Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "High removal depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

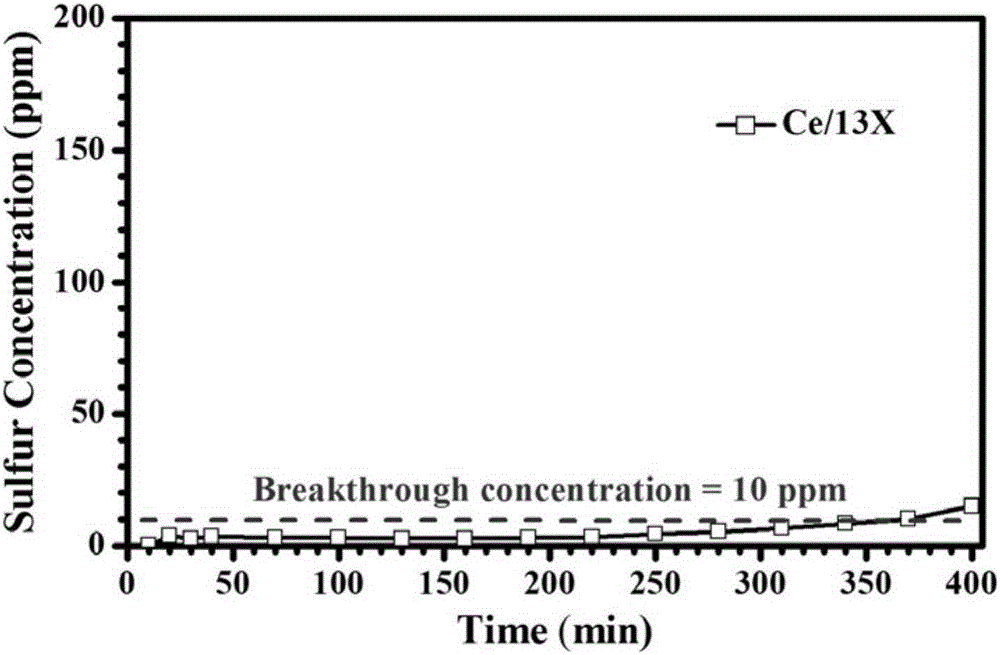

Metal-modified 13X molecular sieve desulphurization adsorbent and its preparation method and use

InactiveCN105289476AHigh content of active ingredientsGood dispersionOther chemical processesAluminium silicatesFiltrationIon exchange

The invention relates to a metal-modified 13X molecular sieve desulphurization adsorbent and its preparation method and use. The preparation method comprises preparing a metal salt solution as an active ingredient ion exchange salt solution for next use, taking a 13X molecular sieve, adding the 13X molecular sieve into the ion exchange salt solution for ion exchange reaction, carrying out filtration, washing the filter residues, carrying out drying, putting the dried filter residues into a tube furnace, carrying out roasting activation, and carrying out furnace cooling to obtain the molecular sieve desulphurization adsorbent subjected to metal ion exchange. The molecular sieve desulphurization adsorbent can be used for ultra-deep removal of sulfocompounds such as thiophene and its derivatives in gasoline and diesel oil. The metal-modified 13X molecular sieve desulphurization adsorbent has a large specific surface area and a rich micropore structure, can effectively remove a trace amount of sulfocompounds in gasoline, has the advantages of low cost, simple preparation processes, high removal depth and regeneration convenience, can be used for deep removal of sulfocompounds in fuel oil products and preparation of ultral-low sulphur clean fuel oil, reduces oil product combustion sulfide discharge-caused environmental pollution and improves environment quality.

Owner:SHANGHAI RES INST OF CHEM IND

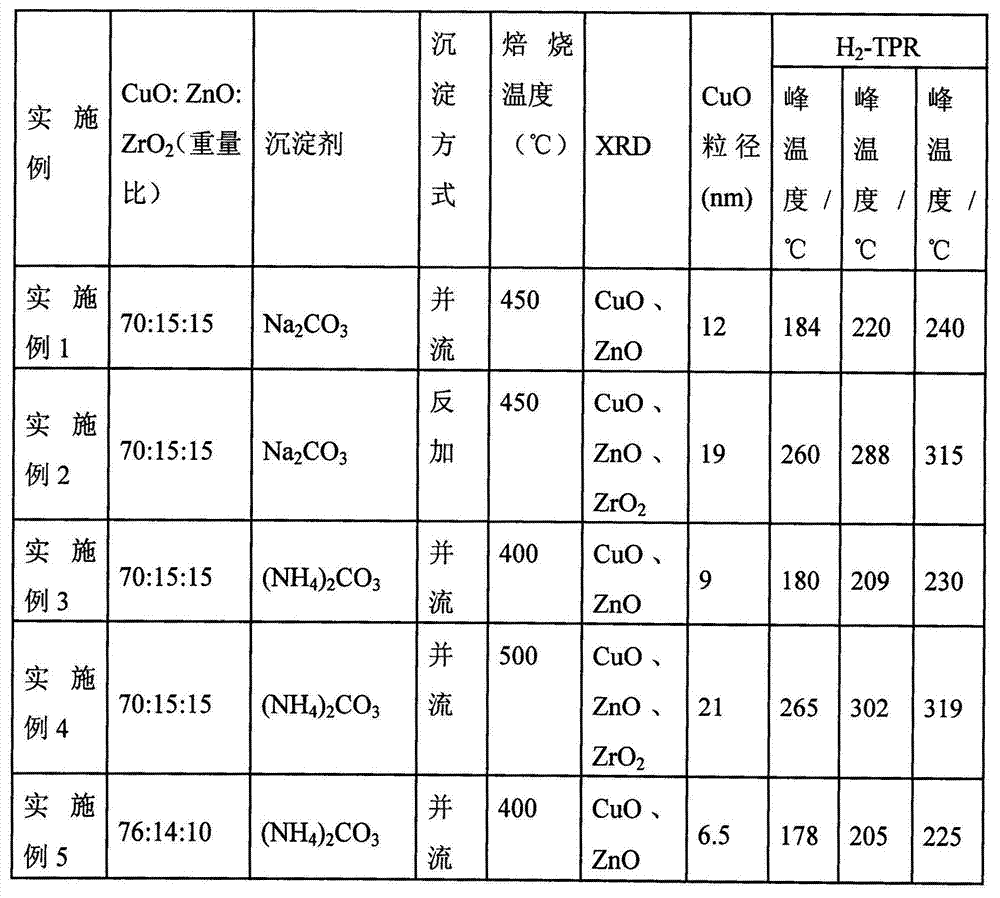

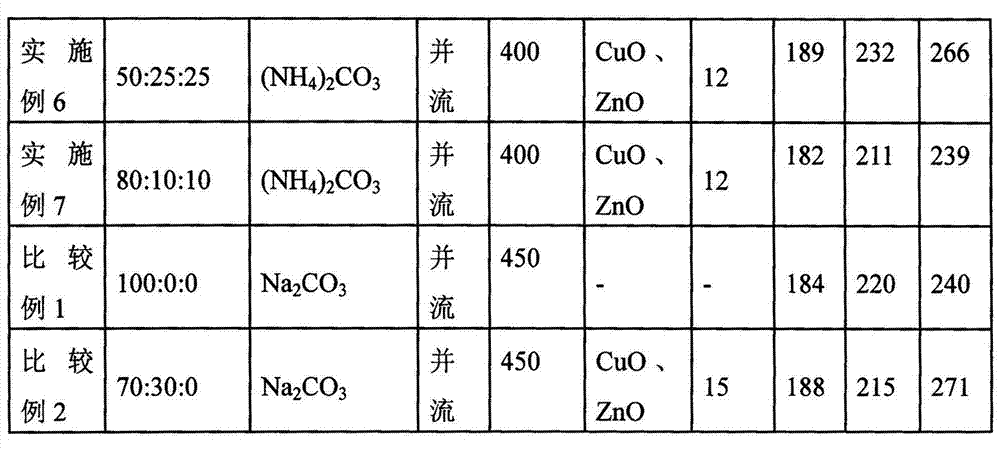

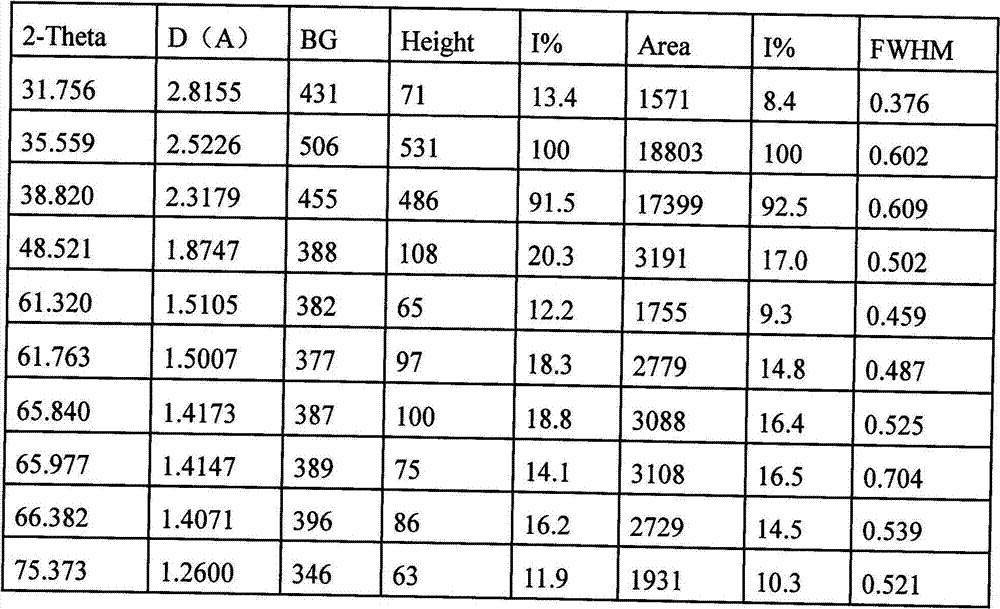

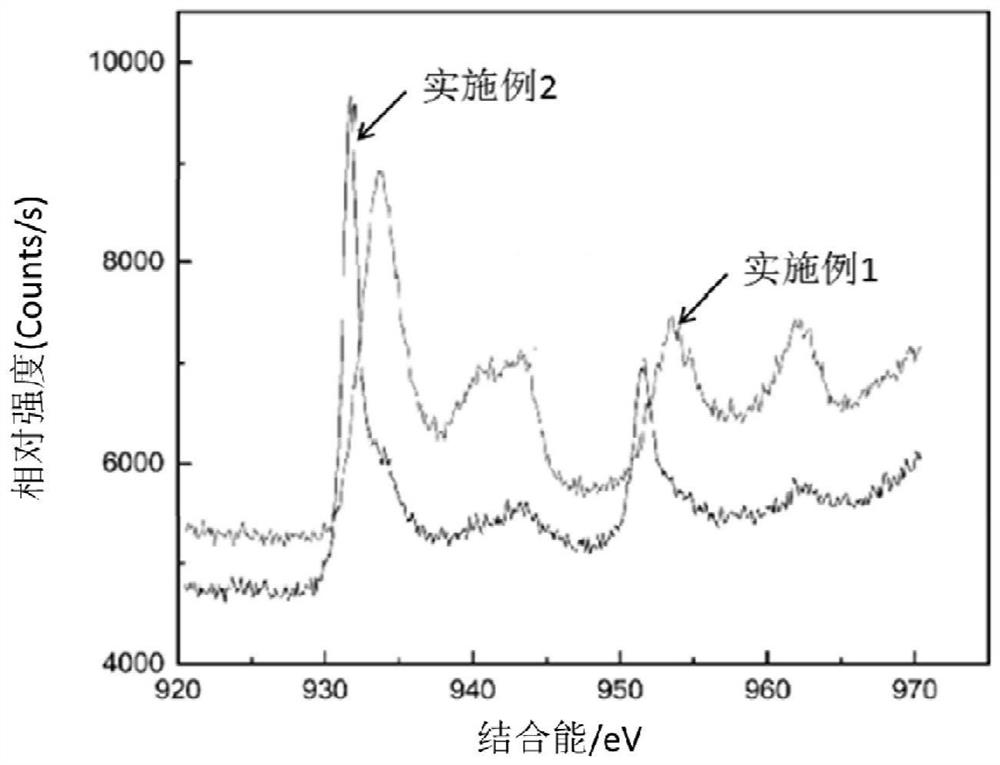

Catalyst for deeply removing CO at low temperature as well as preparation and activation methods and application thereof

InactiveCN102773103AHigh content of active ingredientsGood dispersionNitrogen purification/separationMetal/metal-oxides/metal-hydroxide catalystsActivation methodCopper oxide

The invention relates to a catalyst for deeply removing CO at low temperature as well as the preparation and activation methods and the application thereof. The catalyst is the CuO-ZnO-ZrO2 composite catalyst which comprises 50-90wt% of CuO, 5-40wt% of ZnO and 5-40wt% of ZrO2. The copper-containing component has the reduction degree of 70-80%, and the reduction degree is represented by the ratio of the weight of the metallic copper to the total weight of the metallic copper and the copper oxide calculated according to the CuO. Compared with the prior art, the catalyst is used for removing the CO in the liquid or gaseous hydrocarbon and / or inert gas and has the characteristics of high activity at low temperature of 0-50 DEG C, high removal depth of 20ppb or lower and long service life. The process for preparing the catalyst is simple, and the cost spent in preparing the catalyst can be lowered.

