Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Improve machining accuracy and machining efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ceramic bond super-hard abrasive tool

ActiveCN101913122AImprove machining accuracy and machining efficiencyImprove self-sharpening abilityGrinding devicesSurface finishingPolyimide

The invention relates to a method for preparing a ceramic bond super-hard abrasive tool, which comprises the following steps of: mixing ceramic bond, super-hard abrasive (diamond and cubic boron nitride), filler (common abrasive such as corundum, silicon carbide and the like) and pore-forming agent, adding temporary bond into the mixture, uniformly filling the mixture into a molding mold, molding the mixture under the pressure of 60 to 200MPa, and preparing the ceramic super-hard abrasive tool with pores by the processes of drying, roasting, surface treatment, adhesion, modification and shaping treatment and detection. The ceramic super-hard abrasive tool comprises the following components in part by weight: 40 to 75 parts of super-hard abrasive, 30 to 10 parts of filler, 30 to 15 parts of ceramic bond, 3 to 10 parts of temporary bond and 5 to 15 parts of pore-forming agent, wherein the pore-forming agent is macromolecular resin spherical granules (one of acrylic resin, polyimide resin and solid phenolic resin); and the roasting is step temperature-controlled burning. The ceramic super-hard abrasive tool has the advantages of good pore-forming effect, good pore adjustability, novelty and environmental protection, no toxin or harm, and convenience for use and popularization.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

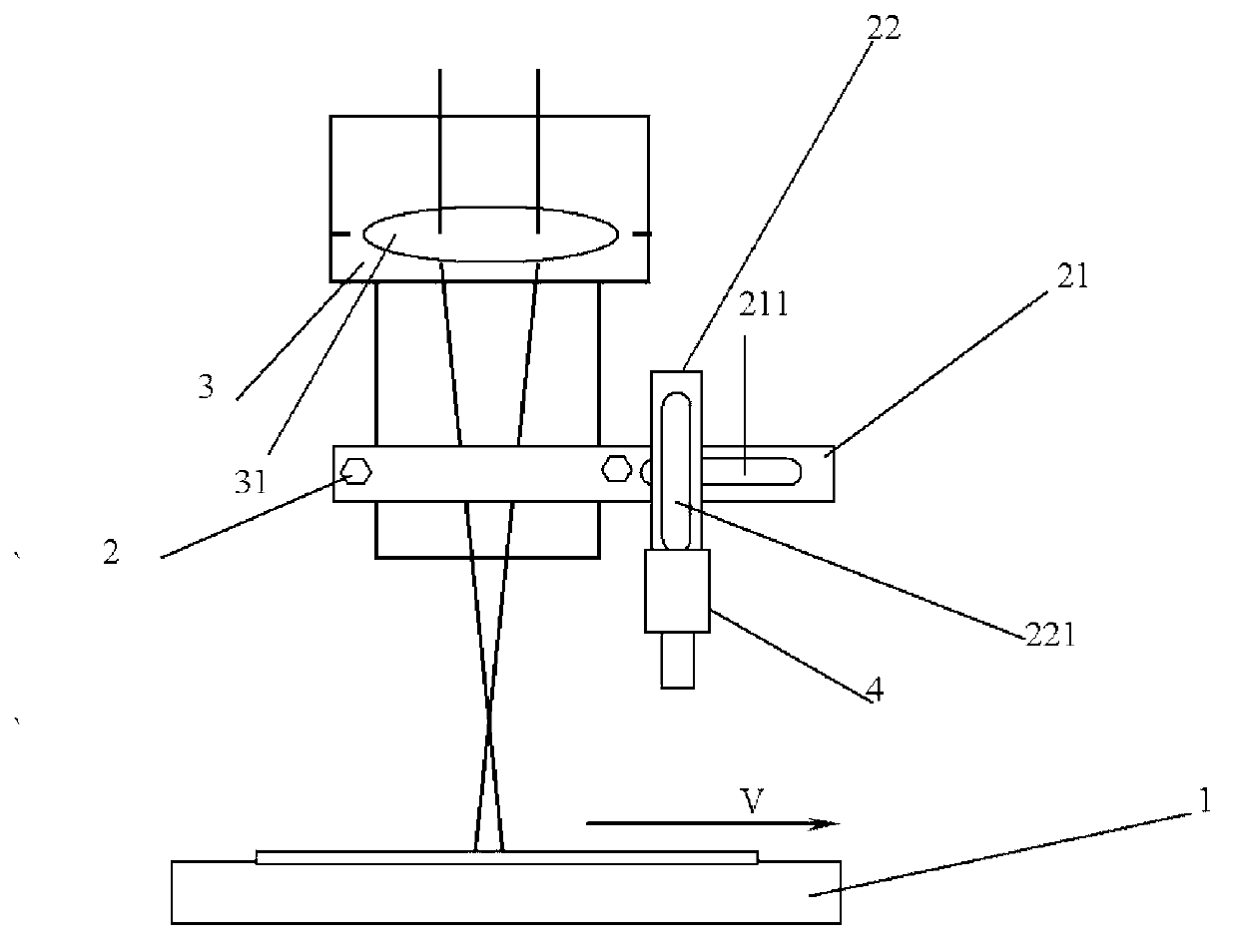

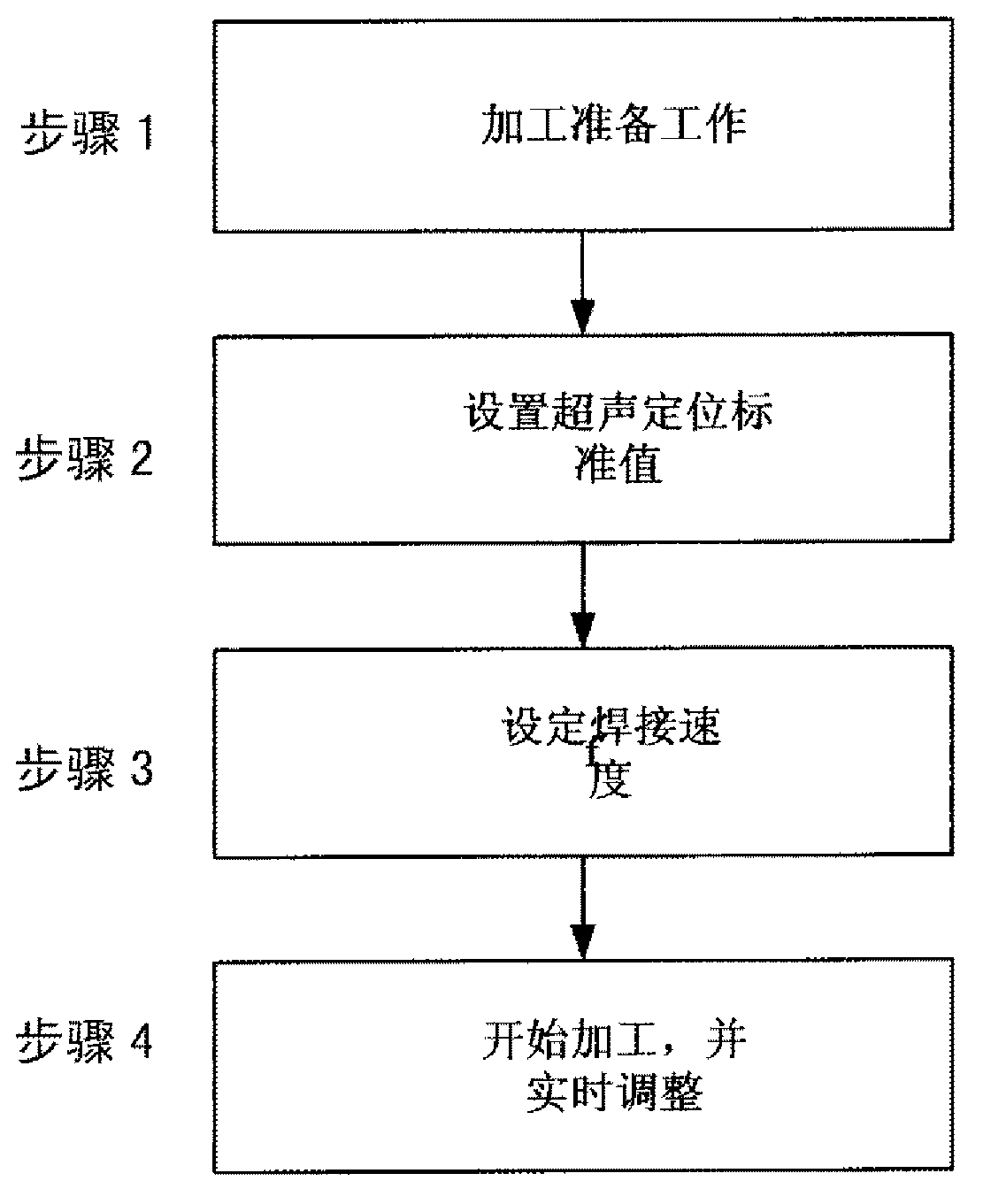

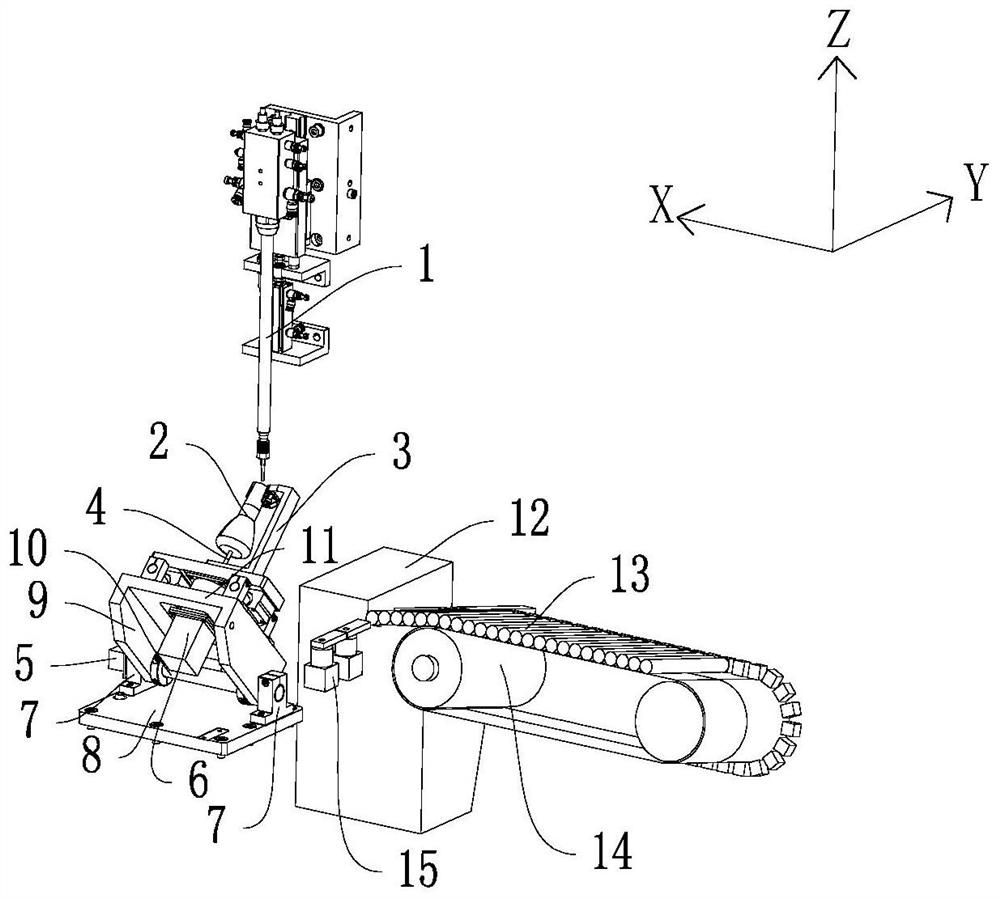

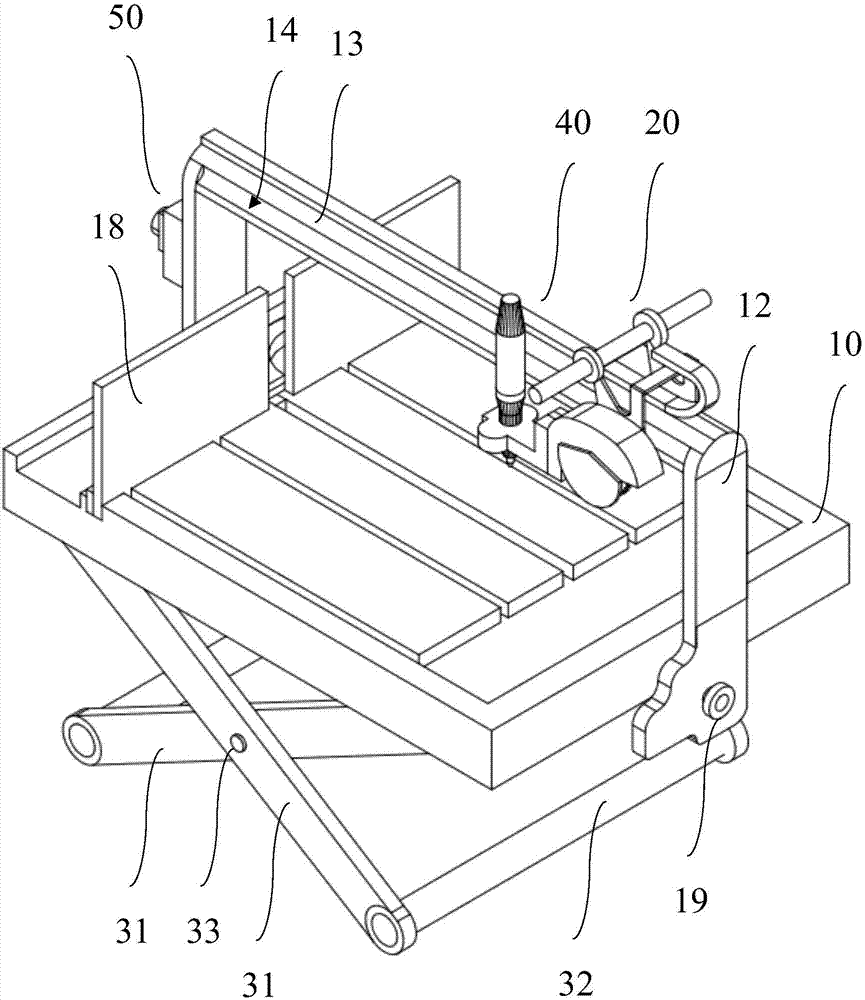

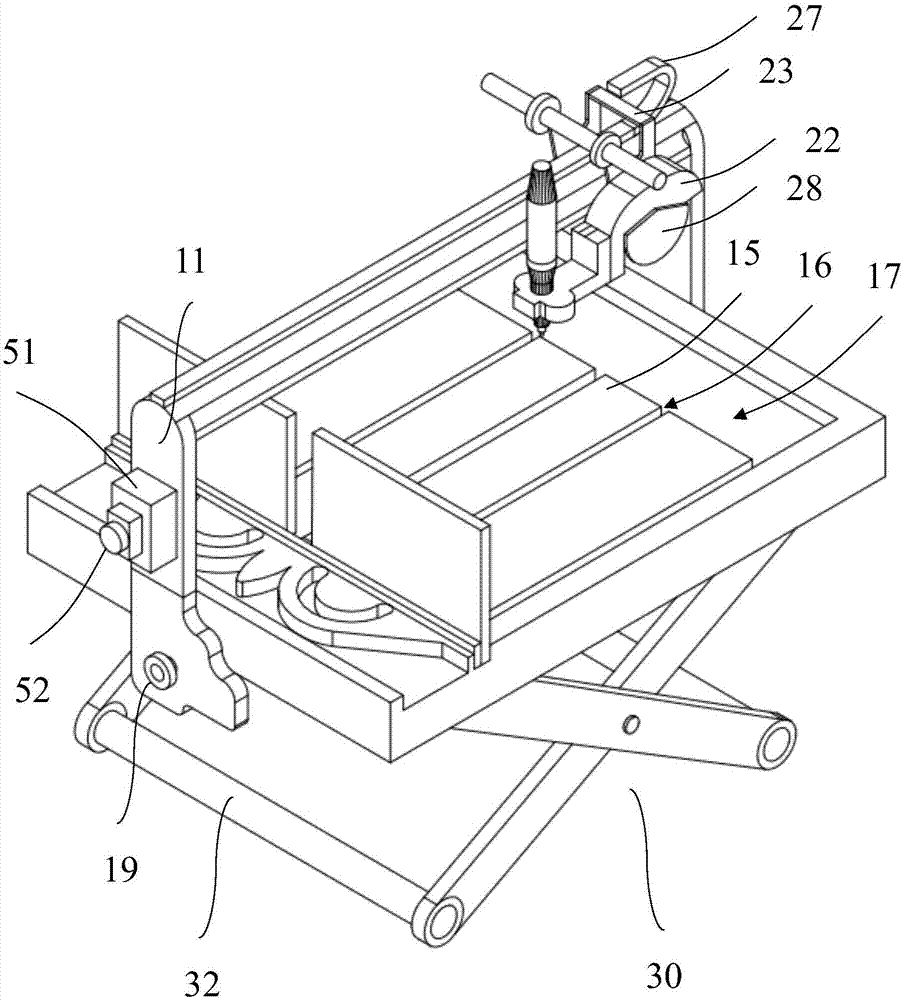

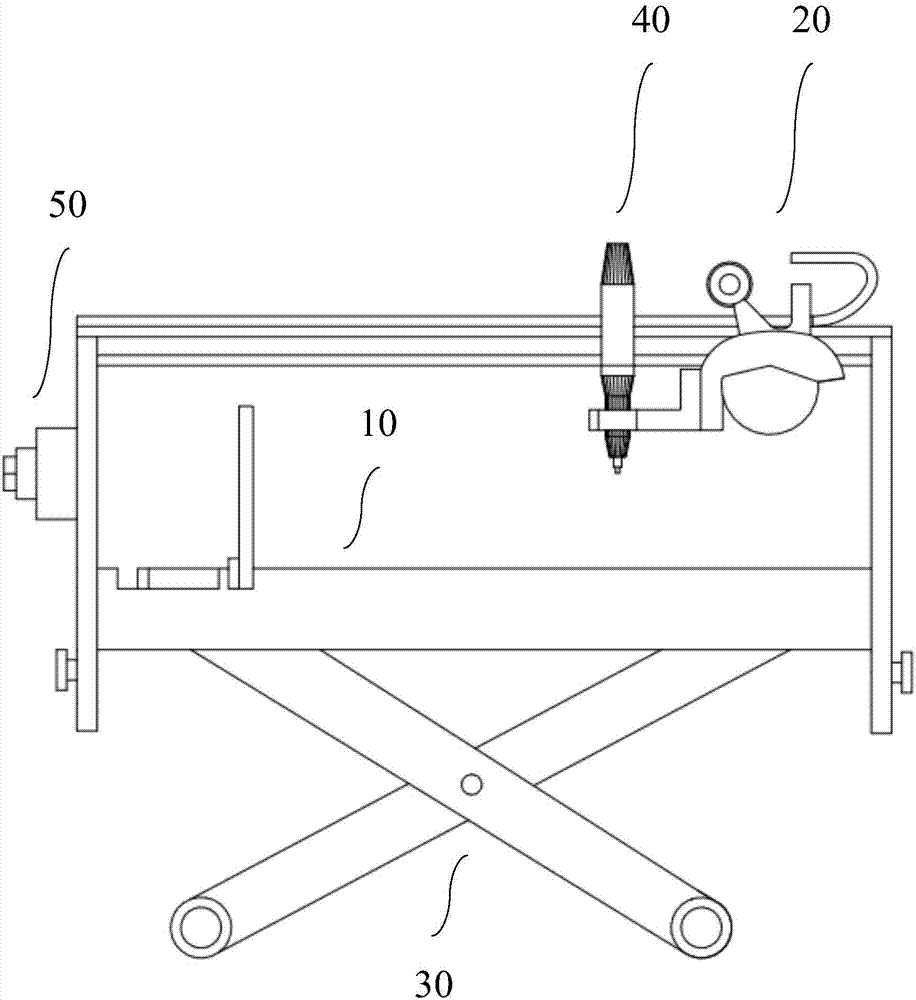

Laser machining device based on ultrasonic location and machining method

ActiveCN102974937AAvoid cumbersomenessImprove machining accuracy and machining efficiencyLaser beam welding apparatusPhysicsMachining

The utility model provides a laser machining device based on an ultrasonic location and a machining method. The laser machining device based on the ultrasonic location comprises a machining platform, a clamping device, a laser head and an ultrasonic range-measurement device, wherein the clamping device arranged above the machining platform comprises a transverse clamping connecting part and a longitudinal clamping connecting part, the transverse clamping connecting part and the longitudinal clamping connecting part are connected with each other in a pivot mode, the laser head is in pivot connection with the transverse clamping connecting part of the clamping device and arranged above the machining platform, and the ultrasonic range-measurement device is in pivot connection with the longitudinal clamping connecting part of the clamping part. The laser machining device based on the ultrasonic location can guarantee laser machining quality, improves machining accuracy, and can fast and conveniently confirm change situations of defocusing amount during machining.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

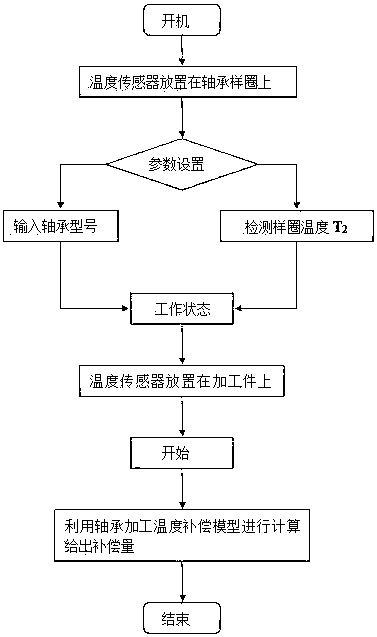

Dimension compensation quantity determining method for bearing machining

InactiveCN108262667AAvoid errorsImprove machining accuracy and machining efficiencyGrinding feed controlGrinding machinesEngineeringExperience base

The invention belongs to the technical field of bearing machining, and particularly relates to a dimension compensation quantity determining method for bearing machining. The dimension compensation quantity determining method for bearing machining comprises the steps that the type of a to-be-machined workpiece is determined; the standard workpiece temperature T2 and the machined workpiece temperature T1 are detected; a pre-stored machining model and corresponding machining parameters are selected according to the type of the to-be-machined workpiece; and the bearing machining model is assignedaccording to the standard workpiece temperature T2, the machined workpiece temperature T1 and the corresponding machining parameter, so that the dimension compensation quantity of the to-be-machinedworkpiece is obtained through calculation. By adoption of the dimension compensation quantity determining method for bearing machining, machining dimension compensation quantity errors caused by experience-based judgment by operators are avoided, the machining precision and machining efficiency of bearings are improved, the machining repair rate of the bearings is greatly decreased, and the numberof rejected products is reduced; and operation is easy.

