Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Hinders fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

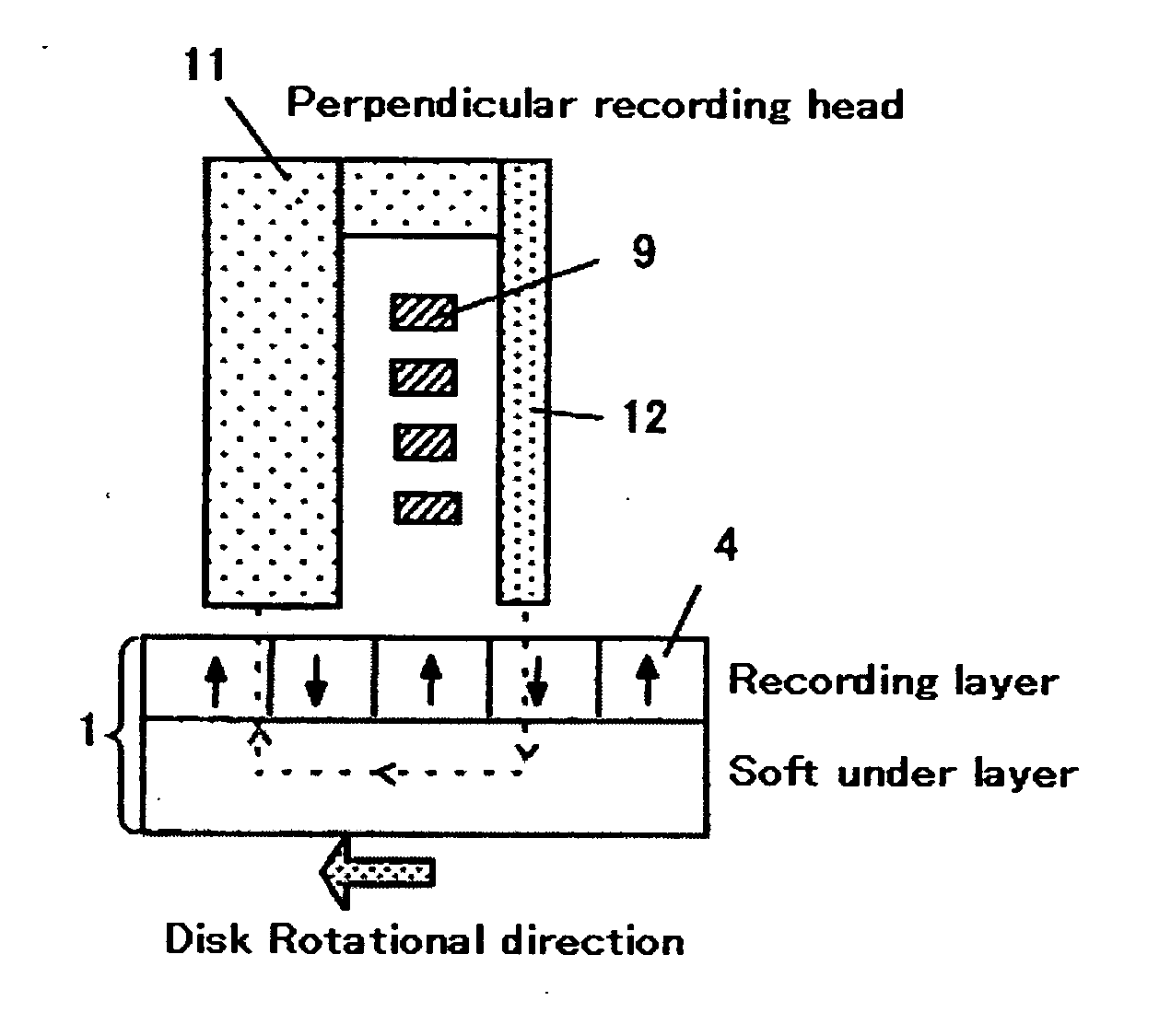

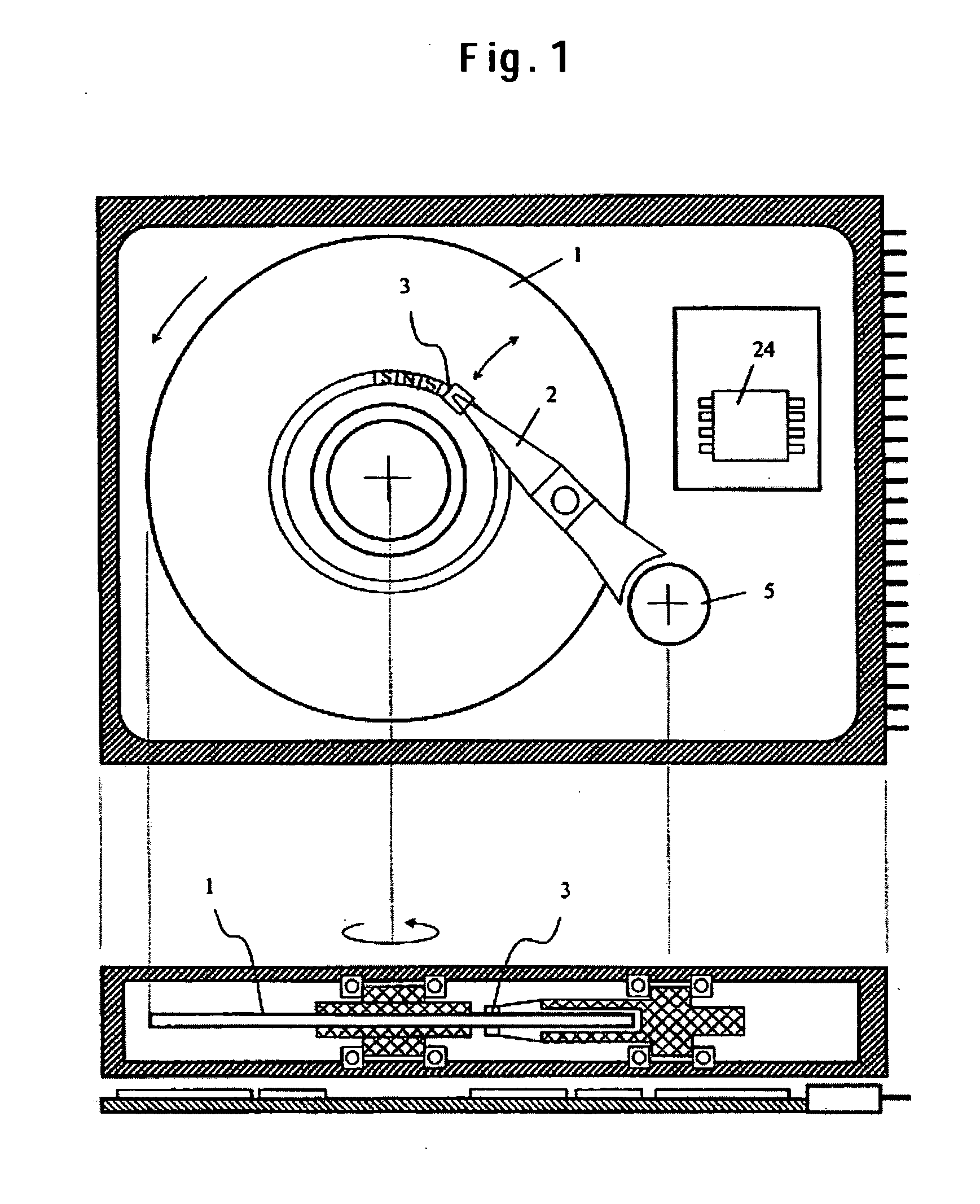

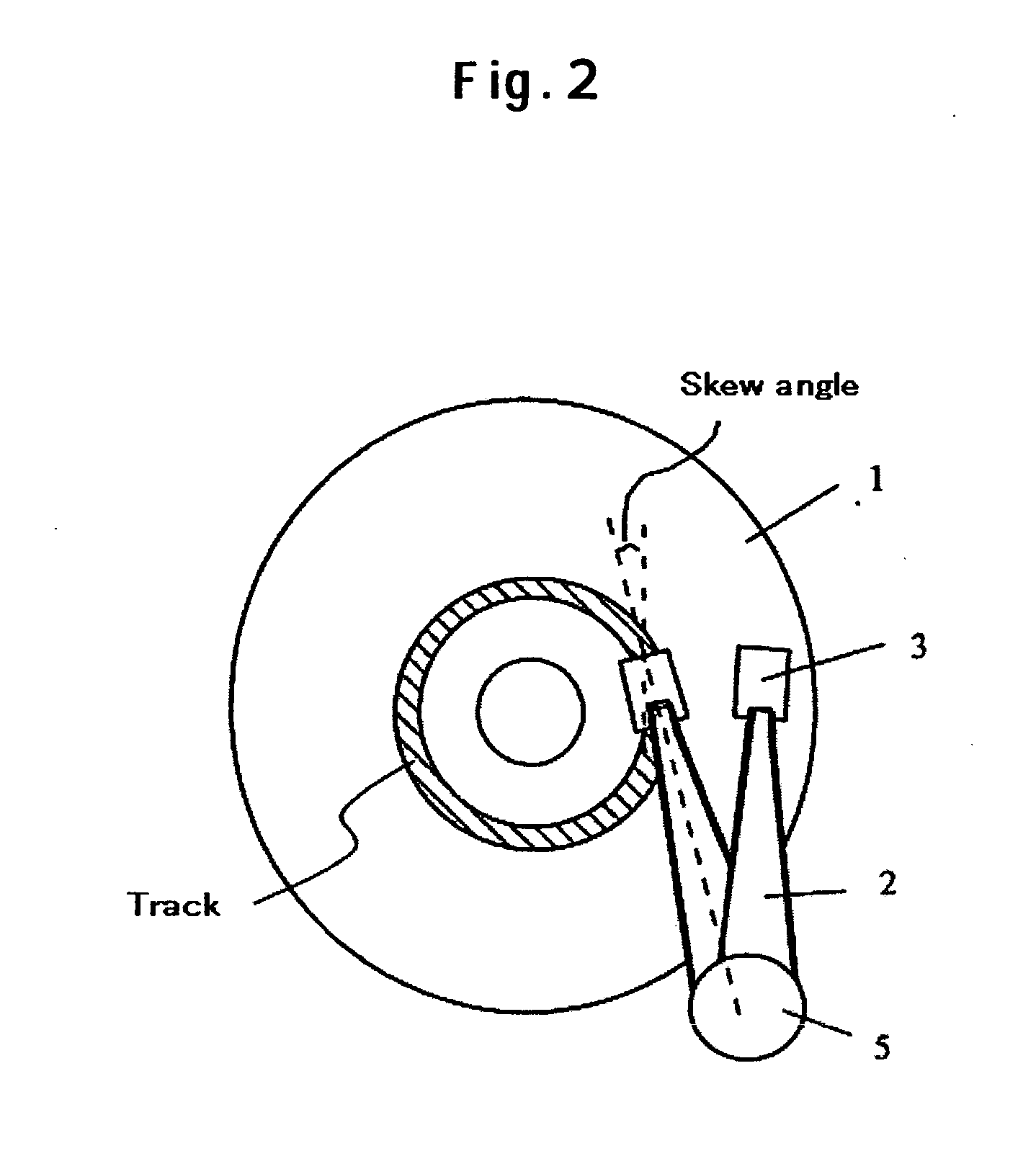

Magnetic recording head for perpendicular recording, fabrication process, and magnetic disk storage apparatus mounting the magnetic head

InactiveUS20050141137A1Improving recording magnetic field gradientIncreasing the thicknessManufacture head surfaceHeads using thin filmsMagnetic field gradientMagnetic media

Embodiments of the invention provide a perpendicular magnetic writing head with a suppressed effective track width to be written on a magnetic medium while increasing writing magnetic field gradient. In one embodiment a trailing side shield is disposed by way of a gap film to a main pole of a perpendicular writing magnetic head. A gap distance (Gt) on a trailing side of the main pole and a gap distance (Gs) on a lateral side of the main pole is defined as Gt<Gt, and a thickness (Gd) from an air bearing surface of the shield is made equal to or less than a throat height. Alternatively, the thickness of Gd on the side of the main pole is reduced to less than that on the trailing side of the main pole. Further, for preventing defoliation of the shield upon fabrication of the air bearing surface, a thickness for a portion away from the main pole is increased.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

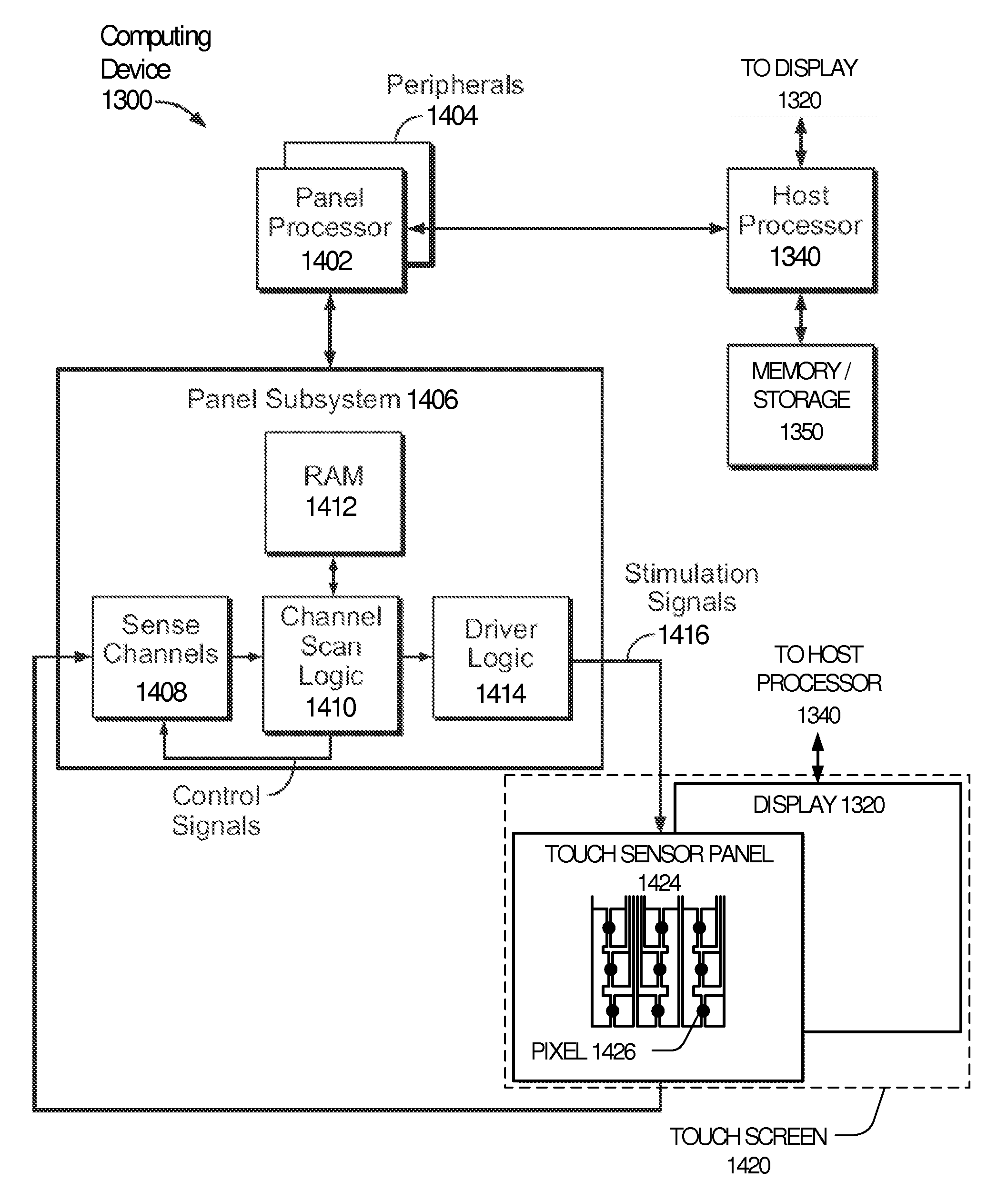

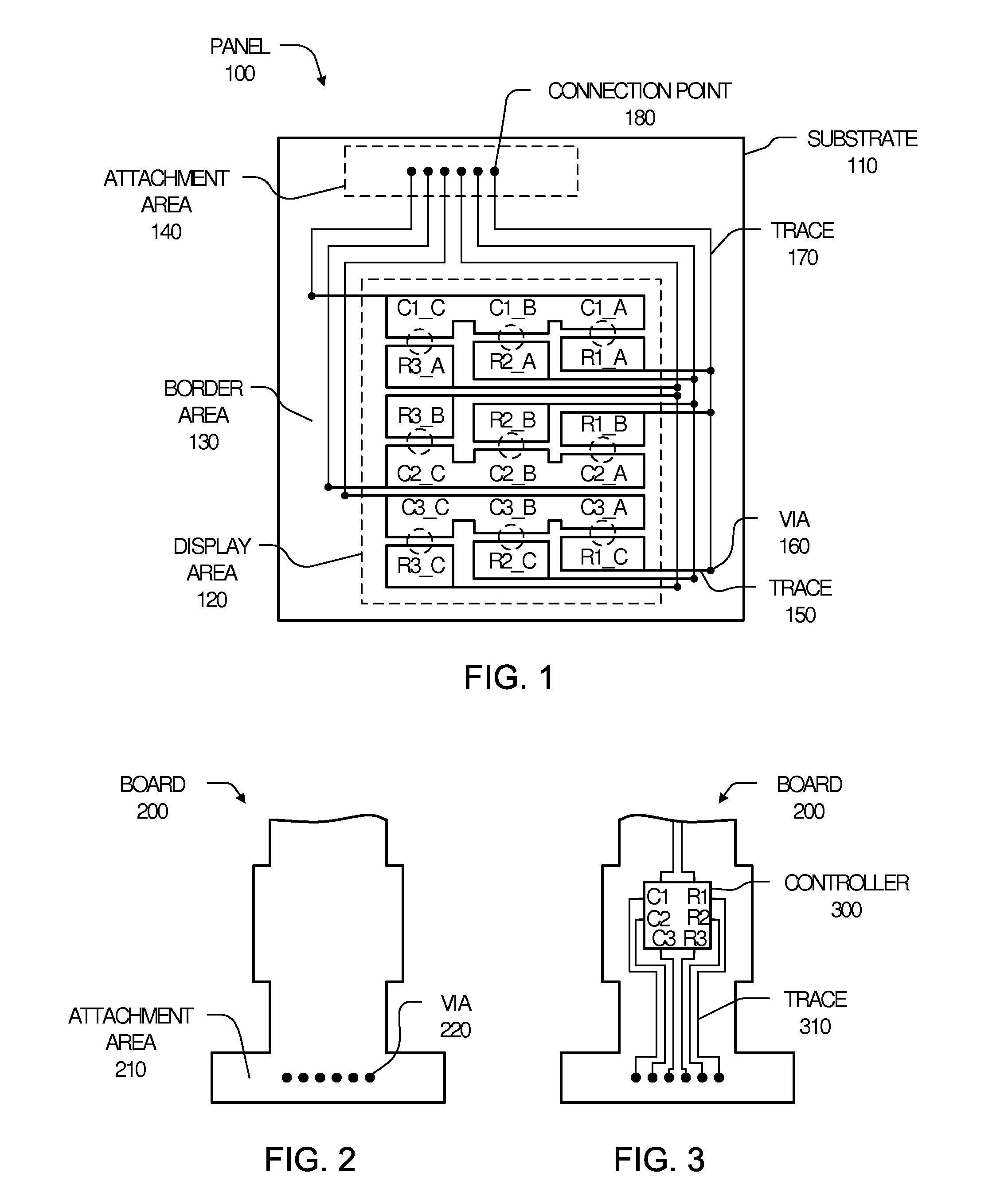

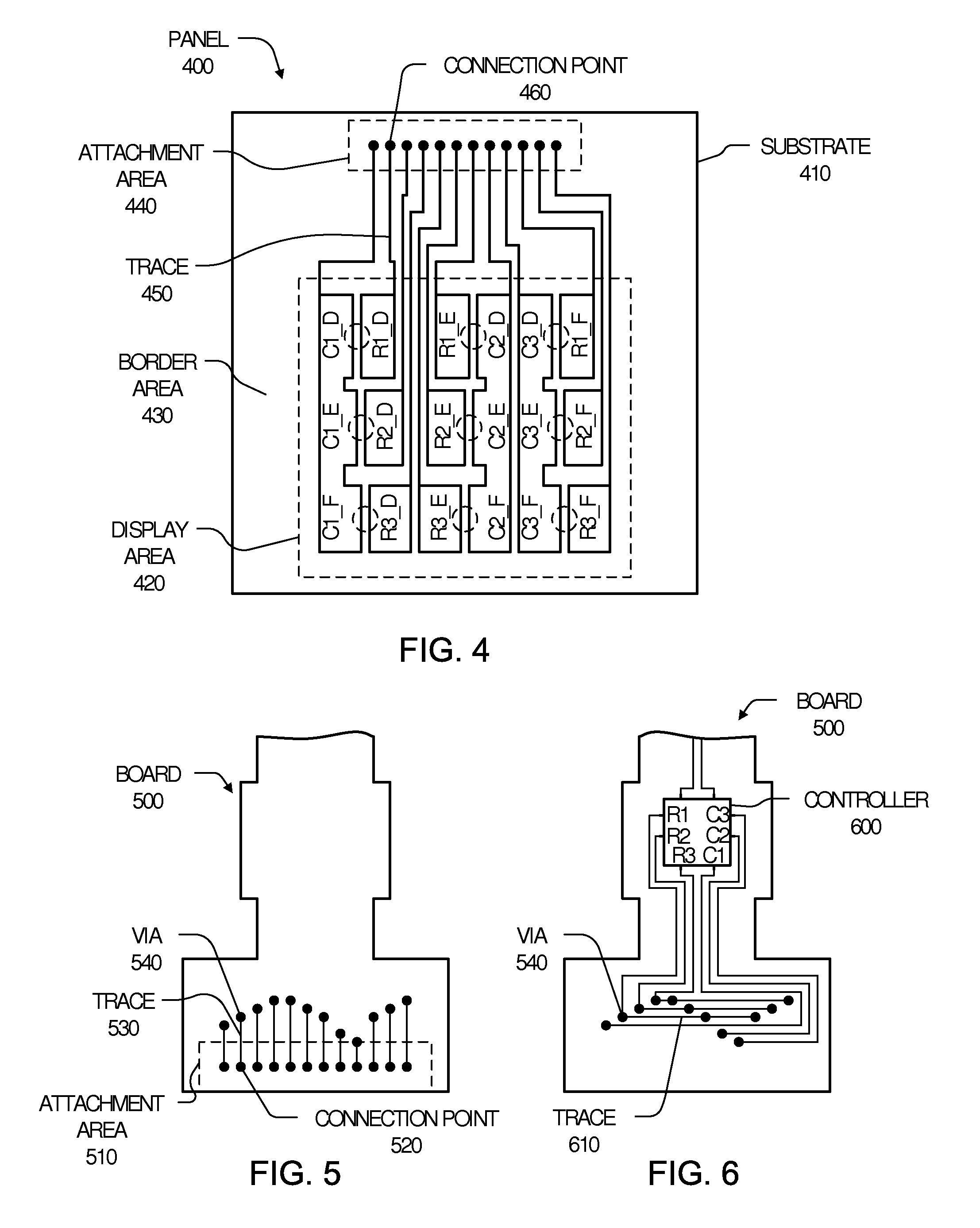

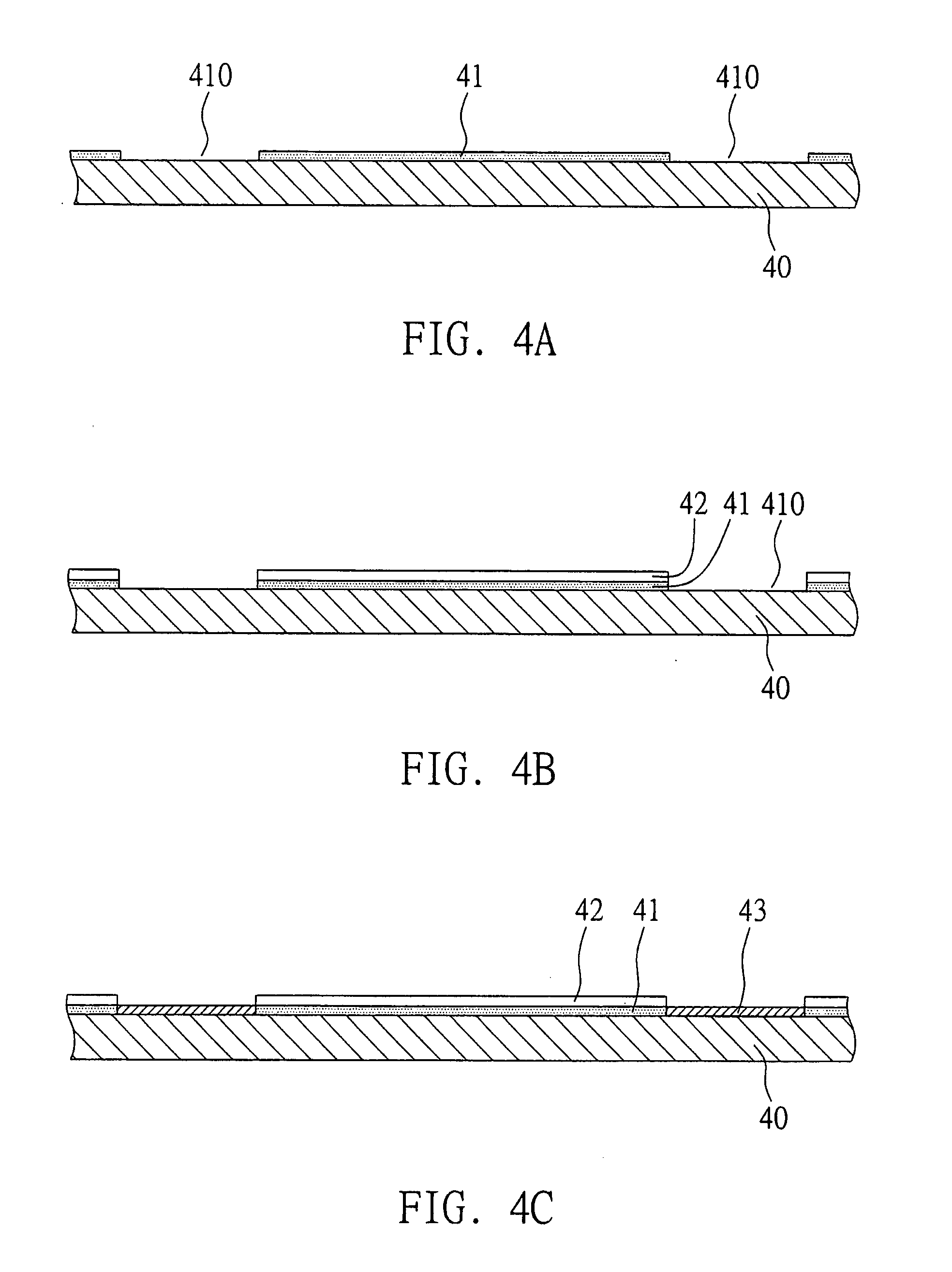

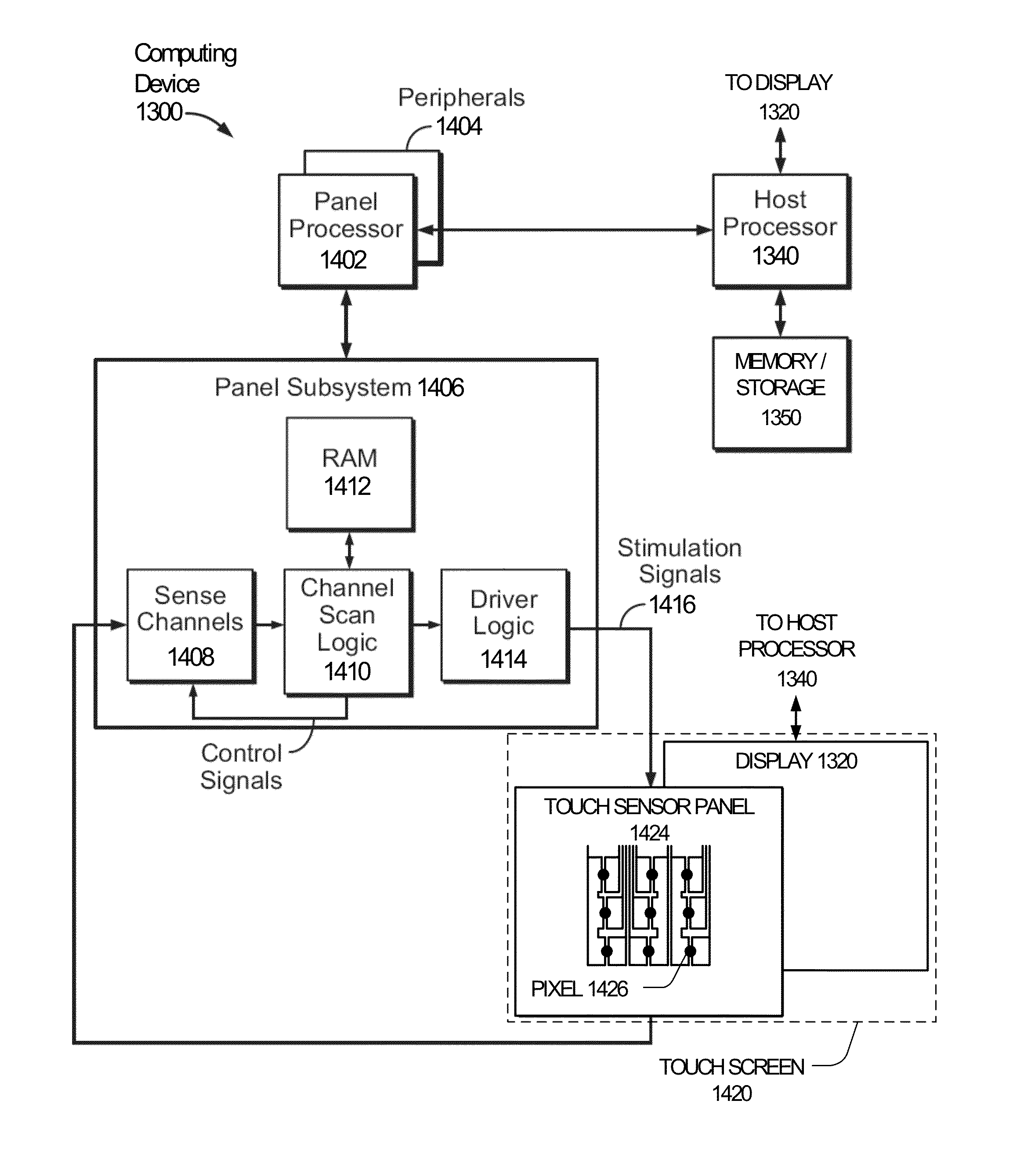

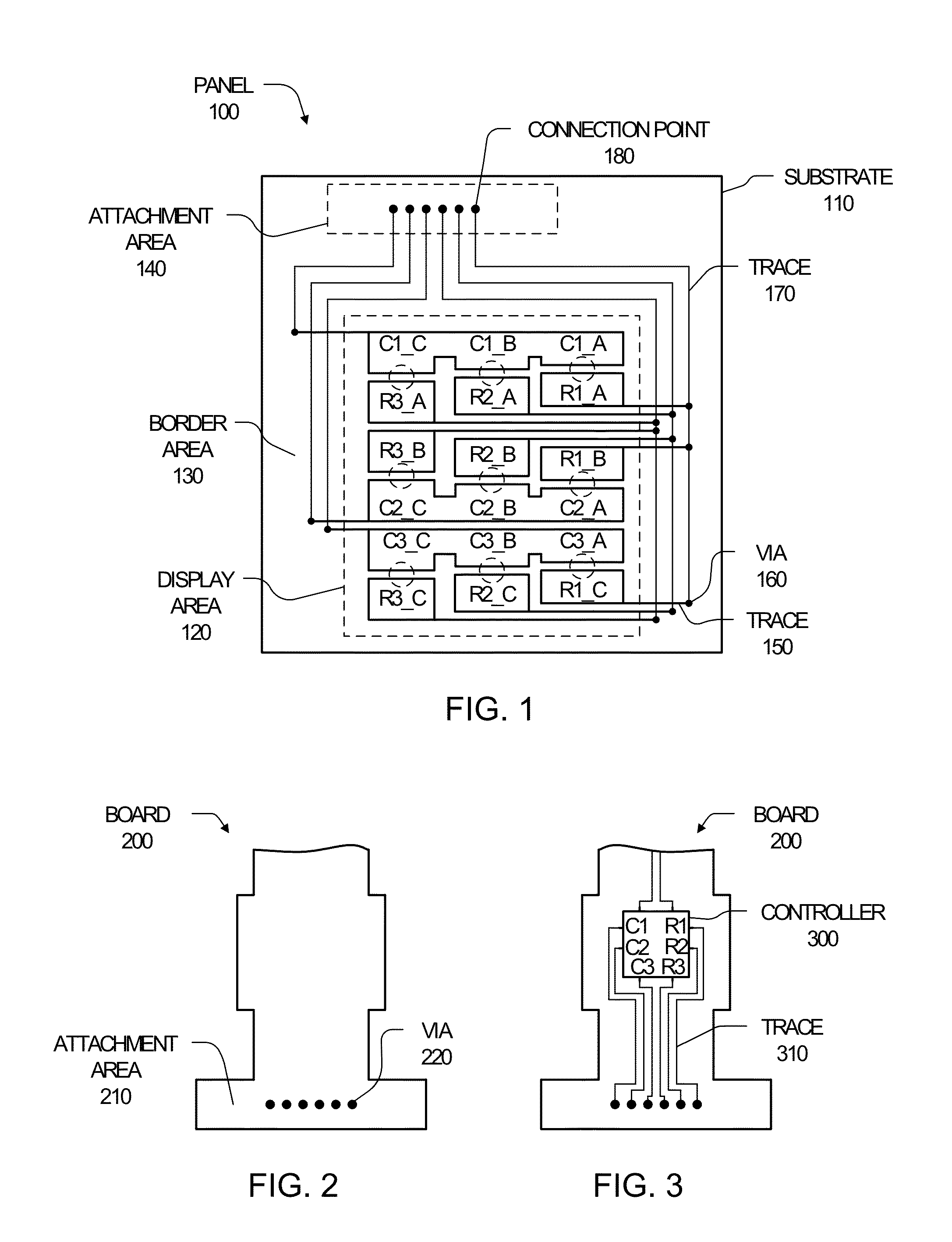

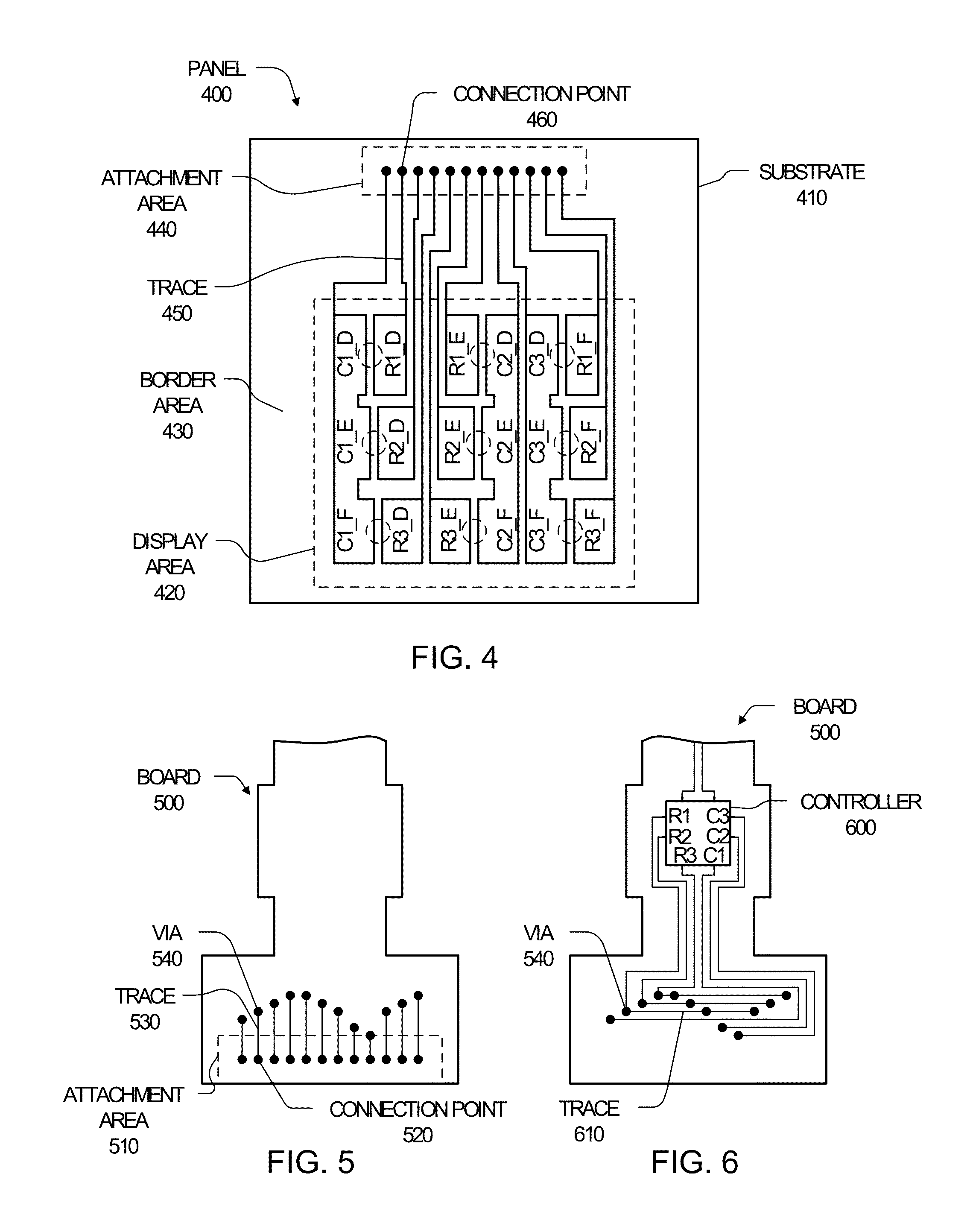

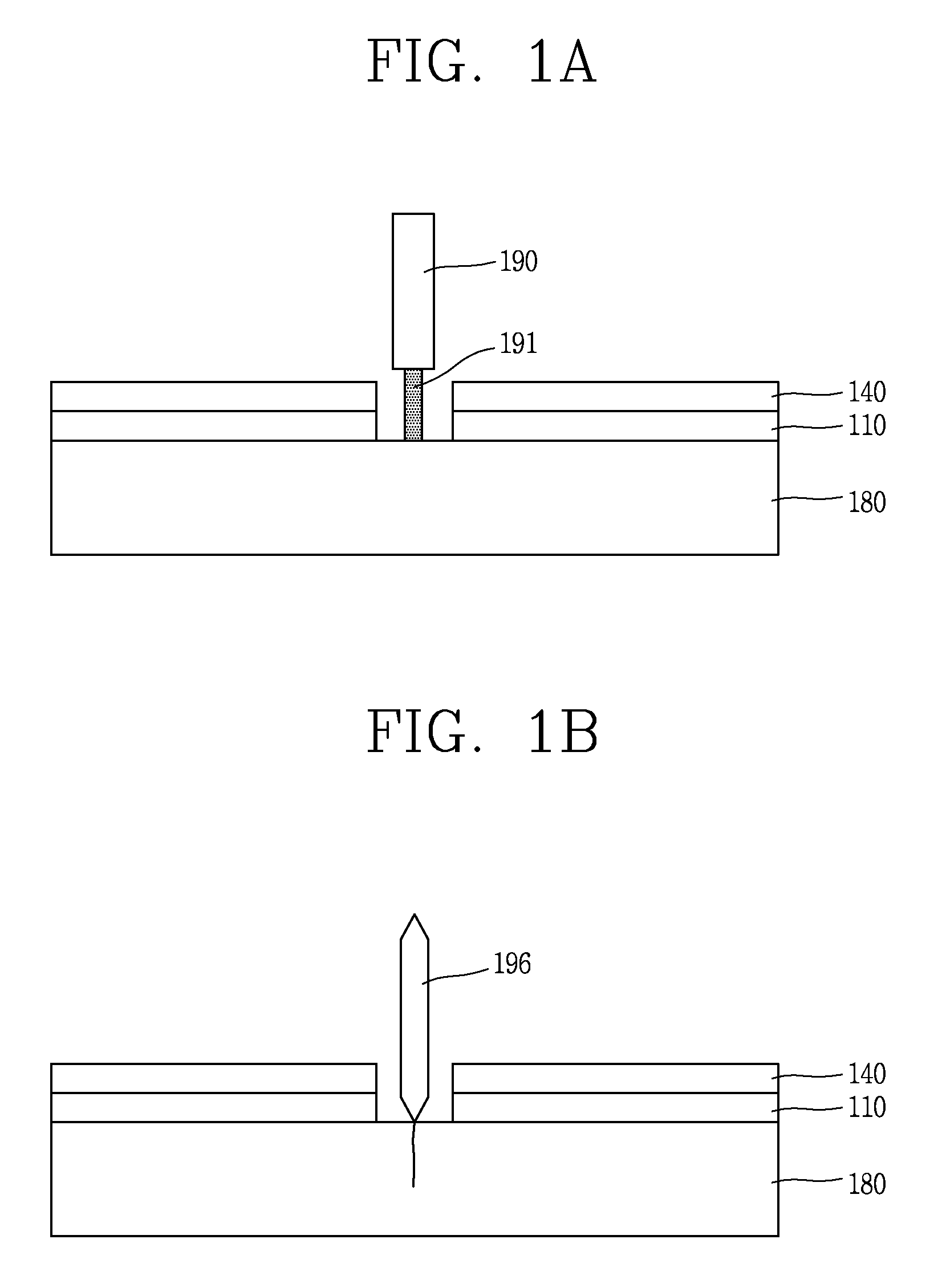

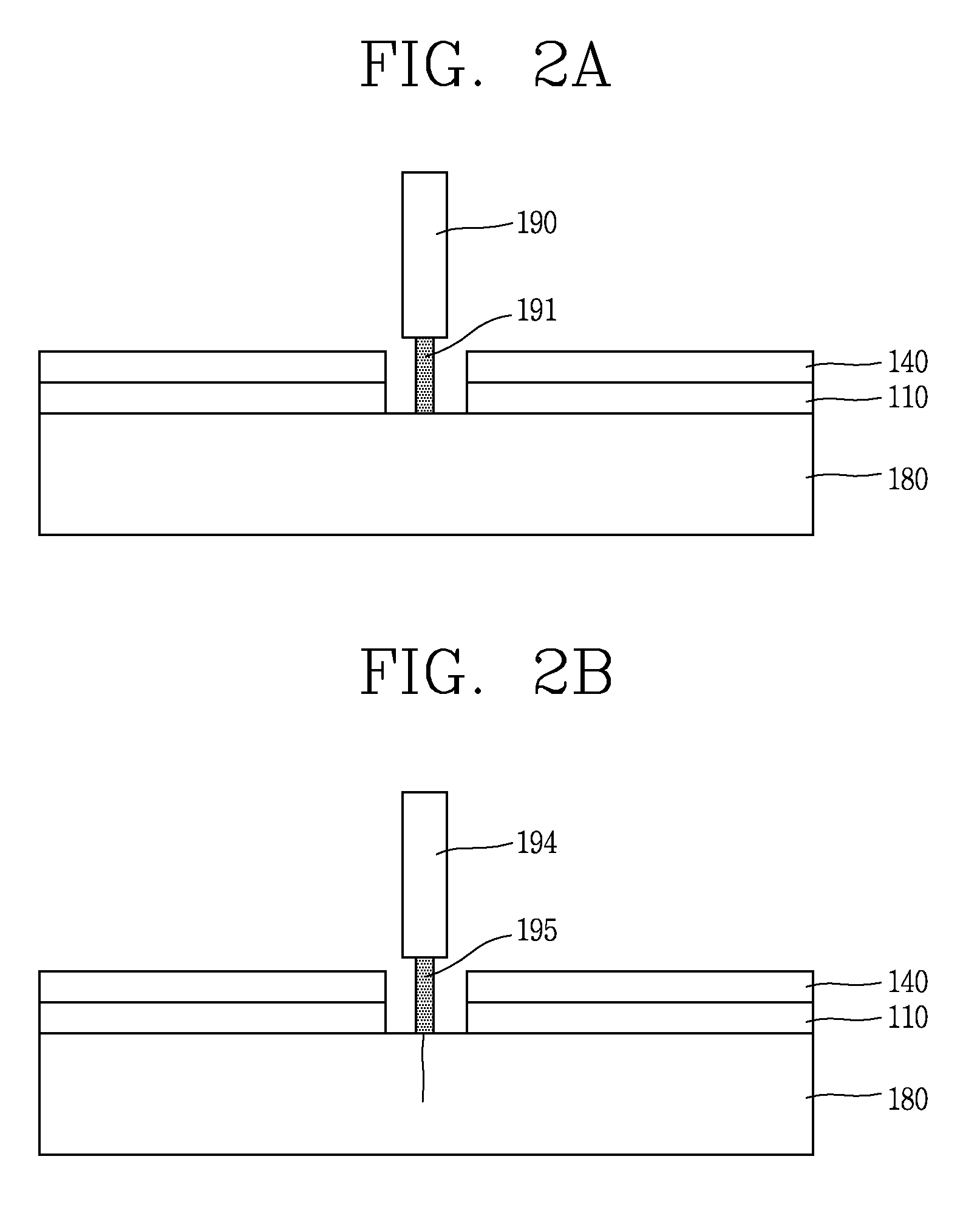

Direct Connect Single Layer Touch Panel

InactiveUS20100321326A1Hinders fabricationSimple manufacturing processInput/output processes for data processingMultiple sensorConductive materials

A substantially transparent touch sensor panel having co-planar single-layer touch sensors and traces fabricated on a single side of a substrate for detecting single or multi-touch events. The touch sensor elements can be fabricated in columns and rows, with each sensor element in a row adjacent to a sensor element in a column. By using a board as the dielectric to connect traces from multiple sensor elements in each row, rather than using a dielectric layer on the substrate upon which the sensor elements and traces are formed, the sensor elements and traces on the substrate can be formed by simply patterning a single layer of conductive material on the substrate, which can simplify the manufacturing process of the substrate from a complexity and cost perspective.