Owner:SHANGHAI RES INST OF CHEM IND

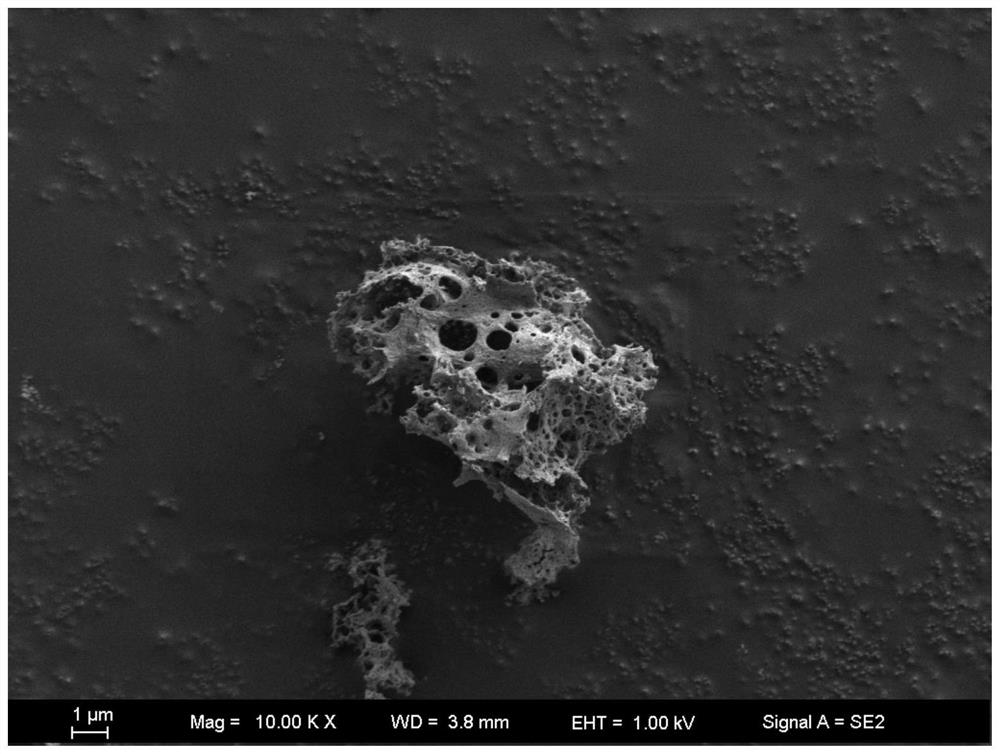

Polycrystalline diamond composite sheet and treatment method thereof

InactiveCN104594813AImprove stabilityExtended service lifeDrill bitsTurning toolsAlloy substratePolycrystalline diamond

The invention provides a polycrystalline diamond composite sheet and a treatment method thereof. The polycrystalline diamond composite sheet comprises a hard alloy substrate, a polycrystalline diamond layer and protection layers, wherein the polycrystalline diamond layer is compounded on the hard alloy substrate and comprises a layer without residual metal and a layer with the residual metal; the layer with the residual metal is located between the layer without the residual metal and the hard alloy substrate; the thickness of the polycrystalline diamond layer is 1.9mm-2.2mm; the thickness of the layer without the residual metal is 30-50 microns; the protection layers cover the bottom surface and all side faces of the hard alloy substrate, and part of the side face of the polycrystalline diamond layer. Compared with the prior art, the removing depth of the residual metal of the polycrystalline diamond layer of the polycrystalline diamond composite sheet provided by the invention is large and the hard alloy substrate is not corroded, so that the stability of the polycrystalline diamond composite sheet in a utilization process is improved and the service life is prolonged.

Owner:HENAN JINGRUI SUPERHARD MATERIAL

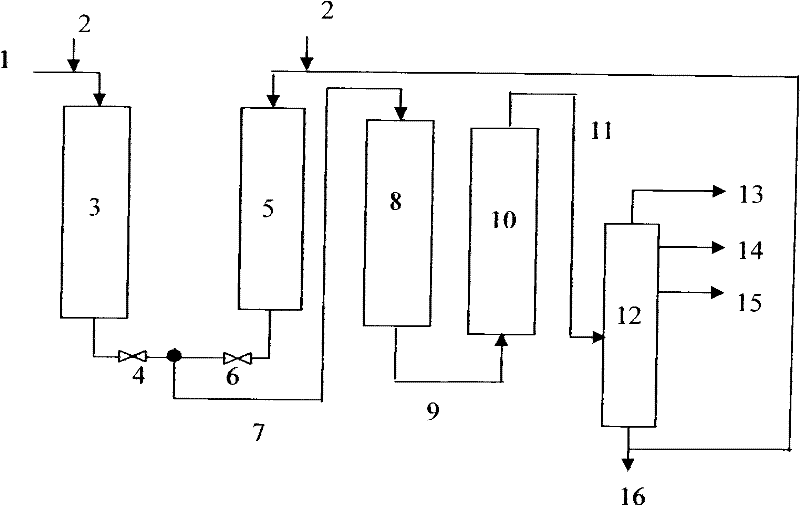

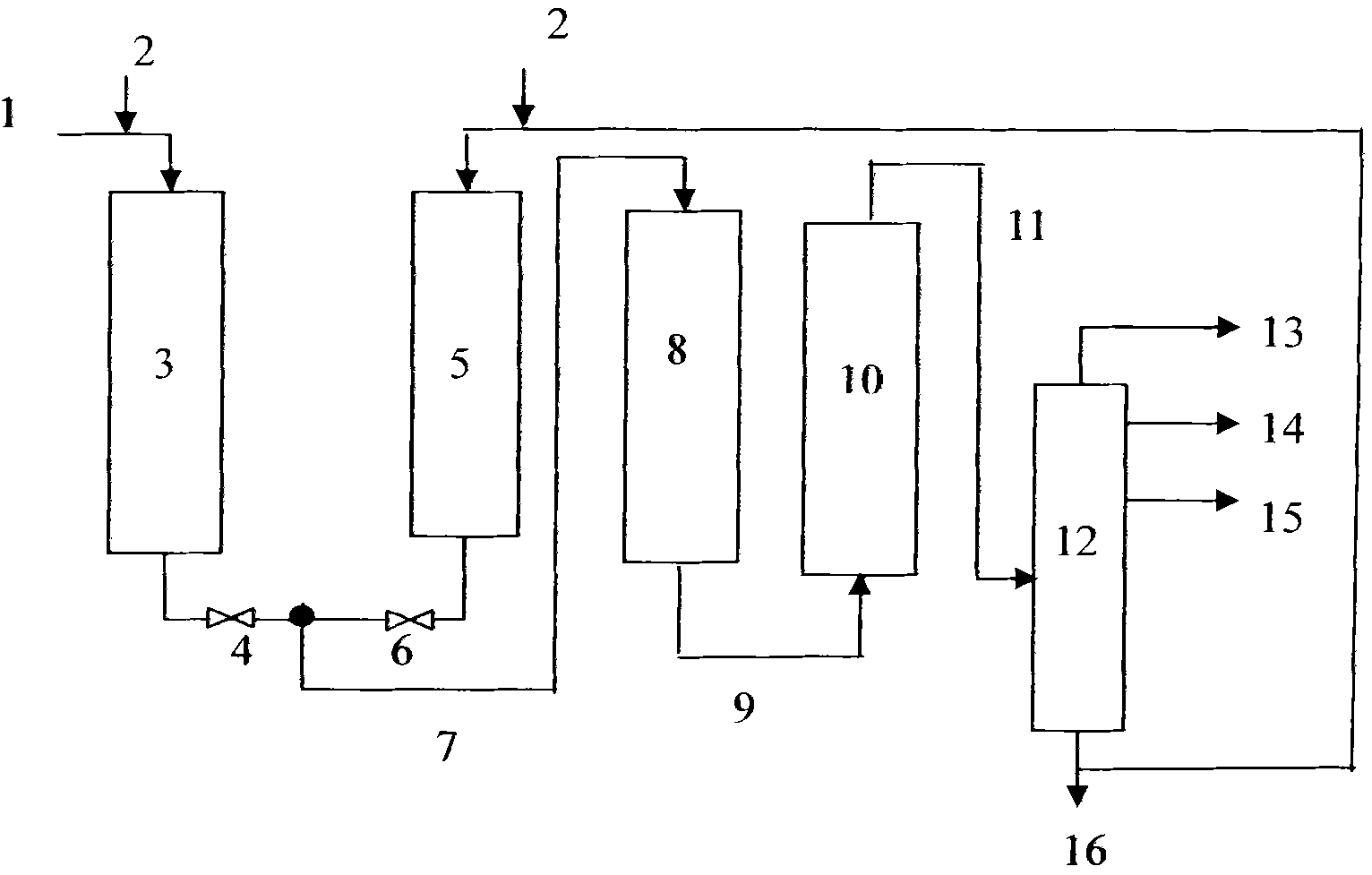

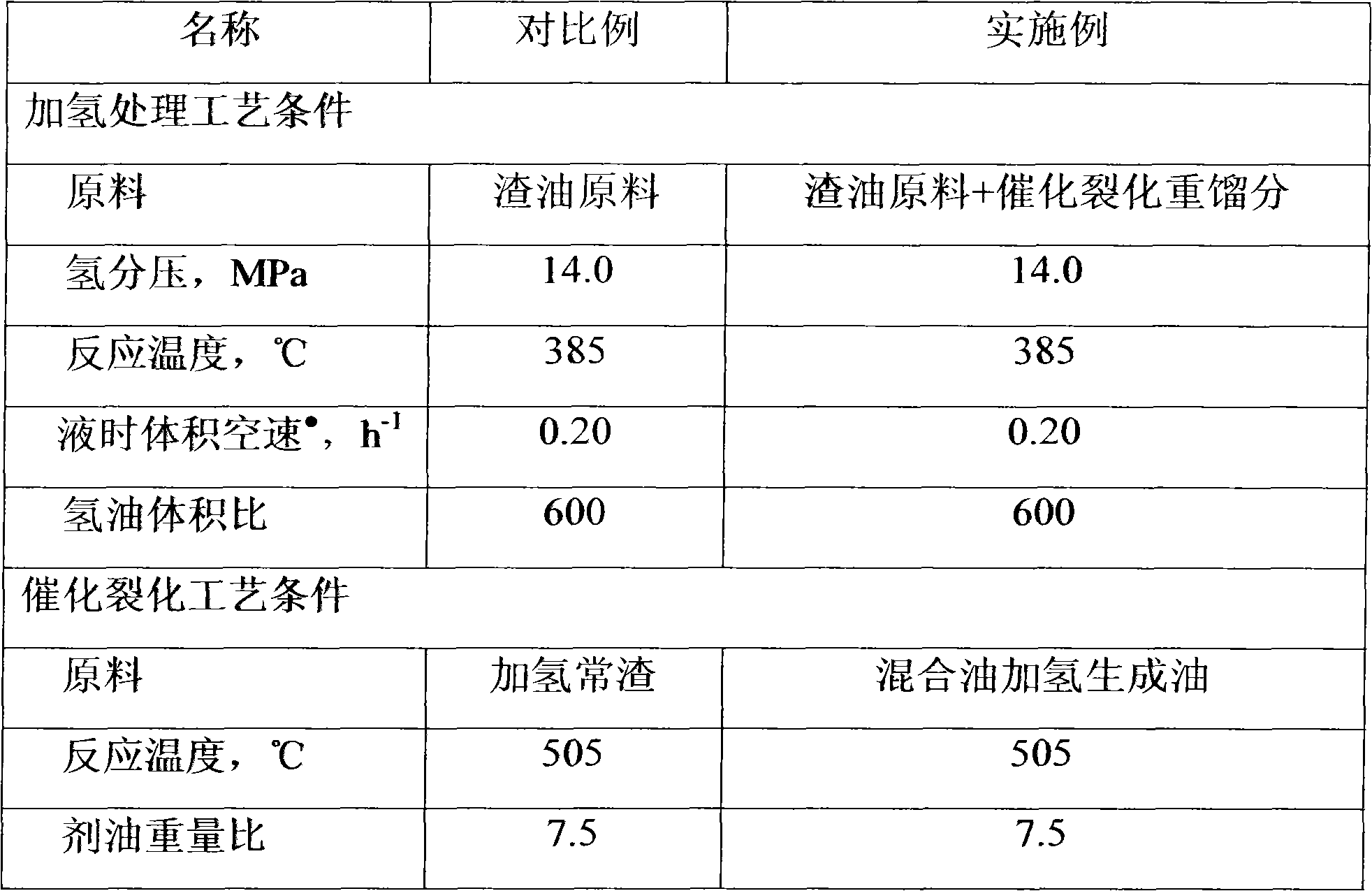

Residual oil hydrogenation treatment and catalytic cracking combination method

ActiveCN102453544AHigh aromatic contentLow cetane numberTreatment with hydrotreatment processesGas phaseFractionation

The present invention discloses a residual oil hydrogenation treatment and catalytic cracking combination method. According to the method, the residual oil hydrogenation treatment process comprises two hydrogenation protection reactors, wherein the two hydrogenation protection reactors are arranged in parallel connection, the feed material of the first hydrogenation protection reactor is the residual oil raw material, and the feed material of the second hydrogenation protection reactor is the catalytic cracking heavy fraction; the effluents of the two reactors are mixed, and the resulting mixture enters a hydrogenation treatment reaction zone to carry out a hydrogenation reaction; the effluent of the hydrogenation reaction is subjected to gas-liquid separation, wherein the resulting gas phase is circularly adopted for the hydrogenation reaction, and the liquid phase directly enters a catalytic cracking apparatus without fractionation; the effluent of the catalytic cracking reaction is separated to obtain dry gas, liquefied gas, catalytic cracking gasoline, and catalytic cracking heavy fraction after catalytic cracking of the gasoline, wherein the catalytic cracking heavy fraction is adopted as the feed material of the second hydrogenation protection reactor. With the method, the operating period of the residual oil hydrogenation apparatus can be prolonged, the maximum amount of the catalytic cracking gasoline can be produced, and the equipment investment can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

