Solid polycondensation type phosphate ester inflaming retarding ABS/PC (Acrylonitrile Butadiene Styrene/Polycarbonate) alloy and preparation method thereof

A technology of solid polycondensation and phosphate ester, which is applied in the field of solid polycondensation phosphate ester flame-retardant ABS/PC alloy and its preparation, can solve the problems of fluidity, surface brightness, mechanical properties, poor aging resistance, and high cost, and achieve aging resistance Good, low cost, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

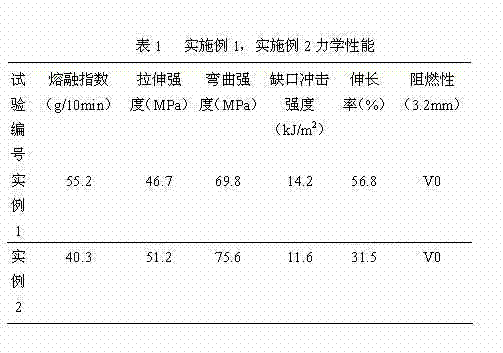

Examples

Embodiment 1

[0018] 1) Production of flame retardant masterbatch

[0019] Pour 30kg of CBT resin, 69kg of solid polycondensation type phosphate flame retardant, 0.2kg of phenolic antioxidant and 0.8kg of phosphite or thioester antioxidant into a high-speed mixer, and mix for 60 seconds at a low speed. The mixed raw materials are fed into a twin-screw extruder for forced feeding, blending and extruding. The blending processing temperature is 180-200°C, the screw speed is 250-350r / min, the product is thermally cut into pellets, air-dried and cooled, and packed for later use. CBT resin has a macrocyclic oligoester structure and is a mixture of different low molecular weight cyclic oligomers. The unique composition and low melt viscosity make it an ideal base resin for concentrated masterbatches, and can be mixed with amorphous, semi-crystalline and crystalline Compatible with permanent resins and improves fluidity. Solid polycondensation type phosphate flame retardant has good flame retarda...

Embodiment 2

[0025] 1) Production of flame retardant masterbatch

[0026] Pour 25kg of CBT resin, 74kg of solid polycondensation type phosphate flame retardant, 0.1kg of phenolic antioxidant and 0.9kg of phosphite or thioester antioxidant into a high-speed mixer, and mix for 60 seconds at low speed. The mixed raw materials are fed into a twin-screw extruder for forced feeding, blending and extruding. The blending processing temperature is 180-200°C, the screw speed is 250-350r / min, the product is thermally cut into pellets, air-dried and cooled, and packed for later use.

[0027] 2) ABS / PC alloy production

[0028]Dry 10kg of polycarbonate (PC) at 120°C for 4 hours; 50kg of acrylonitrile-butadiene-styrene copolymer (ABS) and 8kg of acrylonitrile-EPDM-styrene copolymer (AES) at 80°C Let dry for 4 hours. Pour the dried polycarbonate (PC), acrylonitrile-butadiene-styrene copolymer (ABS), acrylonitrile-EPDM-styrene copolymer (AES) and 30kg flame retardant masterbatch into In a high speed m...

Embodiment 3

[0030] The present invention can also be realized by the percentage by weight shown in the following examples, and its preparation method is identical with the foregoing examples:

[0031] 1) Flame retardant masterbatch

[0032] CBT resin 19, solid polycondensation type phosphate flame retardant 80, phenolic antioxidant 0.4, phosphite or thioester antioxidant 0.6. Phenolic antioxidants: such as β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, etc. Phosphite or thioester antioxidants: such as tris(2,4-di-tert-butylphenyl) phosphite, dilauryl thiodipropionate, etc.

[0033] 2) ABS / PC alloy material

[0034] Acrylonitrile-butadiene-styrene copolymer 35, polycarbonate 15, the aforementioned flame retardant masterbatch 40, acrylonitrile-EPDM rubber-styrene copolymer 8, toughening compatibilizer 1, polytetrafluoroethylene Ethylene 0.4, lubricant 0.6. Toughening compatibilizer: it is a graft compound containing acrylate functional groups, such as ethylene grafted acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com