Owner:WAFANGDIAN BEARING GRP STATE BEARING ENG TECH RES CENT CO LTD

System with double inner liquid spraying tool cathodes and electrolytic grinding and milling method of system with double inner liquid spraying tool cathodes

ActiveCN105855649AImprove machining accuracy and machining efficiencyGreat processing flexibilityThin walledThrough transmission

The invention relates to a system with double inner liquid spraying tool cathodes and an electrolytic grinding and milling method of the system with the double inner liquid spraying tool cathodes and belongs to the field of electrolytic grinding composite machining. A machine tool main shaft drives two hollow transmission shafts to rotate through a transmission straight gear set so that rotating connector inner rings at the top ends of the transmission shafts and water stopping chucks at the tail ends of the transmission shafts can be driven to rotate at the same time. The tool cathodes of different design requirements can be clamped on the water stopping chucks. Rotating connectors input electrolyte into a dynamic rotating system from a static system, and the electrolyte is directly jetted to a machined surface of a workpiece through transmission shaft through holes and tool cathode inner holes. In this way, complicated thin-wall structures, symmetrical molded faces and the like can be machined in an inner liquid spraying electrolytic grinding and milling manner through a main shaft transmission device, the machine tool main shaft is free of influences of electrolyte corrosion, the machining allowance difference is reduced, the machining depth is increased, and the machining precision, the machining efficiency and the machining flexibility are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

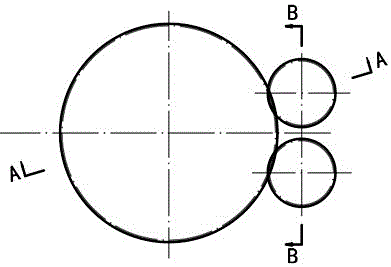

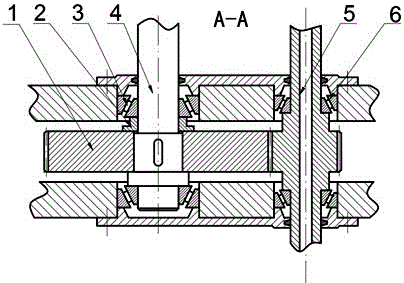

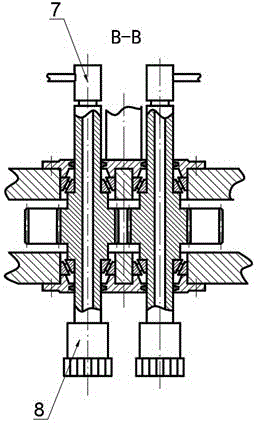

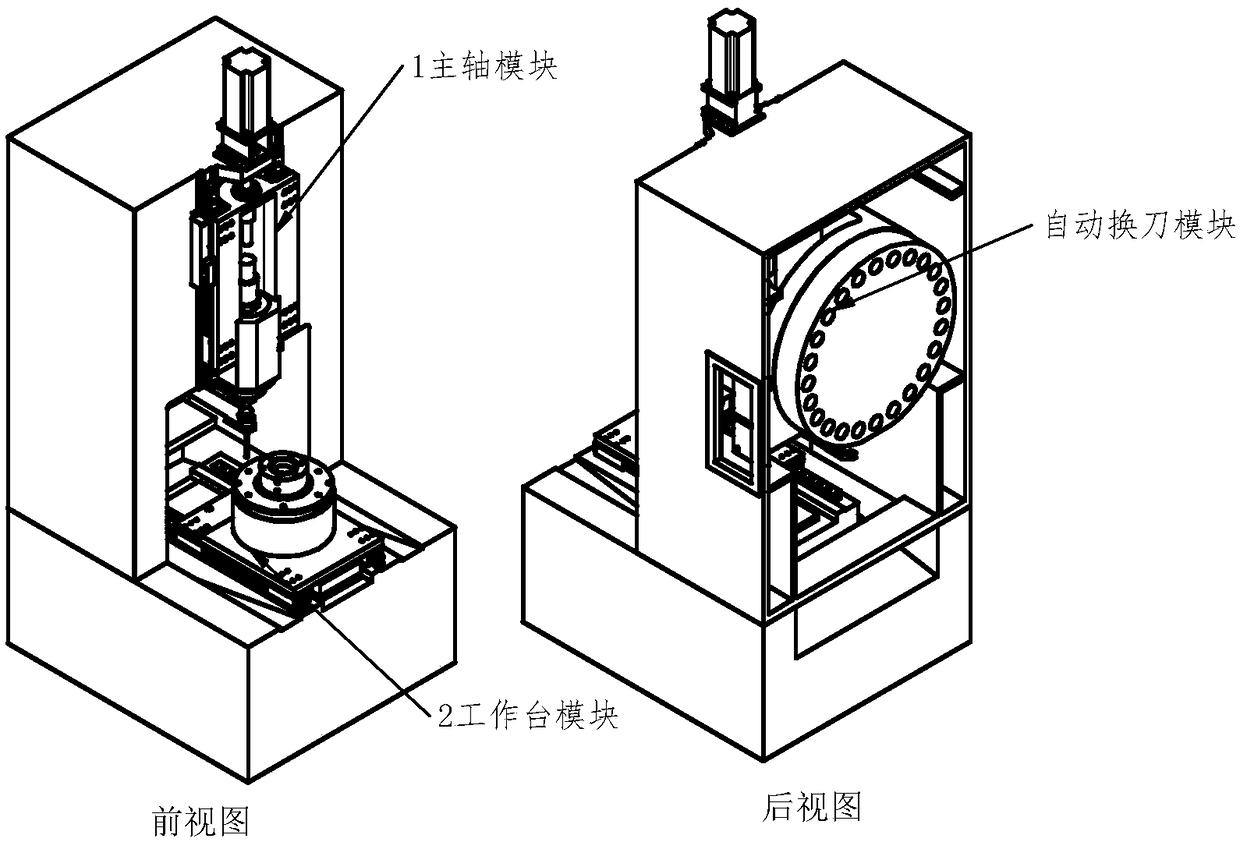

Special scroll machining machine tool and machining method thereof

PendingCN108747439AImprove production accuracyReduce machining errorsFeeding apparatusLarge fixed membersLubricationMotor drive

The invention discloses a special scroll machining machine tool and a machining method thereof. The special scroll machining machine tool comprises a base, a spindle module, a workbench module, an automatic tool changing module and a cooling lubrication module, wherein the spindle module, the workbench module, the automatic tool changing module and the cooling lubrication module are arranged on the base. The machining movement mechanism of the special scroll machining machine tool is that an electric spindle drives a tool to rotate at a high speed, tool cutting-in feed is achieved through Z-axis servo, a workbench DD motor drives a workpiece to do rotary motion, workpiece radial feed movement is achieved through X-axis servo feed of the workbench DD motor, a polar coordinate motion interpolation track is achieved through the combination of the above two motions, and the mode is the optimal movement mode for scroll spiral line machining; a film hydraulic operated clamp or a film pneumatic clamp is used for workpiece clamping, and high-precision clamping and positioning are achieved; and the high precision and high efficiency requirements for scroll plate machining are achieved through the special scroll machining machine tool and the machining method thereof.

Owner:ZHEJIANG DEREBAO ELECTRIC TECH

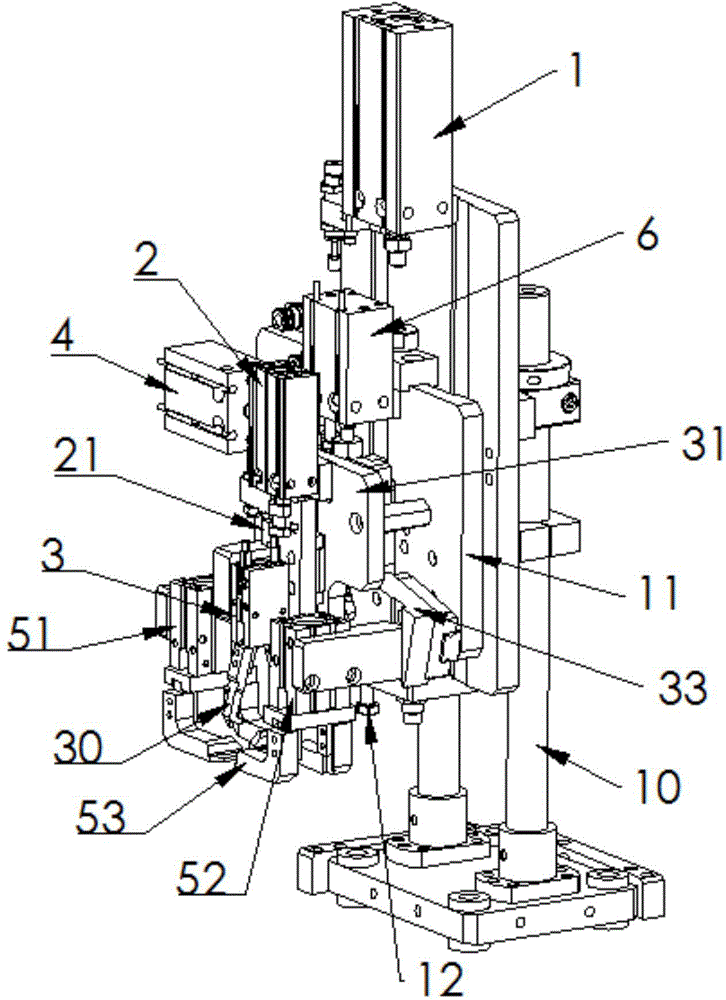

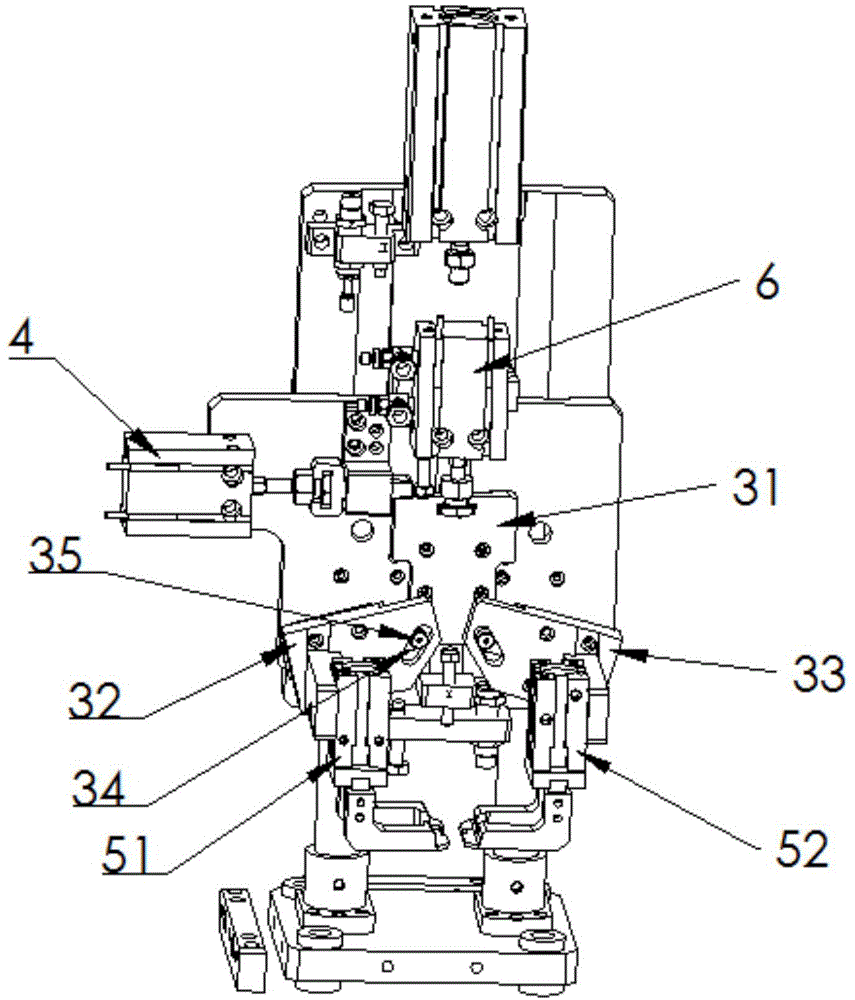

Cable neatening and dividing mechanism

ActiveCN104526211ASimple structureImprove machining accuracy and machining efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention discloses a cable neatening and dividing mechanism. The cable neatening and dividing mechanism comprises a support, a first sliding block capable of vertically sliding along the support and a vertical air cylinder capable of driving the first sliding block to vertically slide along the support are arranged on the support; a second sliding block capable of vertically sliding along the first sliding block and a cable neatening air cylinder capable of driving the second sliding block to slide vertically relative to the first sliding block are arranged on the first sliding block; a cable neatening clamping jaw air cylinder is further fixedly arranged on the second sliding block, is provided with two first clamping jaws, and can drive the two clamping jaws to be opened and closed. The cable neatening and dividing mechanism comprises a cable neatening mechanism and a cable dividing mechanism; firstly, two cluttered cables are clamped through the cable neatening mechanism to be straightened, then the two cables are divided by a certain angle through the cable dividing mechanism, the dividing angle can be set according to requirements, and the structure is concise; in addition, automatic neatening and straightening and automatic cable dividing can be achieved, the machining efficiency and the machining accuracy are greatly improved, and guarantees are provided for stability and the reliability of the product quality.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

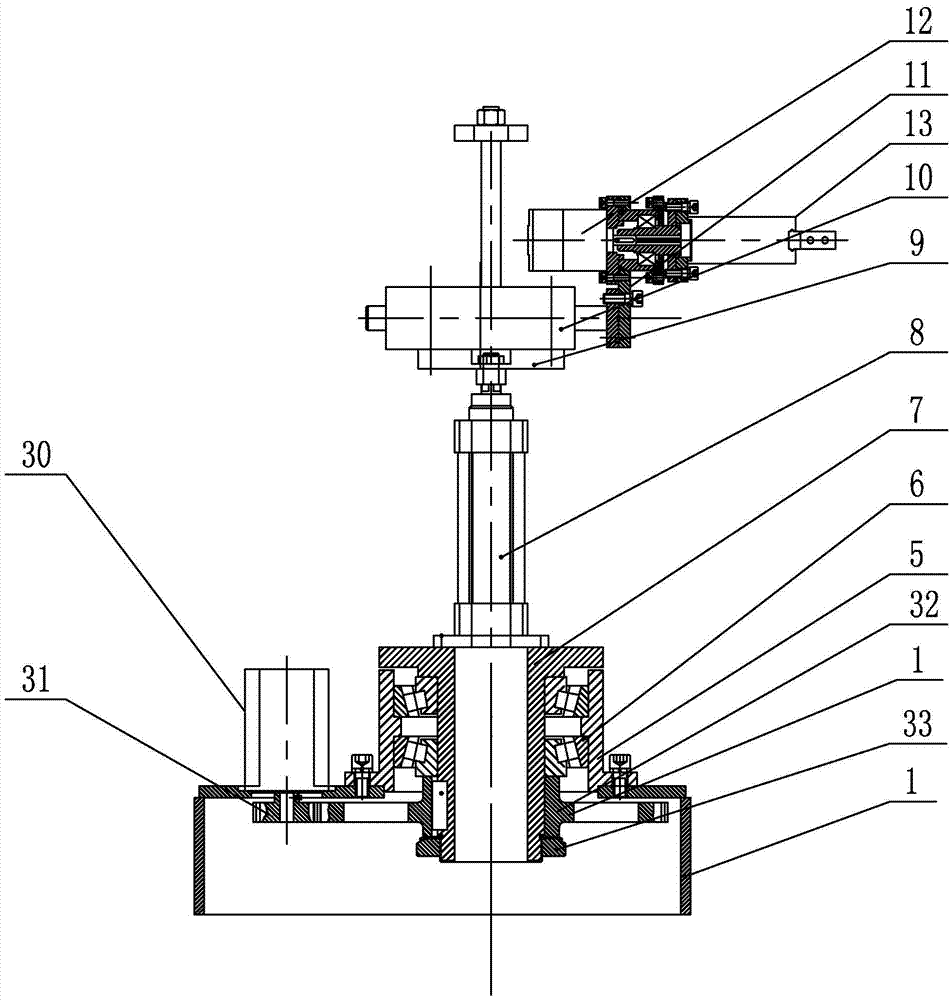

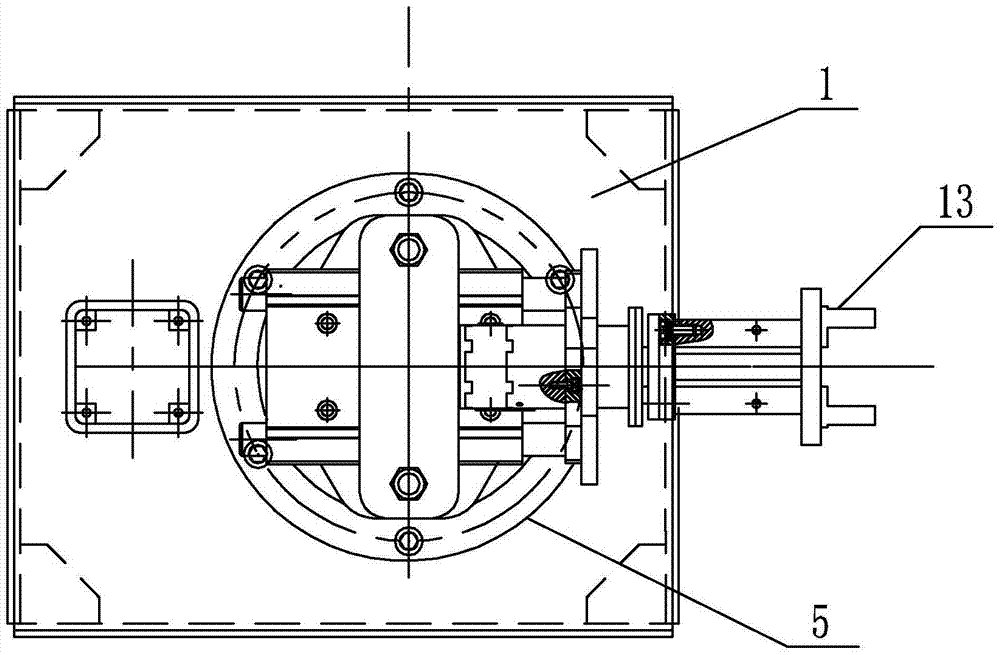

Industrial robot for gear machining

InactiveCN105436976AImprove machining accuracy and machining efficiencyHigh dustproof and anti-interference abilityMetal working apparatusManipulatorEngineeringCylinder block

The invention provides an industrial robot for gear machining and relates to an industrial robot. The industrial robot for gear machining solves the problems of low machining efficiency and low machining accuracy of manual operations adopted for existing machining in steps of tooth profile chamfering and deburring. A main shaft bearing block is fixedly mounted on an upper end face of a base; a rotating main shaft is vertically mounted on the main shaft bearing block through a main shaft bearing; a main shaft driving device drives the rotating main shaft to rotate; a cylinder block of a lifting cylinder is fixedly mounted on an upper end face of the rotating main shaft; a cylinder block of an arm cylinder is fixedly mounted on an upper end face of a piston rod of the lifting cylinder; a wrist portion is mounted on a piston rod of an arm cylinder through an arm transition plate and a gripper is connected to the wrist portion; a gripper rotating shaft is horizontally mounted in a bearing block assembly through a self-aligning ball bearing; and one end of the gripper rotating shaft is fixedly connected with an output shaft of a first stepping motor through a coupling, while the other end of the gripper rotating shaft is connected with a pneumatic gripper. The industrial robot for gear machining is applicable to tooth profile chamfering and deburring in gear machining.