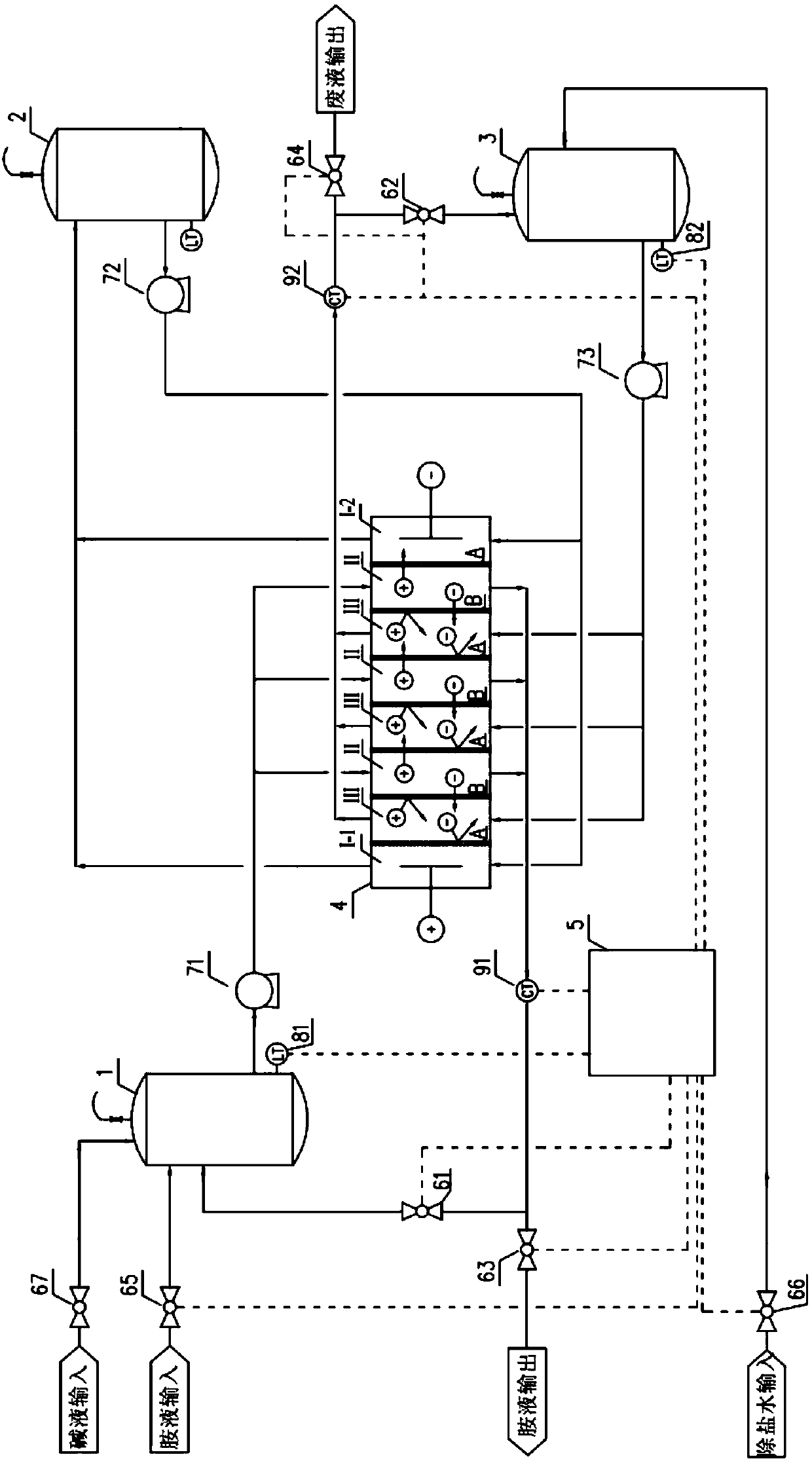

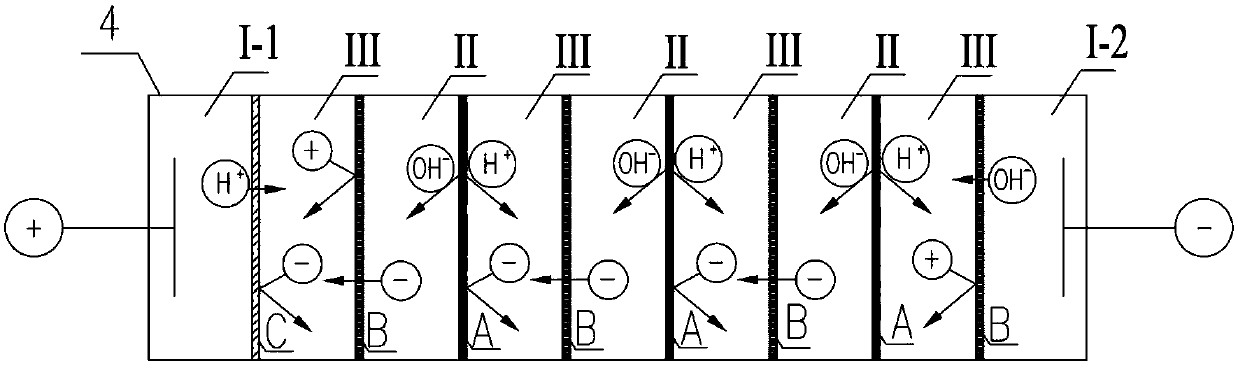

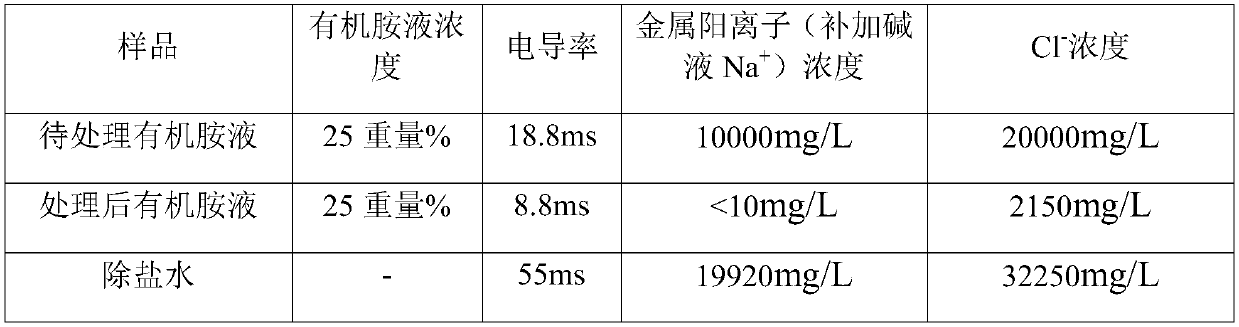

System for removing heat-stable salt in organic amine liquid and method

PendingCN110721553AEmission reductionEnhanced repeatable lifeGas treatmentGeneral water supply conservationEnvironmental engineeringLiquid circulation

The invention relates to the field of purification of organic amine liquid, and discloses a system for removing a heat-stable salt in organic amine liquid and a method for treating the organic amine liquid by adopting the system. The system comprises an organic amine liquid storage device, an electrode liquid storage device, a desalting water storage device and a membrane stack, wherein the membrane stack communicates with the organic amine liquid storage device, the electrode liquid storage device and the desalting water storage device separately, and an organic amine liquid circulation loop,an electrode liquid circulation loop and a desalting water circulation loop are formed separately, the system further comprises conductivity meters and a control center, and the control center is used for receiving conductivity signals from the conductivity meters, and for adjusting circulation flows of the organic amine liquid circulation loop and the desalting water circulation loop, reuse of the organic amine liquid and discharge of waste liquid according to the conductivity signals of the conductivity meters. When the organic amine liquid is treated by the system, anions and cations in the amine liquid can be removed synchronously, so that consumption of alkali liquid and discharge of the waste liquid are reduced.

Owner:BEIJING SIJIANTONG TECH&DEV

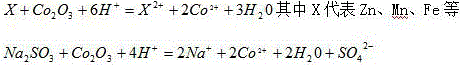

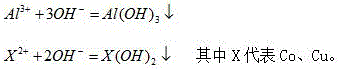

Production method comprehensively utilizing high-zinc cobalt raw materials

InactiveCN106755994AImprove extraction abilityHigh extraction selectivityProcess efficiency improvementAluminium hydroxideCobalt

The invention relates to a production method comprehensively utilizing high-zinc cobalt raw materials. The method comprises the following steps that firstly, the high-zinc cobalt raw materials are subjected to reduction leaching, soluble valuable metals such as zinc and cobalt enter a solution, and solid-liquid separation is conducted; secondly, after solid-liquid separation, the solution is subjected to deironing through a jarosite method, the PH value is adjusted to 4.7+ / -0.2 at the same time, aluminum in the solution is precipitated to be removed in an aluminum hydroxide mode, and solid-liquid separation is conducted; and thirdly, the solution enters a P507 extraction tank, 20%-30% of a P507 extraction agent is adopted, caustic soda liquid is added, the saponification rate is controlled to be 50-60%, Zn2+ in the solution is extracted into organic phases, the organic phases are washed through dilute sulfuric acid, other metal ions are co-extracted and washed down, then the organic phases are subjected to reverse extraction, the Zn2+ enters aqueous phases from the organic phases through reverse extraction by means of a dilute sulfuric acid solution, and a high-purity zinc sulfate solution is generated, concentrated and crystallized into zinc sulfate monohydrate crystals.

Owner:GEM JIANGSU COBALT IND CO LTD

Process for separating copper in nickel-cobalt-copper system by solvent extraction method

InactiveCN102234722AHigh recovery rateRealize separation and purificationProcess efficiency improvementHigh concentrationSulfonate

The invention provides a process for separating copper in a nickel-cobalt-copper system by a solvent extraction method. The process comprises the following steps: by taking N902-sulfonated kerosene as an extracting agent, controlling the volume ratio of an organic phase to a water phase at (3:1) to (4:1); regulating the pH value of a material liquid to 2.0-2.5; extracting at room temperature; and after carrying out clearing and phase separation on raffinate, based on sulfuric acid as a reverse extraction acid for the copper-supported organic phase, controlling the volume ratio of the organic phase to the reverse extraction acid at (6:1)-(4:1), carrying out reverse extraction at room temperature, and eluting a reverse extraction liquid to obtain a copper sulfate solution. In the process, the N902-sulfonated kerosene is used as the extracting agent, sulfuric acid is used as a reverse extraction agent, copper is separated out of the high-concentration nickel-cobalt-copper system in a high selectivity and high reverse extraction property mode, and copper is output in a pure copper sulfate solution form, thereby avoiding the retreatment and recovery of copper slag with a chemical method, and the recovery of copper is high; and after nickel-cobalt raffinate with copper removed is subjected to sodium jarosite iron removal, P204 deep impurity removal and P507 separation of nickel-cobalt, nickel-cobalt salt products are produced, thereby achieving the purification and separation of copper in a nickel-cobalt-copper impure material and the comprehensive recovery of nickel-cobalt-copper.

Owner:JINCHUAN GROUP LIMITED

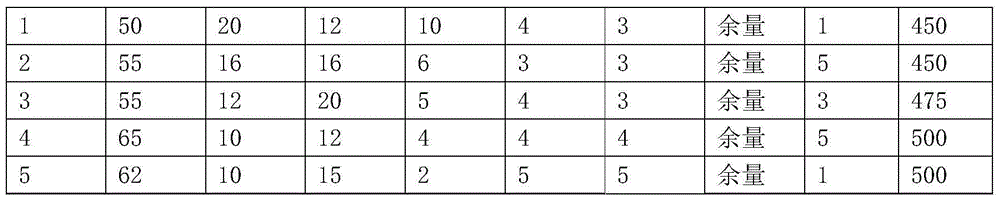

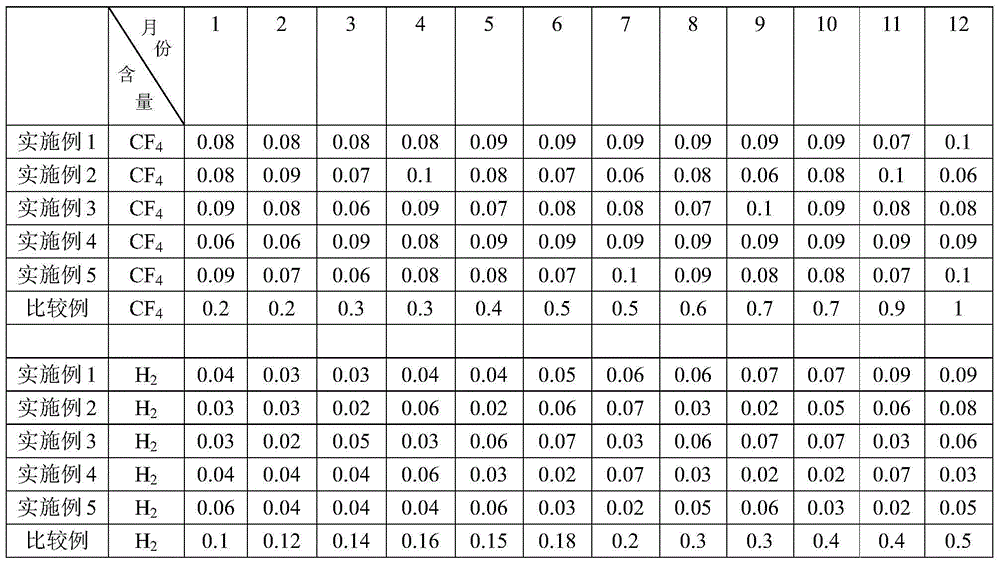

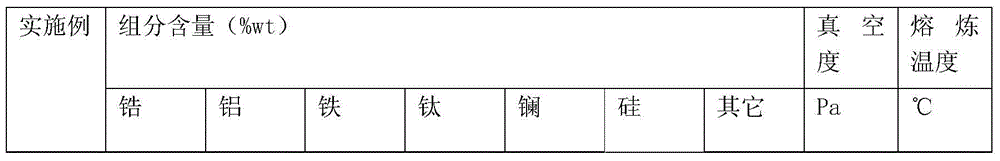

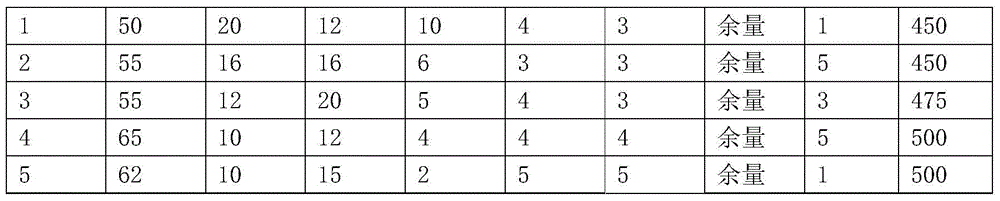

Getter for purifying krypton and xenon, and preparation method of getter

ActiveCN104307461AHigh removal depthLower reaction energy levelOther chemical processesNoble gas compoundsKryptonAlloy

The invention relates to a multi-element alloy getter for purifying krypton and xenon, and a preparation method of the getter, and the getter can be used for solving the problems that the existing getter is poorer in pertinence, insufficient in handling capacity, high in energy consumption, easy in pulverization and short in service life, and the like. The multi-element alloy getter comprises the following components: 50-65% of zirconium, 10-20% of aluminum, 5-10% of iron, 2-10% of titanium, 3-5% of lanthanum, 3-5% of silicon and the balance of unavoidable impurities. The method comprises the steps of pretreatment of alloy simple substances, alloy smelting and alloy crushing. The getter can meet the purity requirement of high-purity krypton and xenon (99.999%), is large in fluctuation ranges of anti-raw gas fluorocarbon and oxygen nitrogen compound, large in raw gas impurity adsorption capacity, high in raw gas impurity removal depth, wide in service temperature range (300-1000 DEG C) and long in service life, and is not pulverized.

