonitrile and dimethylamine solution in a certain proportion, inject the microchannel reaction device, carry out addition reaction under certain temperature and pressure conditions, obtain the first reaction solution containing dimethylaminopropionitrile, wherein The conversion rate of acrylonitrile is 100%, and the selectivity of dimethylaminopropionitrile is above 99.8%;

[0045] (2) The first reaction solution is mixed with hydrogen, and after preheating, it enters the continuous hydrogenation reactor 8 equipped with a Ni-based alloy hydrogenation catalyst for hydrogenation reaction to obtain a hydrogenation reaction containing N,N-dimethyl-1,3- Propylenediamine second reaction solution, wherein the conversion rate of dimethylaminopropionitrile is 100%, and the product selectivity is greater than 99.8%;

[0046] (3) The ...

Embodiment 1

[0049] Using the ethanol solution of acrylonitrile and 30% dimethylamine as raw materials, the addition reaction is carried out through a microchannel reaction device to obtain the addition reaction liquid, wherein the molar ratio of acrylonitrile and dimethylamine is 1:1.05, and the reaction temperature is 40°C , pressure 1bar, residence time 40s. The reaction product was collected from the outlet of the microchannel reaction device for analysis. The conversion rate of acrylonitrile was 100%, and the selectivity of dimethylaminopropionitrile was 99.82%. The above-mentioned addition reaction solution and hydrogen are mixed and preheated and then entered into a fixed-bed hydrogenation reactor, and a Ni-based alloy hydrogenation catalyst is installed in the reactor. The hydrogenation reaction temperature is 60°C, the pressure is 3 bar, and the residence time of the reaction liquid is 30 min. The preparation method of the hydrogenation catalyst is as follows: the alloy composed ...

Embodiment 2

[0051] Using the methanol solution of acrylonitrile and 35% dimethylamine as raw materials, the addition reaction is carried out through a microchannel reaction device to obtain the addition reaction solution, wherein the molar ratio of acrylonitrile and dimethylamine is 1:1.1, and the reaction temperature is 60°C , pressure 1.5bar, residence time 30s. The reaction product was collected from the outlet of the microchannel reaction device for analysis. The conversion rate of acrylonitrile was 100%, and the selectivity of dimethylaminopropionitrile was 99.80%. The above-mentioned addition reaction liquid and hydrogen are mixed and preheated, and then enter a trickle bed hydrogenation reactor, and a Ni-based alloy hydrogenation catalyst is installed in the reactor. The hydrogenation reaction temperature is 40°C, the pressure is 4 bar, and the residence time of the reaction liquid is 30 min. The preparation method of the hydrogenation catalyst is as follows: the alloy composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com