Low-cost heat-resistant sintered Ce-containing magnet containing Al magnetic hardening layer structure and preparation method

A hardened layer, low-cost technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., to improve the coercive force, broaden the scope of market application, and improve the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

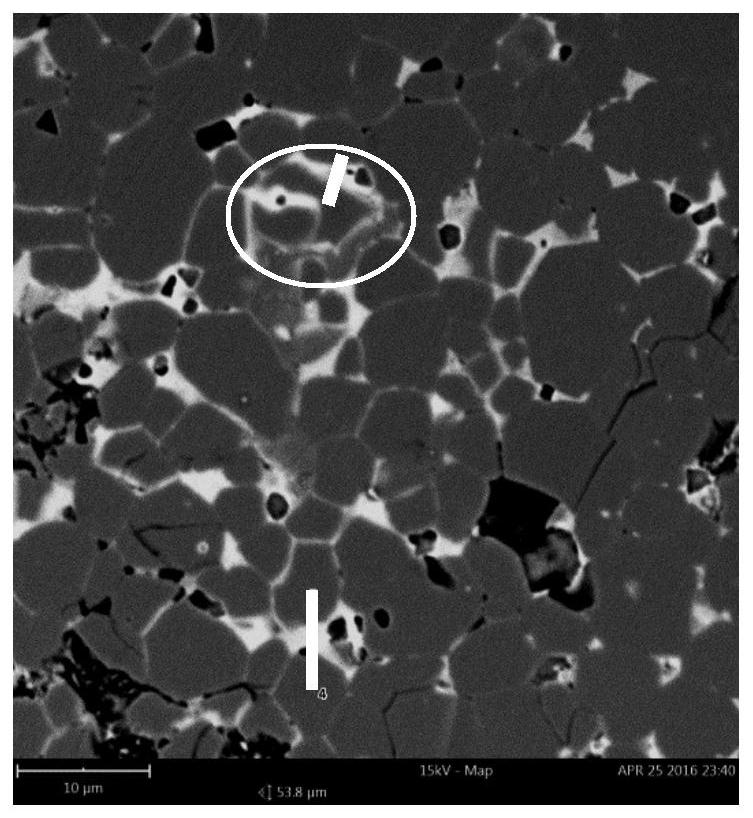

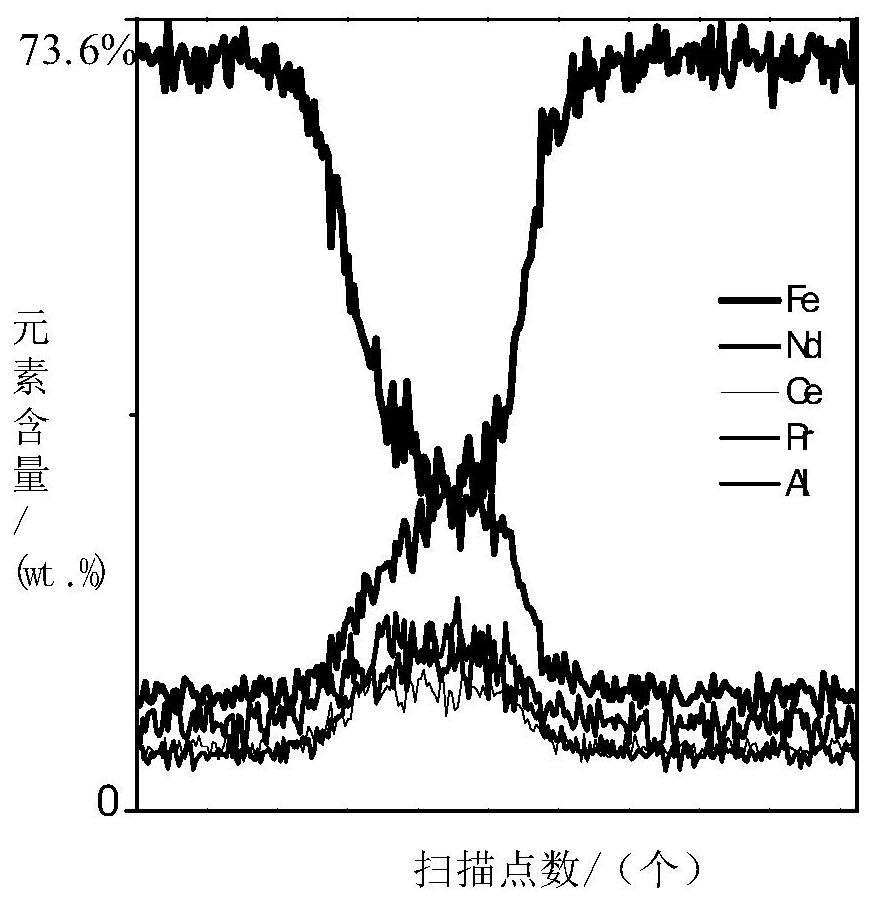

[0054] The preparation method of the low-cost heat-resistant sintered Ce-containing magnet containing Al magnetically hardened layer structure of the present invention comprises the following specific steps:

[0055] (1) prepare the quick-setting non-magnetic alloy sheet, the weight percent composition of the quick-setting non-magnetic alloy sheet is (Pr a Nd b ) c Al d , among them, 0≤a≤30, 70≤b≤100, 10≤d≤20, c+d=100; prepared by rapid solidification under the protection of argon, the casting temperature is 750 ° C ~ 900 ° C, the copper roller speed It is 43r / min~45r / min, and the thickness is 0.1μm~0.3μm.

