Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Improve the scope of market application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying-free polyester composition having special aesthetic effects and preparation method and application thereof

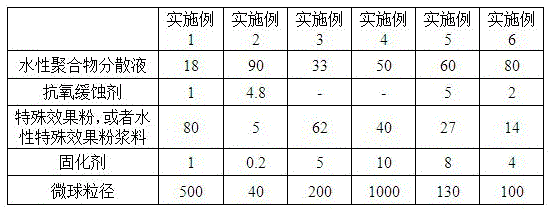

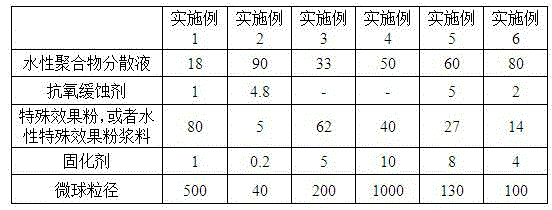

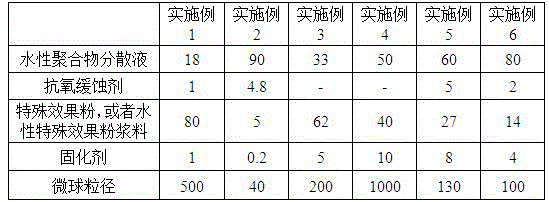

The invention discloses a spraying-free polyester composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free polyester composition comprises the following components: 70-98 wt% of polyester, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the polyester, so that the compatibility of the special-effect powder and the polyester can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free polyester composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

High-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and preparation method thereof

InactiveCN105199294AImprove the lubrication effectImprove wettabilityAntioxidantAcrylonitrile butadiene styrene

The invention relates to the technical field of polymer materials, in particular to a high-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and a preparation method thereof. The composite material comprises, by weight: 70-90 parts of ABS resin, 4.0-10 parts of a compatilizer, 5.0-10 parts of a toughener, 1.0-3.0 parts of white oil, 0.4-0.6 part of a composite antioxidant, 0.5-1.0 part of a lubricant, and 1.0-5 parts of pearl powder. The preparation method is simple, and the prepared ABS composite material has good mechanical properties, low aid emigration rate, significant pearl effect, smooth surface free of flow marks and scratch resistant, and long service life.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

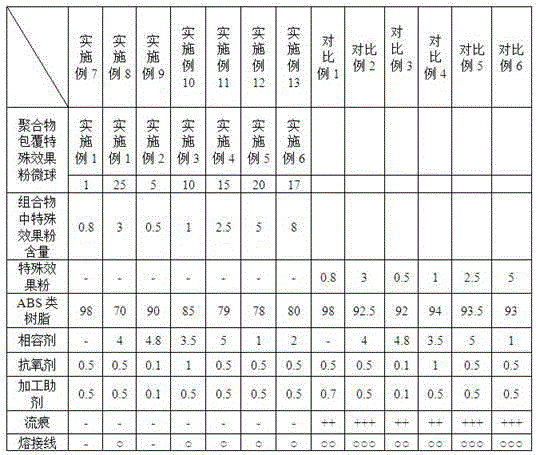

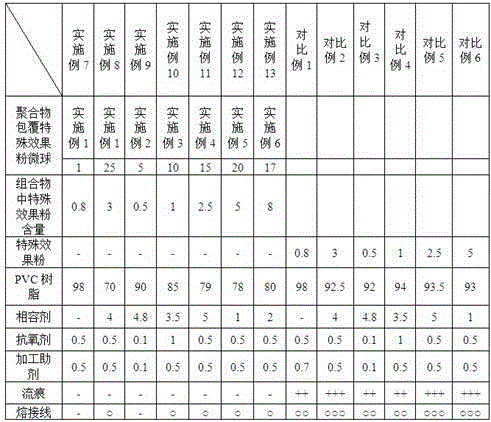

Spraying-free ABS composition with special aesthetic effect, preparation method and applications thereof

The invention discloses a spraying-free ABS composition with a special aesthetic effect, a preparation method and applications thereof. The ABS composition consists of 70 to 98 wt% of ABS resin, 1 to 25 wt% of polymer-coated microspheres with a special effect, 0 to 10 wt% of compatilizer, 0.1 to 1 wt% of antioxidant, and 0.1 to 0.5 wt% of processing aid. The powder with a special effect is coated by aqueous dispersion liquid to form microspheres, then the microspheres are dispersed into the ABS resin so as to improve the compatibility between the powder with a special effect and the ABS resin, thus the flow marks on the surface during the extrusion or injection moulding process can be eliminated, and the weld lines can be reduced. The prepared spraying-free ABS composition has a prominent metal texture and special aesthetic effects such as pearl-liked sparkling, and the application range of spraying-free materials is greatly enlarged.

Owner:TIANJIN KINGFA NEW MATERIAL

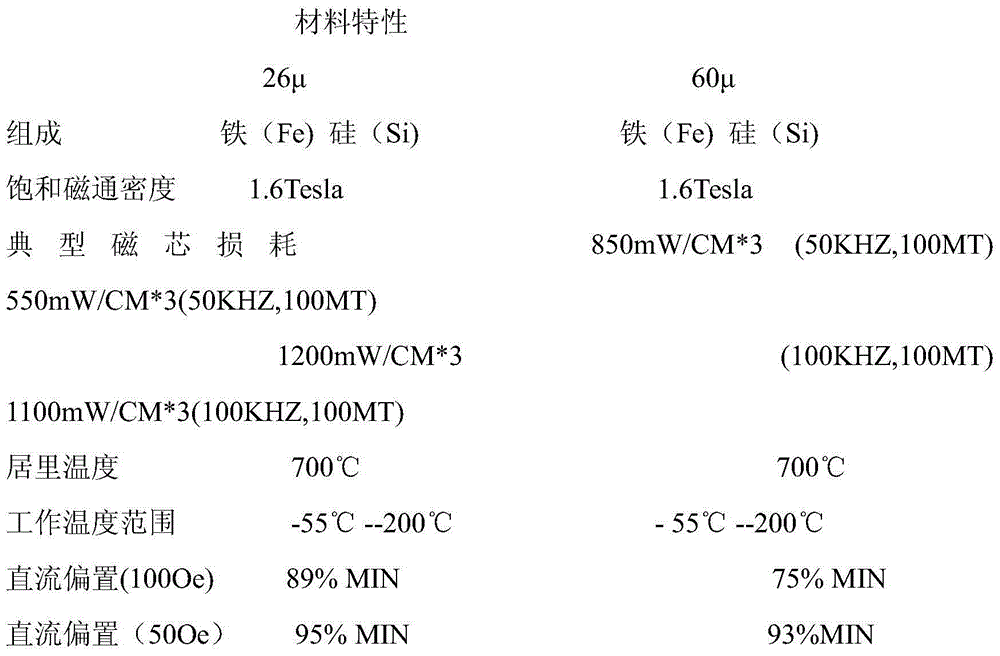

Method for preparing magnetic powder core with high-flux magnet ring performance

InactiveCN104103413AHigh Flux Ferrite PerformanceHigh saturationInductances/transformers/magnets manufactureAlloyAlternating current

The invention discloses a method for preparing a magnetic powder core with high-flux magnet ring performance. The method comprises the following steps of alloy smelting, gas atomization crushing, annealing, insulation coating, compression molding, heat treatment, reinforcing and surface paint spraying. The magnetic powder core prepared by the method has high-saturation magnetic induction intensity, high alternating current / direct current superposition property and good temperature stability, is low in iron core loss and cost, meets the requirements of high frequency, high power, miniaturization and electromagnetic interference resistance of electron devices, and is greatly noticed by the electron industry, and the market application scope is enlarged continuously.