Owner:APPLE INC

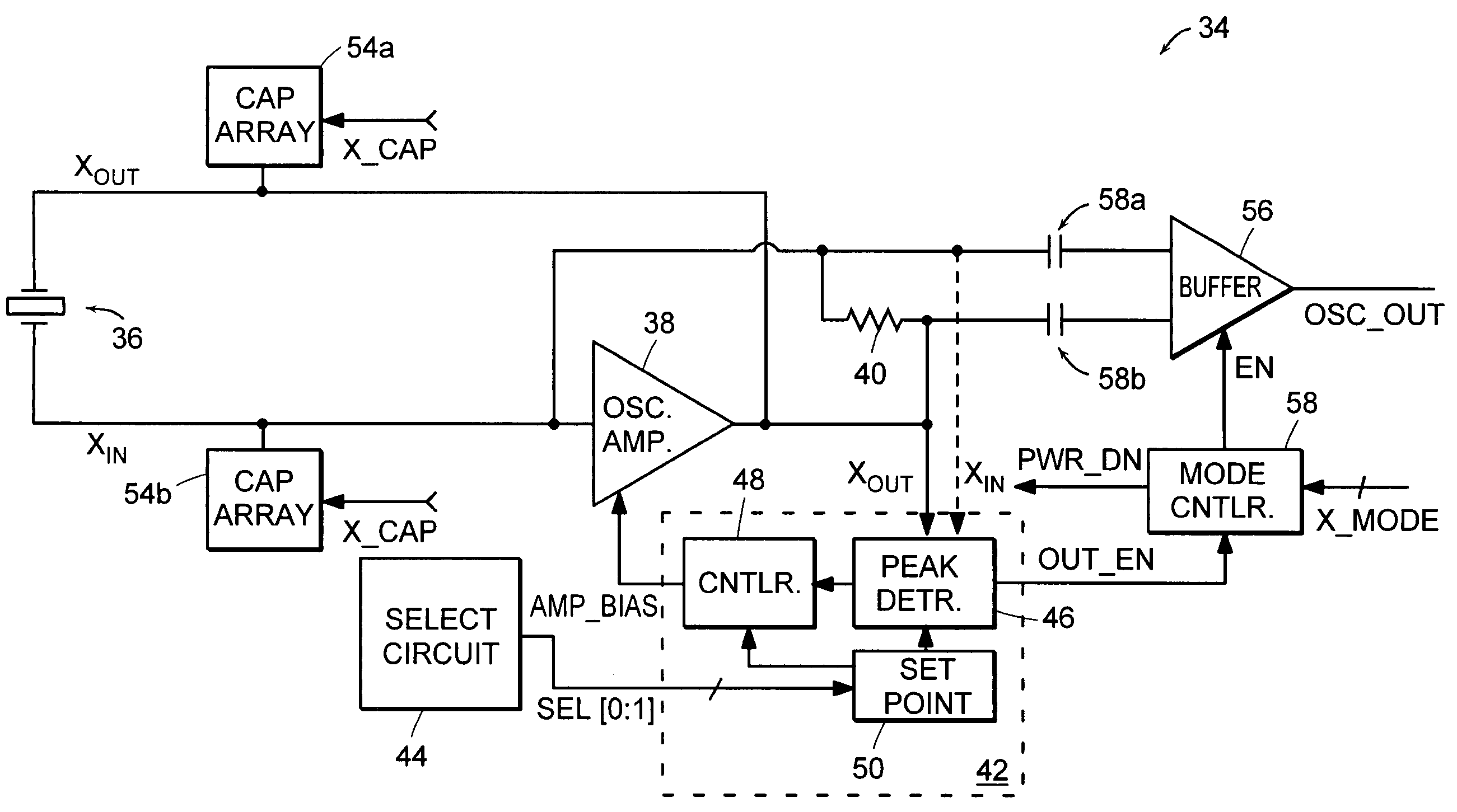

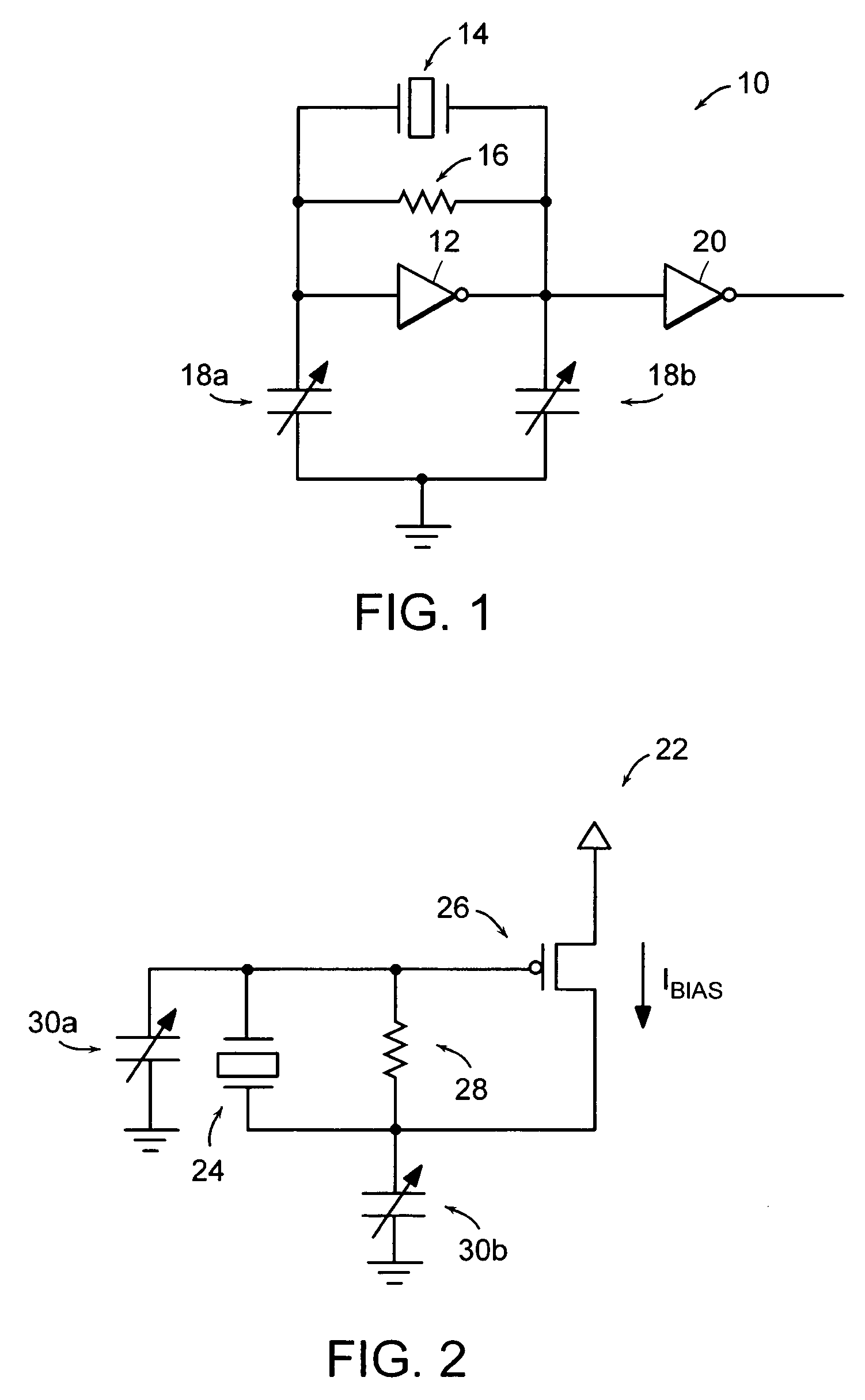

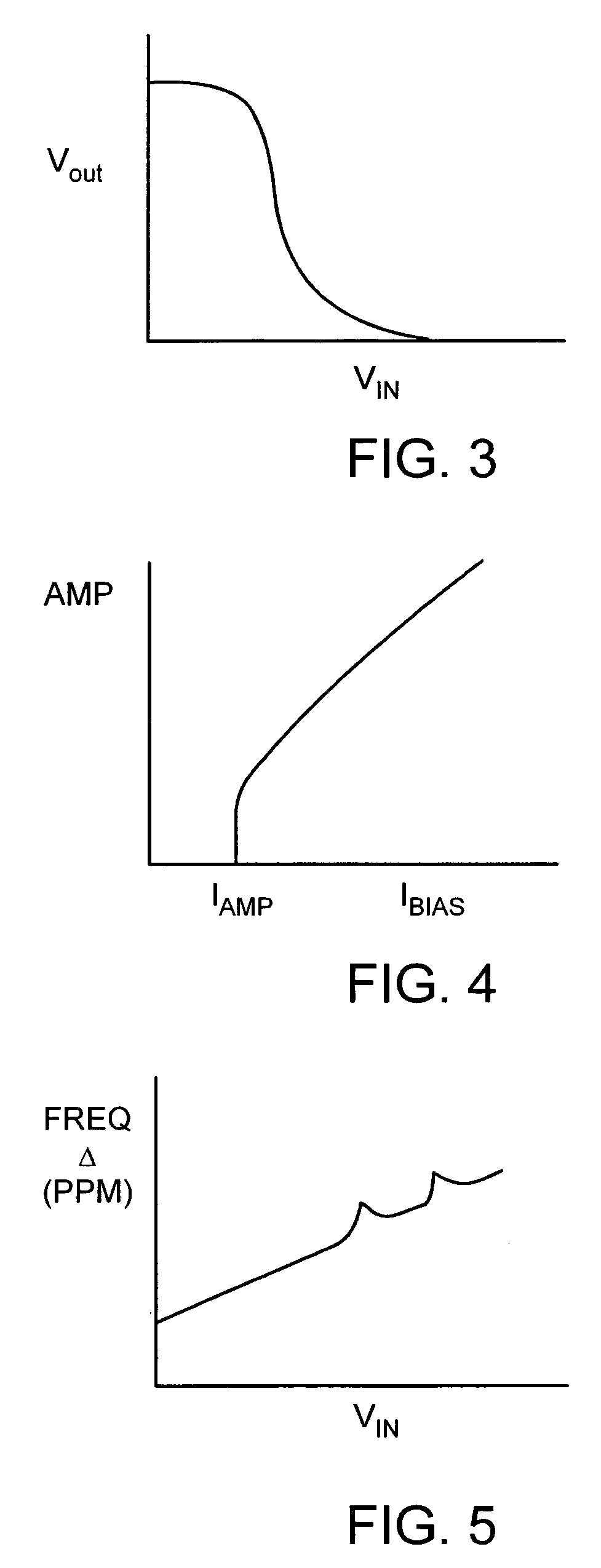

Regulated, symmetrical crystal oscillator circuit and method

ActiveUS7123113B1Reduce stimulationMinimizing stimulationPulse automatic controlGenerator stabilizationAudio power amplifierPeak value

An oscillator circuit is provided that is preferably a crystal oscillator, where voltage placed across the crystal is regulated. The regulated voltage or amplitude of the cyclical signal across the crystal is monitored and maintained through a regulation circuit that measures a peak voltage across the crystal. Once the peak voltage exceeds a predetermined setpoint value, then a controller within the regulation circuit will reduce a biasing current through an amplifying transistor within the amplifier coupled across the crystal input and output nodes. By regulating the biasing current, gain from the amplifier is also regulated so that unwanted non-linearities and harmonic distortion is not induced within the crystal to cause frequency distortion and unwanted modes of oscillation within the crystal. The amplifier is preferably symmetrical in that the amplifier sources and sinks equal current to reduce unwanted peaks at the negative or positive half cycles of the sinusoidal signal.

Owner:MONTEREY RES LLC

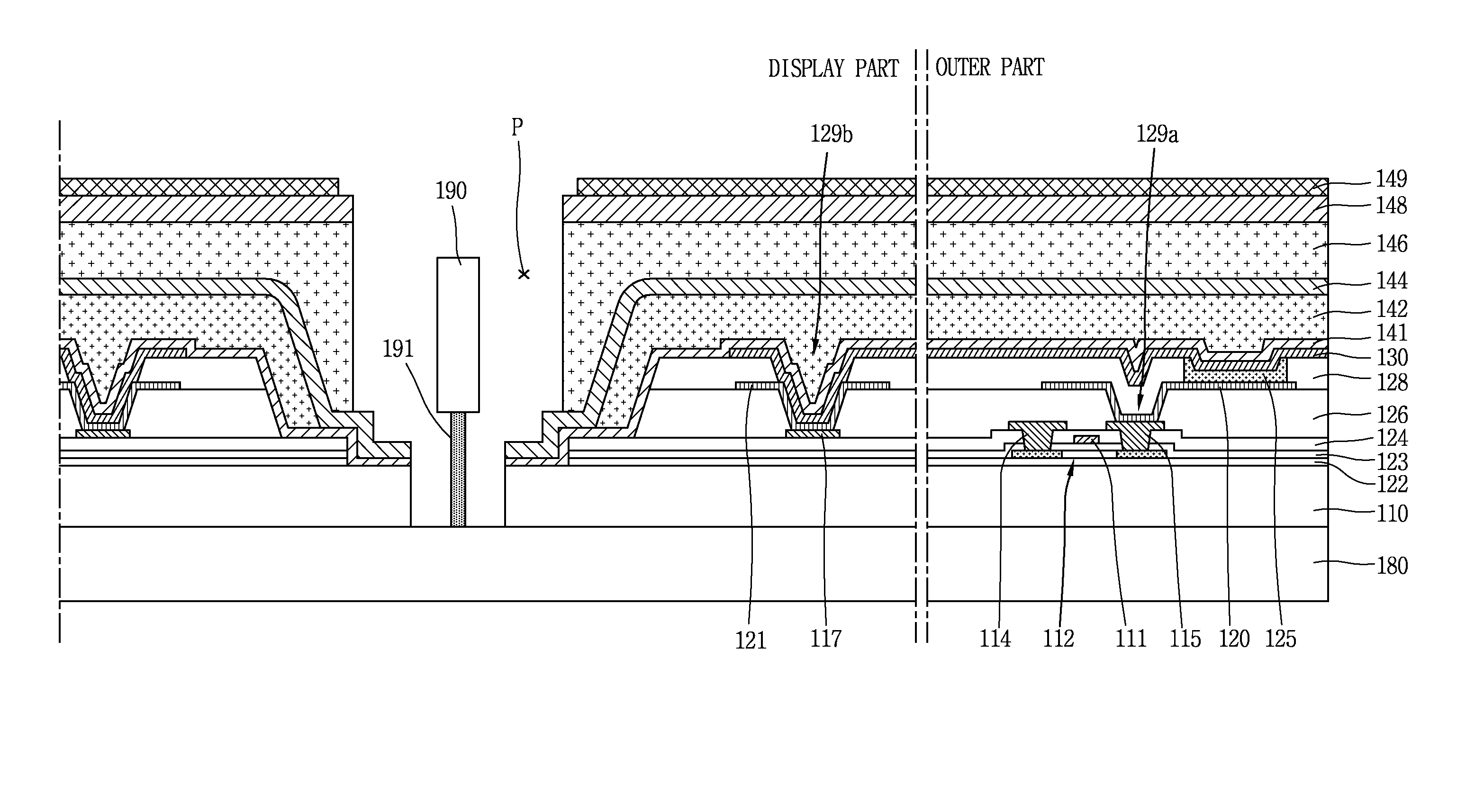

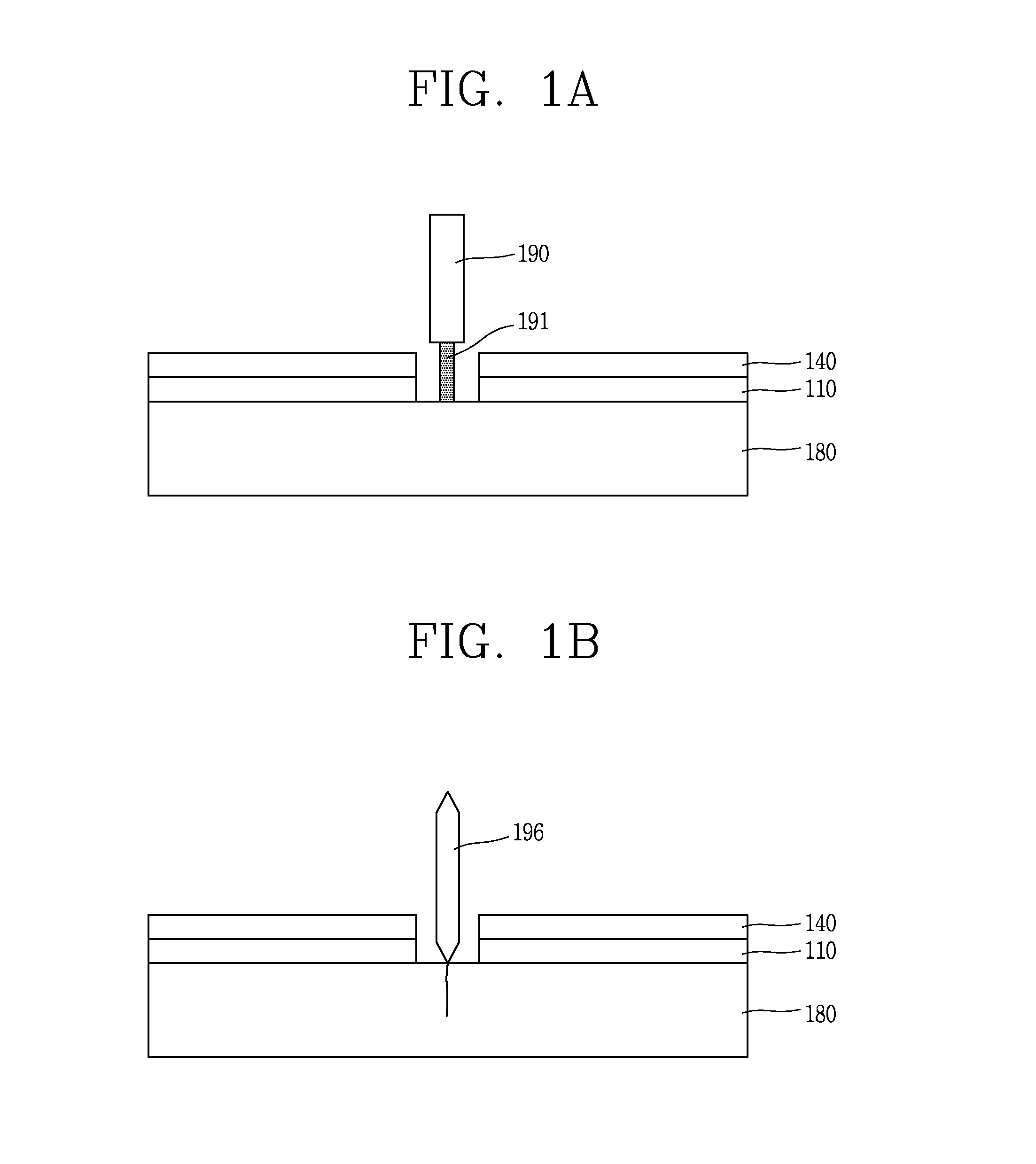

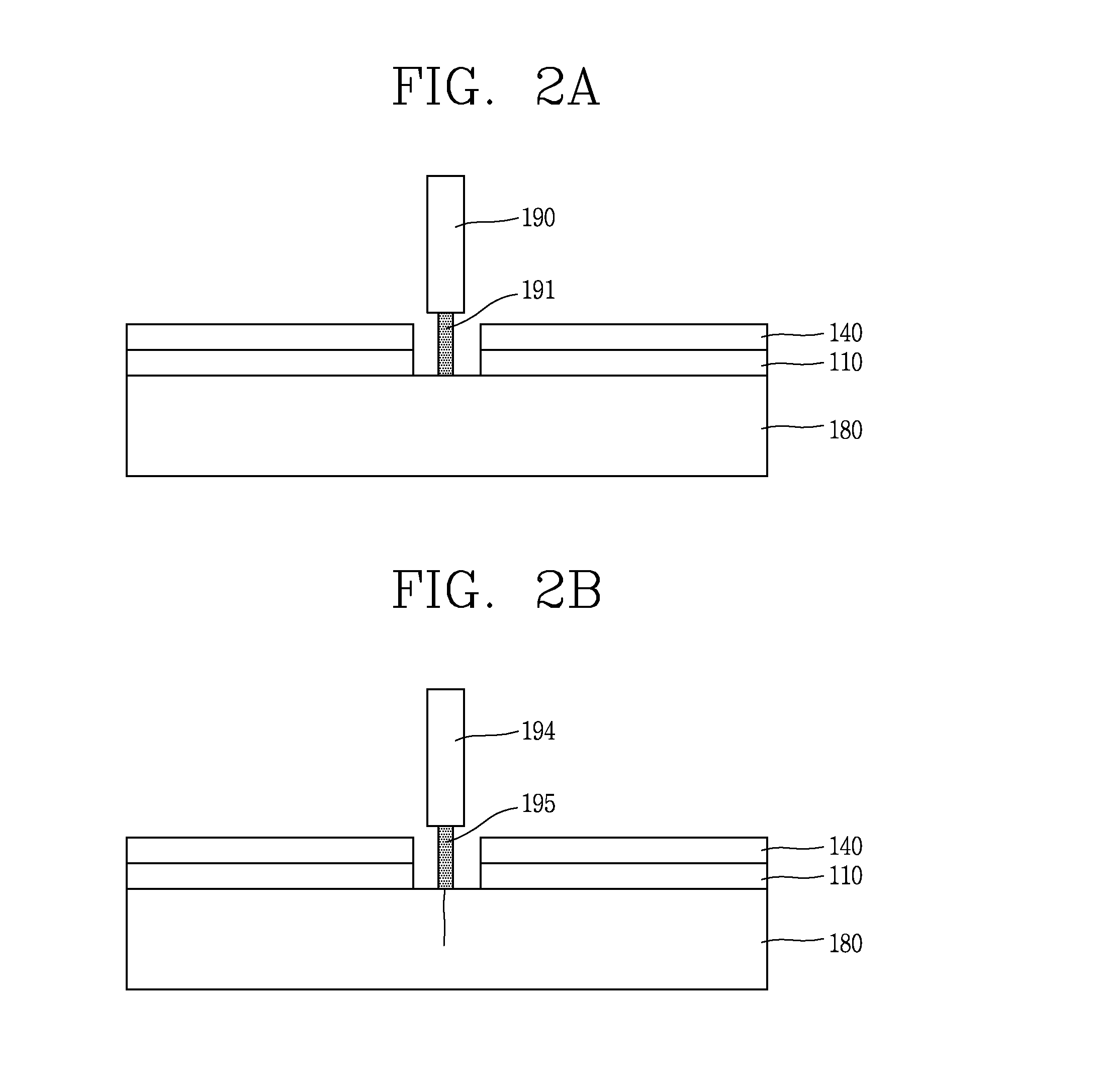

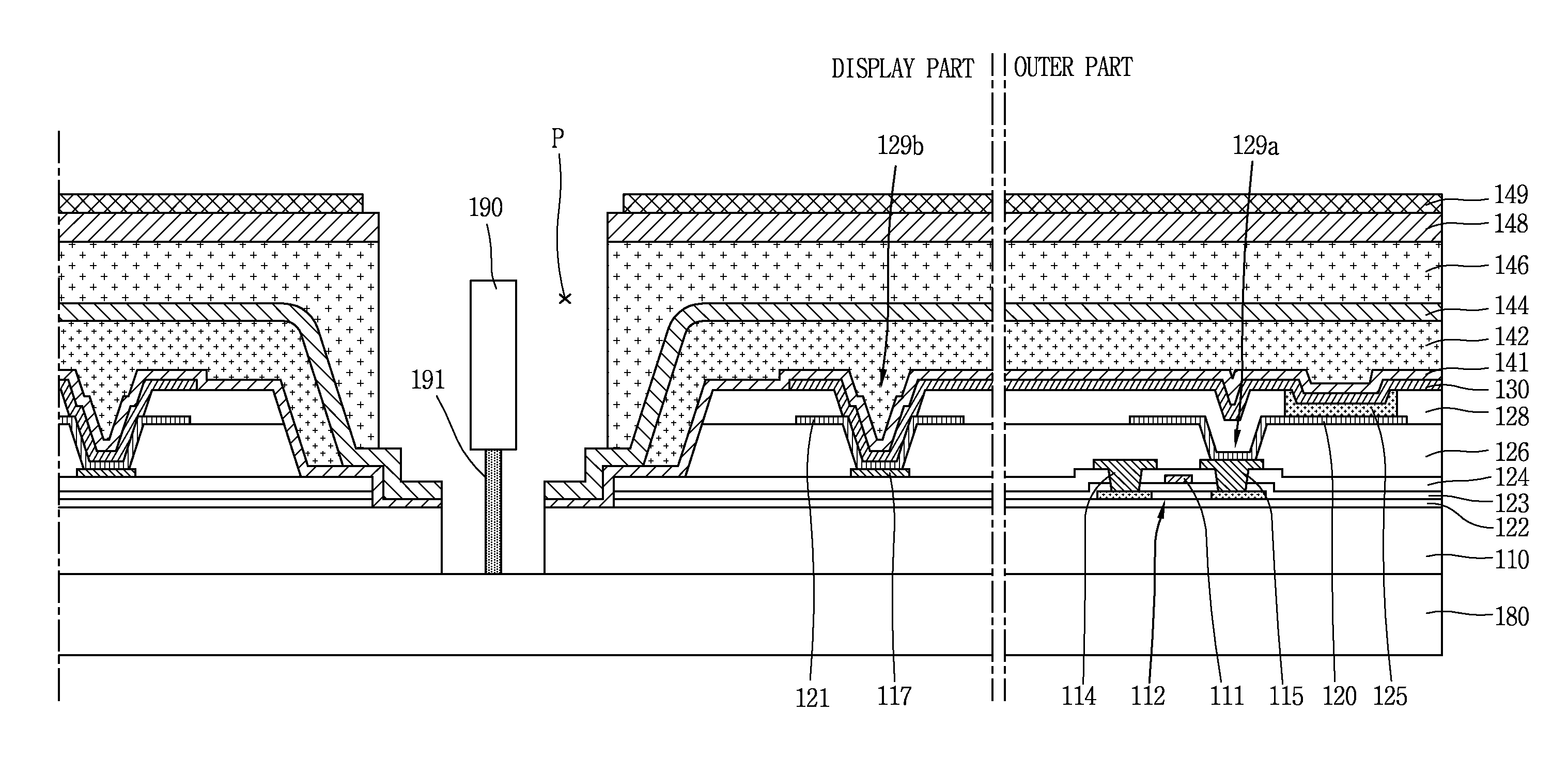

Method of cutting flexible display device and method of fabricating flexible display device using the same

ActiveUS20140134763A1Inhibition of defect generationPrevent surfaceElectroluminescent light sourcesSolid-state devicesEngineeringIrradiation

The present disclosure relates to a method of cutting a flexible display device, capable of preventing a generation of a defect at the time of cutting the flexible display device, the method including providing a glass mother substrate having a flexible substrate attached thereon and an insulating layer formed on the flexible substrate; melting the flexible substrate and the insulating layer on the mother substrate by irradiating with a first laser beam; and cutting the mother substrate exposed by the irradiation of the first laser beam using a cutting device.

