Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Full thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

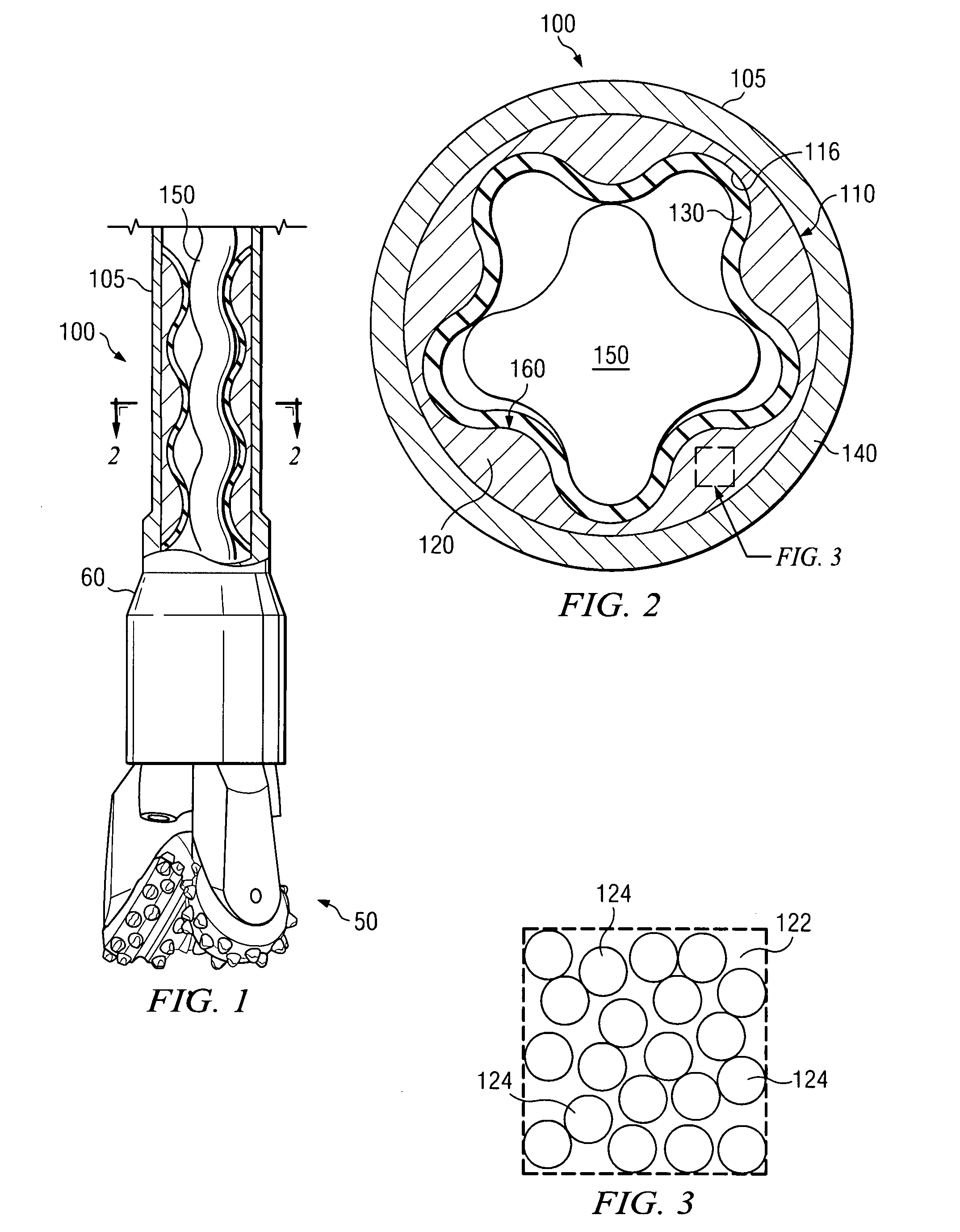

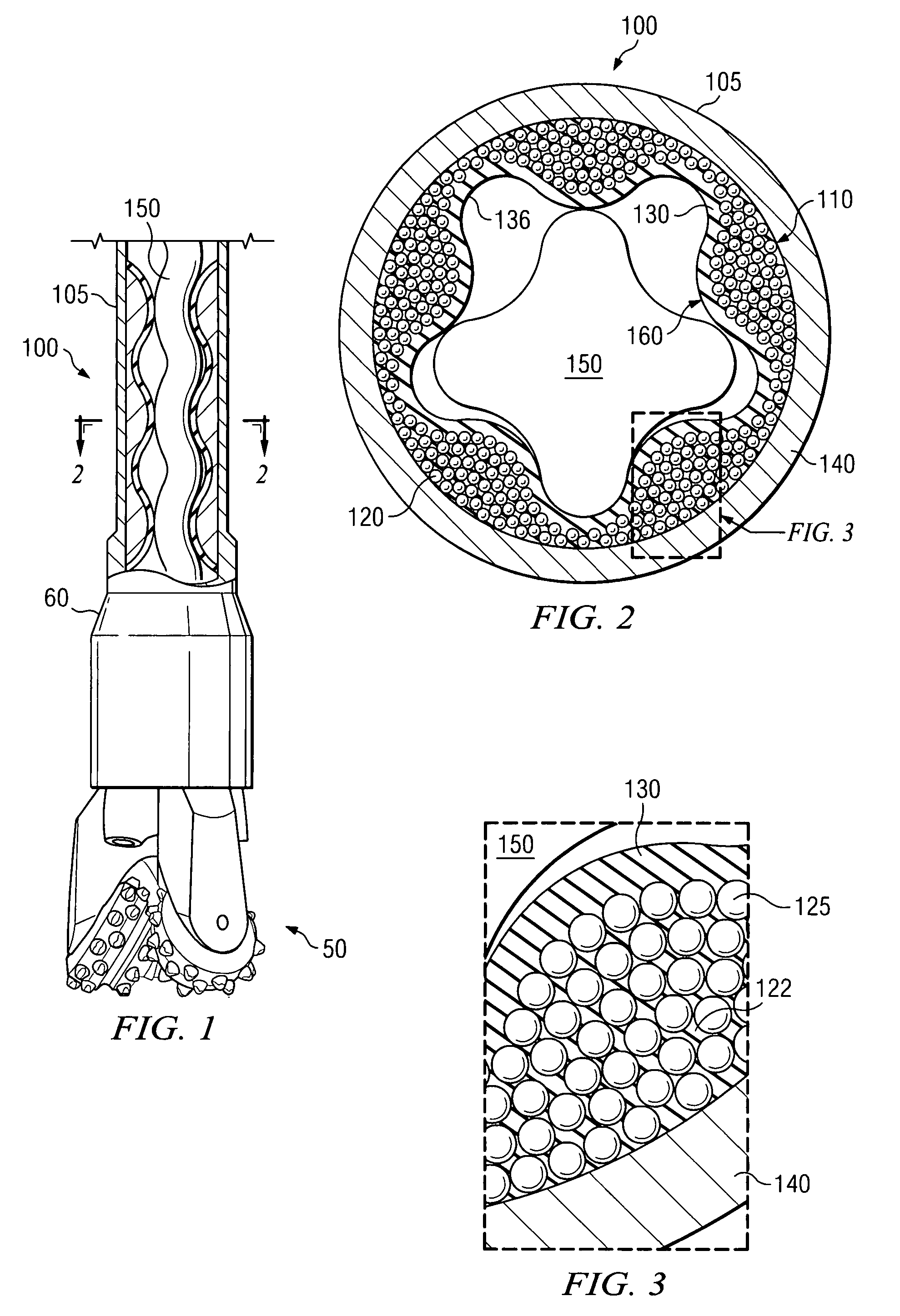

Braze or solder reinforced moineu stator