Owner:湖州泰元精密制造有限公司

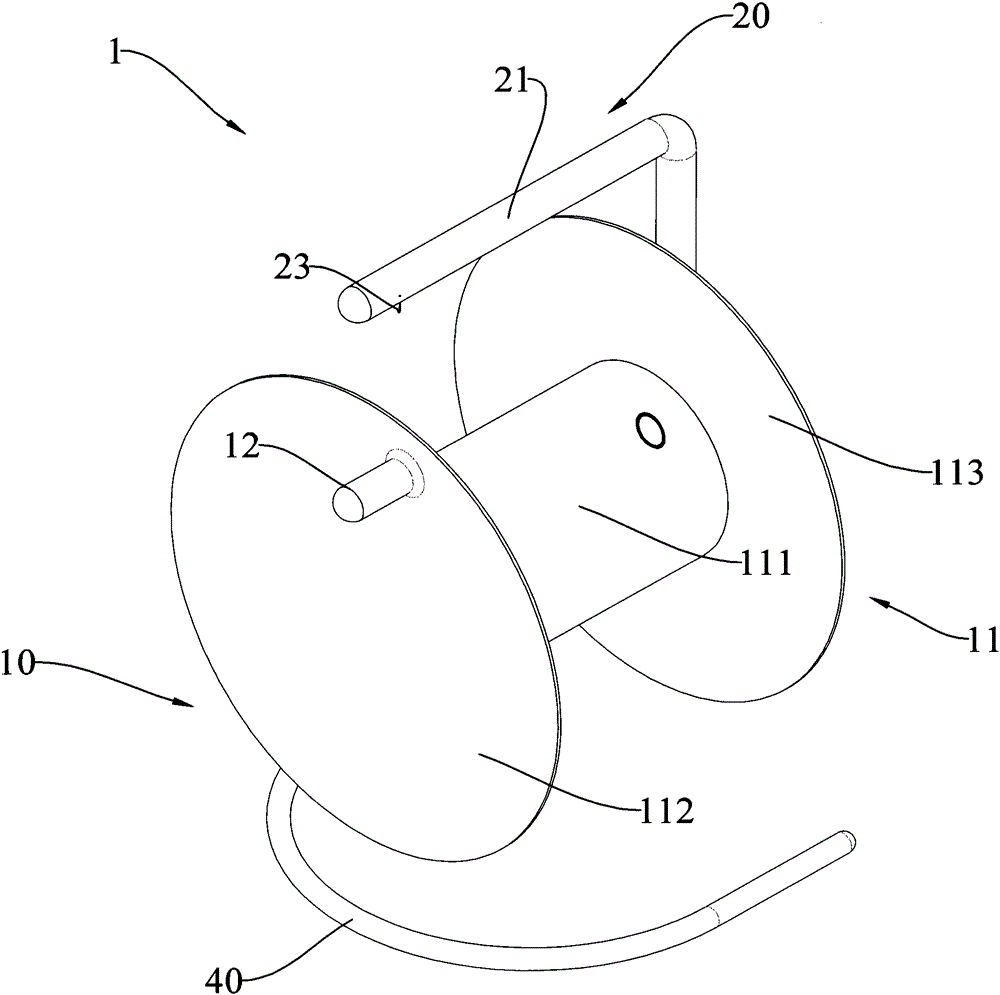

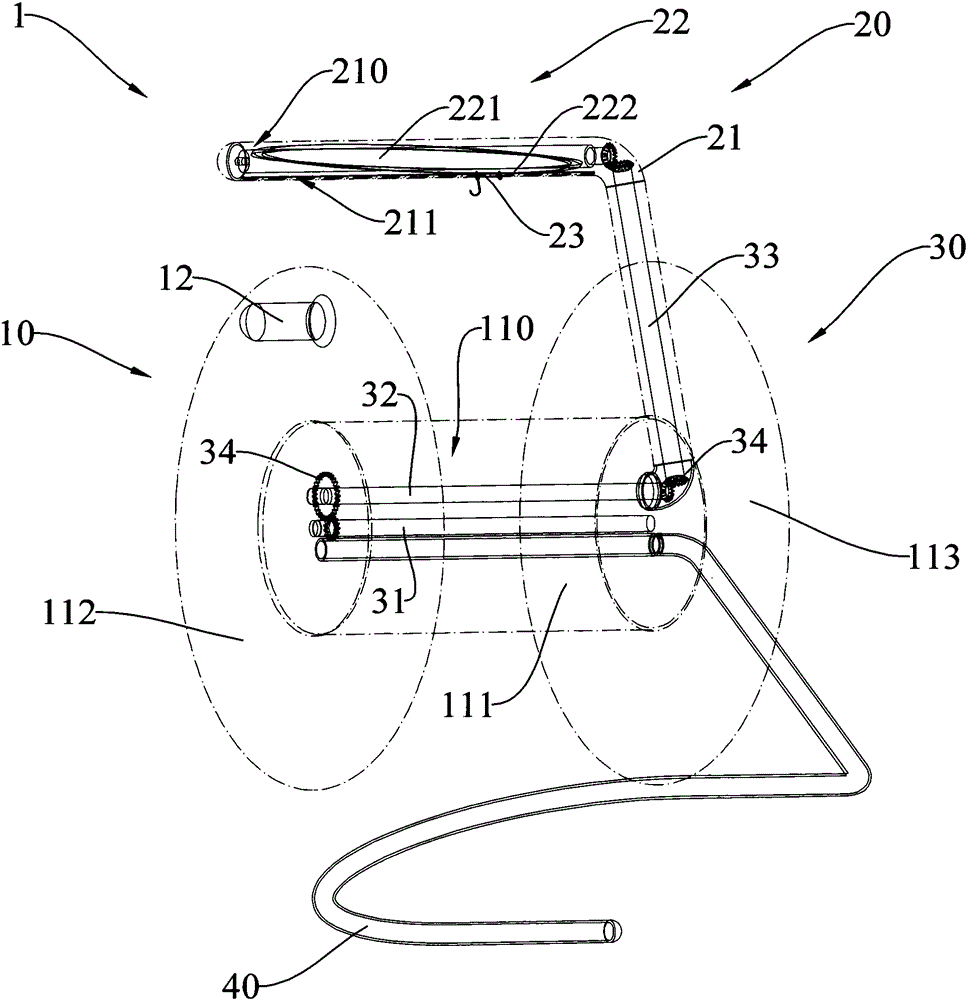

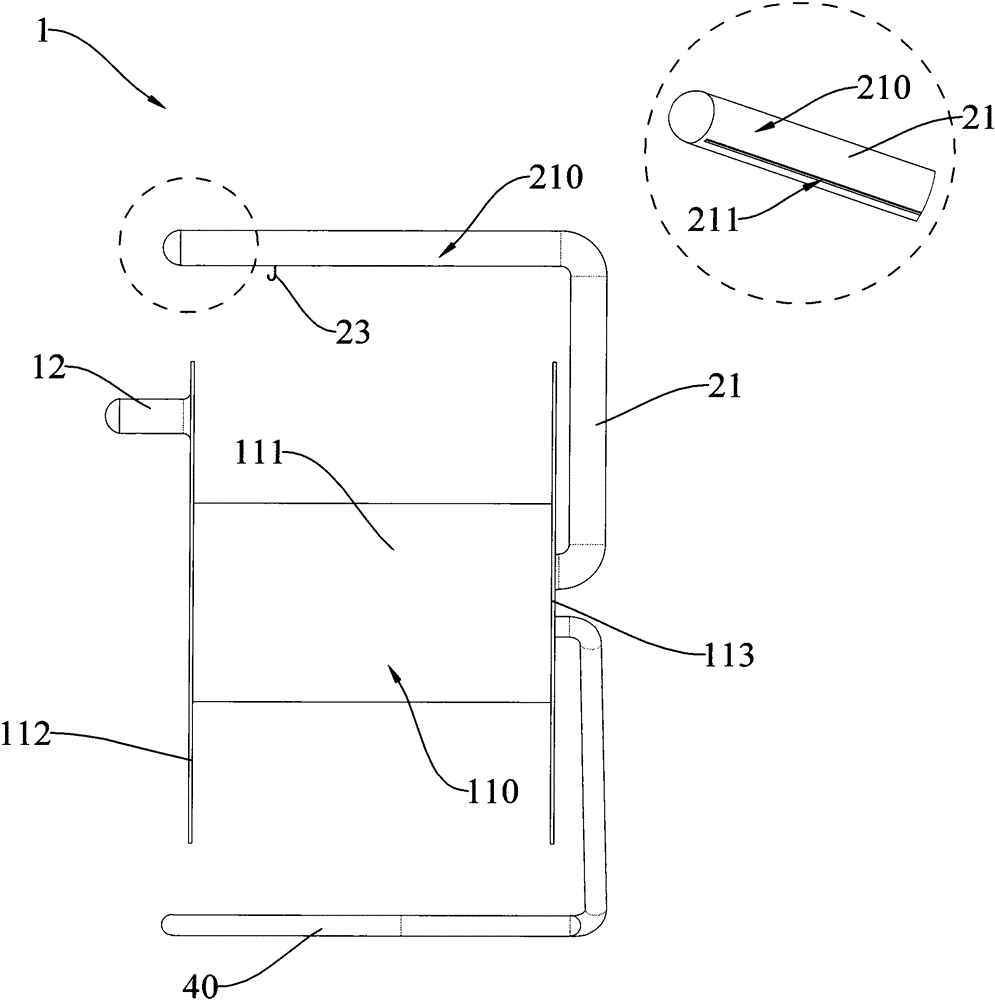

Novel winding device and use method thereof

ActiveCN105173926AReduce the difficulty of operationReduce manufacturing costFilament handlingConductor CoilMechanical engineering

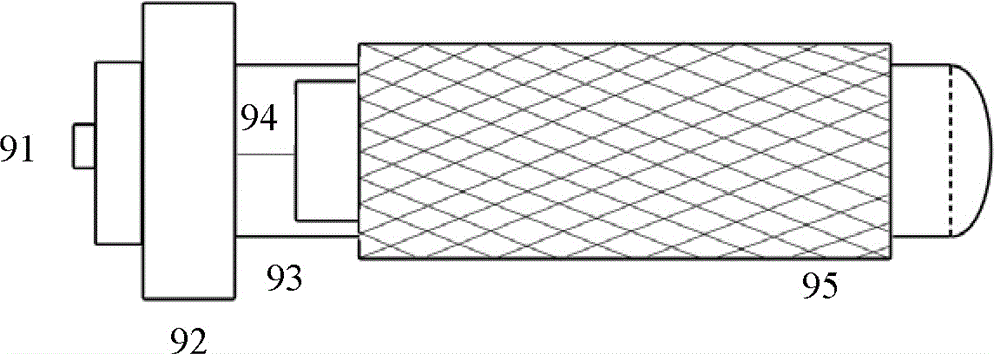

The invention discloses a novel winding device and a use method for the novel winding device. The winding device comprises a winding mechanism, a wire arranging mechanism, a guiding part and a sliding part. The winding mechanism comprises a winding pipe. The winding pipe comprises a winding pipe body, a movable side plate and a fixed side plate, wherein the winding pipe body can be rotationally jointed between the movable side plate and the fixed side plate. The wire arranging mechanism comprises a wire arranging pipe. The wire arranging pipe is provided with a wire arranging pipe cavity and a guiding groove, and the guiding groove is communicated with the wire arranging pipe cavity and the outside and downwards faces the winding pipe body. The guiding part is horizontally installed in the wire arranging pipe cavity. The guiding part comprises a guiding shaft and a protruding ridge part which protrudes out of the guiding shaft and integrally extends in a ring shape. A preset route is formed between the protruding ridge part and the guiding groove. The sliding part is reversely arranged in the guiding groove and extends towards the winding pipe body from the guiding part so as to be used for conducting reciprocating wire arranging. The two sides of the sliding part are transversely internally tangent to the inner side and the outer side of the protruding ridge part respectively so that the sliding part can slide along the preset route to conduct reciprocating wire arranging relative to the rotation of the winding pipe.

Owner:JUNHE PUMPS HLDG

Cellulose foam material and method for improving tensile strength of cellulose foam material

ActiveCN106008724AHigh tensile strengthImprove the scope of market applicationCellulose fiberNatural fiber

The invention provides a cellulose foam material. The tensile strength of the foam material is 0.30-1.60 MPa. The invention further provides a method for improving the tensile strength of the cellulose foam material. The method comprises an alkali processing step. The alkali processing step includes the sub-step that natural cellulose fibers are added to sodium hydroxide for treatment. The natural cellulose fibers are natural cotton and hemp fibers, and the length of the natural fibers is 10-70 mm. The prepared cellulose foam material is higher in tensile strength, and the tensile strength is up to 0.30-1.60 MPa and is far higher than the tensile strength of a foam material in the prior art, and the market application range of the foam material can be greatly widened. In the preparation process of the cellulose foam material, the raw materials are natural and biodegradable and have the environmentally friendly and environmental-pollution-free characteristics.

Owner:潍坊欣龙生物材料有限公司

High-performance alkenyl magnesium alloy material and preparation method thereof

The invention provides a high-performance alkenyl magnesium alloy material which mainly comprises the following components in percentage by mass: 5-8% of graphene substances, 1-2% of Co, 1-2% of Y, 4-7% of Al, 1-3% of Mn, 0.2-0.8% of Li, 0.2-1.0% of Zr, 0.1-0.5% of Ca, 0.1-0.5% of Zn, 0.2-1.0% of Cd, 0.3-0.7% of Yb, 0.3-0.7% of Ni, 0.1-1% of Sb, 0.1-1% of Mo and the balance Mg. A preparation method for the high-performance alkenyl magnesium alloy material comprises the following steps of: pre-heating pure magnesium metal, smelting the pure magnesium metal and other raw materials containing metal elements under protection of inert gases, and preserving the temperature after smelting; and increasing the temperature after preserving the temperature, adding graphene substance raw materials, standing after uniformly stirring, and filtering to obtain a crude magnesium alloy liquid. The alkenyl magnesium alloy material provided by the invention has relatively excellent performance indexes such as heat resistance, strength and hardness.

Owner:冯军 +1

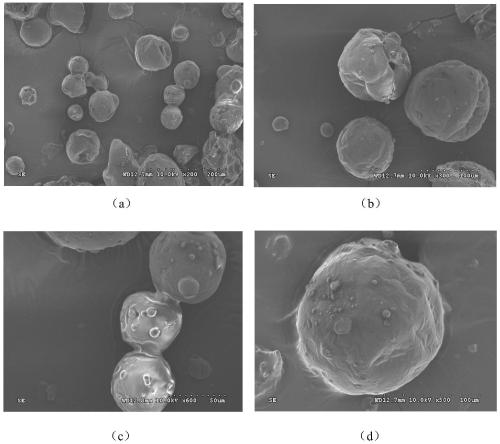

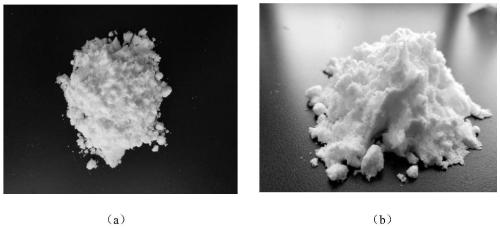

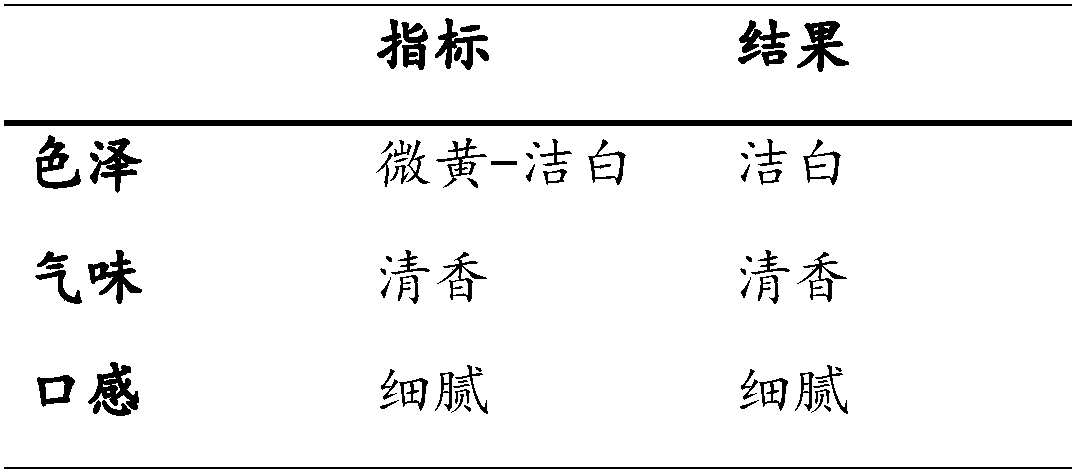

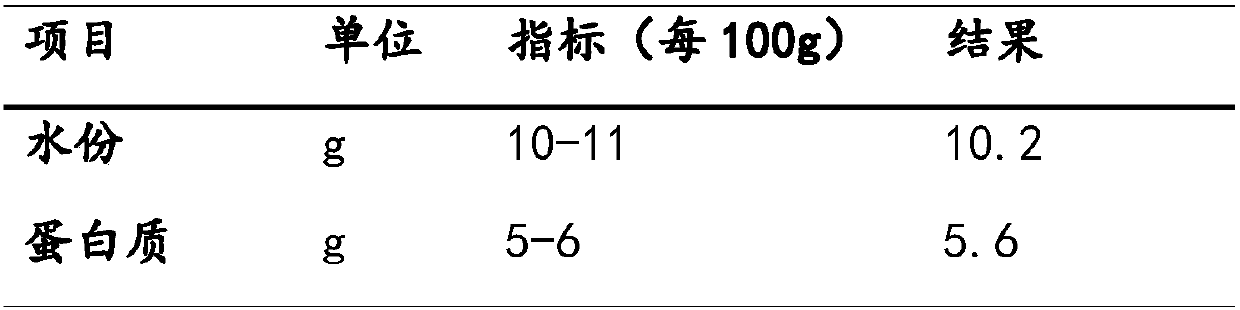

Preparation method of power coconut oil with coconut flavor

InactiveCN110205196AImprove solubilityNot cause discomfortFatty-oils/fats productionFresh coconutSlag

The invention relates to a preparation method of power coconut oil with coconut flavor, and belongs to the field of functional food processing. The method includes the following steps: 1) cleaning, crushing and squeezing fresh coconut pulp, and then carrying out filtration to remove slag to obtain coconut milk; 2) adding a color-protecting agent to the coconut milk, evenly mixing the color-protecting agent and the coconut milk to obtain original coconut milk, or carrying out centrifugal condensation or vacuum cryoconcentration to obtain concentrated coconut milk; 3) adding an emulsifier, a thickening agent, a dispersant and a sweetener into the original coconut milk or the concentrated coconut milk, and fully dissolving and evenly mixing the materials to obtain emulsified coconut milk; 4)sterilizing the emulsified coconut milk; 5) carrying out colloidal grinding on the sterilized emulsified coconut milk, and carrying out further homogenization and emulsification by using a homogenizer; and 6) freeze-drying or spray-drying the homogenized emulsified coconut milk to obtain the power coconut oil with coconut flavor. The power coconut oil prepared by the preparation method is good inembedding and regular in shape under microscopic conditions, has good fluidity, good instant dissolvement and high power yield, and can be directly brewed with water for drinking.