Owner:LG DISPLAY CO LTD

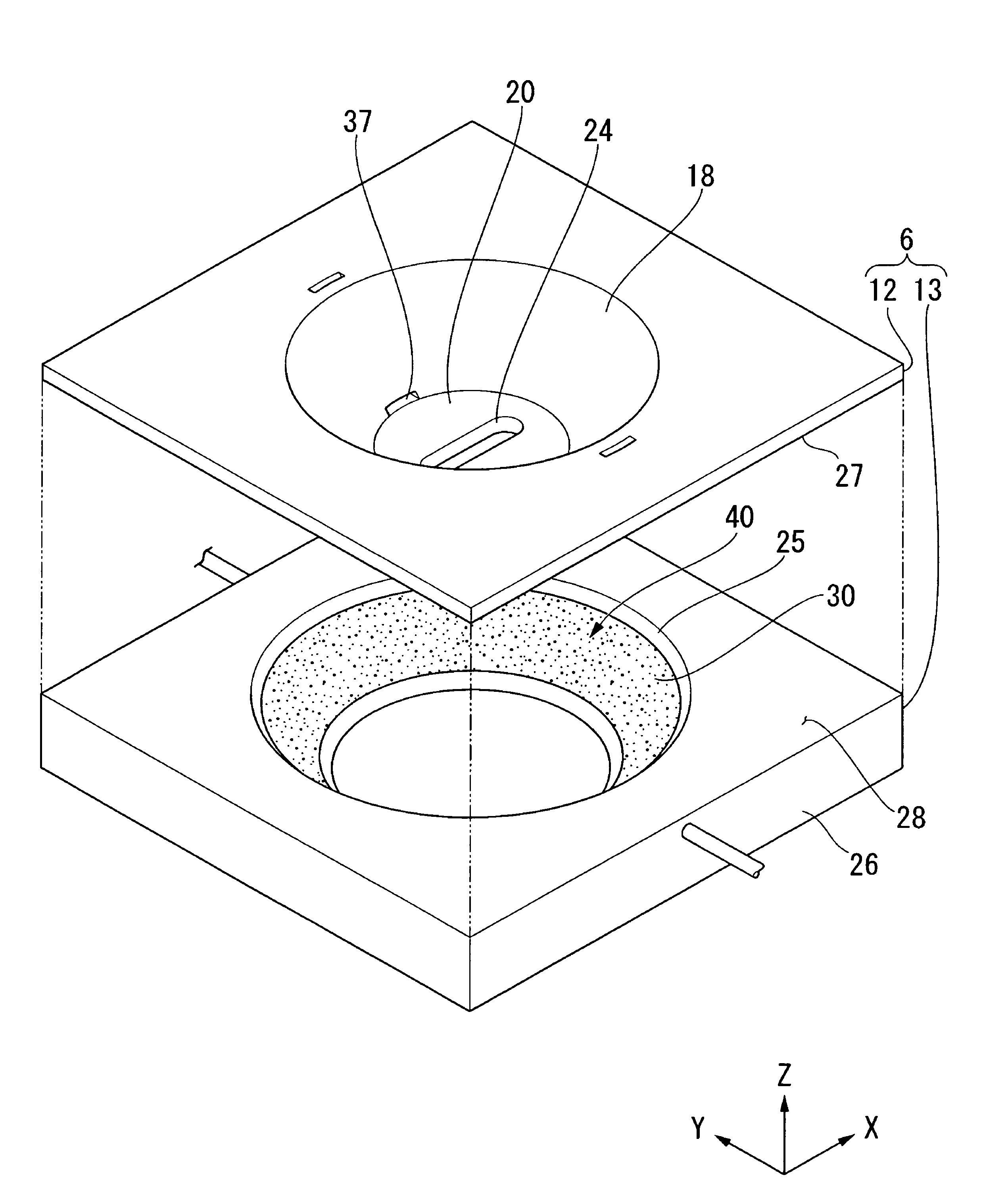

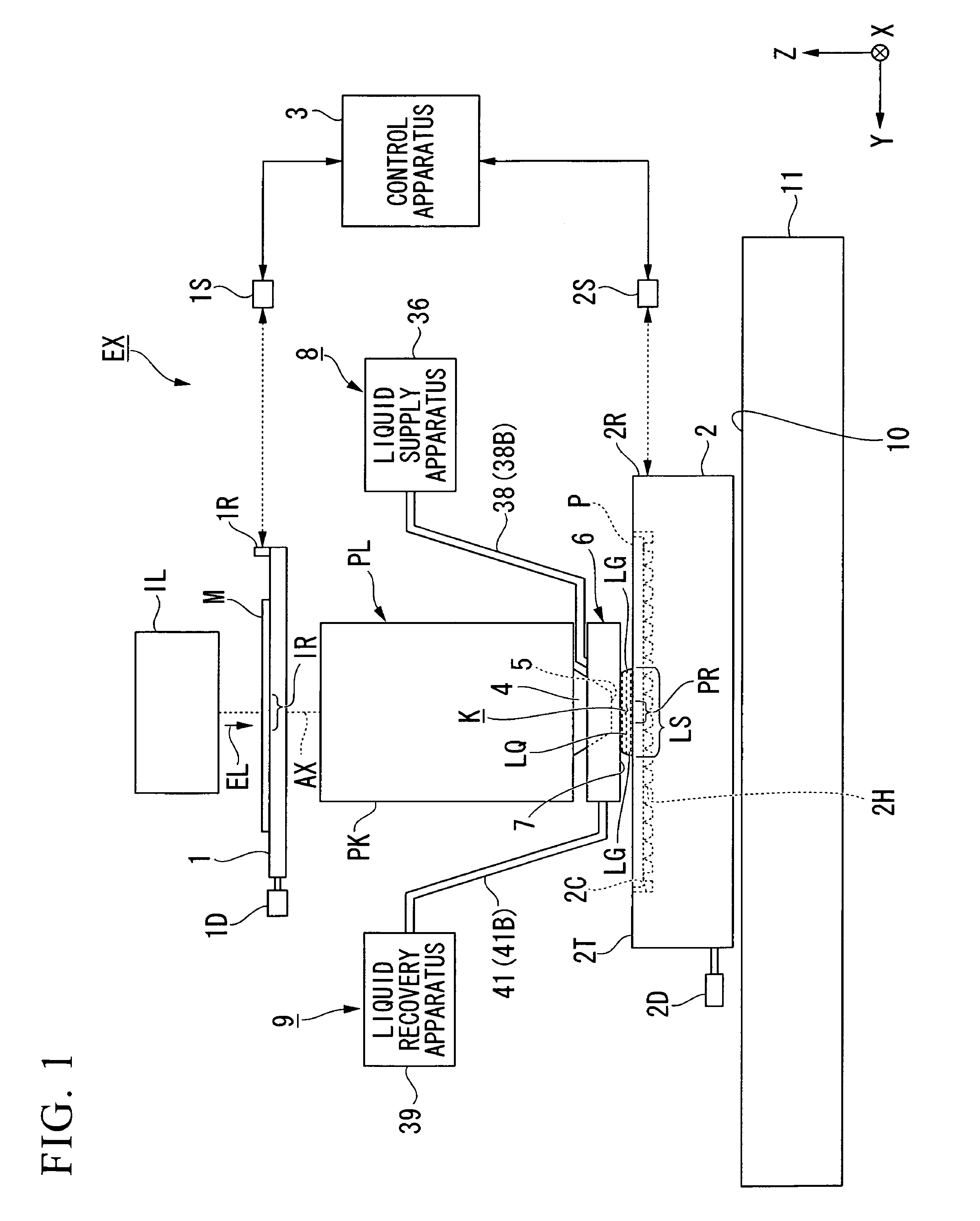

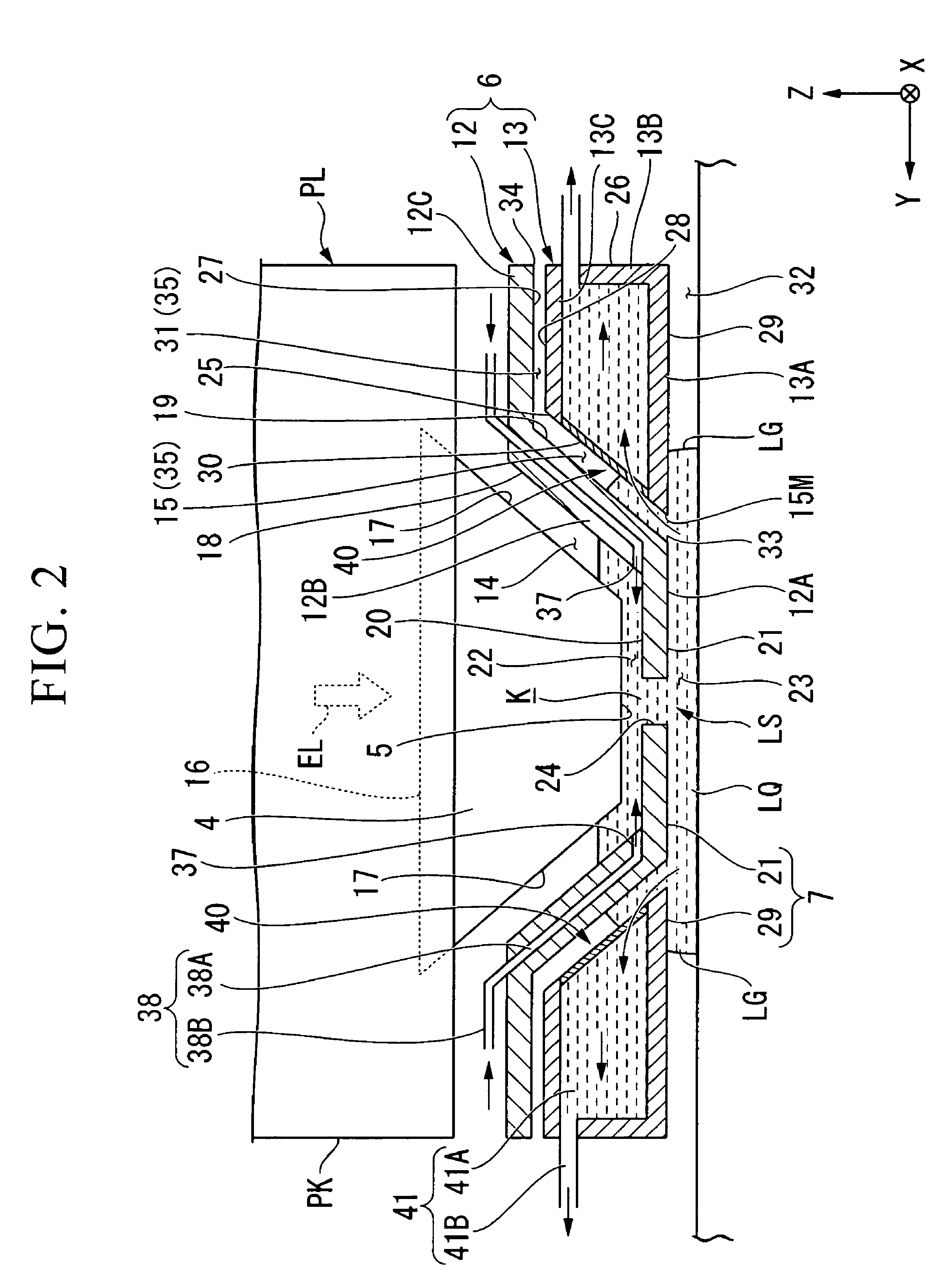

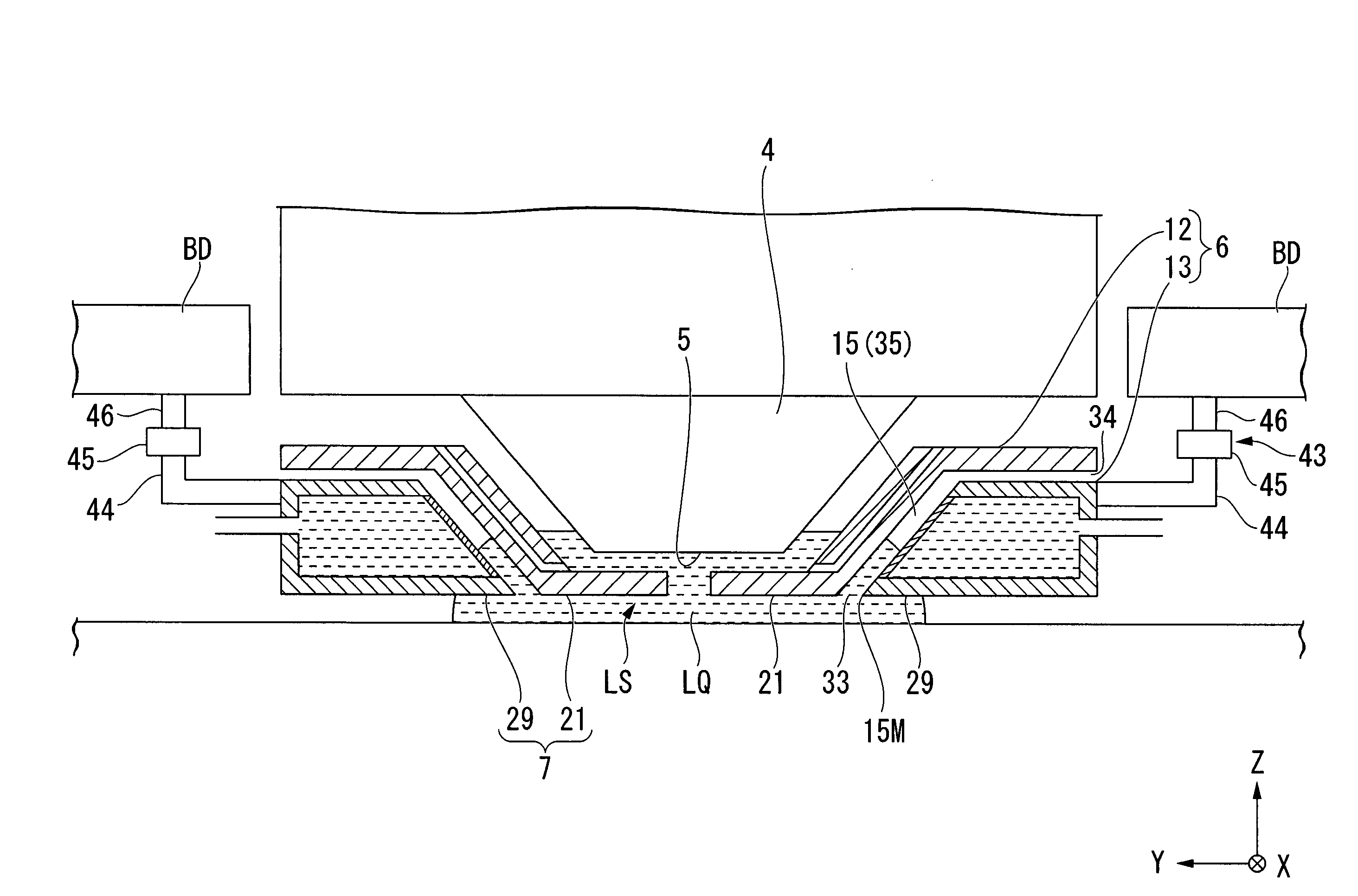

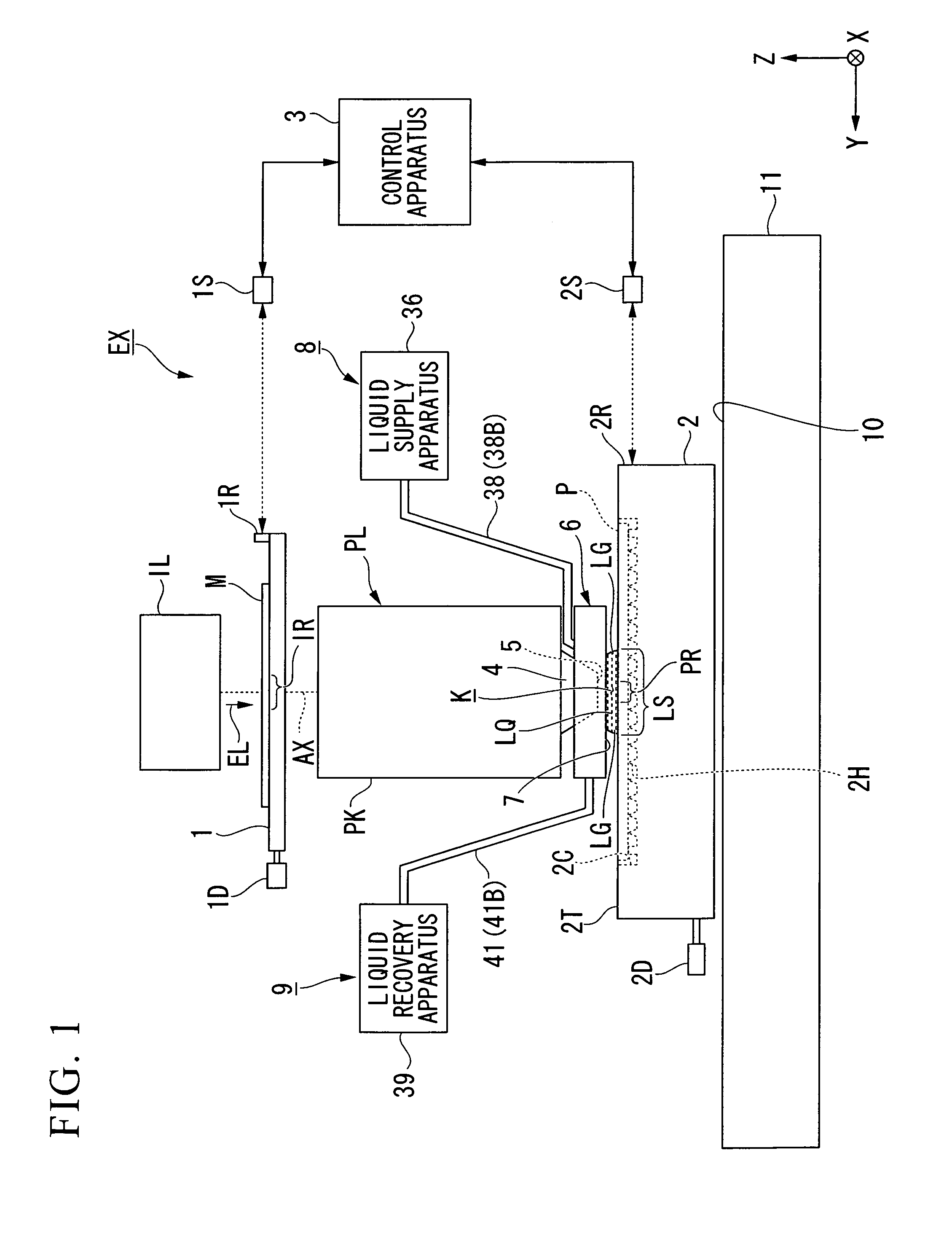

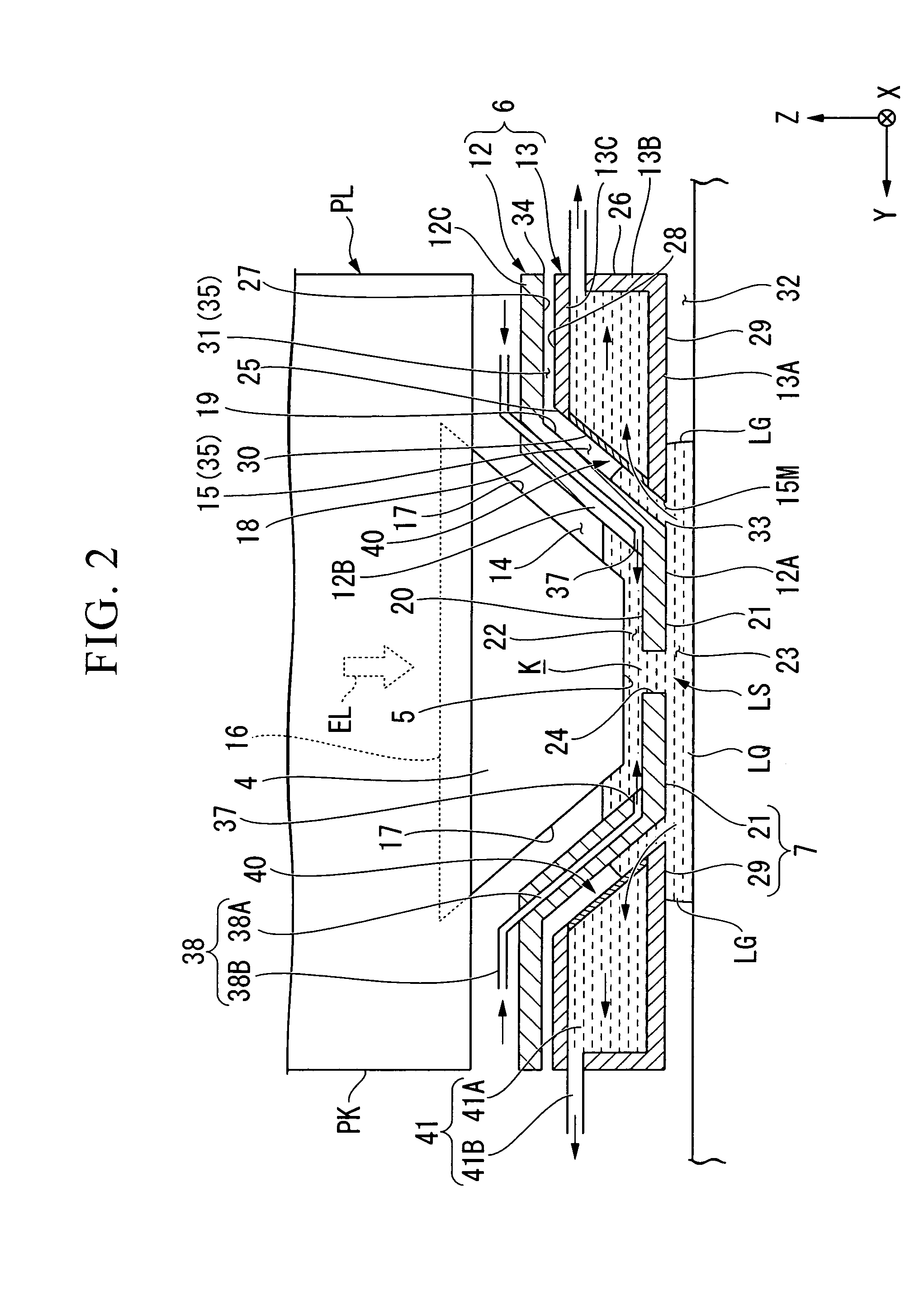

Liquid recovery system, immersion exposure apparatus, immersion exposing method, and device fabricating method

InactiveUS8004651B2Recover the liquid satisfactorilyAvoid failureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringMechanical engineering

A liquid recovery system is used by an immersion exposure apparatus. The liquid recovery system is provided with a first opening; a gap portion that is provided so that a liquid on an object that opposes the first opening can flow into the gap portion through the first opening; a liquid recovery part that suctions, through a porous member, at least part of the liquid that flows into the gap portion; and a second opening that is different from the first opening. The gap portion is open to the atmosphere through the second opening.

Owner:NIKON CORP

Liquid recovery system, immersion exposure apparatus, immersion exposing method, and device fabricating method

InactiveUS20080174748A1Recover the liquid satisfactorilyAvoid failureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringMechanical engineering

A liquid recovery system is used by an immersion exposure apparatus. The liquid recovery system is provided with: a first opening; a gap portion that is provided so that a liquid on an object that opposes the first opening can flow into the gap portion through the first opening; a liquid recovery part that suctions, through a porous member, at least part of the liquid that flows into the gap portion; and a second opening that is different from the first opening. The gap portion is open to the atmosphere through the second opening.

Owner:NIKON CORP

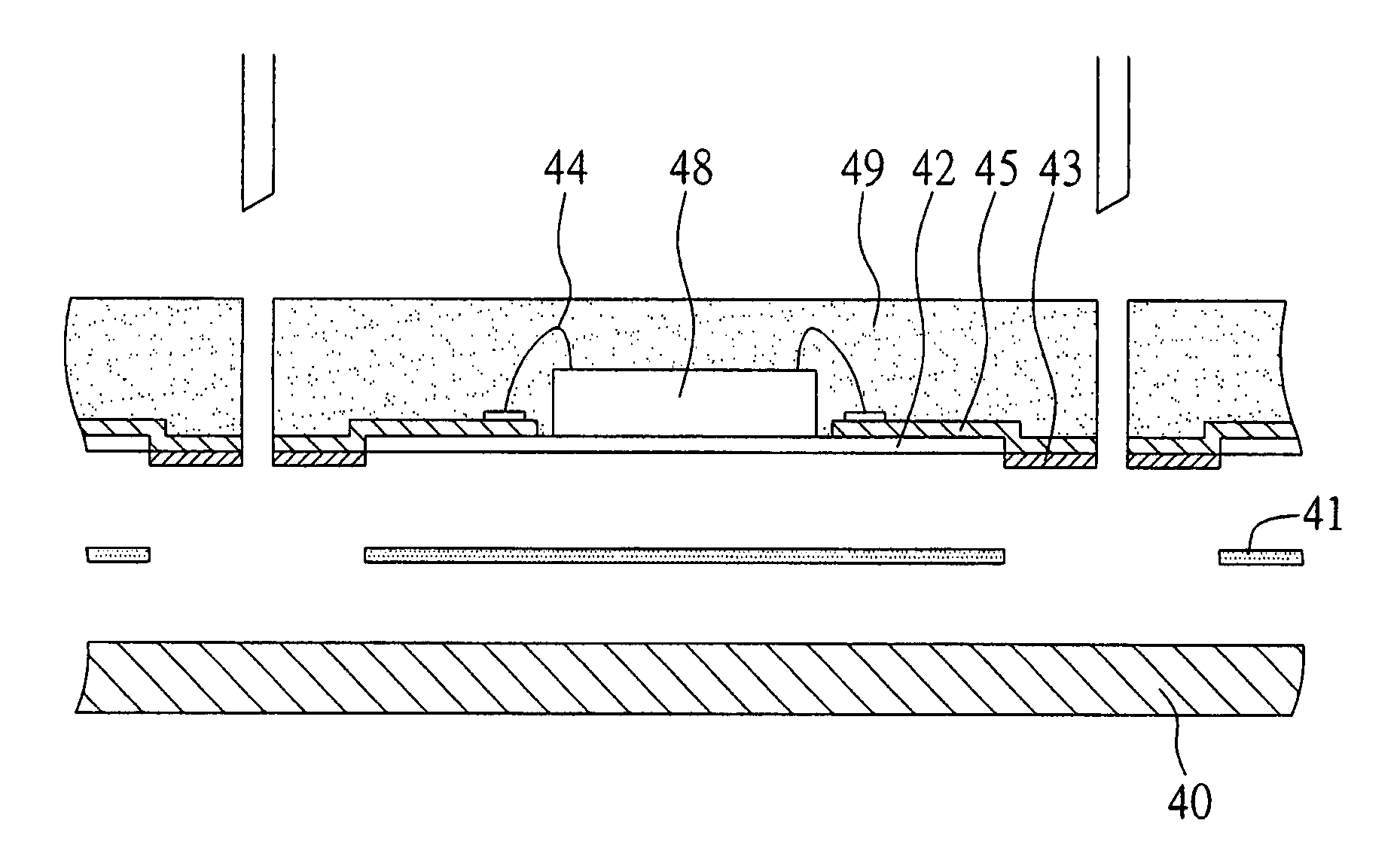

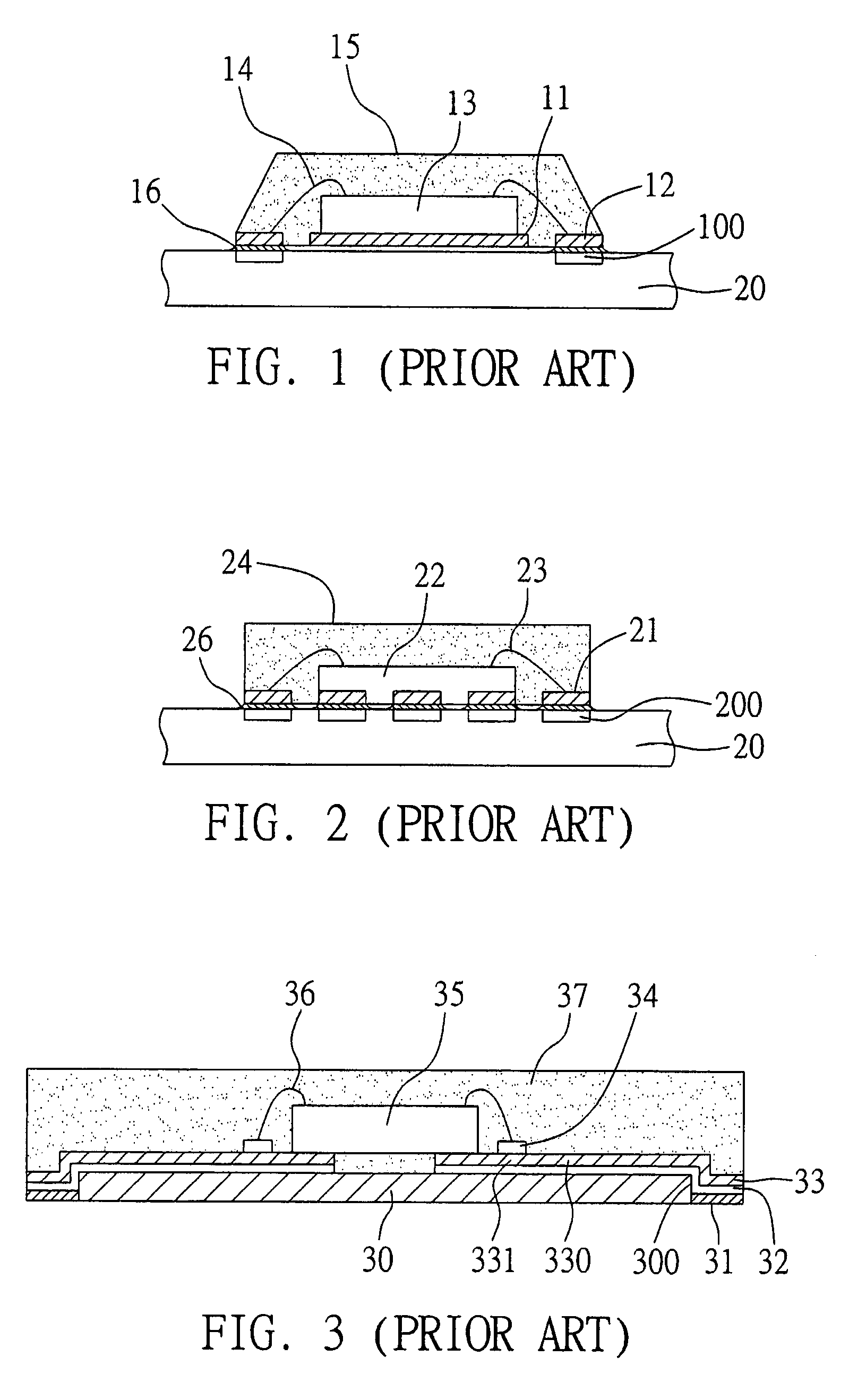

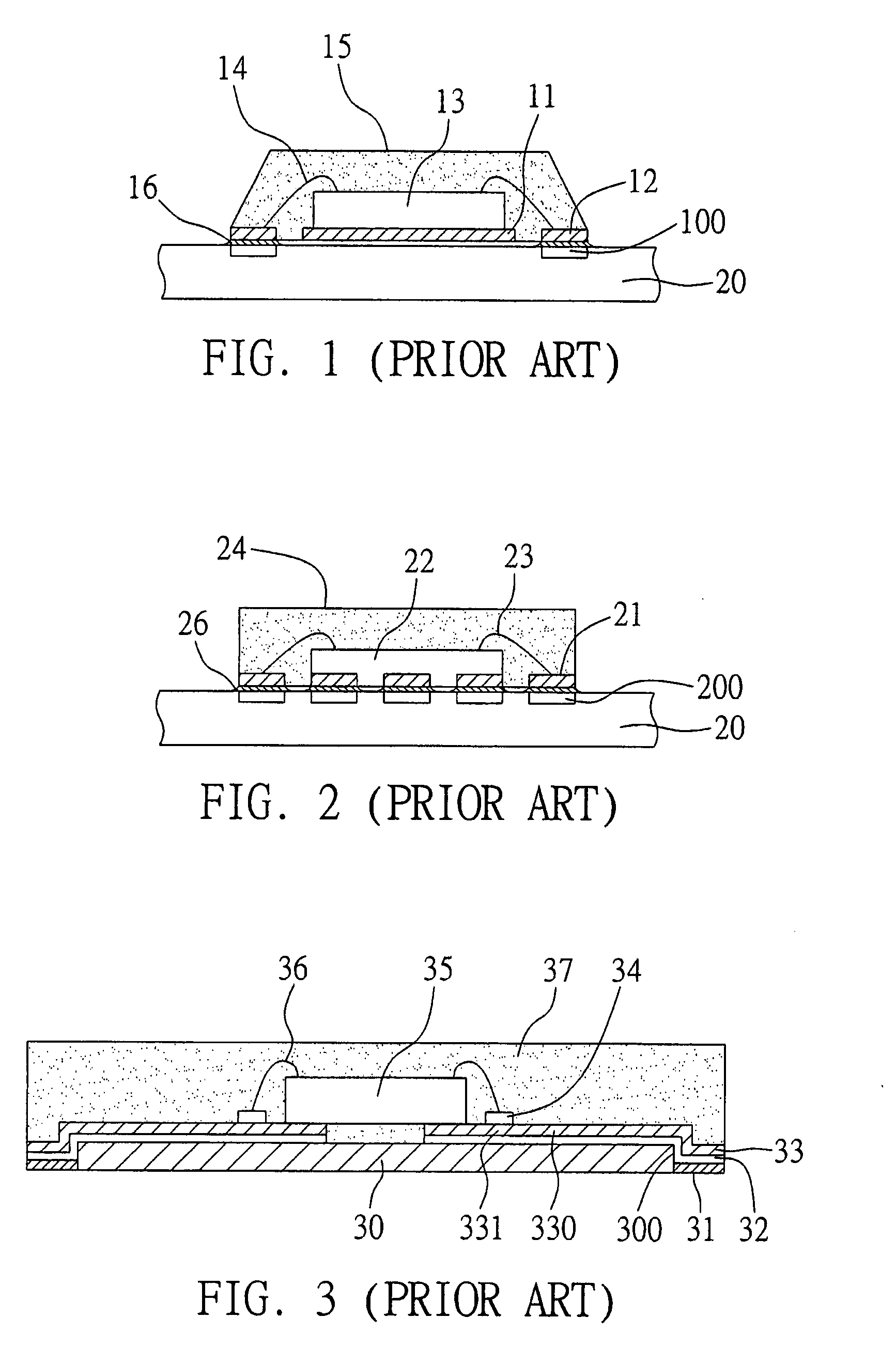

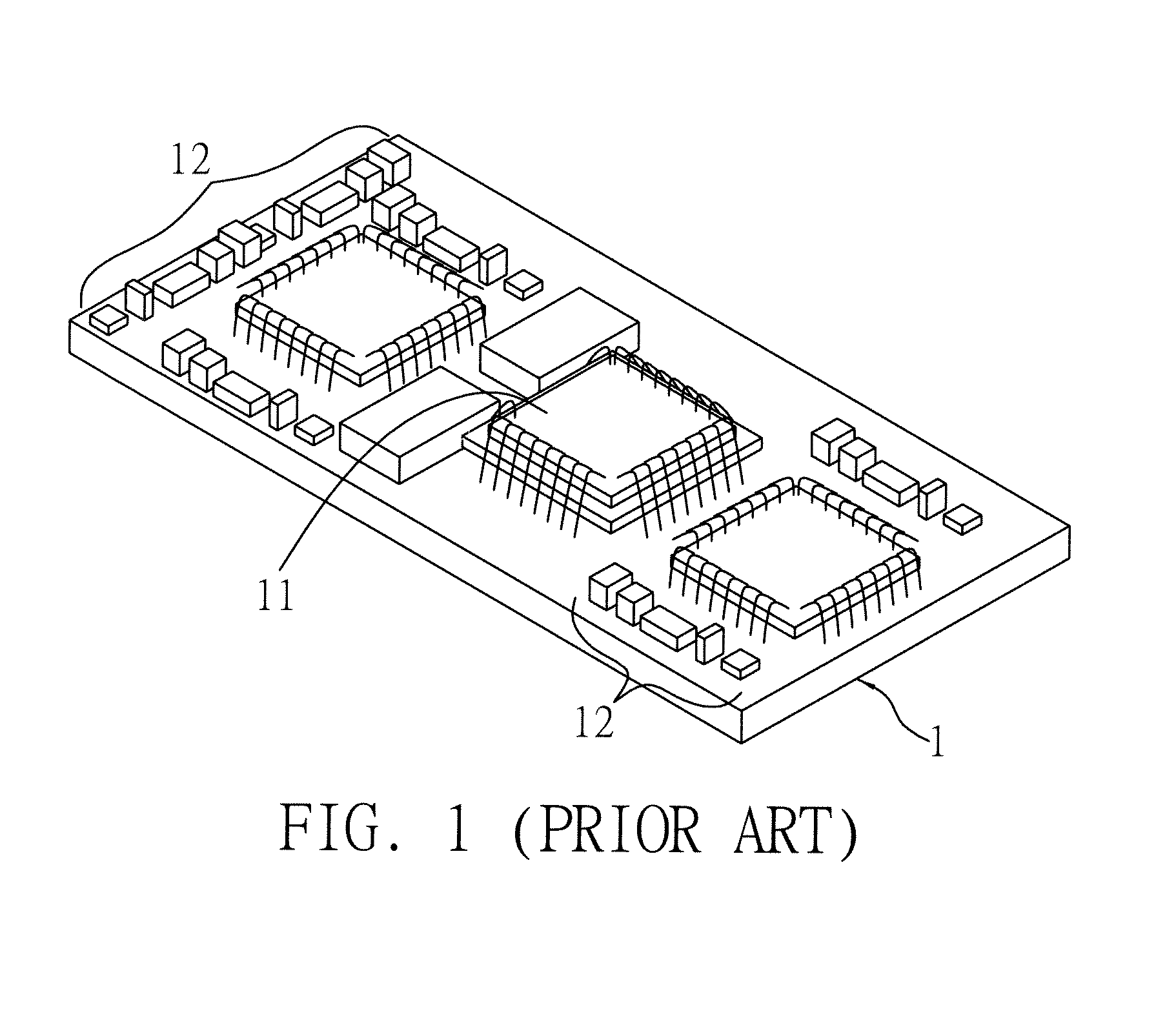

Semiconductor package and fabrication method thereof

ActiveUS7638879B2Reduce thermal stressImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerSemiconductor package

Owner:SILICONWARE PRECISION IND CO LTD

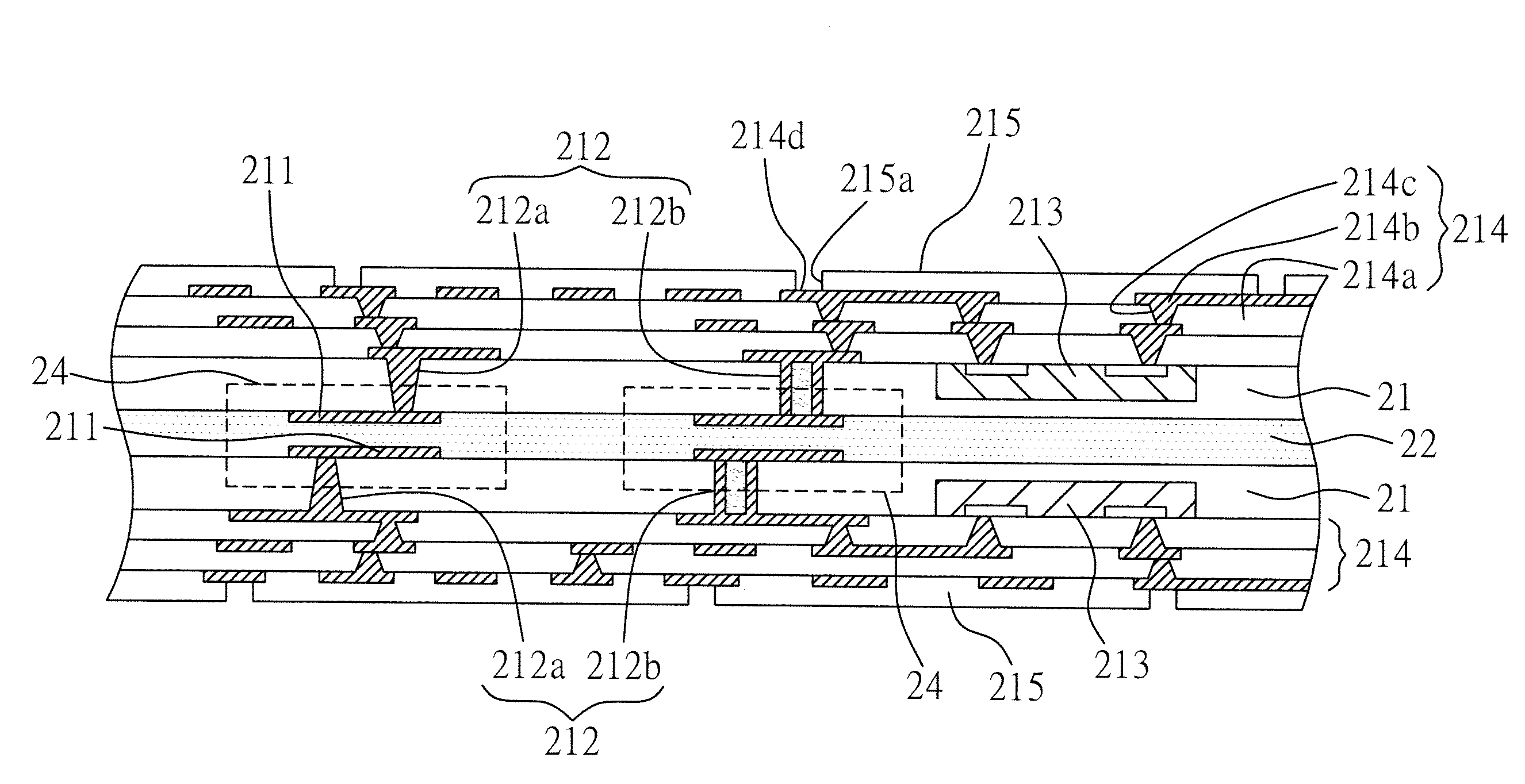

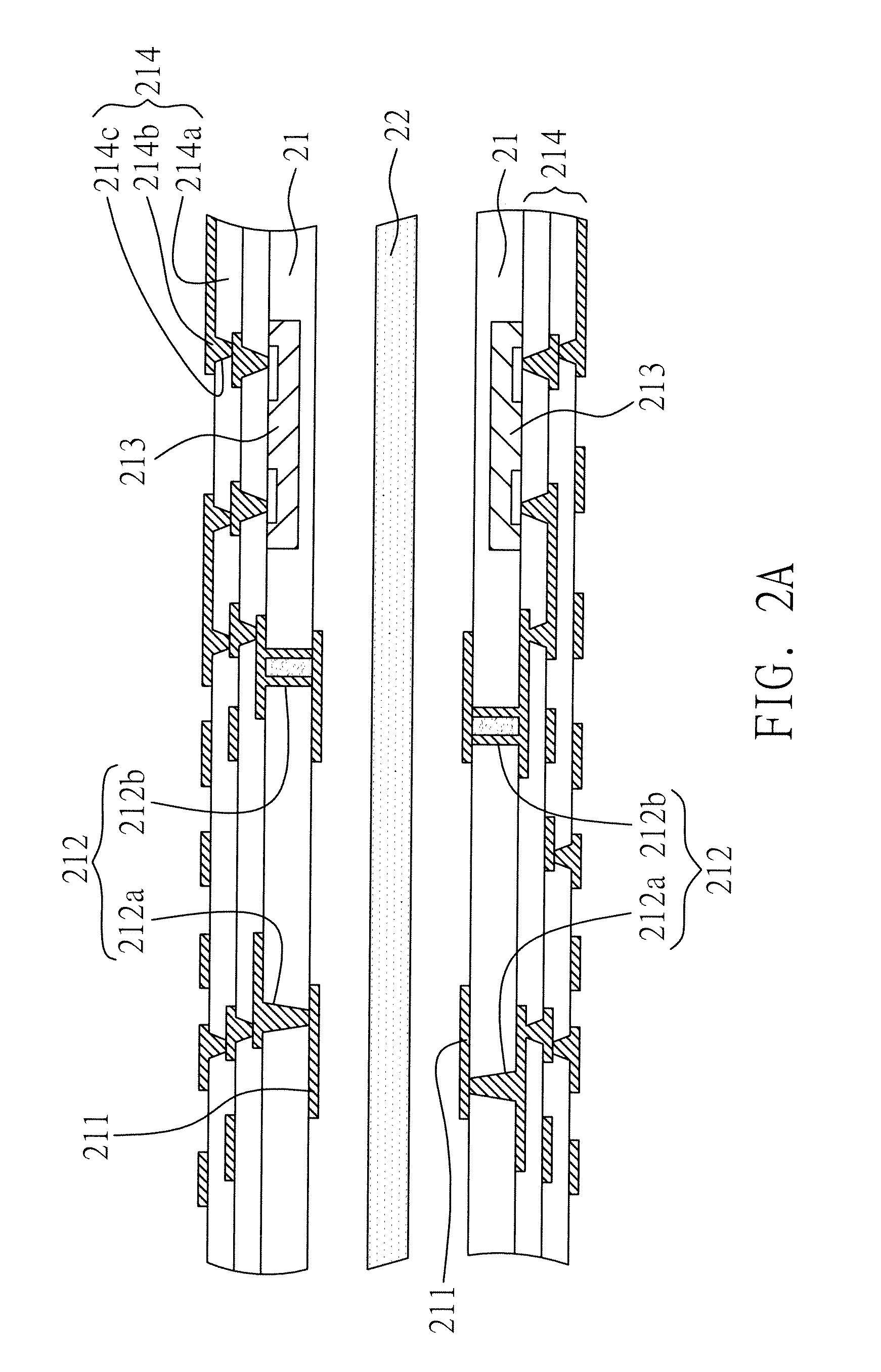

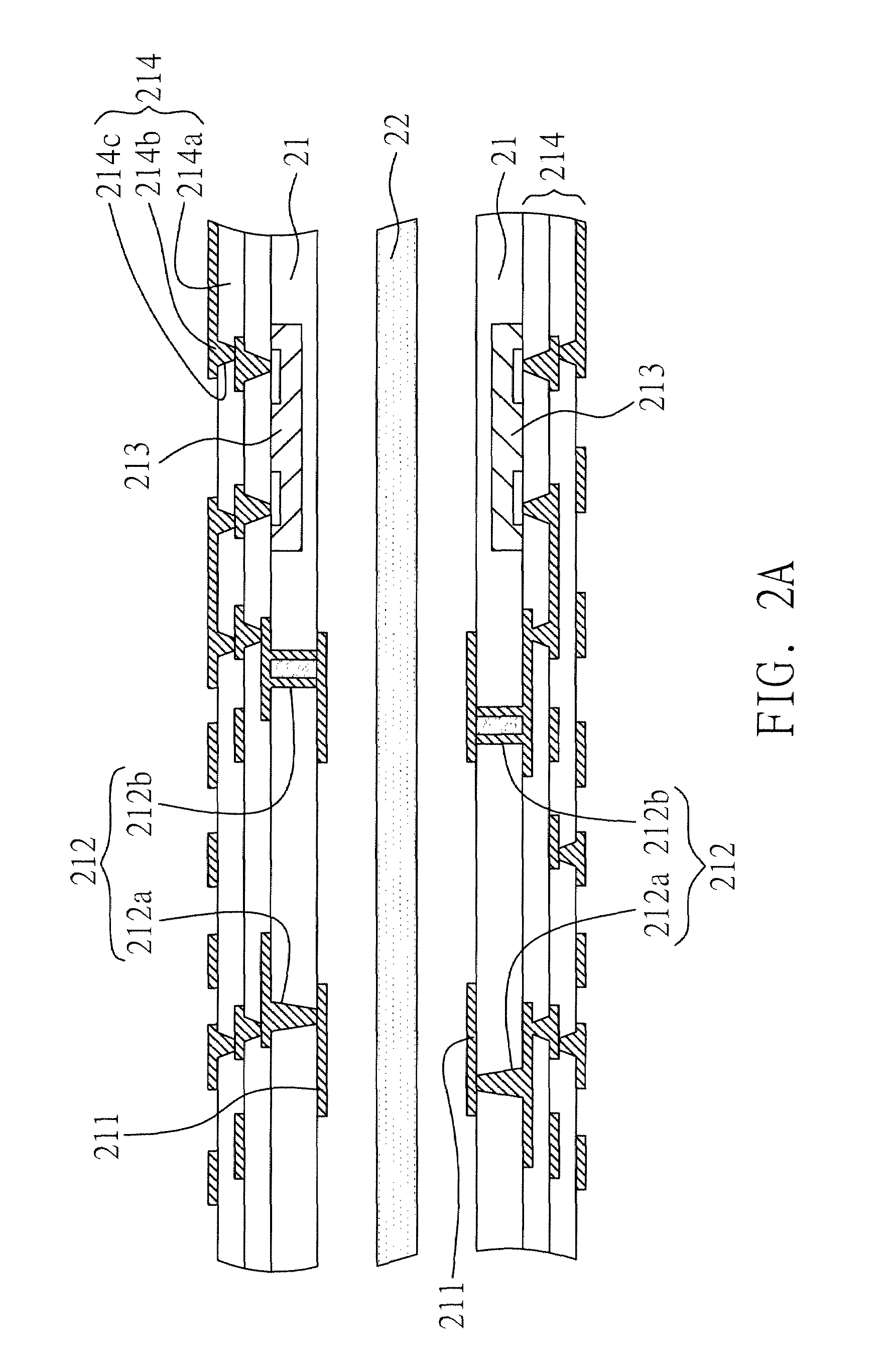

Circuit Board Structure Having Capacitor Array and Embedded Electronic Component and Method for Fabricating the Same

ActiveUS20070147014A1Simple preparation procedureLow-profilePrinted circuit aspectsSolid-state devicesEngineeringElectronic component

A circuit board structure having a capacitor array and an embedded electronic component and a method for fabricating the same are proposed. Two carrier boards and a high dielectric constant material layer are provided, wherein the carrier boards have electronic components embedded therein and one surface of each carrier board has a plurality of electrode plates. The two carrier boards are laminated with the dielectric constant material layer interposed between them. The electrode plates on the surfaces of the carrier boards are opposite to each other across the high dielectric constant material layer to constitute a capacitor array. Therefore, the capacitor assembly for design of electronic devices is provided.