[0056] (2) prepare quick-setting basic alloy sheet, the weight percentage composition of described quick-setting basic alloy sheet is: [(Pr a Nd b ) e Ce f ] g (Fe 100-k ,TM k ) h B i , where, 0≤a≤30, 70≤b≤100, 26≤f≤32, e+f=100; 29.5≤g≤30.5, 0.92≤i≤1.05, g+h+i=100; 80≤kh ≤200; TM is one or more of Cu, Al, Nb, Zr, Ag, Co elements. The basic magnet alloy sheet...

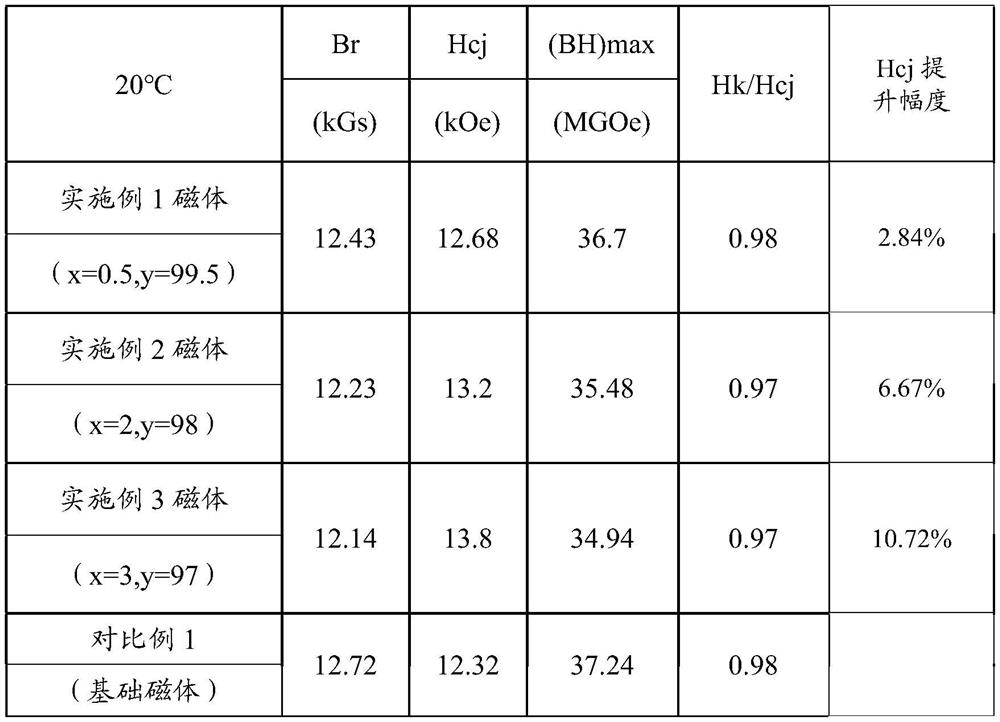

Embodiment 1、2、3

[0066] A low-cost heat-resistant sintered Ce-containing magnet with an Al magnetically hardened layer structure, its weight percent chemical general formula is:

Embodiment 3

[0067] [(Pr 0-30 Nd 70-100 ) 90 al 10 ] x {[(Pr 0-30 Nd 70-100 ) 75 Ce 25 ] 29.5 (Fe 98.8 ,TM 1.2 ) 69.58 B 0.92} y , wherein, 0.5≤x≤3, x+y=100; TM is one or more of Cu, Al, Nb, Zr, Ag, Co elements, wherein, the magnet of embodiment 1 (x=0.5, y= 99.5); Embodiment 2 magnet (x=2, y=98); Embodiment 3 magnet (x=3, y=97)

[0068] The preparation method of the above-mentioned low-cost heat-resistant sintered Ce-containing magnet containing Al magnetically hardened layer structure is carried out as follows:

[0069] (1) prepare quick-setting non-magnetic alloy sheet, the weight percent composition of alloy sheet is:

[0070] (Pr 0-30 Nd 70-100 ) 90 al 10 . It is prepared by rapid solidification under the protection of argon, the casting temperature is 750 ℃ ~ 800 ℃, the copper roller speed is 43r / min ~ 45r / min, and the thickness is 0.1μm ~ 0.3μm.

[0071] (2) prepare quick-setting basic alloy sheet, the weight percent composition of alloy sheet is:

[0072] [(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com