Owner:海南热作高科技研究院有限公司 +1

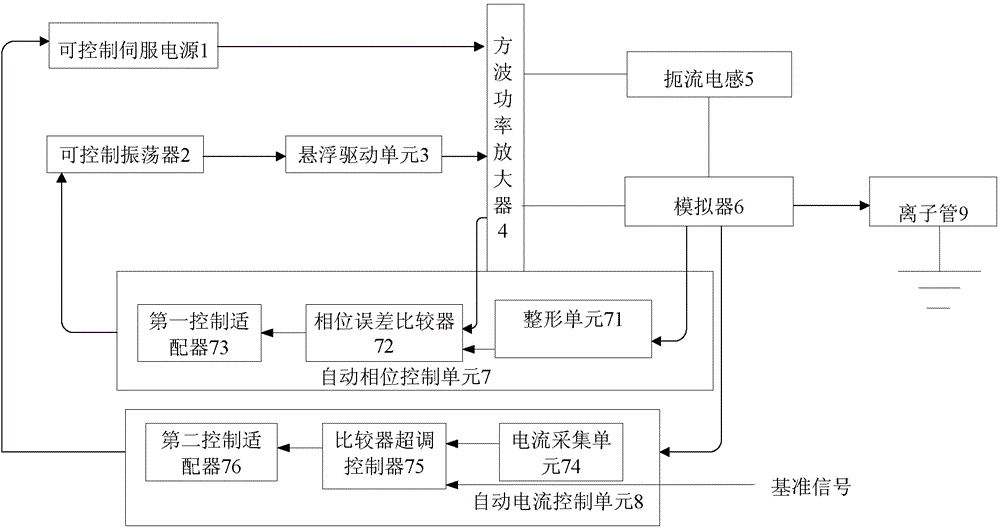

Large-air-volume low-voltage efficient plasma device and air-handling system thereof

InactiveCN104105328ARealize man-machine sharingCompact structureDispersed particle separationDeodrantsAir volumeLow voltage

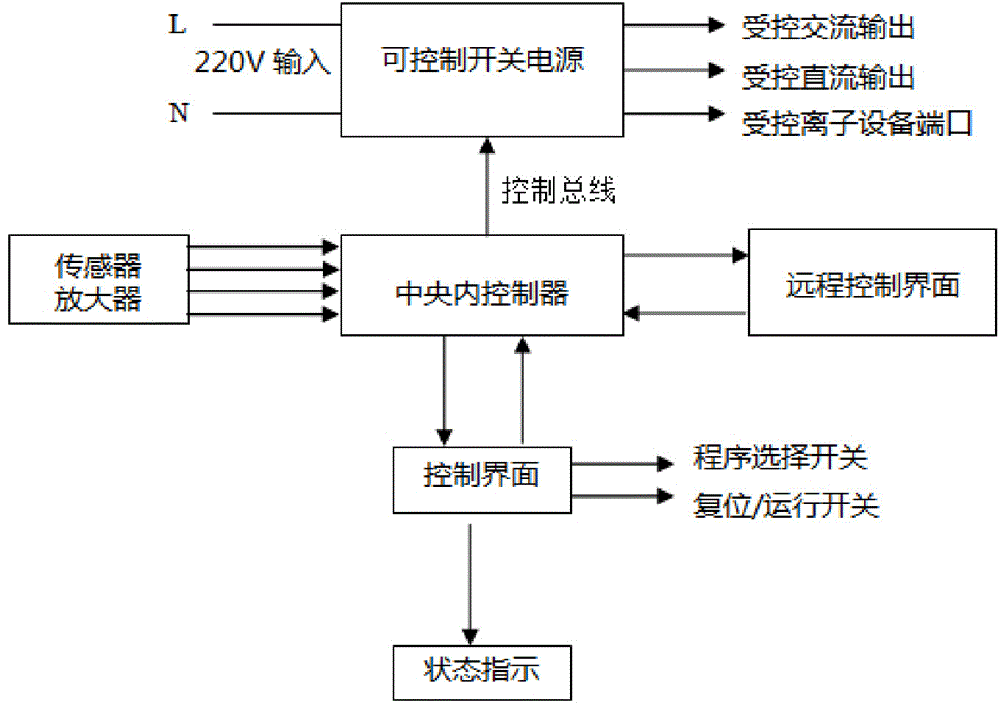

The invention discloses a large-air-volume low-voltage efficient plasma device and an air-handling system thereof. A controllable servo power supply is used for outputting direct current. A square wave power amplifier is respectively connected to the controllable servo power supply and a controllable square wave oscillator and used for generating alternating current square wave signals to be output according to signals output by the square wave power amplifier by utilizing direct current output by the controllable servo power supply. The input end of a simulator is in series connection with a choke flow inductor and then is connected between two output points of the square wave power amplifier in series, the output end of the simulator is connected with an ionic tube and used for converting alternating current square wave signals output by the square wave power amplifier into sine wave signals to be input to the ionic tube. An ionic device and the air-handling system produce about 21-30kHz sine wave signals to be input to the ionic tube, and the required working voltage is an effective value 1600V. The large-air-volume low-voltage efficient plasma device and the air-handling system have the advantages of being efficient in structure, low in energy consumption, low in maintenance cost, long in service life, convenient to use, safe, wide in application range and the like.

Owner:BEIJING INFINITY SKY ENVIRONMENTAL TECH

Feed for metal-powder injection molding and preparation method of feed

InactiveCN109047752ADeformableMeet strength requirementsTransportation and packagingMetal-working apparatusChromium carbidePolyoxymethylene

The invention discloses a feed for metal-powder injection molding and a preparation method of the feed. The feed consists of a forming agent and 316L stainless steel feed powder, wherein the mass ratio of the forming agent to the 316L stainless steel feed powder is 96:4-90:10; the 316L stainless steel feed powder comprises, by mass, 90%-99% of 316L stainless steel powder and 1%-10% of chromium carbide powder; and the forming agent comprises, by mass, 5%-10% of paraffin, 5%-10% of ethylene-acrylic acid copolymer, 5%-10% of polyethylene, 5%-10% of polyethylene glycol and 75%-80% of polyoxymethylene. If the feed is used in the MIM process as a feed of the MIM process, the feed can be processed to produce structural-member products required by various 3C electronic devices. Besides, the feed has a product performance of high hardness and quality.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Low-yield-ratio thin strip steel continuous casting and continuous rolling production line and production process

ActiveCN111589865ALengthen the distanceAvoid Surface Quality IssuesMetal rolling arrangementsProduction lineHigh pressure water

The invention belongs to the technical field of steel continuous casting and continuous rolling, and particularly discloses a low-yield-ratio thin strip steel continuous casting and continuous rollingproduction line and a production process. The production line comprises a continuous casting machine, a high-pressure water rough descaling device, a rough rolling unit, a swing shear, a waste blankpushing and stacking device, an emergency shear, an induction heating furnace, a high-pressure water fine descaling device, a finishing rolling unit, a high-speed flying shear and a coiling unit whichare sequentially arranged in the rolling direction. The production process comprises the steps of continuous casting blank forming, high-pressure water rough descaling, rough rolling, induction heating, high-pressure water fine descaling, finish rolling, high-speed flying shear coil dividing and coiling. According to the low-yield-ratio thin strip steel continuous casting and continuous rolling production line and the production process, by additionally arranging rough descaling, reducing the number of induction heating sets, lengthening the distance between finish rolling middle racks and shortening the distance between a finish rolling tail rack and a recoiling machine, production of thin strip steel with high surface quality and low yield ratio is achieved; and meanwhile, due to the fact that rolling line equipment is reduced and the length of the production line is shortened, the construction and operation investment cost of the production line can be reduced.

