Production method of low-cost and high-quality xanthan gum

A production method and a technology for xanthan gum are applied in the production field of low-cost and high-quality xanthan gum, which can solve the problems that production enterprises have no time to take into account product quality, are unfavorable for the promotion and application of xanthan gum, and have fierce competition in the product market, thereby reducing production costs. Cost, continuous automation, effect of long dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

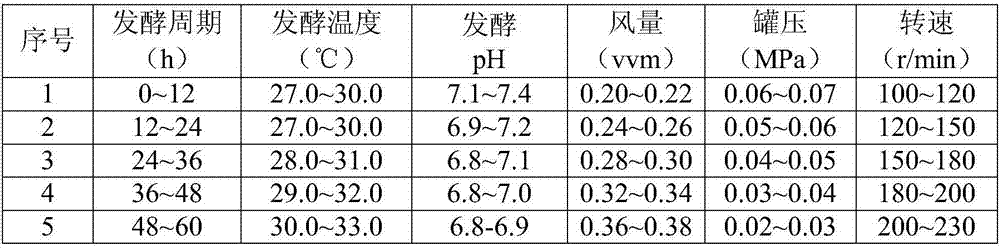

Embodiment 1

[0043] Present embodiment provides a kind of production method of low-cost high-quality xanthan gum, the method comprises the steps:

[0044] (1) The 250L fermentation tank is empty, the temperature is set at 129-130°C, the tank pressure is 0.19-0.20MPa, and the time is 30min;

[0045] (2) 25L fed-batch tank is empty, the temperature is 129~130℃, the tank pressure is 0.18~0.20MPa, and the time is 30min;

[0046] (3) Add culture medium to 250L fermenter, the medium is: dry corn flour 10.8Kg, light calcium carbonate 576g, yeast extract 54g, peptone 108g, MnSO 4 18g, MgSO 4 18g, polyether polyol defoamer 54g, add 100L water and stir for 30min, then add pure water to set the volume to 180L;

[0047] (4) Add 900g cottonseed meal into a 25L hydrolysis tank, add about 5L water and stir for 30 minutes until the cottonseed meal is evenly suspended in water, add water and stir to make it 20L, then add 10% NaOH aqueous solution to adjust the pH to 11.3, Heat up to 83°C for hydrolysi...

Embodiment 2

[0058] Present embodiment provides a kind of production method of low-cost high-quality xanthan gum, the method comprises the steps:

[0059] (1) 2.5m 3 The fermentation tank is empty, the temperature is set at 128-129°C, the tank pressure is 0.18-0.19MPa, and the time is 30min;

[0060] (2) 250L fed-batch tank is empty, the temperature is 128~129℃, the tank pressure is 0.18~0.19MPa, and the time is 30min;

[0061] (3) The 250L seed tank is empty, the temperature is 128~129℃, the tank pressure is 0.18~0.19MPa, the time is 30min, after cooling down, the ingredients are 2.0Kg of sugar, 130g of peptone, 1.05Kg of soybean powder, 250g of yeast extract, and 160g of sodium chloride. , light calcium carbonate 160g, defoamer 50g, K 2 HPO 4 30g, MgSO 4 30g, add pure water to make the volume 200L;

[0062](4) Add 9Kg cottonseed meal into the 250L hydrolysis tank, add about 50L water and fully stir for 30 minutes until the cottonseed meal is evenly suspended in water, add water and ...

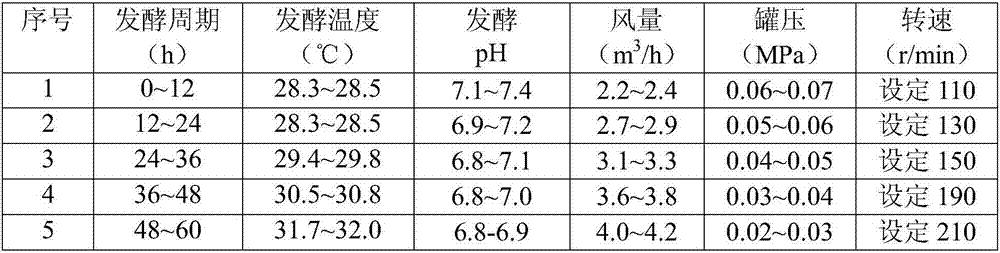

Embodiment 3

[0076] Present embodiment provides a kind of production method of low-cost high-quality xanthan gum, the method comprises the steps:

[0077] (1) 25m 3 The fermentation tank is empty, the temperature is set at 128-129°C, the tank pressure is 0.18-0.19MPa, and the time is 30min;

[0078] (2)2.5m 3 The feeding tank is empty, the temperature is 128-129°C, the tank pressure is 0.18-0.19MPa, and the time is 30min;

[0079] (3) The 250L primary seed tank is empty, the temperature is 128~129℃, the tank pressure is 0.18~0.19MPa, the time is 30min, after cooling down, the ingredients are 2.0Kg white sugar, 130g peptone, 1.05Kg soybean powder, 250g yeast extract, chlorinated Sodium 160g, light calcium carbonate 160g, defoamer 50g, K 2 HPO 4 30g, MgSO 4 30g, add pure water to make the volume 200L;

[0080] (4)2.5m 3 The second-level seed tank is empty, the temperature is 128-129°C, the tank pressure is 0.18-0.19MPa, and the time is 30min. After cooling down, the ingredients includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com