Owner:PHOENIX PRECISION TECH CORP

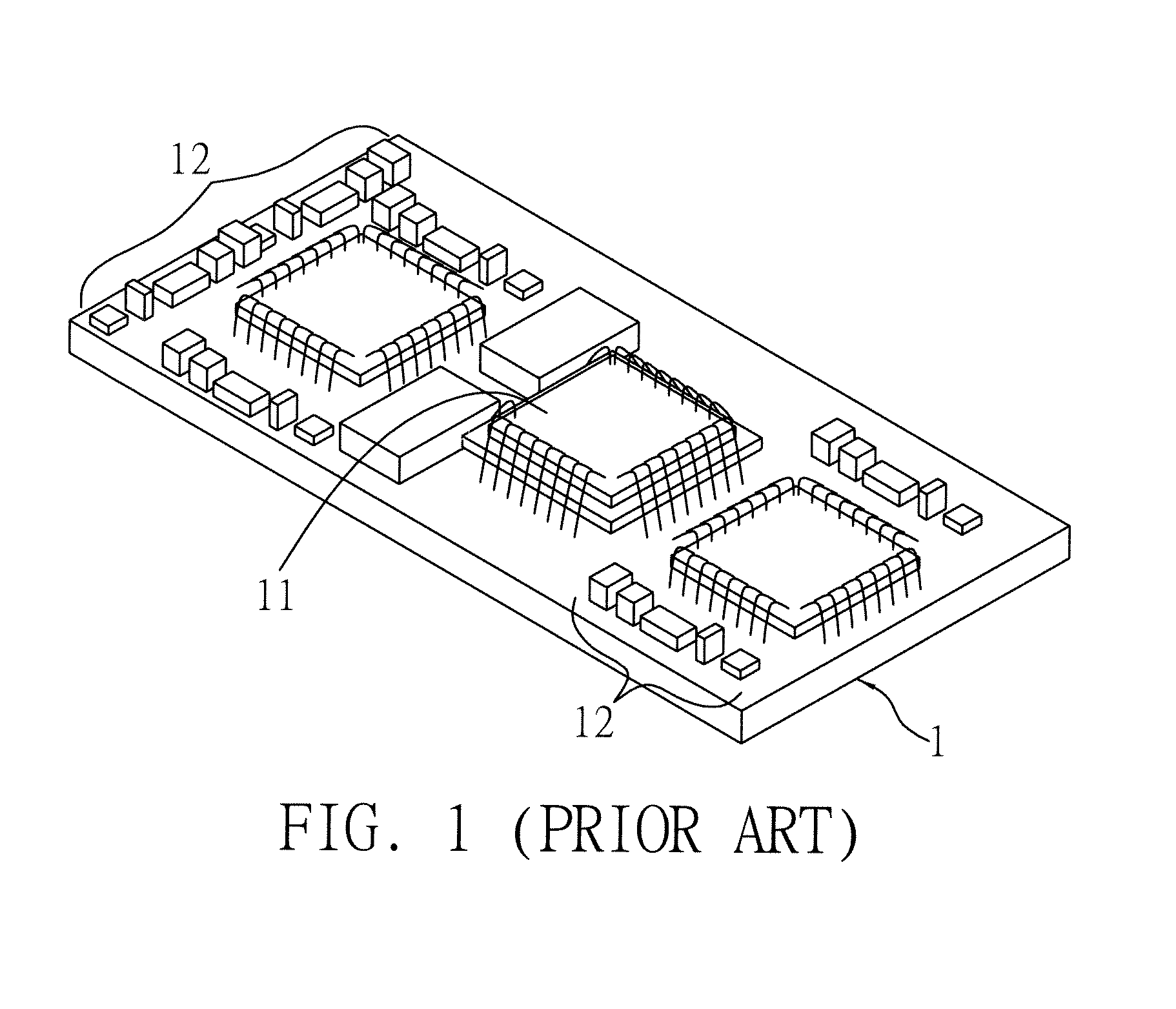

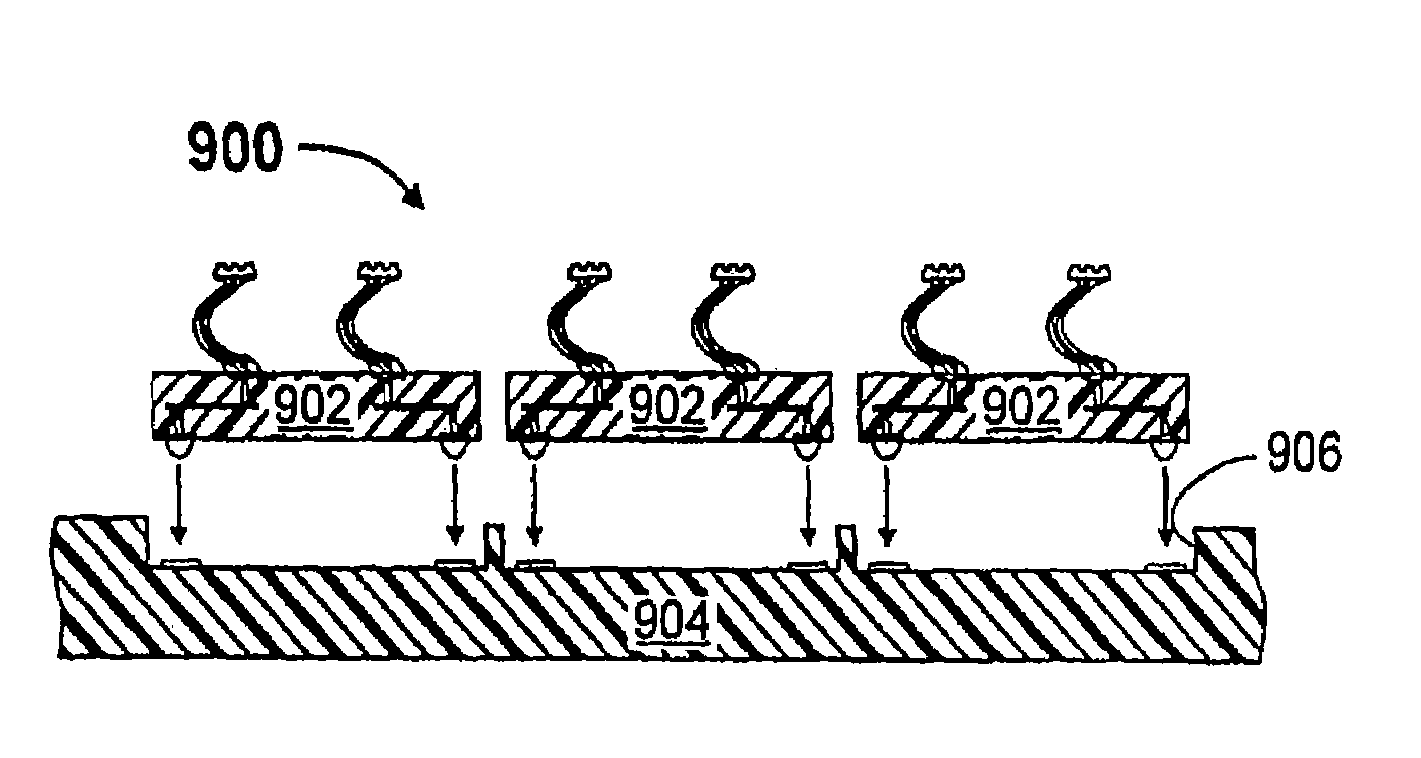

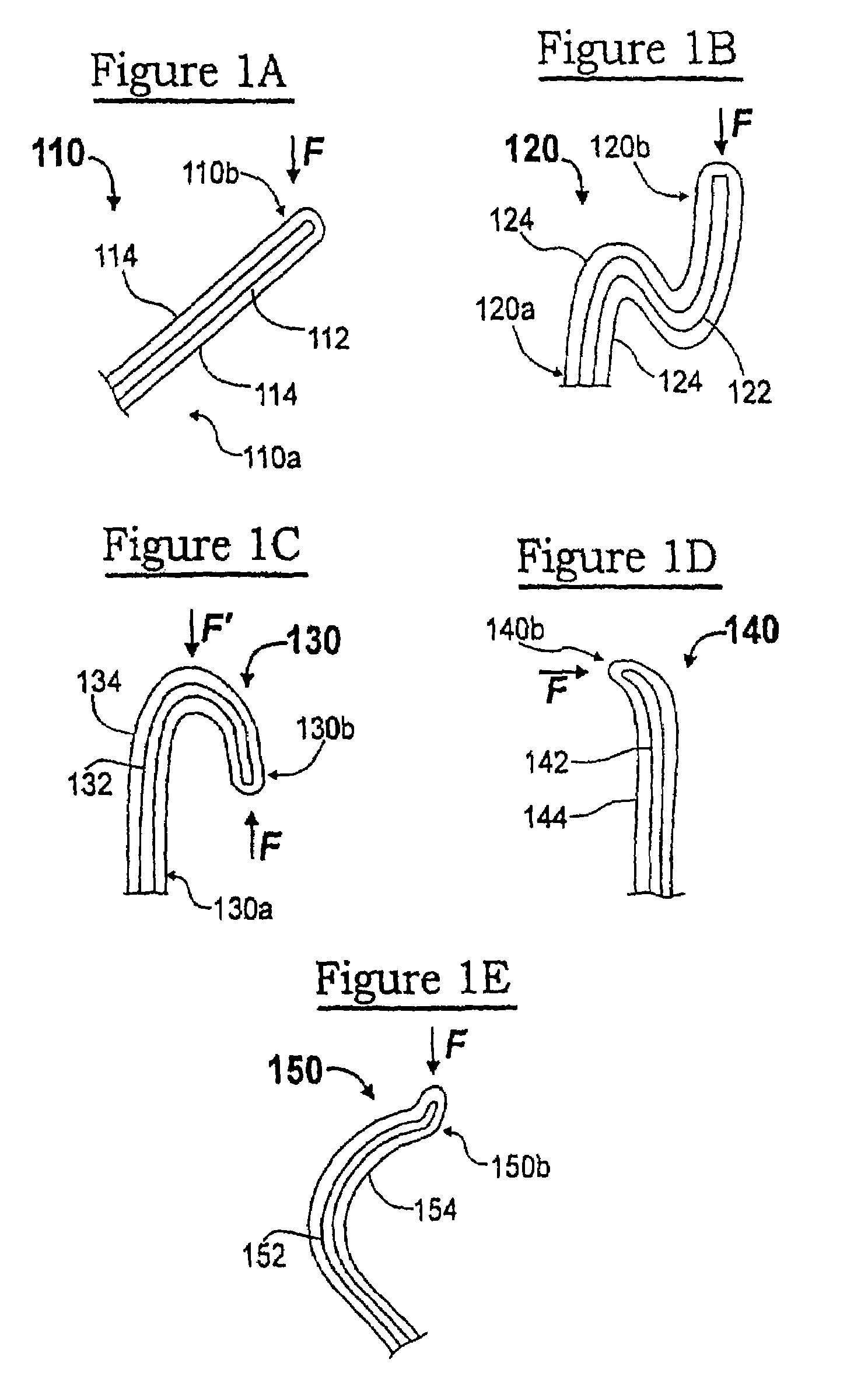

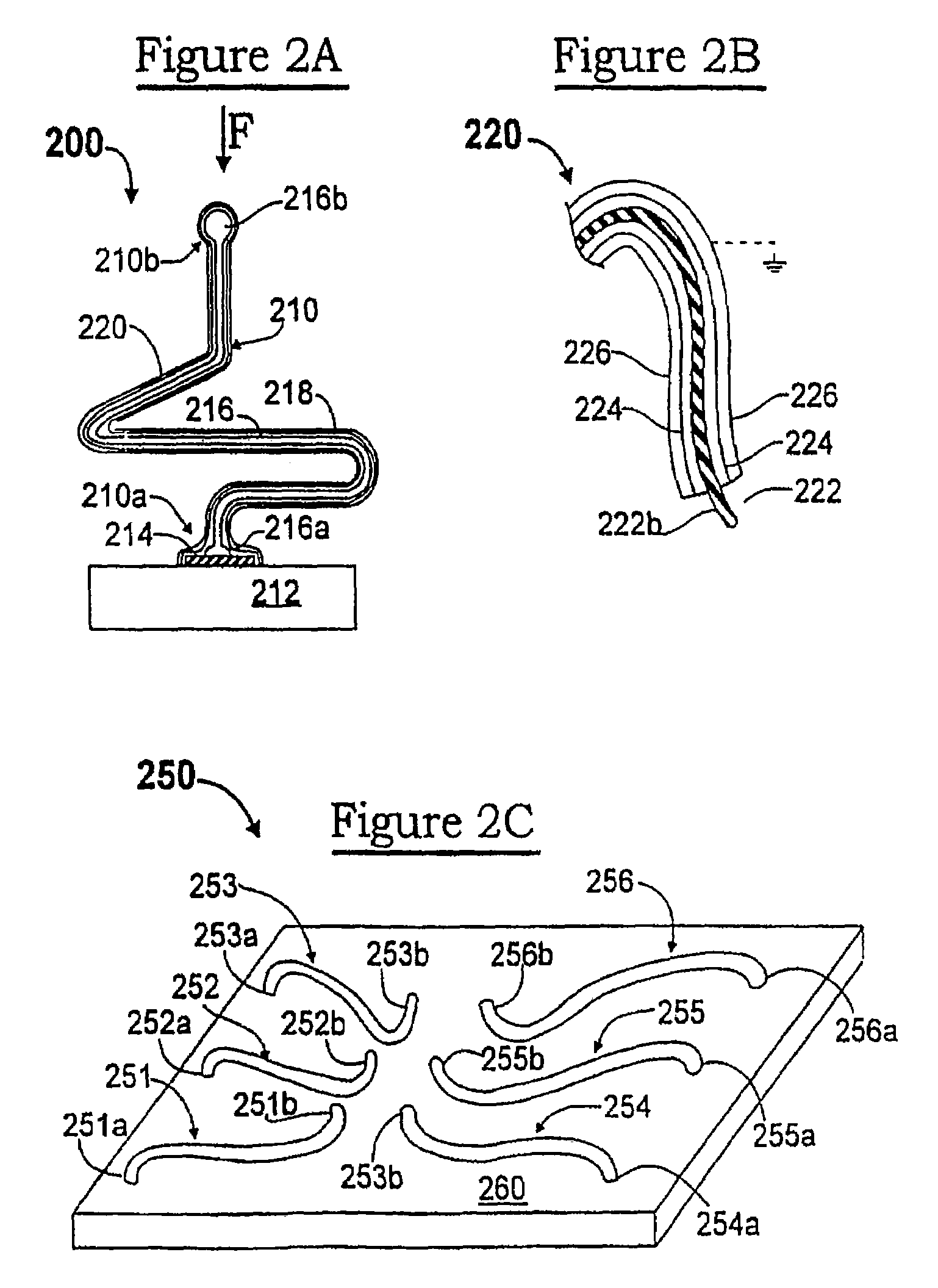

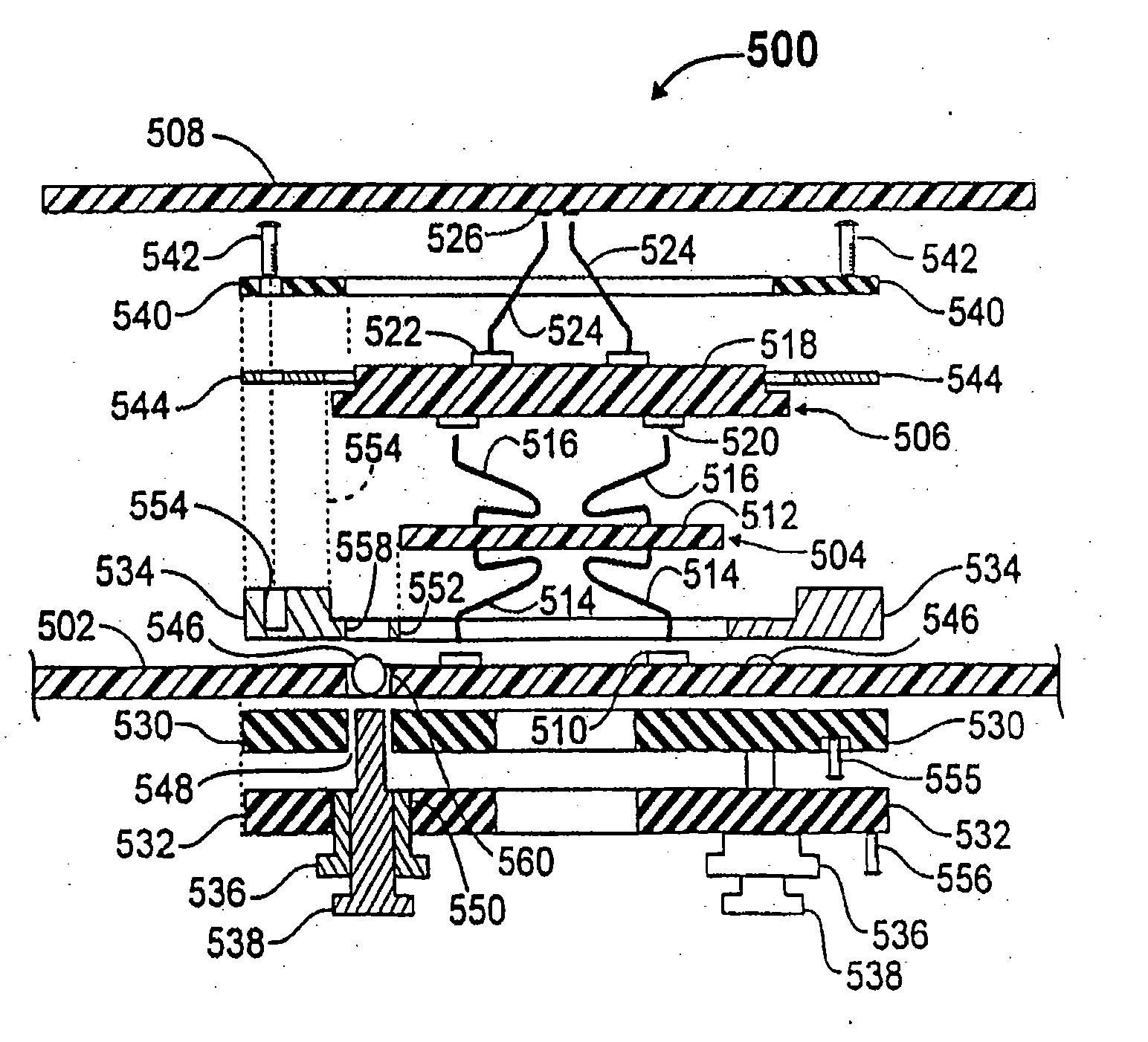

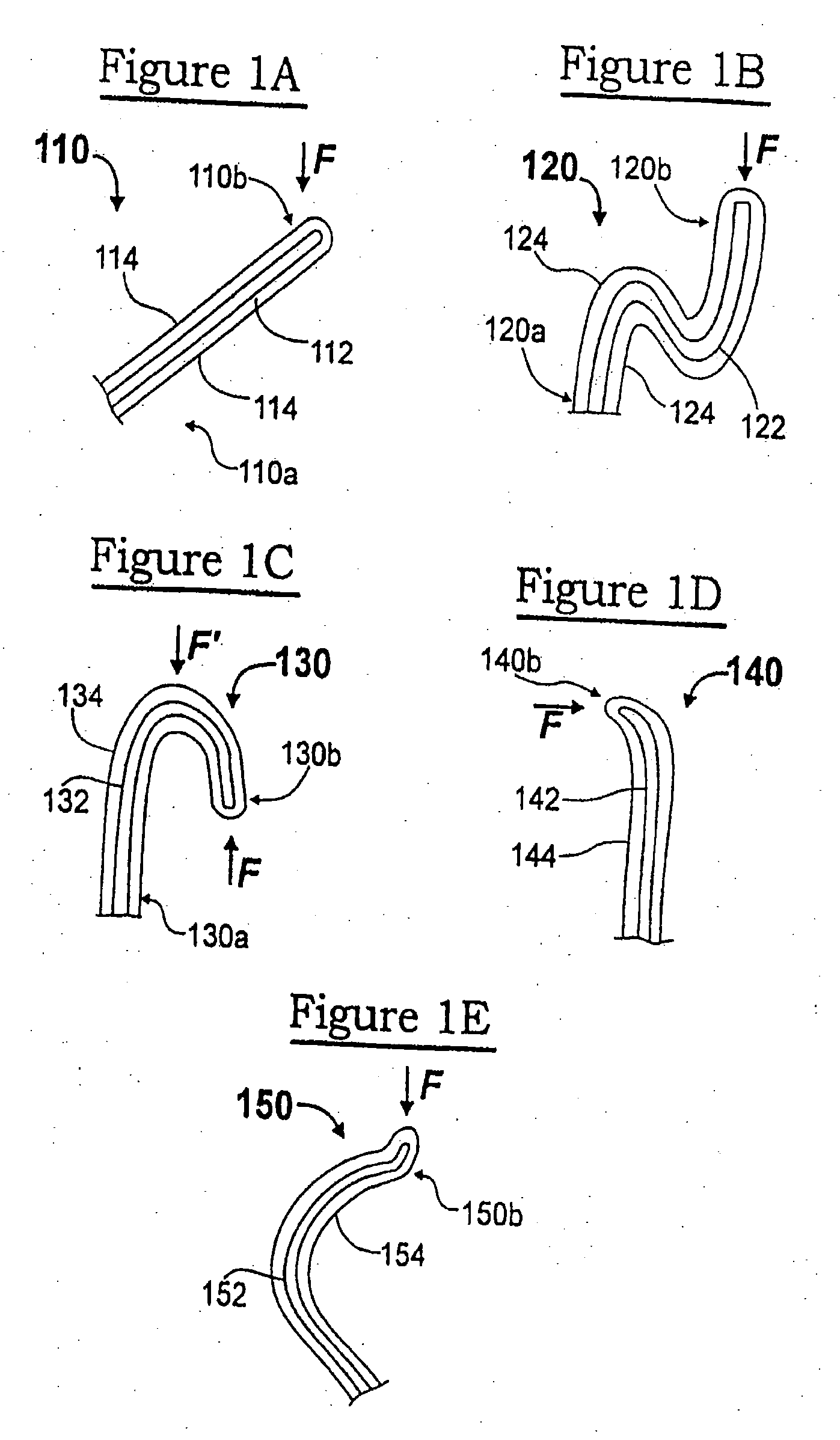

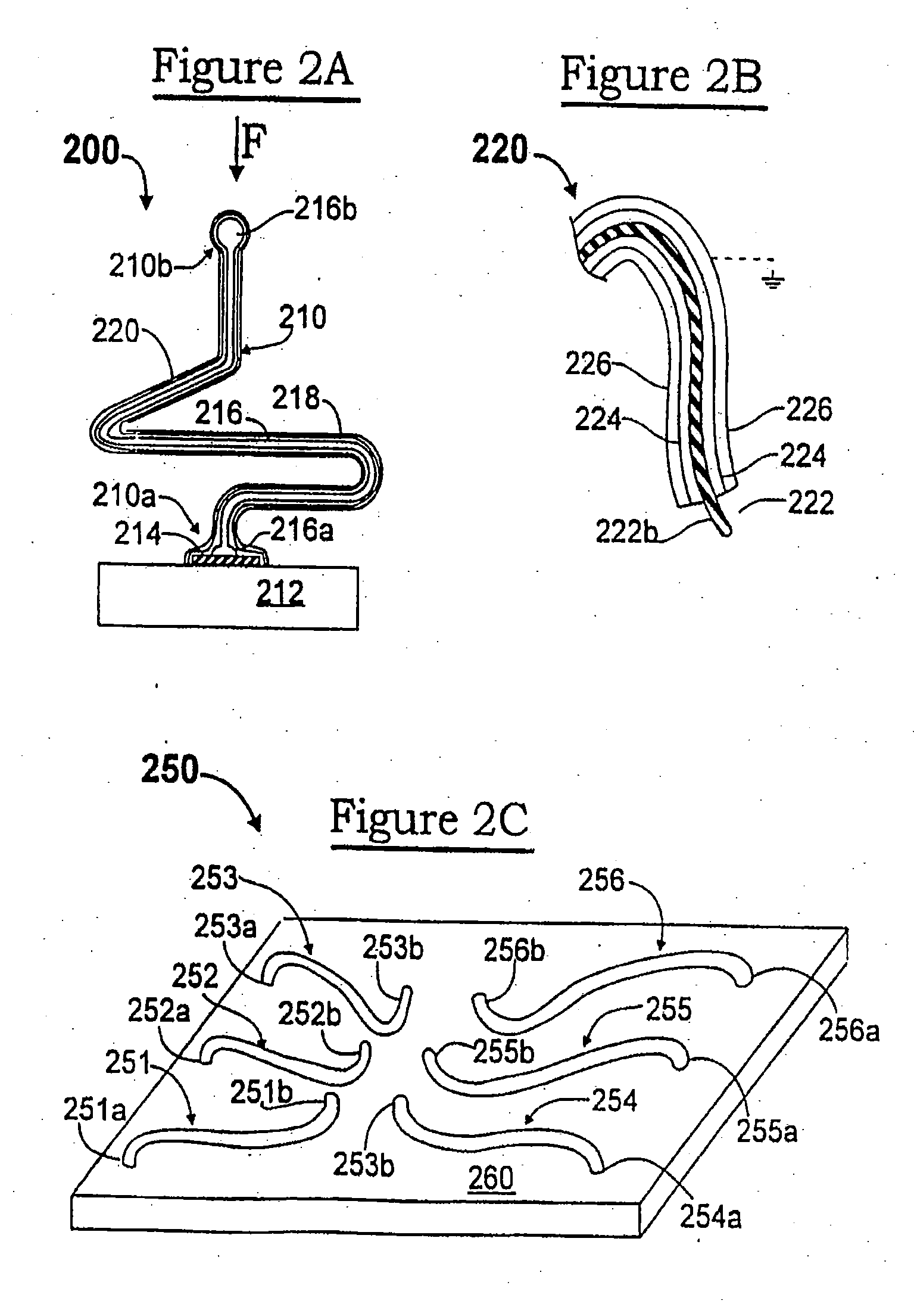

Contact carriers (tiles) for populating larger substrates with spring contacts

InactiveUS7347702B2Easy to installHinders fabricationContact member assembly/disassemblySemiconductor/solid-state device testing/measurementInterconnectionEngineering

An interconnection apparatus and a method of forming an interconnection apparatus. Contact structures are attached to or formed on a first substrate. The first substrate is attached to a second substrate, which is larger than the first substrate. Multiple such first substrates may be attached to the second substrate in order to create an array of contact structures. Each contact structure may be elongate and resilient and may comprise a core that is over coated with a material that imparts desired structural properties to the contact structure.

Owner:FORMFACTOR INC

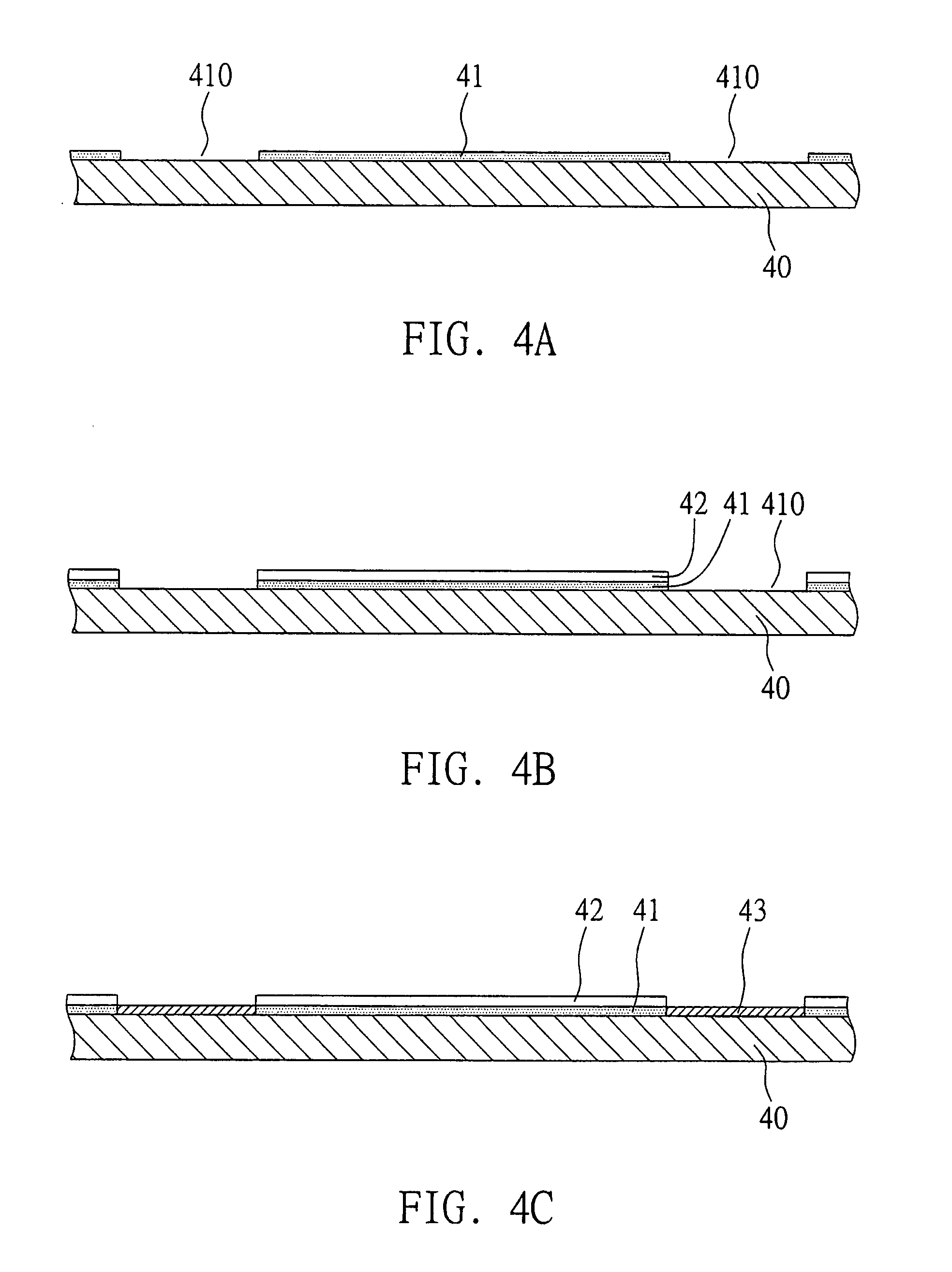

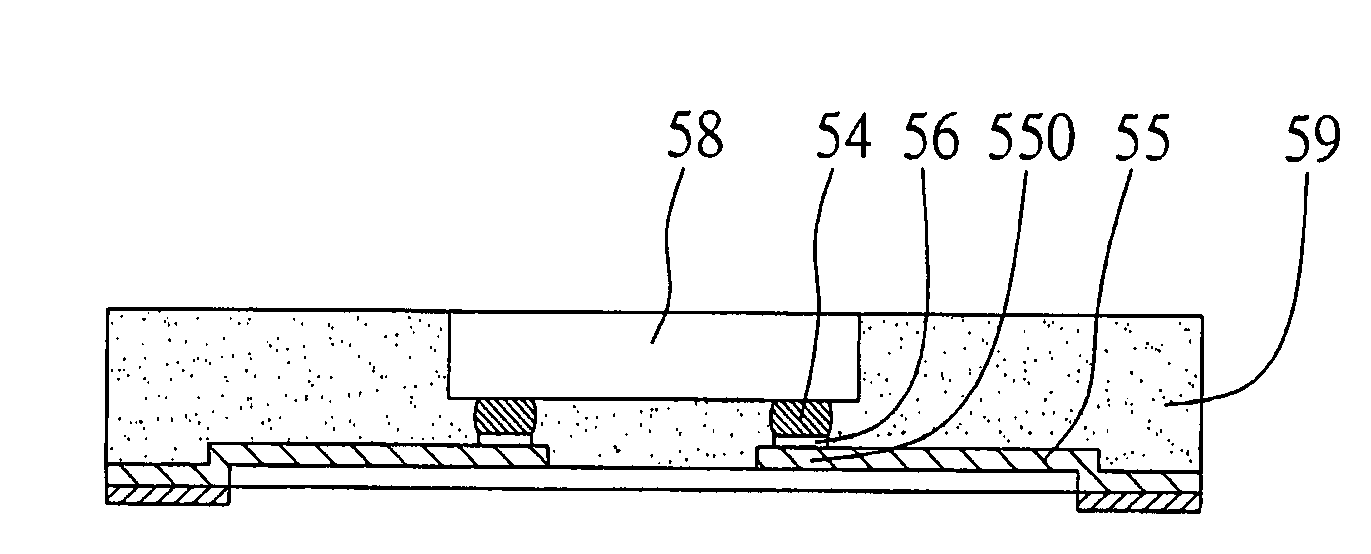

Semiconductor package and fabrication method thereof

ActiveUS20080116580A1Reduce thermal stressImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerSemiconductor package

A semiconductor package and a fabrication method are disclosed. The fabrication method includes applying a sacrificial layer on one surface of a metal carrier, applying an insulation layer on the sacrificial layer, and forming through holes in the sacrificial layer and the insulation layer to expose the metal carrier; forming a conductive metallic layer in each through hole; forming a patterned circuit layer on the insulation layer to be electrically connected to the conductive metallic layer; mounting at least a chip on the insulation layer and electrically connecting the chip to the patterned circuit layer; forming an encapsulant to encapsulate the chip and the patterned circuit layer; and removing the metal carrier and the sacrificial layer to expose the insulation layer and conductive metallic layer to allow the conductive metallic layer to protrude from the insulation layer. In the present invention, the distance between the semiconductor package and the external device is increased, and thermal stress caused by difference between the thermal expansion coefficients is reduced, so as to enhance the reliability of the product.