Owner:CISDI ENG CO LTD +1

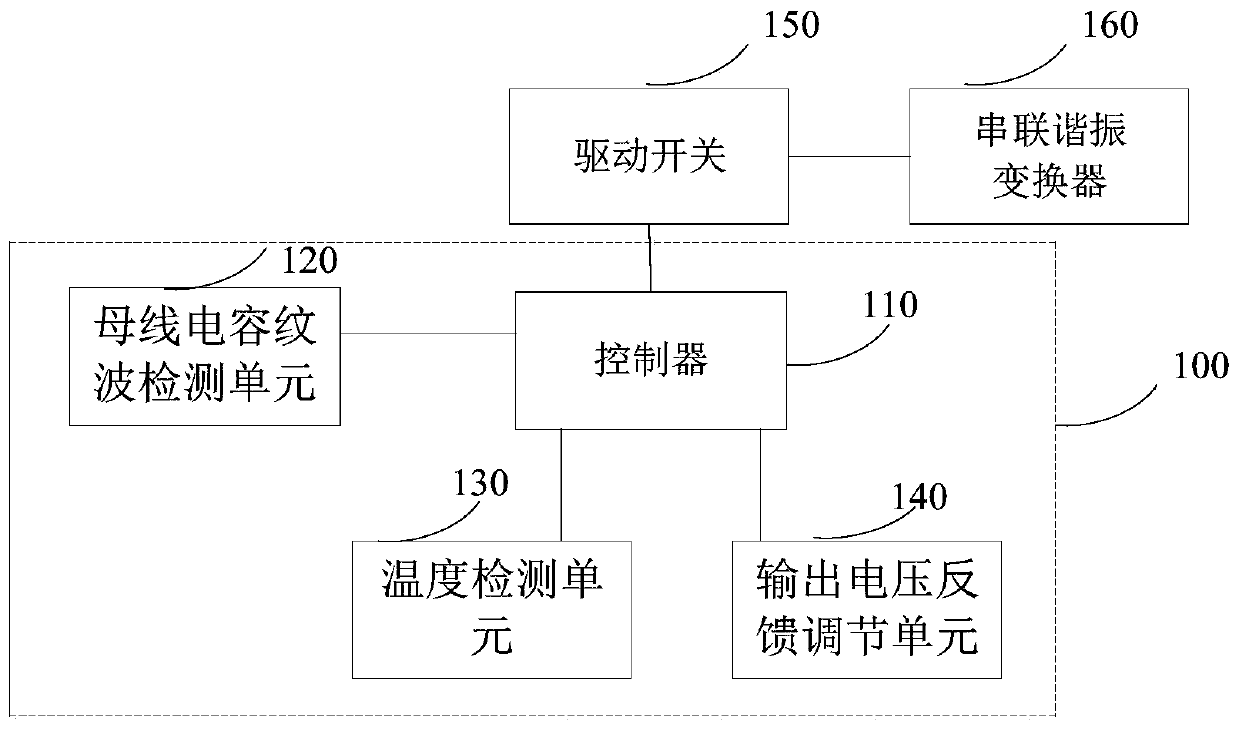

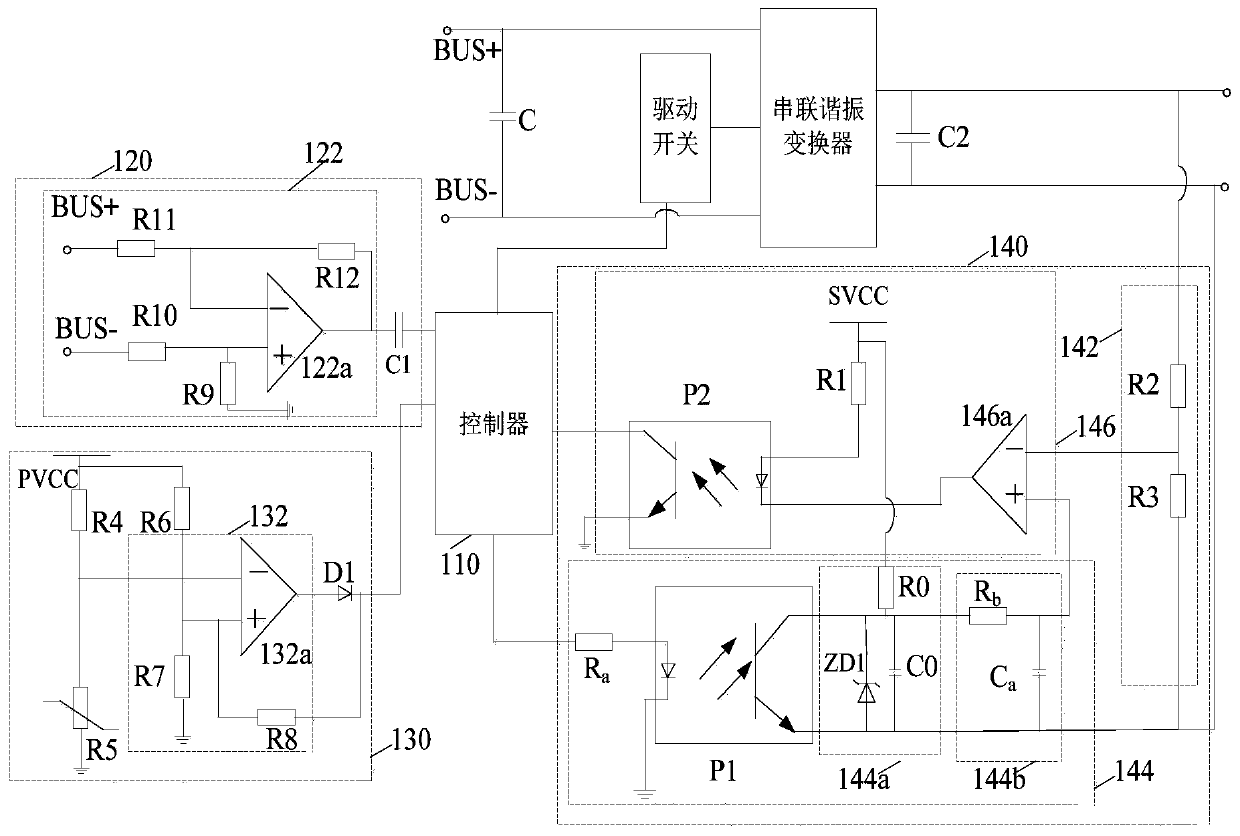

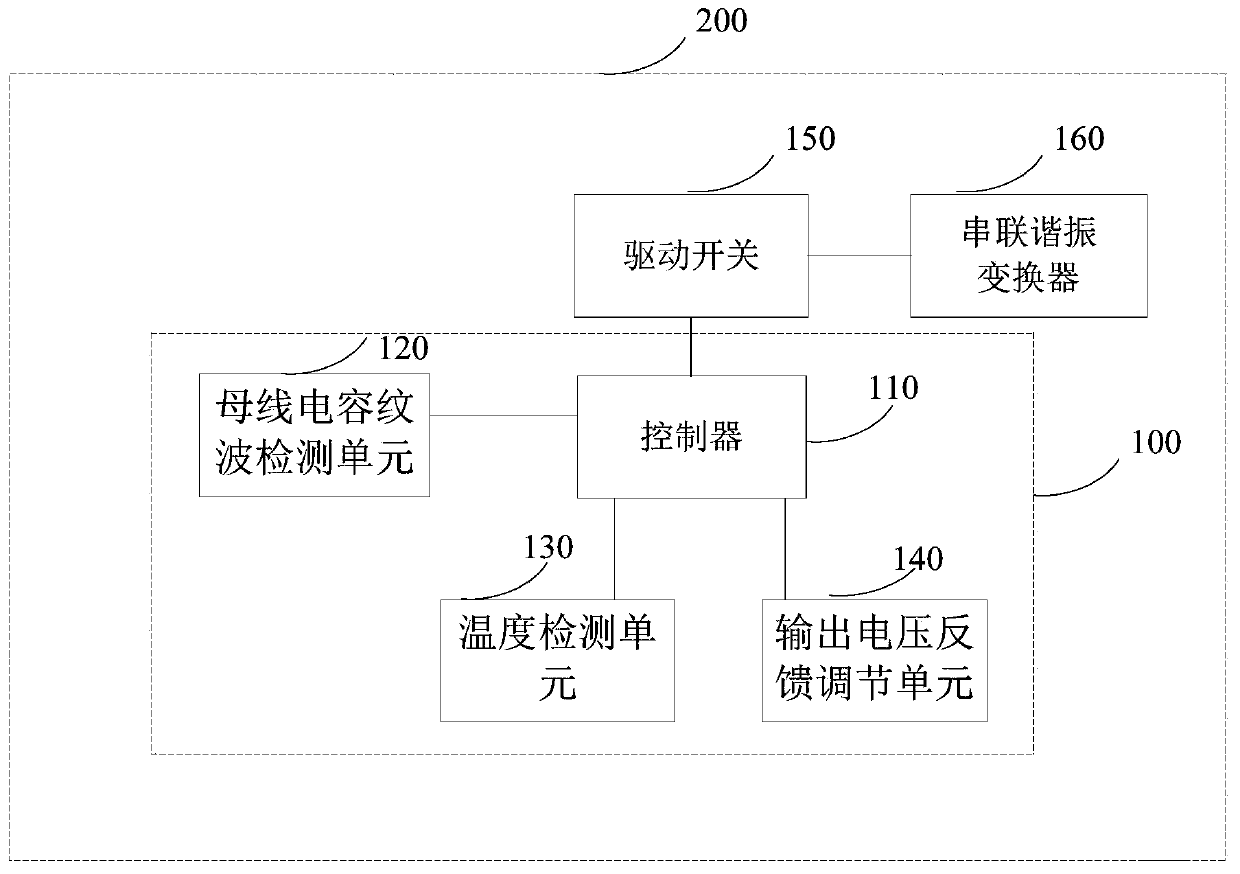

Starting circuit, series resonance conversion device and switching power supply

PendingCN111146935ALow costImprove low temperature performanceEfficient power electronics conversionPower conversion systemsCapacitanceResonant converter

The invention relates to a starting circuit, a series resonance conversion device and a switching power supply. The starting circuit comprises a controller; a bus capacitor ripple detection unit, a temperature detection unit and an output voltage feedback adjustment unit which are connected with the controller. The temperature detection unit is used for sending a temperature detection signal to the controller; the controller is used for controlling the temperature sensor to detect the ambient temperature when the temperature detection signal judges that the ambient temperature is lower than apreset temperature threshold; a corresponding control mode is set as a pulse width modulation mode; the output voltage feedback adjustment unit is used for generating a feedback adjustment signal andsending the feedback adjustment signal to the controller; the controller is also used for adjusting the duty ratio of the pulse width modulation signal according to the feedback adjustment signal; thebus capacitor ripple detection unit is used for generating ripple voltage detection signals and sending the ripple voltage detection signals to the controller, the controller is further used for adjusting a corresponding control mode into a frequency modulation mode when judging that the bus capacitor ripple voltage is smaller than a preset voltage threshold value, and the starting circuit improves the low-temperature working characteristic of the series resonant converter.

