Leaching-purifying method for rare earth concentrate

A rare earth concentrate and leaching technology, which is applied in the field of non-ferrous metallurgy, can solve the problems of poor impurity removal effect, low filtration efficiency, and large loss of rare earth, and achieve the effect of high impurity removal depth, quality improvement, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

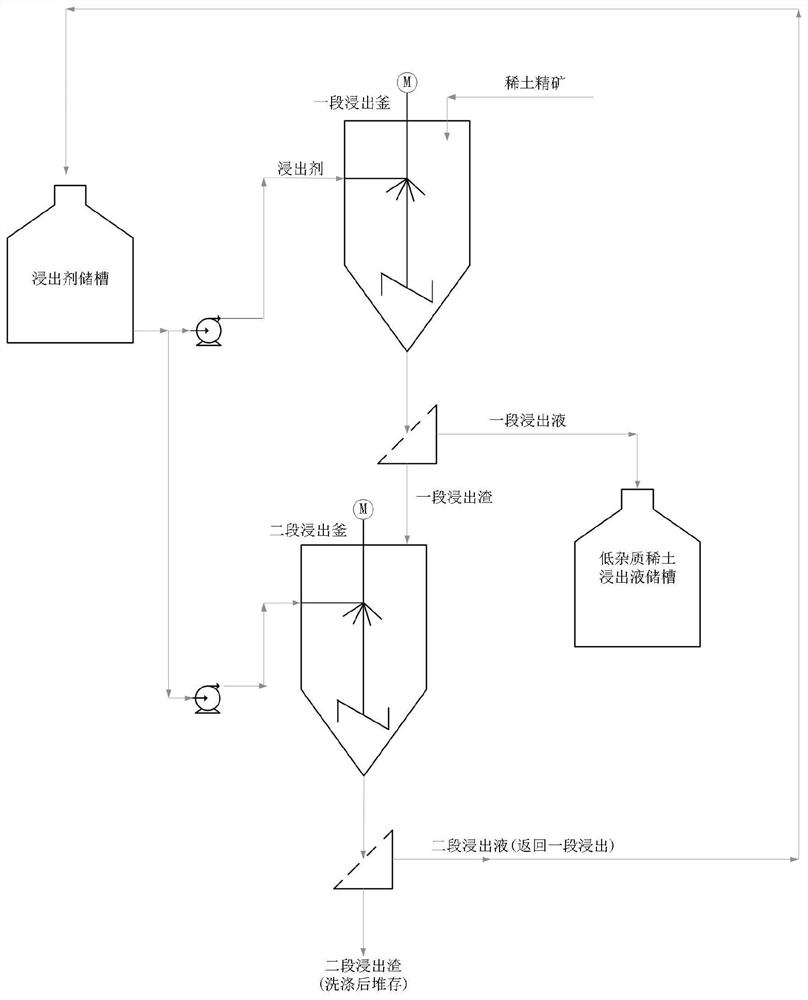

Method used

Image

Examples

Embodiment 1

[0048] One-stage leaching: first measure 500mL water into a 2L beaker, then add 0.5kg rare earth concentrate (TREO: 57.42%, Fe: 1.2%, Al: 0.28%, SiO 2 :.2.33%) and 4g activated carbon powder (seed), then start stirring to form the bottom liquid, then add the first leaching agent (hydrochloric acid and the mixed solution of the second-stage leaching solution used in circulation in the form of spraying), and in the mixed solution, The concentration of hydrochloric acid is 0.5M), the feeding rate of the leaching agent is 6L / h, and the pH at the end point is 5.2. After the feeding is completed, continue to stir the reaction until the temperature of the feed liquid drops below 50°C, then filter, and separate a section of leaching solution and a section of leaching residue. The filtration time was 38 minutes. A section of leachate was sampled and tested, and the concentrations of iron, aluminum, and silicon in a section of leachate were measured to be 1.1, 246.2, and 32.6 mg / L, resp...

Embodiment 2

[0056] One-stage leaching: First measure 500mL of water into a 2L beaker, then add 0.5kg of rare earth concentrate (TREO: 51.67%, Fe: 2.47%, Al: 0.34%, SiO 2 :.1.58%) and 5g graphite powder (seed crystal), then start stirring to form the bottom liquid, then add hydrochloric acid concentration as the first leaching agent of 1.0M in the form of spraying, the feeding speed of the leaching agent is 4.5L / h, the end point pH is 5.3. After the feeding is completed, continue to stir the reaction until the temperature of the feed liquid drops below 50°C, then filter, and separate a section of leaching solution and a section of leaching residue. The filtration consumption time was 32min. A section of the leachate was sampled and tested, and the concentrations of iron, aluminum, and silicon in the section of leachate were measured to be 0.9, 201.8, and 27.5 mg / L, respectively.

[0057] Second-stage leaching: Weigh 0.8kg of the first-stage leaching residue (H 2 (0:38%), measure 400mL wa...

Embodiment 3

[0064] One-stage leaching: First measure 500mL of water into a 2L beaker, then add 0.6kg of rare earth concentrate (TREO: 51.67%, Fe: 2.47%, Al: 0.34%, SiO 2 :.1.58%) and 3g graphite powder (seed), then start stirring to form the bottom liquid, then add hydrochloric acid concentration in the form of atomization and be the first leaching agent of 0.8M, the feeding speed of the leaching agent is 3.6L / h, and the terminal pH is 5.2. After the feeding is completed, continue to stir the reaction until the temperature of the feed liquid drops below 50°C, then filter, and separate a section of leaching solution and a section of leaching residue. The filtration consumption time was 44min. A section of leachate was sampled and tested, and the concentrations of iron, aluminum, and silicon in a section of leachate were measured to be 1.4, 279.8, and 46.8 mg / L, respectively.

[0065] Second-stage leaching: weigh 1.1kg of the first-stage leaching residue (H 2 (0:33%), measure 550mL water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com