Owner:WUHAN IRON & STEEL GRP GAS CO LTD +1

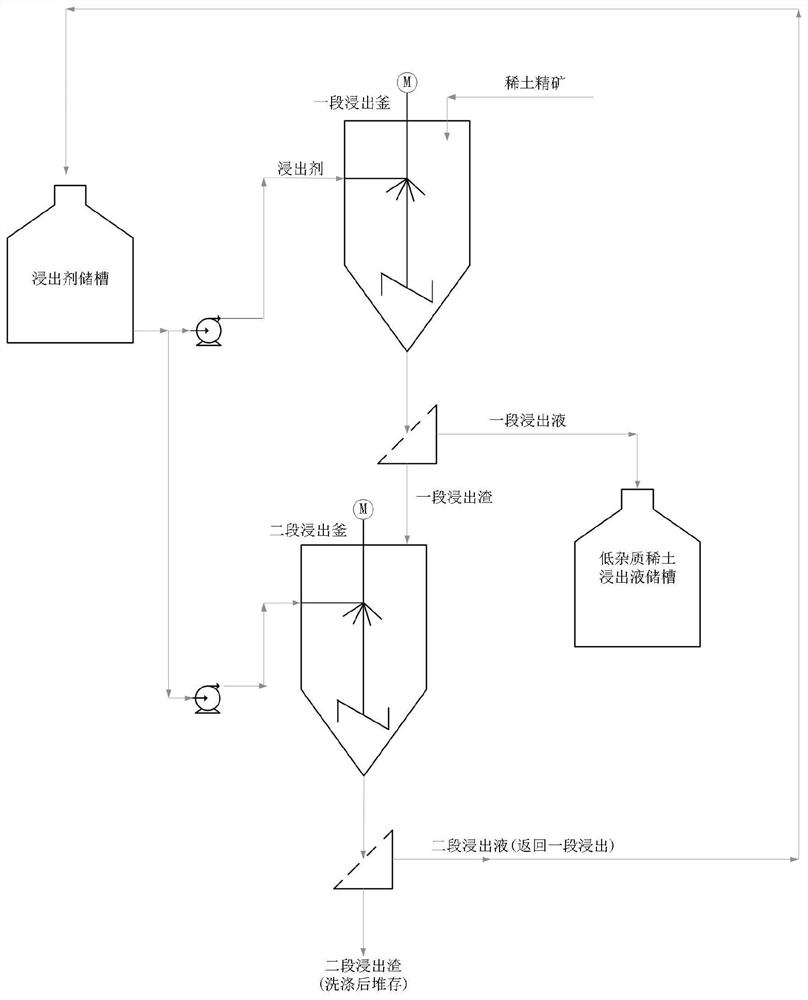

Leaching-purifying method for rare earth concentrate

ActiveCN113699389AIncreased solubility selectivityImprove separation characteristicsProcess efficiency improvementPregnant leach solutionNonferrous metal

The invention relates to a leaching-purifying method for rare earth concentrate, and belongs to the field of non-ferrous metallurgy. According to the method, a leaching process is adjusted, and a two-stage reverse feeding countercurrent process is adopted, namely, in first-stage leaching, rare earth concentrate slurry is used as a base solution, and a leaching agent is added into the base solution, so that low-impurity rare earth leaching liquid is obtained; in second-stage leaching, first-stage leaching residues serve as raw materials, after a certain number of seed crystals are added, a leaching agent hydrochloric acid is added into the first-stage leaching residues, so that the leaching residues low in rare earth content and an acid leaching solution high in impurity content are obtained, and the acid leaching solution is returned to the first-stage leaching for use; and by means of the leaching process, separation of impurities can be achieved, and rare earth resources can be fully utilized. The method has the advantages of being simple in process, low in cost, high in impurity removal rate, high in rare earth recovery rate and the like, and has good industrial application prospects.

Owner:JIANGXI UNIV OF SCI & TECH

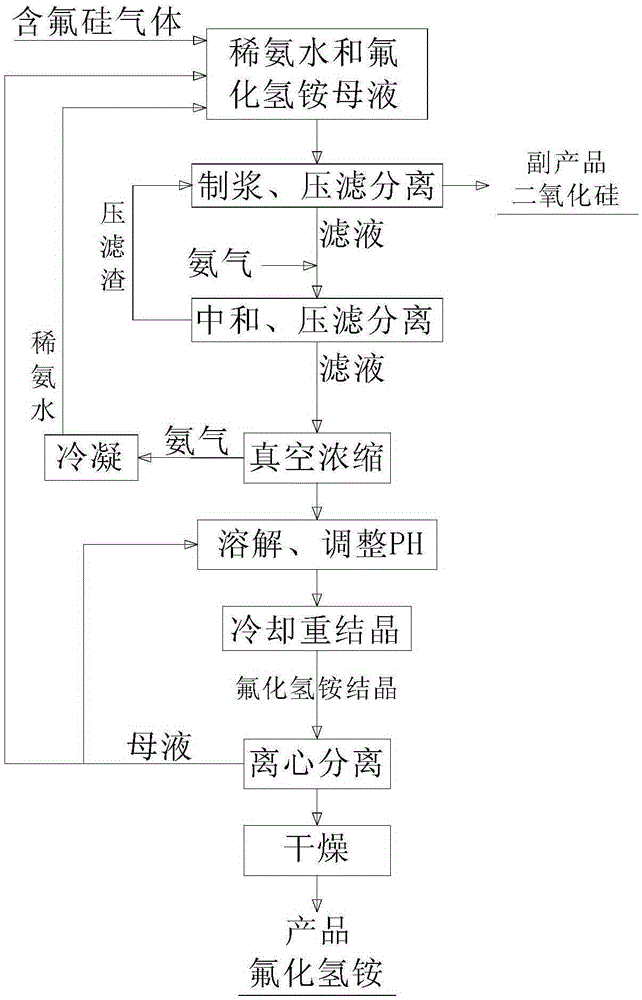

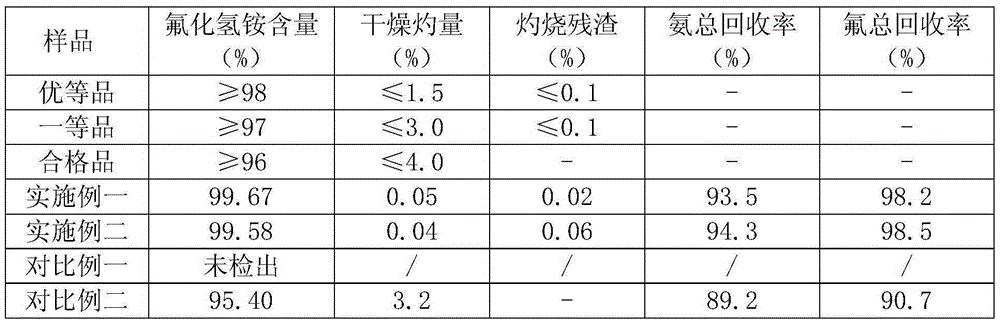

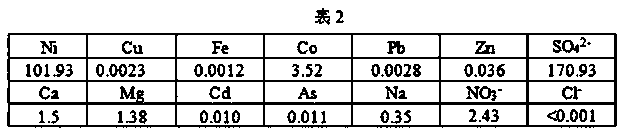

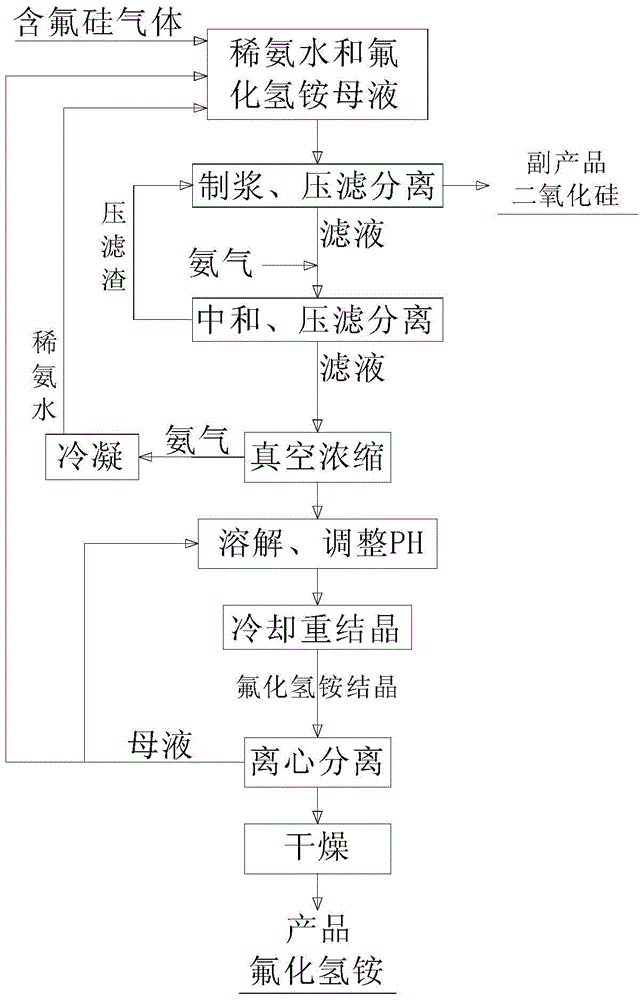

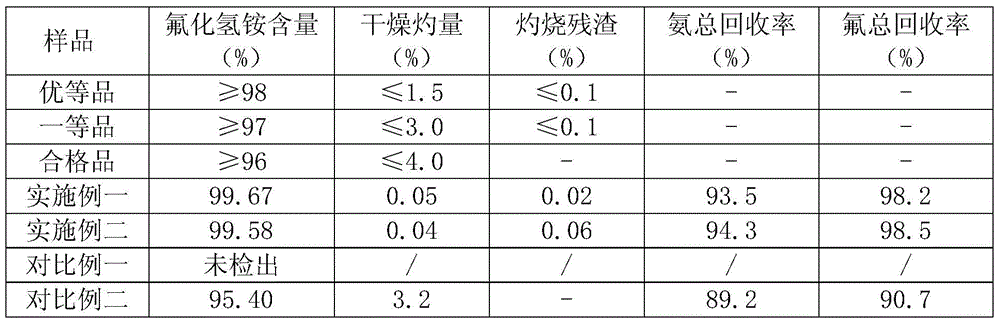

Preparation method of ammonium bifluoride

The invention discloses a preparation method of ammonium bifluoride. The method comprises steps as follows: a, dilute ammonia water and ammonium bifluoride mother liquor are mixed to adsorb gas containing fluorine and silicon, and a mixed solution is obtained; b, the mixed solution and filter-press residues obtained in Step d are mixed for slurry making and filter-press separation, and a filtrate and a silica by-product are obtained; c, ammonia is introduced into the filtrate; d, slurry is subjected to filter-press separation, and an ammonium fluoride filtrate and filter-press residues are obtained; e, the ammonium fluoride filtrate is subjected to vacuum concentration; f, concentrated slurry is dissolved, the pH value of the solution is adjusted with hydrogen fluoride, and cooling crystallization is performed; g, ammonium bifluoride crystals are filtered, separated and dried, and the ammonium bifluoride product is obtained. With the adoption of the method, the utilization rate of fluorine and ammonia is increased, the gas containing fluorine and silicon is changed into the ammonium bifluoride product with the high economic value in the phosphoric acid production process, the production cost is low, the economic benefit is significant, meanwhile, the purity and other indexes of the product meet the requirement for superior products, and the method is suitable to be popularized and applied in the field.

Owner:GUIZHOU CHANHEN CHEM CO LTD

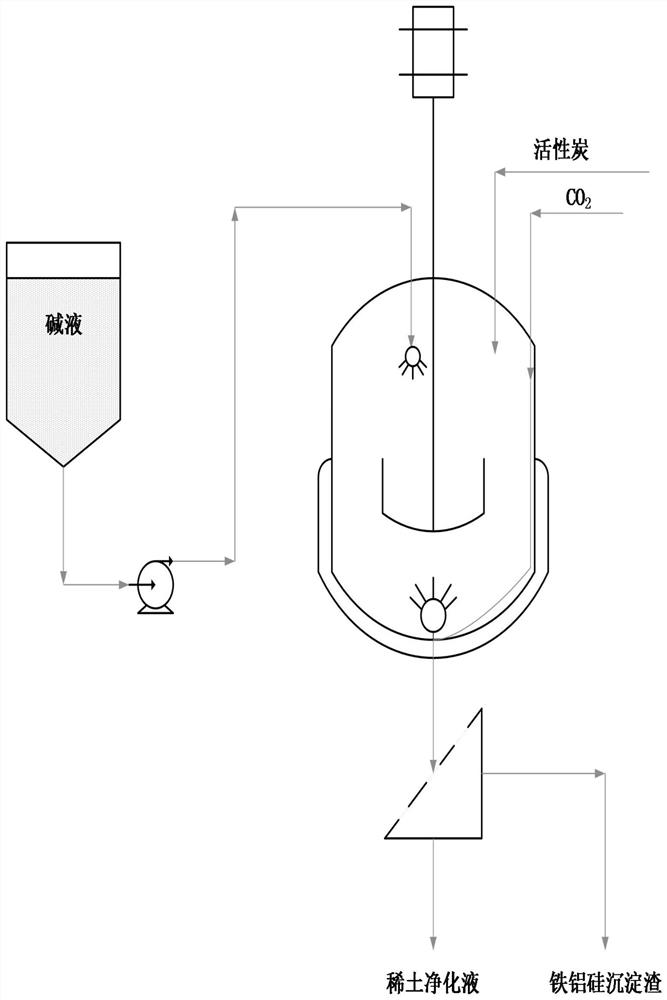

Impurity removal method for rare earth leaching solution

The invention belongs to the field of non-ferrous metallurgy, and relates to an impurity removal method for a rare earth leaching solution. The method comprises the following steps of under the condition of adding seed crystals, adding alkali liquor into the rare earth leaching solution by adopting an atomization charging mode, precipitating to remove iron, aluminum and silicon impurities, after the alkali liquor is completely added, blowing CO2, continuously reacting for a certain time, and filtering to obtain a rare earth leaching solution with low impurity content and impurity precipitation slag with low rear earth content. The method has the advantages of being simple in process, low in cost, high in impurity removal rate, good in precipitated slag filtering performance, low in slag rare earth content and the like, and has a good industrial application prospect.