Owner:深圳市毂梁源技术有限公司

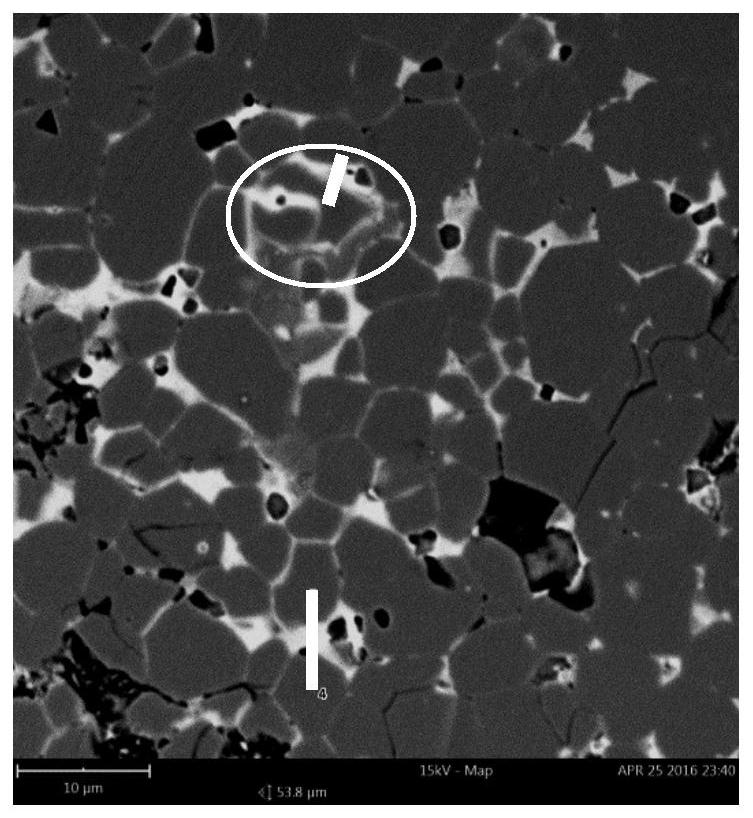

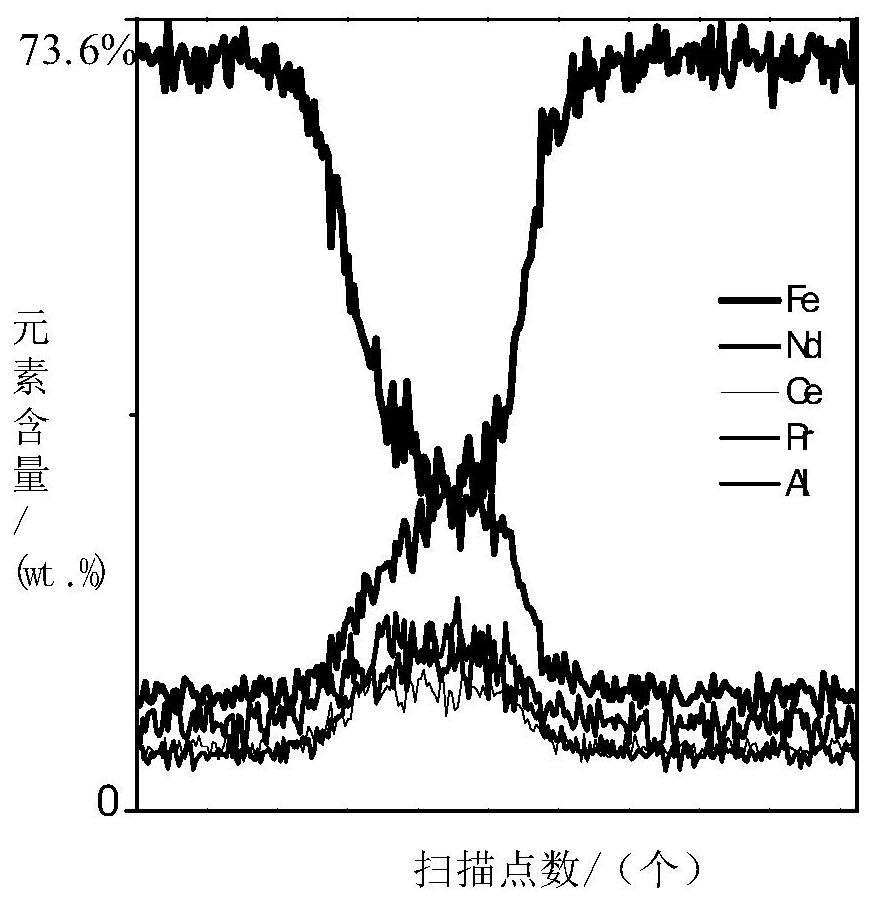

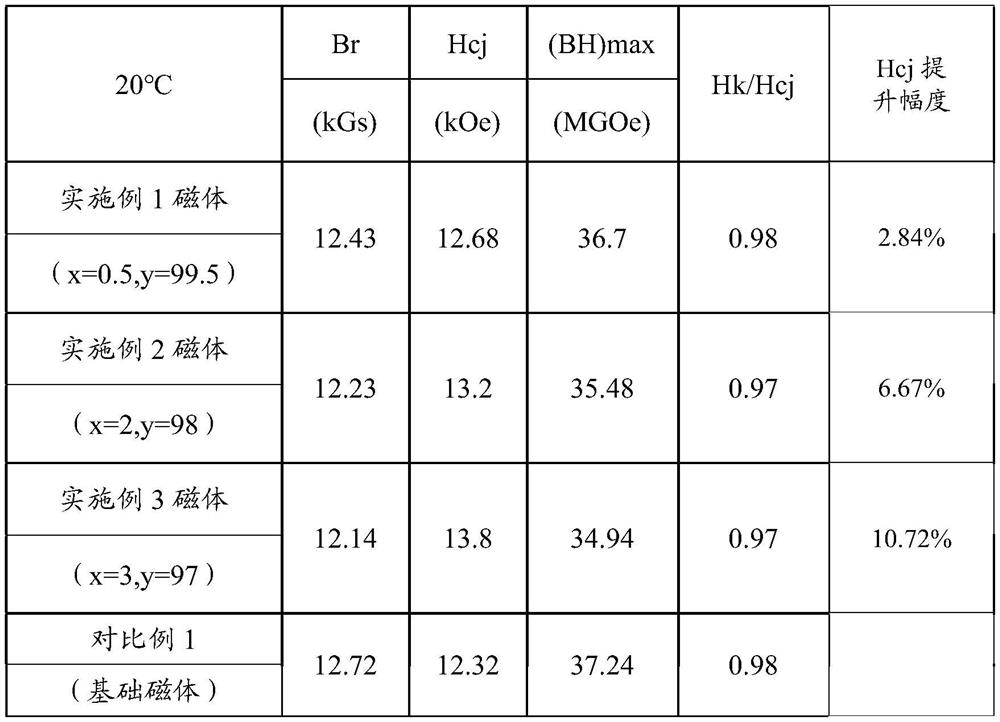

Low-cost heat-resistant sintered Ce-containing magnet containing Al magnetic hardening layer structure and preparation method

ActiveCN111952031AInhibit entryImprove thermal stabilityInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementRemanence

The invention relates to a low-cost heat-resistant sintered Ce-containing magnet containing an Al magnetic hardening layer structure and a preparation method thereof. The permanent magnet comprises the following chemical components by weight percentage of [(PraNdb) cAld]x{[(PraNdb) eCef]g(Fe100-k, TMk)hBi}y, wherein 0 <= a <= 30, 70 <= b <= 100, 10 <= d <= 20, c+d=100; 26 <= f <= 32, and e+f =100;g is greater than or equal to 29.5 and less than or equal to 30.5, i is greater than or equal to 0.92 and less than or equal to 1.05, and the sum of g, h and i is equal to 100; 80 <= kh <= 200; x ismore than or equal to 0.5 and less than or equal to 3, and the sum of x and y is equal to 100; TM is one or more of Cu, Al, Nb, Zr, Ag and Co, and does not contain any heavy rare earth element or gallium element. The microstructure of the permanent magnet comprises a permanent magnet main phase, an Al-containing main phase epitaxial magnetic hardening thin layer and a white rare-earth-rich phase with the Fe weight percentage smaller than 40%. The Al-containing main phase epitaxial magnetic hardening thin layer and the permanent magnet main phase form a double-main-phase structure, so that a large amount of Al is prevented from entering the permanent magnet main phase. According to the method, the coercive force can be obviously improved, the thermal stability is obviously improved, the Curie temperature is hardly reduced, and the residual magnetism is not obviously reduced.

Owner:CENT IRON & STEEL RES INST +1

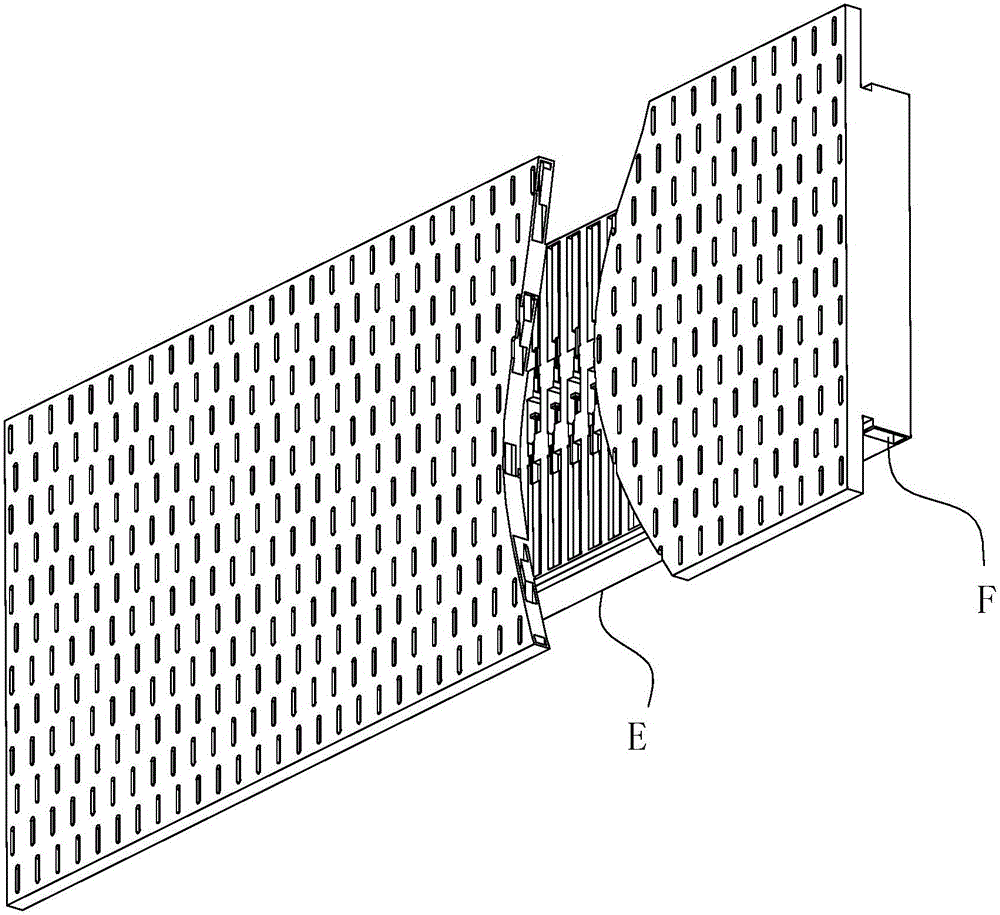

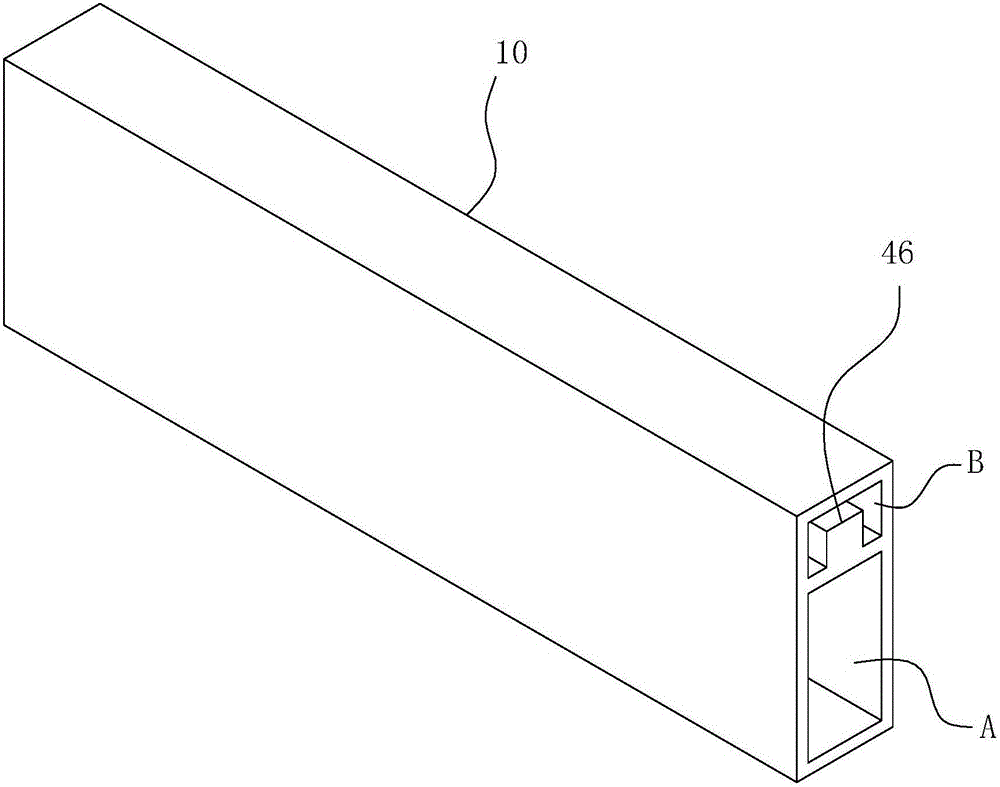

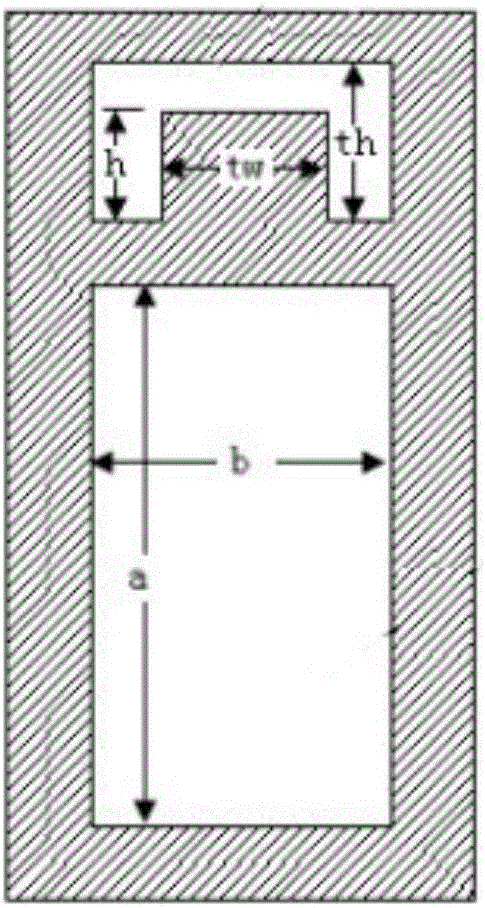

Feeding structure for waveguide slot frequency scanning antenna

ActiveCN105789914AReduce lossImprove work efficiencyAntenna arraysSlot antennasWaveguideAntenna array

The invention belongs to the technical field of panel antennae, and particularly relates to a feeding structure for a waveguide slot frequency scanning antenna. The feeding structure comprises a tube wall member. A transverse baffle plate is configured in the tube chamber of the tube wall member, thereby forming a double-layer chamber wall structure in which the upper layer is a ridge waveguide layer and the lower layer is a rectangular waveguide layer. A metal diaphragm is configured in the rectangular waveguide layer. The top wall of the rectangular waveguide layer is provided with a coupling window. The ridge waveguide layer is composed of a left ridge waveguide layer and a right ridge waveguide layer which are configured in axis symmetry. In the signal advancing path of the wedge waveguide layer, the side wall of the left ridge waveguide and the side wall of the right ridge waveguide respectively have a five-segment stepped chamber structure. The ridge waveguide further comprises ridge blocks and foreign-shaped branches. The feeding structure has advantages of more compact and smaller structure, and lower working loss. Furthermore purposes of horizontal polarization characteristic conversion and vertical polarization characteristic conversion are realized according to the requirement. Overall efficiency and application range of an antenna array can be further improved.

Owner:ANHUI SUN CREATE ELECTRONICS

Finger millet starch extraction process and application thereof

The invention discloses a finger millet starch extraction process and application thereof. The finger millet starch extraction process comprises the steps of rinsing, soaking, defibrination, filtering, sedimentation, freezing, unfreezing, die-filling and drying to obtain the product. According to the finger millet starch extraction process disclosed by the invention, relatively coarse and moistureless quality and taste of finger millet are improved, and the application domain is widened while the taste of finger millet is improved.