Owner:SILICONWARE PRECISION IND CO LTD

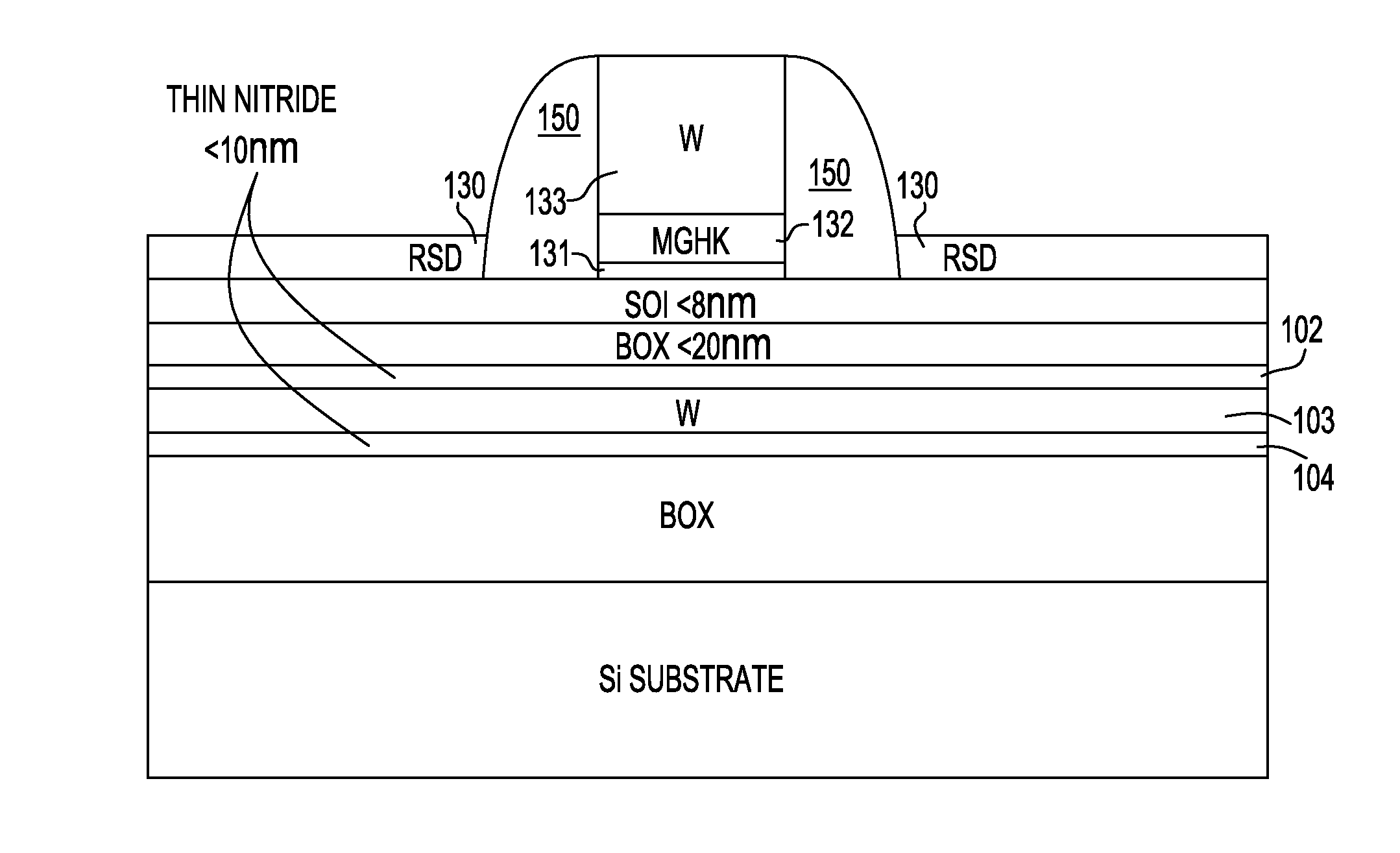

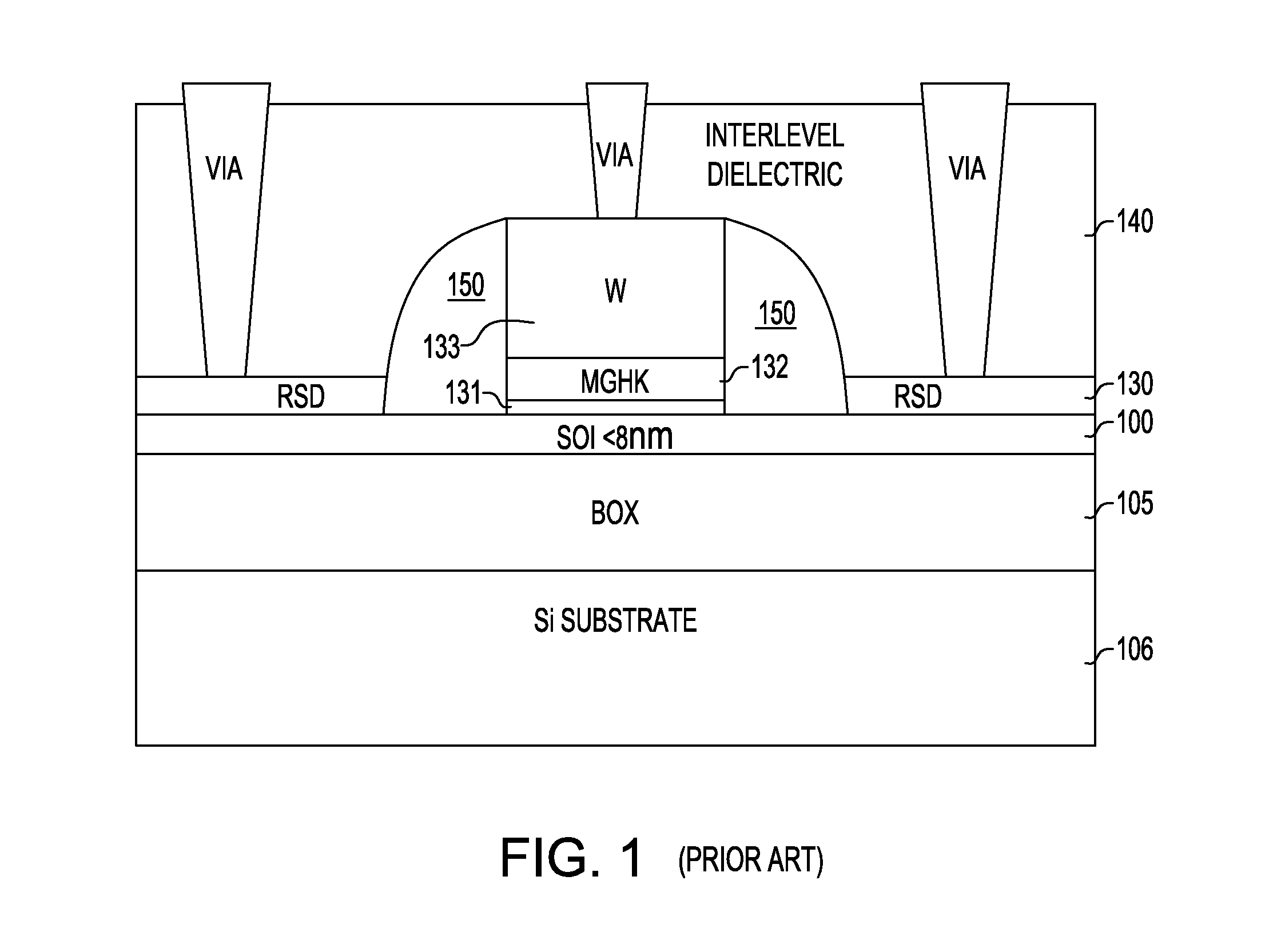

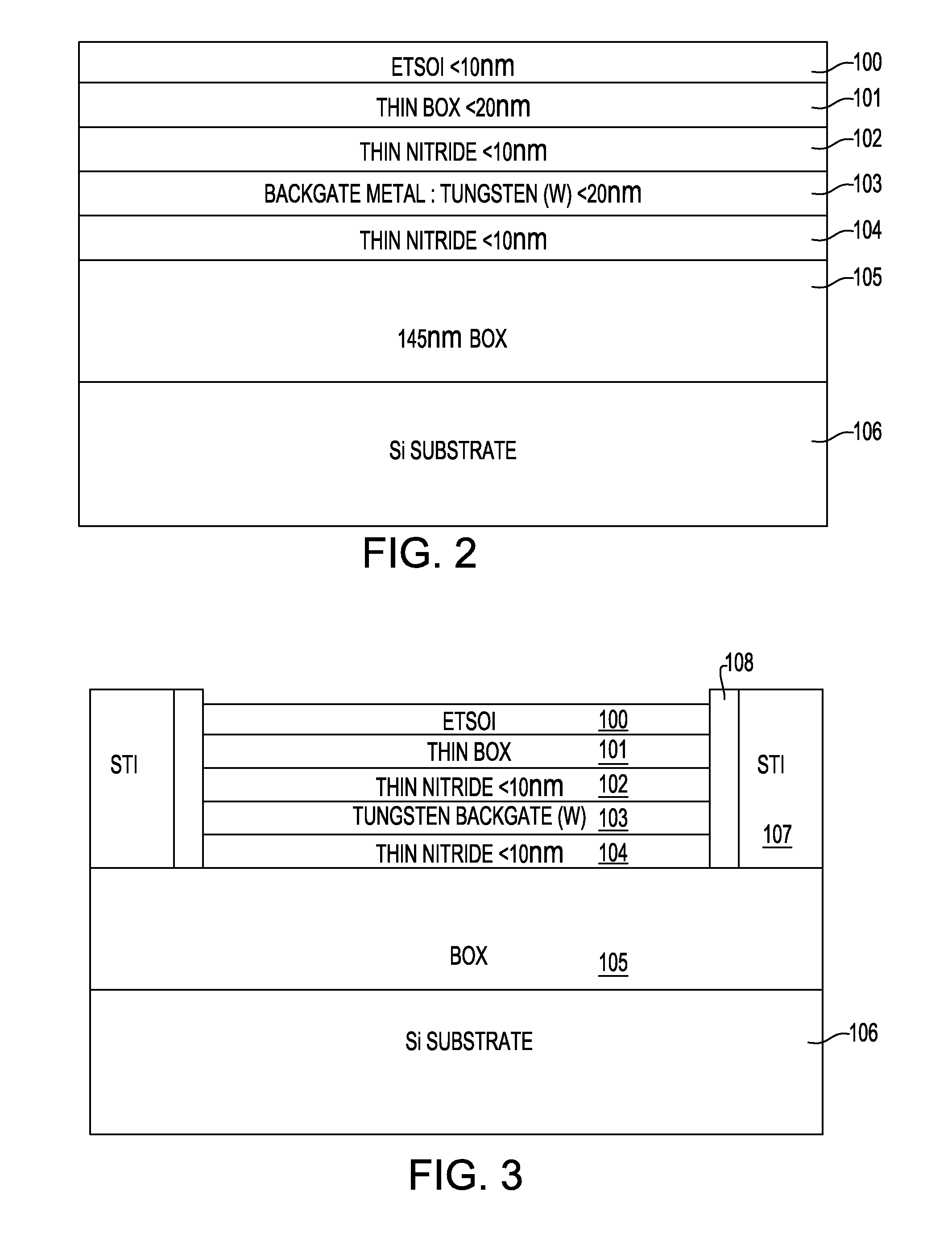

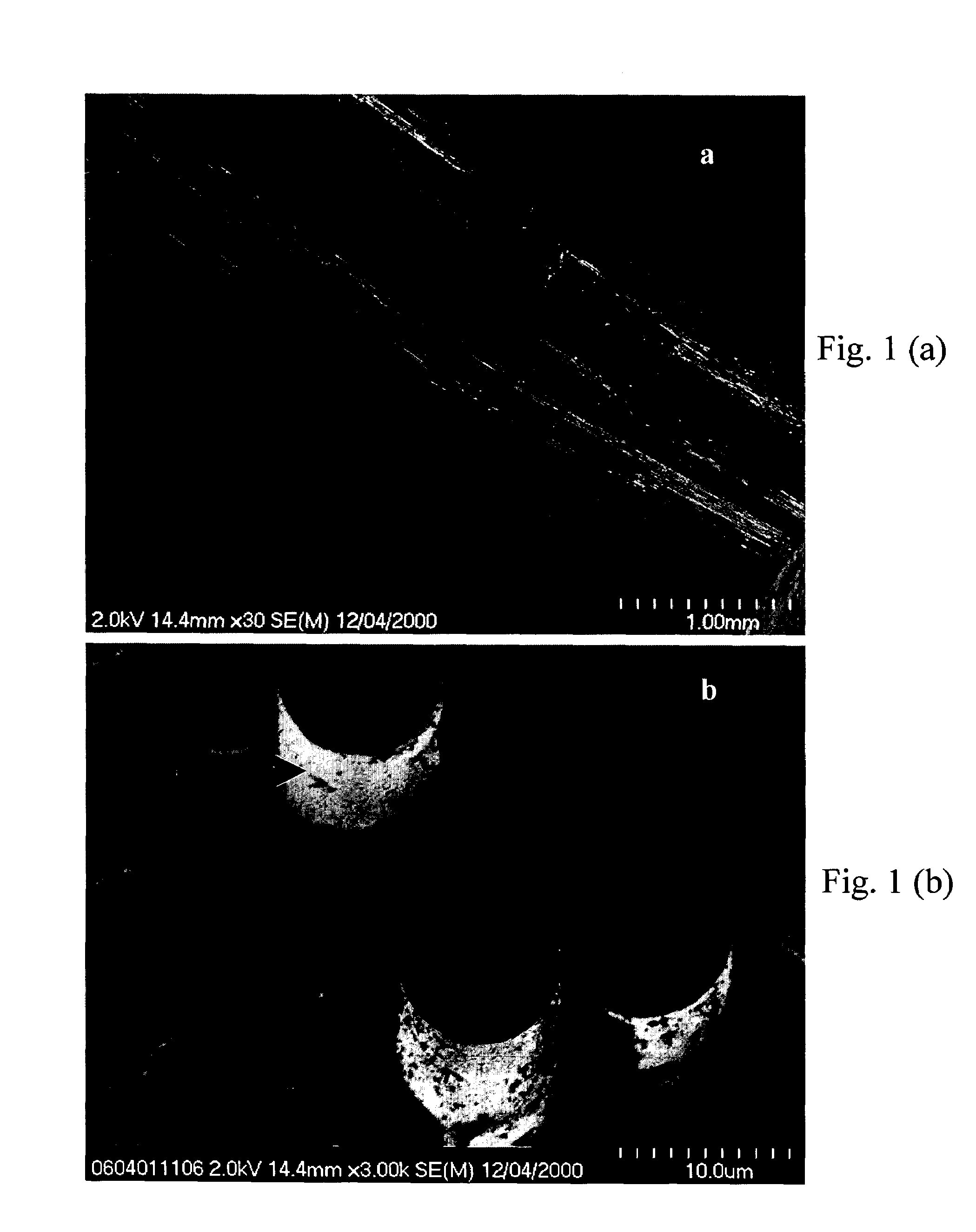

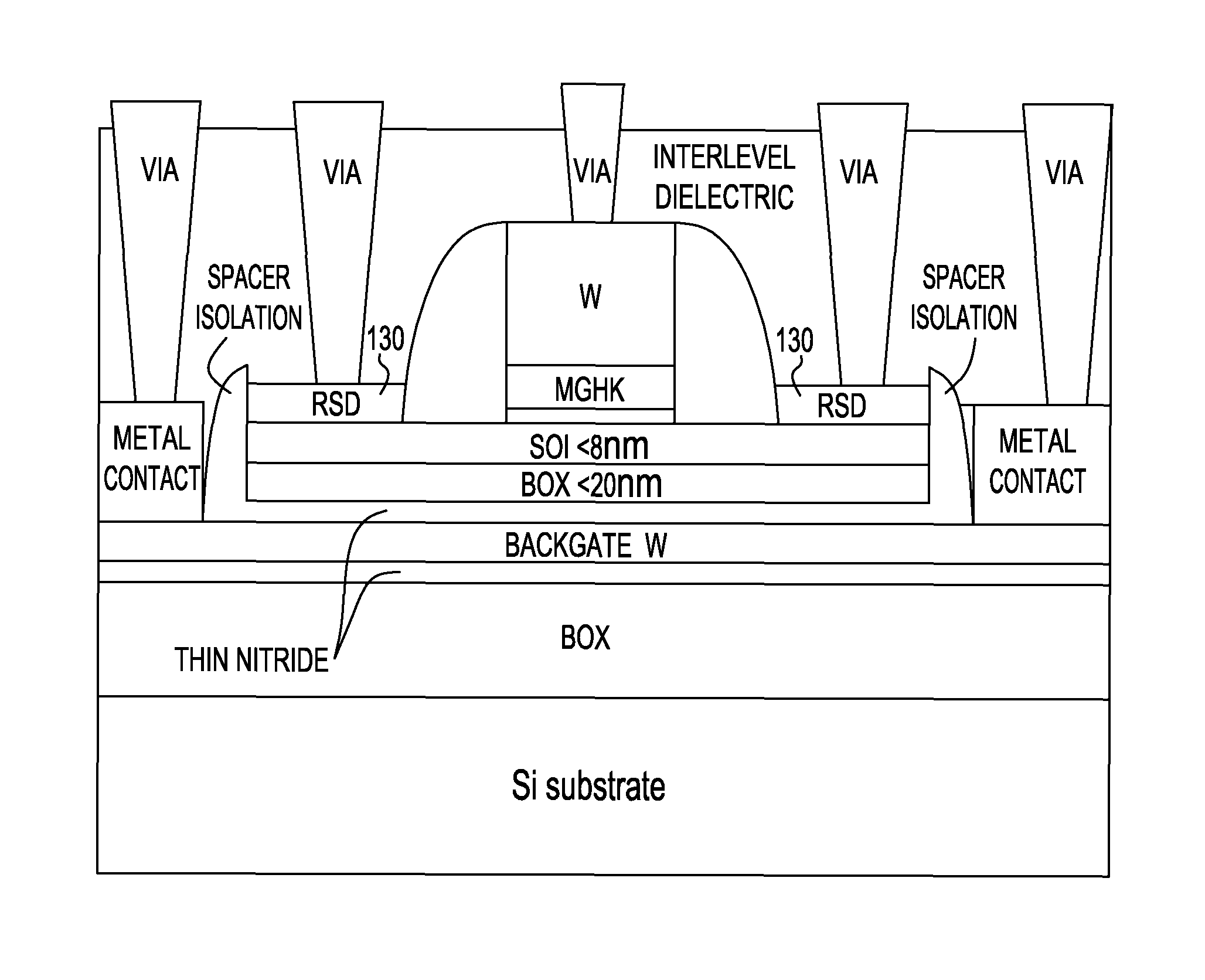

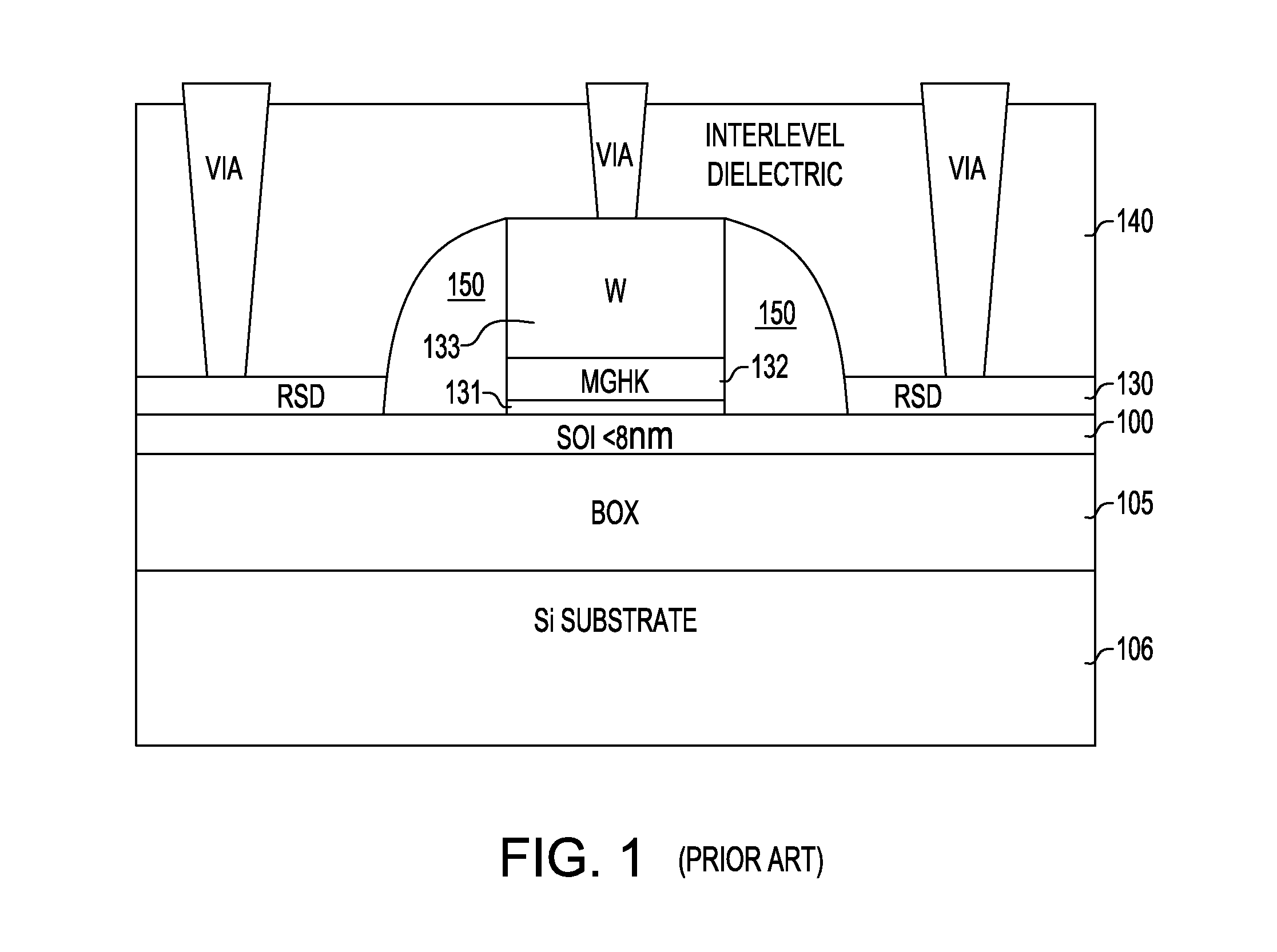

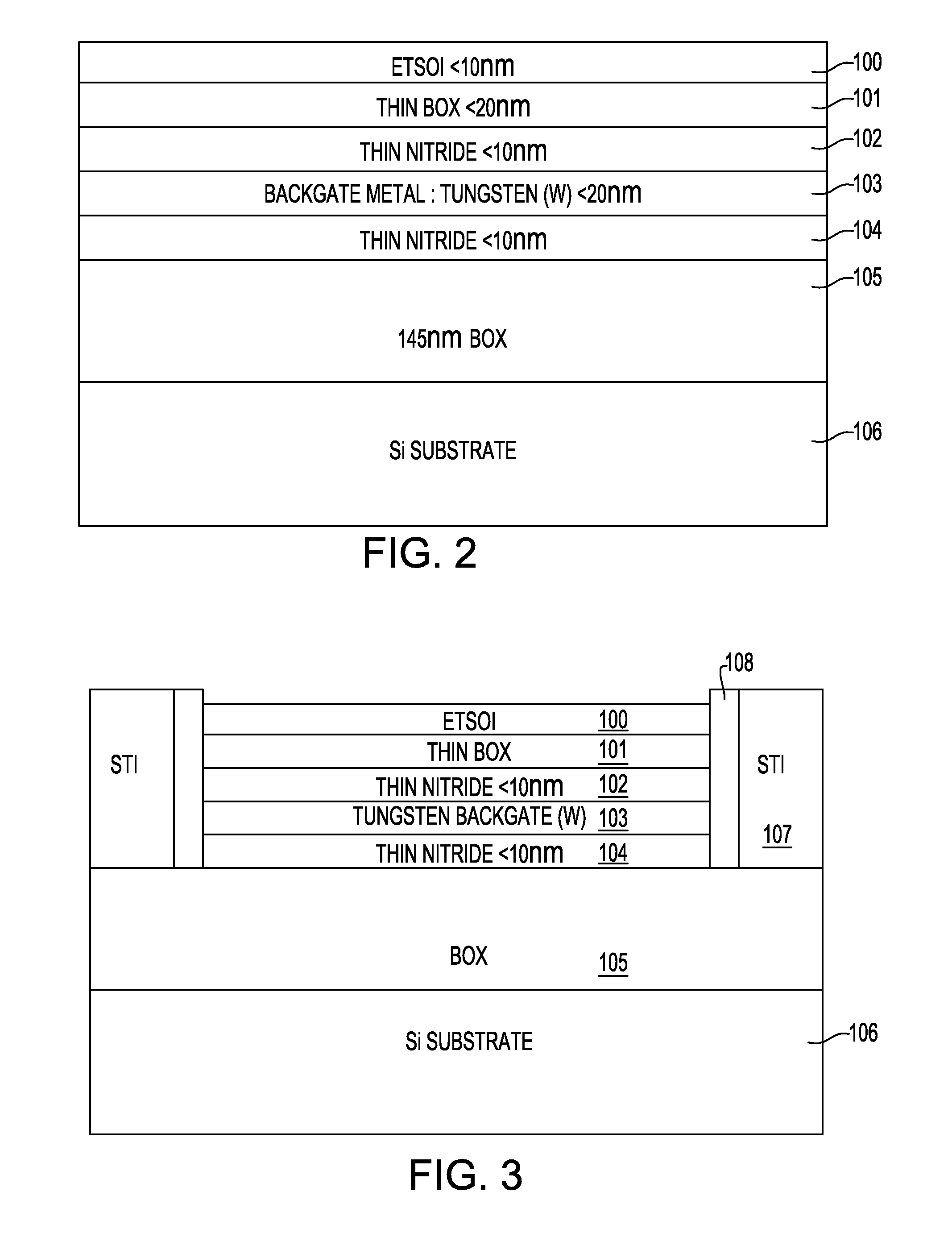

Thin-box metal backgate extremely thin soi device

InactiveUS20110227159A1Excellent short channel controlLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialGate stack

Silicon-on-insulator (SOI) structures with silicon layers less than 20 nm thick are used to form extremely thin silicon-on-insulator (ETSOI) semiconductor devices. ETSOI devices are manufactured using a thin tungsten backgate encapsulated by thin nitride layers to prevent metal oxidation, the tungsten backgate being characterized by its low resistivity. The structure further includes at least one FET having a gate stack formed by a high-K metal gate and a tungsten region superimposed thereon, the footprint of the gate stack utilizing the thin SOI layer as a channel. The SOI structure thus formed controls the Vt variation from the thin SOI thickness and dopants therein. The ETSOI high-K metal backgate fully depleted device in conjunction with the thin BOX provides an excellent short channel control and significantly lowers the drain induced bias and sub-threshold swings. The present structure supports the evidence of the stability of the wafer having a tungsten film during thermal processing, and especially during STI and contact formation.

Owner:IBM CORP

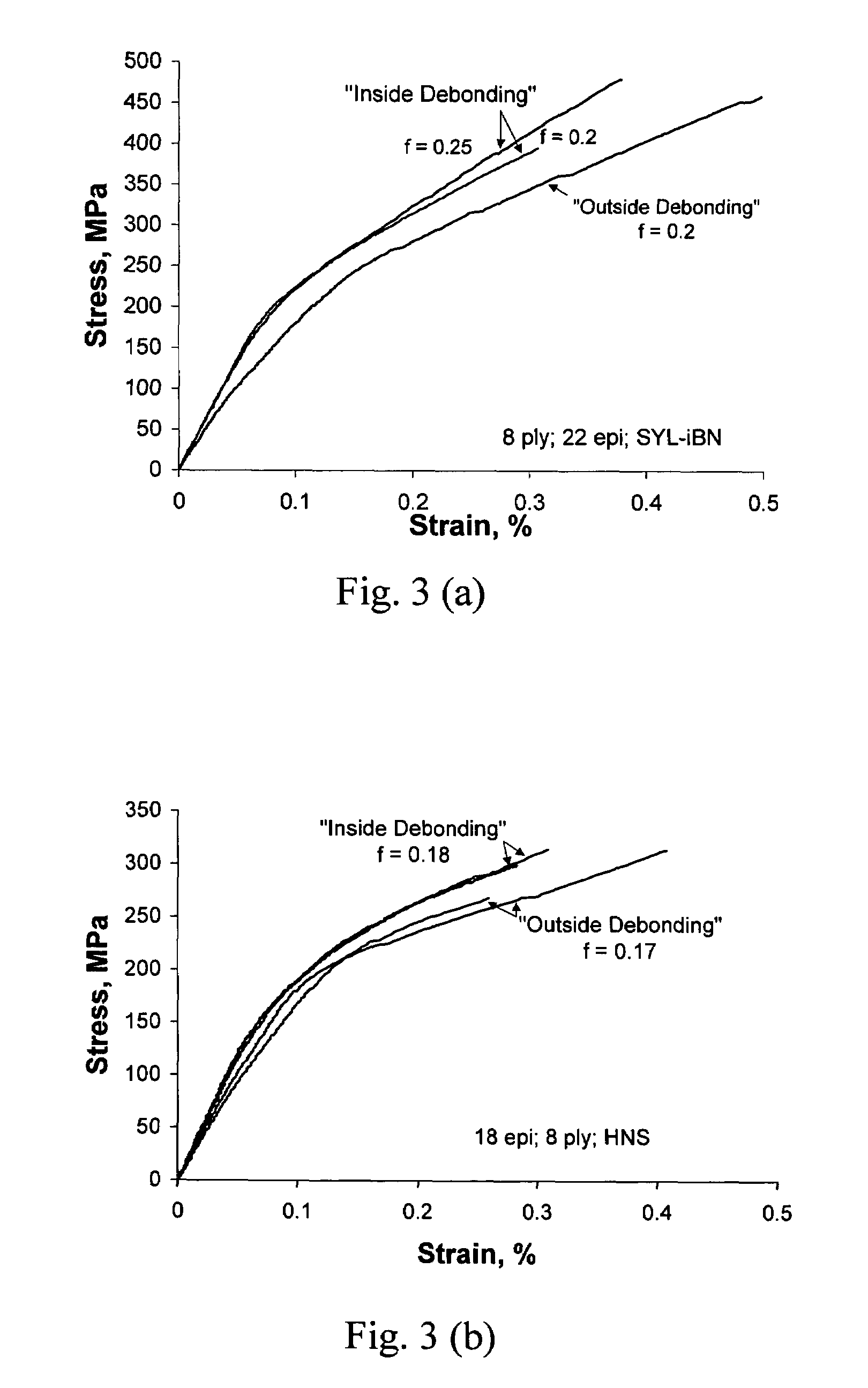

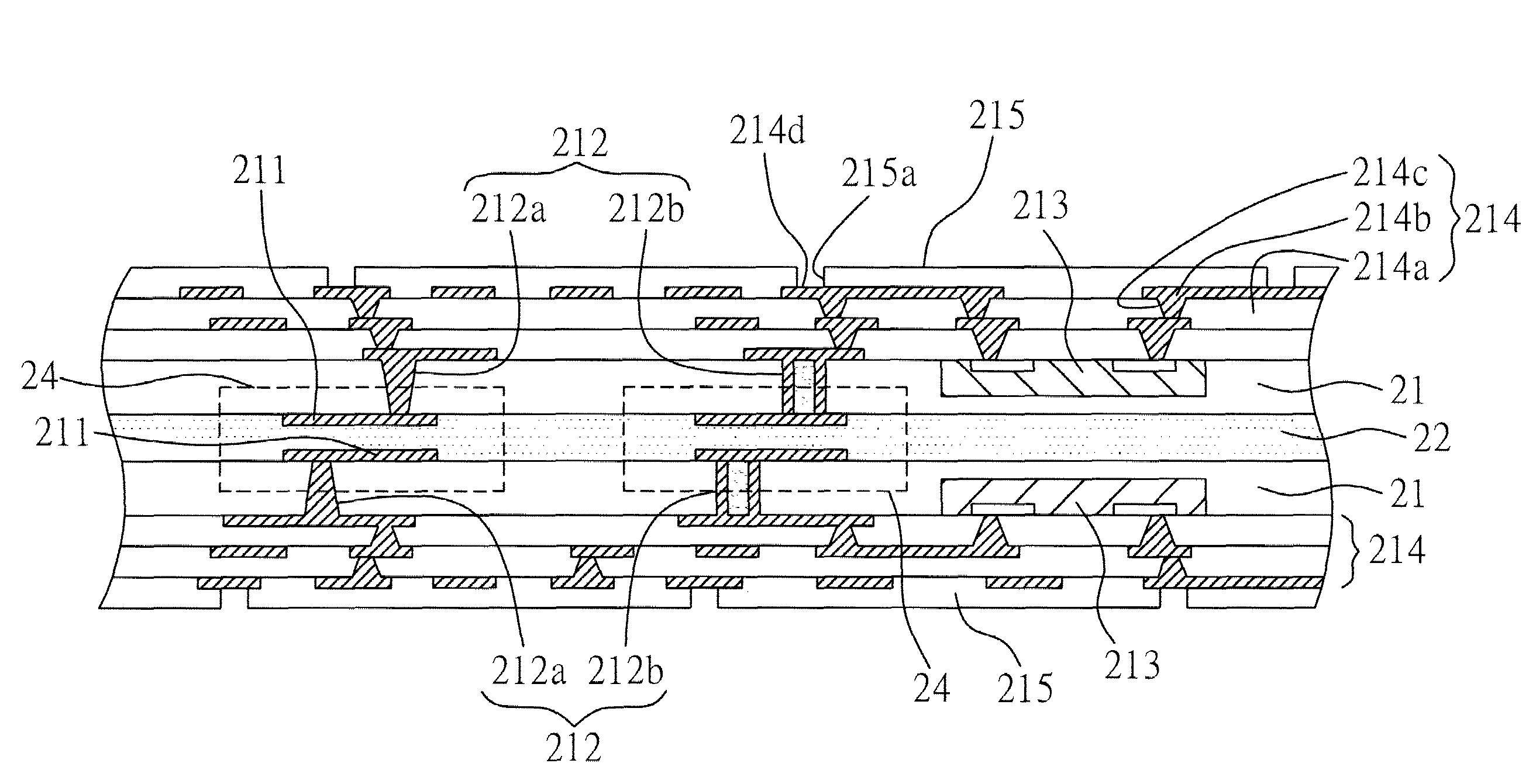

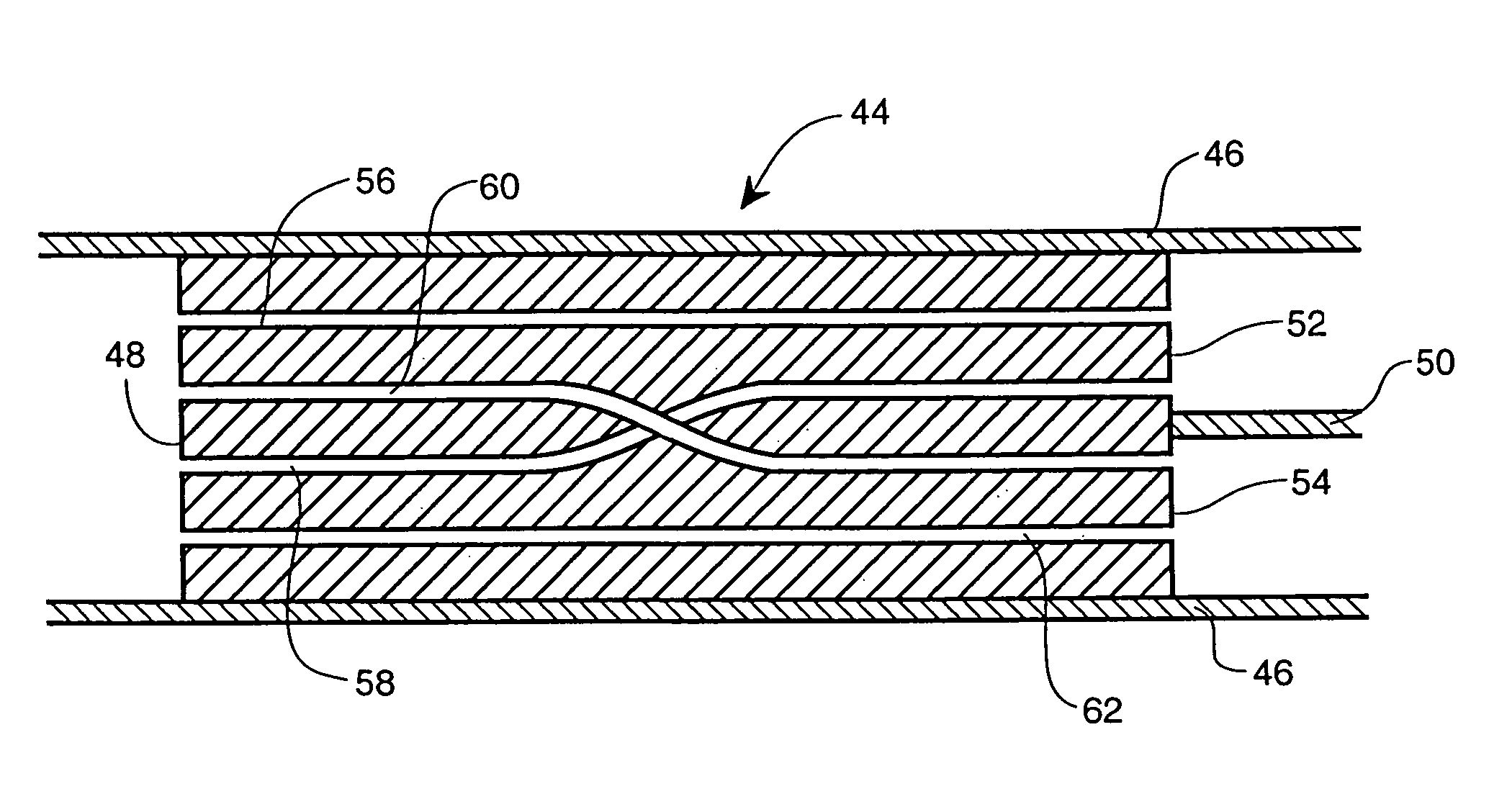

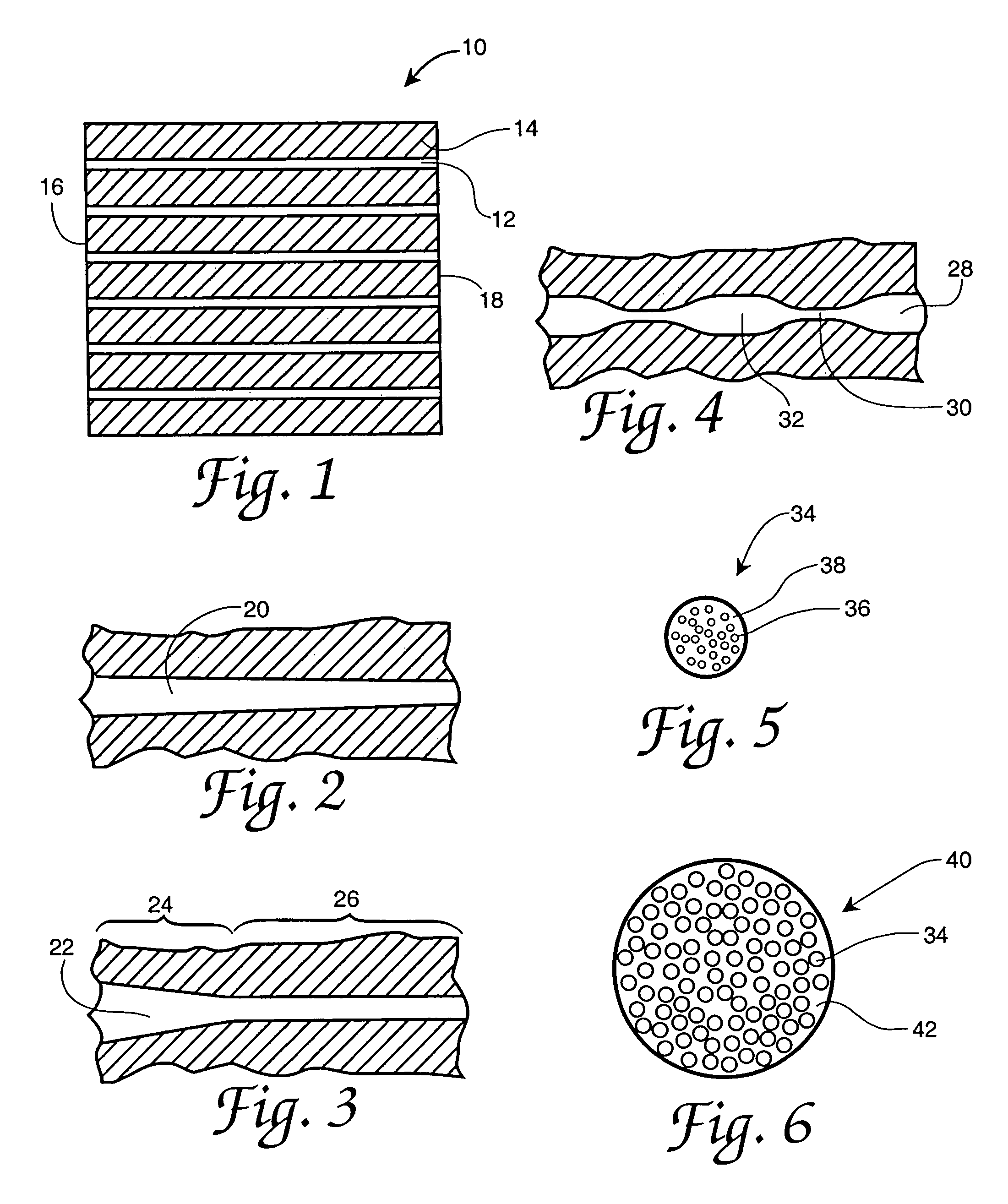

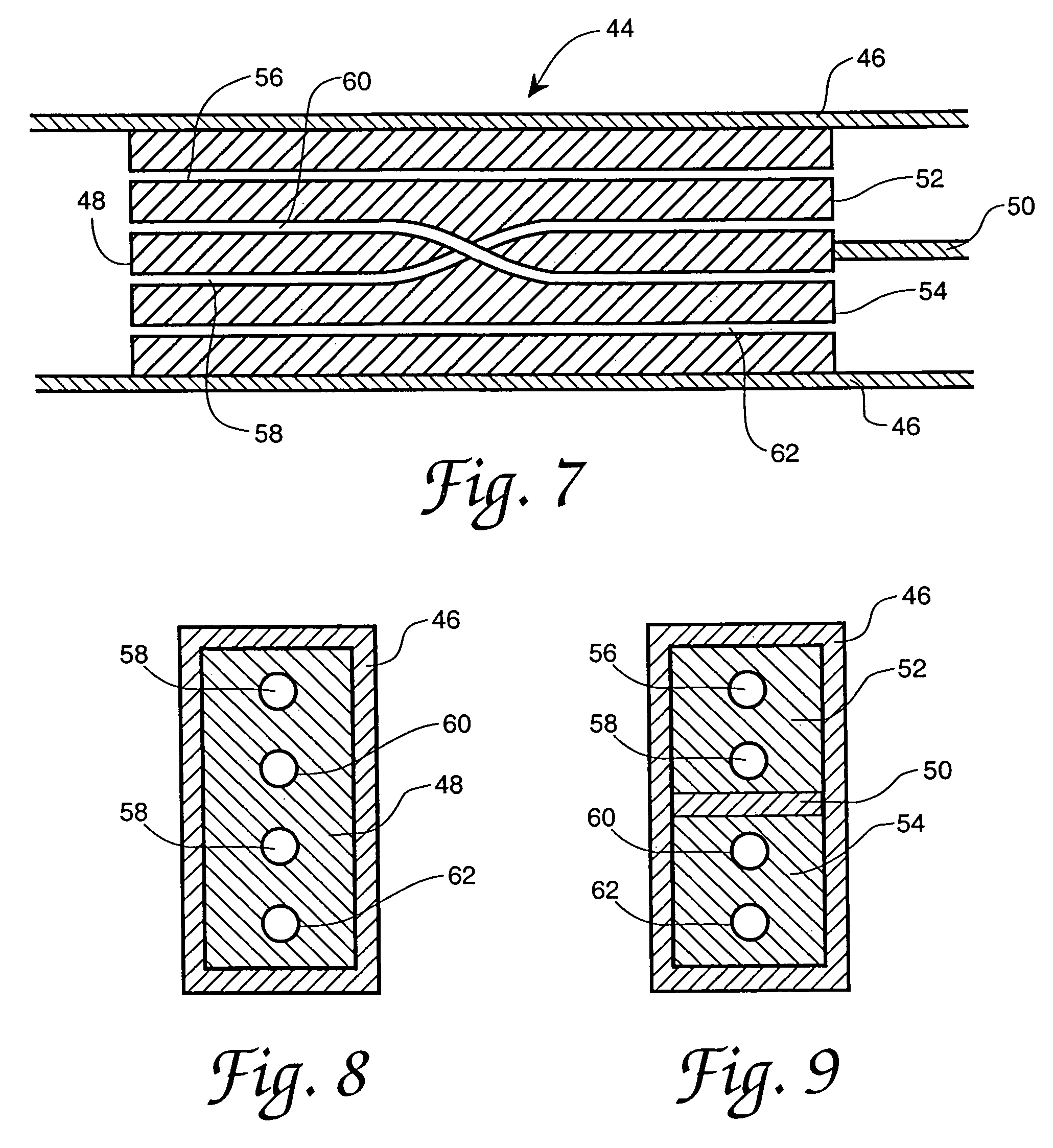

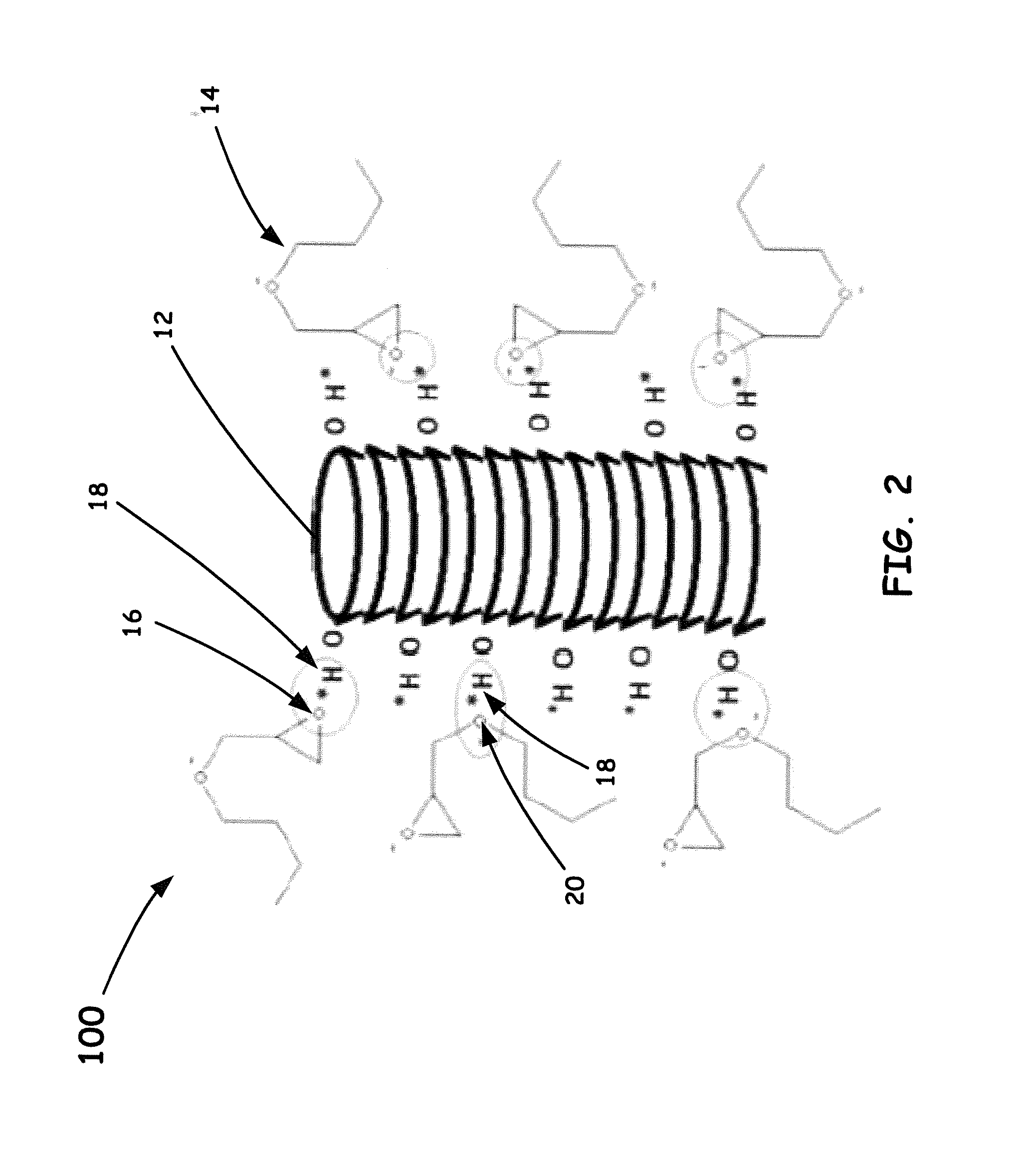

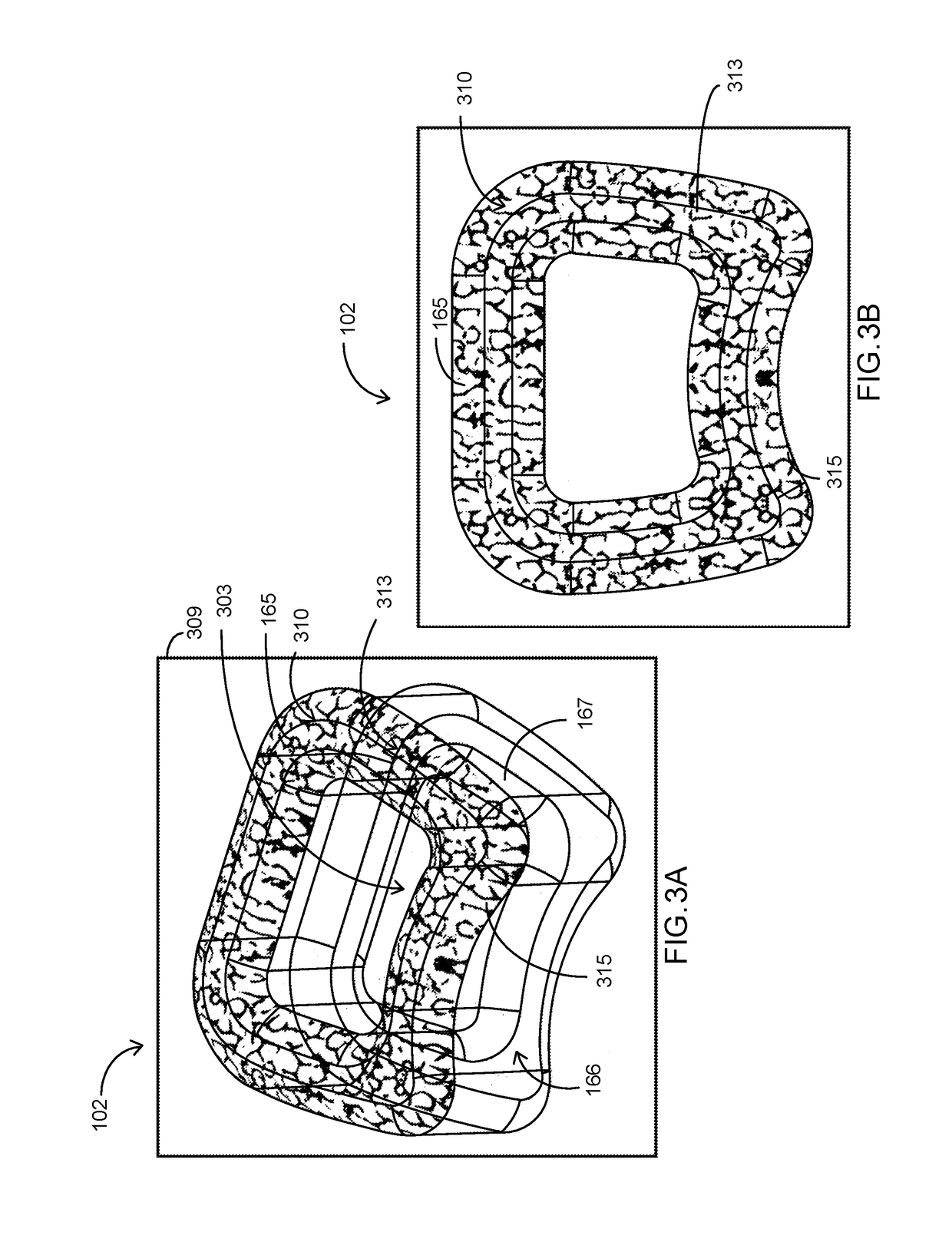

Interphase for ceramic matrix composites reinforced by non-oxide ceramic fibers

ActiveUS7427428B1Improve the oxidative durability of ceramic matrix composite materialsMaintain reliabilityLayered productsPretreated surfacesOxide ceramicNon oxide ceramics

A ceramic matrix composite material is disclosed having non-oxide ceramic fibers, which are formed in a complex fiber architecture by conventional textile processes; a thin mechanically weak interphase material, which is coated on the fibers; and a non-oxide or oxide ceramic matrix, which is formed within the interstices of the interphase-coated fiber architecture. During composite fabrication or post treatment, the interphase is allowed to debond from the matrix while still adhering to the fibers, thereby providing enhanced oxidative durability and damage tolerance to the fibers and the composite material.