Owner:JIANGXI UNIV OF SCI & TECH

Getter for krypton and xenon gas purification and preparation method thereof

ActiveCN104307461BHigh removal depthLarge fluctuation rangeOther chemical processesNoble gas compoundsKryptonAlloy

Owner:WUHAN IRON & STEEL GRP GAS CO LTD +1

Hydroxyquinoline filler as well as preparation method and application thereof

PendingCN114534694ASimple processFast removalIon-exchange process apparatusOther chemical processesMolecular sieveOrganic acid

The invention provides a chelating adsorption filler as well as a preparation method and application thereof. The filler is molecular sieve filler loaded with a hydroxyquinoline compound, and organic acid can be loaded on the molecular sieve loaded with the hydroxyquinoline compound. The filler can be used for effectively removing a residual catalyst in a polyolefin solution, has the advantages of high ash removal speed, large adsorption capacity and small pressure drop, and is suitable for removing the catalyst in a plurality of olefin solution polymerization processes.

Owner:WANHUA CHEM GRP CO LTD

Combined process of hydrotreatment and light fraction-conversion for residual oil

ActiveCN103102944BImprove the effect of hydrotreating reactionAct as a diluentTreatment with hydrotreatment processesFluidized bedFixed bed

The invention discloses a combined process of hydrotreatment and light fraction-conversion for residual oil. The combined process comprises the following steps: (1) allowing an inferior heavy oil feedstock to enter into a solvent deasphalting device so as to obtain deasphalted oil and de-oiled asphalt; (2) mixing the de-oiled asphalt obtained in step (1) with at least a part of oil slurry and allowing an obtained mixture to enter into a fluidized bed hydrotreatment unit for fluidized bed hydrotreatment; (3) mixing an effluent of fluidized bed hydrotreatment obtained in the step (2) with the deasphalted oil, adding at least a part of recycle oil of a catalytic cracking unit at the same time and allowing an obtained mixture to enter into a fixed bed hydrotreatment unit, wherein generated oil of an effluent of fixed bed hydrotreatment is used as a feedstock for the catalytic cracking unit; and (4) carrying out treatment in a fractionating tower of the catalytic cracking unit so as to obtain catalytic cracking reaction products including a gasoline fraction, a diesel oil fraction, recycle oil and oil slurry. Compared with the prior art, the combined process provided by the invention has the advantages of wide sources of the feedstocks, low equipment investment, stable operation, a long operation period and a good synergistic and coordination effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

C4 component selective hydrogenation catalyst and preparation method thereof

ActiveCN110124670ATaking into account the activityTake into account optionalityHydrocarbon purification/separationHydrocarbonsActive componentOrganic chemistry

The invention discloses a C4 component selective hydrogenation catalyst giving consideration to both the removal depth of butadiene and the yield of 1-butene, and a preparation method thereof. The C4component selective hydrogenation catalyst is composed of an active component, selective assistants and a support carrier, the active component is Pd, the selective assistants are Ru and Ag, and the support carrier is a mixture of gamma-Al2O3, CeO2-ZrO2 and attapulgite; and the Pd accounts for 0.05-1.5% of the mass of the support carrier, the selective assistants Ru and Ag respectively account for0.05-2% of the mass of the support carrier, and the support carrier comprises, by mass, 50-60% of the gamma-Al2O3, 30-40% of the CeO2-ZrO2 and 10-20% of the attapulgite.

Owner:大连华邦化学有限公司 +1

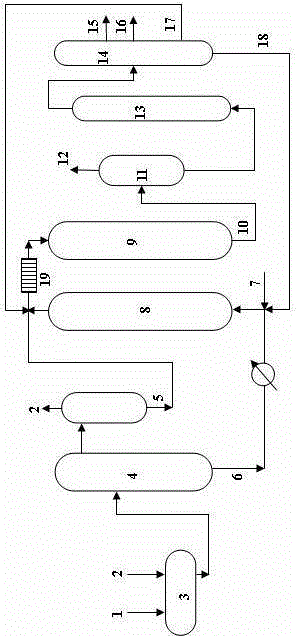

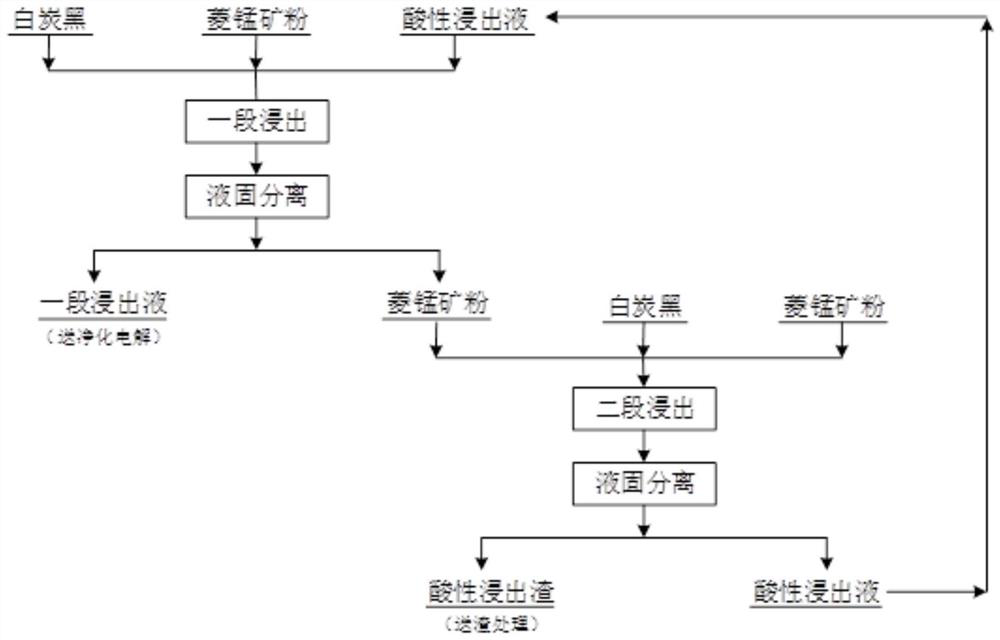

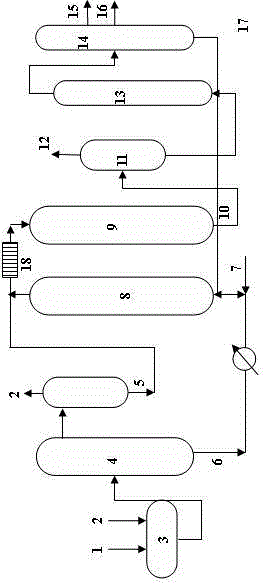

Green smelting method based on rhodochrosite leaching-purification

InactiveCN113737028ASimple processMature technologyPhotography auxillary processesProcess efficiency improvementPregnant leach solutionEnvironmental engineering

The invention belongs to the field of manganese metallurgy, and particularly discloses a green smelting method based on rhodochrosite leaching-purification. The method adopts a two-stage reverse feeding countercurrent leaching process, namely in the first-stage leaching process, rhodochrosite slurry is used as a base solution, anolyte, sulfuric acid solution or acid leaching solution is added into the base solution, the terminal pH is controlled to be greater than or equal to 4.5, and the manganese leachate with low impurity content can be obtained; in the second-stage leaching process, first-stage leaching residues serve as raw materials, anolyte or sulfuric acid solution is added into the first-stage leaching residues, the terminal pH is controlled to be smaller than or equal to 1.5, so that manganese in the first-stage leaching residues is thoroughly extracted, second-stage leaching residues low in manganese content and acid leaching liquid are obtained, the acid leaching liquid is returned to the first-stage to be used for leaching, and the second-stage leaching residues are washed and then sent to a residue field to be piled up or serve as mine filling materials; and through the leaching process, the separation of impurities can be realized, the manganese resource can be fully utilized, and the consumption of acid and alkali is reduced. The method has the advantages of simple process, low cost, high manganese recovery rate, low auxiliary material consumption and the like, and has a good industrial application prospect.

Owner:AKETAO KEBANG MANGANESE IND MFG CO LTD +1

Residual oil conversion combined process method

ActiveCN103102982BRealize comprehensive utilizationGuarantee normal productionTreatment with hydrotreatment processesFluidized bedFixed bed

Owner:CHINA PETROLEUM & CHEM CORP +1

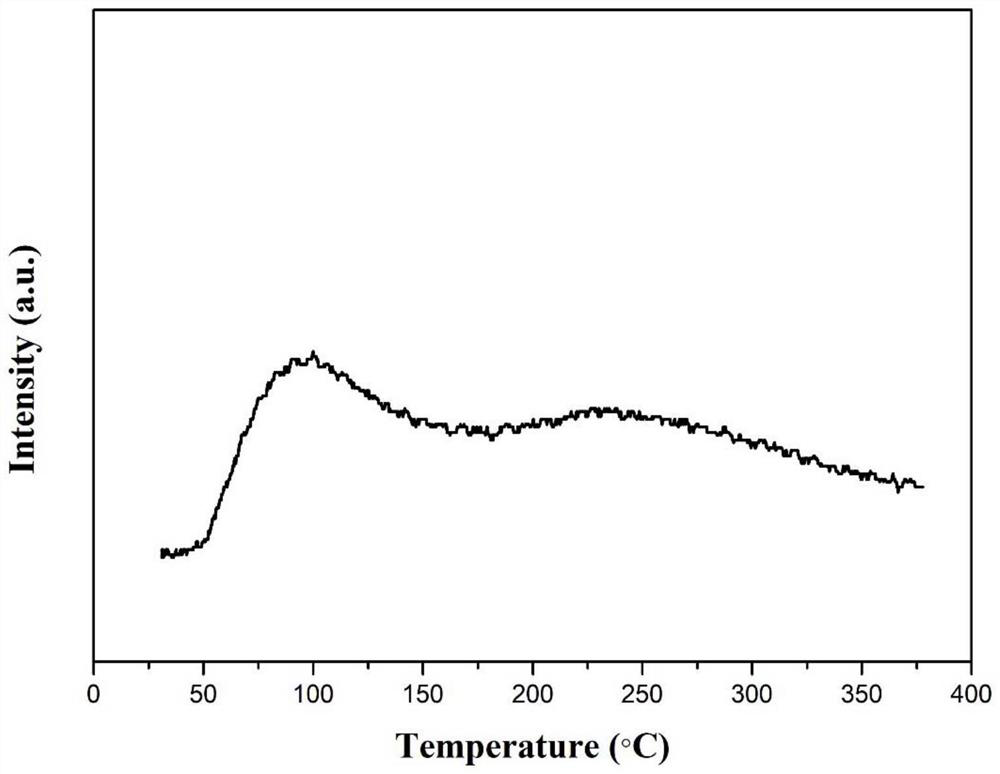

Catalyst for purifying CO in hydrogen-rich gas as well as preparation method and application of catalyst

ActiveCN114042457ALarge specific surface areaEnhanced mass transferGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention relates to a catalyst for purifying CO in hydrogen-rich gas as well as a preparation method and application of the catalyst. The preparation method of the catalyst comprises the following steps: pretreating a pore-expanding base material; preparing a copper salt precursor, a cerium salt precursor, a metal M salt precursor with tetravalence and sepiolite powder to prepare slurry; infiltrating the pretreated pore-expanding base material by using the slurry; and drying the pore-expanding base material infiltrated with the slurry, and then roasting to obtain the CO purification catalyst in the hydrogen-rich gas. Compared with the prior art, in the preparation process of the catalyst, the pore-expanding base material participates, the preparation raw materials are low in price and easy to obtain, and the catalyst has mesh-shaped morphology, multi-level pore channels, high CO trapping capacity, low selective oxidation reaction temperature of CO in hydrogen-rich gas, high removal depth and relatively high moisture resistance.