Owner:HARBIN INST OF TECH

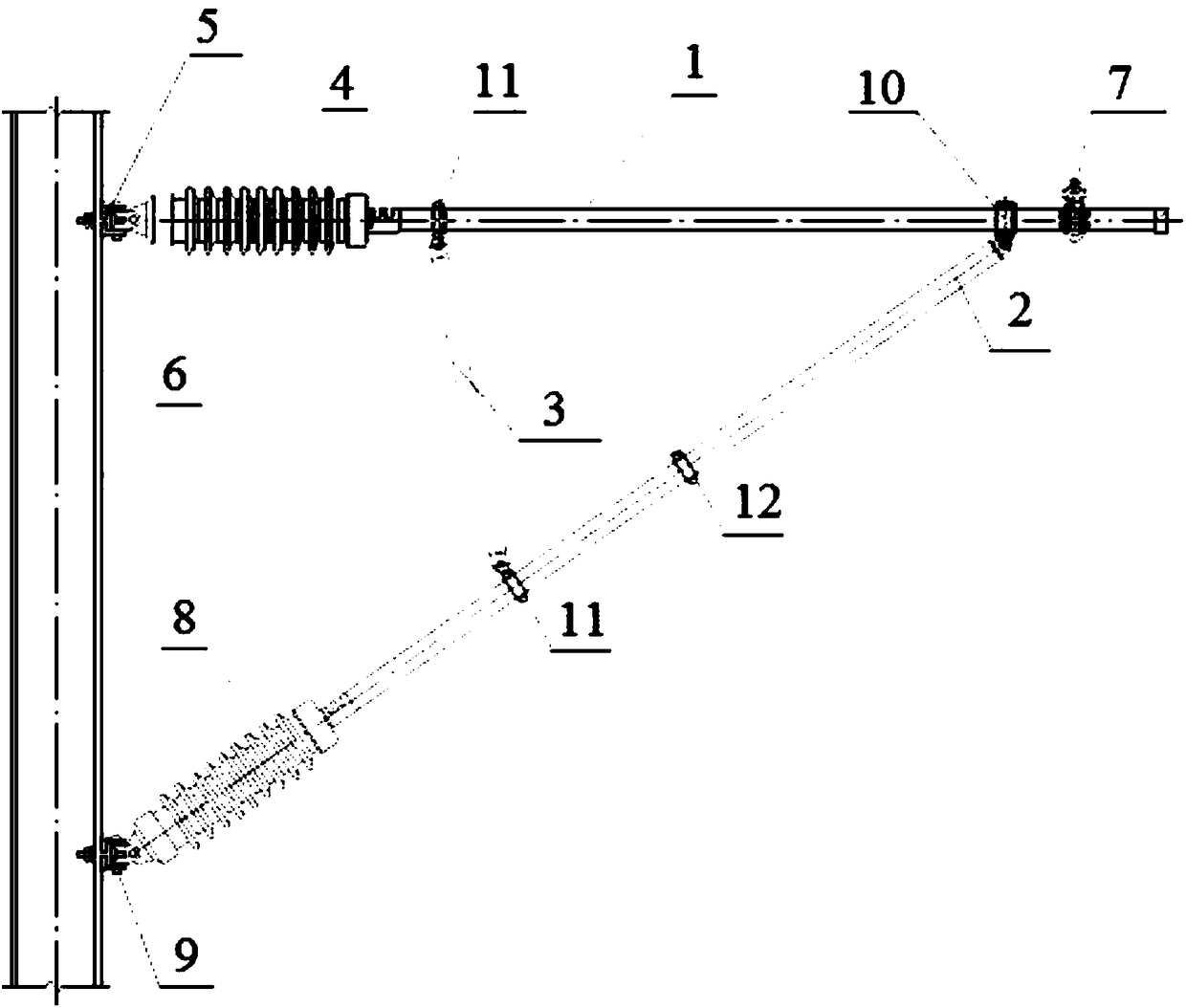

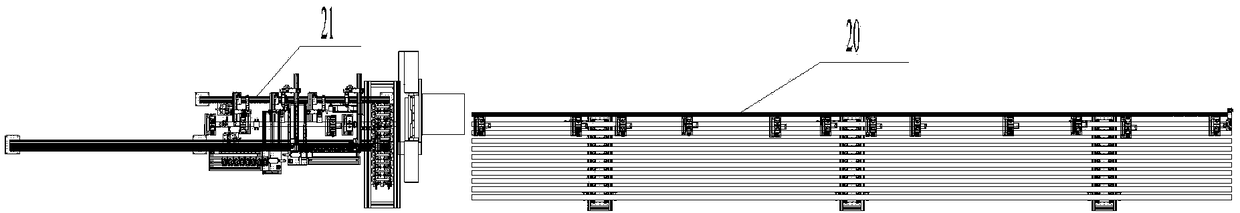

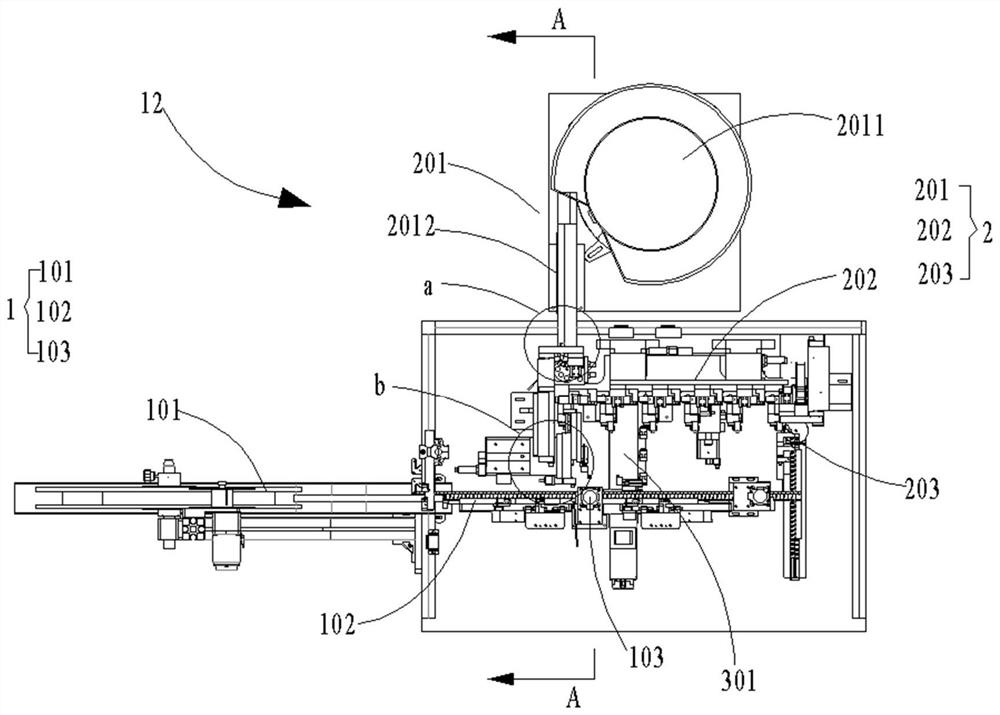

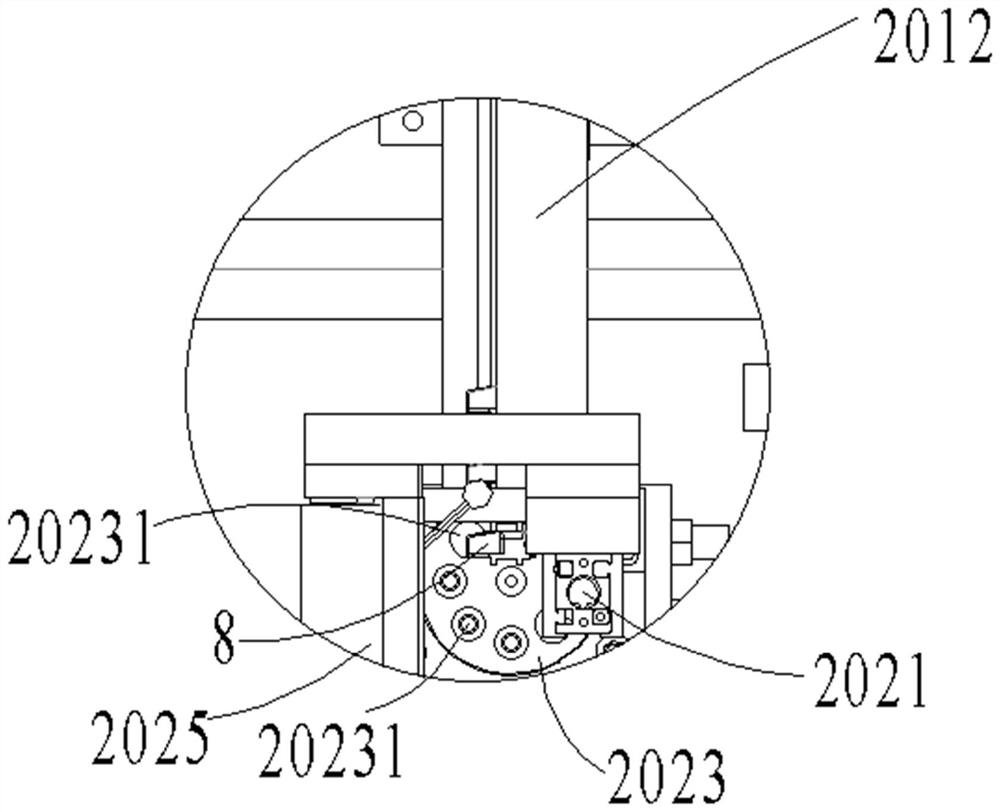

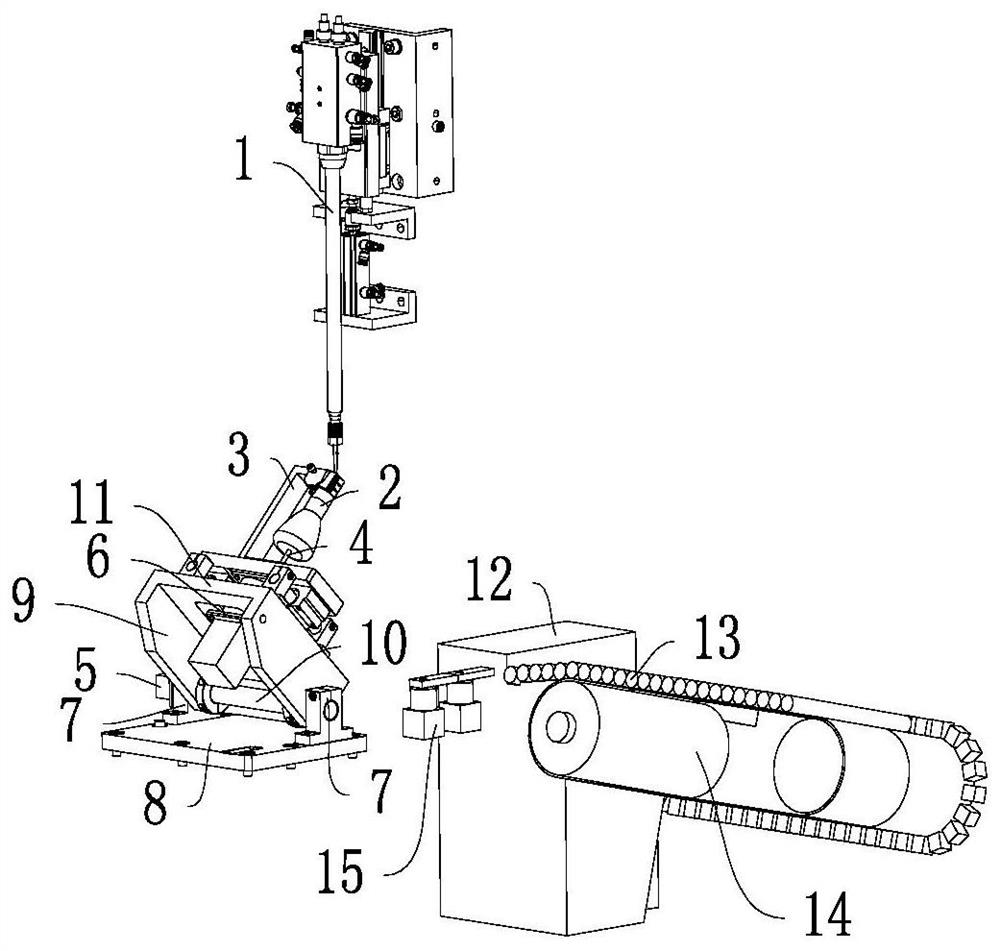

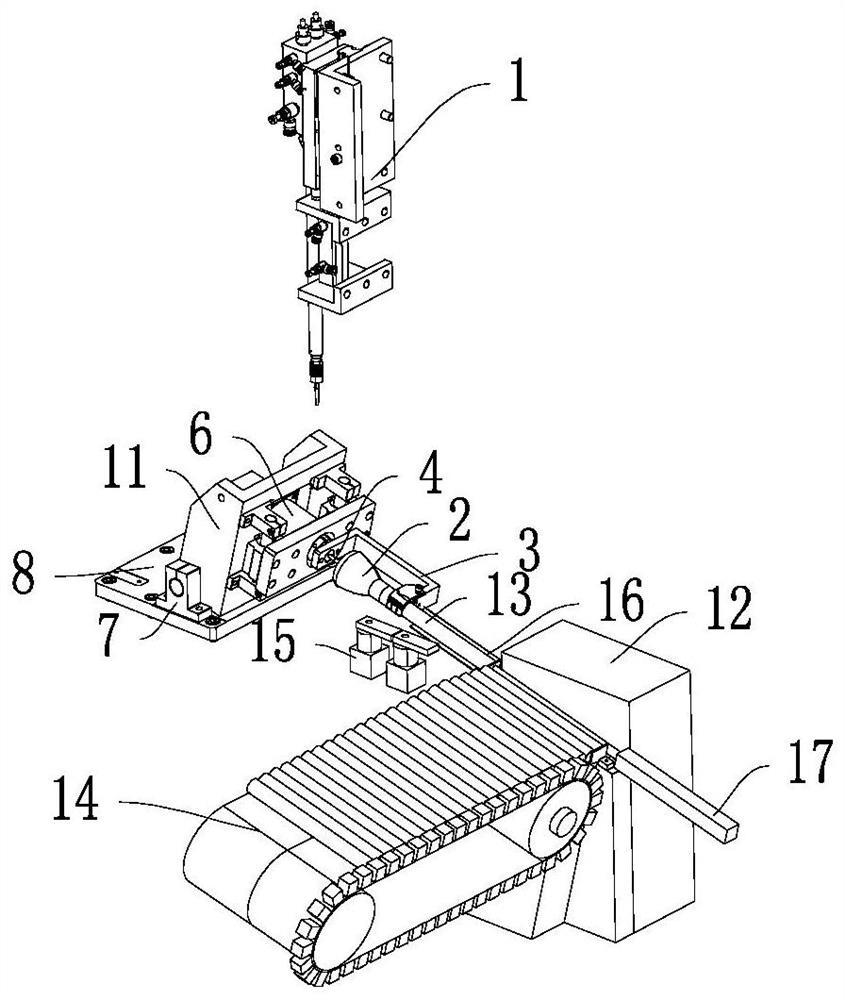

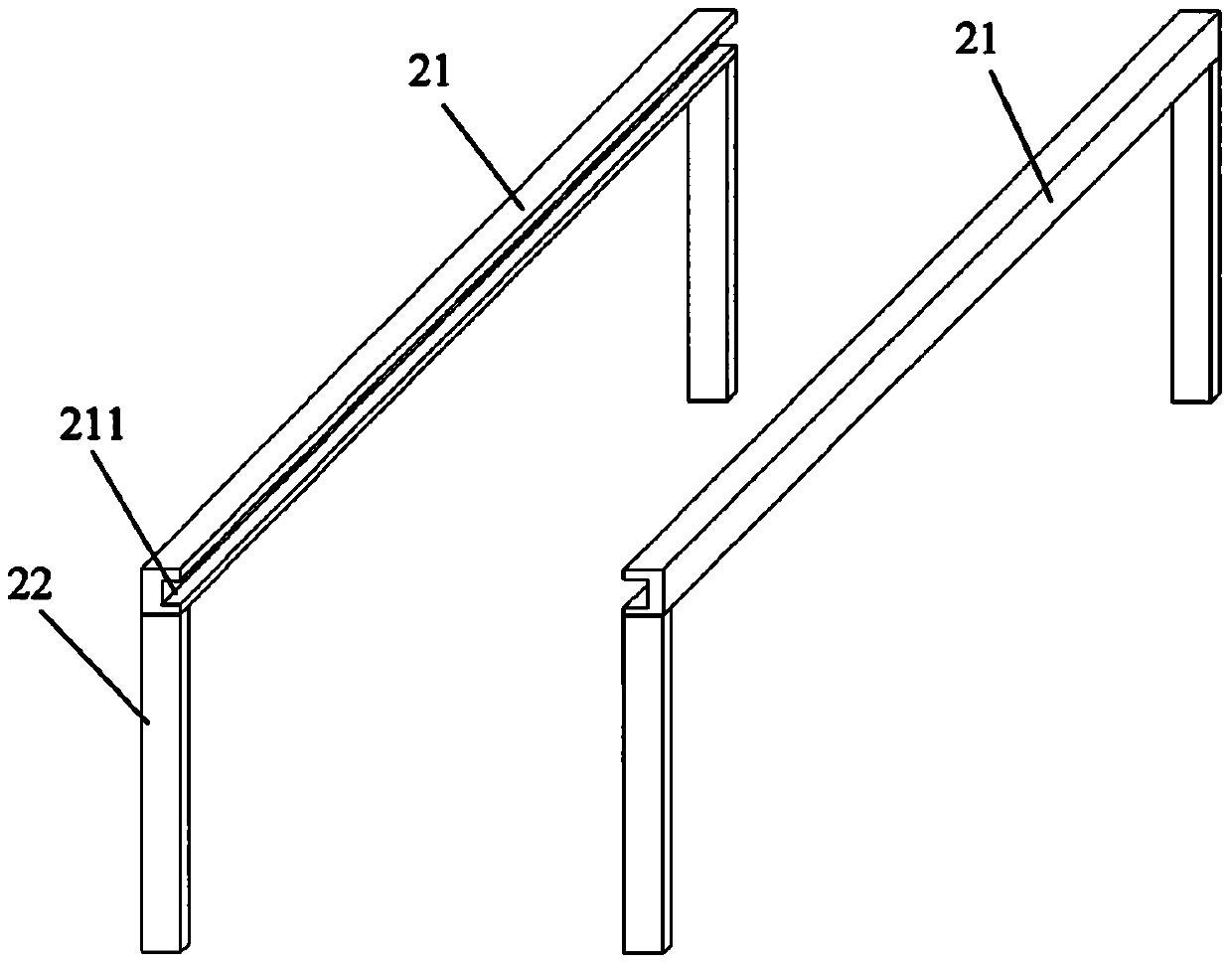

Catenary cantilever machining device

ActiveCN108583371ARealize fully automatic processingImprove machining accuracy and machining efficiencyTrolley linesOther manufacturing equipments/toolsCatenaryManipulator

The invention discloses a catenary cantilever machining device. The catenary cantilever machining device comprises a flat cantilever machining device, an inclined cantilever machining device and a cantilever combining device; the flat cantilever machining device and the inclined cantilever machining device are arranged side by side, and the cantilever combining device is located at the tail ends of the flat cantilever machining device and the inclined cantilever machining device; the flat cantilever machining device and the cantilever combining device are connected through a flat cantilever combining manipulator truss; the inclined cantilever machining device and the cantilever combining device are connected through an inclined cantilever combining manipulator truss; the flat cantilever combining manipulator truss is used for providing a movement track for a flat cantilever combining manipulator; the inclined cantilever combining manipulator truss is used for providing a movement trackfor an inclined cantilever combining manipulator; and the cantilever combining device is used for combining a machined flat cantilever with a machined inclined cantilever. According to the catenary cantilever machining device, the machining precision and efficiency of the cantilevers can be improved.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

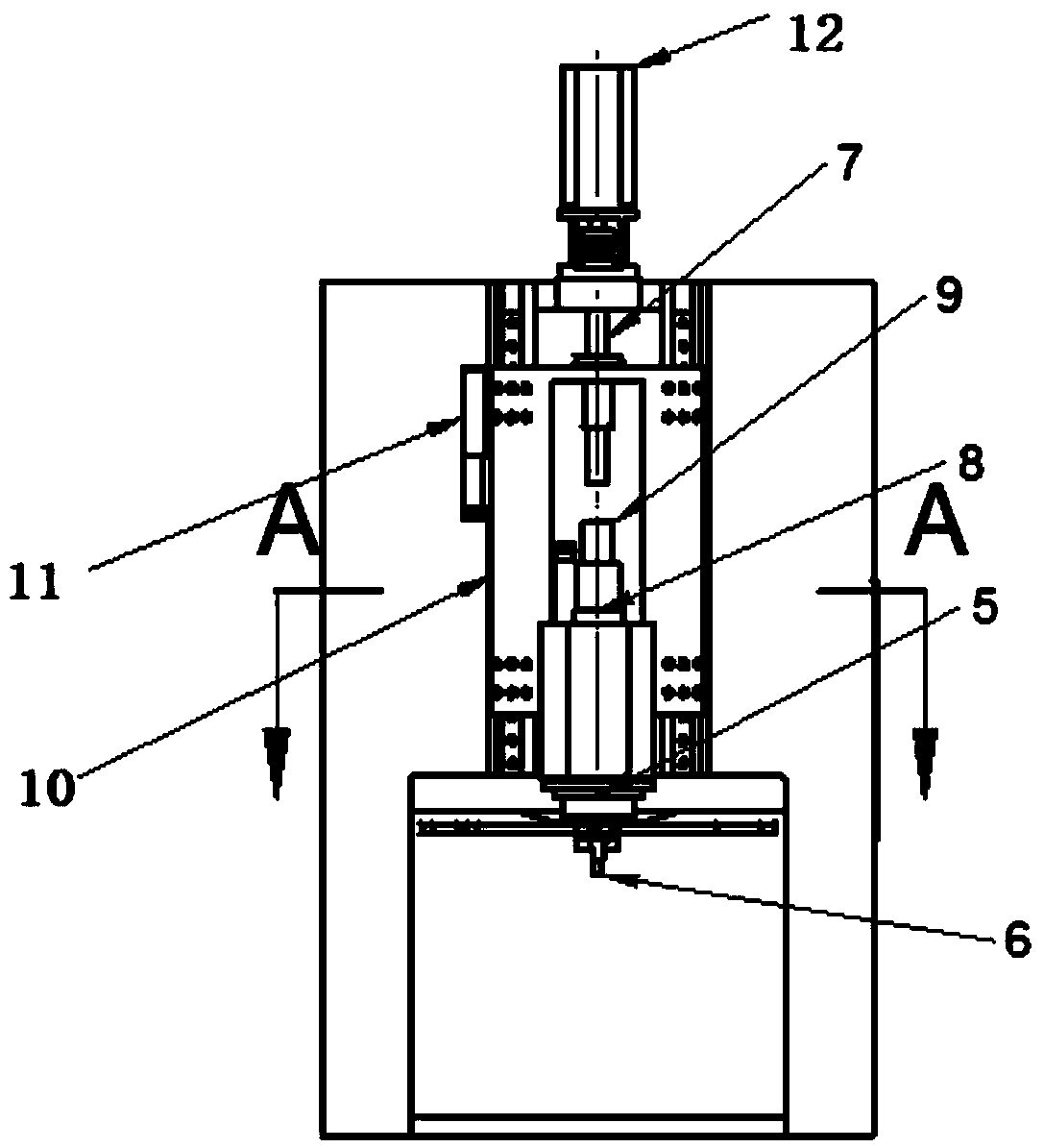

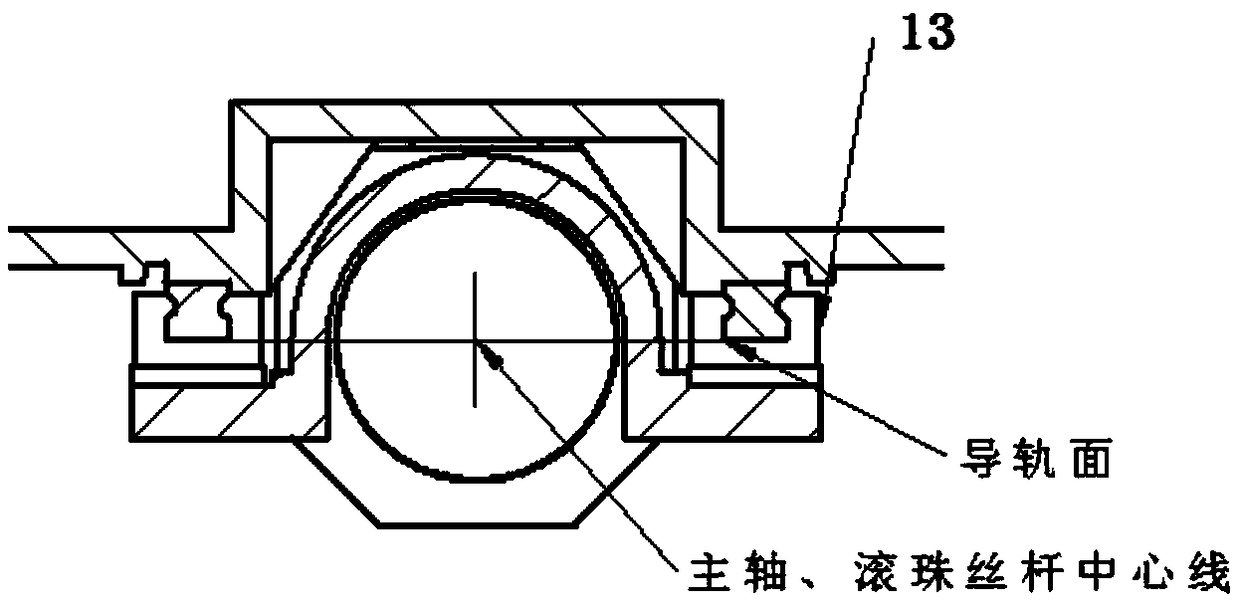

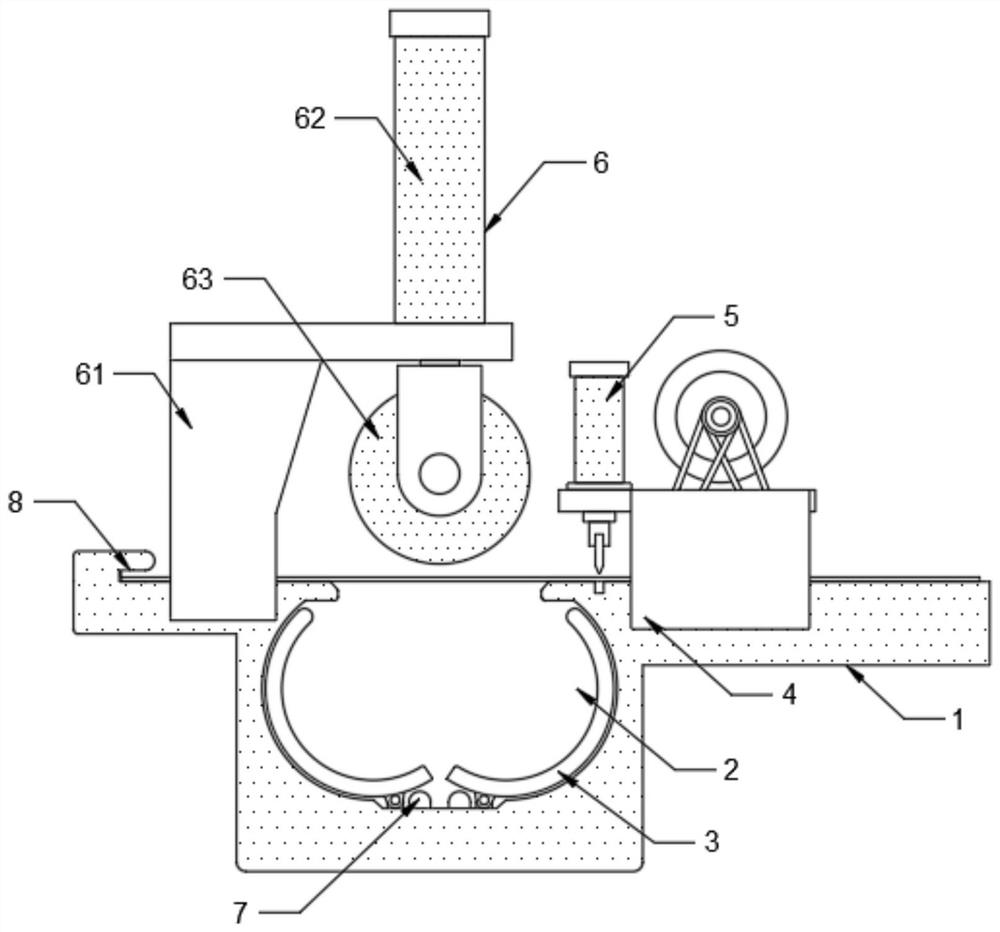

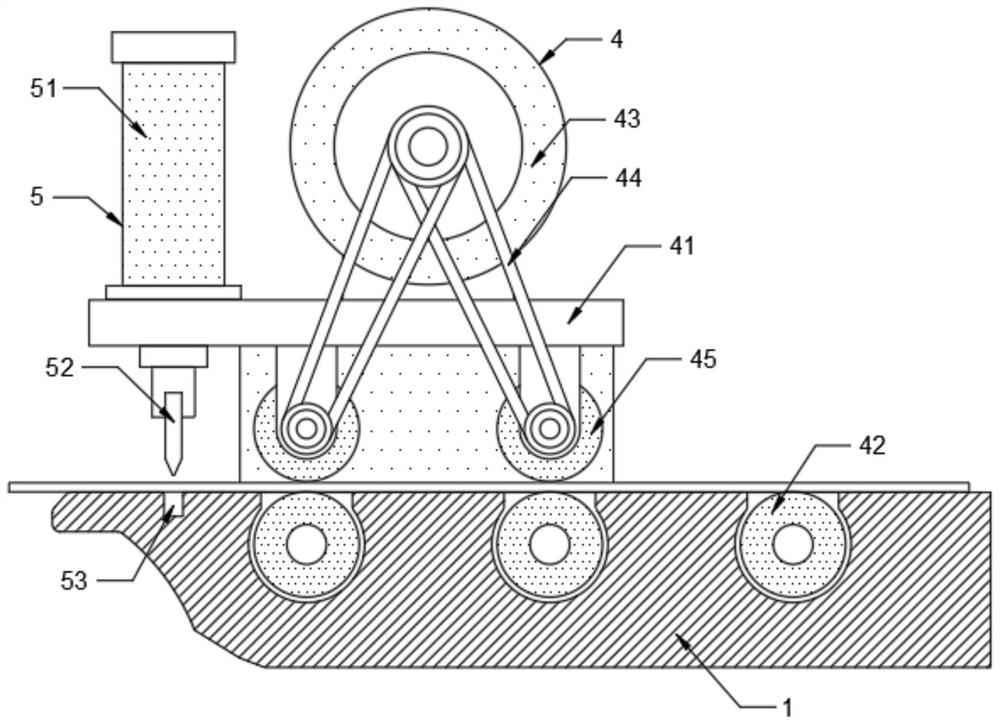

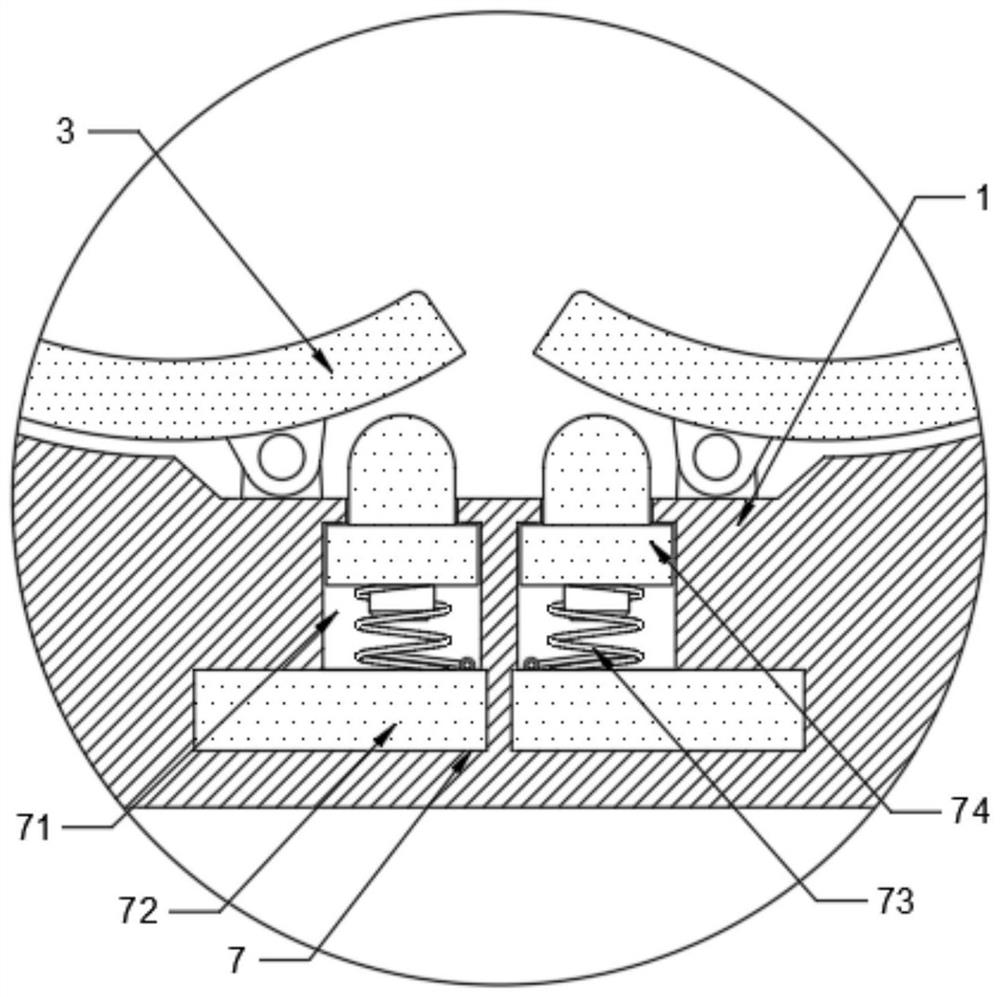

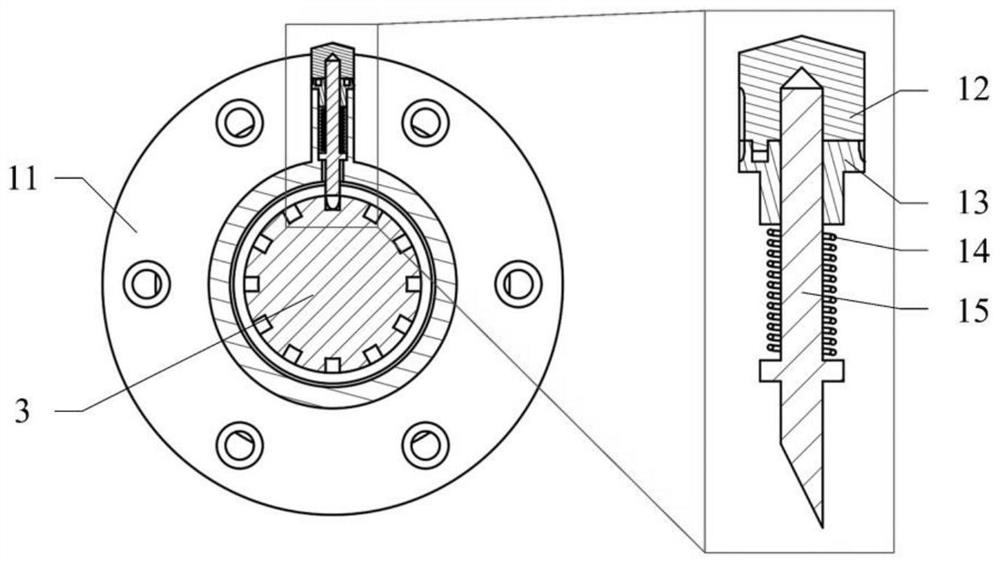

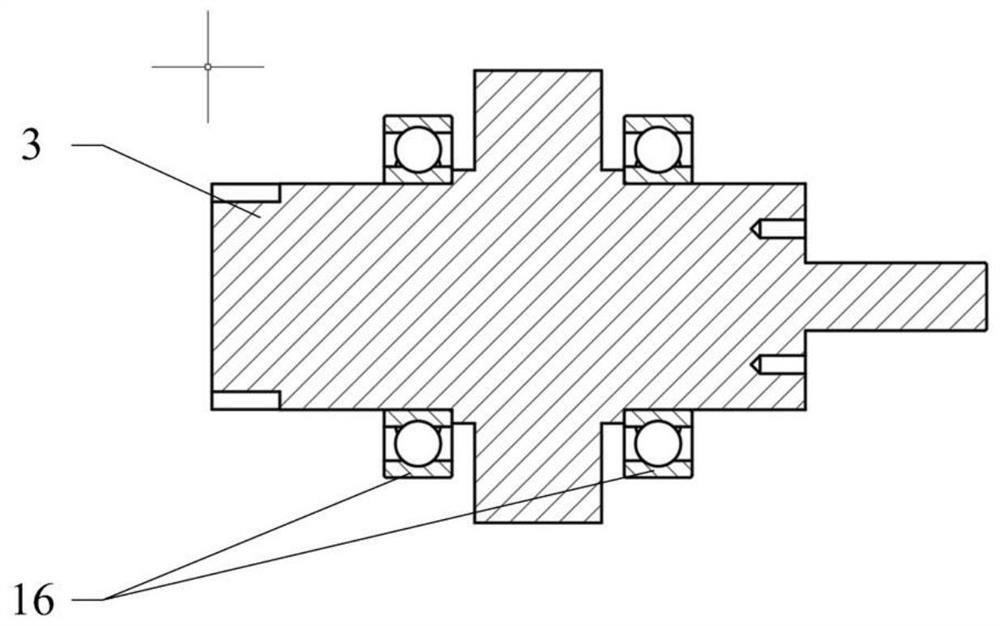

End surface grooving device

ActiveCN104551016AReduce investment in fixed assetsImprove machining accuracy and machining efficiencyTurning machinesProcessing accuracyMachining process

The invention relates to the technical field of machining equipment, in particular to a grooving device for machining the end surface of a rotary body component by utilizing a lathe. An end surface grooving device comprises a grooving machine frame, a grooving motor which is mounted on the grooving machine frame, and a cutter disk which is driven by the grooving motor; the grooving machine frame can move forward, backward, leftward, rightward, upward and downward relative to a chuck of a main shaft of a common numerical control lathe; a grooving cutter is mounted on the cutter disk; a spindle motor and the grooving motor are controlled through a synchronizing device, so that the ratio of the angular velocity of the chuck of the main shaft to the angular velocity of the cutter disk is 1:2N, wherein N is a positive integer. Theoretically, N grooves can be formed in a workpiece to be machined; the angle between every two grooves is decided by the rotating precision of the main shaft of the lathe, and is greatly superior to that decided by a rotary dial plate. Compared with the prior art, the end surface grooving device has the advantages that the investment is reduced, the machining efficiency and the machining precision are improved by replacing a subsequent milling and turning machining process and replacing a turning and milling integrated composite machining center with a lathe in the past.