Owner:NASA UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE

Circuit board structure having capacitor array and embedded electronic component and method for fabricating the same

ActiveUS7674986B2Solve complexityEasy to manufacturePrinted circuit aspectsSolid-state devicesElectronic componentBoard structure

A circuit board structure having a capacitor array and an embedded electronic component and a method for fabricating the same are proposed. Two carrier boards and a high dielectric constant material layer are provided, wherein the carrier boards have electronic components embedded therein and one surface of each carrier board has a plurality of electrode plates. The two carrier boards are laminated with the dielectric constant material layer interposed between them. The electrode plates on the surfaces of the carrier boards are opposite to each other across the high dielectric constant material layer to constitute a capacitor array. Therefore, the capacitor assembly for design of electronic devices is provided.

Owner:PHOENIX PRECISION TECH CORP

Contact Carriers (Tiles) For Populating Larger Substrates With Spring Contacts

InactiveUS20070075715A1Easy to installHinders fabricationContact member assembly/disassemblySemiconductor/solid-state device testing/measurementEngineeringInterconnection

An interconnection apparatus and a method of forming an interconnection apparatus. Contact structures are attached to or formed on a first substrate. The first substrate is attached to a second substrate, which is larger than the first substrate. Multiple such first substrates may be attached to the second substrate in order to create an array of contact structures. Each contact structure may be elongate and resilient and may comprise a core that is over coated with a material that imparts desired structural properties to the contact structure.

Owner:FORMFACTOR INC

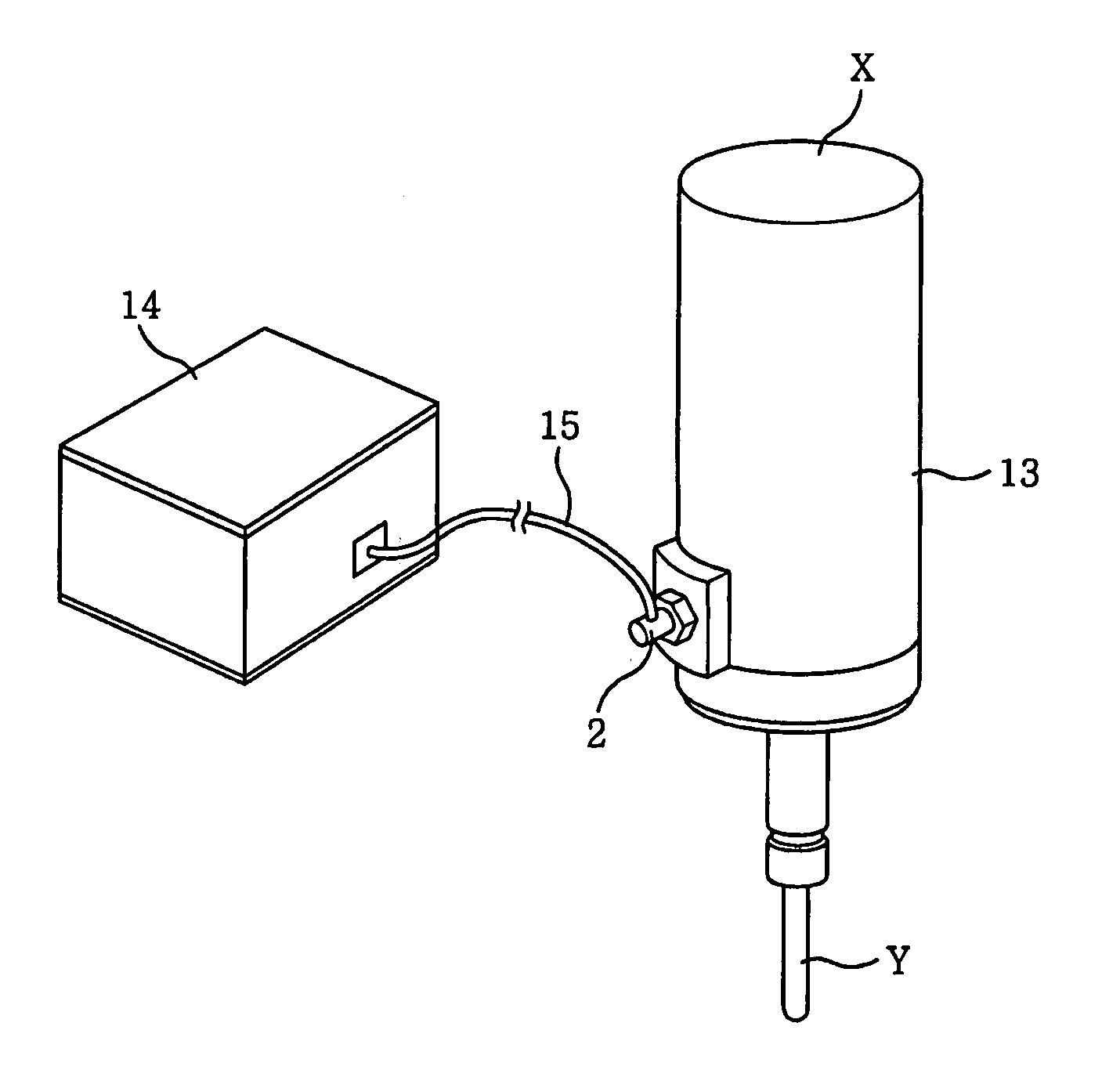

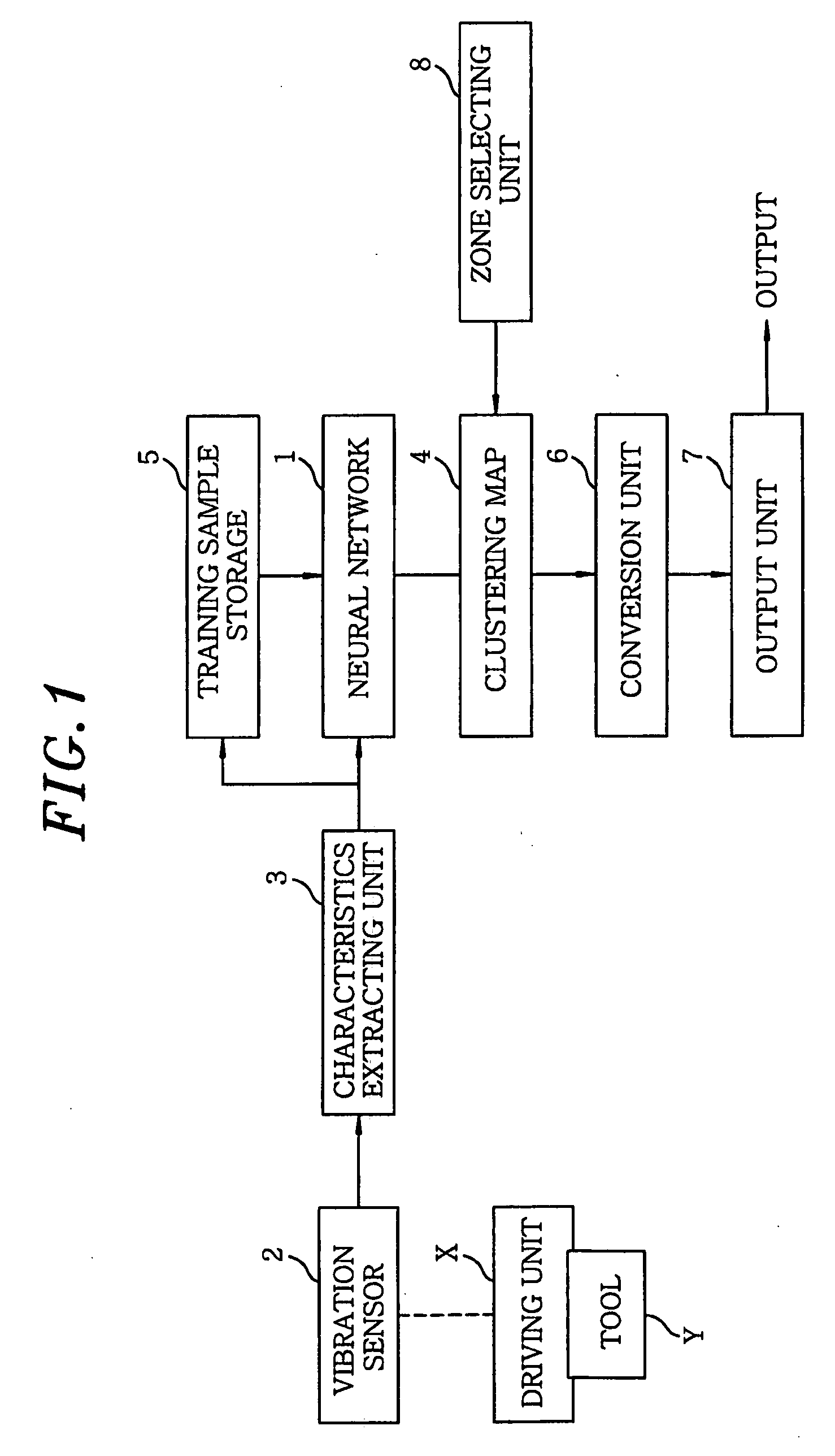

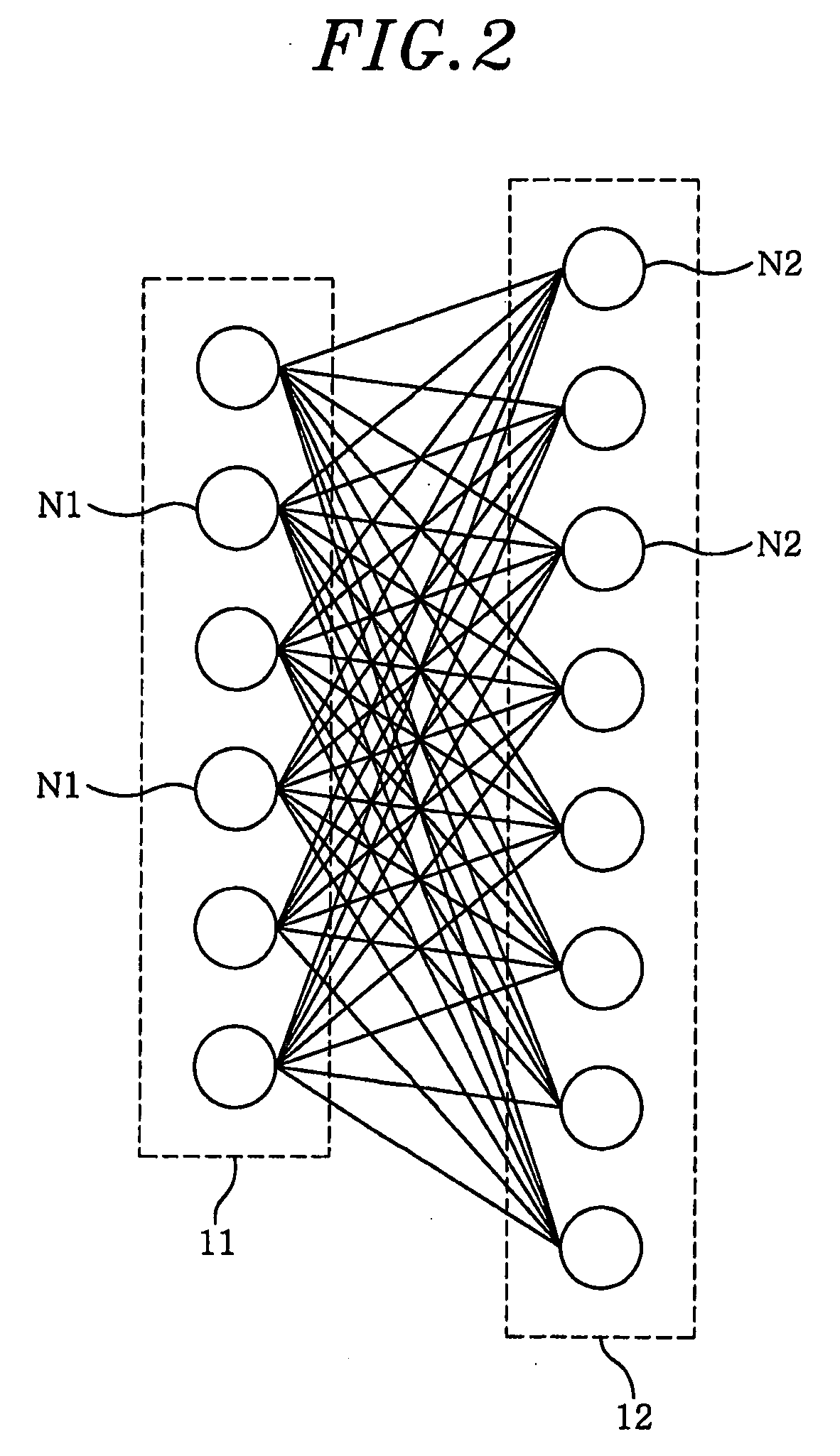

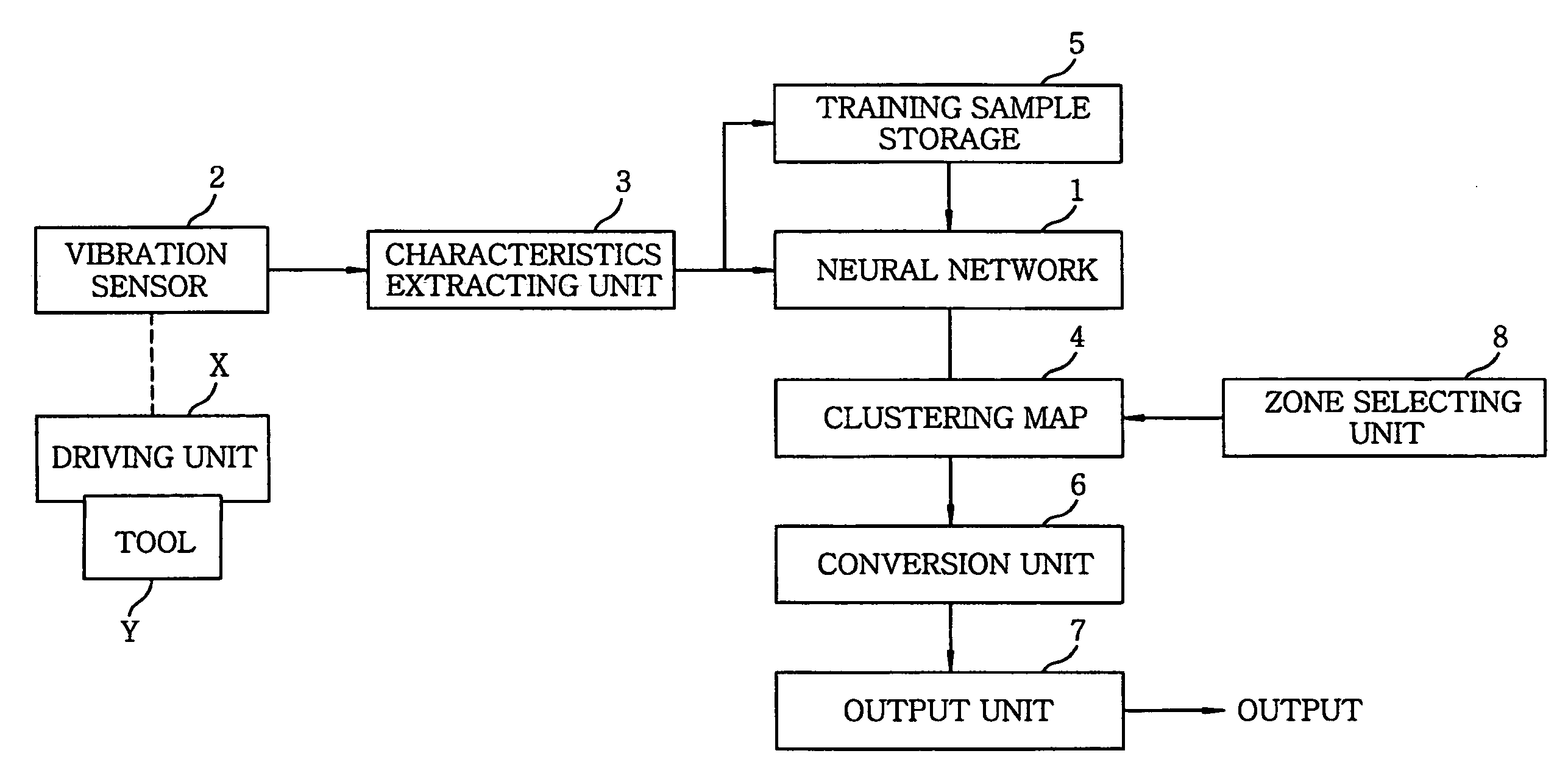

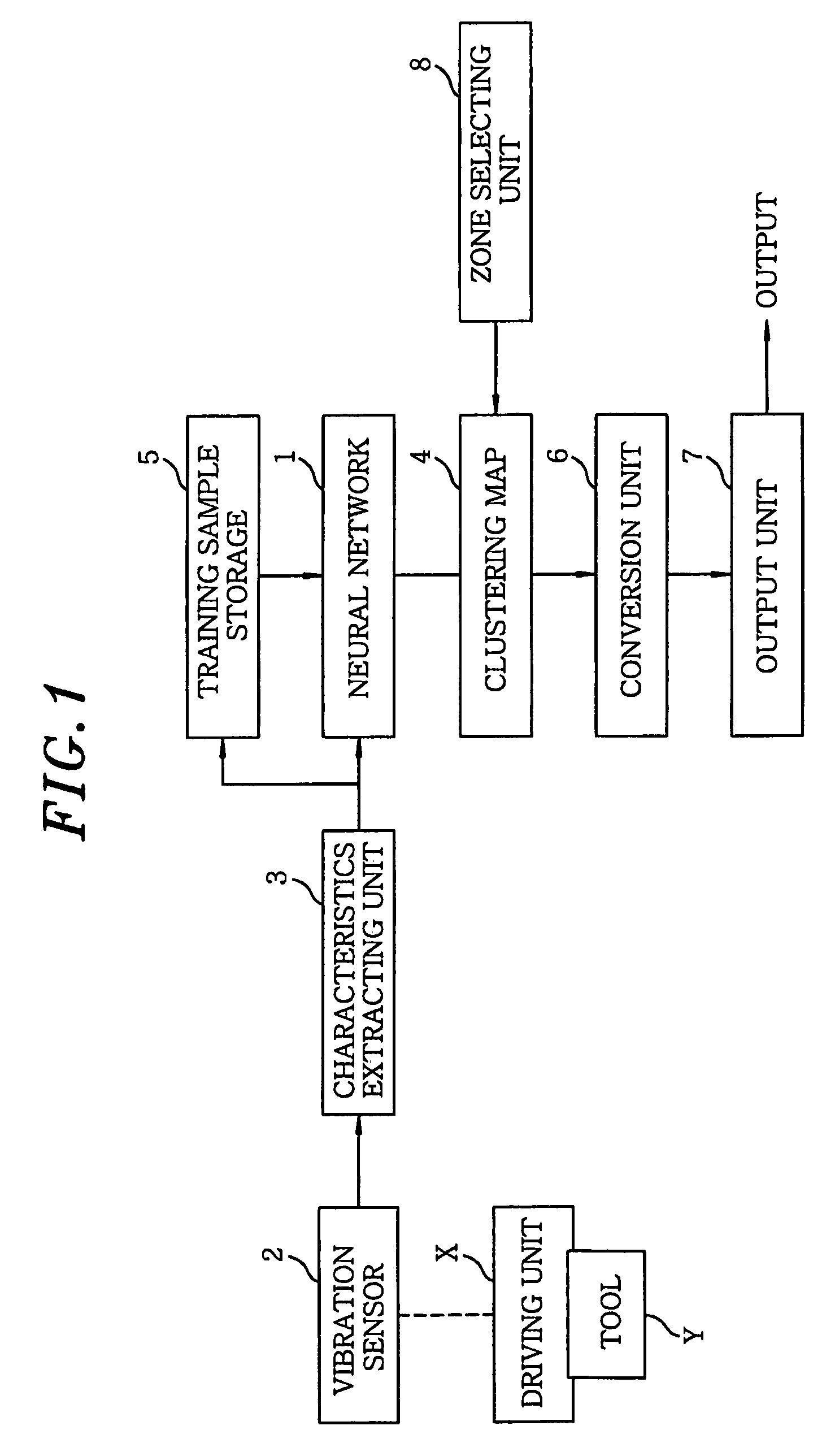

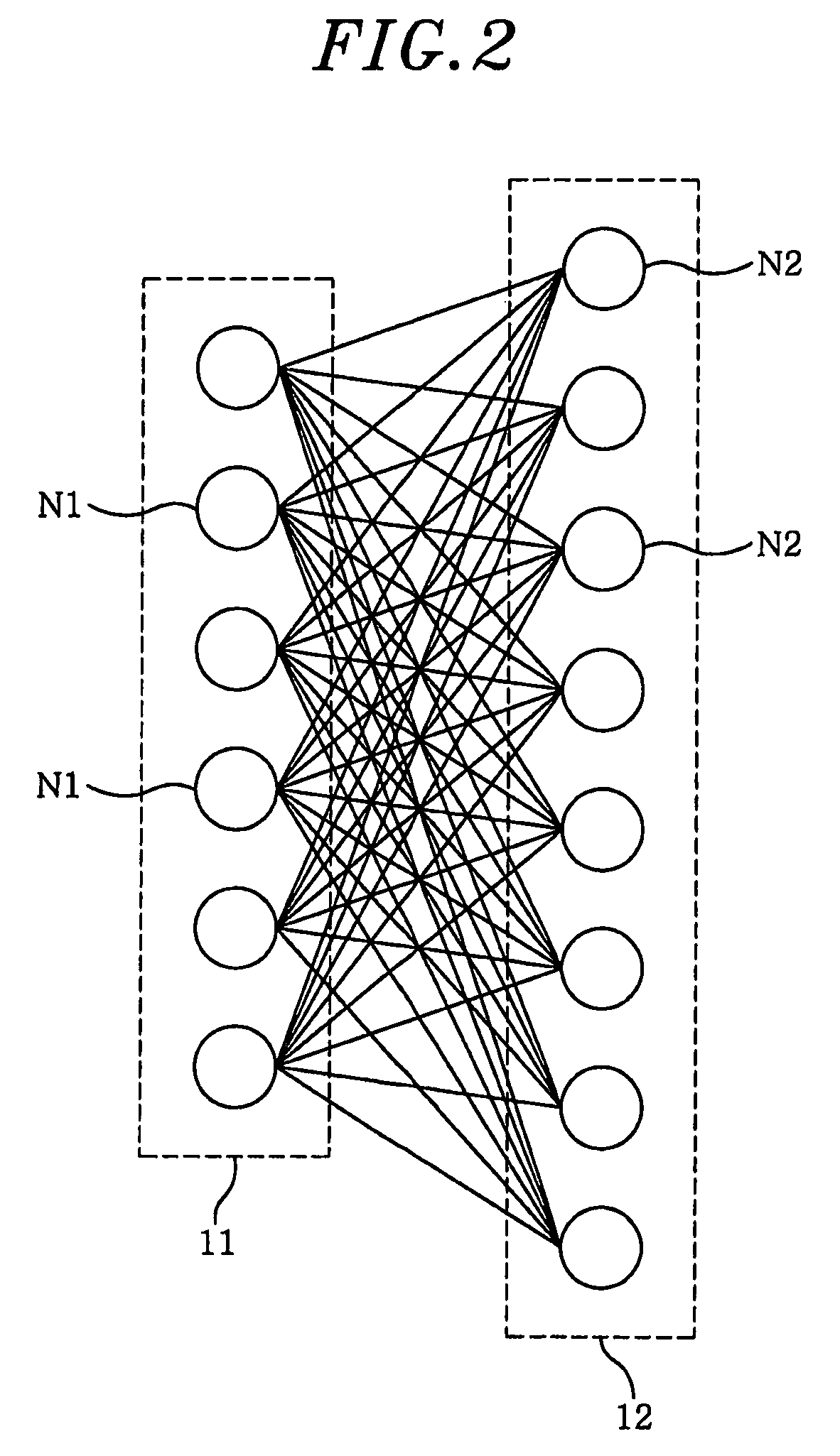

Device for estimating machining dimension of machine tool

InactiveUS20080082200A1Reduce wasteHinders fabricationProgramme controlLathesFeature extractionPartition of unity

A device for estimating machining dimensions of a machine tool which employs tool members each being rotatably driven by a driving unit includes: a vibration sensor; a characteristics extracting unit for extracting amounts of characteristics from an output of the vibration sensor; a neural network for classifying the amounts of characteristics into categories; and a conversion unit. Amounts of characteristics of generated output by racing the tool member are used for training the neural network, and inputted again to the trained competitive learning neural network to excite neurons so that the relationships between Euclidean distances and machining dimensions of workpieces are registered in the conversion unit. The Euclidean distances are obtained between weight vectors of the excited neurons and respective corresponding training samples, and the machining dimensions are obtained when the workpieces are machined by the tool members at the same condition as the respective corresponding training samples are obtained.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Method of manufacture of separation devices

InactiveUS7790084B1Hinders fabricationEconomical and fastSemi-permeable membranesSolvent extractionEngineering

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

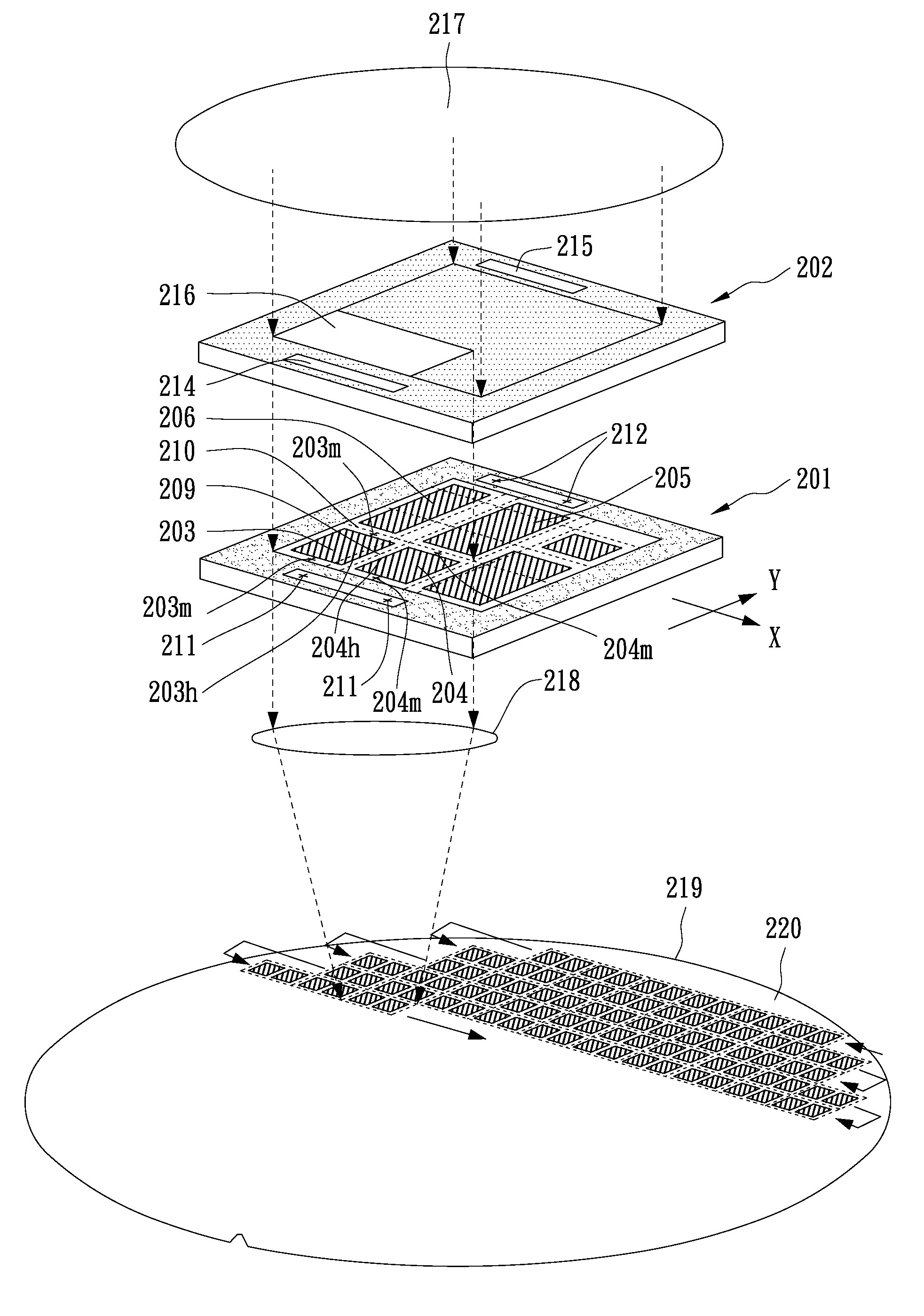

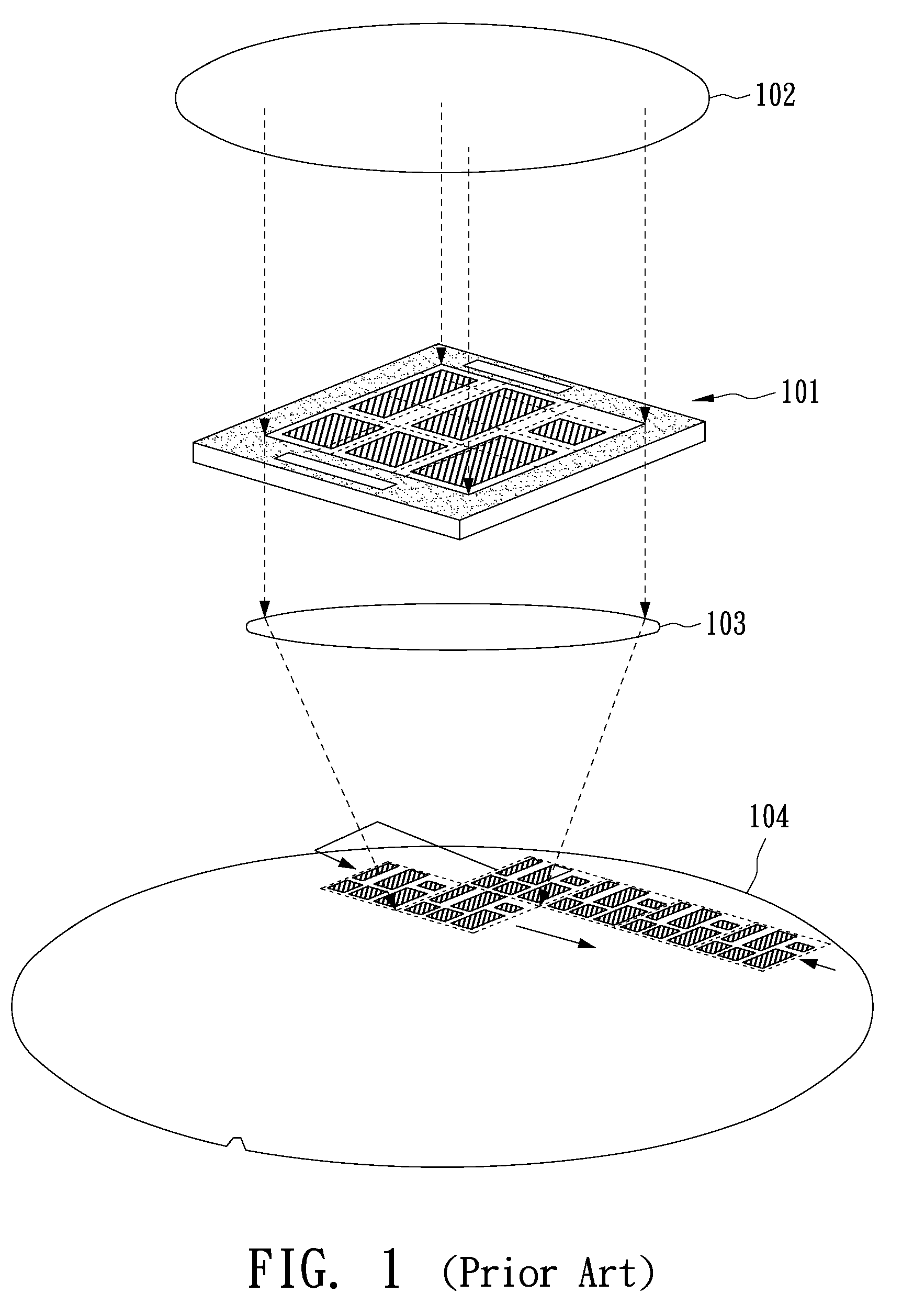

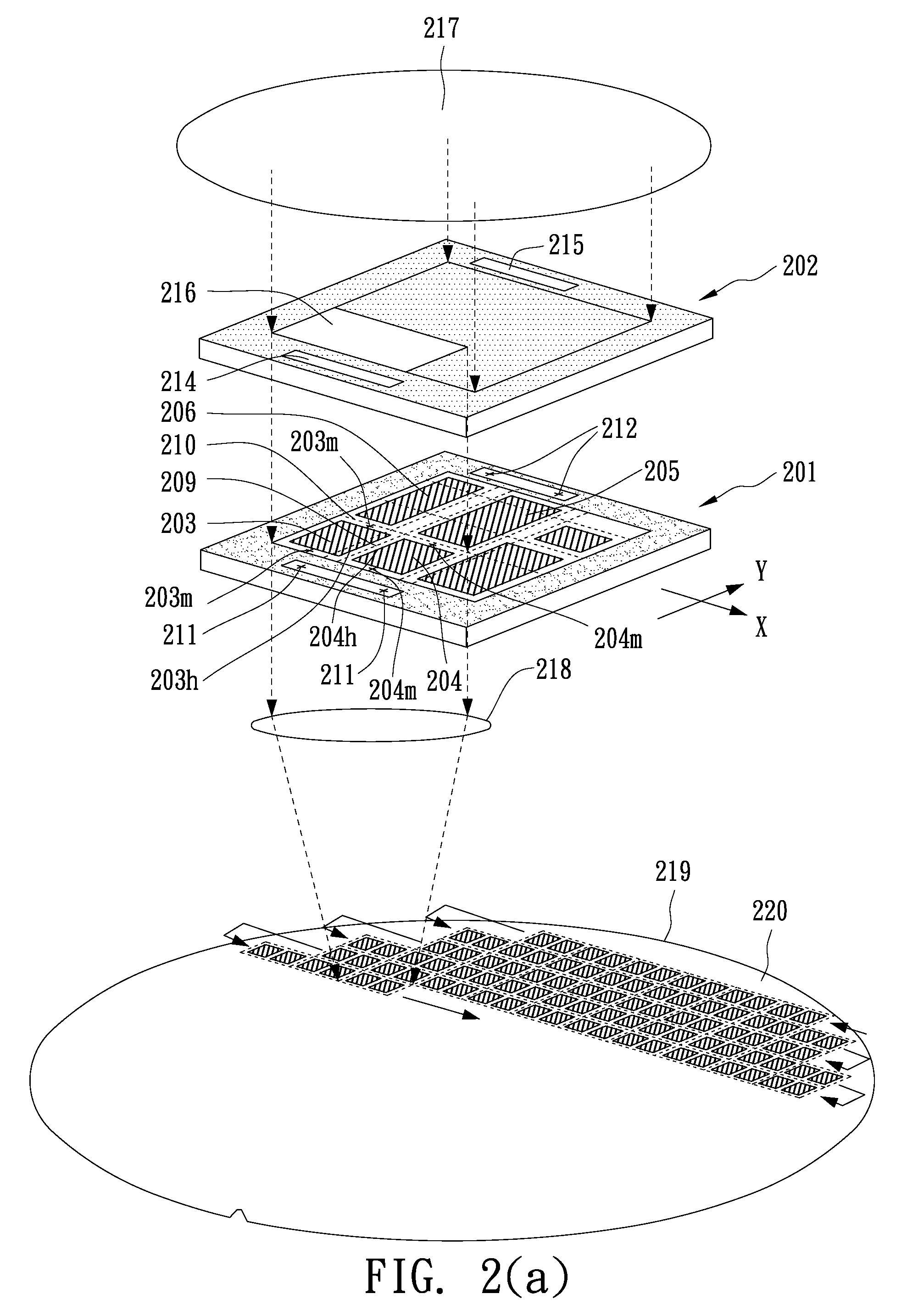

Direct connect single layer touch panel

InactiveUS8711108B2Hinders fabricationSimple manufacturing processElectrical connection printed elementsPrinted circuits structural associationsElectricityMultiple sensor

A substantially transparent touch sensor panel having co-planar single-layer touch sensors and traces fabricated on a single side of a substrate for detecting single or multi-touch events. The touch sensor elements can be fabricated in columns and rows, with each sensor element in a row adjacent to a sensor element in a column. By using a board as the dielectric to connect traces from multiple sensor elements in each row, rather than using a dielectric layer on the substrate upon which the sensor elements and traces are formed, the sensor elements and traces on the substrate can be formed by simply patterning a single layer of conductive material on the substrate, which can simplify the manufacturing process of the substrate from a complexity and cost perspective.

