Machining method for grinding short holes by large-length-diameter-ratio weak-rigidity grinding rods

A technology with a large length-to-diameter ratio and a processing method, which is applied in the field of precision grinding, can solve problems such as low production efficiency, difficulty in meeting the processing accuracy requirements of parts, and difficulty in automatic processing, so as to improve processing accuracy and processing efficiency and realize precision automation. The effect of trimming and improving the level of intelligent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

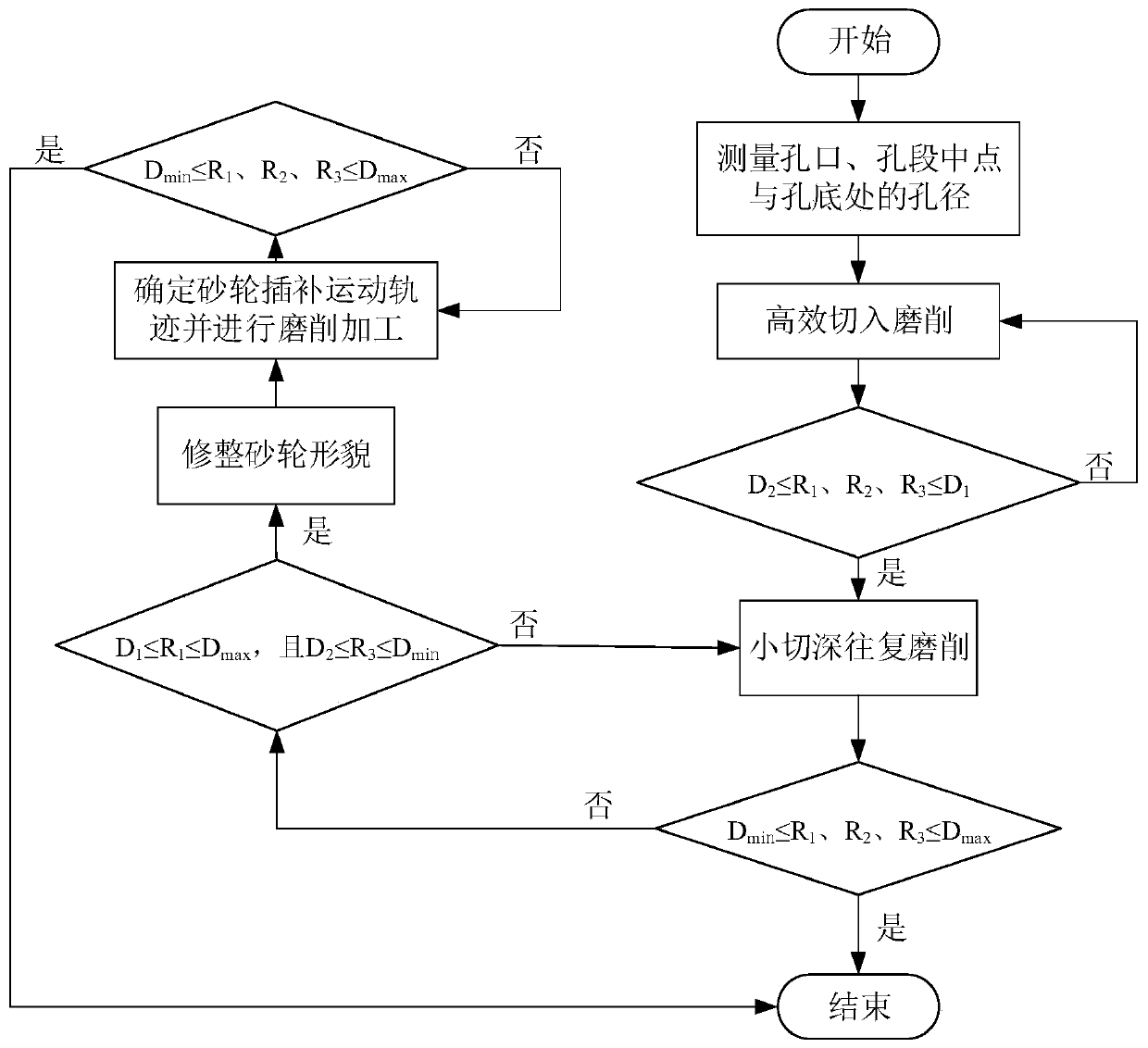

[0040] A processing method for grinding short holes with a weak rigid grinding rod with a large length-to-diameter ratio, such as figure 1 shown, including the following steps:

