Method for mfg. semiconductor device with element separating insulation film

A technology for component separation and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve the problems of short circuit of etching residues, deep level difference problems, and messing up the impurity concentration on the surface of the substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

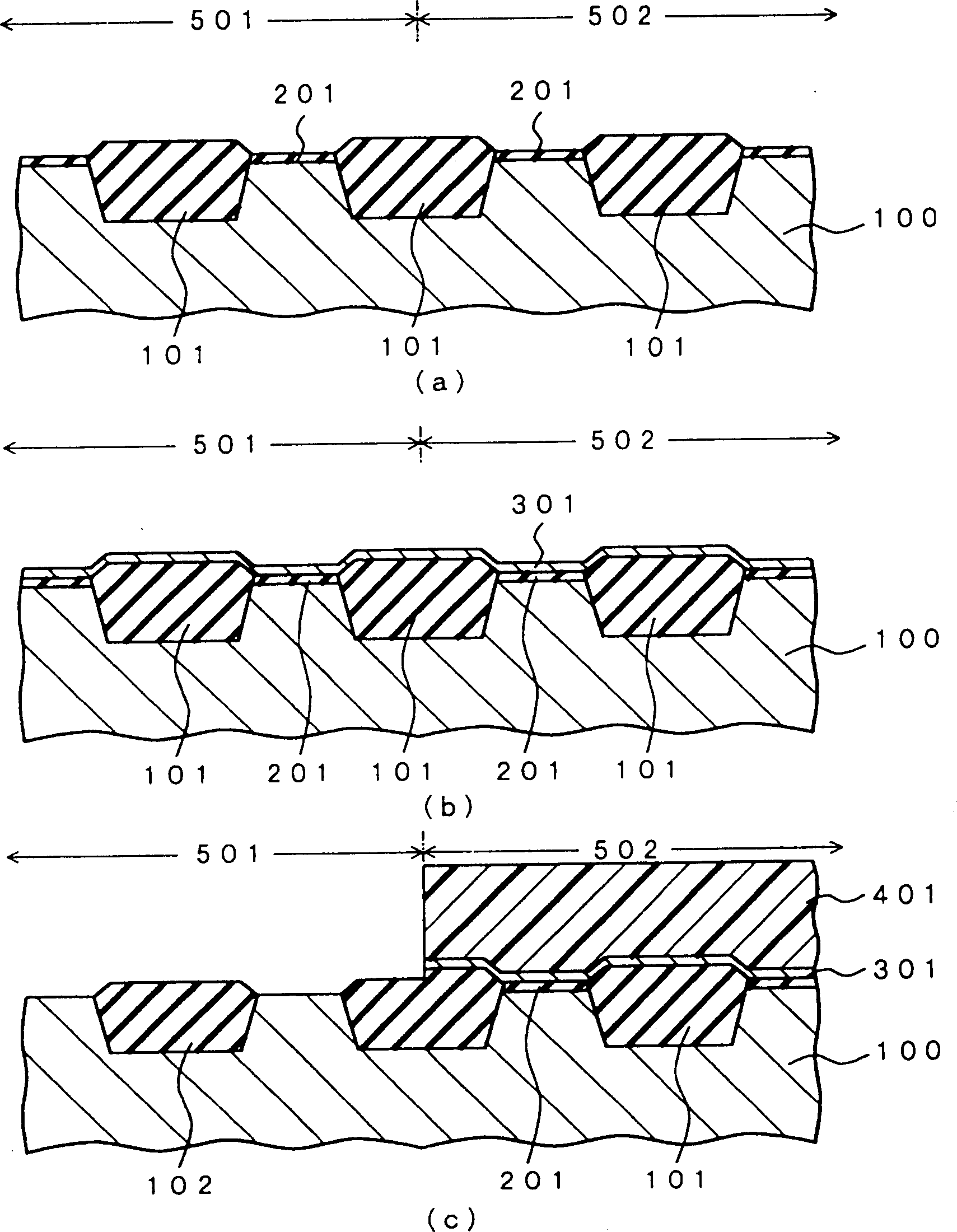

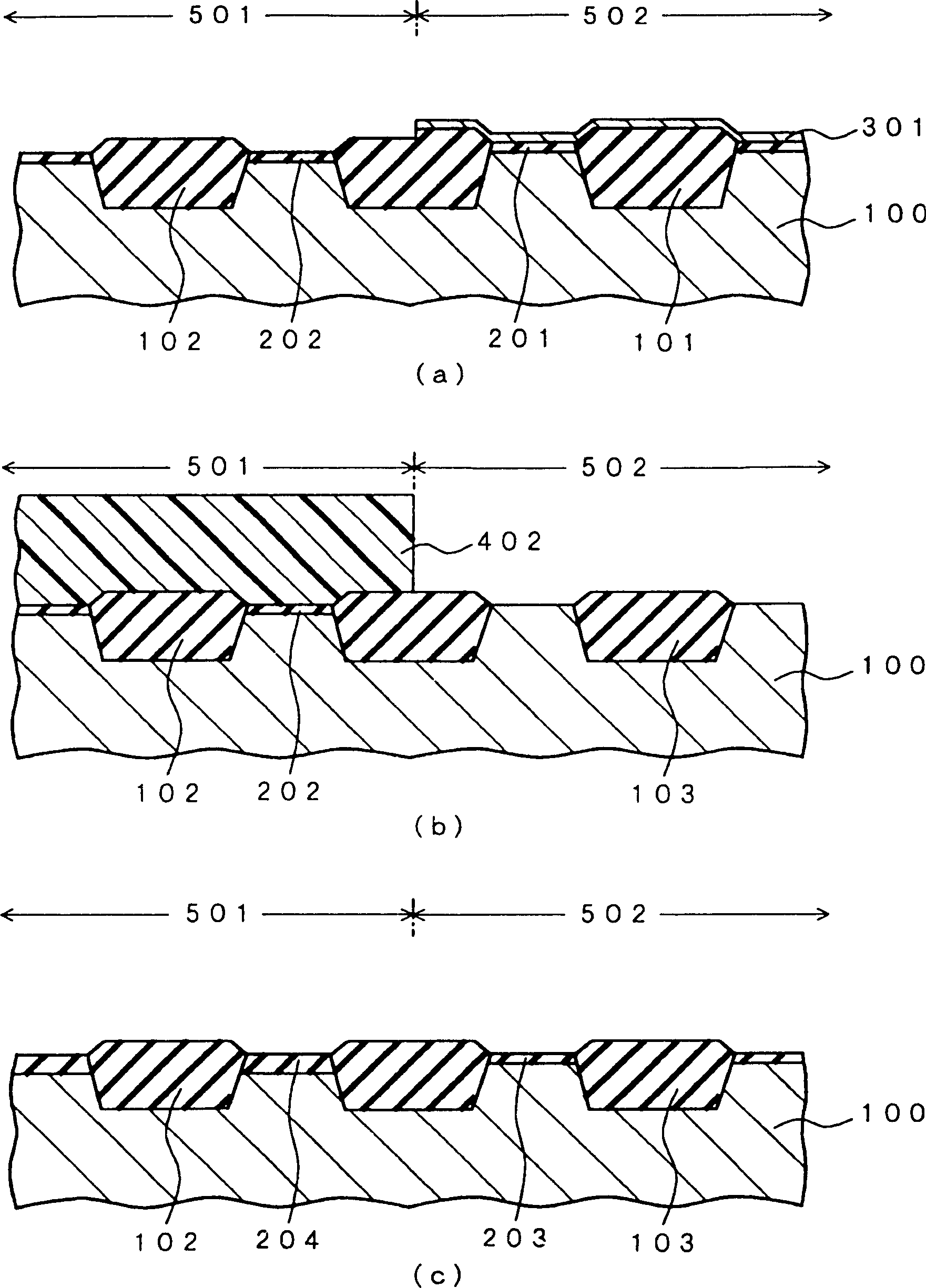

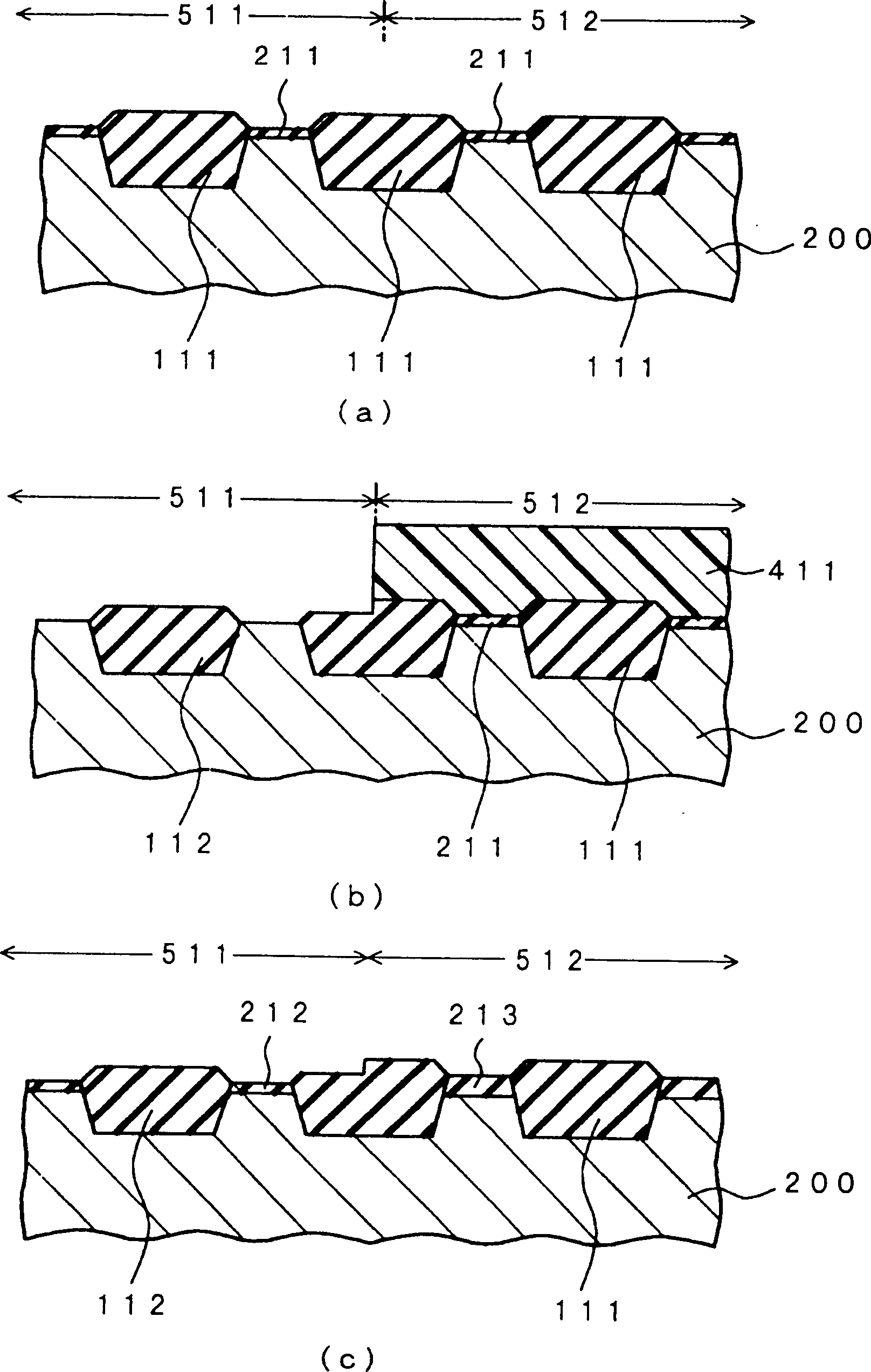

[0030] Hereinafter, a method of manufacturing a semiconductor device having an element isolation insulating film according to an embodiment of the present invention will be specifically described with reference to the drawings. figure 1 (a)~(c) and figure 2 (a) to (c) are cross-sectional views showing the sequence of steps of a method of manufacturing a semiconductor device having an element isolation insulating film according to Embodiment 1 of the present invention.

[0031] figure 1 (a) shows the element isolation insulating film 101 formed on the surface of the silicon substrate 100 to electrically isolate elements, and the thin oxide film 201 formed to protect the substrate during ion implantation in the active region sandwiched by the element isolation insulating film 101 cross-sectional view of the state. As shown in the figure, the silicon substrate 100 has an element region 501 that requires a thick gate oxide film for a high withstand voltage circuit such as a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com