Owner:APPLE INC

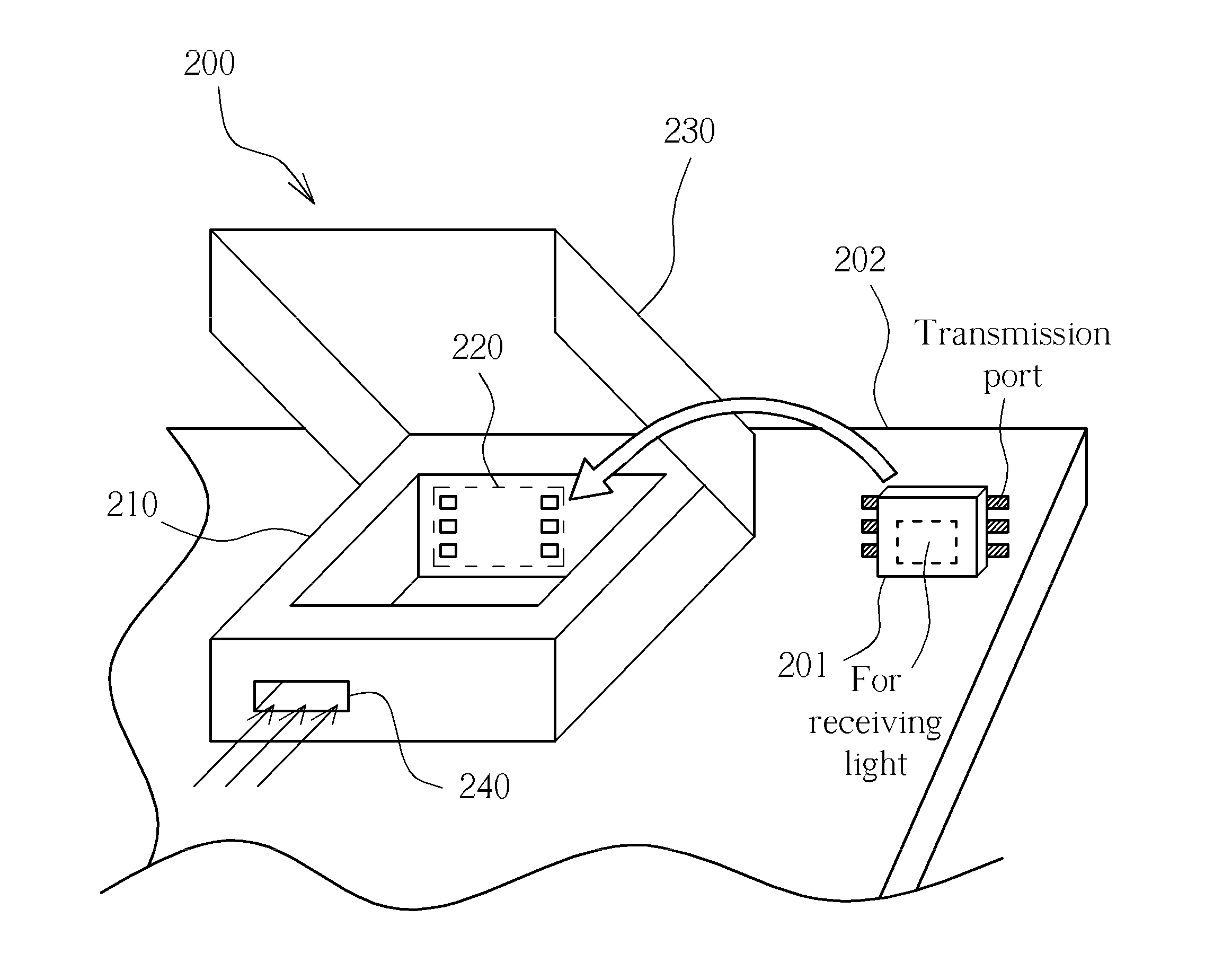

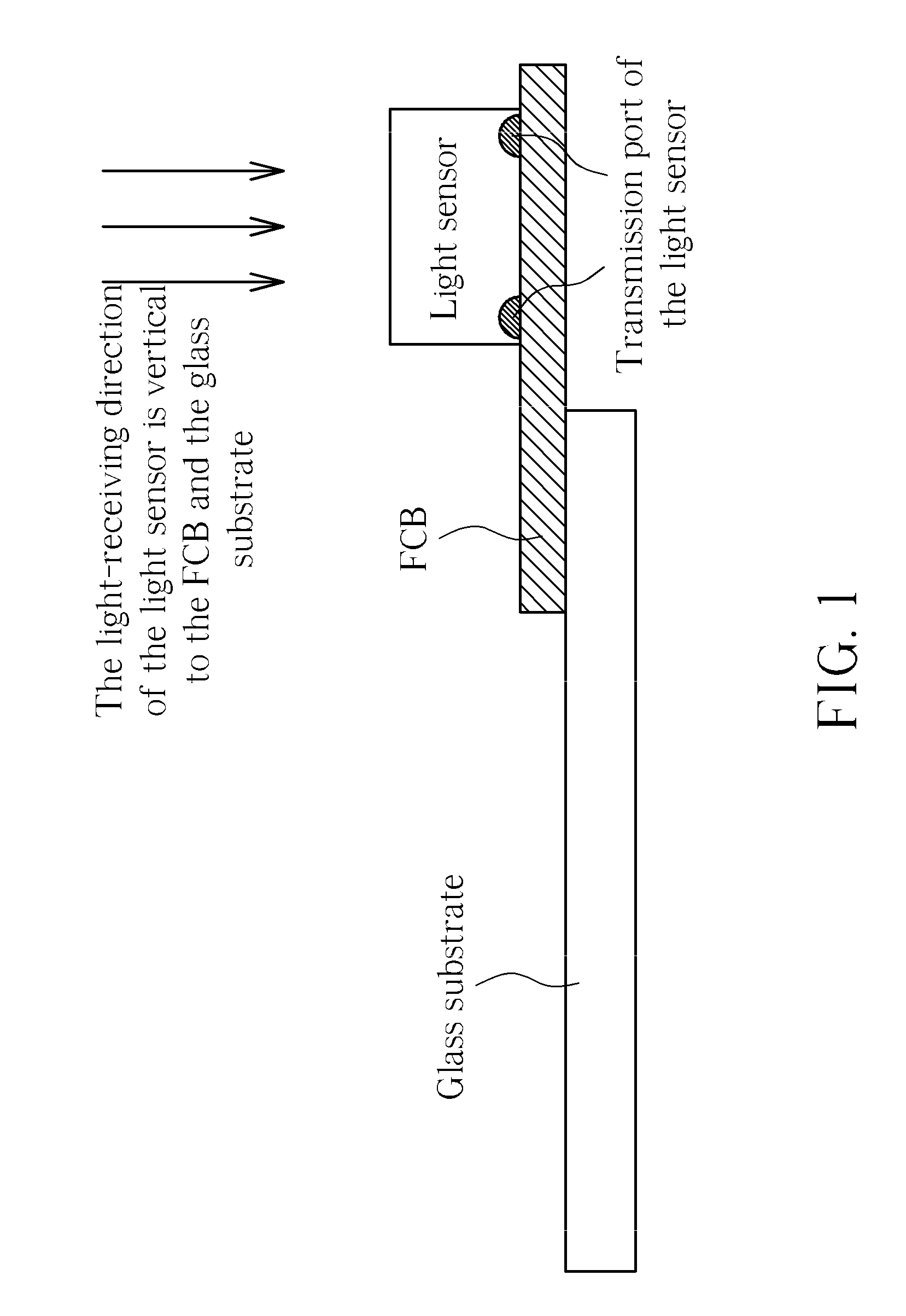

Connector of connecting light sensor and substrate and method of fabricating light sensor

InactiveUS20100295822A1Hinders fabricationSolid-state devicesMaterial analysis by optical meansOptoelectronicsFlat panel

A connector of connecting a light sensor and a substrate is utilized for rotating the light sensor so that the light-receiving direction of the light sensor is parallel with the substrate. When the connector is utilized in an optical touch system, the light sensor can be disposed on the substrate of the optical touch system by means of general manufacturing facilities of flat display panels. Meanwhile, the light-receiving direction of the light sensor is parallel with the substrate of the optical touch system.

Owner:PIXART IMAGING INC

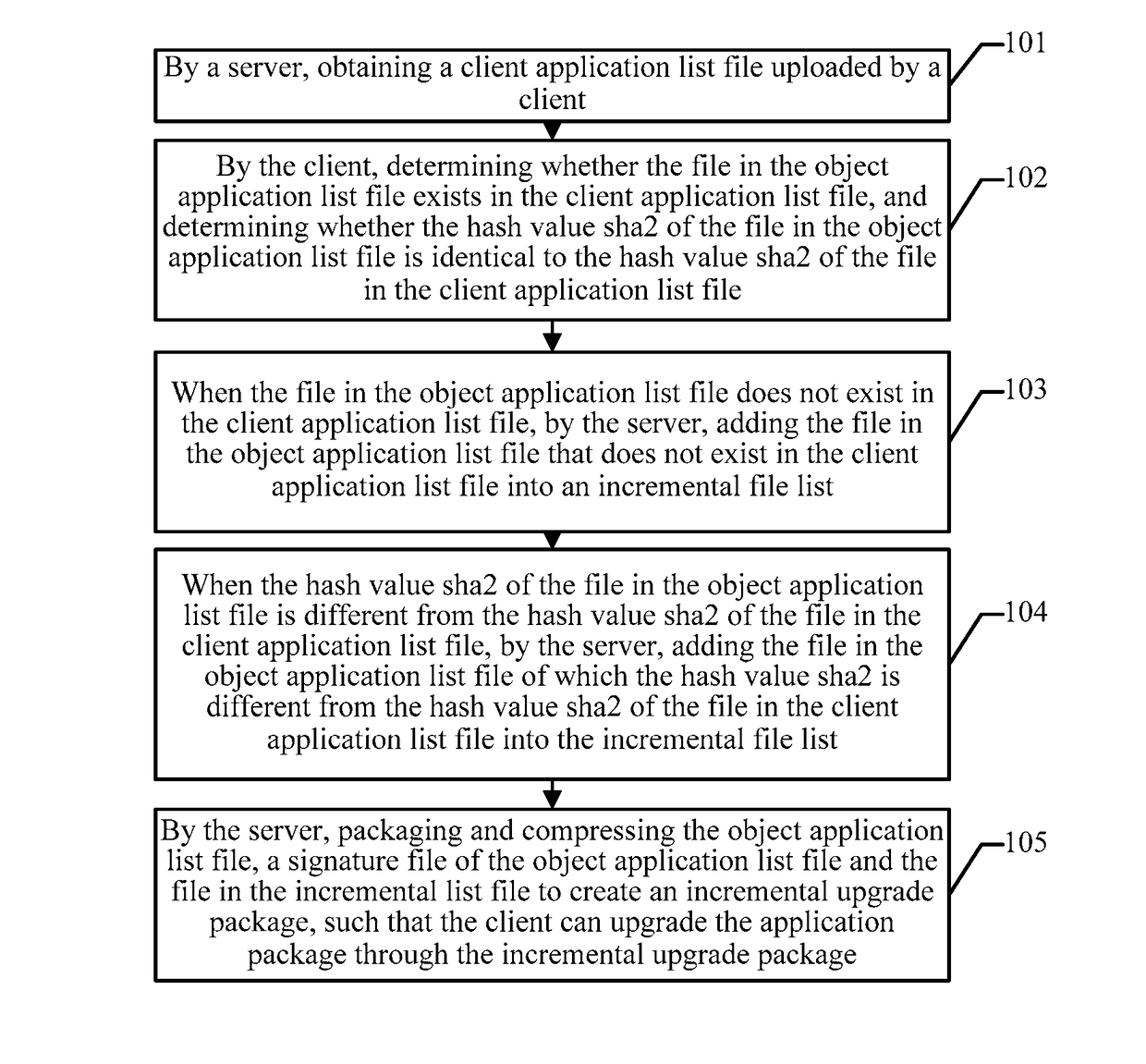

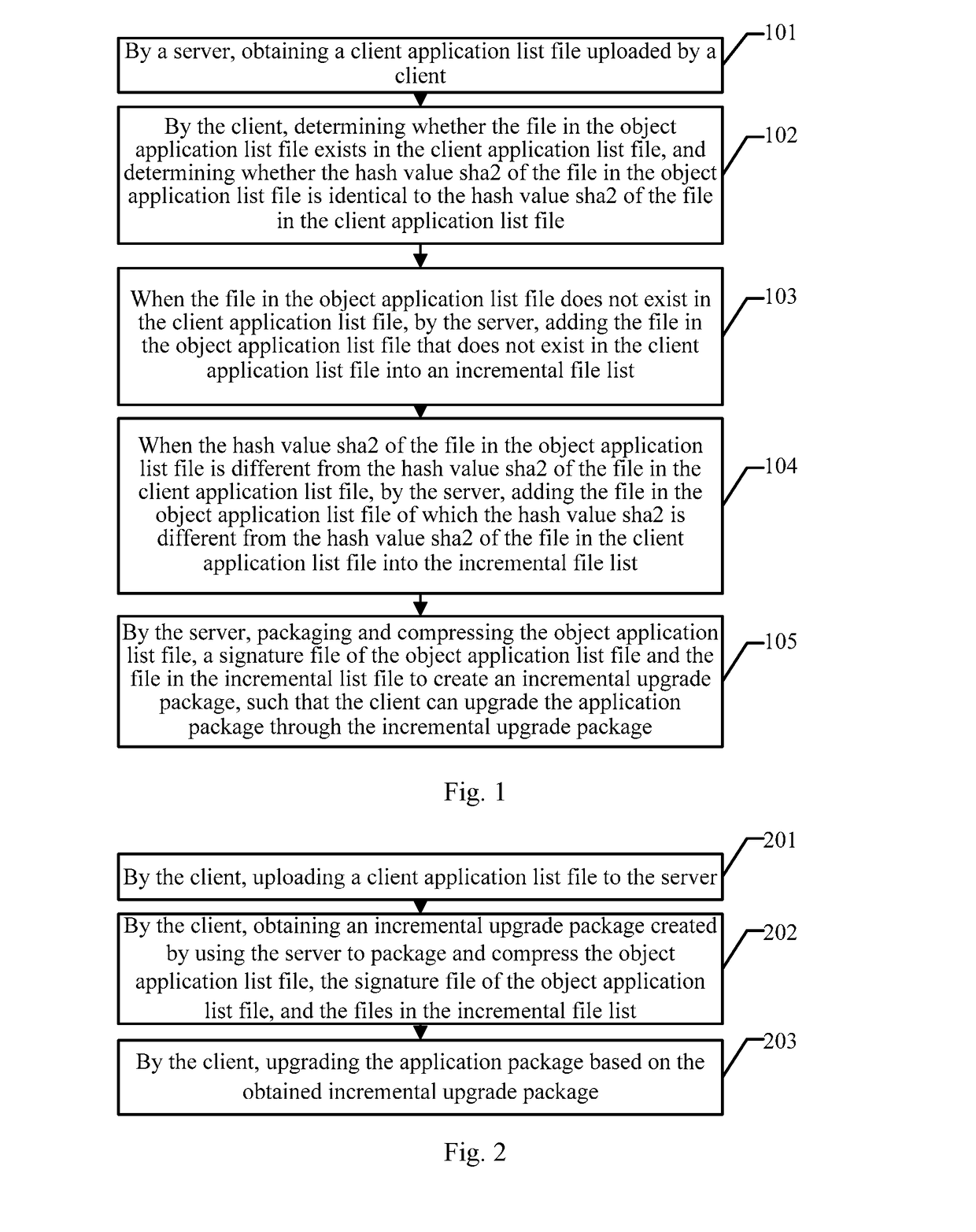

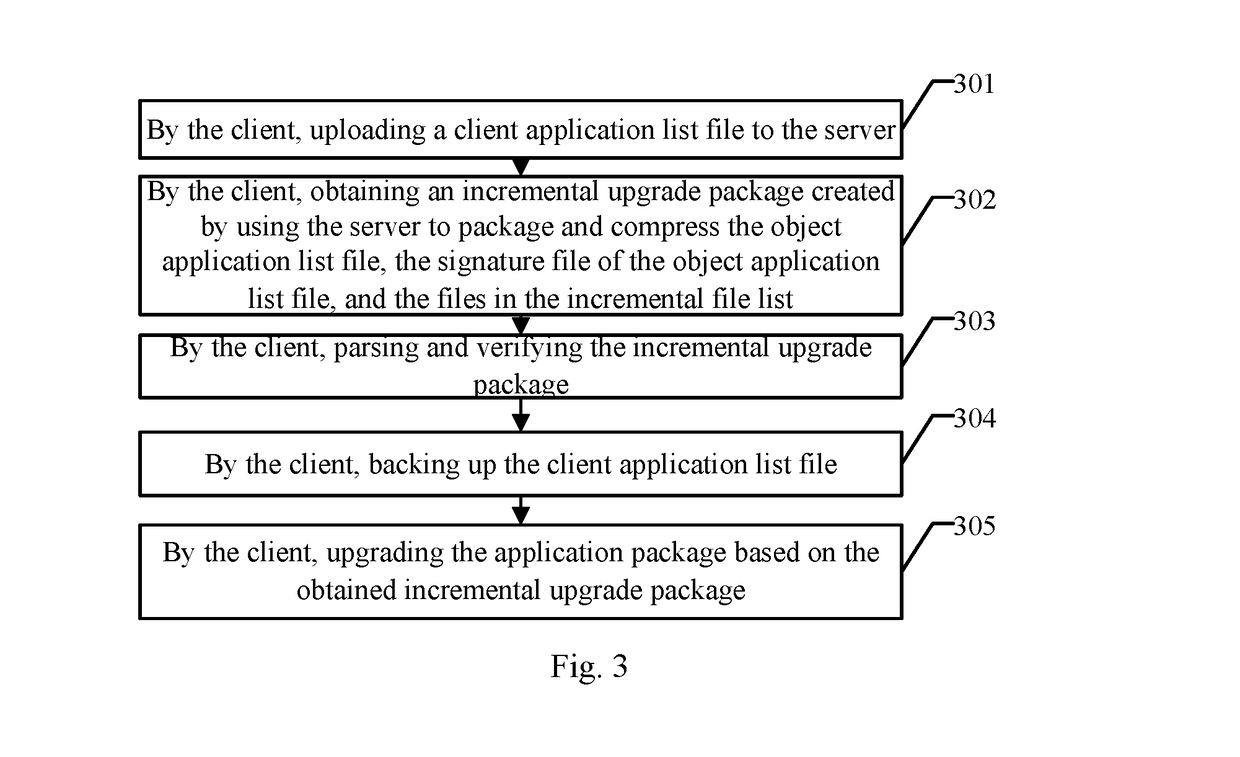

Data transmitting method, server and client

ActiveUS20170111166A1Hinders fabricationIncrease application speedEncryption apparatus with shift registers/memoriesCryptography processingClient-sideData transmission

Embodiments of the invention disclose a data transmitting method, a server and a client. The method embodiments of the invention include: obtaining a client application list file uploaded by a client; determining whether a file in a object application list file exists in the client application list file, and determining whether a hash value sha2 of the file in the object application list file is identical to a hash value sha2 of a file in the client application list file; adding the non-existed file into an incremental file list when the file in the object application list file does not exist in the client application list file; adding a file which is not identical into the incremental file list when the hash value sha2 of the file in the object application list file is different from the hash value sha2 of the file in the client application list file; packaging and compressing the object application list file, a signature file of the object application list file and the file in the incremental list file to create an incremental upgrade package such that the client can upgrade the application package through the incremental upgrade package.

Owner:PAX COMP TECH SHENZHEN

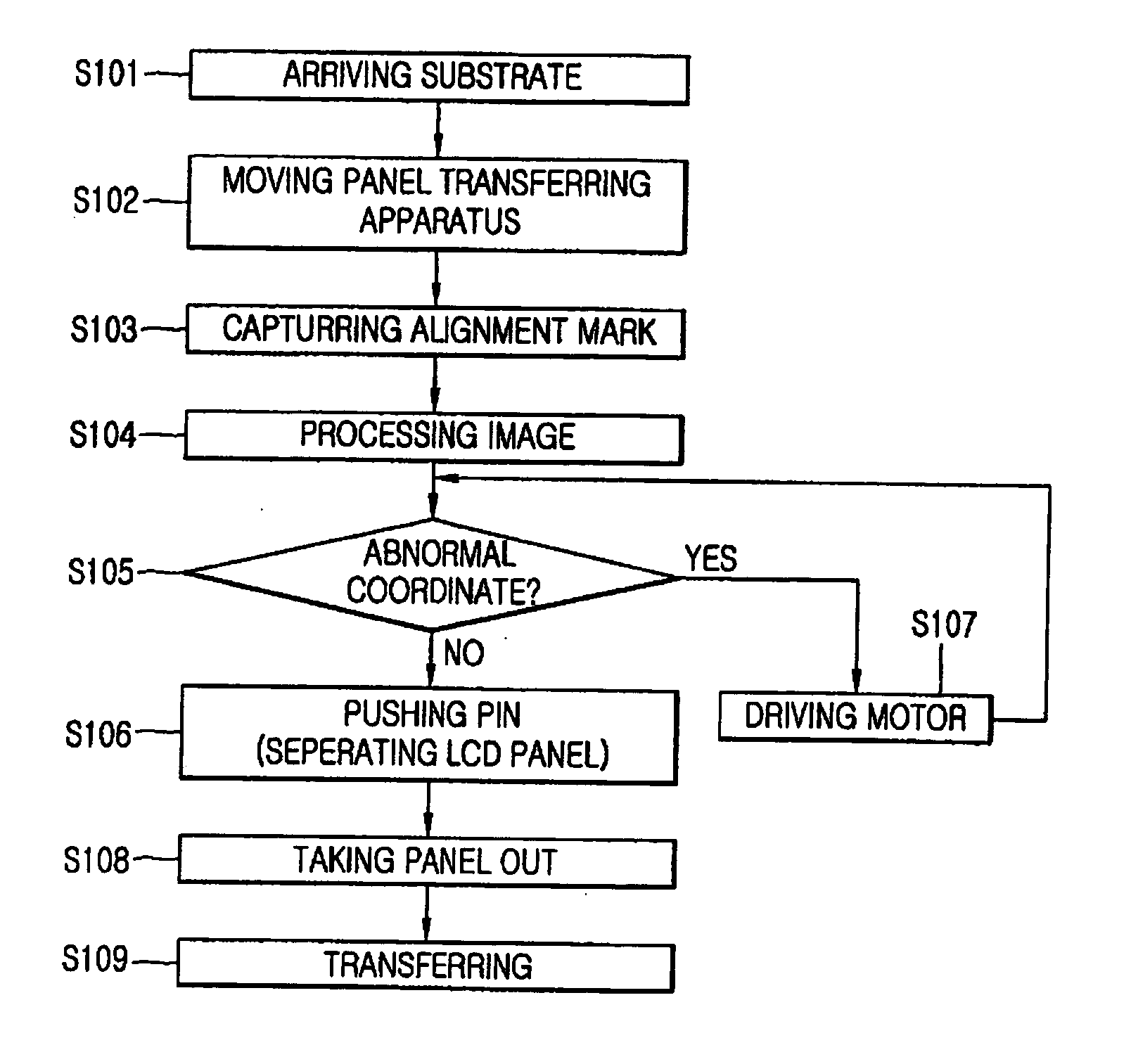

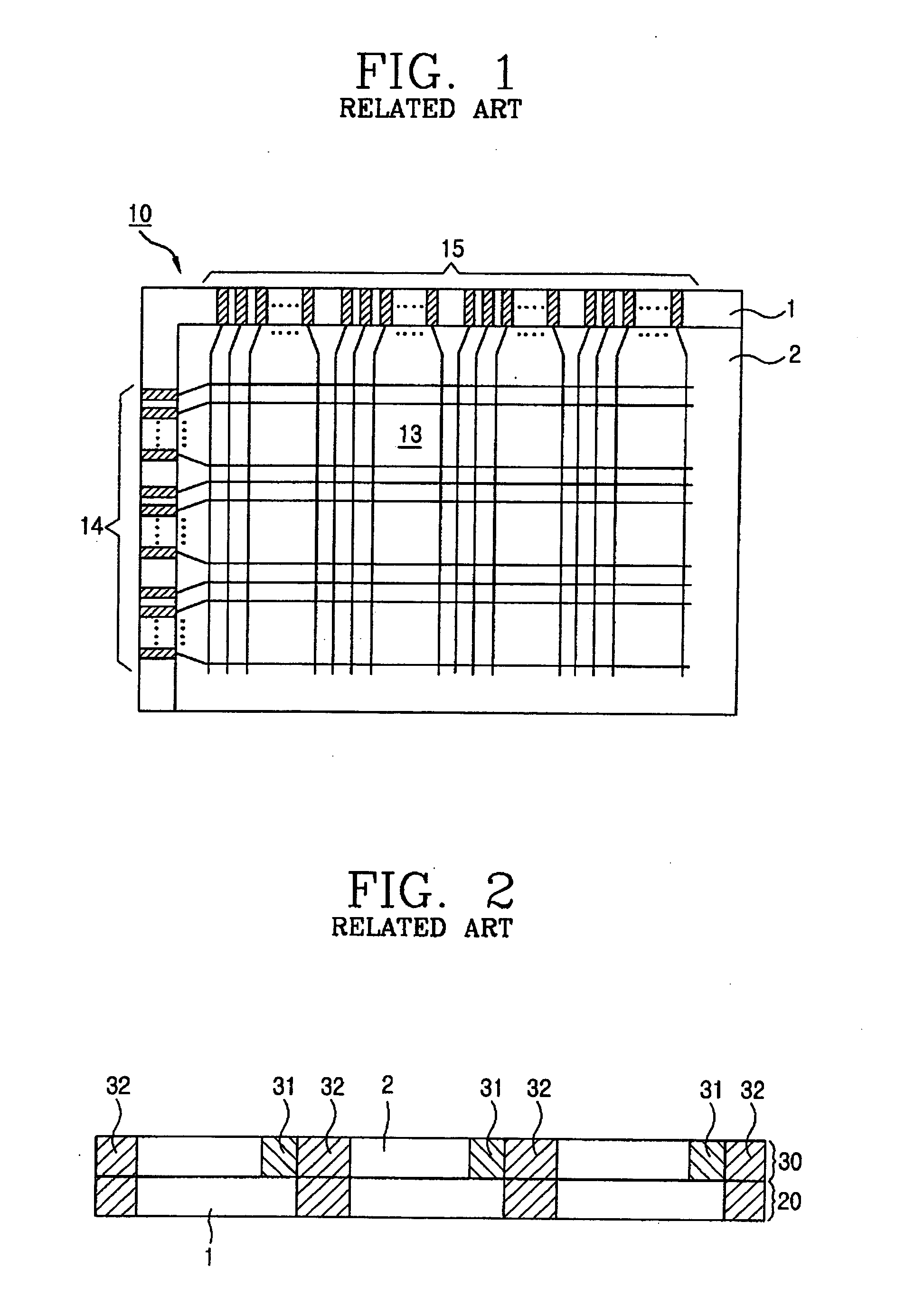

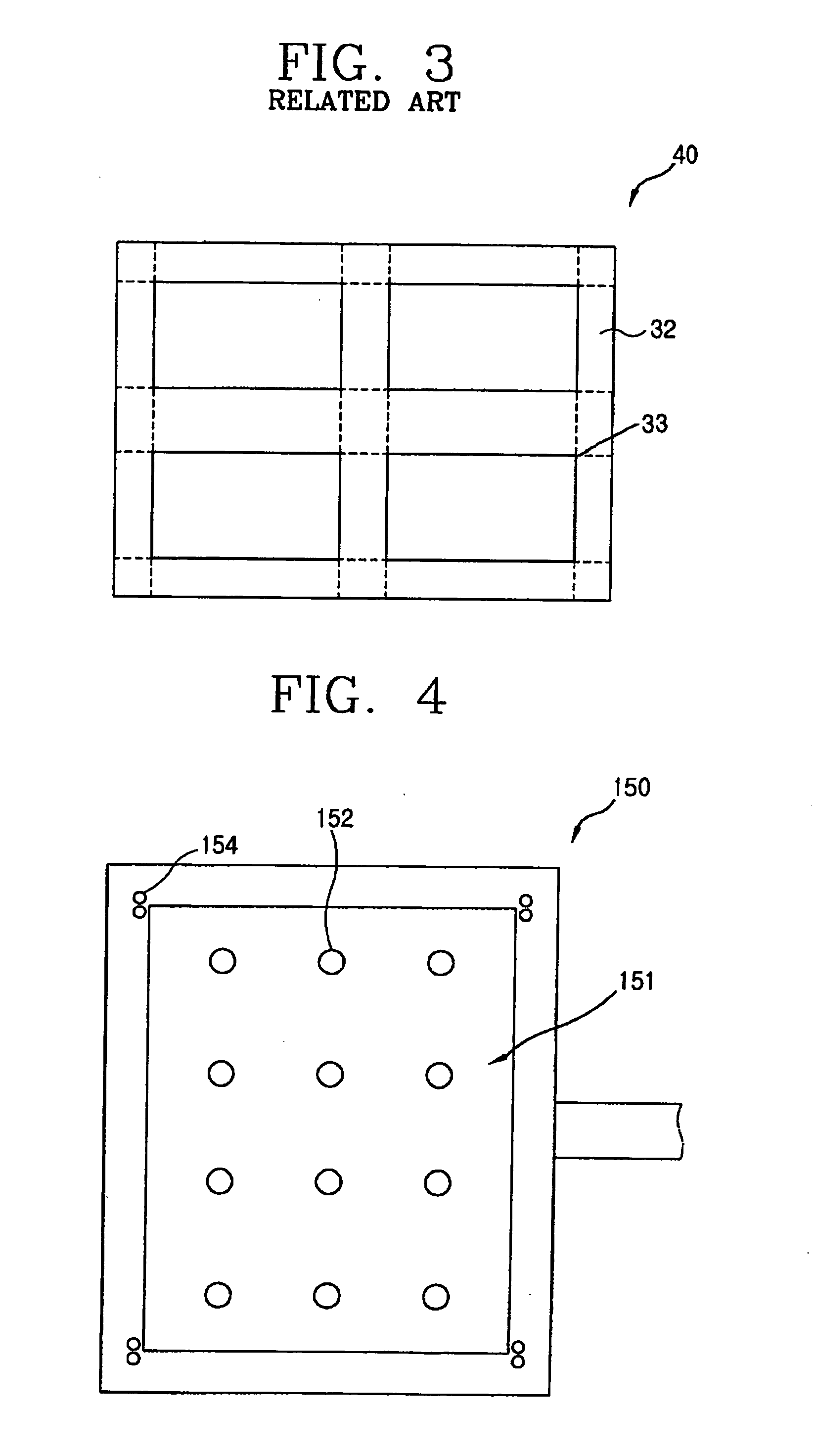

Liquid crystal display panel transferring system and method thereof

A liquid crystal display (LCD) panel transferring system including a panel transferring apparatus that takes out and transfers a LCD panel formed at a surface of a substrate; a camera installed at the panel transferring apparatus that captures an image of the LCD panel; and a controlling unit that aligns the LCD panel with the panel transferring apparatus based on an image captured using the camera. The panel transferring apparatus includes a main body; a plurality of suction holes formed at the main body that fix an LCD panel to the main body; and a pin formed at the peripheral area of the main body that applies an impact to a dummy region to separate the LCD panel from the substrate.

Owner:LG DISPLAY CO LTD

Thin-BOX metal backgate extremely thin SOI device

InactiveUS8431994B2Excellent short channel controlLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingContact formationDopant

Silicon-on-insulator (SOI) structures with silicon layers less than 20 nm thick are used to form extremely thin silicon-on-insulator (ETSOI) semiconductor devices. ETSOI devices are manufactured using a thin tungsten backgate encapsulated by thin nitride layers to prevent metal oxidation, the tungsten backgate being characterized by its low resistivity. The structure further includes at least one FET having a gate stack formed by a high-K metal gate and a tungsten region superimposed thereon, the footprint of the gate stack utilizing the thin SOI layer as a channel. The SOI structure thus formed controls the Vt variation from the thin SOI thickness and dopants therein. The ETSOI high-K metal backgate fully depleted device in conjunction with the thin BOX provides an excellent short channel control and significantly lowers the drain induced bias and sub-threshold swings. The present structure supports the evidence of the stability of the wafer having a tungsten film during thermal processing, and especially during STI and contact formation.

Owner:IBM CORP

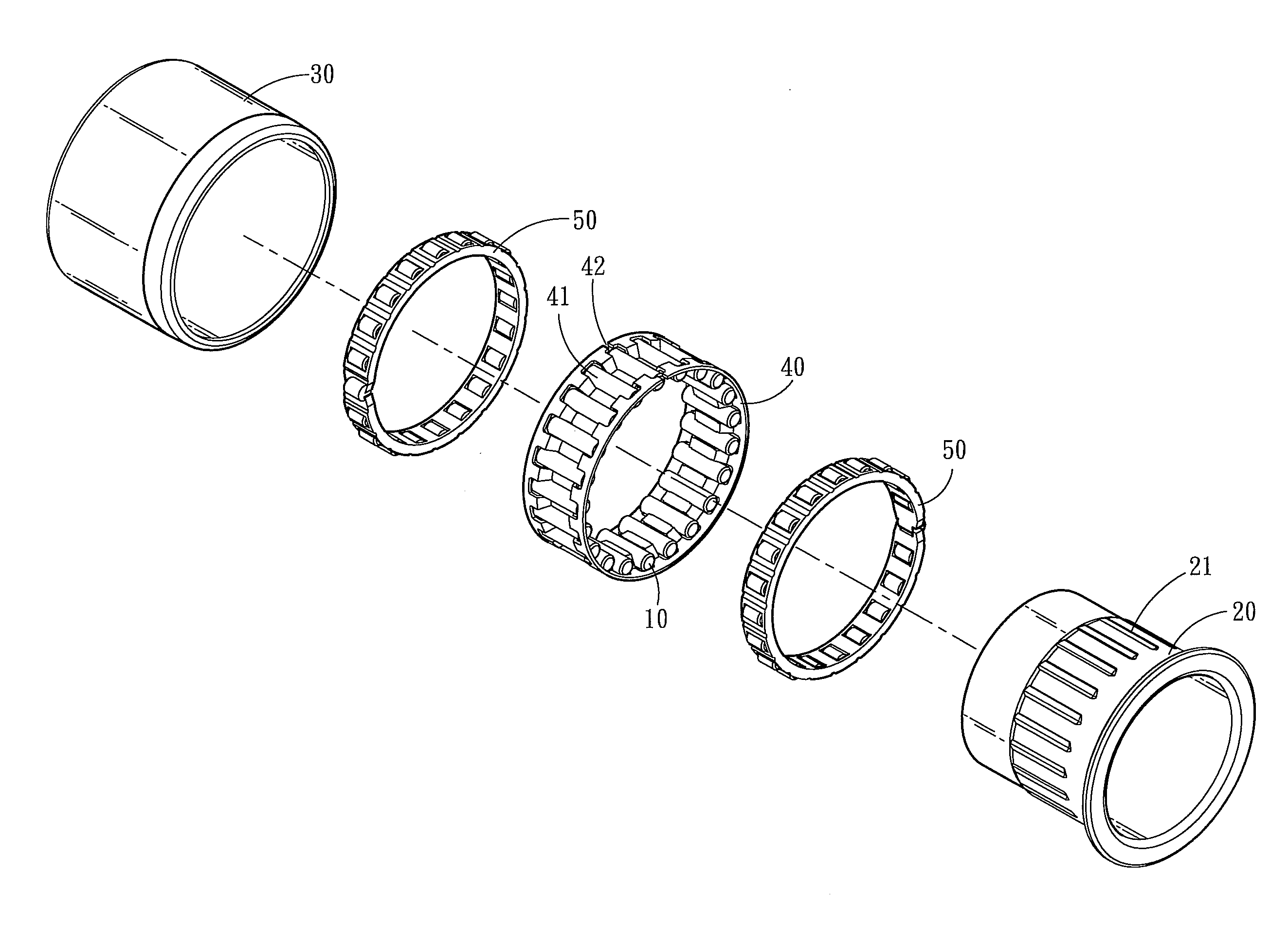

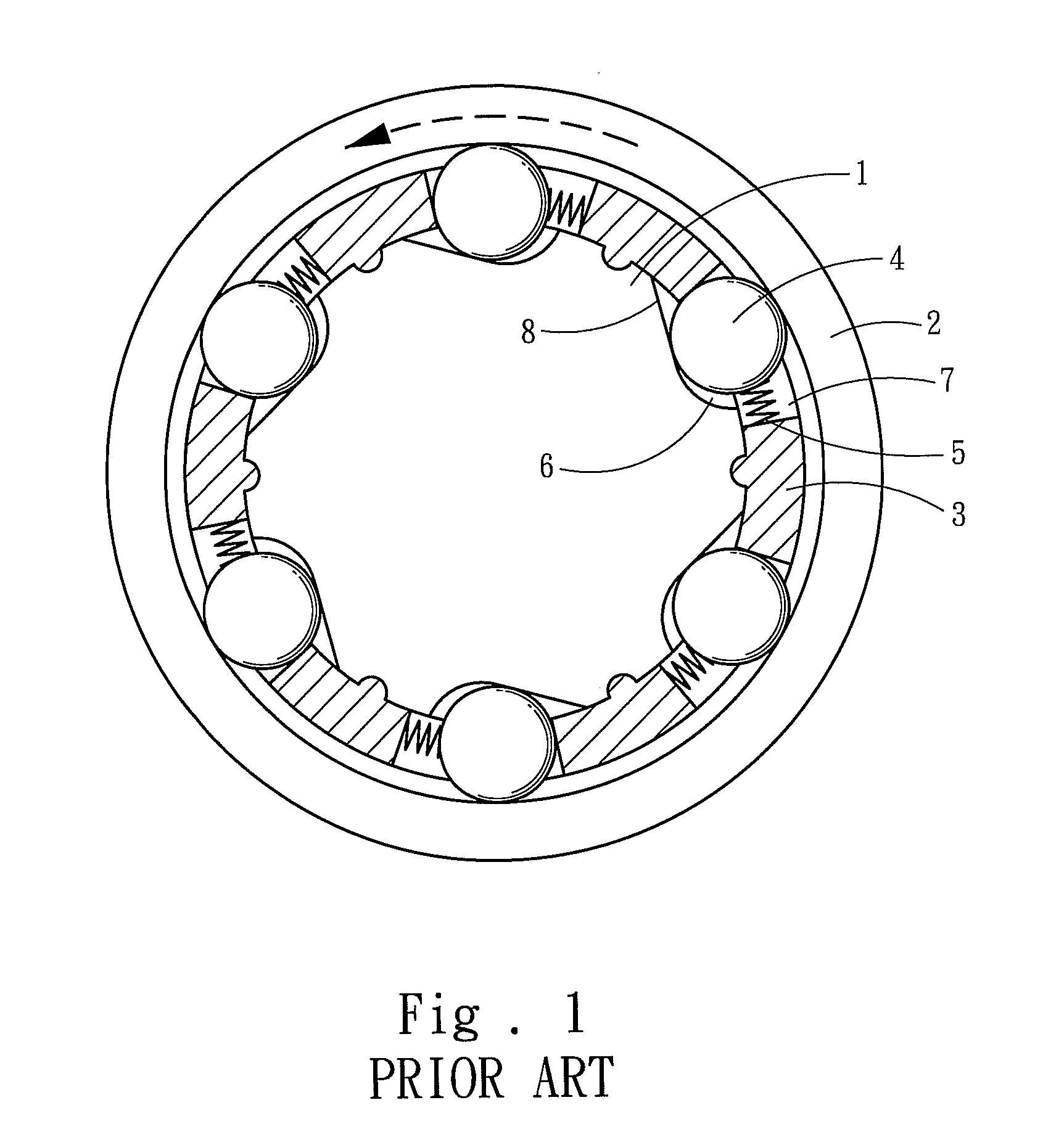

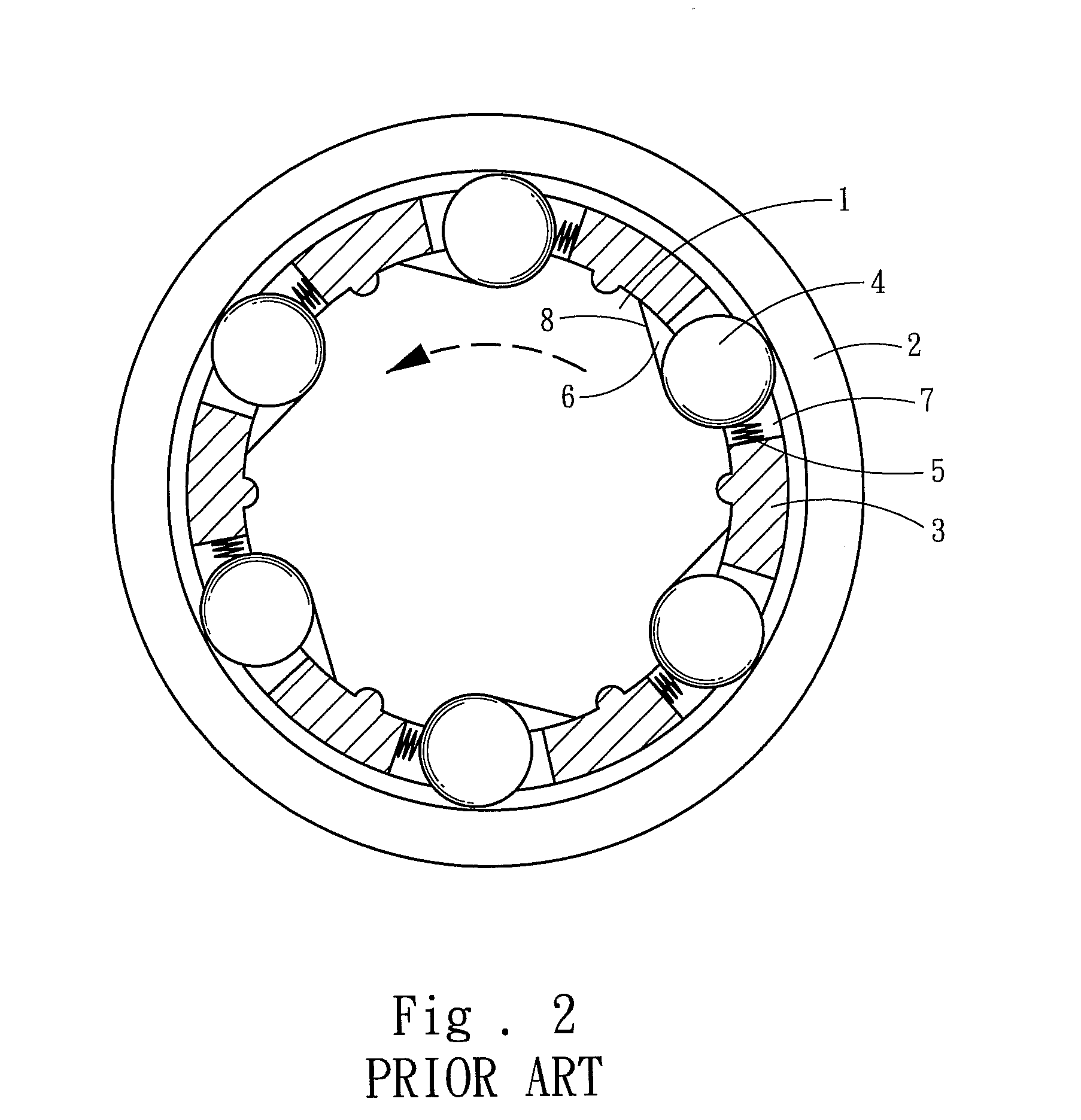

One-way clutch

InactiveUS20130092493A1Torsional force is increasedIncrease forceMechanical actuated clutchesAutomatic clutchesEngineeringShaft collar

A one-way clutch includes multiple rollers, a first collar and a second collar that are coupled together to form relative rotation between them, and a circular holding frame. The first collar has multiple cavities each having an inclined bottom surface. The circular holding frame has multiple slots corresponding to the rollers and exposing the cavities. The second collar is rotated to drive the circular holding frame rotating through friction force so that each roller is pushed to contact a higher portion of the inclined bottom surface and also the second collar drives the first collar rotating via pushing of the rollers. When rotational speed of the first collar is greater than that of the second collar, each roller enters a lower portion of the inclined bottom surface and separates from the second collar without transmitting torsional force between the second collar and first collar.