Owner:龙口市蓝牙数控装备有限公司

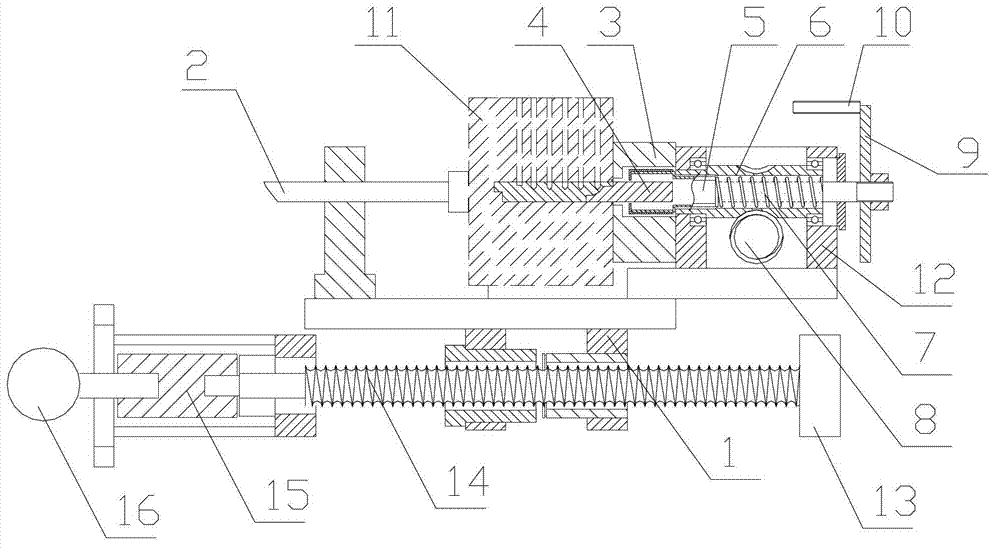

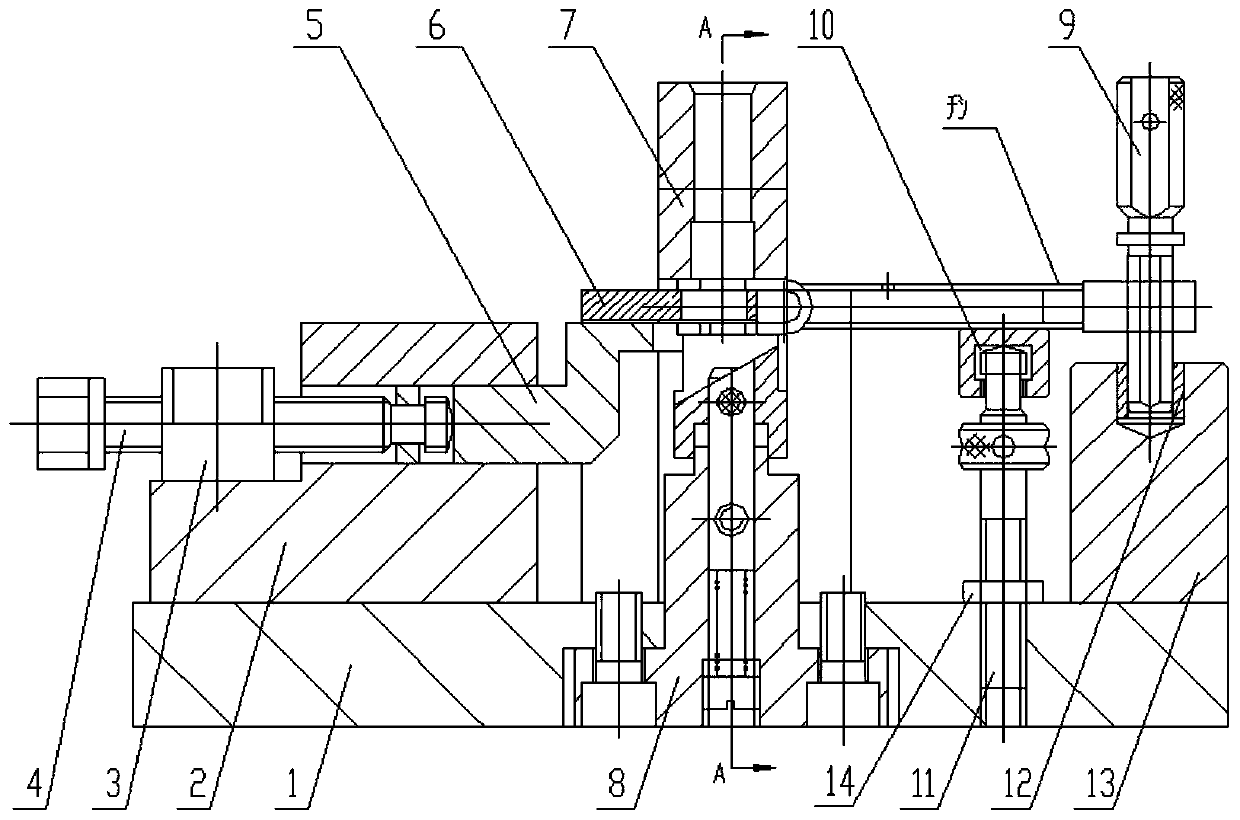

Fixture on lockset perforating machine

ActiveCN102729068AImprove machining accuracy and machining efficiencyImprove machining accuracyFeeding apparatusPositioning apparatusDrive motorEngineering

The invention relates to a lockset perforating machine. The fixture on lockset perforating machine comprises a fixture moving device and a position adjusting device, wherein the position adjusting device is installed on the fixture moving device; the fixture moving device comprises a motor, a lead screw, a mounting frame, a slide block, a movable clamping block and a fixed clamping block; and the position adjusting device comprises an enclosure, a worm, a worm wheel, a rotating shaft, a rotating core, a drive motor, a locating plate, a pressure spring and an adjusting bolt. The fixture on lockset perforating machine has the advantages that structure is novel and the lockset perforating precision is improved.

Owner:安徽格太信控科技有限公司

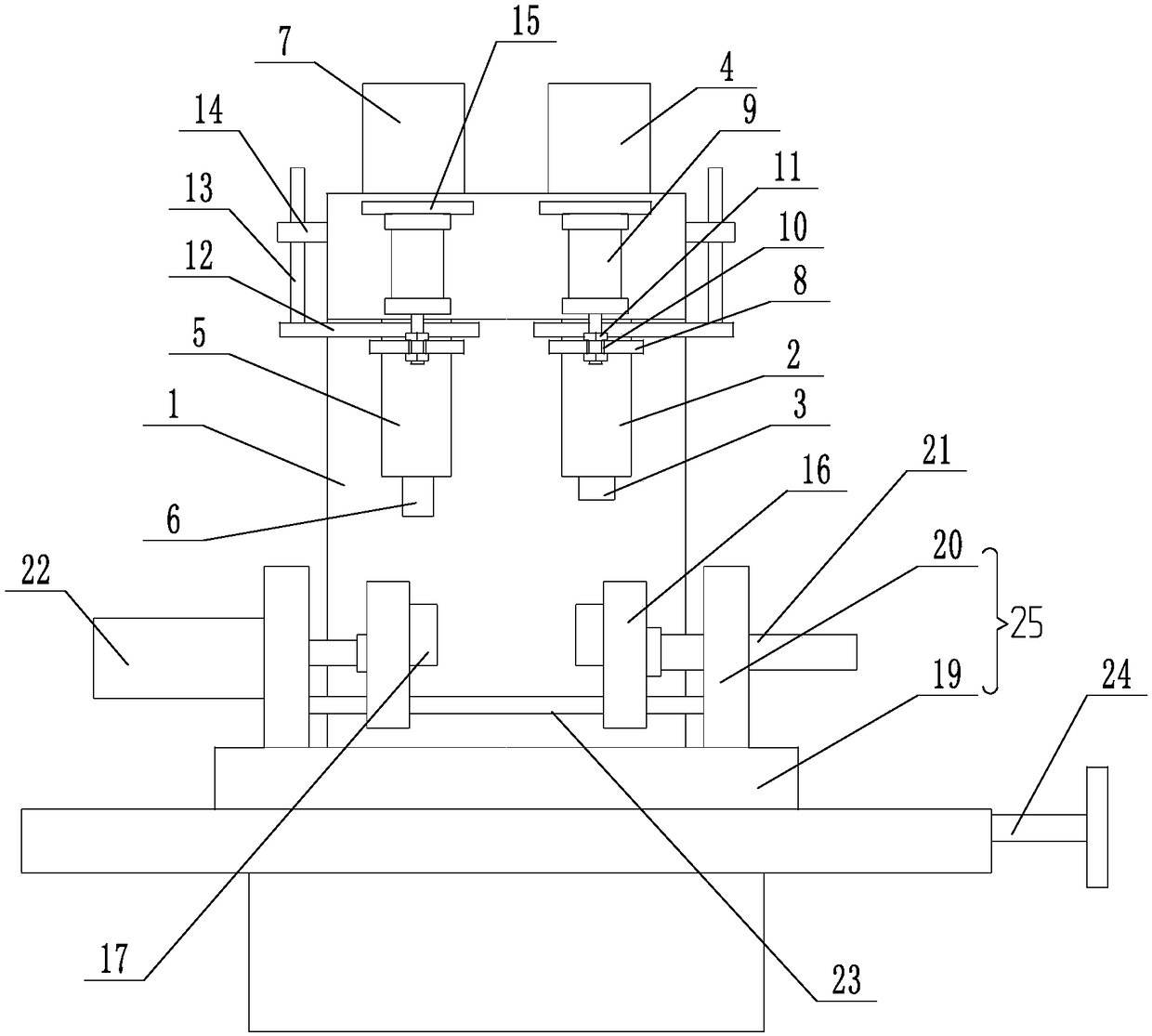

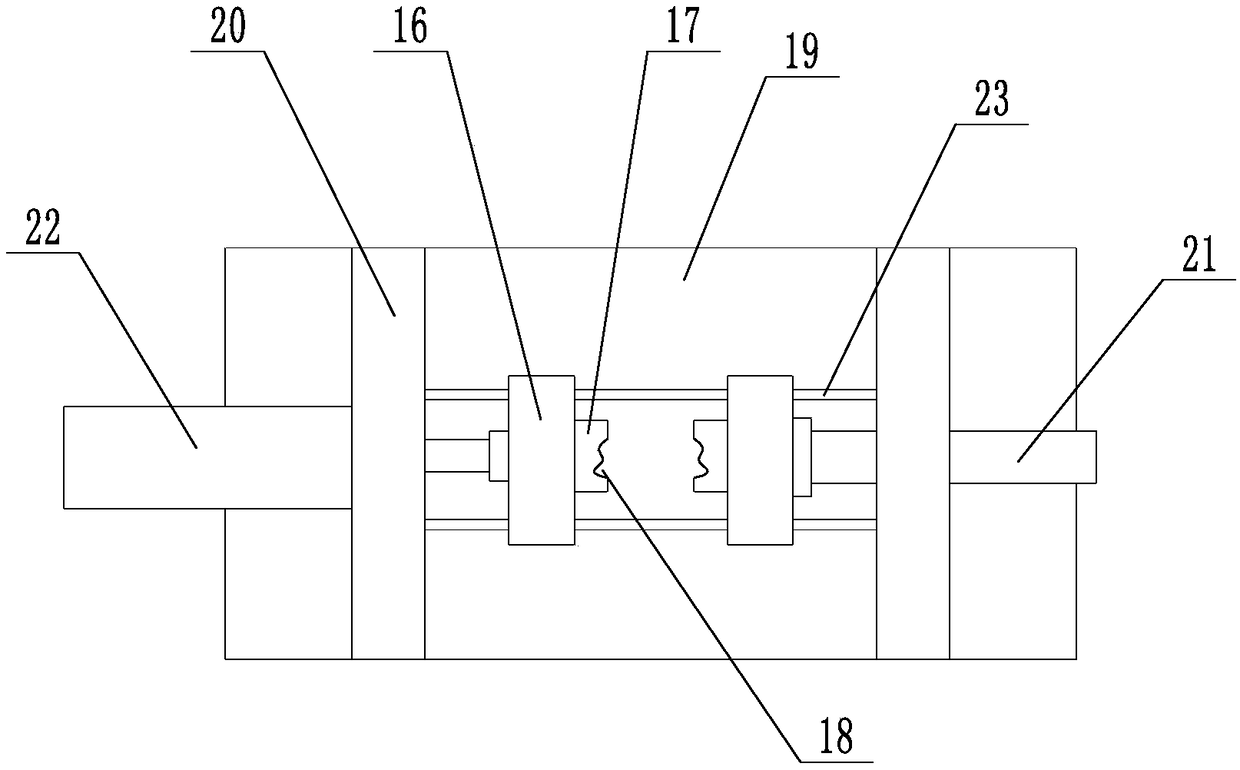

Automatic drilling and tapping equipment

InactiveCN109277831AImprove machining accuracy and machining efficiencyEasy to operateWork clamping meansFeeding apparatusMechanical engineeringEngineering

The invention discloses automatic drilling and tapping equipment. The automatic drilling and tapping equipment comprises a machine seat, and a drilling mechanism and a tapping mechanism are arranged on the machine seat. The drilling mechanism comprises a first main shaft, a drilling cuter installed on the first main shaft and a first motor for driving the drilling cutter to rotate. The tapping mechanism comprises a second main shaft, a tapping cutter installed on the second main shaft and a second motor used for driving the tapping cutter to rotate. The first main shaft and the second main shaft are connected with driving plates. The machine seat is provided with two first cylinders connected with the two driving plates correspondingly, a moving seat which can move and adjust left and right is further arranged at the position, located under the drilling mechanism and the tapping mechanism, on the machine seat, and a clamp mechanism used for clamping workpieces is arranged on the movingseat. The automatic drilling and tapping equipment can reduce the labor intensity of workers and improve the machining efficiency and the machining precision.

Owner:HESHAN OVIT KITCHEN & BATH IND CO LTD

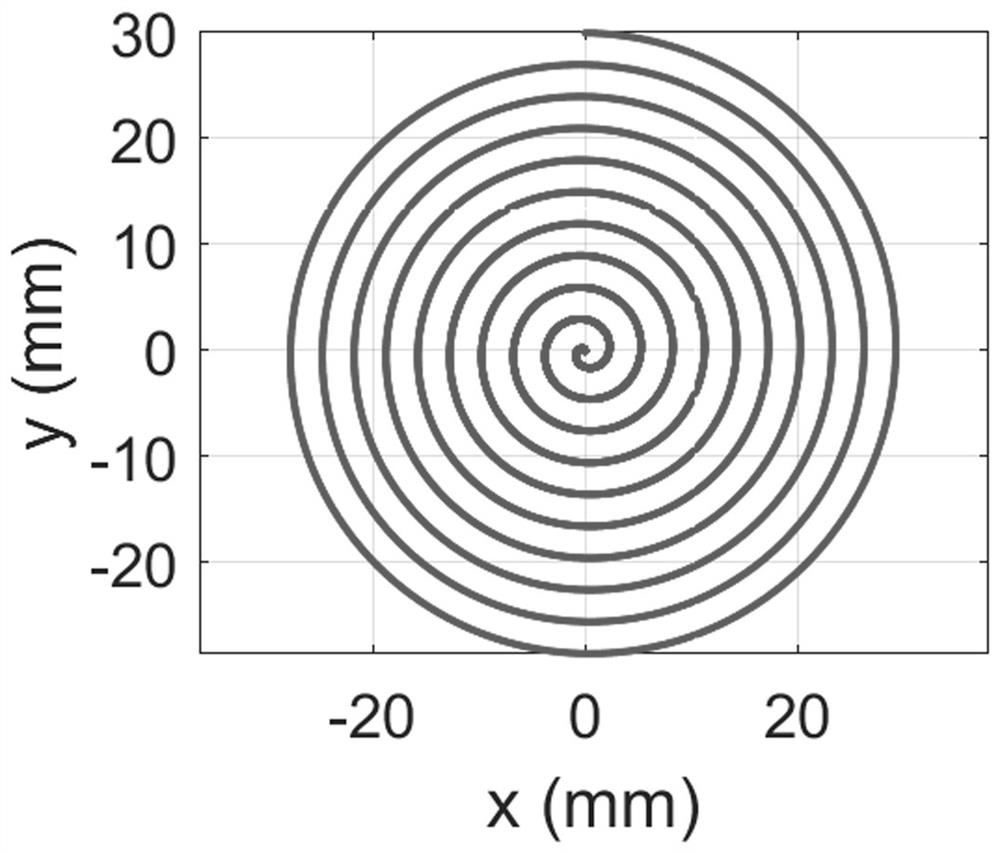

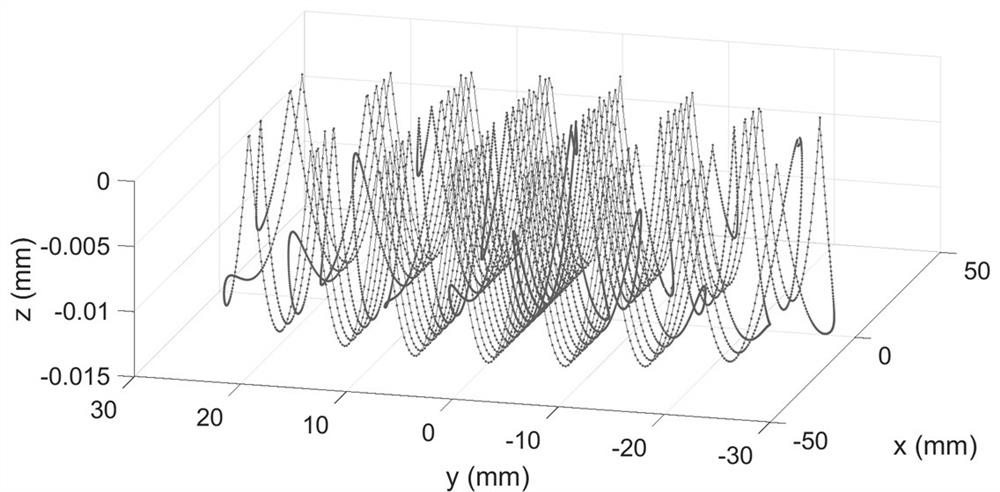

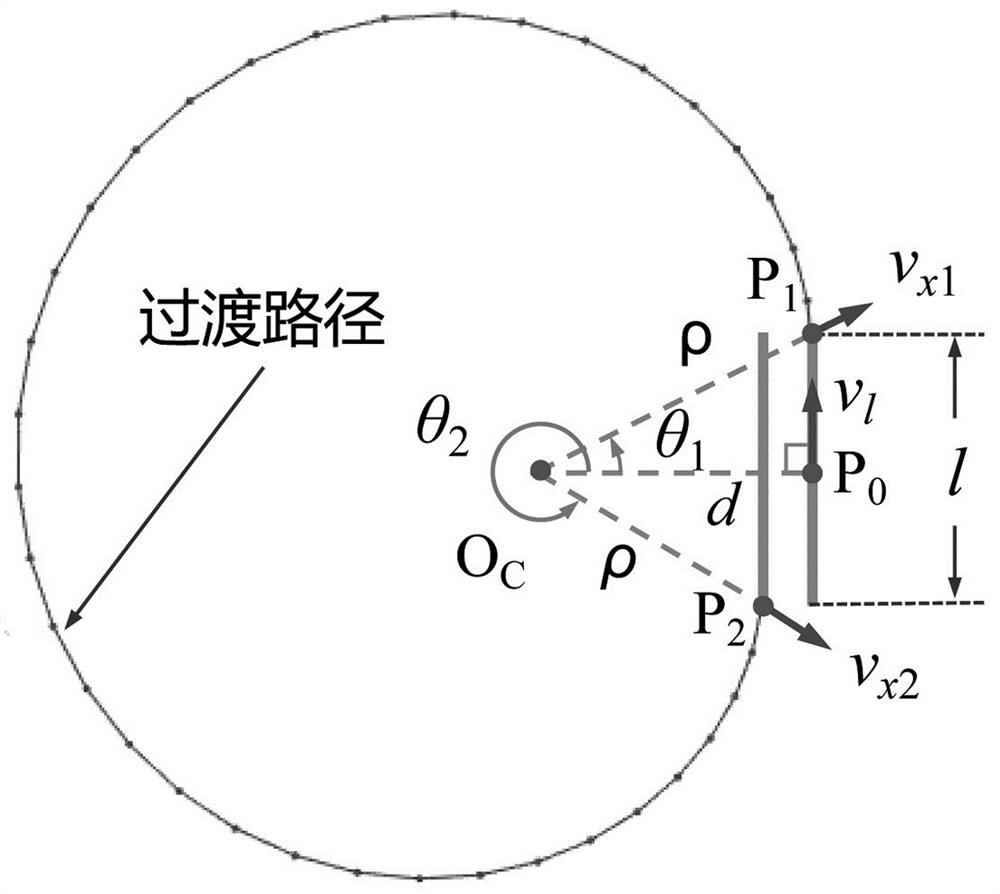

Slow cutter servo cutter path and design method thereof

ActiveCN111880472AEasy to calculateImprove machining accuracy and machining efficiencyTotal factory controlNumerical controlEngineeringUltra precision

The invention discloses a slow-tool servo tool path and a design method thereof. The slow-tool servo tool path is achieved on an ultra-precise single-point diamond lathe by utilizing linear motion axes X and Z and a turning main shaft C with angle positioning. The tool path is divided into a cutting zone and a non-cutting zone. In the cutting area, the cutter does linear motion relative to the machined workpiece to cut the to-be-machined workpiece; and in the non-cutting area, the cutter smoothly moves from the tail end of the previous cutting track of the cutting area to the starting point ofthe next cutting track. In the whole tool path running process, the feeding speed of the X axis of the lathe is kept smooth and continuous. The absolute value of the non-cutting area lathe X-axis feeding speed is not larger than the absolute value of the cutting area lathe X-axis feeding speed. Compared with the prior art, the cutter path designed by the invention needs a small amount of data, the processing quality is higher, and the cutter compensation calculation is simple. The design method of the tool path is provided, and the design method is simple in calculation and high in executionefficiency.

