Laser machining device based on ultrasonic location and machining method

A laser processing method and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems that affect welding or cutting quality, workpiece does not meet requirements, changes, etc., to improve processing efficiency and processing accuracy , to avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

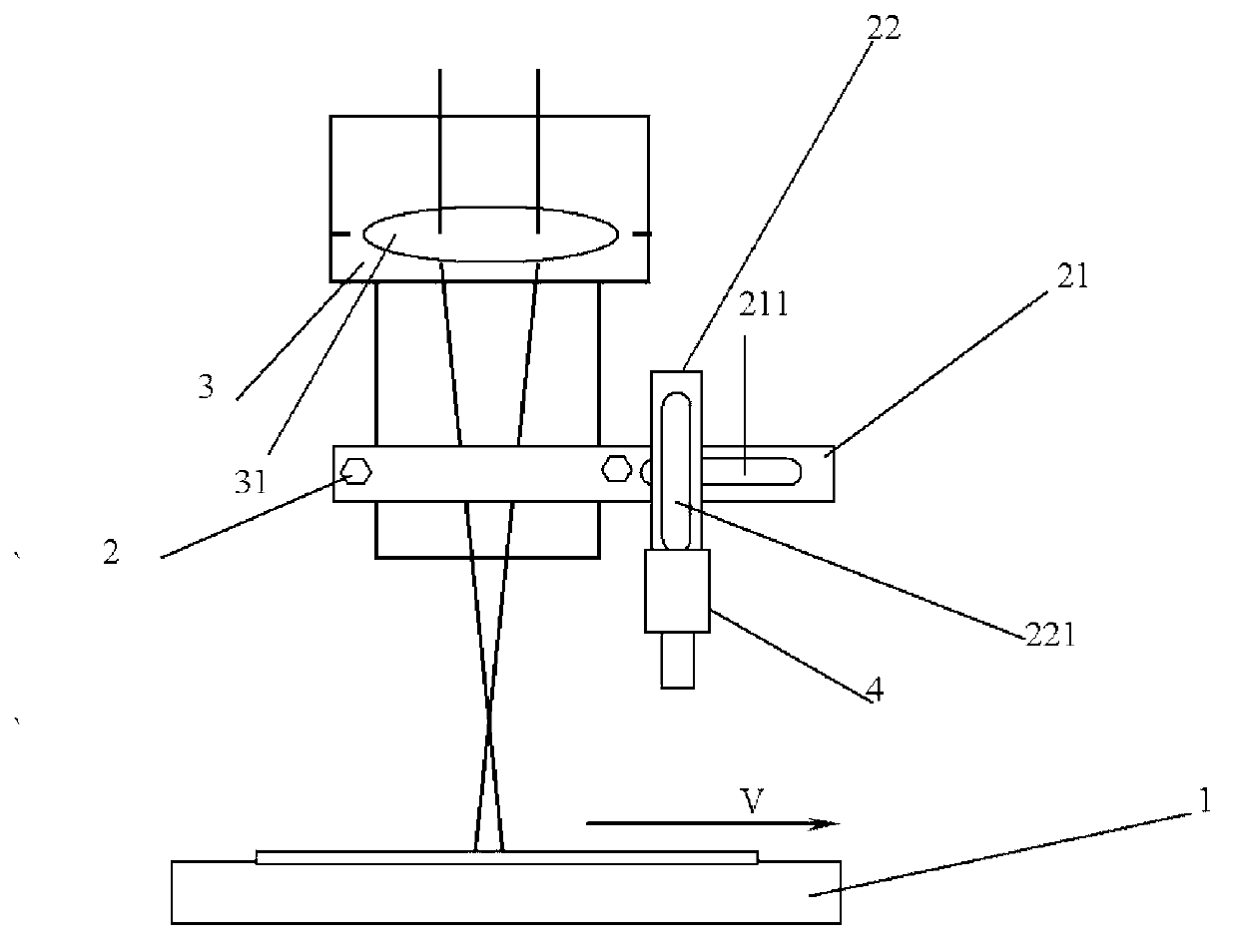

[0018] see figure 1 As shown, the present invention provides a laser processing device based on ultrasonic positioning, including:

[0019] A processing platform 1;

[0020] A clamping device 2, which is located above the processing platform 1, the clamping device 2 includes a transverse clamping connection part 21 and a longitudinal clamping connection part 22, and the horizontal clamping connection part 21 and the longitudinal clamping connection part 22 are pivoted to each other Then, there is a transverse sliding groove 211 on the transverse clamping connection part 21 of the clamping device 2, which facilitates the sliding of the longitudinal clamping connection part 22 of the clamping device 2, and there is a longitudinal clamping connection part 22 on the clamping device 2 The longitudinal chute 221 facilitates the sliding of the ultrasonic distance measuring device 4 pivotally connected to the longitudinal clamping connection part 22 of the clamping device 2;

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com