Catalytic rectifying column plate allowing online replacement of catalyst

A catalytic rectification tower and catalyst technology, which is applied in the field of catalytic rectification trays, can solve problems affecting plate efficiency and reaction effect, catalyst wear, large leakage, slow liquid phase replacement, etc., to increase equipment processing capacity, diffusion transmission, etc. Effect of reduced mass resistance, narrow residence time distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

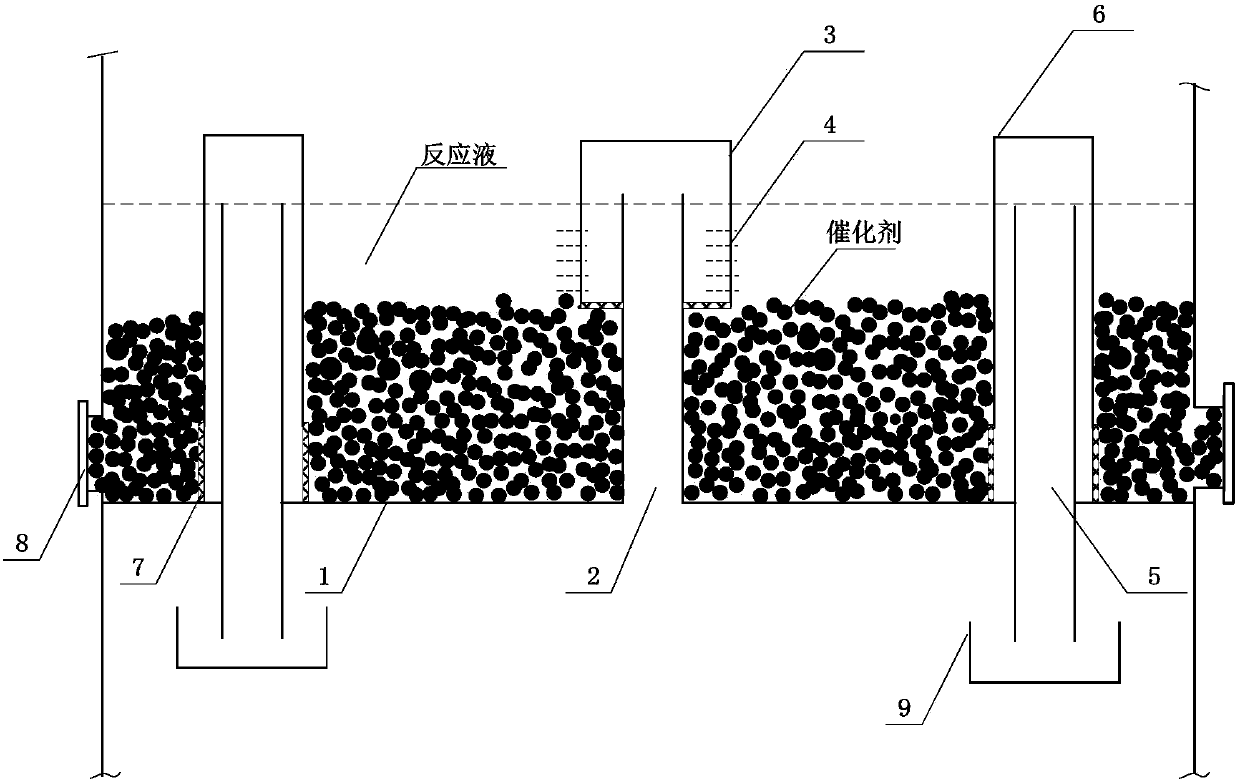

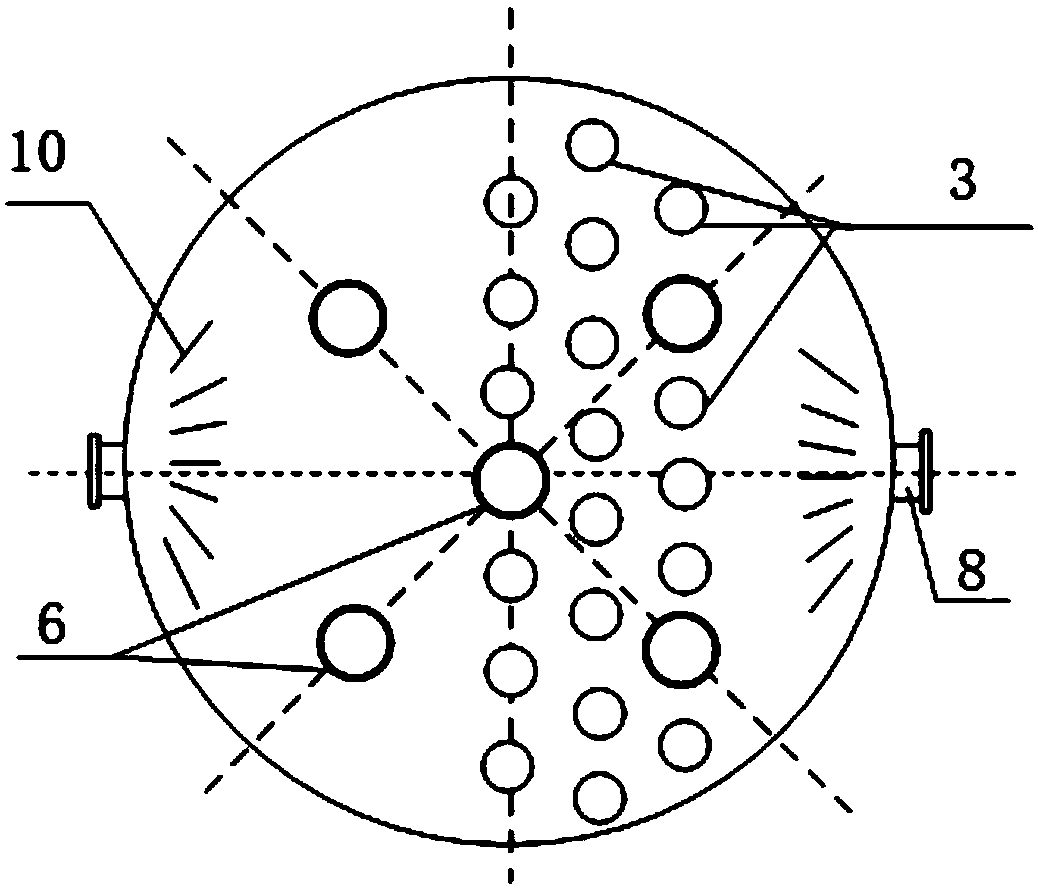

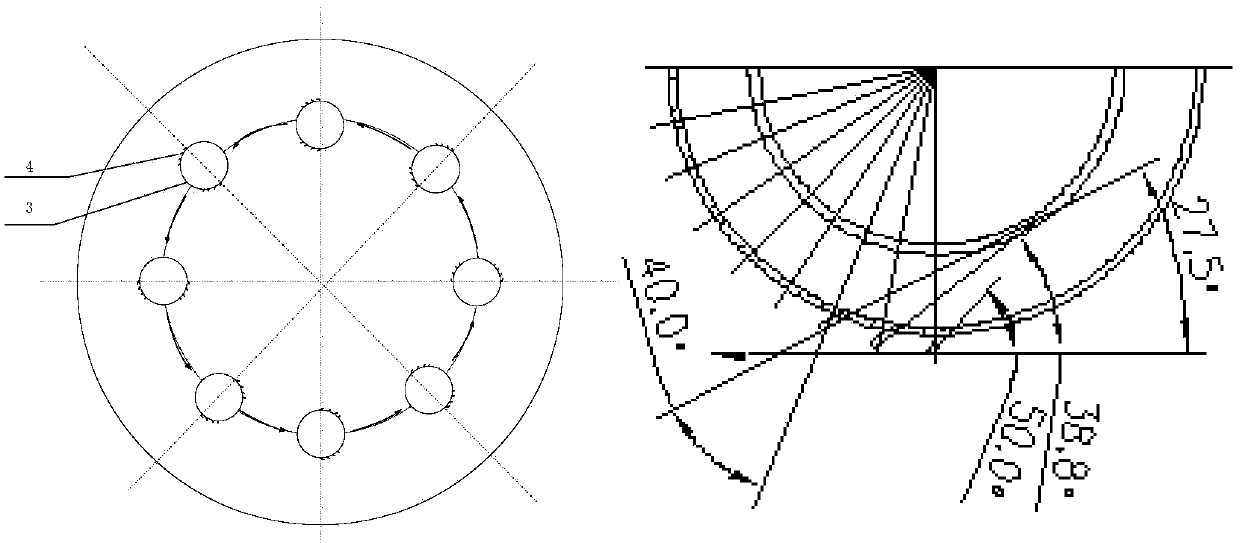

[0039] Such as Figure 1-5 As shown, a catalytic rectification tray that can replace the catalyst on-line includes a tray 1, a plurality of gas-liquid contact elements arranged on the tray, a plurality of suspended downcomers, and a suspended tray below the suspended downcomer. The liquid receiving tray 9 and the catalyst loading and unloading hole 8 for loading and unloading the catalyst on the tray, wherein the suspended downcomer includes the inner downcomer 5 (such as 5 diameters of 65mm) passing through the tray and the inner downcomer that covers the inner downcomer. The outer guide cover 6 of the part above the bottom of the tray, the gas-liquid contact element includes the gas riser 2 installed on the tray and the spray cap 3 (for example, 40 diameters 50mm) installed on the top of the gas riser, the spray cap 3 3 Gas injection holes 4 are provided at the lower end and / or the lower part and below the liquid surface. A deflector 19 is arranged beside the gas injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com