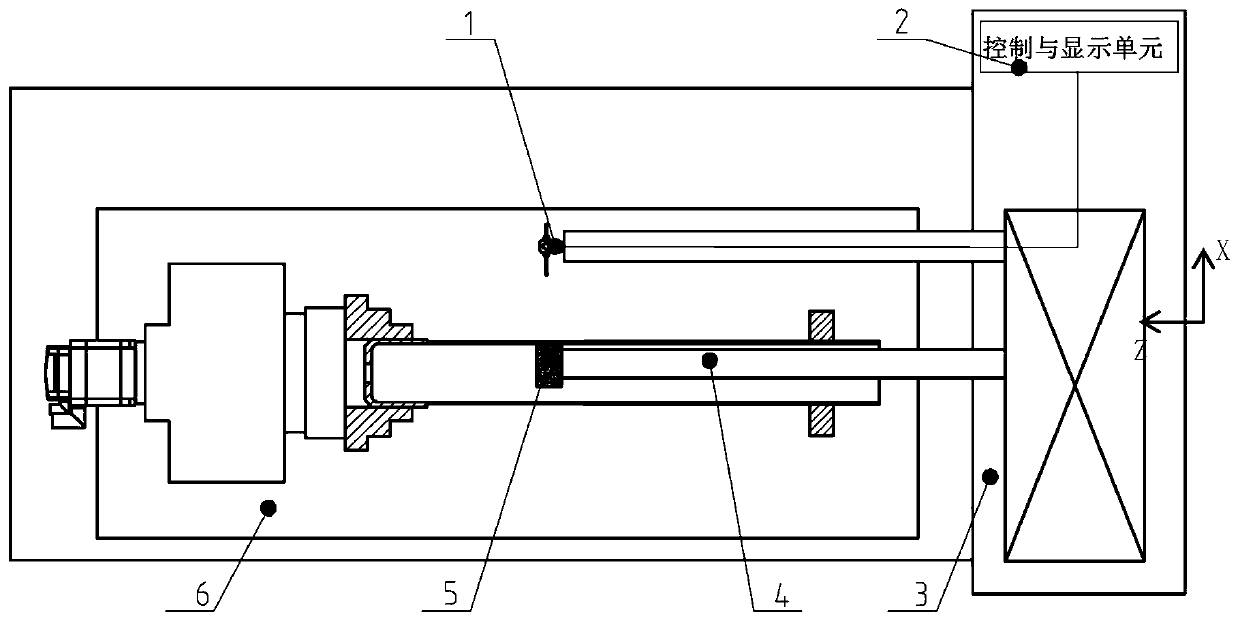

[0041] S1. Measure the hole diameter of the orifice, the midpoint of the hole section and the hole bottom of the processed hole: control the feed of the X-axis worktable and the Z-axis worktable of the machine tool, and measure the diameter of the orifice, the midpoint of the hole section and the bottom of the hole Aperture, and the measurement results are sequentially written into the R variable of the CNC system for storage, and the corresponding R parameter is R 1 , R 2 and R 3 , where R 1 is the aperture at the orifice, R 2 is the hole diameter at the midpoint of the hole segment, R 3 is the hole diameter at the bottom of the hole.

[0042] S2. High-efficiency plunge grinding: put the front end of the grinding wheel into the cavity of the section to be processed, and use the preloading amoun...

Embodiment 2

[0051] A processing method for grinding short holes with a weak rigid grinding rod with a large length-to-diameter ratio, such as figure 1 shown, including the following steps:

[0052] S1. Measure the hole diameter of the orifice, the midpoint of the hole section and the hole bottom of the processed hole: control the feed of the X-axis worktable and the Z-axis worktable of the machine tool, and measure the diameter of the orifice, the midpoint of the hole section and the bottom of the hole Aperture, and the measurement results are sequentially written into the R variable of the CNC system for storage, and the corresponding R parameter is R 1 , R 2 and R 3 , where R 1 is the aperture at the orifice, R 2 is the hole diameter at the midpoint of the hole segment, R3 is the hole diameter at the bottom of the hole.

[0053] S2. High-efficiency plunge grinding: put the front end of the grinding wheel into the cavity of the section to be processed, and use the preloading amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com