Homodromous self-cleaning double-screw extruder with stretching function and processing method thereof

A twin-screw extruder and screw technology, applied in presses, manufacturing tools, material forming presses, etc., can solve problems such as twin-screw inability to extrude and mix, low work efficiency, and long processing history

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

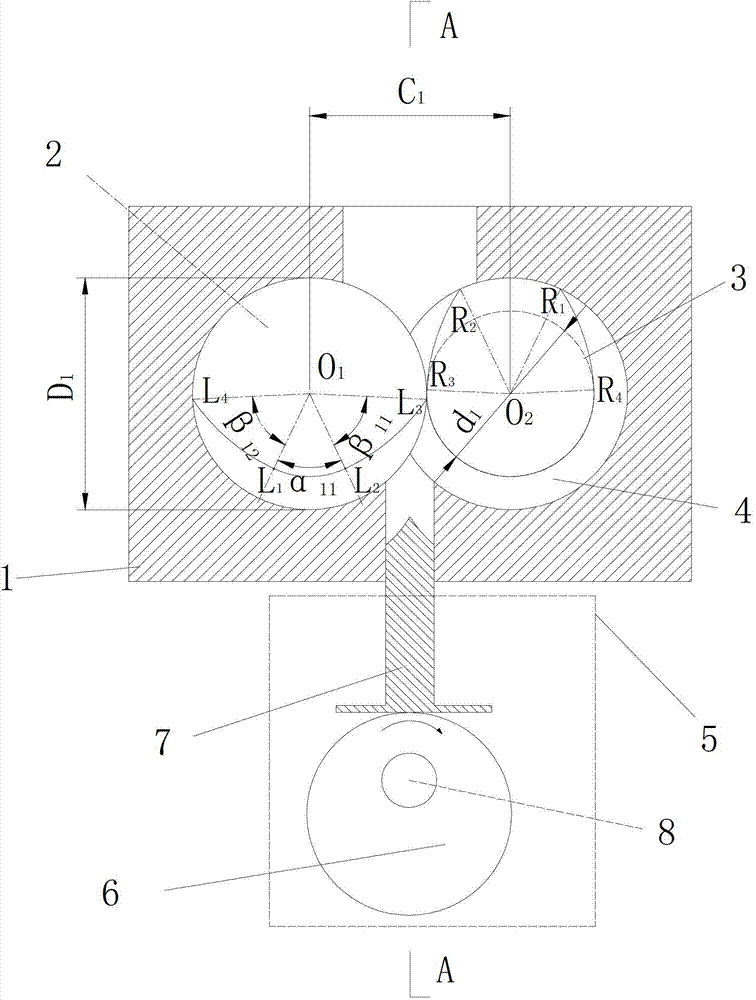

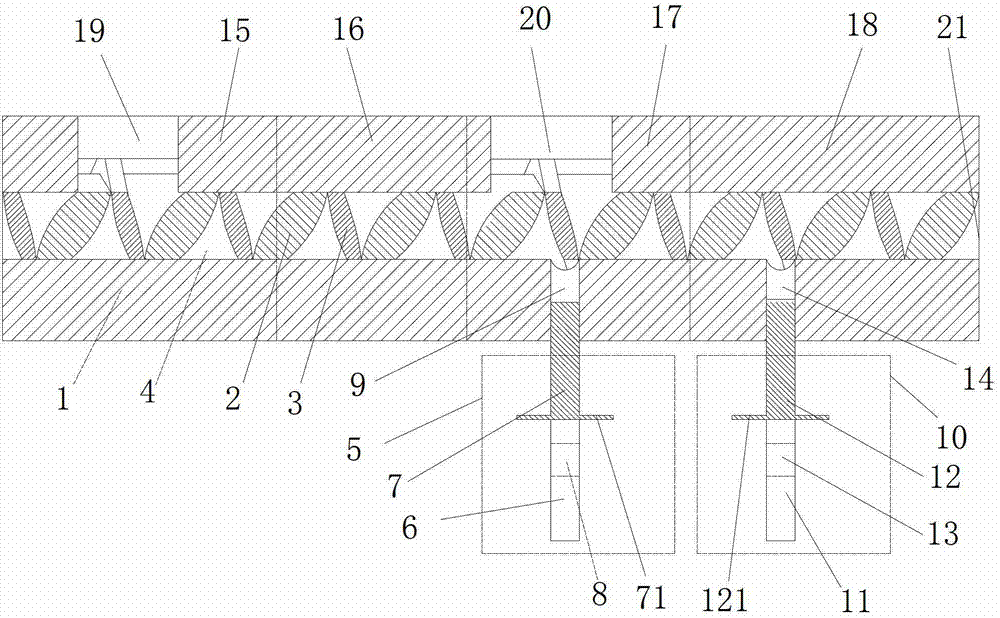

[0051] like figure 1 and figure 2 The shown co-direction self-cleaning twin-screw extruder with stretching effect includes a barrel 1 and a screw mechanism. The barrel 1 is provided with an inner cavity 4, and the screw mechanism is installed in the inner cavity 4. The screw The mechanism includes a first screw 2 and a second screw 3, the first screw 2 and the second screw 3 are engaged with each other, and both the first screw 2 and the second screw 3 are tangent to the inner wall of the cavity 4; The first screw 2, the second screw 3 and the inner cavity 4 of the barrel 1 form flow passages; the cross-sections of the first screw 2 and the second screw 3 are composed of multiple circular arcs with different radii of curvature, and the first The cross-sectional shapes of the screw 2 and the second screw 3 are different, but the arc numbers of the two cross-sections are equal; when the first screw 2 and the second screw 3 rotate, the cross-sectional shape of the flow channel ...