Owner:SHANGHAI RES INST OF CHEM IND

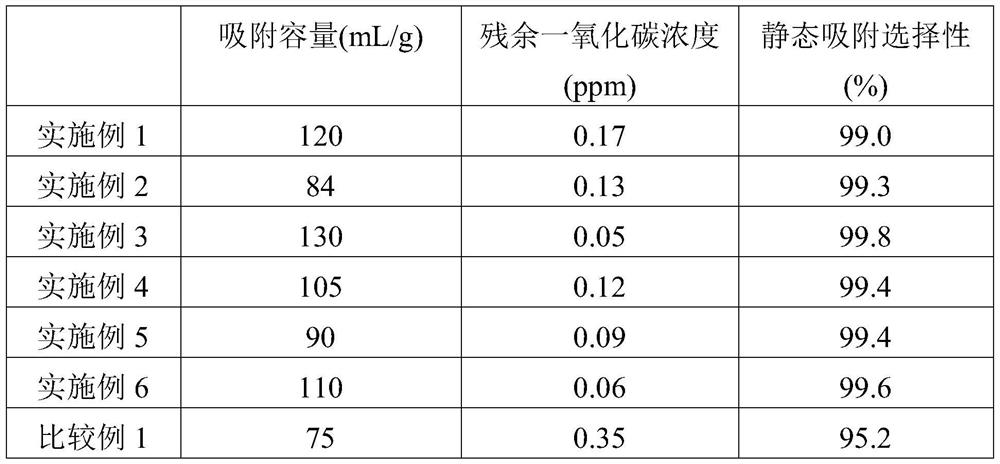

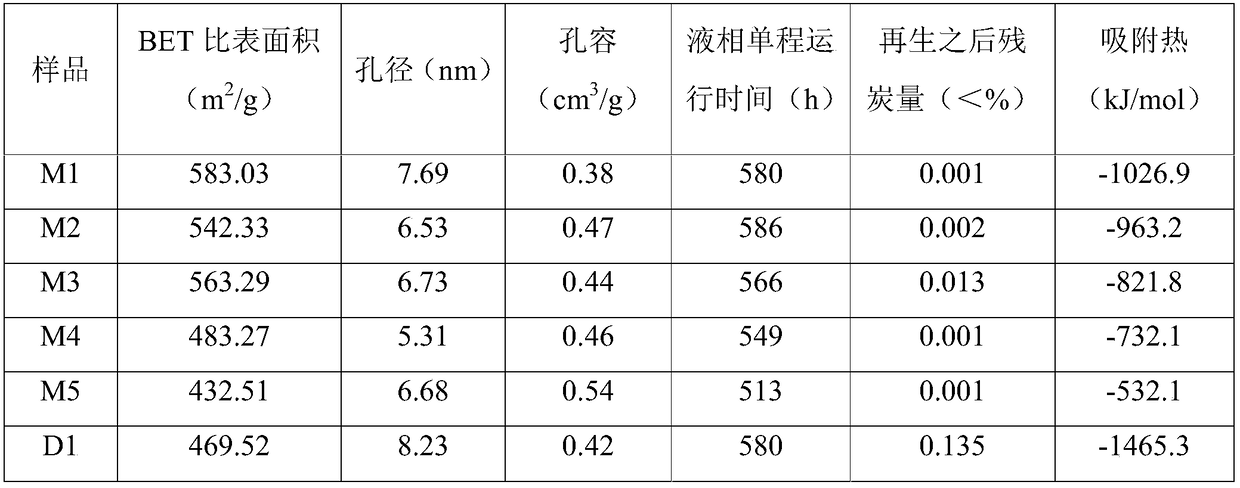

Adsorbent for deeply removing carbon monoxide in hydrogen, preparation method of adsorbent and method for removing carbon monoxide in hydrogen by adopting adsorbent

PendingCN113351159AHigh adsorption selectivityImprove adsorption capacityGas treatmentOther chemical processesActivated carbonActive carbon

An adsorbent for deeply removing trace carbon monoxide in hydrogen comprises an active component and a high-specific-surface-area active carbon carrier loading the active component, and the active component is a monovalent copper or bivalent copper compound. The preparation method comprises the following steps of: (1) dissolving an active component precursor in water, and fully stirring to obtain a precursor solution; (2) dispersing and impregnating an activated carbon carrier with a high specific surface area by using the obtained precursor solution; (3) integrally drying the impregnated carrier and the precursor solution at the temperature of 40-100 DEG C; and (4) sintering the dried carrier in an inert atmosphere at the temperature of 150-300 DEG C for 3-6 hours to obtain the adsorbent. The adsorbent is uniform in active component dispersion, high in removal depth, high in selectivity, large in capacity, low in activation temperature, easy to regenerate and suitable for deeply removing carbon monoxide in hydrogen fuel of a fuel cell. The preparation method is simple in process, low in cost, free of active component loss in the preparation process and easy to industrially amplify.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrogenation treatment and catalytic cracking combination method

ActiveCN102453544BHigh aromatic contentLow cetane numberTreatment with hydrotreatment processesGas phaseFractionation

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon four-component selective hydrogenation catalyst and preparation method

ActiveCN110124670BHigh removal depthHigh yieldHydrocarbon purification/separationHydrocarbonsButeneButadiene Dioxide

The invention discloses a carbon four-component selective hydrogenation catalyst and a preparation method taking into account the depth of butadiene removal and the yield of 1-butene. The carbon four-component selective hydrogenation catalyst consists of active components, selectivity The active component is Pd, the selective additives are Ru and Ag, and the support carrier is γAl 2 o 3 , CeO 2 -ZrO 2 and attapulgite; the Pd is 0.05% to 1.5% of the mass of the support carrier, the selective additives Ru and Ag are respectively 0.05 to 2% of the mass of the support carrier, and the γAl in the support carrier 2 o 3 , CeO 2 -ZrO 2 , The quality of attapulgite is 50~60%, 30~40%, 10~20% respectively.

Owner:大连华邦化学有限公司 +1

Method for capturing carbon dioxide from flue gas

ActiveCN114669163AReduce energy consumptionEasy desorption and regenerationGas treatmentOther chemical processesFlue gasSorbent

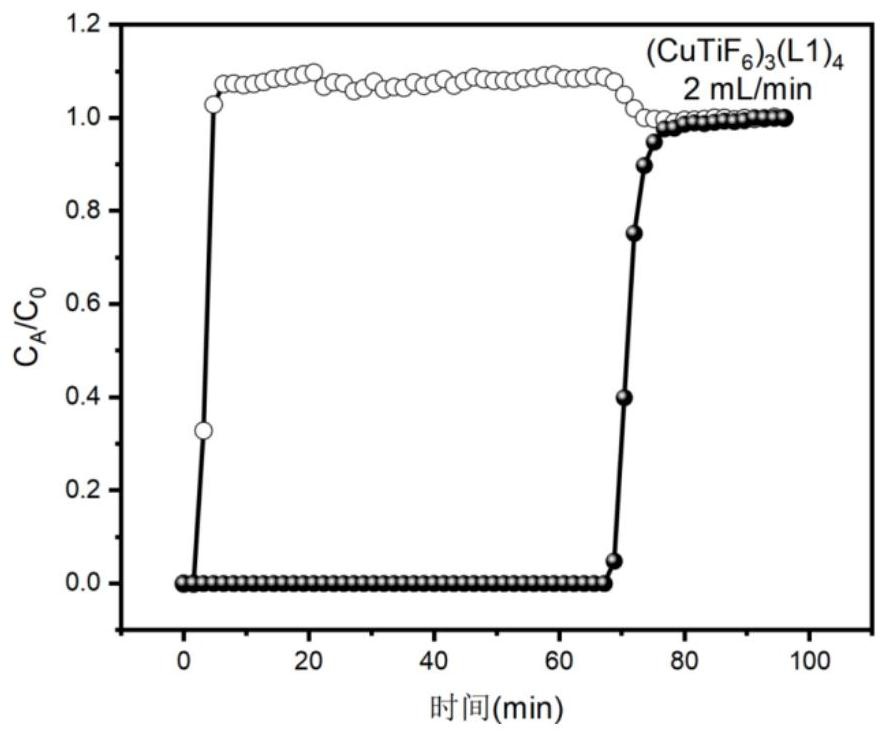

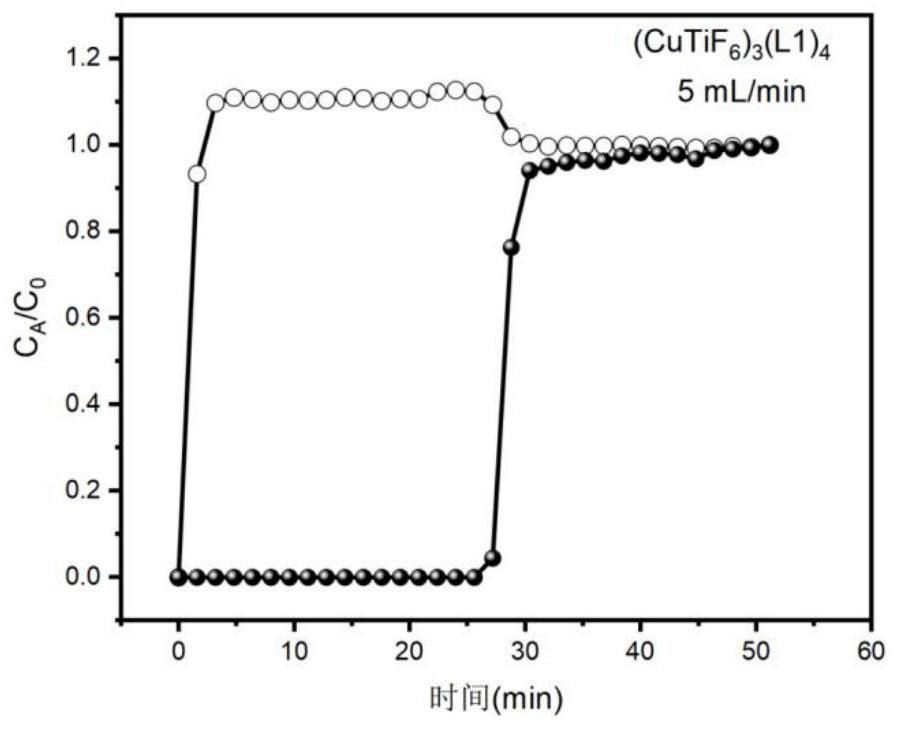

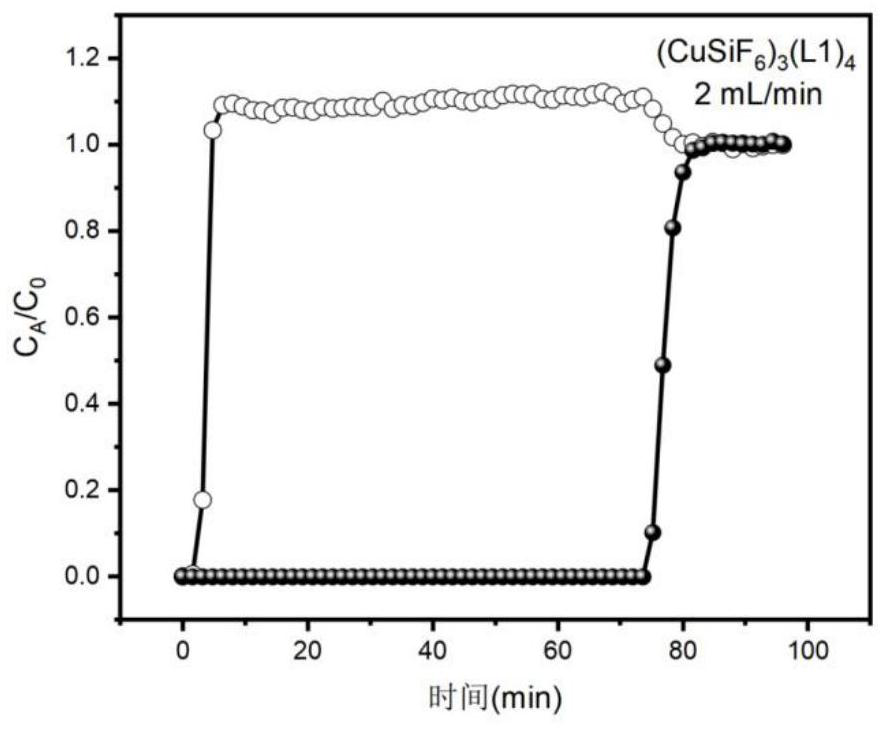

The invention discloses a method for capturing carbon dioxide from flue gas, which comprises the following step of: selectively adsorbing carbon dioxide in the flue gas by using an anion-containing hydrothermal stable column cage type metal-organic framework material as an adsorbent. The structure of the anion-containing hydrothermal stable column cage type metal-organic framework material is that hexa-coordinated metal ions M and a tridentate nitrogen-containing ligand L are coordinated to form a cage type structure, and then the cage type structure is connected through inorganic anions A to form a cross-linked column cage type structure. According to the method provided by the invention, carbon dioxide can be captured from the flue gas in a high-capacity and high-selectivity manner, the removal depth is high, the adsorbent is easy to regenerate, and the hydrothermal stability is good.