Owner:SUZHOU UNIV OF SCI & TECH

Erected-inverted machine tool with double spindles and double knife towers

PendingCN111761079AImprove machining accuracy and machining efficiencyHigh degree of automationLarge fixed membersMetal working apparatusProcessing accuracyContinuous production

The invention provides an erected-inverted machine tool with double spindles and double knife towers, and belongs to the field of numerically-controlled machine tools. The erected-inverted machine tool with the double spindles and the double knife towers comprises a machine body, wherein an installation platform is horizontally arranged on the machine body along the X axis; an X-axis guide rail ishorizontally arranged on the installation platform; a first vertical column and a second vertical column are sequentially vertically arranged above the installation platform; a first drive part driving the first vertical column to move along the X-axis guide rail, and a second drive part driving the second vertical column to move along the X-axis guide rail are further arranged on the machine body; a first spindle part is arranged on the first vertical column; a second knife tower part is arranged on the second vertical column; a first knife tower part is arranged on a part located at one side of the first spindle part, of the machine body; and a second spindle part is arranged on a part located between the first vertical column and the second vertical column, of the machine body. The erected-inverted machine tool with the double spindles and the double knife towers has the functions of automatically loading, automatically machining and automatically unloading, and is high in automation degree; the erection and the inversion of the machine tool are combined, and overturning is not needed during workpiece machining, so that continuous production can be carried out; the X-axis guiderail is horizontally arranged, so that more stable movement and high machining accuracy are achieved; and moreover; the mechanisms of the machine tool are compact in structure, and the machine tool is compact in overall layout.

Owner:湖北山铁智能装备有限公司

Sliding switch sliding cover assembly equipment and sliding switch assembly system

ActiveCN112171265AHigh degree of mechanizationImprove machining accuracy and machining efficiencyAssembly machinesEngineeringStructural engineering

The invention discloses sliding switch sliding cover assembly equipment and a sliding switch assembly system. The sliding switch sliding cover assembly equipment comprises a movable spring conveying mechanism, a sliding sheet conveying mechanism, a movable spring inserting mechanism and a movable spring taking mechanism, wherein a movable spring cutting assembly for cutting off adjacent movable springs is arranged in the movable spring conveying mechanism, the movable spring taking mechanism takes out the movable spring cut by the movable spring cutting assembly and transmits the movable spring to the movable spring inserting mechanism, and the movable spring inserting mechanism inserts the movable spring into a sliding sheet of the sliding sheet conveying mechanism. Through cooperation ofthe movable spring conveying mechanism, the sliding sheet conveying mechanism, the movable spring inserting mechanism and the movable spring taking mechanism, a cutting process of the adjacent movable springs and an inserting installation process of the movable spring and the sliding sheet are achieved, the mechanical degree is high, and the machining efficiency and the machining precision are greatly improved.

Owner:AMPHENOL AUTOMOTIVE CONNECTION SYST CHANGZHOU CO LTD

Fixture of clamping radiating fins at high precision

ActiveCN104889781AImprove machining accuracy and machining efficiencyWill not process quality problemsWork clamping meansPositioning apparatusTool marksHeat sink

The invention relates to a fixture of clamping radiating fins at high precision. The fixture comprises a base plate and a hold-down device; the hold-down device is arranged in holes formed in the base plate along the rotating axis; the hold-down device comprises a rotating hold-down cylinder, a rotating arm, a rotating arm holder and a cushion; the rotating hold-down cylinder is mounted in a hole formed in the rotating axis of the base plate; the rotating arm is used for holding down or avoiding the radiating fin workpiece by rotating by different angles. The clamping device comprises a cylinder mounting base, a two-axis clamping cylinder mounted on the cylinder mounting base, a first baffle plate fixed on one side, close to the radiating fin workpiece, of the two-axis clamping cylinder, a base plate mounted on the other side of the radiating fin workpiece, and a positioning block corresponding to the first baffle plate. The fixture is capable of actively avoiding the machining region during radiating fin surface machining; the whole upper surface of the radiating fin can be machined at a time without the machining quality problems such as tool mark; the production efficiency and the machining accuracy are improved.

Owner:FOSHAN PRATIC CNC SCI & TECH

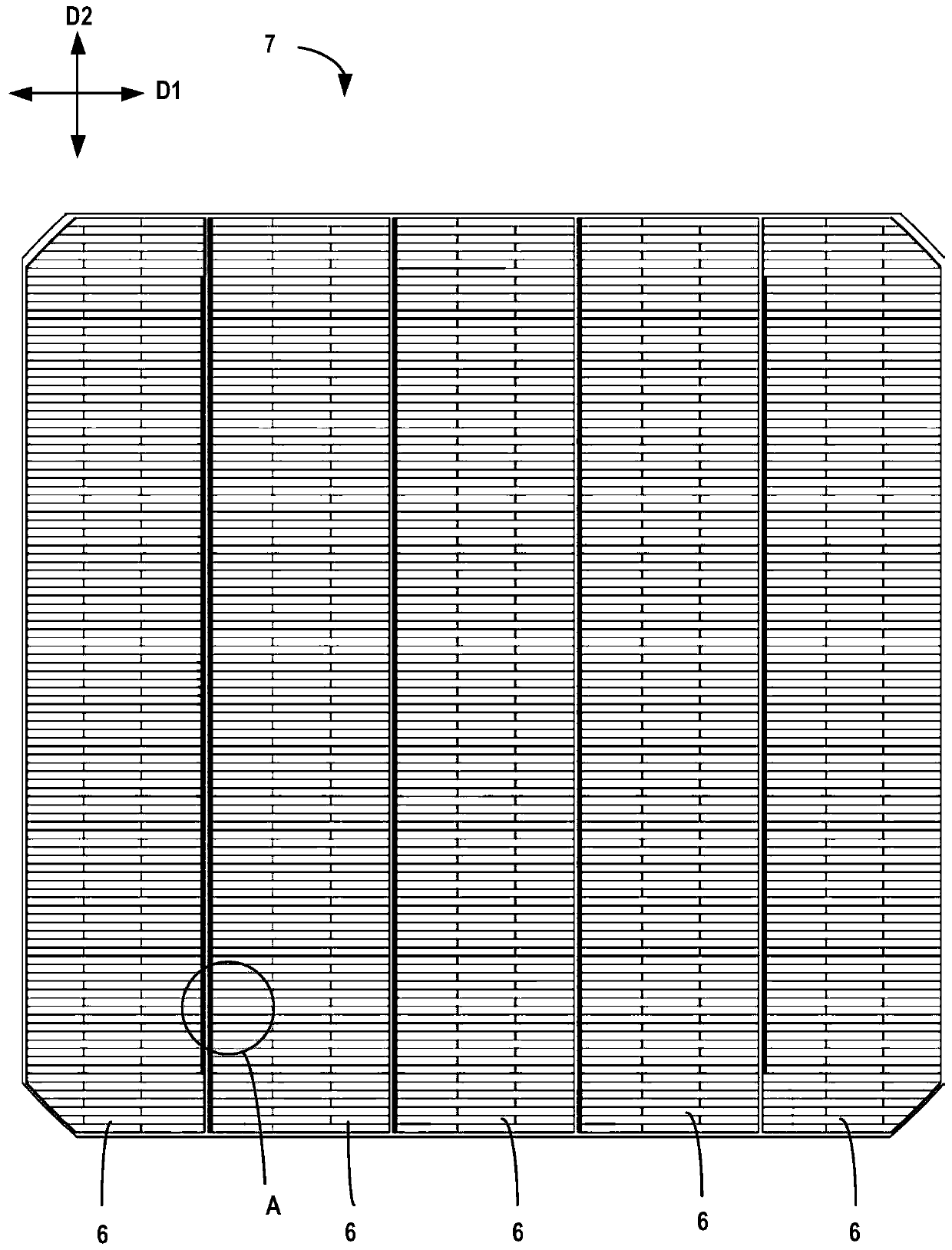

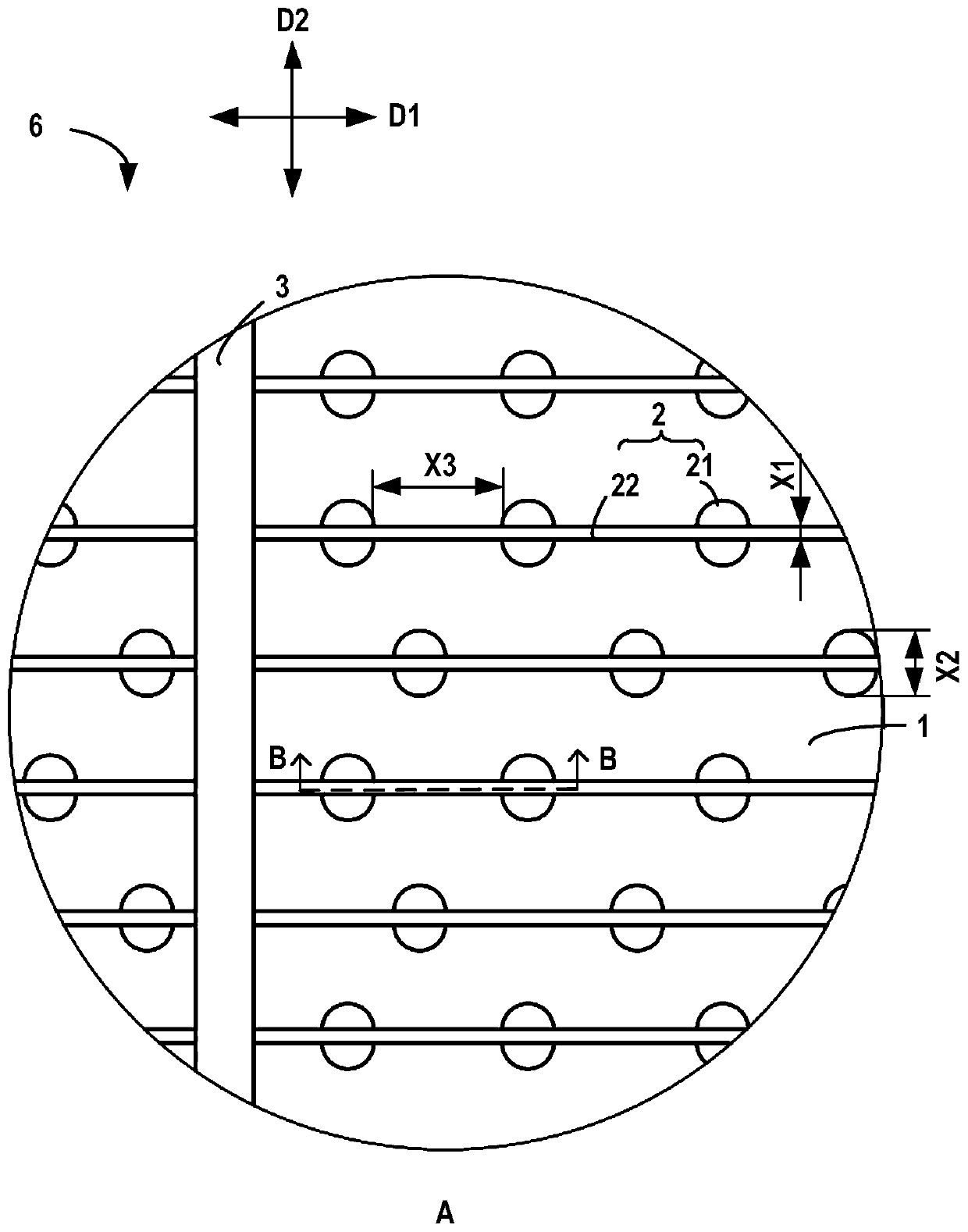

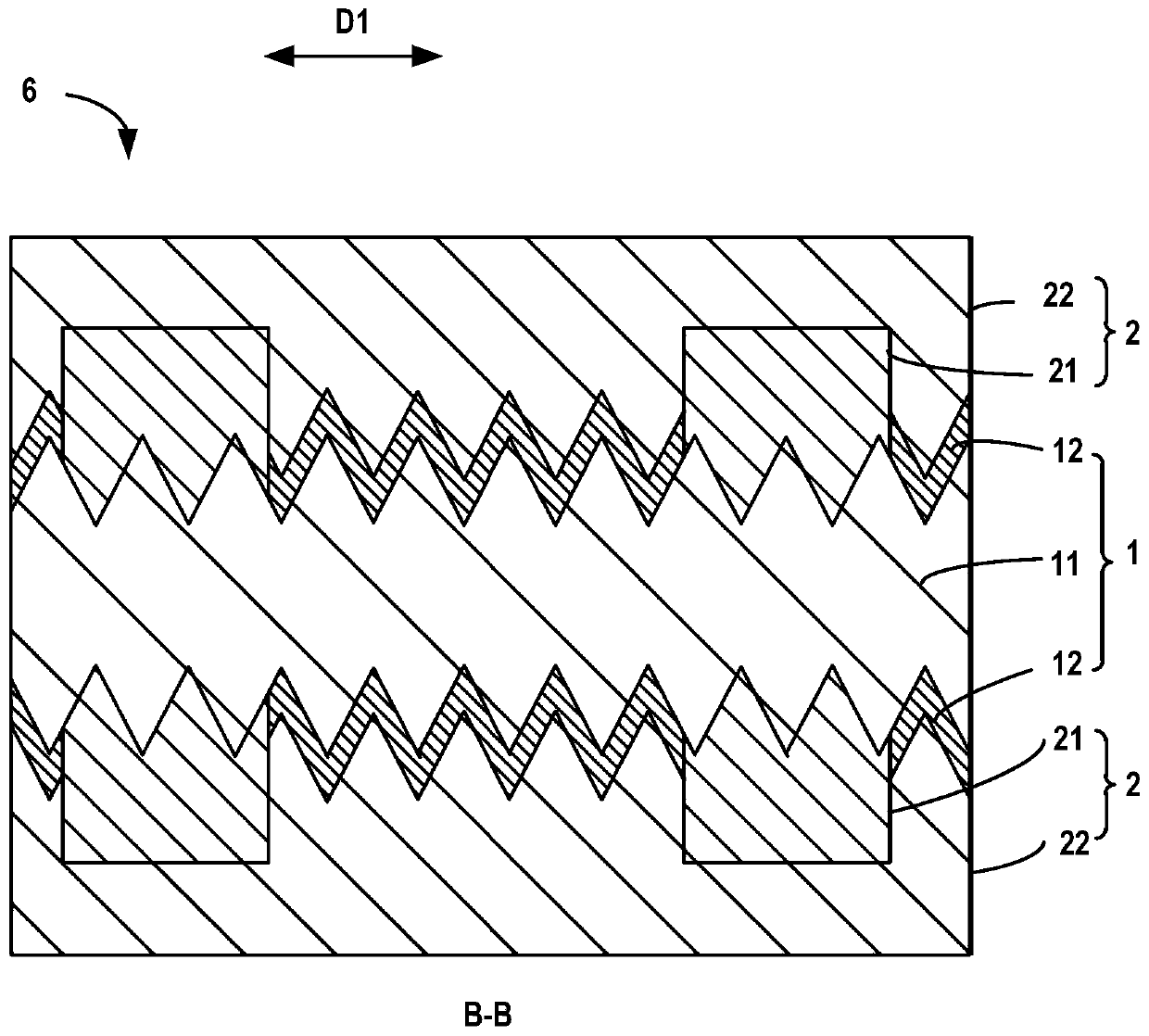

Grid line structure, solar cell, imbrication assembly, printing method and manufacturing method

PendingCN110890433AImprove machining accuracy and machining efficiencyStable characteristicsFinal product manufacturePhotovoltaic energy generationPhysicsSilicon chip

The invention relates to a grid line structure, a solar cell, an imbrication assembly, a printing method and a manufacturing method. The grid line structure is positioned on the top surface and / or thebottom surface of a matrix sheet and comprises a first layer of grid lines and a second layer of grid lines, the first layer of grid lines is in direct contact with a silicon wafer of the matrix sheet, and the second layer of grid lines is arranged at the side, opposite to the matrix sheet, of the first layer of grid lines and is in contact with a film on the silicon wafer. Each first layer of grid line of the two-layer type grid lines comprises a plurality of point-shaped structures, the point-shaped structures are arranged at intervals in the extending direction of the two-layer type grid lines, and the width of the point-shaped structures is larger than that of the second layer of grid lines. According to the invention, the first layer of grid lines is of a dot-shaped structure and thewidth of the first layer of grid lines is greater than that of the second layer of grid lines, so that the second layer of grid lines can be conveniently aligned at the first layer of grid lines during production and manufacture on the basis of reducing the compound of the grid lines and the silicon wafer due to the contact, and the processing precision and the processing efficiency are improved.

Owner:TONGWEI SOLAR ENERGY MEISHAN CO LTD

Intelligent assembling equipment for cosmetic brush

ActiveCN112460119AHigh degree of automationImprove machining accuracy and machining efficiencyLiquid surface applicatorsMaterial gluingEngineeringMechanical engineering

The invention discloses cosmetic brush intelligent assembling equipment and belongs to the field of cosmetic brush assembling equipment. The cosmetic brush intelligent assembling equipment comprises aclamping seat capable of swinging up and down in a Z-axis direction, a glue injection pipe fitting capable of automatically discharging glue, and a first driving device for driving the clamping seatto swing, wherein a clamping nozzle is arranged on the clamping seat and rotates around a C-axis on the clamping seat; a cosmetic brush head is clamped on the clamping nozzle; and the clamping centerof the clamping nozzle is coincided with the axis C. When the brush head of the cosmetic brush inclines upwards, the brush head falls below the glue injection pipe fitting; the brush head faces the brush rod assembling mechanism when the brush head inclines downwards; the brush rod assembling mechanism inserts a brush rod into the brush head; and the assembled cosmetic brush is disengaged from theclamping nozzle through a pull-out mechanism. According to the cosmetic brush intelligent assembling equipment, the brush head and the brush rod are mechanically and automatically assembled in the assembling process, so that the automation degree is high, the machining efficiency is improved, the manpower consumption and labor intensity are reduced, the manufacturing cost is reduced, and the industrial competitiveness is improved.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Positioning device of fork ear type thin-wall part

ActiveCN110802252AImprove machining accuracy and machining efficiencyAvoid deformationPositioning apparatusMetal-working holdersPhysicsThin walled

The invention discloses a positioning device of a fork ear type thin-wall part. The positioning device comprises a bottom plate, a positioning seat, a guide template and a telescopic supporting frame.A fork ear of the to-be-machined part is inserted into a positioning wall. The telescopic supporting frame is arranged between two supporting arms of the positioning seat, and the top of the telescopic supporting frame abuts against the bottom face of the lower side wall of the fork ear. The guide template is arranged on the top of the positioning seat and arranged on the upper side wall of the fork ear in a press-fit manner, a drill bit guide hole is formed in the guide template, and a drill rod penetrates through the drill bit guide hole to machine the two side walls of the fork ear. According to the device, the two side walls of the fork ear are supported by the supporting arms and the telescopic supporting frame separately, the problem that the to-be-machined part deforms due to the pressure of the drill bit in the machining process is avoided, the machining precision of the fork ear type thin-wall part is guaranteed, and the machining efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

