Gun propellant mixing and extruding device

A technology of mixing and extruding propellants, which is applied in the field of propellant mixing and extruding devices, can solve the problems of propellant production and quality limitations, general propellant mixing effects, and high requirements for mixing effects, so as to improve production efficiency And the quality of the product, the residence time distribution range is narrow, and the effect of self-cleaning is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

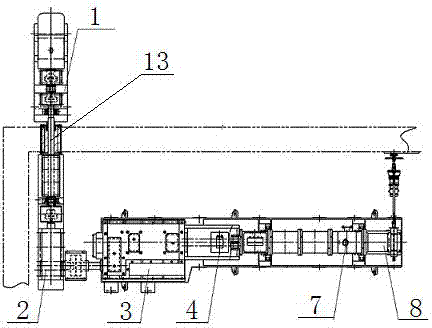

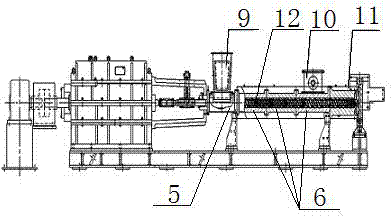

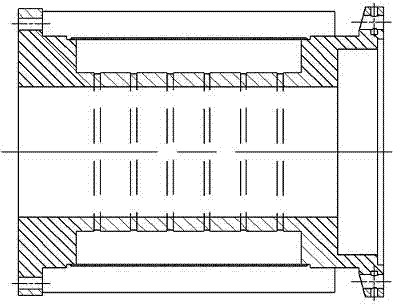

[0014] Such as figure 1 with figure 2 As shown, the propellant mixing and extruding device includes a motor 1, a bevel gear reducer 2, a final reducer 3, a connecting device 4, a feeding barrel 5, a sealing barrel 6, an exhaust barrel 7 and an explosion venting barrel 8. The motor 1 is connected to the bevel gear reducer 2 through a coupling and the wall-through shaft 13, the bevel gear reducer 2 is connected to the main reducer 3 through a coupling, and the main reducer 3 is connected to the spline sleeve coupling The device 4 is connected, the connecting device 4 is connected with the feeding barrel 5, the feeding barrel 5 is connected with the closed barrel 6, the closed barrel 6 is connected with the exhaust barrel 7, the exhaust barrel 7 is connected with the explosion venting barrel 8, The closed barrel 6 is provided with co-rotating twin-screws 12, the feeding barrel 5 is provided with a feeding hopper 9, the exhaust barrel 7 is provided with an exhaust port 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com