Owner:ZHEJIANG NORMAL UNIVERSITY

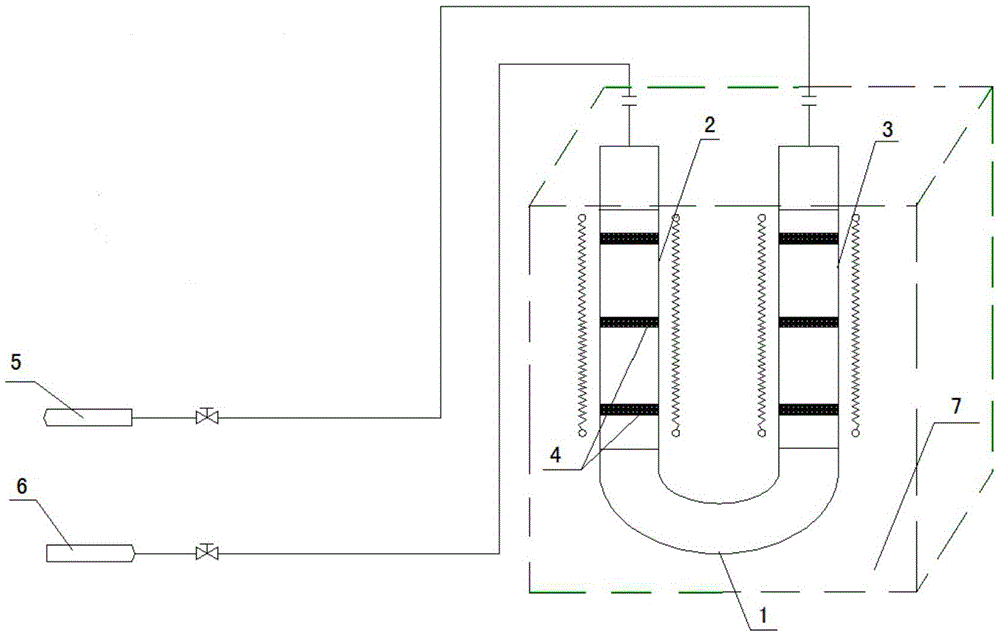

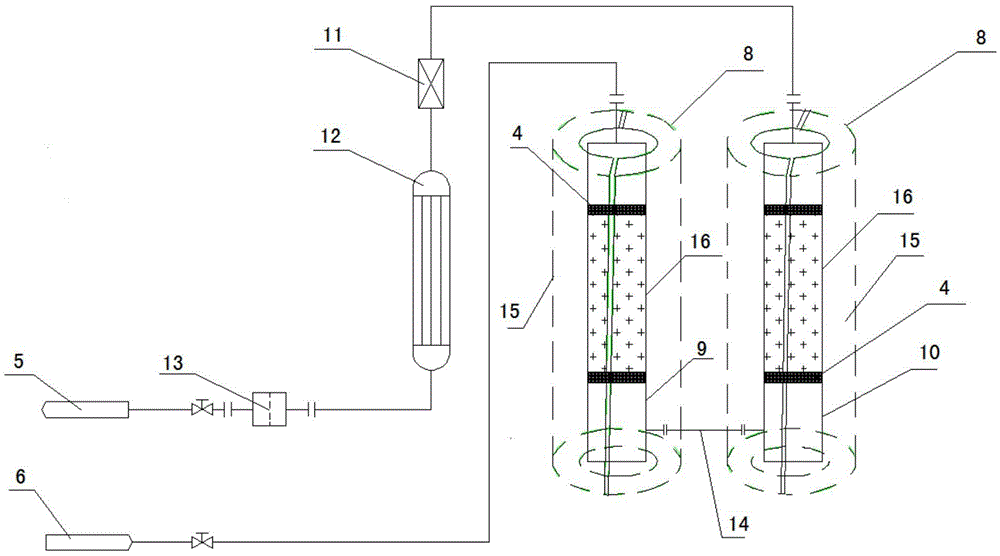

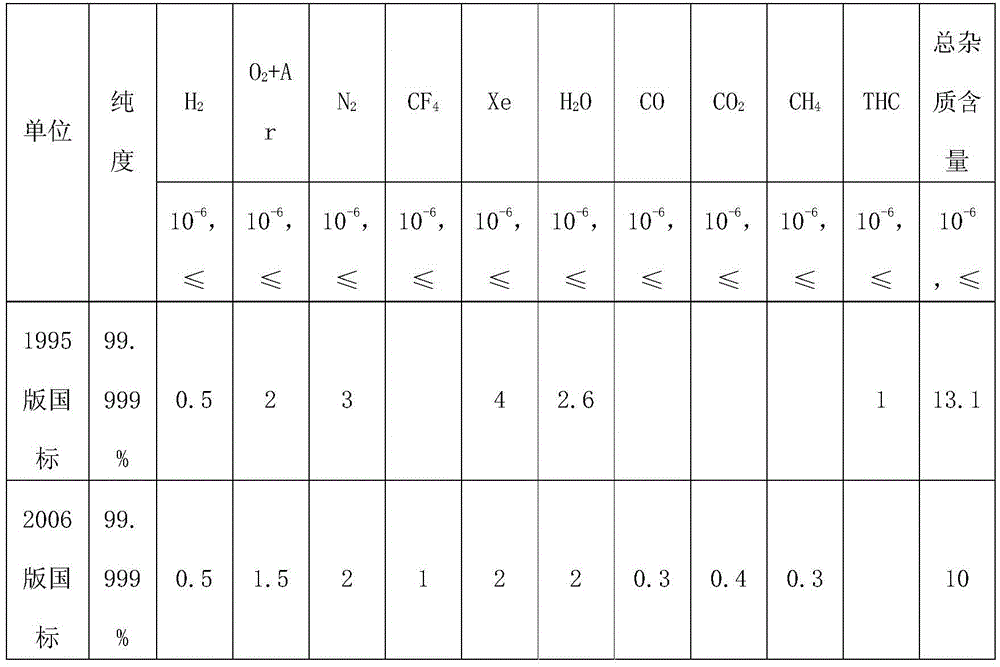

Krypton, xenon gas purification method and device

ActiveCN104310325BEasy to operateImprove performanceOther chemical processesNoble gas compoundsKryptonPurification methods

The invention discloses a krypton-xenon gas purification method and device. The problems that gas production indexes of existing krypton-xenon gas purification cannot reach the standard, the equipment is short in service life and is inconvenient to overhaul and the like are solved. According to the technical scheme, the krypton-xenon gas purification device comprises a first-stage reaction tube and a second-stage reaction tube, which are connected in series, wherein the first-stage reaction tube and the second-stage reaction tube are arranged in a heater; and the outlet of the second-stage reaction tube is sequentially connected with a hydrogen adsorber, a cooler and a precise filter. The krypton-xenon gas purification device is simple in structure, easy to dismantle, low in loss, simple and convenient to maintain, and low in operation cost; the gas purification meets the 2006-edition new national standards of krypton and xenon; the system is stable; and the equipment is long in service life.