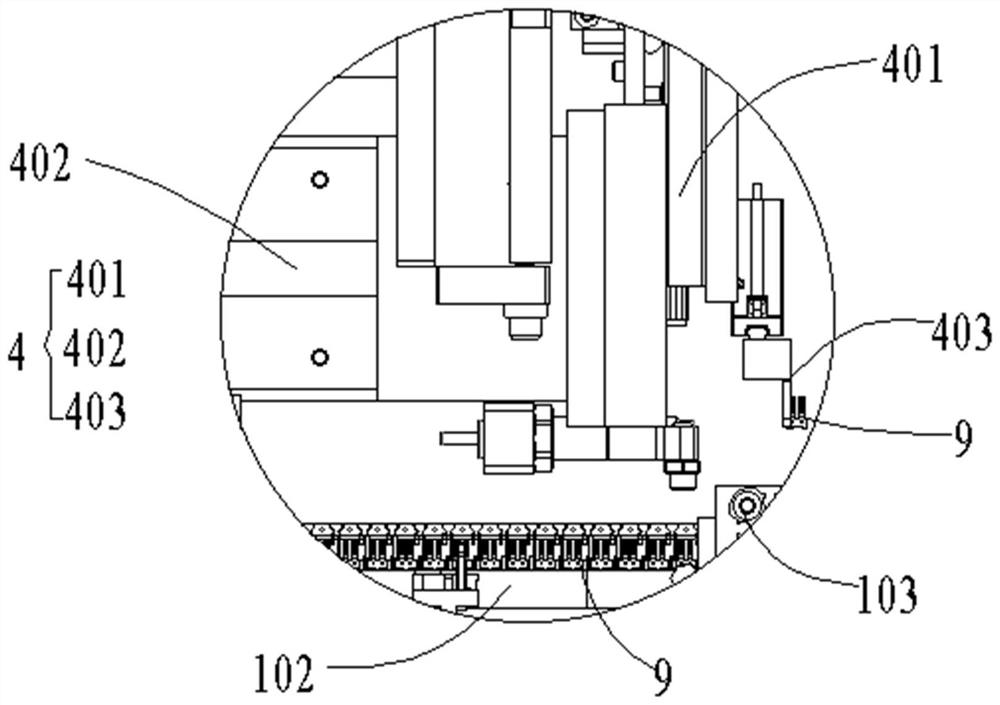

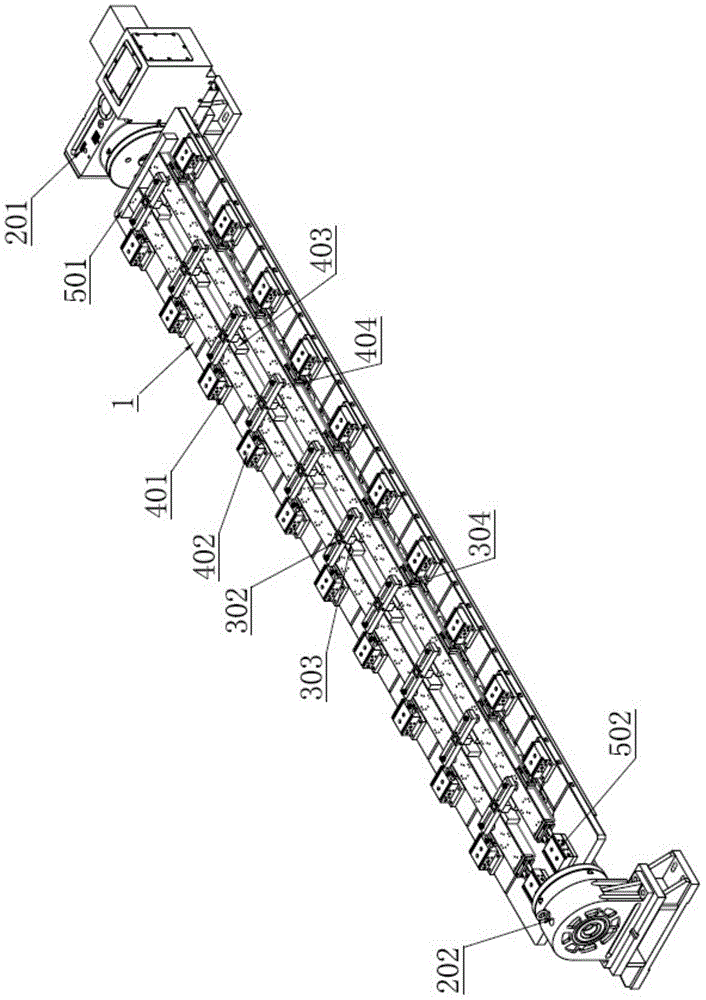

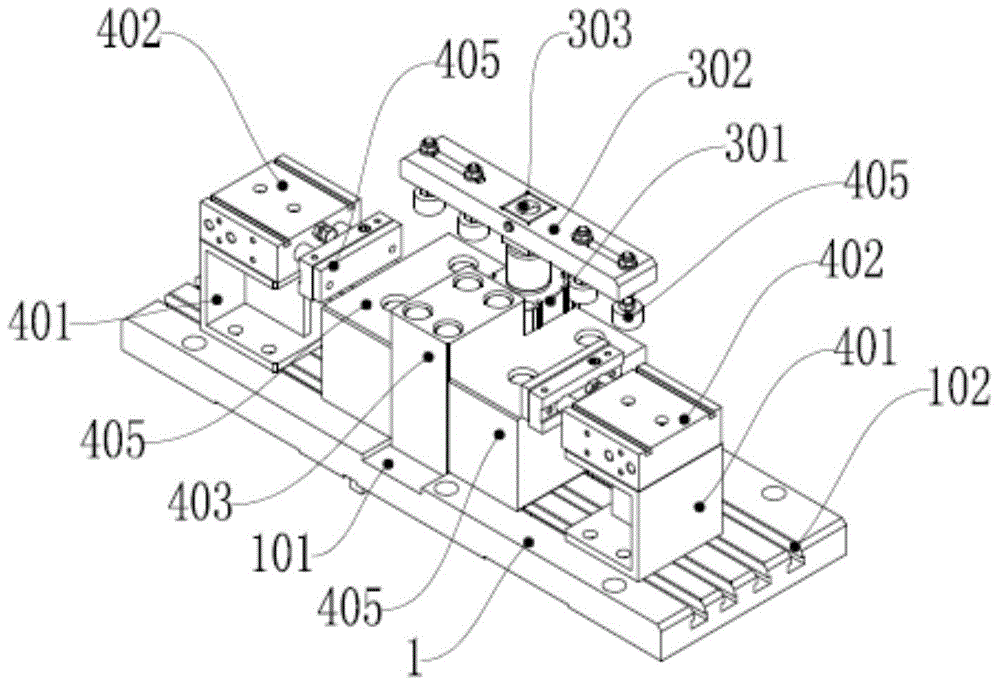

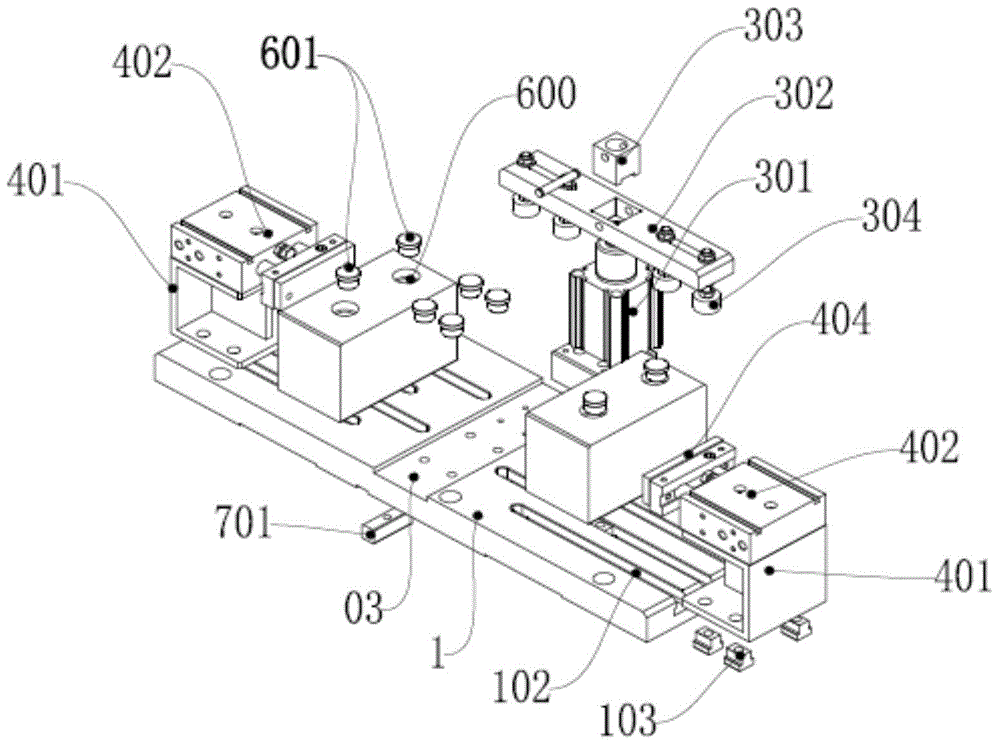

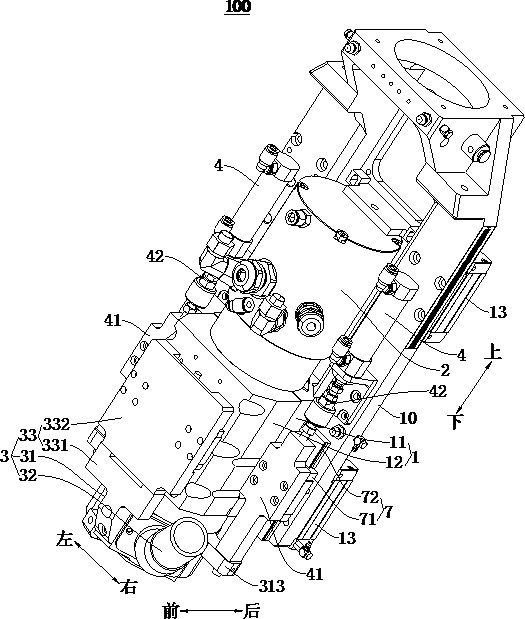

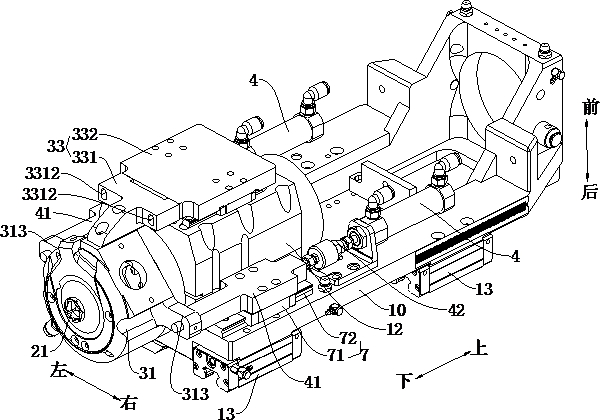

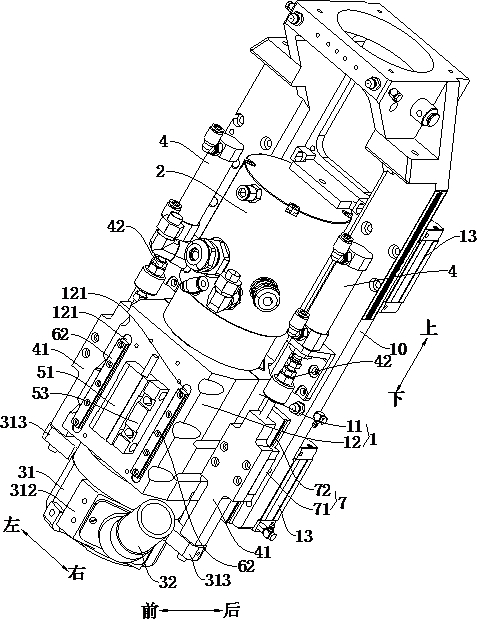

Machining mechanism and machining equipment

ActiveCN112720076AImprove machining accuracy and machining efficiencyImprove detection accuracyMeasurement/indication equipmentsFeeding apparatusProcessing accuracyStructural engineering

The invention discloses a machining mechanism and machining equipment. The machining mechanism comprises a main shaft clamp used for mounting a main shaft, a main shaft mounting frame, a pressure foot assembly, a pressure foot driving mechanism, a position detection device and a first guide assembly. The main shaft clamp is arranged on the main shaft mounting frame, the pressure foot assembly is arranged on the main shaft mounting frame in a manner of being capable of moving up and down, the pressure foot assembly comprises a pressure foot and a connecting plate connected to the pressure foot, and the position detection device is used for detecting the current height position of the pressure foot in real time. The position detection device comprises a first detection component arranged on the main shaft clamp and a second detection component arranged on the connecting plate, the first guide assembly is used for guiding relative movement of the first detection component and the second detection component, and the first guide assembly comprises at least two sets of first sliding block guide rail pairs, wherein the two sets of first sliding block guide rail pairs are located on the two opposite sides of the position detection device. According to the machining mechanism, the machining depth can be controlled in real time, and the machining precision and the machining efficiency can be improved.

Owner:SUZHOU VEGA TECH CO LTD

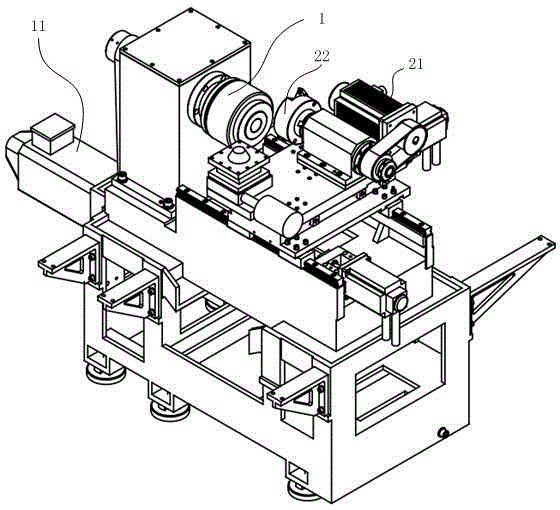

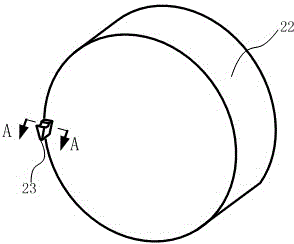

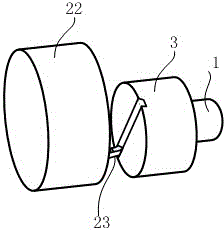

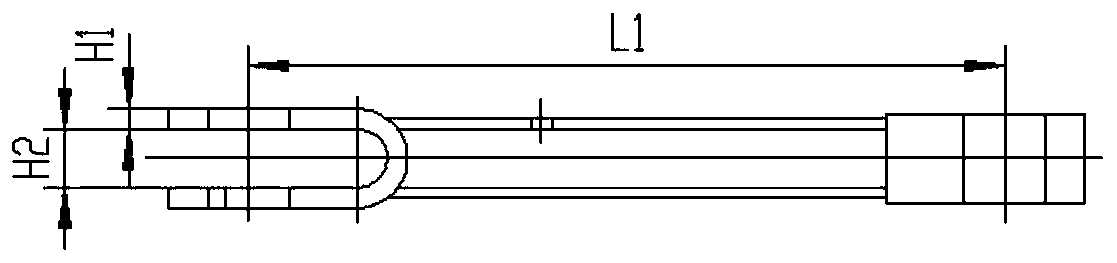

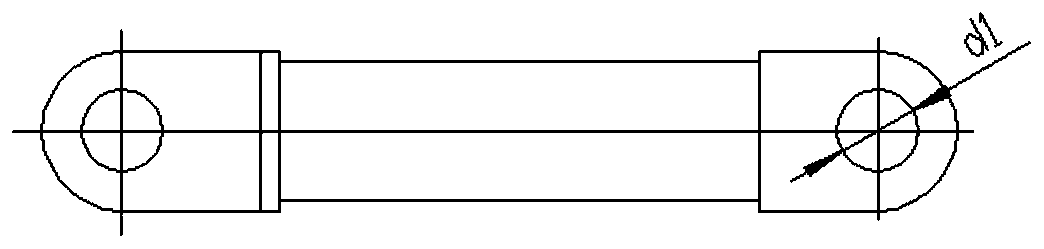

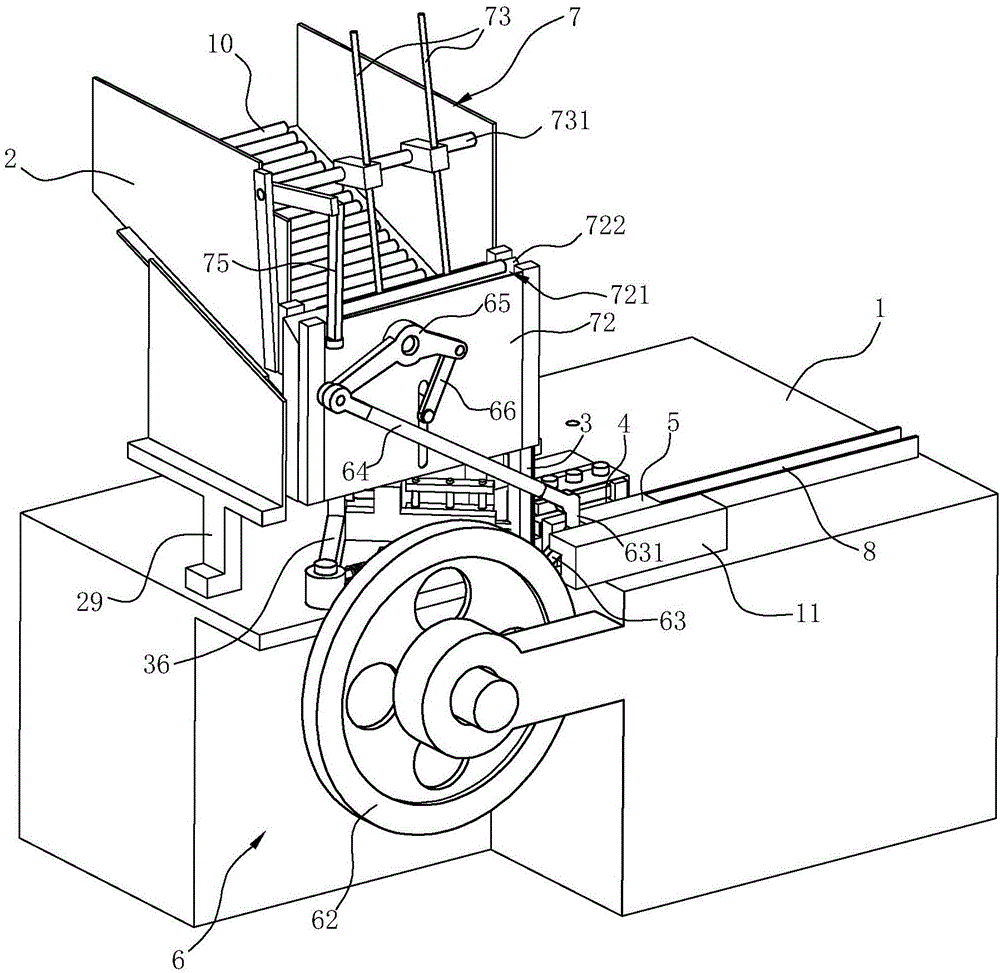

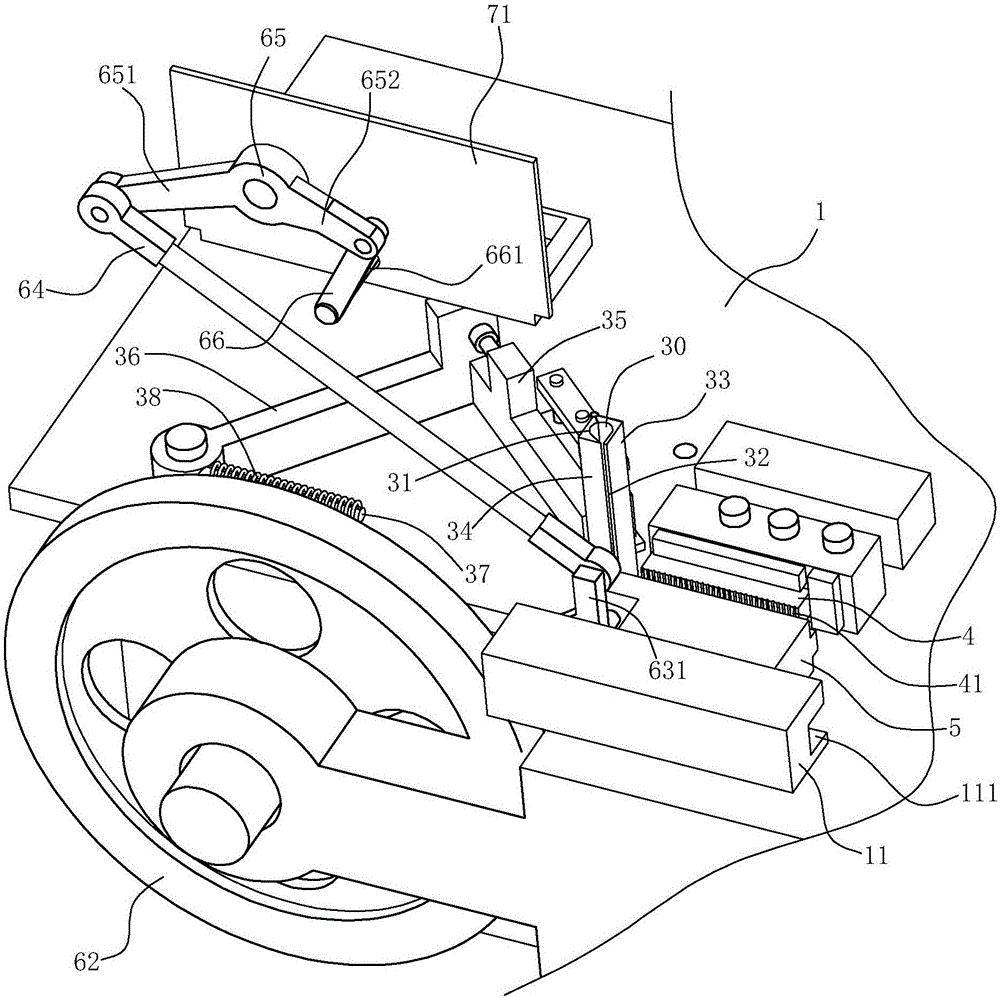

Straight-grain shaft machining equipment

PendingCN107520340ASimple drive structureImprove machining accuracy and machining efficiencyShaping toolsProcessing accuracyMaterial storage

The invention relates to straight-grain shaft machining equipment which comprises a base, a material storage tank, a temporary storage bin, a first machining gear rack, a second machining gear rack and a driving mechanism, wherein the driving mechanism is used for pushing a to-be-machined shaft to pass through the machining gear racks in the vertical rotating state, and then the straight grain is formed on the peripheral surface of the to-be-machined shaft. When the straight-grain shaft machining equipment is in use, the temporary storage bin can be used for transforming the to-be-machined shaft into the vertical state in advance; when the second machining gear rack performs reciprocating movement parallel to the first machining gear rack, the to-be-machined shaft outputted from the temporary storage bin can be taken by the second machining gear rack into the gap between the first machining gear rack and the second machining gear rack; along with the movement of the second machining gear rack, the to-be-machined shaft moves along the machining gear racks while rotating; and during the above process, the peripheral surface of the to-be-machined shaft is squeezed by teeth on both the first machining gear rack and the second gear rack, and then the straight grain is formed on the peripheral surface of the to-be-machined shaft. According to the structure of the straight-grain shaft machining equipment provided by the invention, the continuous machining of the straight grain is achieved, so that the high-density straight grain can be machined, and the machining precision and efficiency can both be remarkably improved.

Owner:NINGBO VISTART INTELLIGENT TECH

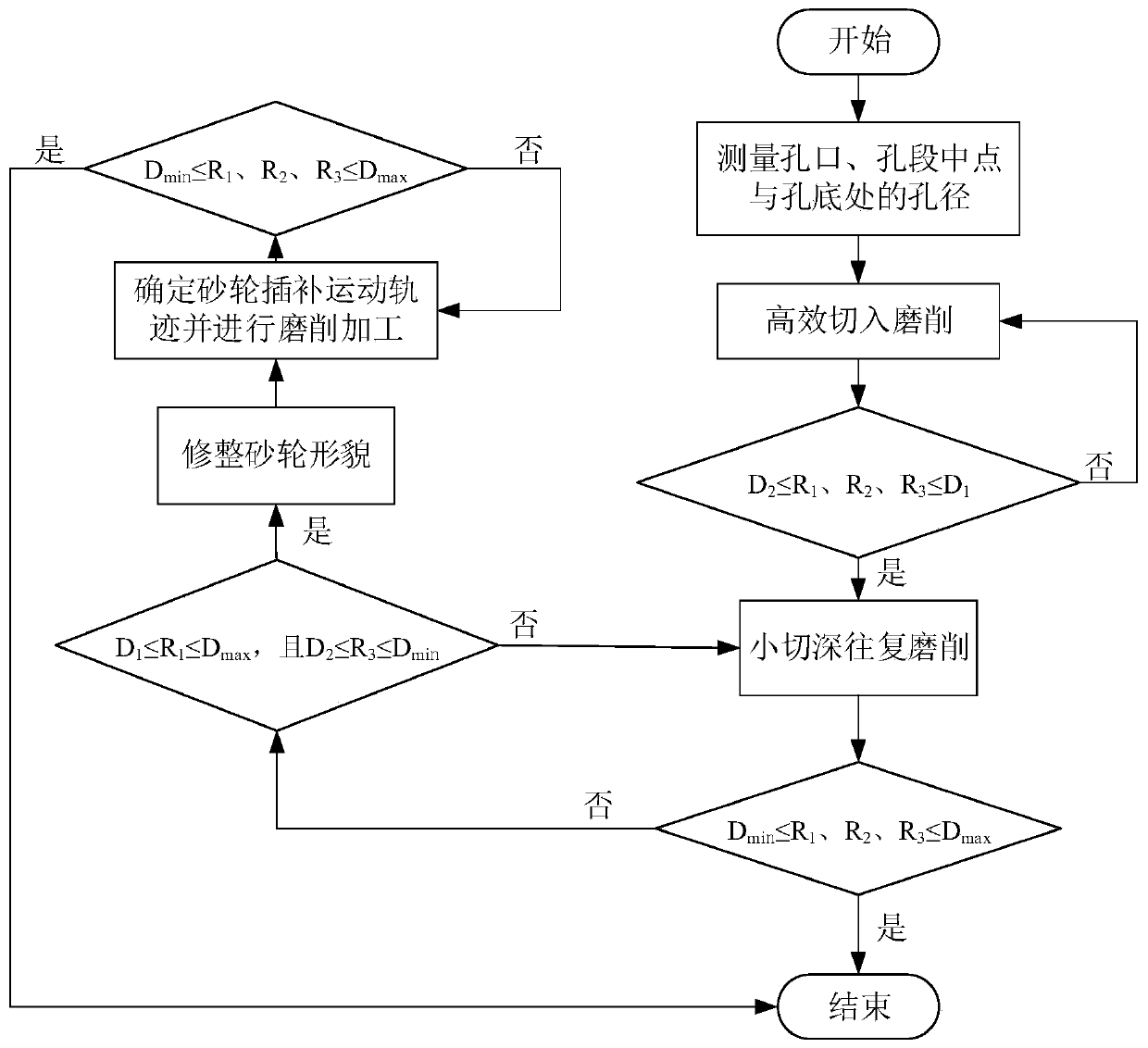

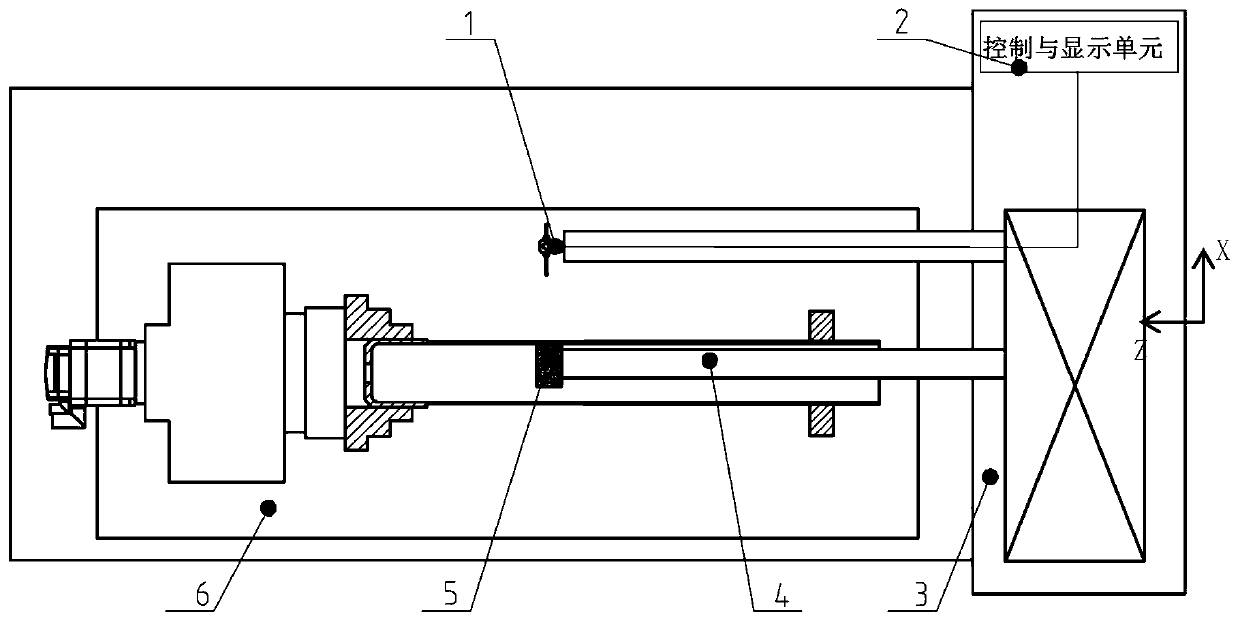

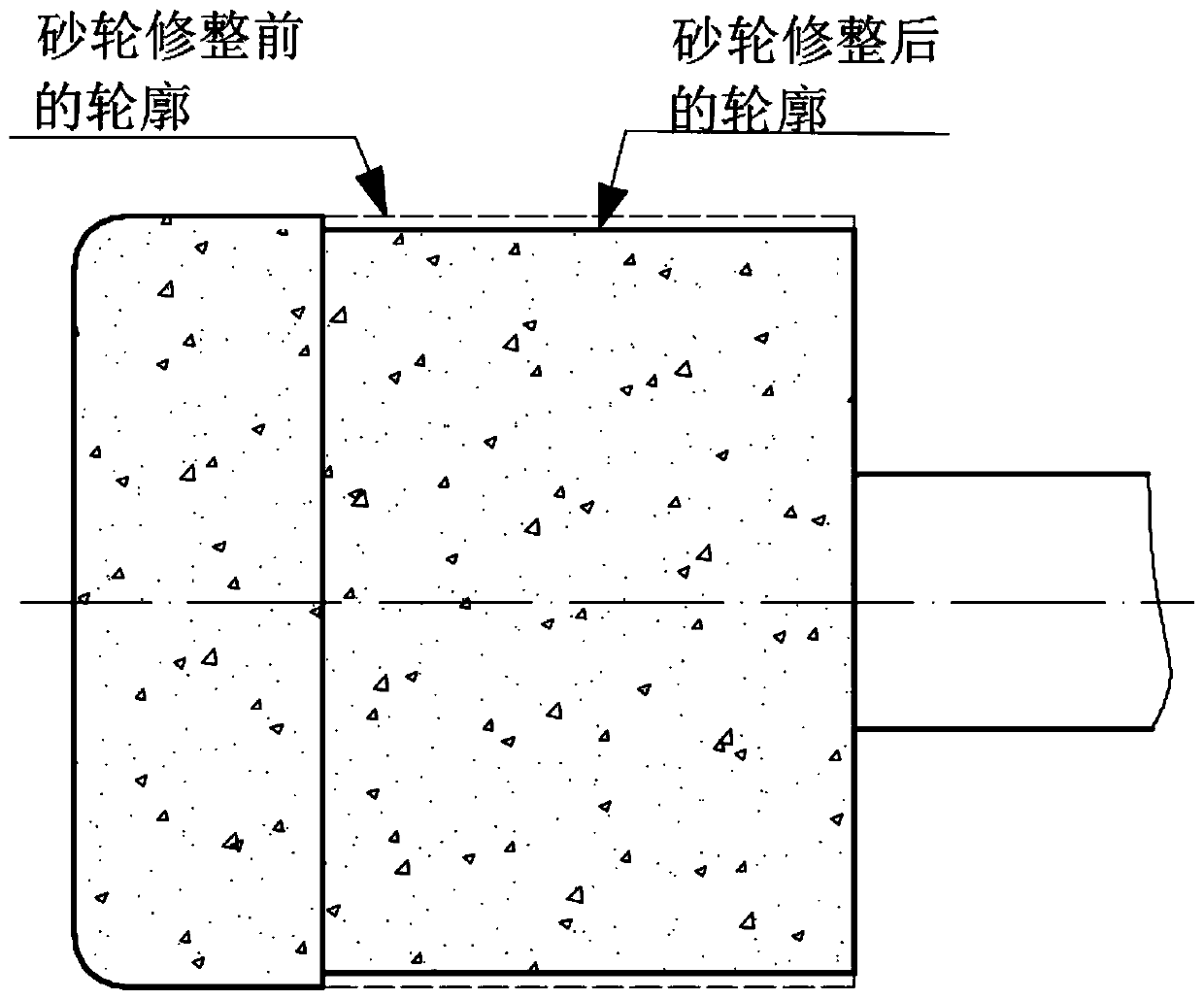

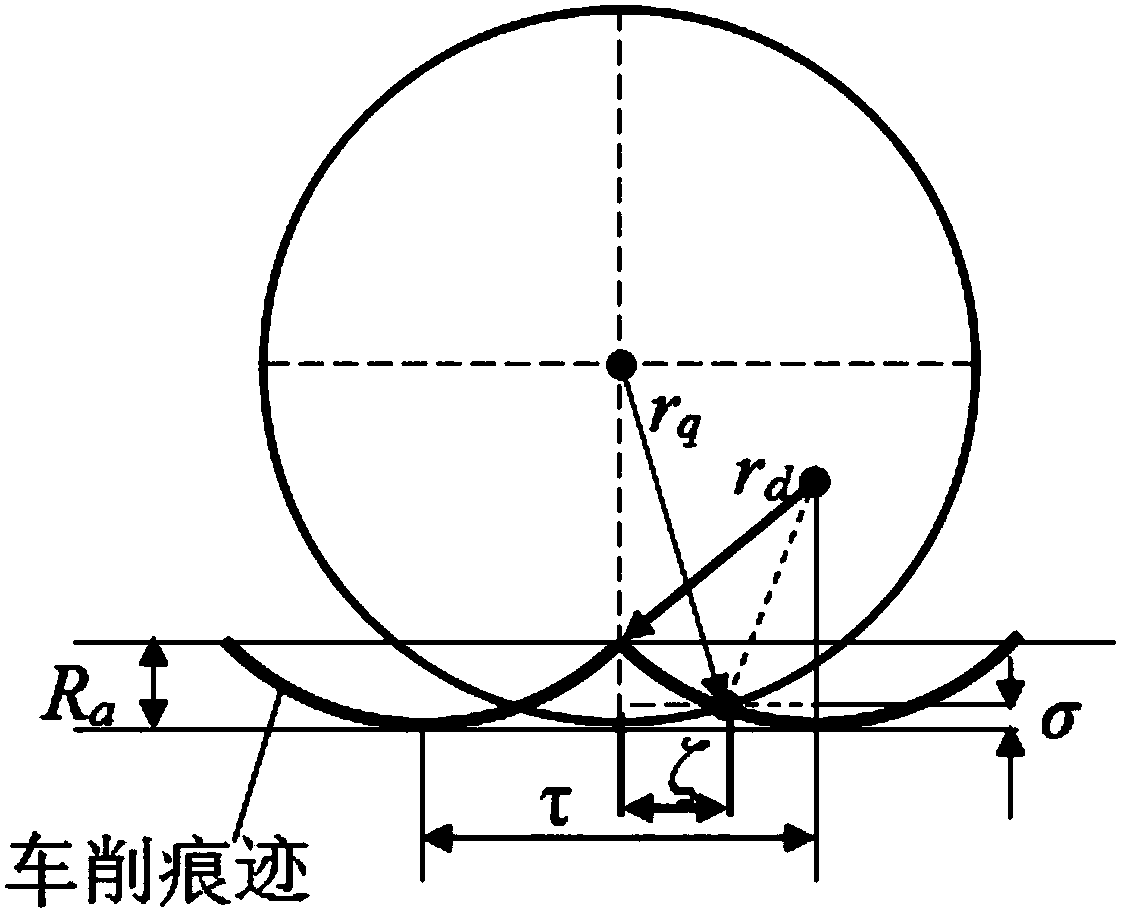

Machining method for grinding short holes by large-length-diameter-ratio weak-rigidity grinding rods