Owner:肖前祝

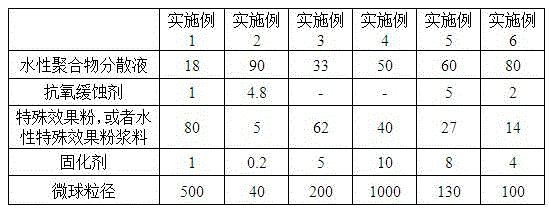

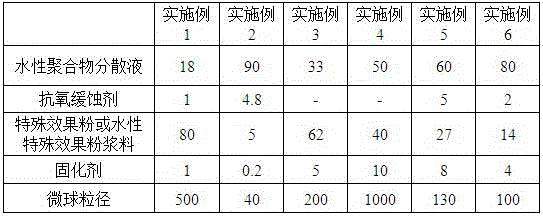

Spraying-free PVC composition having special aesthetic effects and preparation method and application thereof

The invention discloses a spraying-free PVC composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free PVC composition comprises the following components: 70-98 wt% of PVC resin, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the PVC resin, so that the compatibility of the special-effect powder and the PVC resin can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free PVC composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

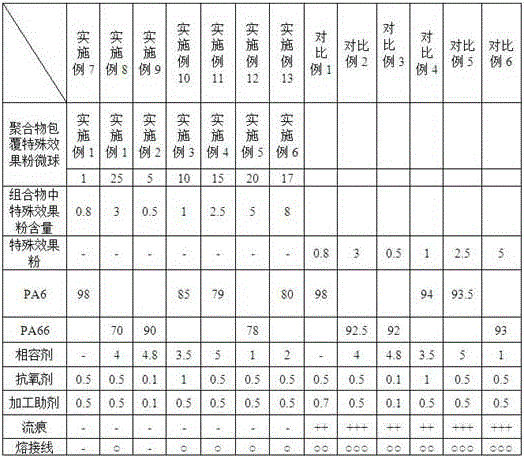

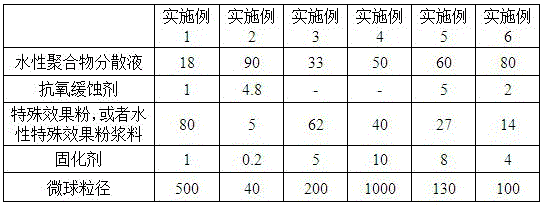

Spray-free nylon resin composition with special aesthetic effect and its preparation method and application

The invention discloses a spraying-free nylon resin composition with special aesthetic effect and a preparation method and application thereof. The composition comprises the following components: 70-98 wt% of nylon resin, 1-25 wt% of polymer coated powder microspheres with special effect, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant and 0.1-0.5 wt% of a processing aid. The powder with special effect coats with an aqueous polymer dispersion liquid to form microspheres which are then dispersed into nylon resin, so as to significantly improve the compatibility of the powder with special effect and nylon resin, and eliminate the flow mark formed on the surface of products in the extrusion or injection molding process and reduce the weld line. The prepared spraying-free nylon resin composition has aesthetic effects of obvious metal texture and pearly flashing, and greatly improves the scope of market application of spraying-free materials.

Owner:KINGFA SCI & TECH CO LTD

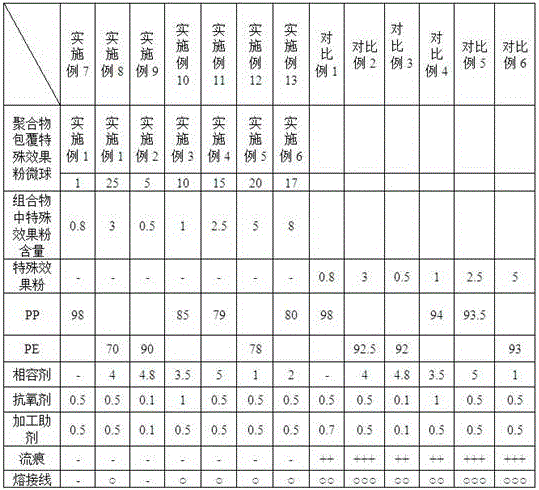

Spray-free polyolefin composition with special aesthetic effect and its preparation method and application

Owner:KINGFA SCI & TECH CO LTD

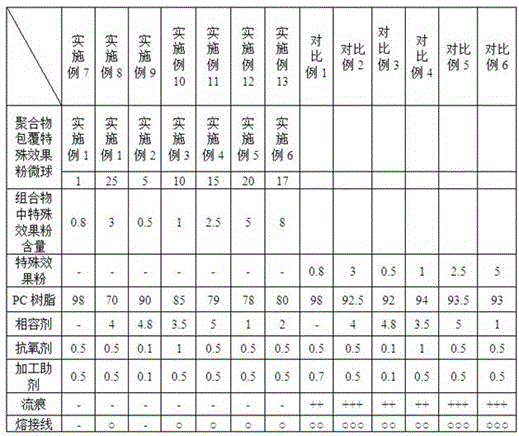

Spray-free PC composition with special aesthetic effect and its preparation method and application

The invention discloses a spray-free PC composition with special aesthetic effects and its preparation method and application, comprising the following components: PC 70-98wt%; polymer-coated special effect powder microspheres 1-25wt%; compatible Antioxidant 0-10wt%; Antioxidant 0.1-1wt%; Processing aid 0.1-0.5wt%; The present invention can be obviously Improve the compatibility of special effect powder and PC, eliminate the flow mark formed on the surface of the product during extrusion or injection molding, and reduce the weld line. The aesthetic effect greatly improves the market application range of spray-free materials.

Owner:KINGFA SCI & TECH CO LTD

Light-resistant and washing-resistant building interior and exterior wall glaze and preparation method thereof

PendingCN113845785AGood light fastnessImprove washing resistanceRadiation-absorbing paintsEmulsionGlaze

The invention discloses a light-resistant and washing-resistant building interior and exterior wall glaze and a preparation method thereof. The light-resistant and washing-resistant building interior and exterior wall glaze at least comprises the following raw materials in percentage by mass: 10-15% of cationic emulsion, 5-15% of sol colloid, 5-10% of modified nanoparticles, 30-50% of mineral salt, 1-5% of auxiliaries and the balance of deionized water. The prepared wall glaze has good light resistance, water resistance and cleaning performance, effectively reduces the content of formaldehyde and other harmful gases, is suitable for being popularized in the field of wall coatings, and has wide development prospects.

Owner:罗翠莲

Purple yam tea and preparation method thereof

InactiveCN109497237AImprove the scope of market applicationRich varietyTea substituesBetacyaninsAfter treatment

The invention provides a preparation method of purple yam tea for overcoming defects in the prior art. The preparation method comprises the following steps: S1, picking fresh purple yams and performing pretreatment; S2, cooking the completely pretreated purple yams in the S1 so as to obtain cooked purple yams; S3, baking the cooked purple yams obtained in the S2 so as to obtain backed purple yams;S4, performing after-treatment on the cooked purple yams in the S3, so as to obtain the purple yam tea. According to the preparation method disclosed by the invention, the purple yam is prepared intopurple yam tea serving as substitutional tea, types of purple yam deep processing products are enriched, new selections are provided for more consumers, and the market application range of the purpleyam is widened. Moreover, the nutritional ingredients, particularly anthocyanin, in the purple yam can be effectively remained. The nutritional ingredients can be gradually released in the later soaking and eating processes.

Owner:麻栗坡县地力利农业科技开发有限公司

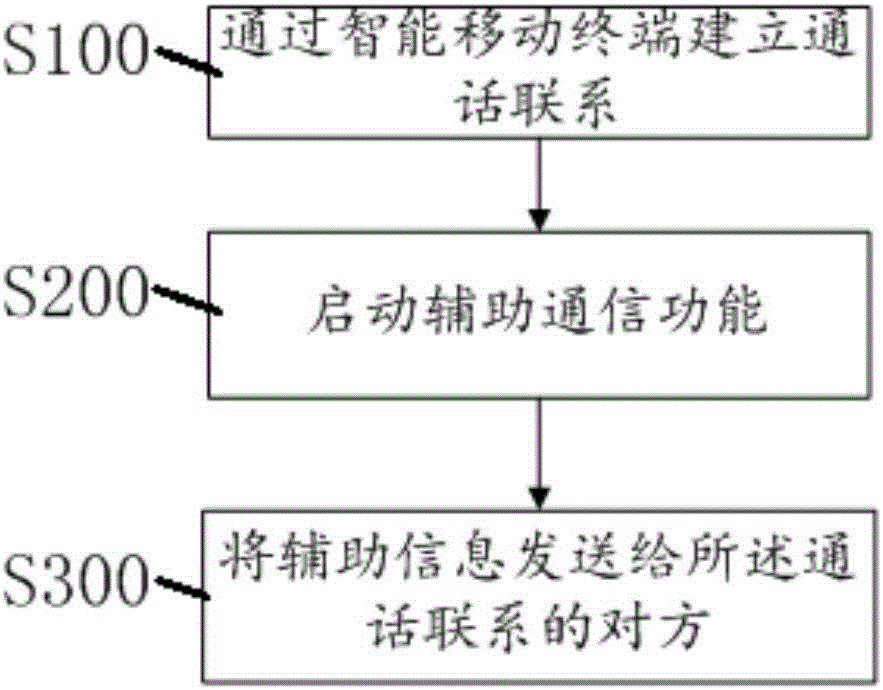

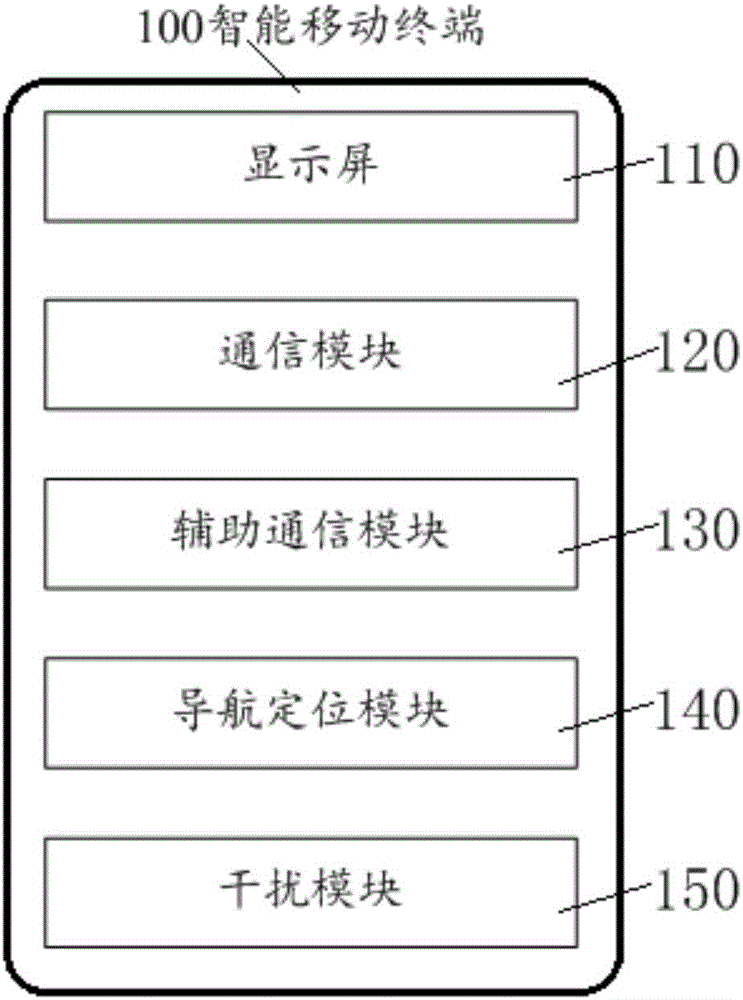

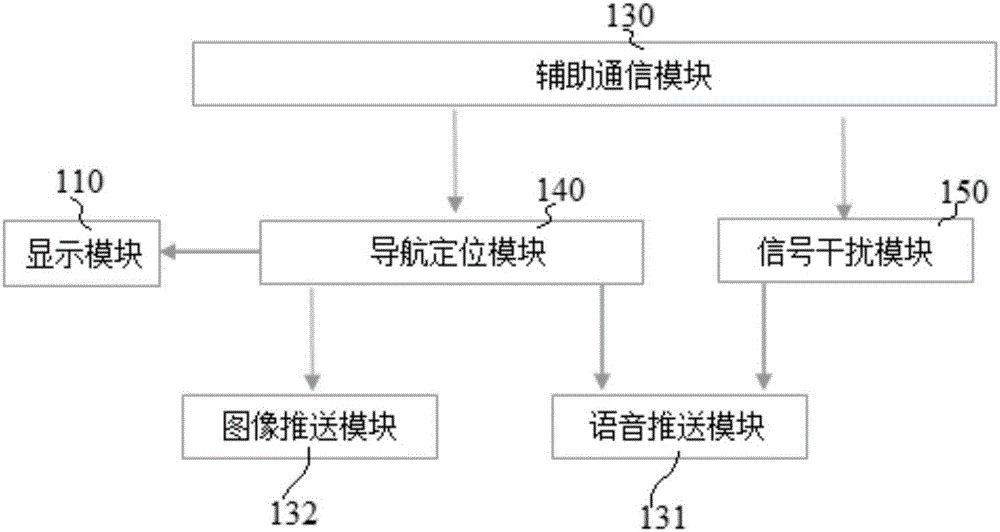

Intelligent mobile terminal and method thereof of sending information in call

InactiveCN106791019AEasy to findEasy to useSubstation equipmentComputer hardwareInterference (communication)

The present invention provides an intelligent mobile terminal and a method thereof of sending information, relating to the technical field of communications and particularly relating to an auxiliary communications technology. The intelligent mobile terminal discloses in the present invention at least comprises a display screen, a communications module, an auxiliary communications module, a navigation positioning module, and an interference module. The communications module is used for communications interaction. The navigation positioning module is used for acquiring latitude and longitude information of the intelligent mobile terminal, and generating a positioning map. The interference module is used for interfering with the communications module working normally. The auxiliary communications module is used for sending the positioning map or noise to an object performing communication interaction with the communications module. The display screen is used for displaying an auxiliary function button when the communications module works normally.