Owner:NEEDLE ROLLER BEARING

Method of cutting flexible display device and method of fabricating flexible display device using the same

ActiveUS9276212B2Inhibition of defect generationPrevent surfaceElectroluminescent light sourcesSolid-state devicesEngineeringFlexible display

The present disclosure relates to a method of cutting a flexible display device, capable of preventing a generation of a defect at the time of cutting the flexible display device, the method including providing a glass mother substrate having a flexible substrate attached thereon and an insulating layer formed on the flexible substrate; melting the flexible substrate and the insulating layer on the mother substrate by irradiating with a first laser beam; and cutting the mother substrate exposed by the irradiation of the first laser beam using a cutting device.

Owner:LG DISPLAY CO LTD

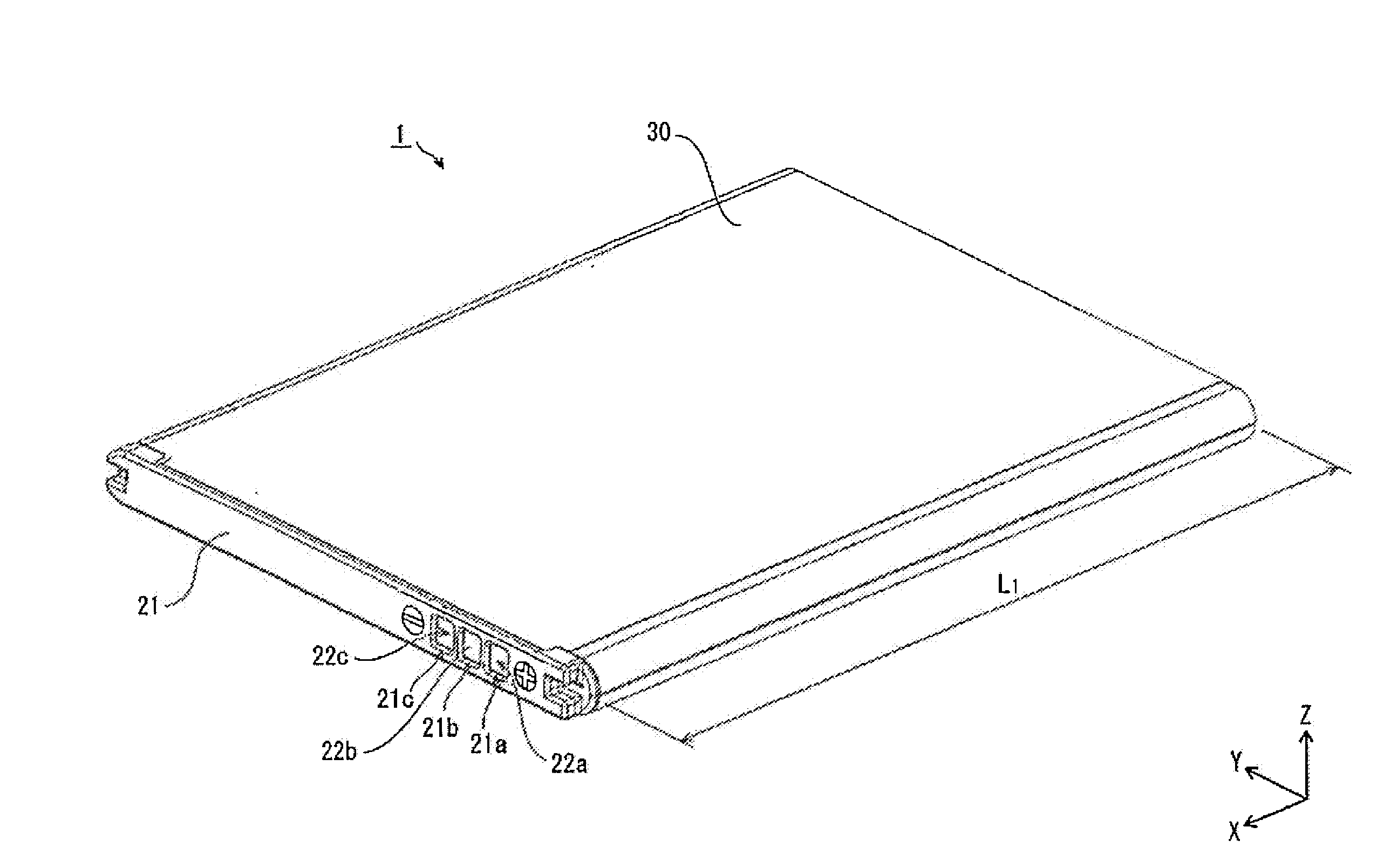

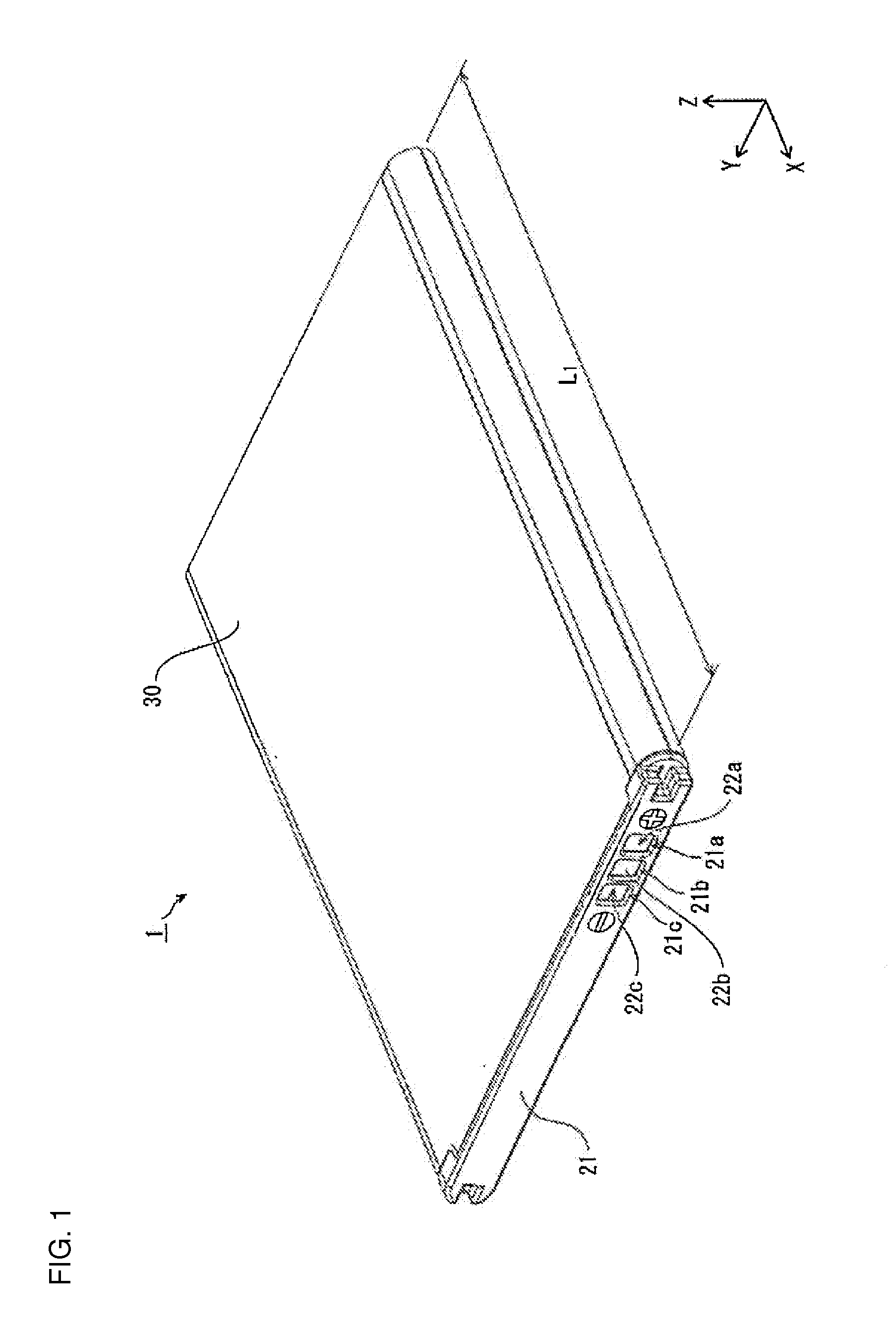

Battery pack with precise dimensions

InactiveUS20110097606A1Eliminate the effects ofHigh precision sizeCurrent conducting connectionsSmall-sized cells cases/jacketsBattery cellBattery pack

The battery pack has a battery cell 11, a circuit board 22 disposed along one end-plane 11a of the battery cell 11,and a circuit board holder 23 that intervenes between the circuit board 22 and the battery cell 11 end-plane 11a. The circuit board holder 23 is provided with a main body that holds the circuit board 22 and four projections 23h-23k protruding towards the end-plane 11a of the battery cell 11 (in the negative direction along the X-axis). Further, the projections 23h-23k on the circuit board holder 23 have lower mechanical strength than the main body and function as buffers to absorb dimension variation in the battery cell 11. Specifically, the end regions of the projections 23h-23k that contact an insulating board 12 disposed on top of the battery cell 11 end-plane 11a are squashed down by just an amount to absorb the battery cell 11 dimension variation.

Owner:SANYO ELECTRIC CO LTD

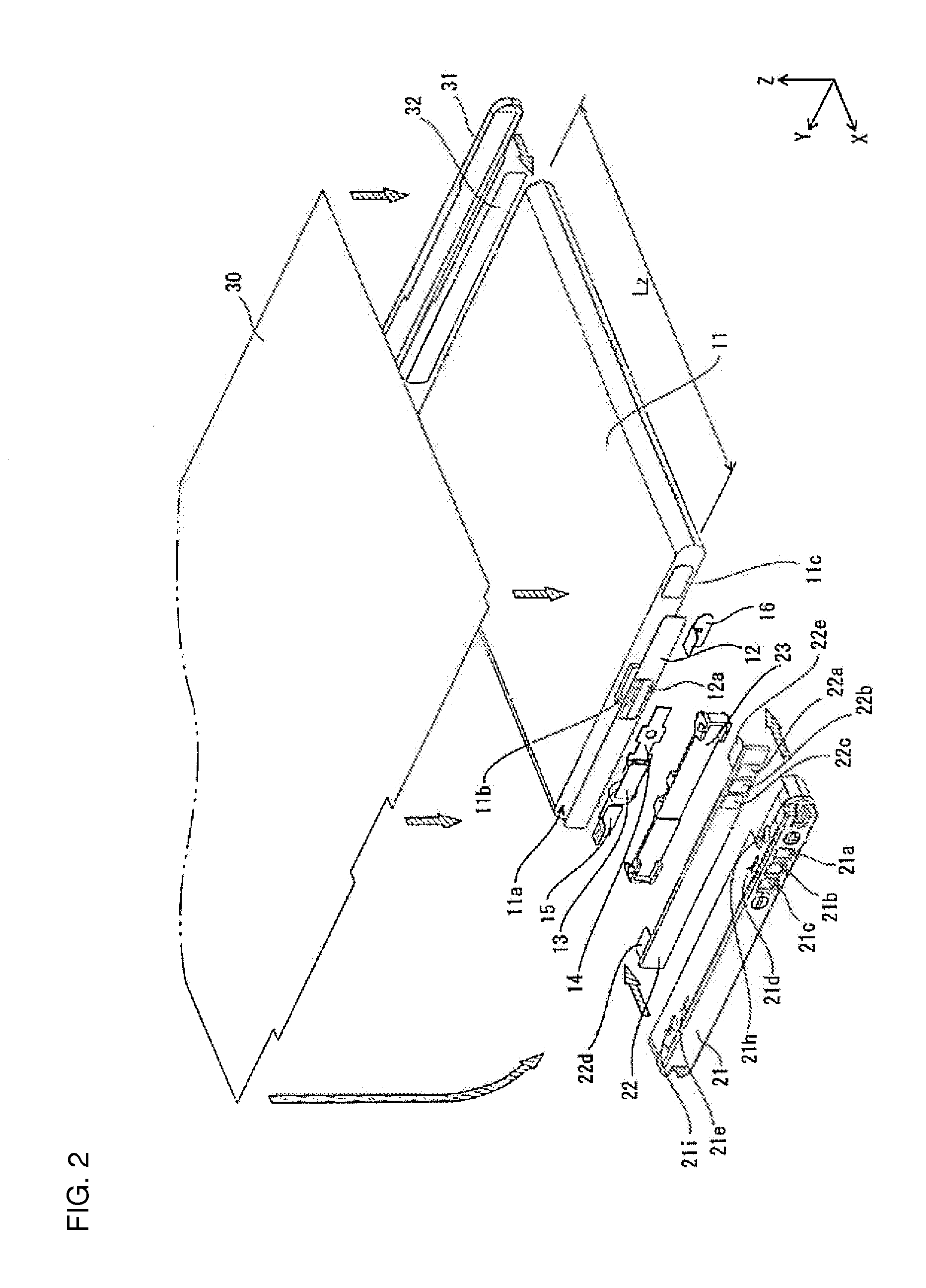

Reticle fabrication method

InactiveUS6925629B2Improves effective availability factorShorten the timeElectric discharge tubesSemiconductor/solid-state device manufacturingComputer Aided DesignSource Data Verification

CAD (Computer Aided Design) data which is reticle design data is input to first and second data conversion devices which respectively convert the CAD data to electron beam (EB) write data and inspection data. The EB write data and inspection data output are input to a data verification device to verify whether or not there is a data conversion error. If no data conversion error is detected by the data verification device, an EB writing device writes a pattern on an unwritten reticle with an electron beam based on the EB write data and develops the reticle, after which the fabricated developed reticle is inspected by a reticle inspection device. As a defect, such as a data conversion error contained in EB write data is detected before fabrication of a reticle, the reticle inspection process is simplified, the effective availability factors of the EB writing device and reticle inspection device and the time needed to fabricate a reticle is made shorter, thereby reducing the fabrication cost.

Owner:NEC CORP

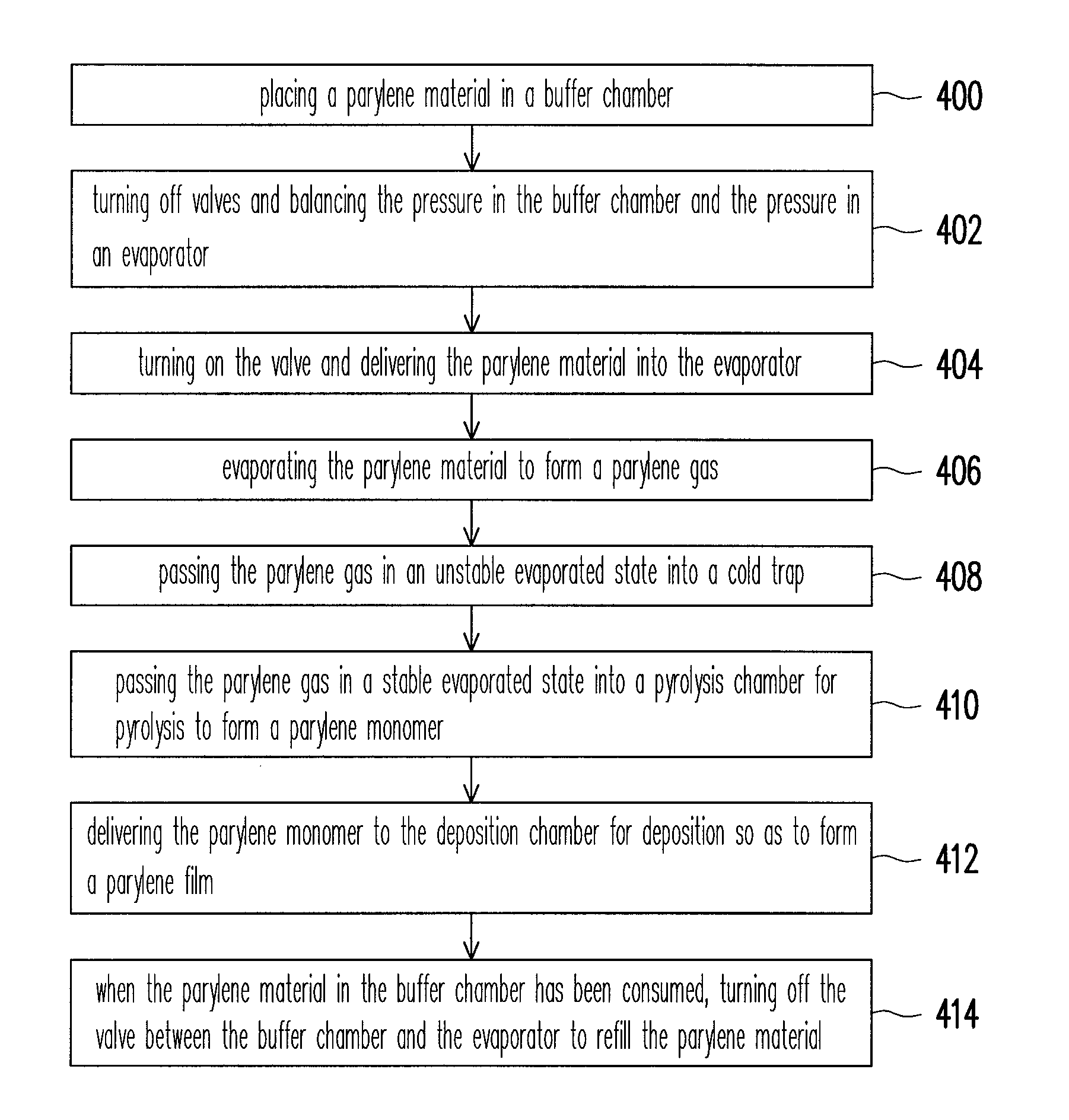

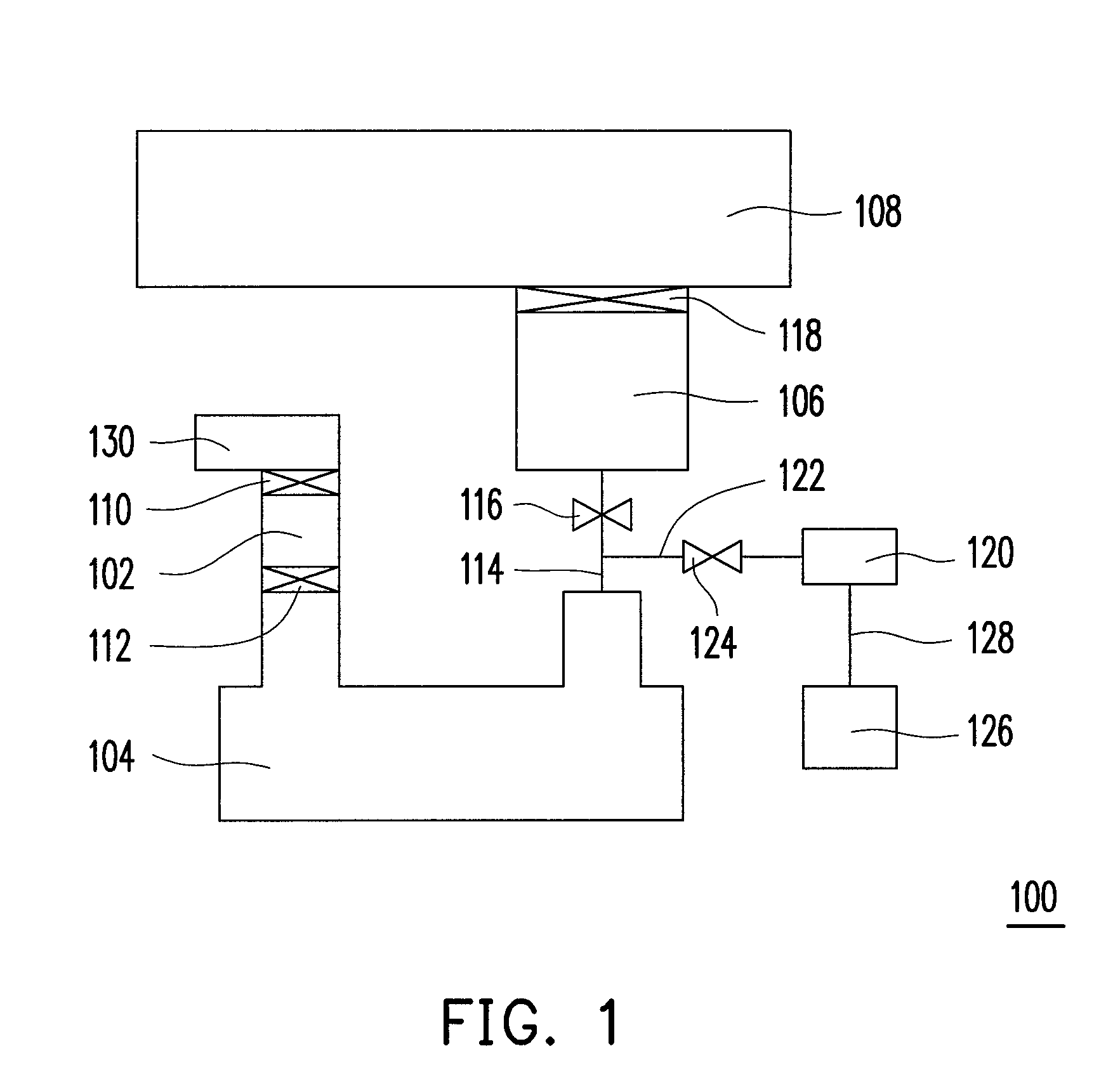

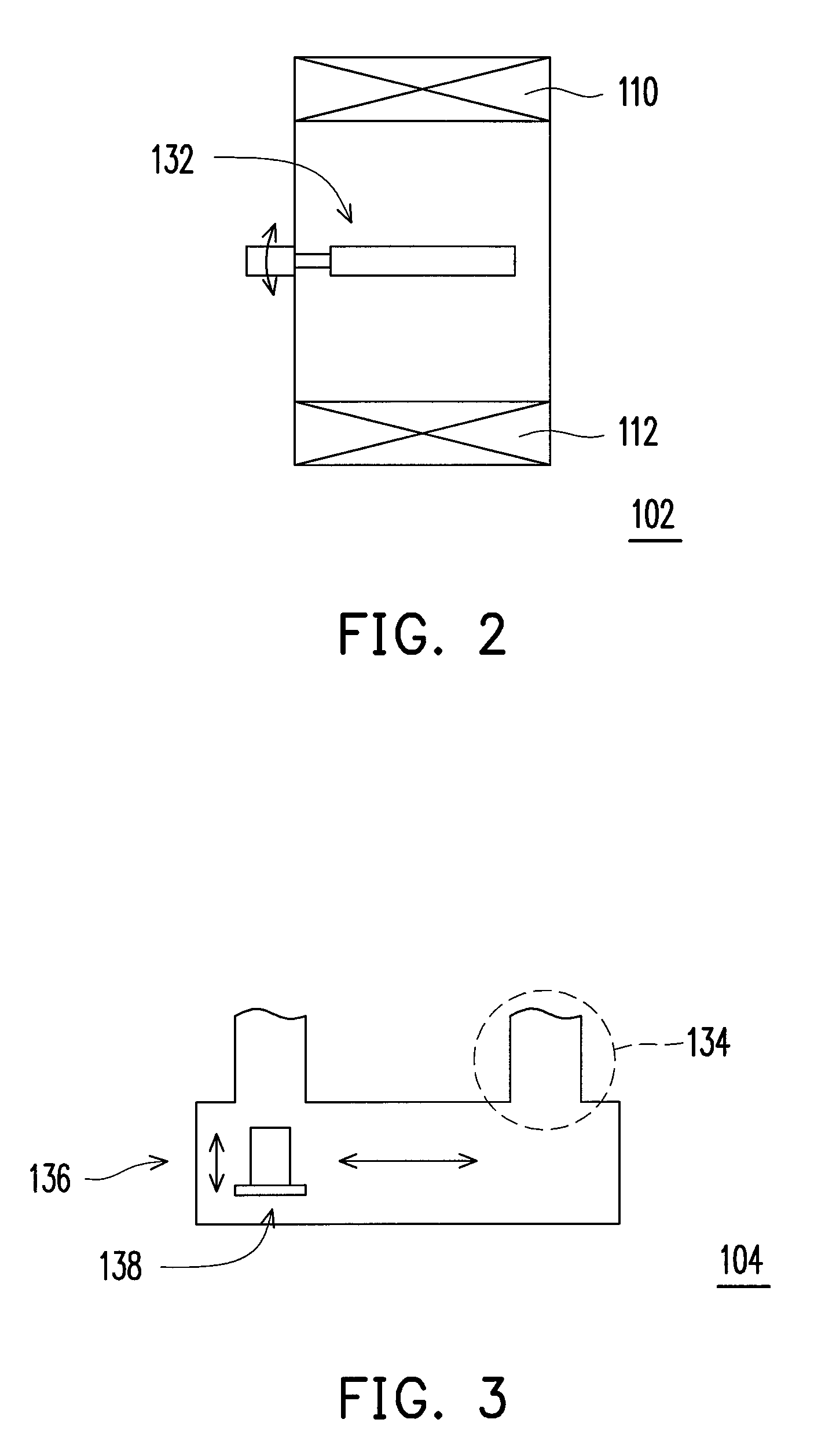

Method of forming parylene film

ActiveUS8889224B2Hinders fabricationAvoid discontinuationLiquid surface applicatorsChemical vapor deposition coatingParyleneEngineering

A method for forming a parylene film is provided, which includes following steps. Providing a chemical vapor deposition apparatus including a buffer chamber having first and second valves and a rotative carrying apparatus, an evaporator connected with the second valve, a pyrolysis chamber connected with the evaporator, and a deposition chamber connected with the pyrolysis chamber. Placing a parylene material in the rotative carrying apparatus of the buffer chamber through the first valve. Turning off the first and second valves and balancing a pressure in the buffer chamber and a pressure in the evaporator. Turning on the second valve and delivering the parylene material into the evaporator. Evaporating the parylene material in the evaporator to form a parylene gas. Pyrolyzing the parylene gas in the pyrolysis chamber to form a parylene monomer. Delivering the parylene monomer to the deposition chamber for deposition so as to form a parylene film.

Owner:IND TECH RES INST

Device for estimating machining dimension of machine tool

A device for estimating machining dimensions of a machine tool which employs tool members each being rotatably driven by a driving unit includes: a vibration sensor; a characteristics extracting unit for extracting amounts of characteristics from an output of the vibration sensor; a neural network for classifying the amounts of characteristics into categories; and a conversion unit. Amounts of characteristics of generated output by racing the tool member are used for training the neural network, and inputted again to the trained competitive learning neural network to excite neurons so that the relationships between Euclidean distances and machining dimensions of workpieces are registered in the conversion unit. The Euclidean distances are obtained between weight vectors of the excited neurons and respective corresponding training samples, and the machining dimensions are obtained when the workpieces are machined by the tool members at the same condition as the respective corresponding training samples are obtained.

Owner:MATSUSHITA ELECTRIC WORKS LTD

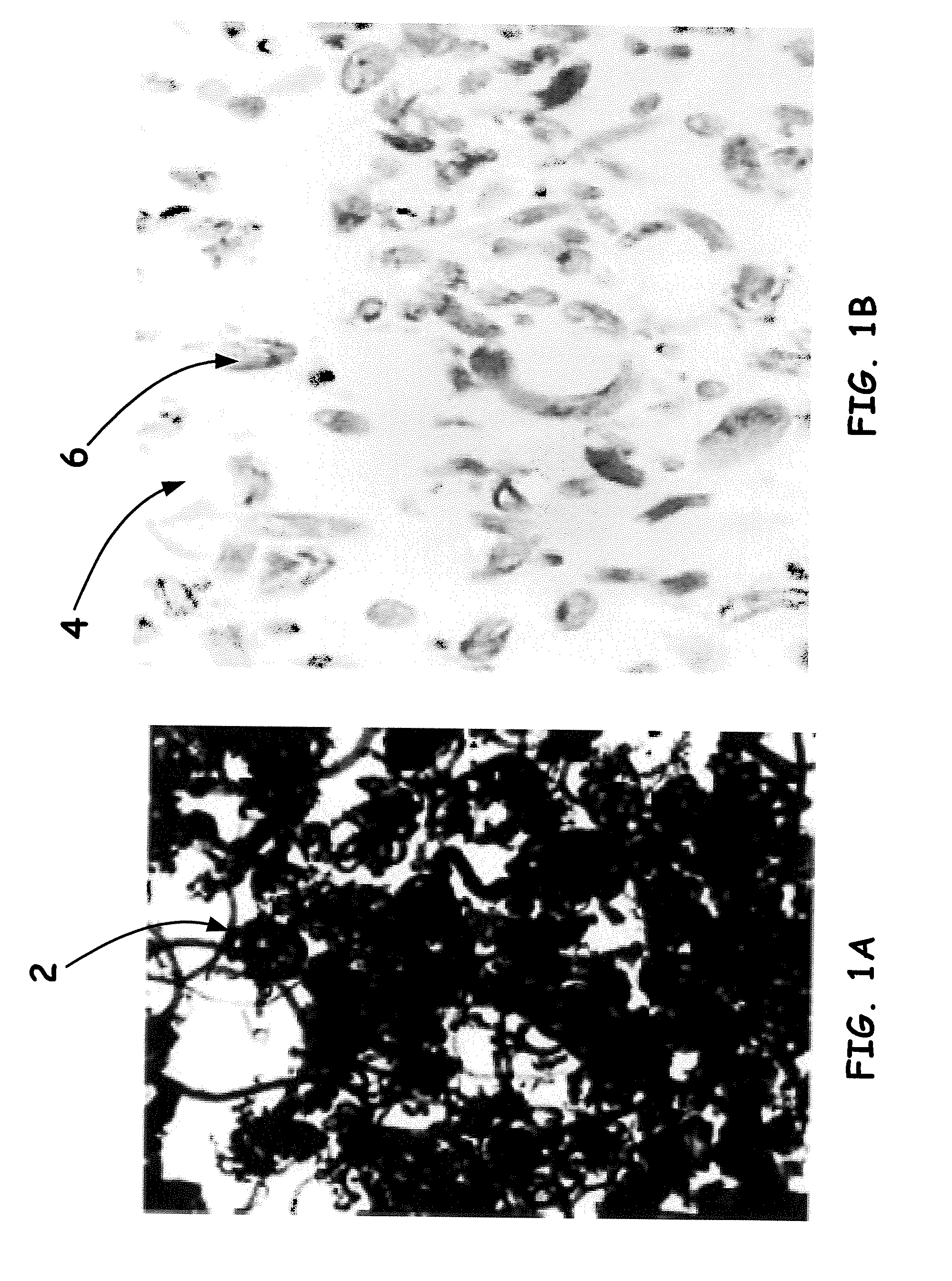

Method for conversion of dry nanomaterials into liquid nano-agents for fabrication of polymer nanocomposites and fiber reinforced composites

InactiveUS20160108183A1Safer and more suitableGood dispersionPolymer scienceFiber-reinforced composite

Unique methods for the efficient and beneficial use of converting dry nanomaterials such as dry carbon particles into liquid nano-agents are disclosed herein. The methods provide for fabrication of polymer and fiber reinforced composites, such as fiber-reinforced resins having such introduced nanomaterials to enable an increased dispersion and other beneficial properties.

Owner:WASHINGTON STATE UNIVERSITY

Wafer Lithographic Mask and Wafer Lithography Method Using The Same

ActiveUS20070216891A1Hinders fabricationReduce tooling costsPhotomechanical apparatusSemiconductor/solid-state device manufacturingLithographic artistWafer fabrication

A wafer lithographic shielding mask for fabricating a multi-project wafer (MPW) and a wafer fabrication method using the same are disclosed. The mask including a light shielding layer and at least one transparent region is used to select the layout patterns of designated chips on an MPW reticle to be exposed onto the photoresist layer on the surface of the wafer. The lithography method of fabricating MPW mainly involves disposing a wafer lithographic shielding mask for selecting the exposure regions on the MPW reticle on the light transmission path from a lithographic light source to a wafer, e.g., between the MPW reticle and the lithographic light source or between the MPW reticle and the wafer, so as to prevent some undesired chips from being fabricated on the wafer using the MPW reticle, thereby decreasing the wafer production cost.

Owner:YUAN ZE UNIV

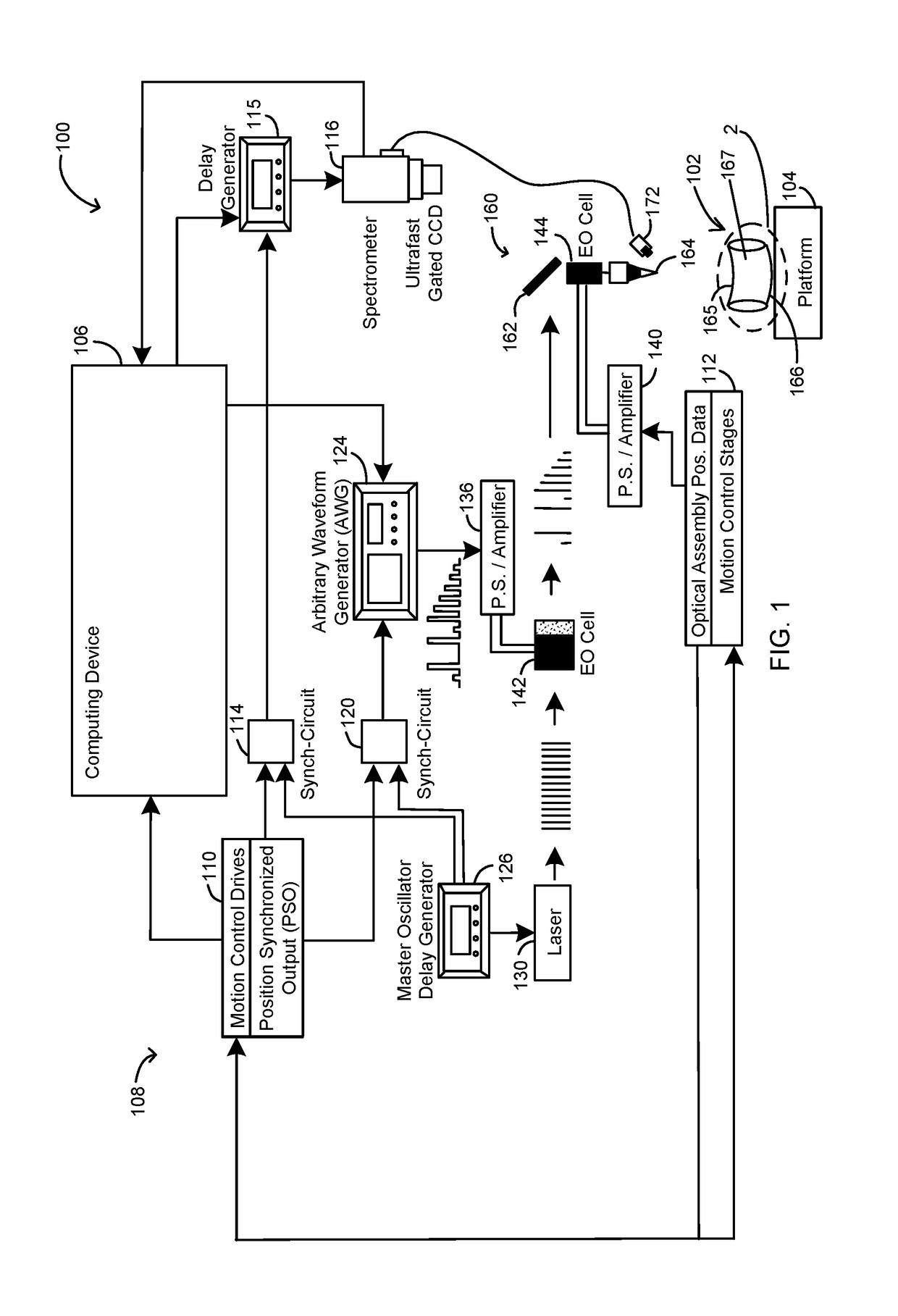

Systems and methods for the patterning of material substrates

ActiveUS20180356797A1Hinders fabricationWide rangeProgramme controlComputer controlComputer graphics (images)Light beam

A system includes a computing device that generates at least one process script for the modification to a glass ceramic substrate and at least one pattern script that corresponds to the process script. The computing device also merges the process script with the pattern script and generates a plurality of command signals that are based on the merged process and pattern scripts. An energy source generates a plurality of light beams based on the generated command signal(s). A waveform apparatus generates at least one waveform signal to customize the generated light beams based on the generated command signal(s). At least one modulating component modulates the generated light beams based on generated command signal(s). An optical assembly is configured to apply the modulated plurality of light beams to the glass ceramic substrate. At least one motion stage encoder is configured to provide at least one three dimensional (3D) coordinate position of the optical assembly with respect to the motion control drive in order to coordinate application of the modulated light beams with a predefined spatial location.

Owner:THE AEROSPACE CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com