ActiveCN110227969AImprove machining accuracyImprove machining accuracy and machining efficiencyProcessing accuracyDiameter ratio

The invention discloses a machining method for grinding short holes by large-length-diameter-ratio weak-rigidity grinding rods, and belongs to the technical field of precise grinding. The machining method comprises the following steps: (S1) apertures of orifices, middle points and bottoms of machined hole sections are measured; (S2) the efficient cutting and grinding are performed; (S3) the efficient-grinded apertures are judged if reaching a set diameter range; (S4) the small-cutting-depth reciprocating grinding is performed; (S5) the precise-grinded apertures are judged if meeting the size requirements; (S6) the morphology of a grinding wheel is finished; (S7) a motion trajectory of the grinding wheel is determined; and an interpolation method is used for grinding; and (S8) the interpolation method is applied to polish the apertures until the size requirements are met. The machining method realizes efficient removal of materials by normal grinding pretightening force between the grinding wheel and workpieces during grinding through adjustment of prebending deformation of the grinding rods during grinding, realizes high-quality and high-efficiency precise grinding of the short holes of large-length-diameter-ratio parts through the morphology change of the grinding wheel, and improves the machining precision and quality and the production efficiency of the short holes.

Owner:DALIAN UNIV OF TECH

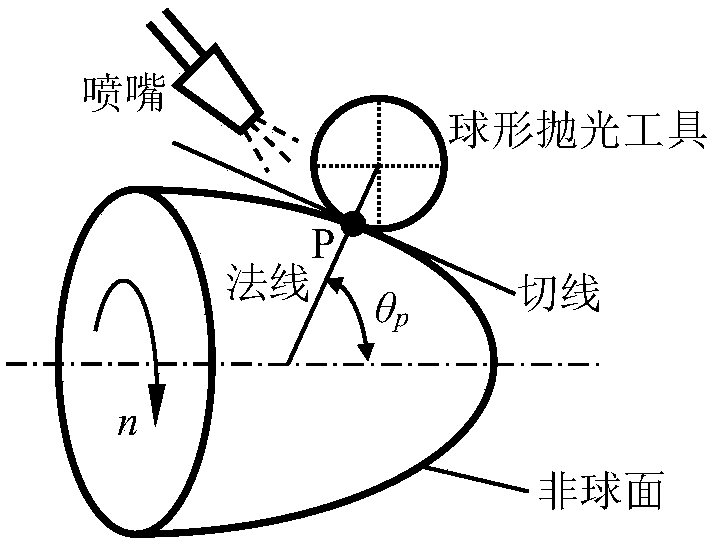

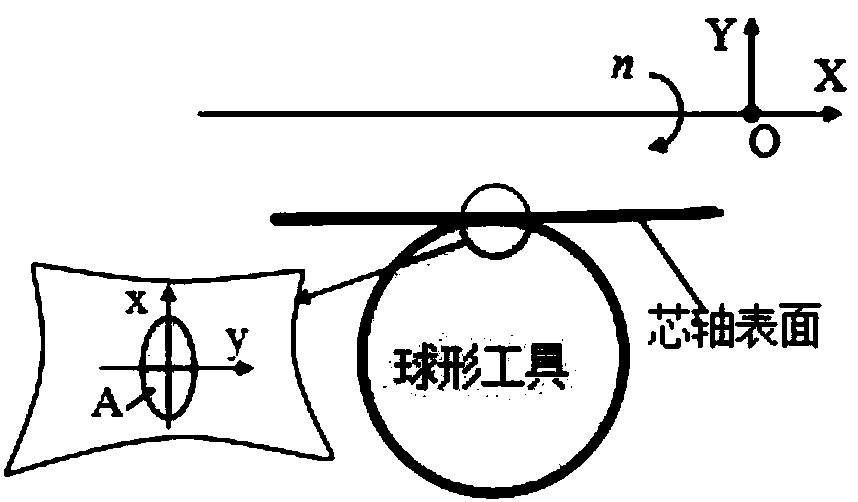

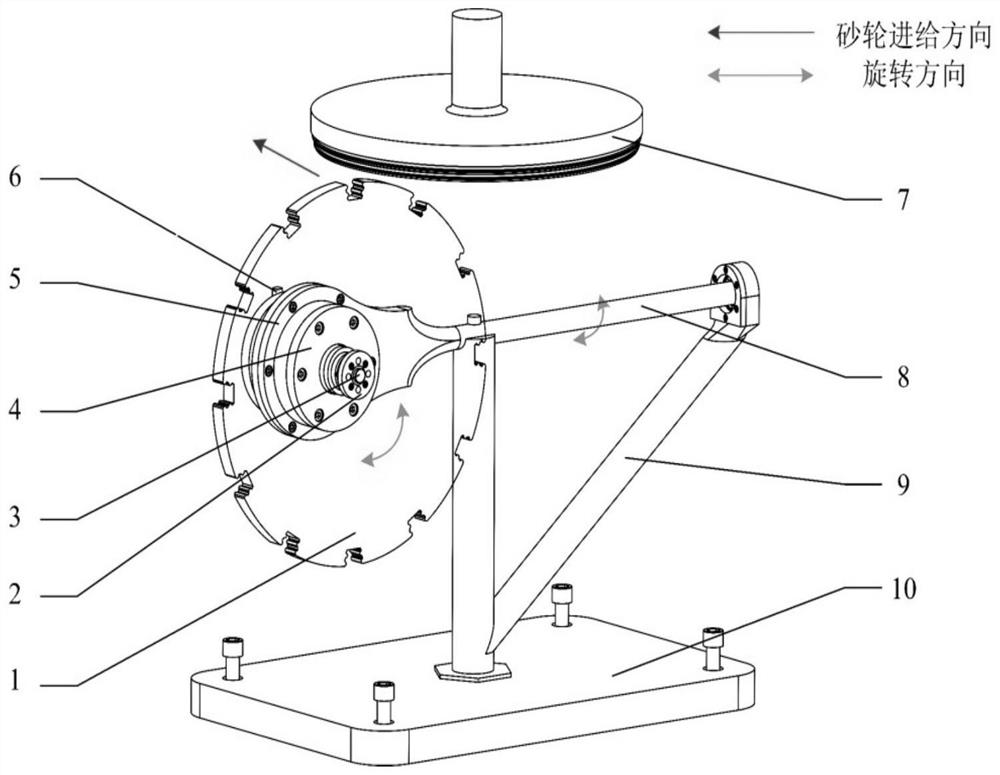

Method for definitively polishing Wolter-I type optical mandrel

ActiveCN108356608AImprove machining accuracy and machining efficiencyIncrease manufacturing costProcessing accuracyEngineering

The invention discloses a method for definitively polishing a Wolter-I type optical mandrel. The method comprises the following steps of: (1) determining removal height and a ball diameter of a polishing ball; (2) determining a radius of a contact area and calculating contact pressure; (3) determining a Preston coefficient; (4) calculating movement track of the ball center of the polishing ball and dwell time at each polishing point; (5) writing numerical-control processing program, realizing control on movement track of an elastic ball body polishing tool, and controlling dwell time t, at thepolishing point, of the elastic ball body polishing tool according to a numerical-control delay instruction; and (6) attaching polishing cloth on the surface of the elastic ball body polishing tool,and selecting a proper polishing solution to polish the surface of the mandrel according to pre-calculated polishing parameters. The polishing method disclosed by the invention can integrate the spherical polishing tool into turning processing equipment, realizes once completing of mandrel turning and polishing processing, and improves mandrel processing precision and processing efficiency.

Owner:HARBIN INST OF TECH

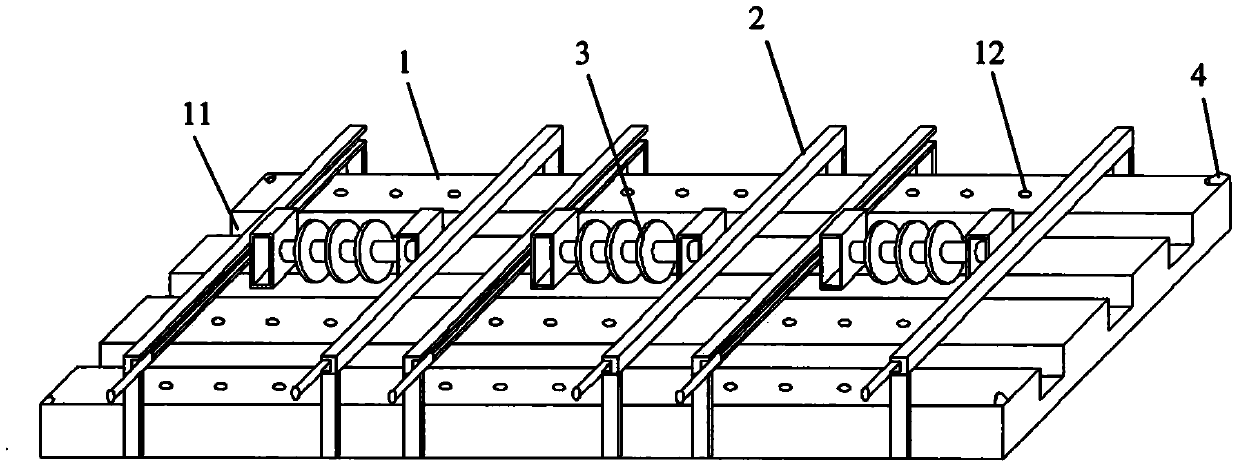

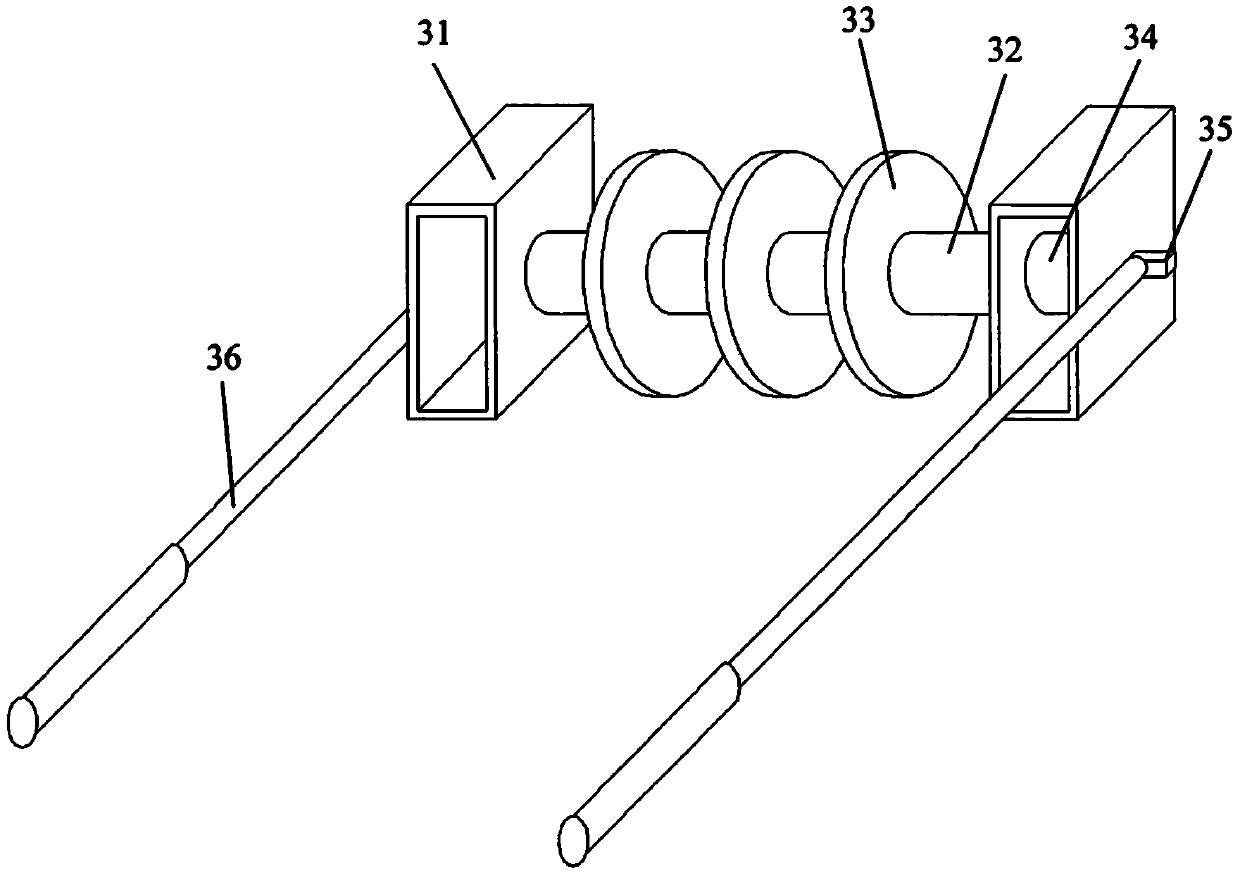

Intelligent rack machining device

ActiveCN110125488AImprove machining accuracy and machining efficiencyImprove processing efficiencyGear teeth manufacturing toolsGear-cutting machinesEngineeringHobbing

The invention discloses an intelligent rack machining device. The intelligent rack machining device comprises a pedestal, supporting frames and hobbing assemblies; the surface of the pedestal is parallelly provided with a plurality of machining grooves; the multiple supporting frames each comprise a transverse rod and a supporting rod; each hobbing assembly comprises a box shaping plate, a rotaryshaft, knife wheels, a motor, a slide block and a hydraulic rod; and the knife wheels on each hobbing assembly are the same in dimension, and the knife wheels of the hobbing assembles on the differentsupporting frames are different. According to the intelligent rack machining device provided by the invention, by arranging the multiple hobbing assemblies provided with the knife wheels, the knife wheels on each hobbing assembly are the same in dimension, thus, multiple racks can be machined at the same time, the multiple racks can be machined through one hobbing assembly, in addition, each rackcan be machined by the corresponding hobbing assembly, and the machining efficiency and the machining precision are improved.

Owner:JINHUA DAZHONG GEAR

Stamping device for hardware fitting machining and using method

PendingCN111872264AImprove machining accuracy and machining efficiencyAchieve ring extrusionMetal-working feeding devicesPositioning devicesProcessing accuracyTorsion spring

The invention discloses a stamping device for hardware fitting machining and a using method. The stamping device comprises a machining table, a stamping groove and a pressing device, wherein the stamping groove is formed in the surface of the machining table, the pressing device is arranged at the position, located above the stamping groove, of the top of the machining table, inner die plates aresymmetrically arranged in the stamping groove, the inner die plates are elastically and rotationally connected with the inner wall of the stamping groove through torsion springs, touch mechanisms forelastically stretch-out and draw-back touch are arranged at the positions, corresponding to the inner die plates, of the bottom of the machining table, a feeding mechanism for rolling extruding guiding is arranged on the side, away from the pressing device, of the top of the machining table, and a cutting mechanism for pneumatic quick punching is arranged at the end of the feeding mechanism. According to the stamping device for hardware fitting machining, an annular pressing mode is adopted, and the inner die plates capable of movable rotating are matched, so that the annular extrusion is carried out on a steel belt, tight annular wrapping is guaranteed, and the one-step forming effect is achieved; and meanwhile, a linkage mechanism is triggered, so that the whole machining process is coherent, and the machining efficiency and the machining precision are improved.

Owner:嘉兴市光炬五金科技有限公司

Clamping platform for integral turbine disc mortise forming and grinding machining and operation process of clamping platform

InactiveCN112296814ASimplify the Form Grinding ProcessImprove machining accuracy and machining efficiencyGrinding carriagesGrinding machinesPhysicsEngineering

The invention relates to a clamping platform for integral turbine disc bucket groove forming and grinding machining and an operation process of the clamping platform. The clamping platform is characterized in that two ends of a rotating middle shaft of the platform are connected with a flange and a two-way positioning mechanism correspondingly, a turbine disc is clamped through the flange, the two-way positioning mechanism can realize clockwise or anticlockwise positioning rotation of the rotating middle shaft according to a fixed angle, an upper supporting rod is connected with a middle shaftshell, bearings are arranged at the two ends of the rotating middle shaft and installed in a shell, the upper supporting rod is provided with a bearing and a positioning pin and connected with a mainsupporting frame, so that two-degree-of-freedom positioning rotation of a turbine disc is achieved, and then under one-time clamping and positioning of the turbine disc, forming and grinding machining of the integral turbine disc bucket groove is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

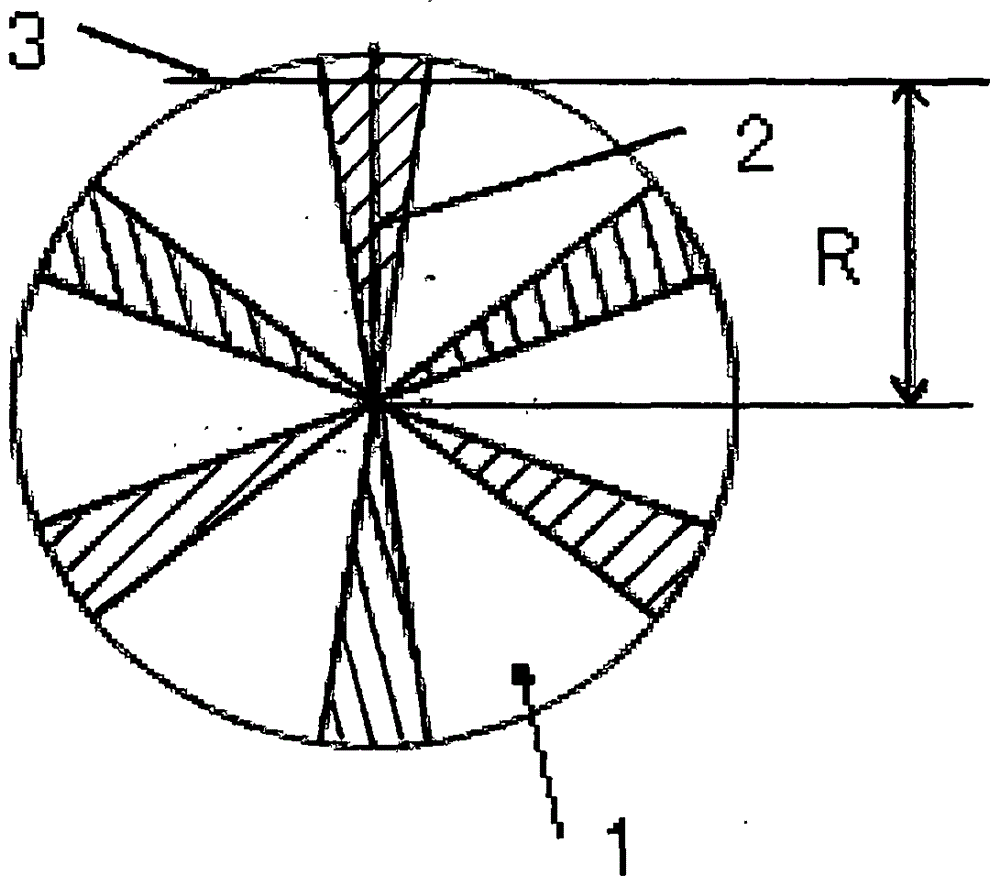

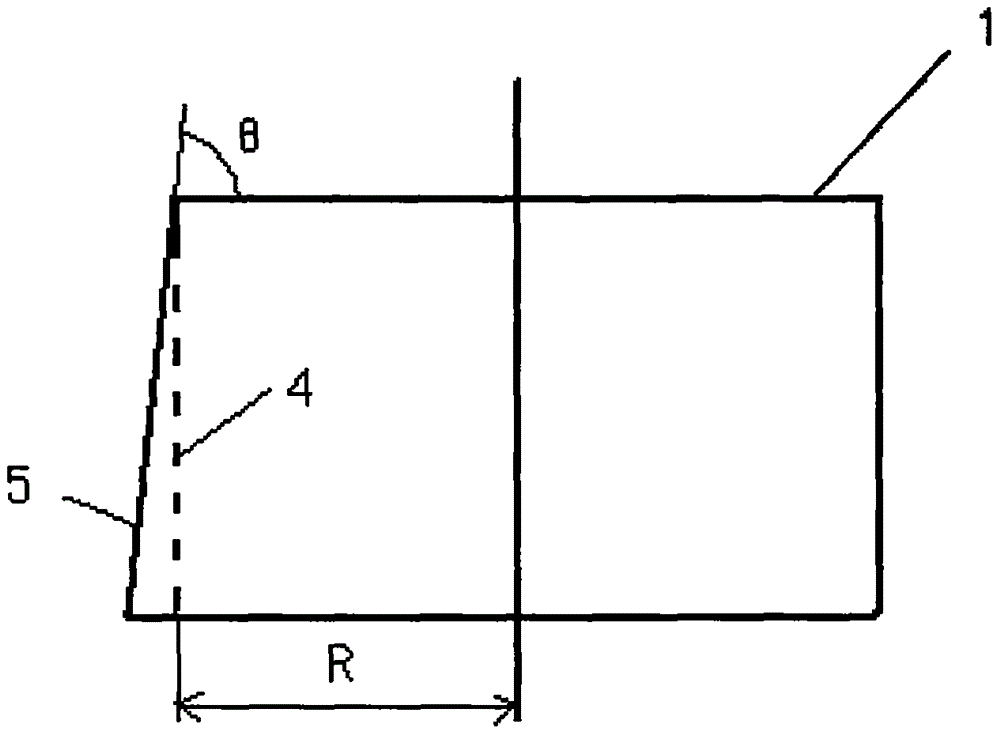

Determination method of first initial side surface of fly-cut monocrystalline germanium two-dimensional six-surface rotating drum

ActiveCN106142367AImprove machining accuracy and machining efficiencyReduce manufacturing costFine working devicesEngineeringWhite Spots

The invention discloses a determination method of a first initial side surface of a fly-cut monocrystalline germanium two-dimensional six-surface rotating drum. The determination method comprises the following steps: (S1) a monocrystalline germanium cylinder rod growing along a crystal surface is cut as upper and lower reference planes; (S2) the upper reference plane is roughly turned as an end surface; (S3) after the end surface is roughly turned, a vertical line is produced perpendicular to the radial center line on the upper reference plane of the monocrystalline germanium cylinder rod from the geometric center point of the monocrystalline germanium rod by a distance R with the radial center line of any white spot petal on the surface as reference; (S4) a normal plane of the radial center line is produced by passing through the vertical line; (S5) the normal plane is deflected to the geometric center axle of the rod around the vertical line; the deflected angle is a theoretic dip angle theta formed between a first surface of the two-dimensional six-surface rotating drum and the upper reference plane; and the obtained deflected plane is the first surface of the two-dimensional six-surface rotating drum; and (S6) on this basis, a radial blank allowance is left for the first surface of the two-dimensional six-surface rotating drum, so that the ultraprecise fly cutting for the first surface of the two-dimensional six-surface rotating drum after rough milling and grinding is convenient.