Owner:PHICOMM (SHANGHAI) CO LTD

Extruded polystyrene board composite heat insulation wallboard

InactiveCN102995823AGood heat insulationImprove insulation effectBuilding componentsWater-setting substance layered productPolystyreneUltimate tensile strength

The invention discloses an extruded polystyrene board composite heat insulation wallboard which is characterized by comprising an extruded polystyrene board layer, a fiber cement compression plate layer and an adhesive layer arranged between the extruded polystyrene board layer and the fiber cement compression plate layer. The extruded polystyrene board composite heat insulation wallboard disclosed by the invention has a good heat insulation effect; and by adding the fiber cement compression plate layer, excellent strength and stretching resistance are obtained, and the market application range of the extruded polystyrene board composite heat insulation wallboard is greatly expanded.

Owner:SUZHOU KEXIN ZHEYANG NEW MATERIAL TECH

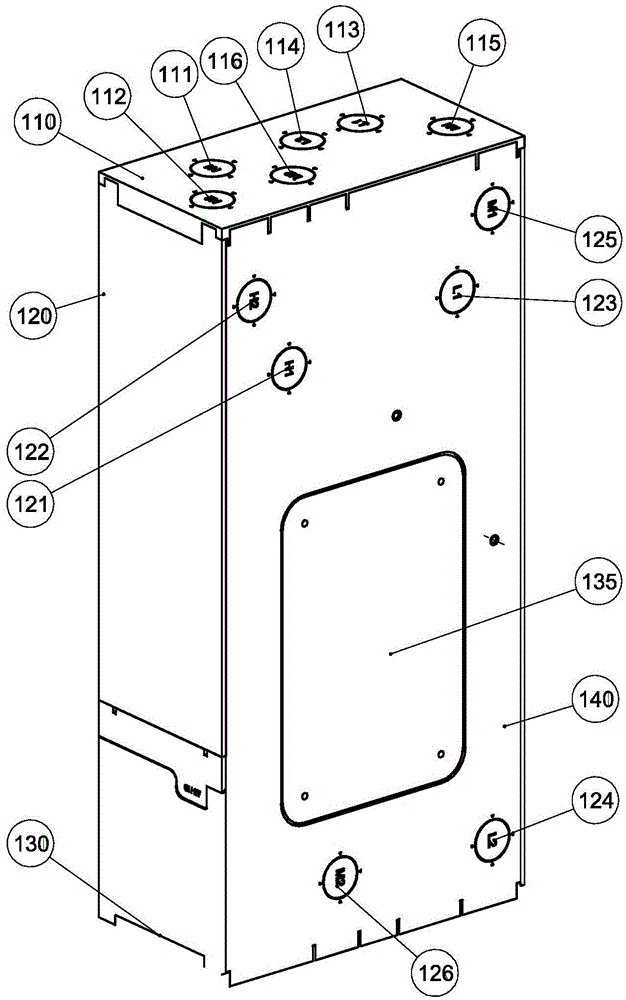

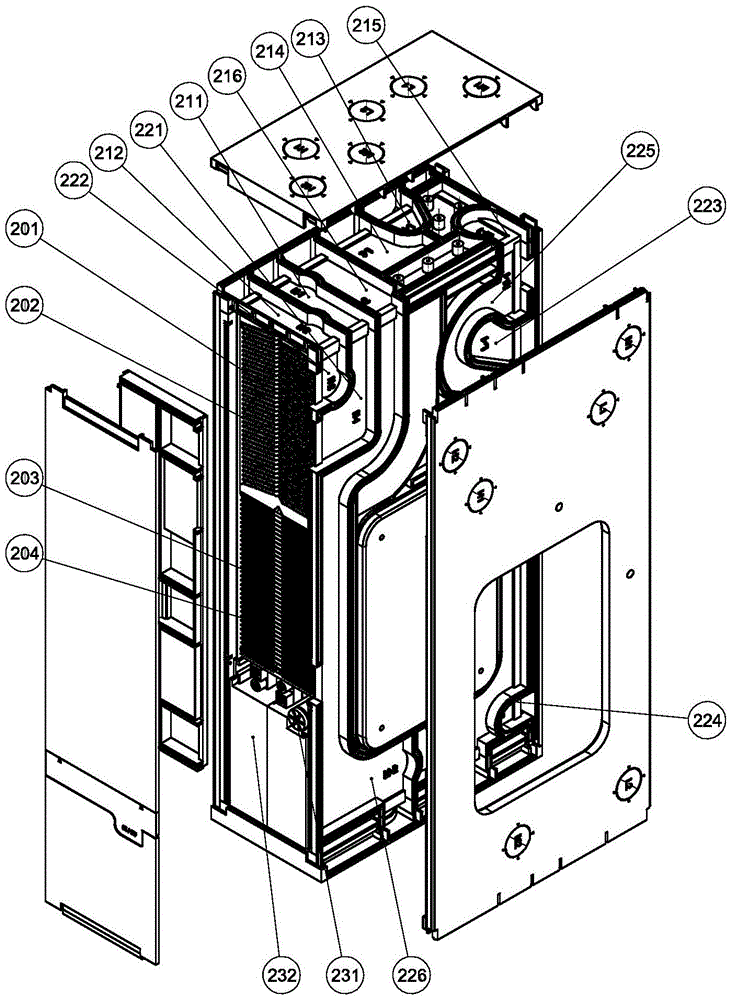

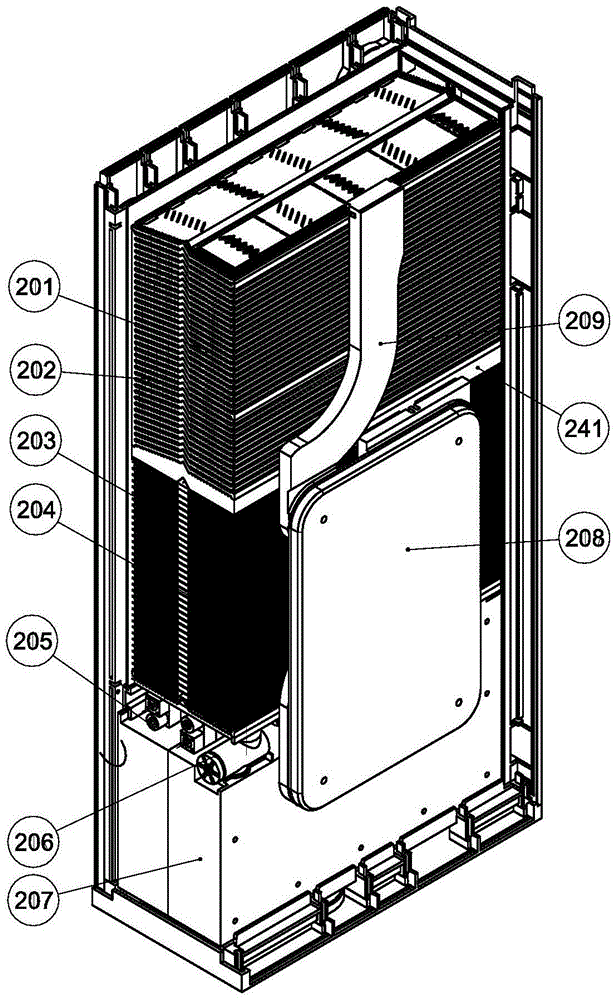

Unit combined refrigerating matrix

ActiveCN106802013ABig market demandGuarantee product qualityClimate change adaptationEnergy efficient heating/coolingProcess engineeringRefrigerated temperature

Owner:SICHUAN JIEYUAN TECH CO LTD

A kind of cellulose foam material and the method for improving the tensile strength of cellulose foam material

ActiveCN106008724BHigh tensile strengthImprove the scope of market applicationPolymer scienceCellulose fiber

The invention provides a cellulose foam material. The tensile strength of the foam material is 0.30-1.60 MPa. The invention further provides a method for improving the tensile strength of the cellulose foam material. The method comprises an alkali processing step. The alkali processing step includes the sub-step that natural cellulose fibers are added to sodium hydroxide for treatment. The natural cellulose fibers are natural cotton and hemp fibers, and the length of the natural fibers is 10-70 mm. The prepared cellulose foam material is higher in tensile strength, and the tensile strength is up to 0.30-1.60 MPa and is far higher than the tensile strength of a foam material in the prior art, and the market application range of the foam material can be greatly widened. In the preparation process of the cellulose foam material, the raw materials are natural and biodegradable and have the environmentally friendly and environmental-pollution-free characteristics.

Owner:潍坊欣龙生物材料有限公司

Spraying-free PPO resin composition having special aesthetic effects and preparation method and application thereof

The invention discloses a spraying-free PPO resin composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free PPO resin composition comprises the following components: 70-98 wt% of PPO resin, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the PPO resin, so that the compatibility of the special-effect powder and the PPO resin can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free PPO resin composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:KINGFA SCI & TECH CO LTD

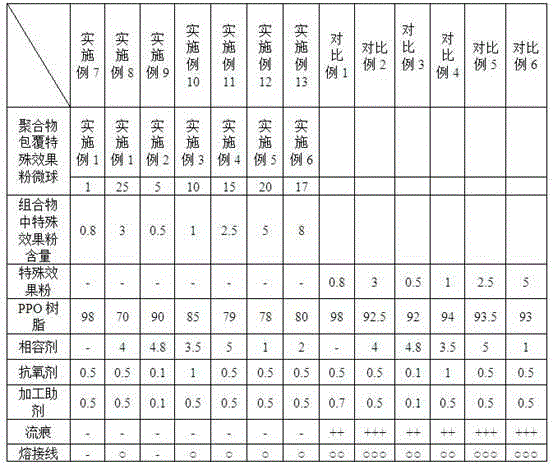

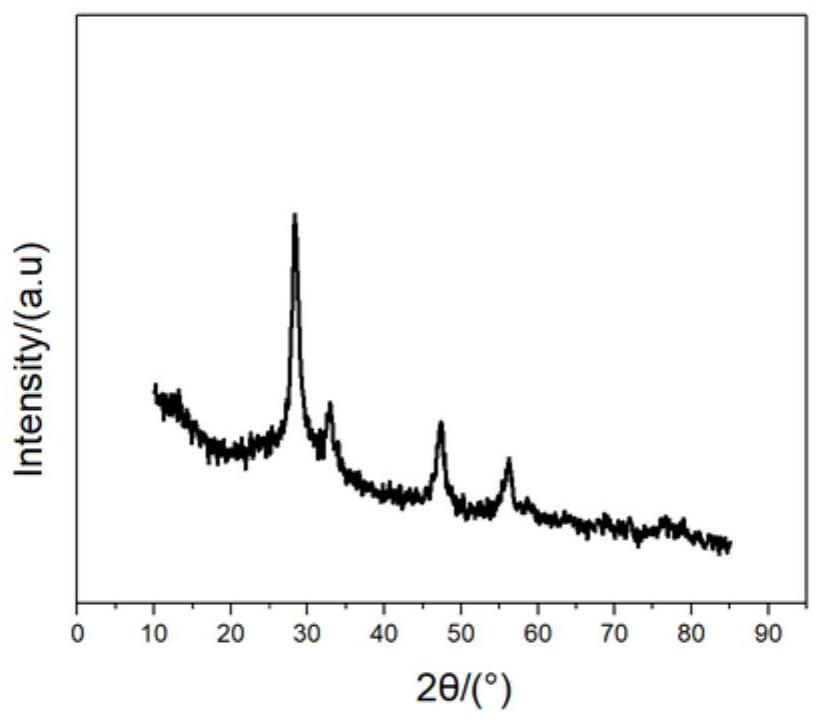

CeO2 nanorod-based urine glucose test paper and preparation method thereof

PendingCN113267492AHigh detection sensitivitySimple preparation stepsMaterial analysis by observing effect on chemical indicatorConcentrations glucosePhysical chemistry

The invention discloses CeO2 nanorod-based urine glucose test paper and a preparation method thereof. The preparation method comprises the steps: firstly, mixing cerium salt and inorganic base, and then fully stirring the mixture, forming white suspension liquid, and then moving thewhite suspension liquid into a high-pressure reaction kettle, and carrying out a hydrothermal reaction in a drying oven; removing the supernatant, washing the precipitate to be neutral, and drying the precipitate to obtain a CeO2 nanorod; mixing the CeO2 nanorod with a color developing agent and glucose oxidase in proportion to prepare a solution, immersing blank test paper into the solution, taking out the test paper, and drying the test paper to obtain the CeO2 nanorod-based urine glucose test paper. The test paper can develop after being placed in an environment containing glucose with different concentrations and taken out, the color is light in a low-concentration stage, the color of the test paper is gradually deepened in a gradient manner along with the deepening of the glucose concentration, the different stages are obviously distinguished, and the detection sensitivity is high; according to the invention, the limitation of the application field of the CeO2 nano material is broken through, and the market application range of the CeO2 nano material is further widened.