Embodiment 2

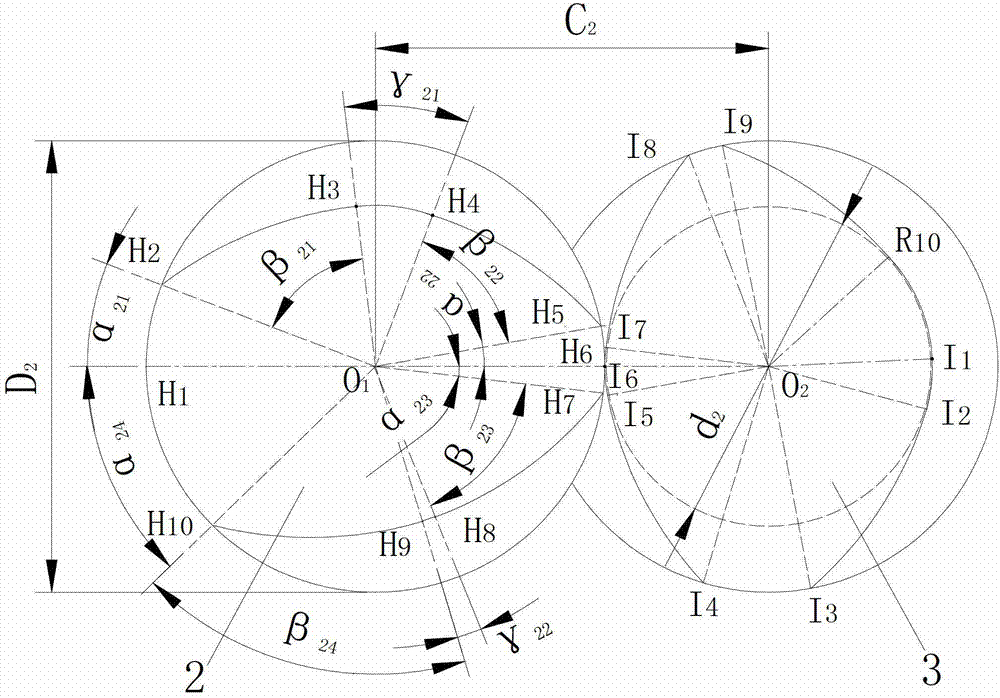

[0067] like image 3 As shown, this co-directional self-cleaning twin-screw extruder with stretching effect is the same as that of Embodiment 1 except for the following features: the number of circular arcs in the cross-section of the first screw 2 and the second screw 3 is 10 segments, wherein , the 10 arcs of the section of the first screw 2 are respectively H 1 h 2 、H 2 h 3 、H 3 h 4 、H 4 h 5 、H 5 h 6 、H 6 h 7 、H 7 h 8 、H 8 h 9 、H 9 h 10 and H 10 h 1 , and the arc H 1 h 2 、H 2 h 3 、H 3 h 4 、H 4 h 5 、H 5 h 6 、H 6 h 7 、H 7 h 8 、H 8 h 9 、H 9 h 10 and H 10 h 1 The central angle of the circle is α 21 , β 21 , γ21 , β 22 、α 22 、α 23 , β 23 , γ 22 , β 24 and alpha 24 , and the arc H 1 h 2 、H 5 h 6 、H 6 h 7 and H 10 h 1 are all tangent to the lumen 4,

[0068] Among them, β 21 =β 22 =β 23 =β 24 ,

[0069]0≤α 23 +α 22 21 +β 22 +β 23 +β 24 ) / 2-(γ 21 +γ 22 ) / 2,

[0070] That is, 0≦α 23 +α 22 21 +α 24 ; at the same...

Embodiment 3

[0076] like Figure 4 As shown, this co-directional self-cleaning twin-screw extruder with stretching effect is the same as that of Embodiment 1 except for the following features: the number of circular arcs in the cross-section of the first screw 2 and the second screw 3 is 7 sections, wherein , the seven arcs of the section of the first screw 2 are respectively M 1 m 2 , M 2 m 3 , M 3 m 4 , M 4 m 5 , M 5 m 6 , M 6 m 7 and M 7 m 1 , and the arc M 1 m 2 , M 2 m 3 , M 3 m 4 , M 4 m 5 , M 5 m 6 , M 6 m 7 and M 7 m 1 The central angle of the circle is α 31 , β 31 , γ 32 , ε 31 , ε 32 , γ 31 and beta 32 , and the arc M 1 m 2 Tangent to lumen 4;

[0077] Among them, β 31 =β 32 , ε 31 =ε 32 ,

[0078] 031 31 +β 32 ) / 2-γ 32 / 2-ε 31 / 2-ε 32 / 2,

[0079] That is, 031 31 ;

[0080] The seven arcs of the section of the second screw 3 are respectively N 1 N 2 , N 2 N 3 , N 3 N 4 , N 4 N 5 , N 5 N 6 , N 6 N 7 and N 7 N 1 , the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com