Owner:CHANGCHUN UNIV OF SCI & TECH

Line cutting machine

PendingCN107379276AImprove machining accuracy and machining efficiencyReduce learning costsWorking accessoriesStone-like material working toolsWall plateCutting self

The invention discloses a line cutting machine. The line cutting machine is provided with a platform and a support fixedly connected with the platform; a cutting wheel is connected with a wheel cover shaft, and the wheel cover is opened downwards to form a semi-closed containing cavity. Two vertical supporting legs located on the same side are in shaft connection through a rotating shaft, and the two ends of a horizontal supporting leg are fixedly connected with the lower ends of the vertical supporting legs located on the two sides simultaneously. The two ends of a sliding rail are fixedly connected with or integrally formed with support columns located on the two sides, sliding grooves are formed in the two sides of the sliding rail, a movable support is connected with the sliding grooves located in the two sides in a sliding mode, and the movable support drives the wheel cover and the cutting wheel to do reciprocating rectilinear motion along the sliding rail simultaneously. According to the line cutting machine, the machining efficiency and the machining precision can be improved conveniently, the operation difficulty and the learning cost of operators are lowered, and the wallboard machining procedures such as line cutting are achieved in a high-quality and high-efficiency mode.

Owner:FSILON BUILDING MATERIAL TECH CO LTD

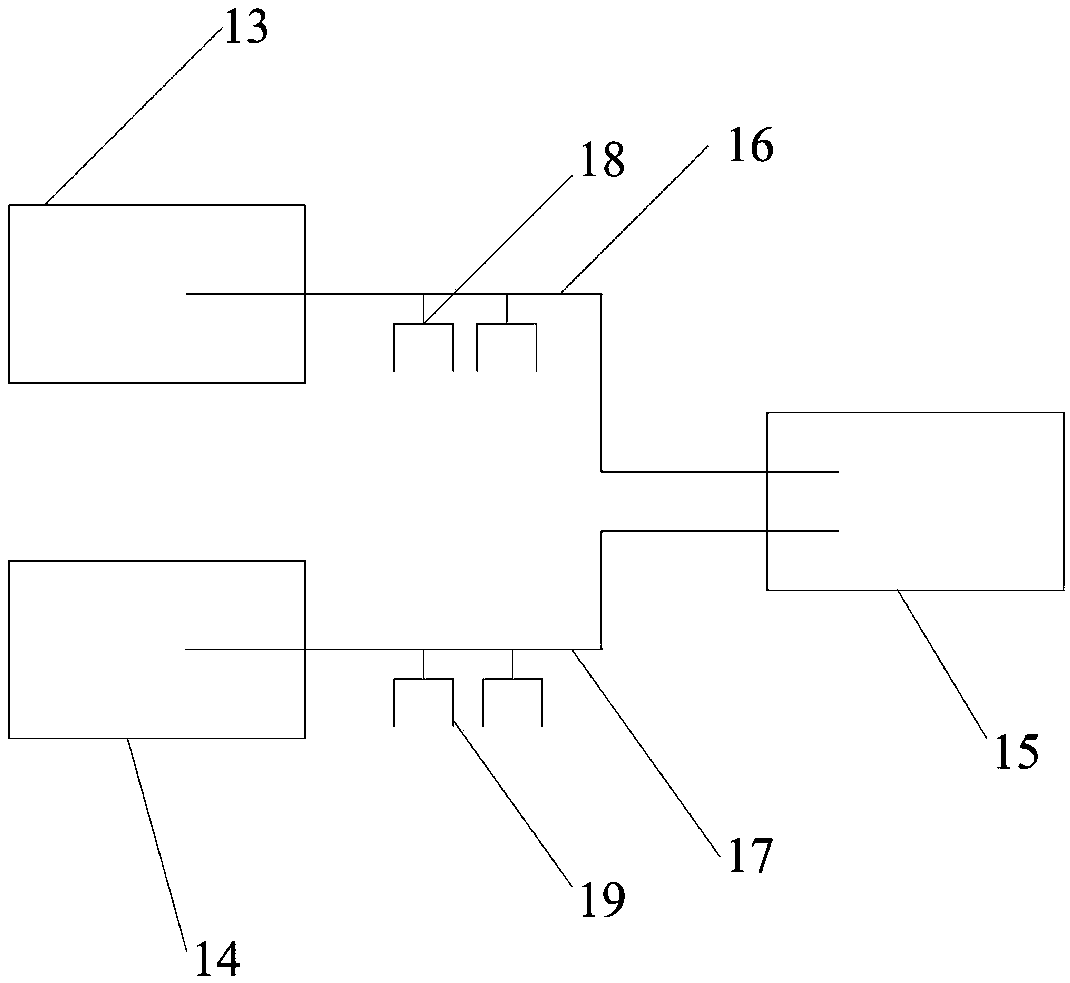

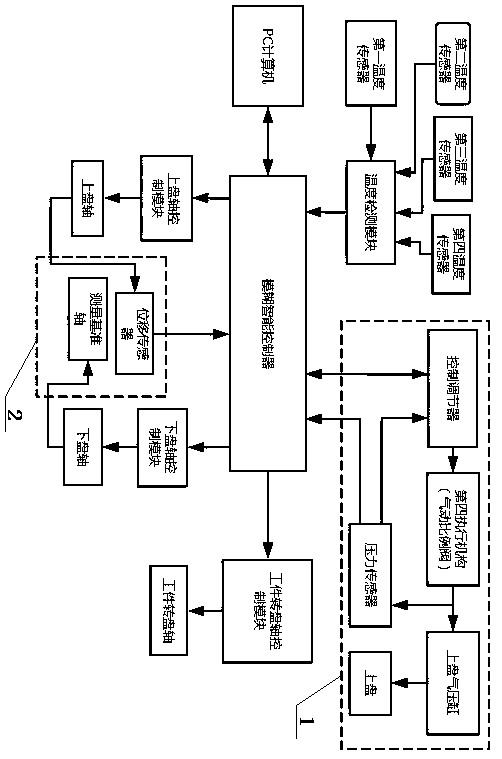

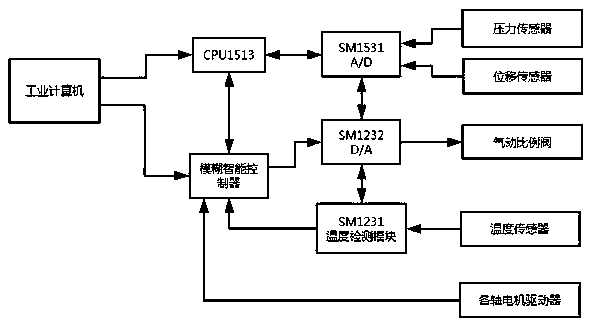

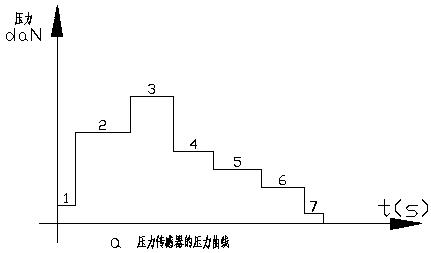

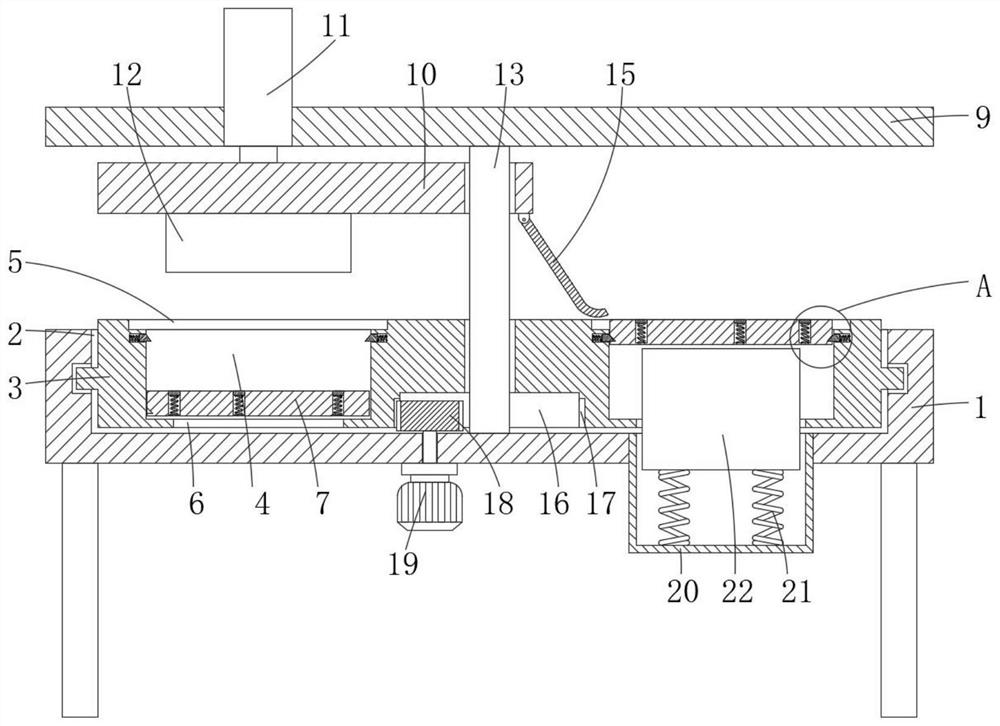

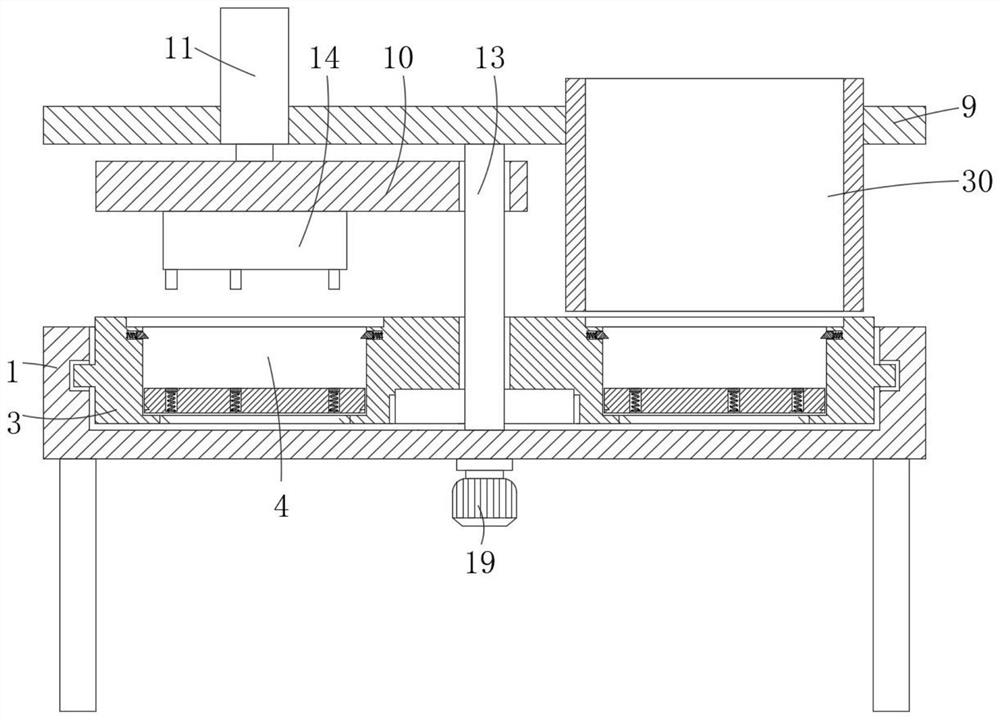

Multivariable intelligent fuzzy control system of double-end-face grinding machine

ActiveCN111037456AImprove machining accuracy and machining efficiencyImprove processing efficiencyLapping machinesProcessing accuracyGrinding mill

The invention relates to a multivariable intelligent fuzzy control system of a double-end-face grinding machine. The system comprises a fuzzy intelligent controller, an industrial computer, a temperature detection module, an upper disc pressure control module, an upper disc shaft control module, a lower disc shaft control module, a workpiece turntable shaft control module and a workpiece measurement module. The fuzzy intelligent controller is a software module combination composed of software modules, an input end of the fuzzy intelligent controller is in signal connection with the temperaturedetection module and the workpiece measurement module, an output end of the fuzzy intelligent controller is connected with the upper disc shaft control module, the lower disc shaft control module andthe workpiece rotating disc shaft control module, and the fuzzy intelligent controller is in data information transmission with the industrial computer and the upper disc pressure control module. According to the system, the machining efficiency serves as the core, the fuzzy control theory is introduced, the temperature of a machine tool mechanical system and the rotating speed of each shaft arecomprehensively controlled, and therefore the machining efficiency and machining precision of a machine tool are greatly improved.

Owner:洛阳聚享新科智能科技有限公司 +1

High-precision adjustable lock machining equipment

PendingCN114346069AImprove machining accuracy and machining efficiencyImprove processing efficiencyMetal-working feeding devicesStripping-off devicesProcessing accuracyMachining

The invention relates to the technical field of lock machining, in particular to high-precision adjustable lock machining equipment, and aims to solve the problems that in the prior art, a lock panel is poor in machining precision and low in machining efficiency, the high-precision adjustable lock machining equipment comprises an operation plate, a mounting groove is formed in the top face of the operation plate, and a rotating plate is mounted on the inner side of the mounting groove; a driving assembly used for driving the rotating plate to rotate is installed on the operation plate, four cavities are formed in the top of the rotating plate, four through holes communicated with the cavities are correspondingly formed in the bottom of the rotating plate, bottom plates are installed on the inner sides of the four cavities, and a top plate is installed on the top of the operation plate; a lifting plate is mounted at the bottom of the top plate through a lifting assembly. The device is reasonable and stable in structure and easy to operate, the machining precision of the lock panel is effectively improved, the machining efficiency of the lock panel is improved, the labor intensity of operators is reduced, and the device is easy to popularize and use.

Owner:贵州华禾制锁有限公司

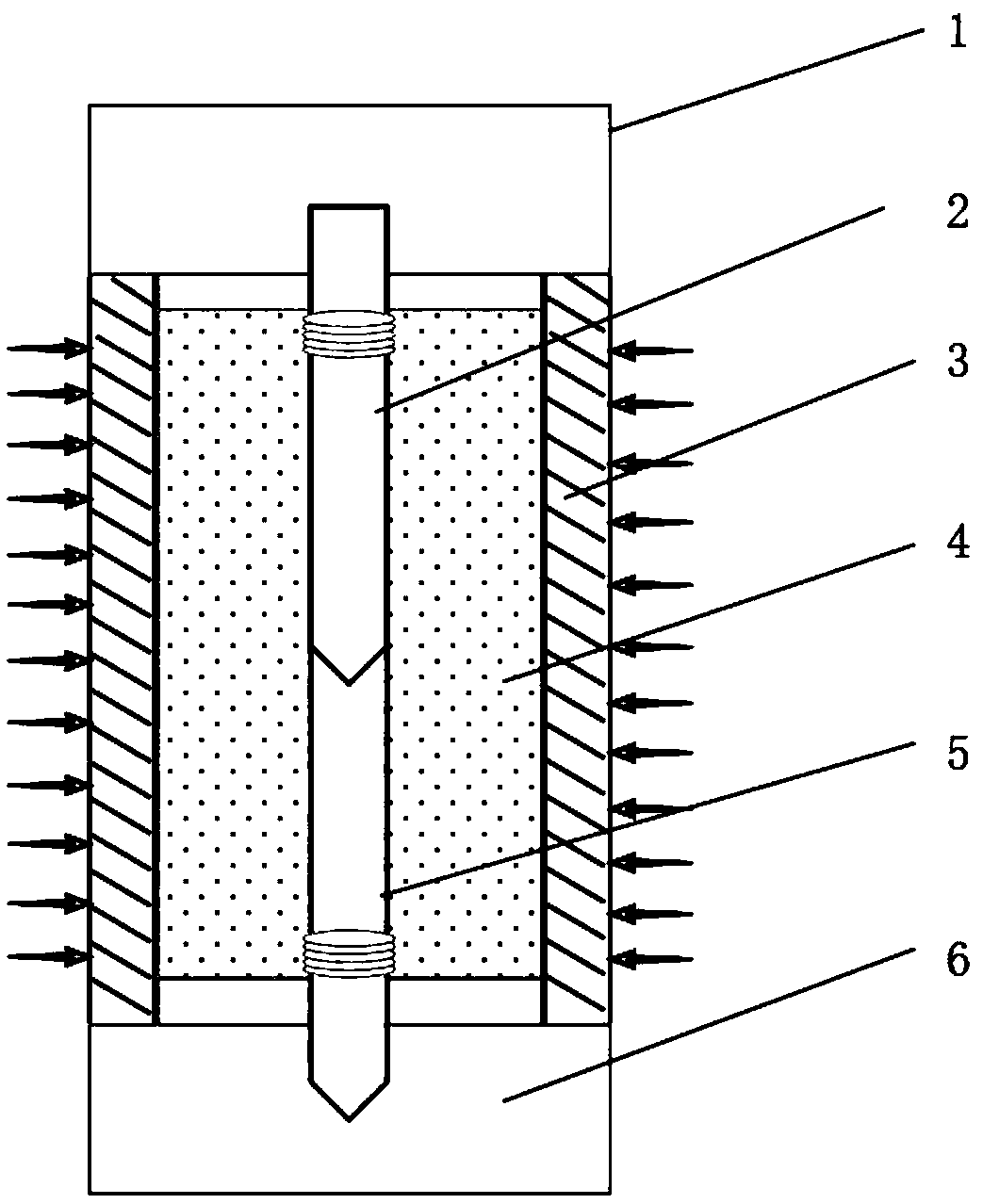

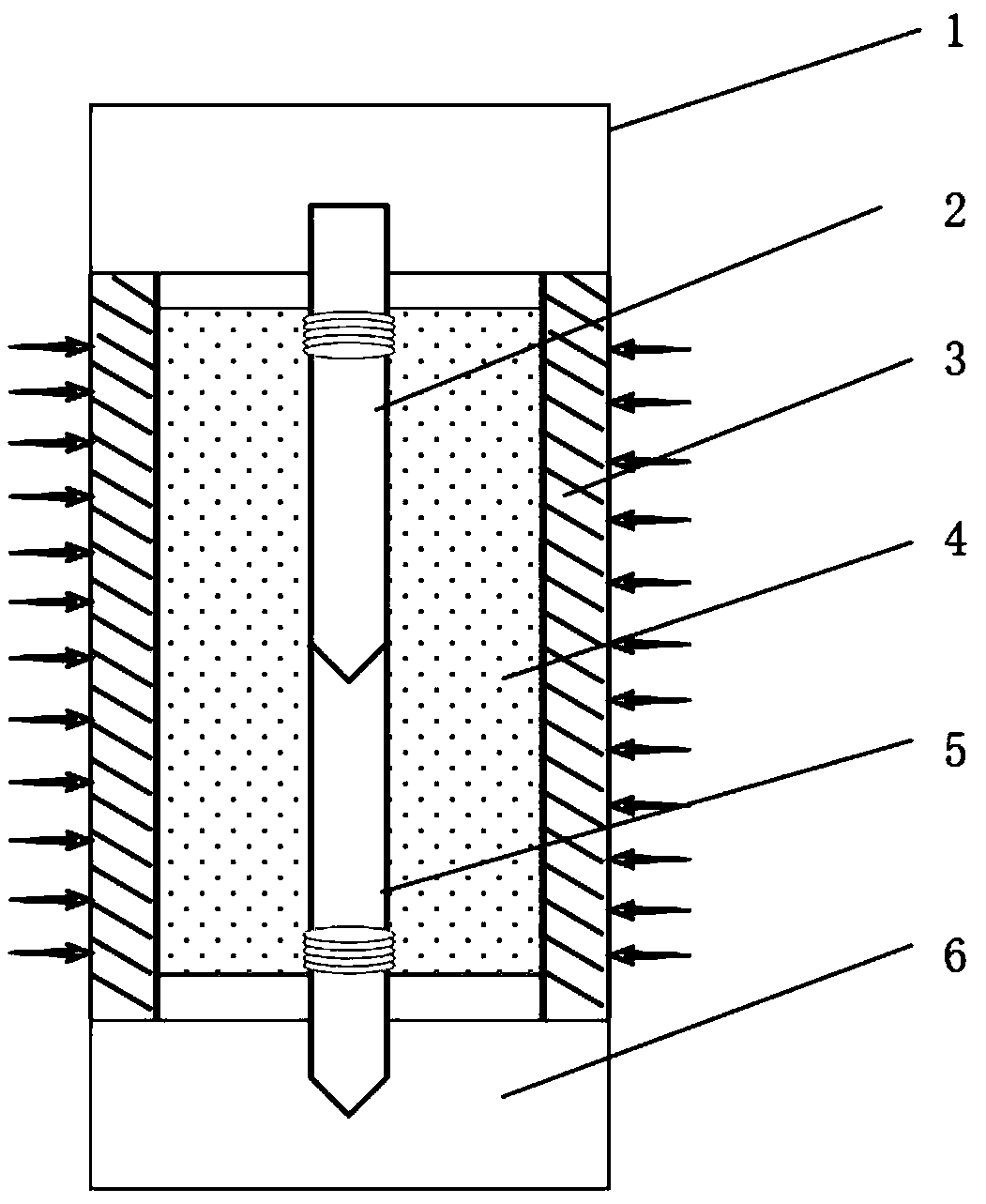

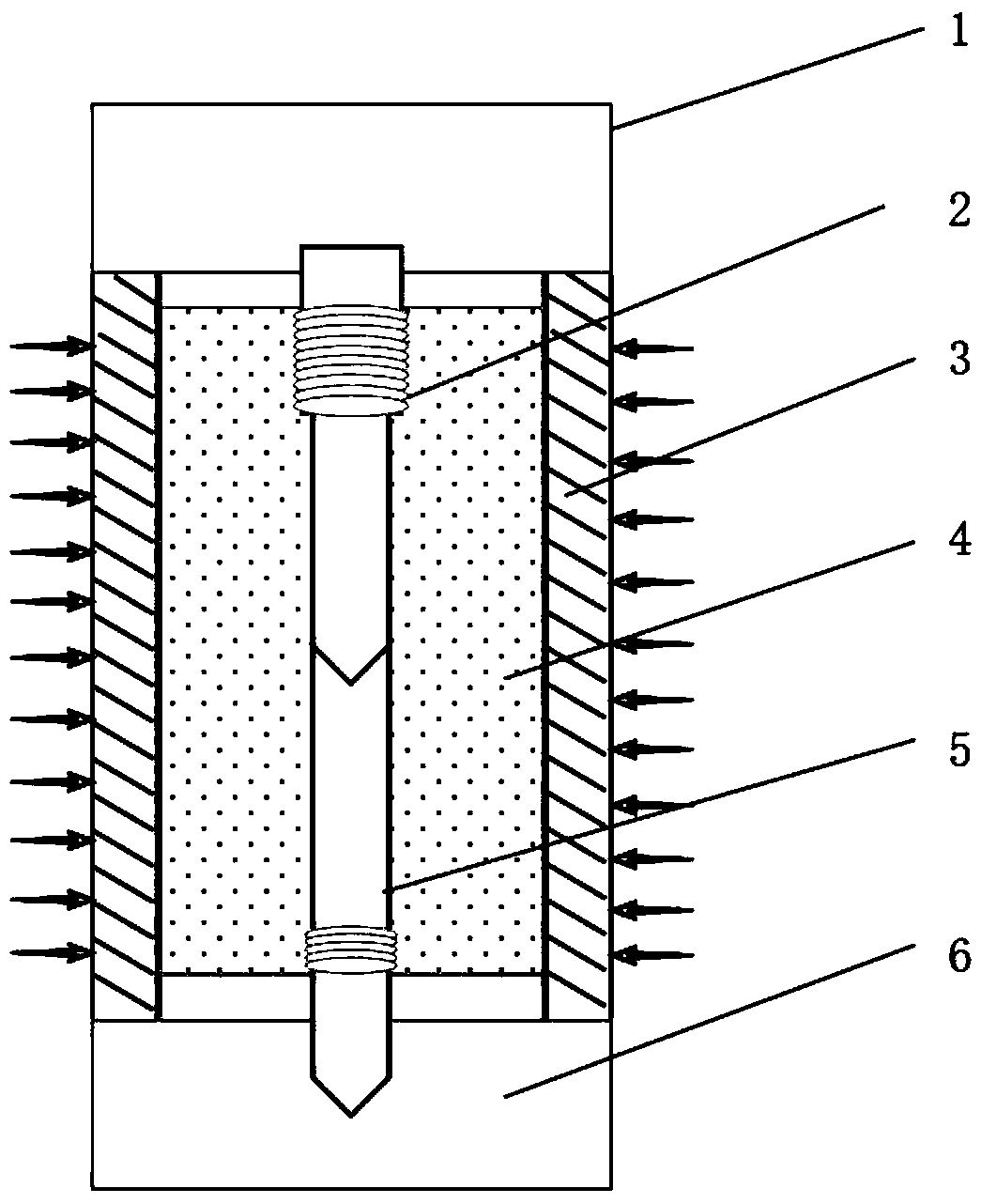

Device and method for pressing threads at two ends of hard alloy cylinder simultaneously

PendingCN109128158AEasy to operateImprove machining accuracy and machining efficiencyEngineeringElectrical and Electronics engineering

The invention discloses a device and method for pressing threads at the two ends of a hard alloy cylinder simultaneously. The device is characterized in that a first plug, a first threaded core shaft,a second plug, a second threaded core shaft and a die sleeve are included; in the using state, the first plug, the first threaded core shaft, the second plug and the second threaded core shaft are all coaxial with the die sleeve; the first plug and the second plug are located at the two ends of the die sleeve correspondingly and fix the first threaded core shaft and the second threaded core shaftcorrespondingly; the first threaded core shaft and the second threaded core shaft are connected in the axis direction; and threaded teeth are arranged on the first threaded core shaft and the secondthreaded core shaft. Hard alloy powder is pressed into the threads, operation is easy, and the machining precision and efficiency are high; and by changing the diameter and direction of the threaded teeth on the two threaded core shafts, the threads with different needs can be obtained at the two ends of the hard alloy cylinder simultaneously, the machining efficiency is greatly improved, and meanwhile the matching degree of the hard alloy cylinder to various different threaded connectors is met.

Owner:GUANGXI WUZHOU GANGDE HARD ALLOY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com