Owner:WUHAN IRON & STEEL GRP GAS CO LTD +1

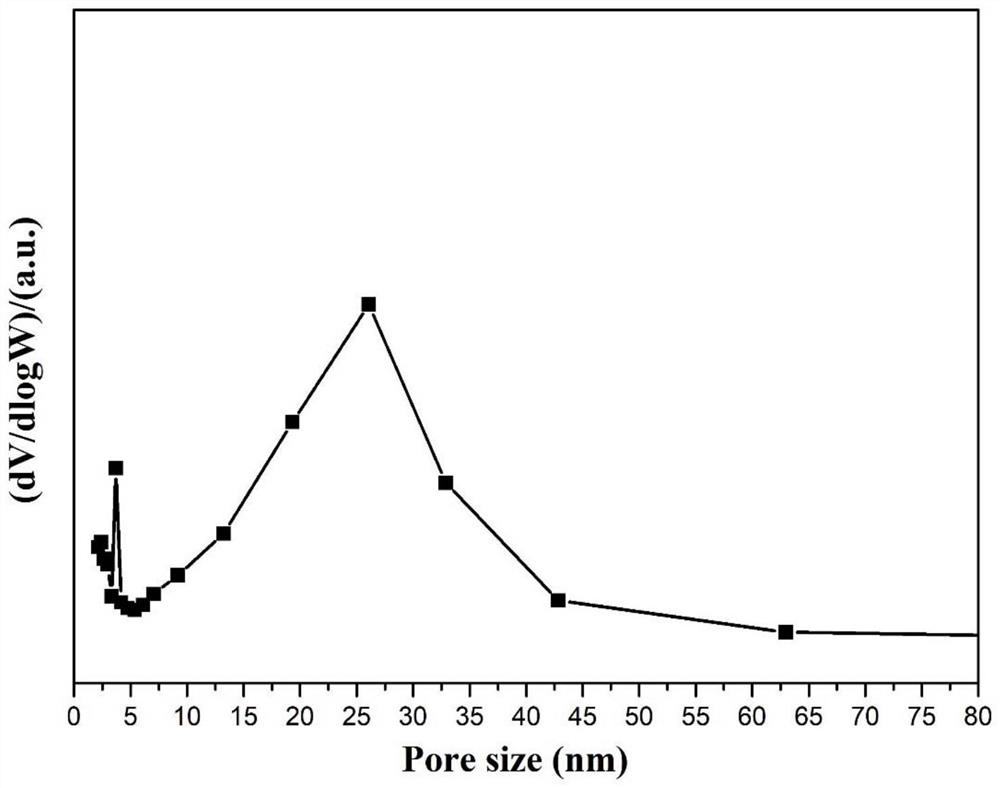

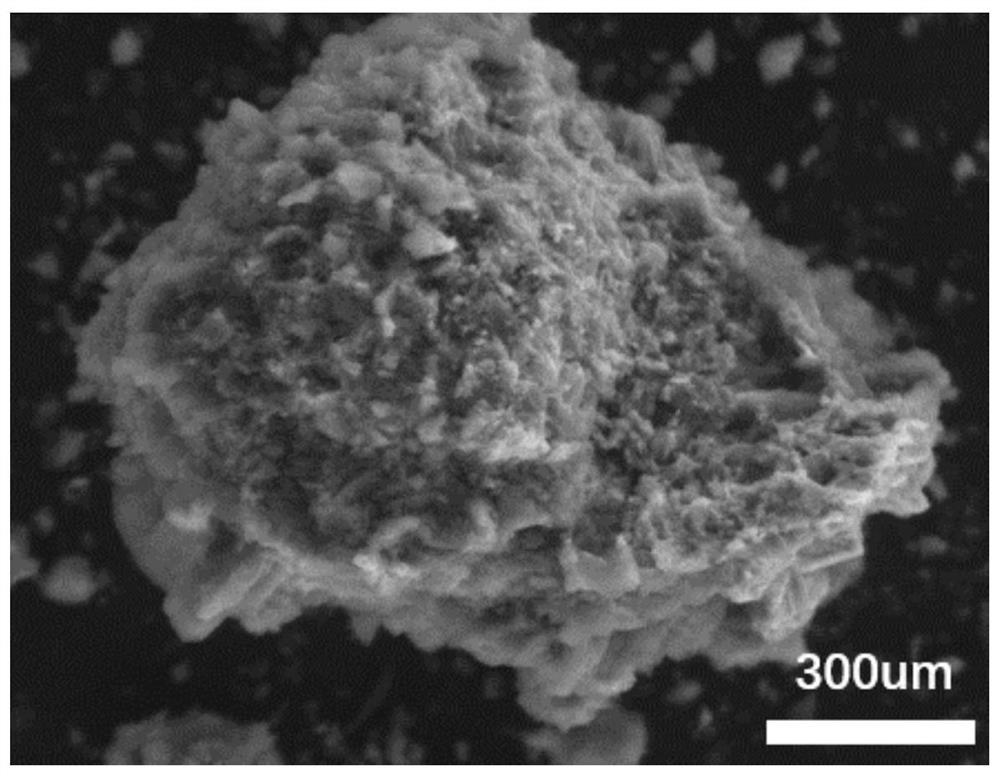

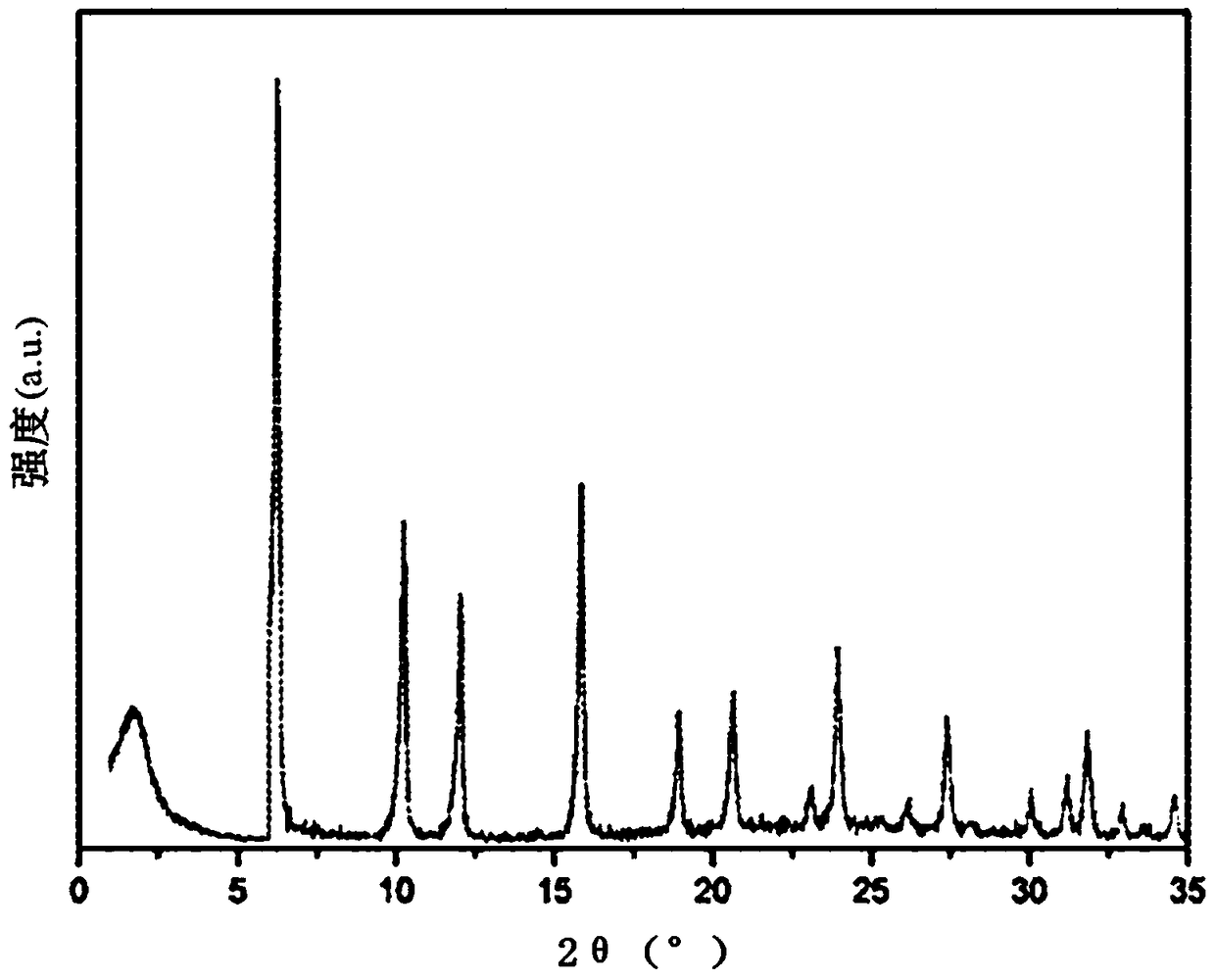

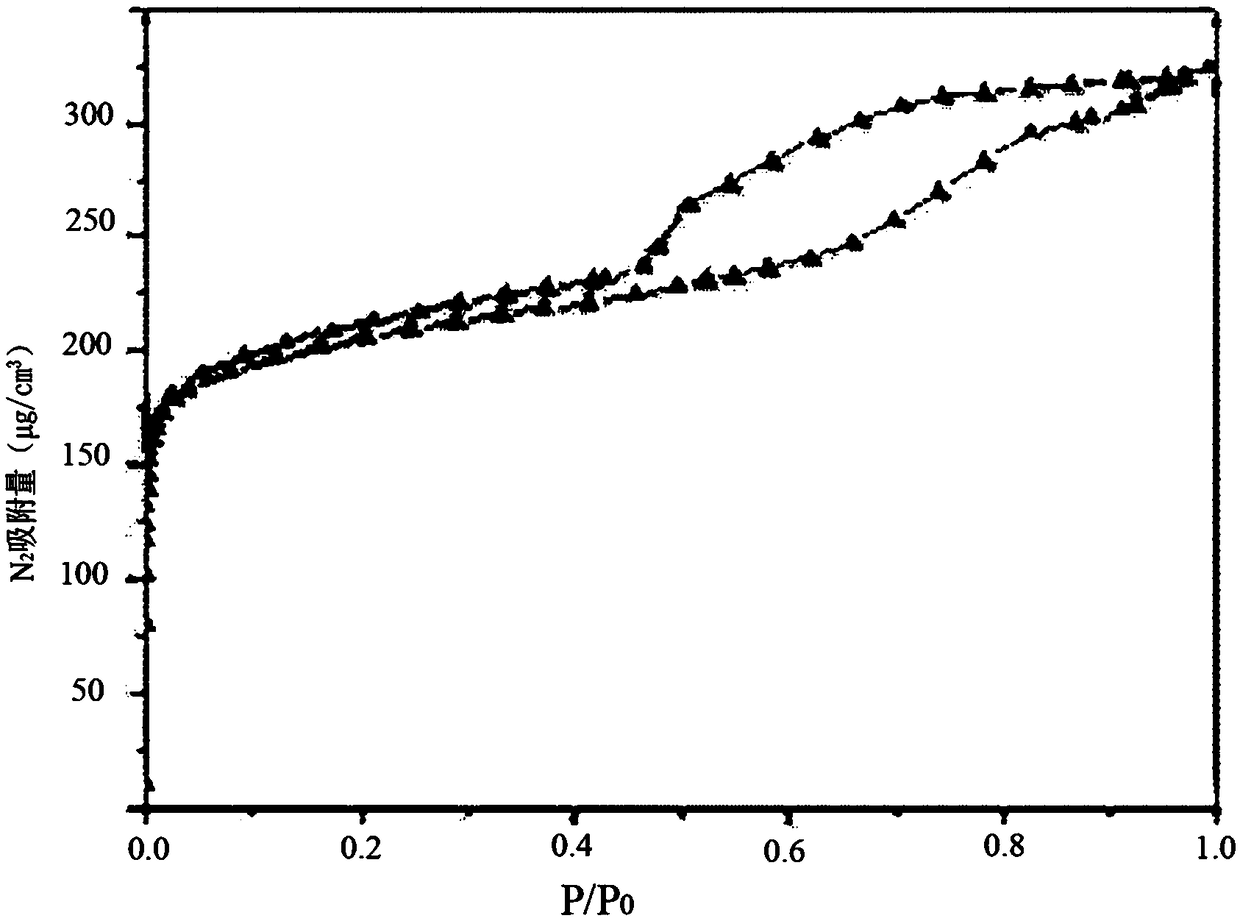

Renewable microporous-mesoporous composite adsorbent and its preparation method and application

ActiveCN106512926BMeet the requirements of deep purificationFast synthesis rateOther chemical processesEthylene productionSorbentImpurity

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Building internal wall waterproof formaldehyde-removing coating applied to indoor environment as well as manufacturing method thereof

InactiveCN109233637AImprove wear resistanceImprove breathabilityLignin material coatingsPectinaseBacillus thuringiensis

The invention discloses a building internal wall waterproof formaldehyde-removing coating applied to an indoor environment as well as a manufacturing method thereof. The waterproof formaldehyde-removing coating comprises three parts, namely a component A, a component B and a component C, wherein the component A is prepared by putting sawdust and green straws under the comprehensive action of cellulase, pectinase and diluted hydrochloric acid to obtain a viscous solution, performing high-temperature sterilization, performing neutralizing treatment by using alkali in an amount which is smaller than that of acid and finally implanting bacillus thuringiensis to cultivate; the component B is obtained by suspending an activated carbon micropowder, a 1000-mesh ash calcium powder and a 1000-mesh triple superphosphate powder into absolute ethanol; and the component C is formed by performing enzymolysis and alcohol washing on the sawdust and the green straws and dehydrating the remaining by using the cellulose taking lignin as a main material. The building internal wall waterproof formaldehyde-removing coating has a spontaneous respiration like property, a durable formaldehyde-removing effect and high removing depth, is green, pollution-free and water-resistant, and can consume water.

Owner:山东天汇防水股份有限公司

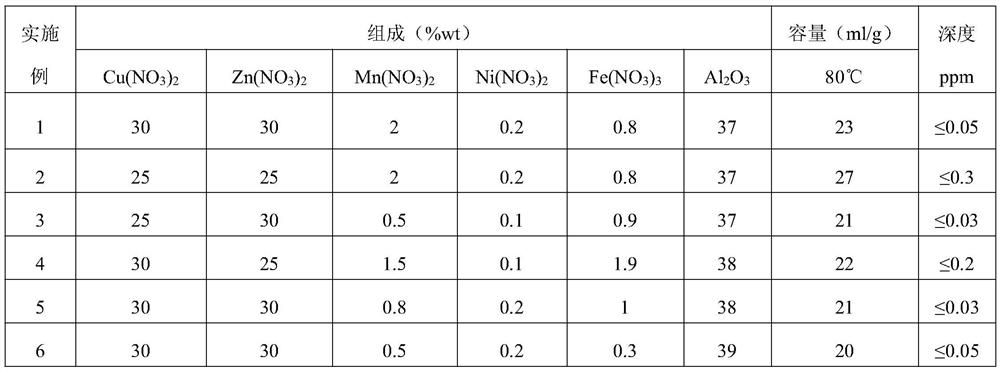

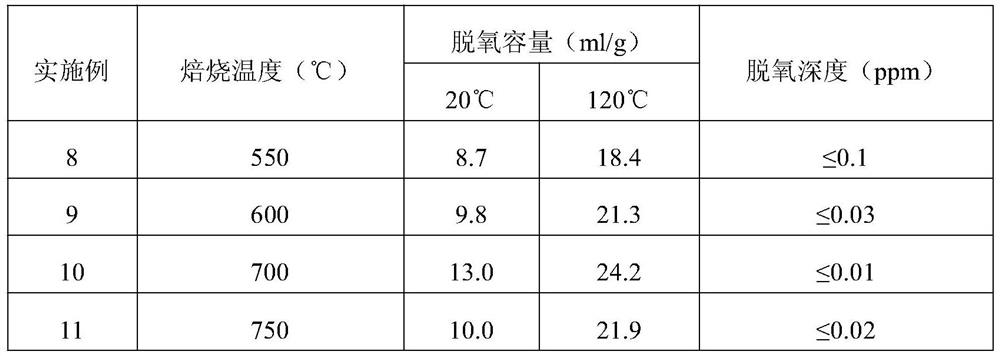

Multivariate highly active component carbon monoxide adsorbent and its preparation method and application

ActiveCN106984259BHigh removal depthHigh mechanical strengthGas treatmentOther chemical processesPtru catalystPhysical chemistry

The invention relates to a multi-element high-activity component carbon monoxide adsorbent as well as a preparation method and application thereof. The multi-element high-activity component carbon monoxide adsorbent is mainly prepared by an active component co-precipitation method; an active component comprises high-valence oxide of Cu, Zn, Mn, Ni and Fe: CuO, ZnO, MnOx, NiO and FeOy as well as dispersing agent Al2O3 powder. The multi-element high-activity component carbon monoxide adsorbent as well as the preparation method and application thereof have the benefits that by utilizing the characteristic of complementary performances of different components, the multiple components reach high-valence states through oxidation, and further, the ability to remove carbon monoxide by chemical adsorption is realized; the effect of a catalyst of the multi-element high-activity component carbon monoxide adsorbent is superior to that of a single or two-component catalyst; the multi-element high-activity component carbon monoxide adsorbent has the advantages of being free from loss of effective component of feed gas, high in removal depth, large in capacity, low in activation temperature, strong in anti-sintering ability, long in service life, high in mechanical strength, hard to pulverize and the like, is suitable for C2H4, C3H6, CH4, H2, N2, He, Ne, Ar, Kr, Xe and deep removal of the carbon monoxide by electron gas, and can be widely applied to large-scale industrial production.

Owner:大连圣得环保新材料有限公司

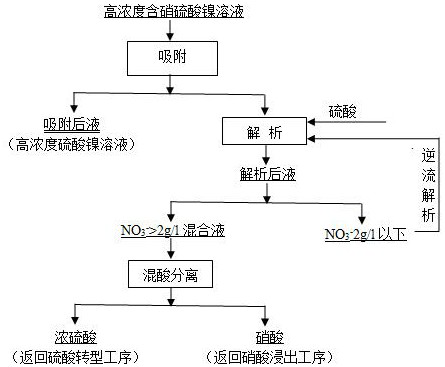

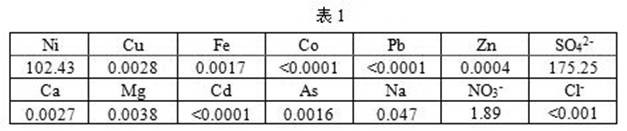

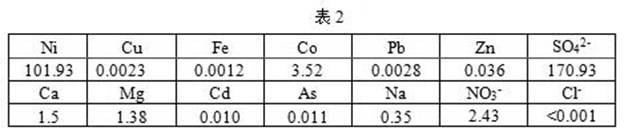

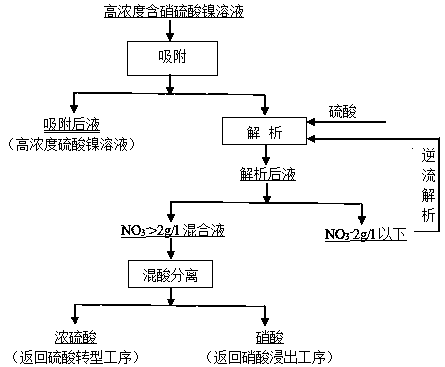

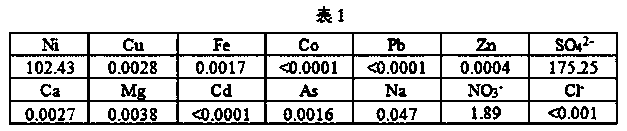

A method for separating nitrate radicals in a high-concentration nickel sulfate solution

ActiveCN109911949BIncrease contentAchieve separationSulfur compoundsNickel sulfatesHigh concentrationNitrate

The invention discloses a method for separating nitrate in high-concentration nickel sulfate solution, which belongs to the field of nonferrous metal hydrometallurgy and aims to solve the problem of separating nitrate in high-concentration nickel nitrate. The method applies the resin to the adsorption of nitrate in high-concentration nickel sulfate solution, washes and pretreats the new resin with sulfuric acid solution, and then uses the treated resin to absorb the nitrate in nickel sulfate; uses sulfuric acid solution to analyze the nitrate on the resin , the solution with a nitrate content higher than 2g / l in the analyzed solution is discharged, and sulfuric acid and nitric acid are reused; the analyzed solution with a nitrate content lower than 2g / l enters the next saturated resin analysis. The method of the invention is simple and easy to operate, has high nitrate removal depth, does not introduce any impurities, ensures the purity and high concentration of the nickel sulfate solution in the whole process, does not produce waste water and waste residue, and belongs to green metallurgy.

Owner:JINCHUAN GROUP LIMITED

Method for separating nitrate from high-concentration nickel sulfate solution

ActiveCN109911949AIncrease contentAchieve separationSulfur compoundsNickel sulfatesHigh concentrationNitrate

The invention discloses a method for separating nitrate from a high-concentration nickel sulfate solution, and belongs to the field of nonferrous metal hydrometallurgy to solve the problem of separation of nitrate from high-concentration nickel nitrate. The method comprises the following steps: adsorbing the nitrate in the high-concentration nickel sulfate solution with resin, washing and pretreating new resin with a sulfuric acid solution, and then adsorbing the nitrate in the nickel sulfate with the treated resin; and analyzing the nitrate on the resin by using the sulfuric acid solution, discharging the analyzed solution having a nitrate content more than 2 g / l, and reusing sulfuric acid and nitric acid; putting the analyzed solution having a nitrate content less than 2 g / l into next saturated resin for analysis. The method disclosed by the invention is simple, easy to operate and high in removal depth of nitrate, and does not introduce any impurities; the whole process ensures thepurity and high concentration of the nickel sulfate solution, does not generate waste water and waste residues, and belongs to green metallurgy.

Owner:JINCHUAN GROUP LIMITED

A kind of preparation method of ammonium bifluoride

The invention discloses a preparation method of ammonium bifluoride. The method comprises steps as follows: a, dilute ammonia water and ammonium bifluoride mother liquor are mixed to adsorb gas containing fluorine and silicon, and a mixed solution is obtained; b, the mixed solution and filter-press residues obtained in Step d are mixed for slurry making and filter-press separation, and a filtrate and a silica by-product are obtained; c, ammonia is introduced into the filtrate; d, slurry is subjected to filter-press separation, and an ammonium fluoride filtrate and filter-press residues are obtained; e, the ammonium fluoride filtrate is subjected to vacuum concentration; f, concentrated slurry is dissolved, the pH value of the solution is adjusted with hydrogen fluoride, and cooling crystallization is performed; g, ammonium bifluoride crystals are filtered, separated and dried, and the ammonium bifluoride product is obtained. With the adoption of the method, the utilization rate of fluorine and ammonia is increased, the gas containing fluorine and silicon is changed into the ammonium bifluoride product with the high economic value in the phosphoric acid production process, the production cost is low, the economic benefit is significant, meanwhile, the purity and other indexes of the product meet the requirement for superior products, and the method is suitable to be popularized and applied in the field.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Mixed carbon four-component selective hydrogenation catalyst and preparation method

ActiveCN109759060BHigh removal depthHigh yieldHydrocarbon by hydrogenationCatalyst activation/preparationButadiene DioxidePtru catalyst

The invention discloses a mixed carbon four-component selective hydrogenation catalyst and a preparation method thereof. The mixed carbon four-component selective hydrogenation catalyst is composed of an active component and a support carrier, the active component is palladium and manganese, and the support carrier is γAl 2 o 3 , CeO 2 -ZrO 2 and attapulgite; palladium accounts for 0.08% to 1.5% of the mass of the support carrier, manganese accounts for 3 to 5% of the mass of the support carrier, γAl 2 o 3 , CeO 2 -ZrO 2 , The mass ratio of attapulgite is 50~60:30~40:10~20. The specific surface area of the support carrier is 120~180m 2 / g, effectively taking into account the catalyst activity and selectivity, the active component Pd interacts with Mn, which is conducive to improving the removal depth of butadiene, carbon tetraacetylene, vinyl acetylene and increasing the yield of monobutene. It does not need to be activated before use, has high mechanical strength and is not easy to pulverize, has the advantages of convenient use and long service life, and can be widely used in large-scale industrial production.

Owner:大连华邦化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com