Grid line structure, solar cell, imbrication assembly, printing method and manufacturing method

A solar cell, solar cell technology, applied in electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve difficult second-layer gridlines and dotted gridlines, alignment, second-layer gridlines The extension direction and the extension direction deviate from each other to achieve the effect of improving the processing accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

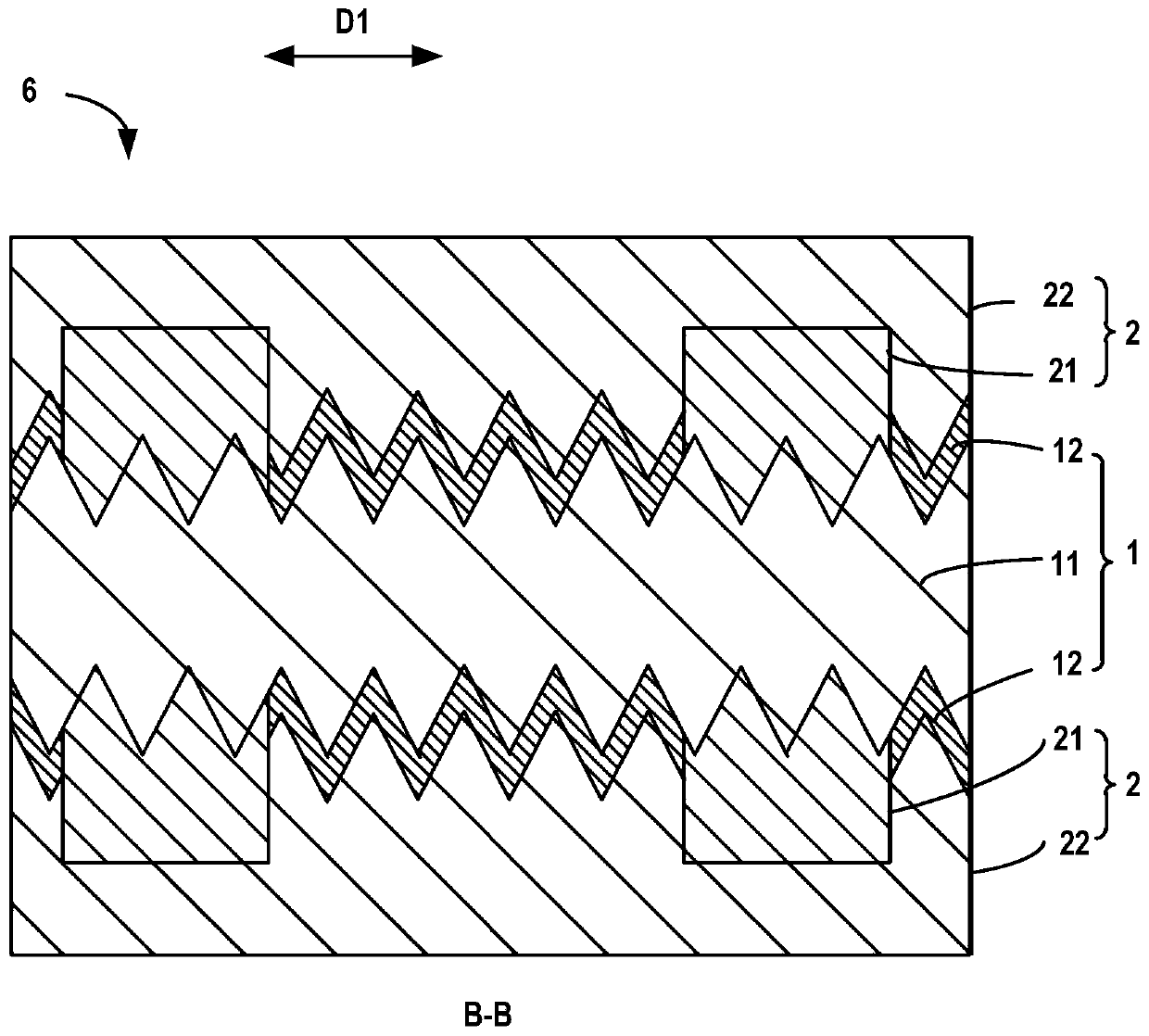

[0058] Referring now to the accompanying drawings, specific embodiments of the present invention will be described in detail. What is described here is only a preferred embodiment of the present invention, and those skilled in the art can think of other ways to realize the present invention on the basis of the preferred embodiments, and the other ways also fall within the scope of the present invention.

[0059] The fabrication of crystalline silicon cells requires multiple steps. For monocrystalline silicon cells, it can be obtained as follows. For example, a Czochralski method is used to grow a wafer rod as a raw material. The wafer bar is squared and polished by a square cutting machine to obtain a square bar, and then the square bar obtained after square cutting and grinding is sliced to obtain a single crystal silicon wafer. Afterwards, steps such as surface texturing, cleaning, diffusion junction, removal of phospho-silicate glass, deposition of anti-reflection film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com