Owner:NANJING UNIV OF POSTS & TELECOMM

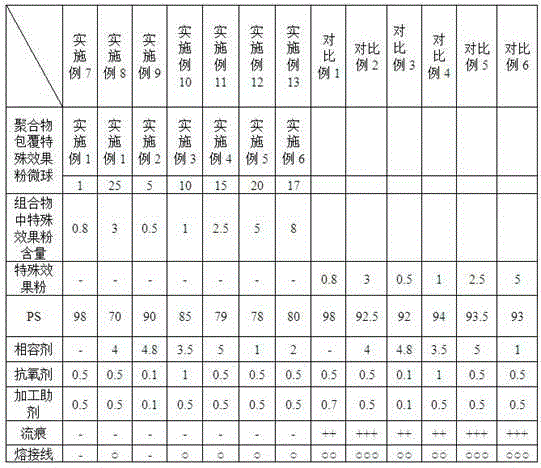

Spraying-free PS composition having special aesthetic effects and preparation method and application thereof

The invention discloses a spraying-free PS composition having special aesthetic effects and a preparation method and an application thereof. The spraying-free PS composition comprises the following components: 70-98 wt% of PS resin, 1-25 wt% of microspheres formed by coating a special-effect powder with a polymer, 0-10 wt% of a compatibilizer, 0.1-1 wt% of an antioxidant, and 0.1-0.5 wt% of a processing auxiliary agent. The special-effect powder is coated with a water-based polymer dispersion liquid to form the microspheres, and then the microspheres are dispersed to the PS resin, so that the compatibility of the special-effect powder and the PS resin can be significantly improved, flow marks formed on the surface of products in an extrusion or injection molding process are eliminated, and weld lines are reduced; and the prepared spraying-free PS composition has relatively obvious metal texture, pearly flashing effects and other special aesthetic effects, and the market application range of spraying-free materials is greatly improved.

Owner:TIANJIN KINGFA NEW MATERIAL

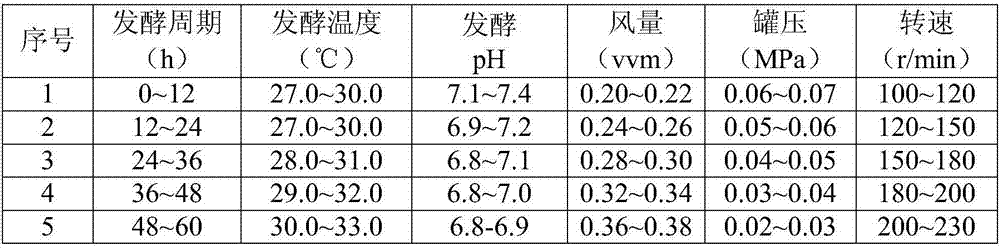

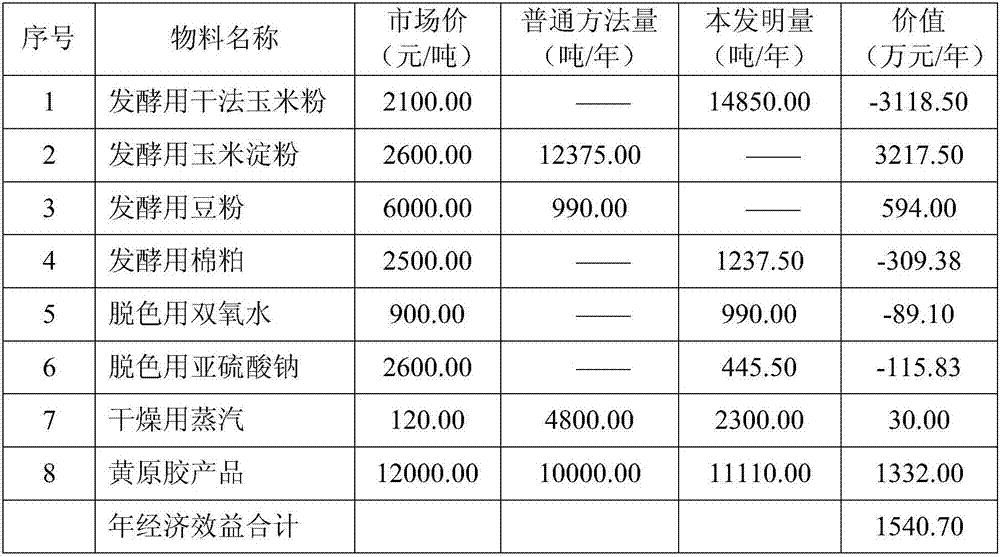

Production method of low-cost and high-quality xanthan gum

ActiveCN107287260AReduce manufacturing costHigh whitenessBacteriaMicroorganism based processesChemistryCulture mediums

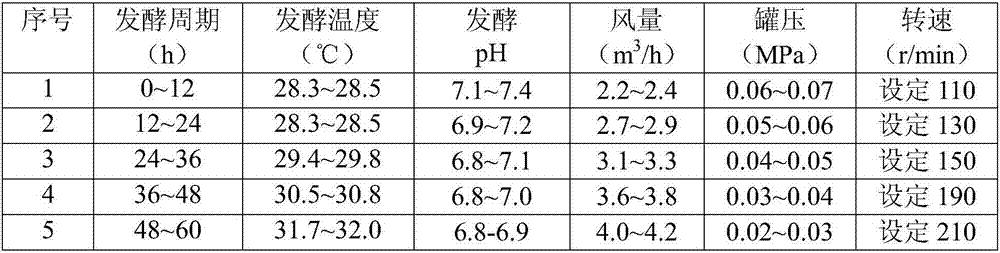

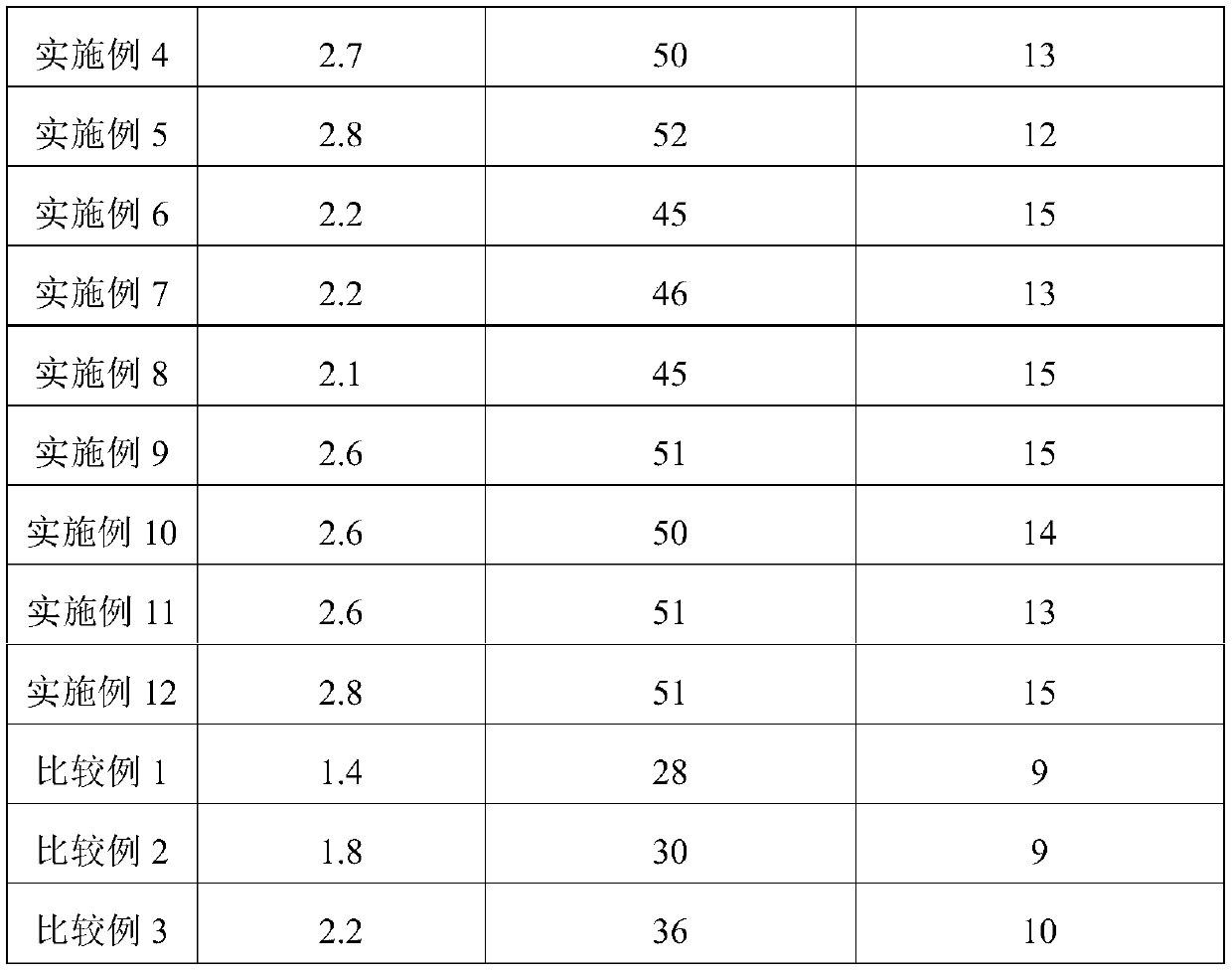

The invention provides a production method of low-cost and high-quality xanthan gum. The method comprises the following steps of using a fermentation culture medium using dry process corn powder as major raw materials; using Xanthomonas arboricola for fermentation to prepare fermentation liquid; obtaining xanthan gum by using a fermentation liquid post treatment step, wherein through being metered by 100 percent of the total volume of the fermentation culture medium, the fermentation culture medium comprises 4 to 7 percent of the dry process corn powder according to the mass volume ratio; the mass volume ratio has the unit of Kg / L. In addition, the fermentation culture medium for producing xanthan gum through Xanthomonas arboricola fermentation provided by the invention comprises the major raw materials of dry process corn powder. Through the replacement of the fermentation raw materials; the production cost of the xanthan gum is reduced.

Owner:新疆梅花氨基酸有限责任公司

High-performance graphene composite polyvinyl alcohol fiber and its preparation method and application

ActiveCN106835326BKeep the active ingredients intactClosely connectedElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolyvinyl acetate

The invention provides a preparation method of a high-performance graphene composite polyvinyl alcohol fiber. The preparation method comprises the following steps of pretreating a graphene substance water solution to obtain a graphene substance graded water solution, wherein a D90 index of a graphene substance is controlled to be 70mu m or lower; mixing and stirring a PVA (Polyvinyl Acetate) water solution, boric acid and the graphene substance graded water solution to obtain a boric acid-contained spinning solution with PVA concentration being 10 to 20 weight percent; filtering the spinning solution, defoaming, spinning and drying to obtain the high-performance graphene composite polyvinyl alcohol fiber. The high-performance graphene composite polyvinyl alcohol fiber prepared by adopting the preparation method is widely applied in a building industry and a transportation industry. Indexes such as the tensile strength, the tensile modulus and the elongation at break of the composite fiber are qualitatively improved, and higher tenacity, hot water resistance and antistatic property are additionally endowed to a fiber material.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com