InactiveUS20080304992A1Extended service lifeImprove efficiencyOscillating piston enginesEngine of intermeshing engagement typeElastomerState of art

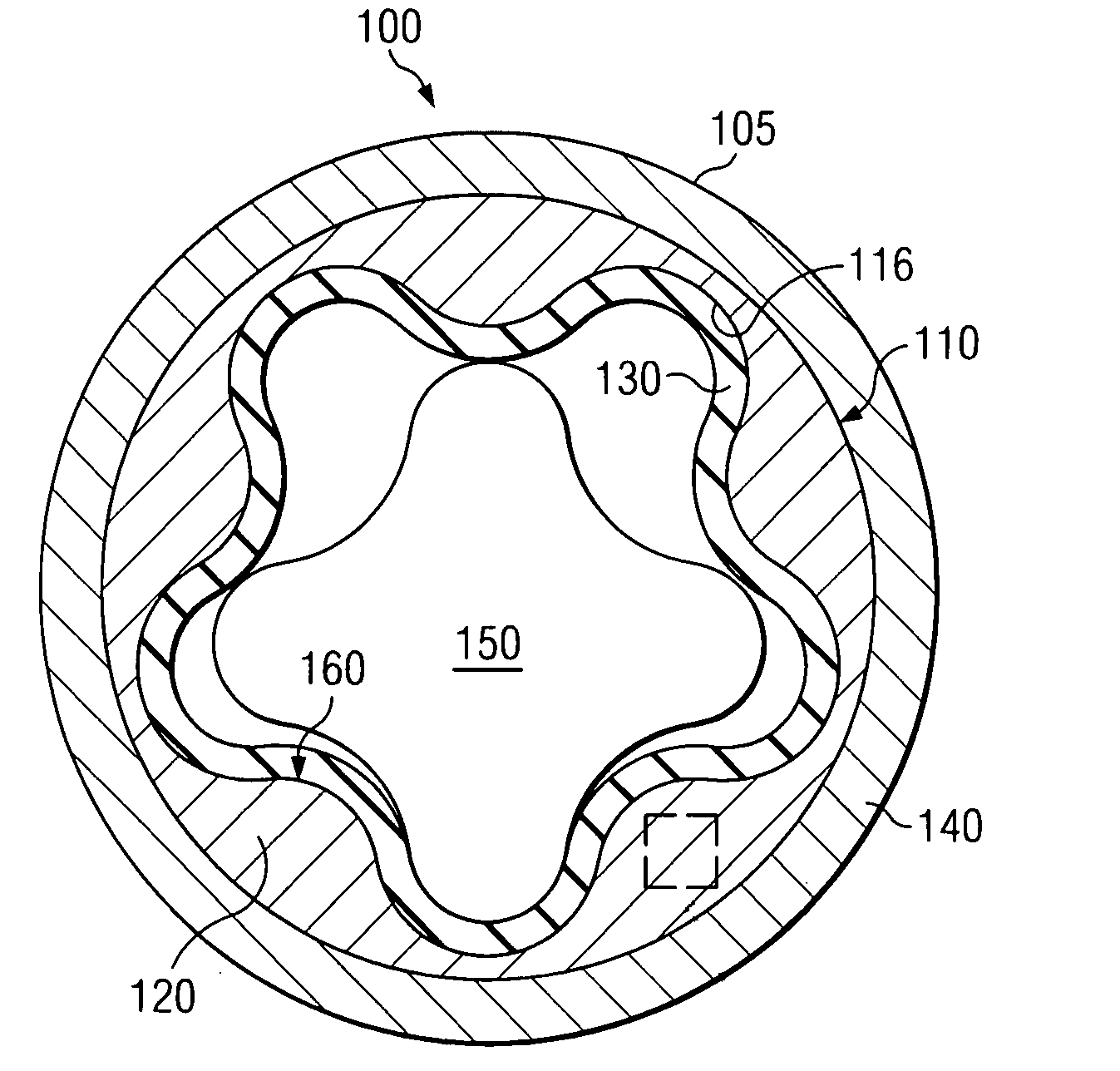

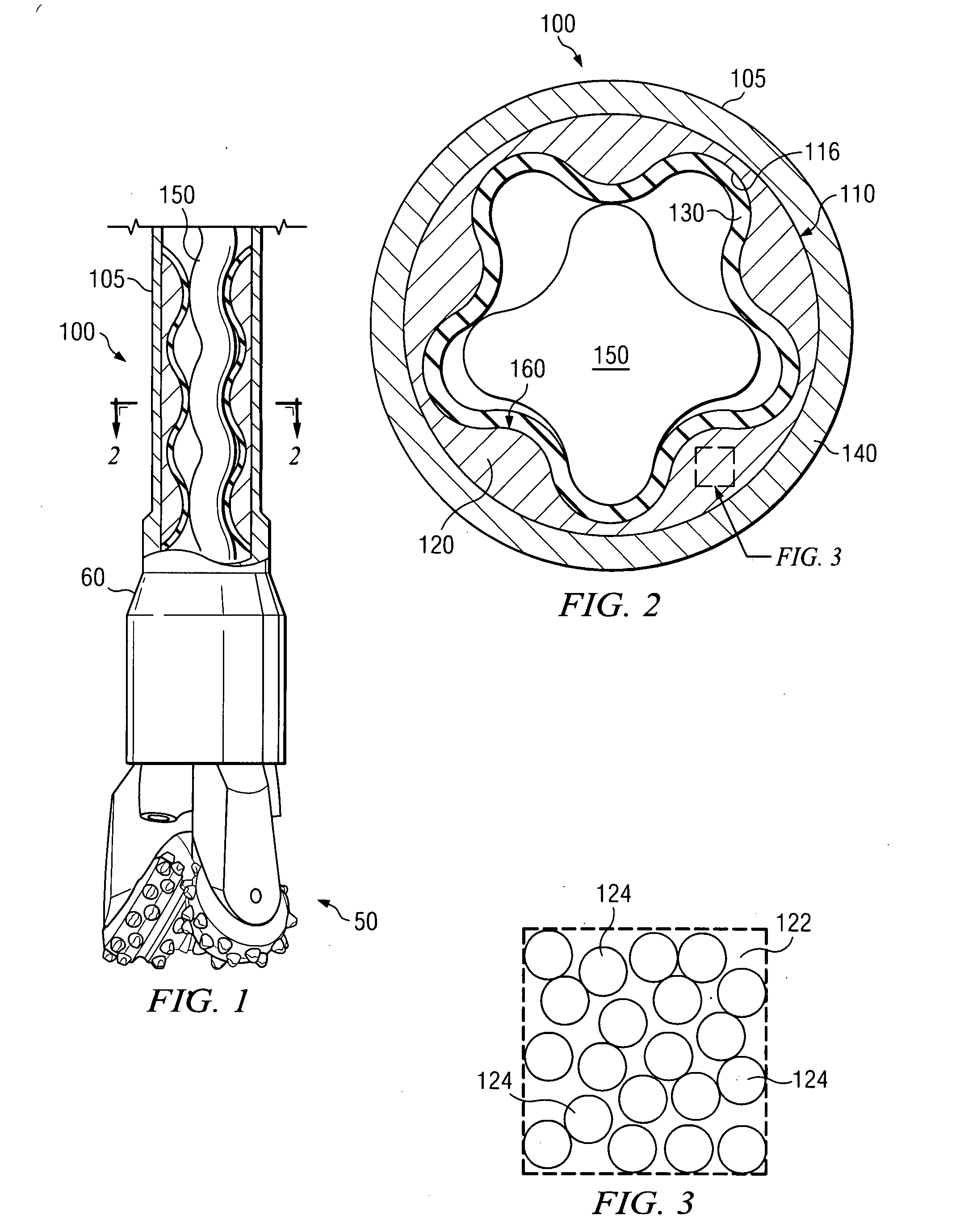

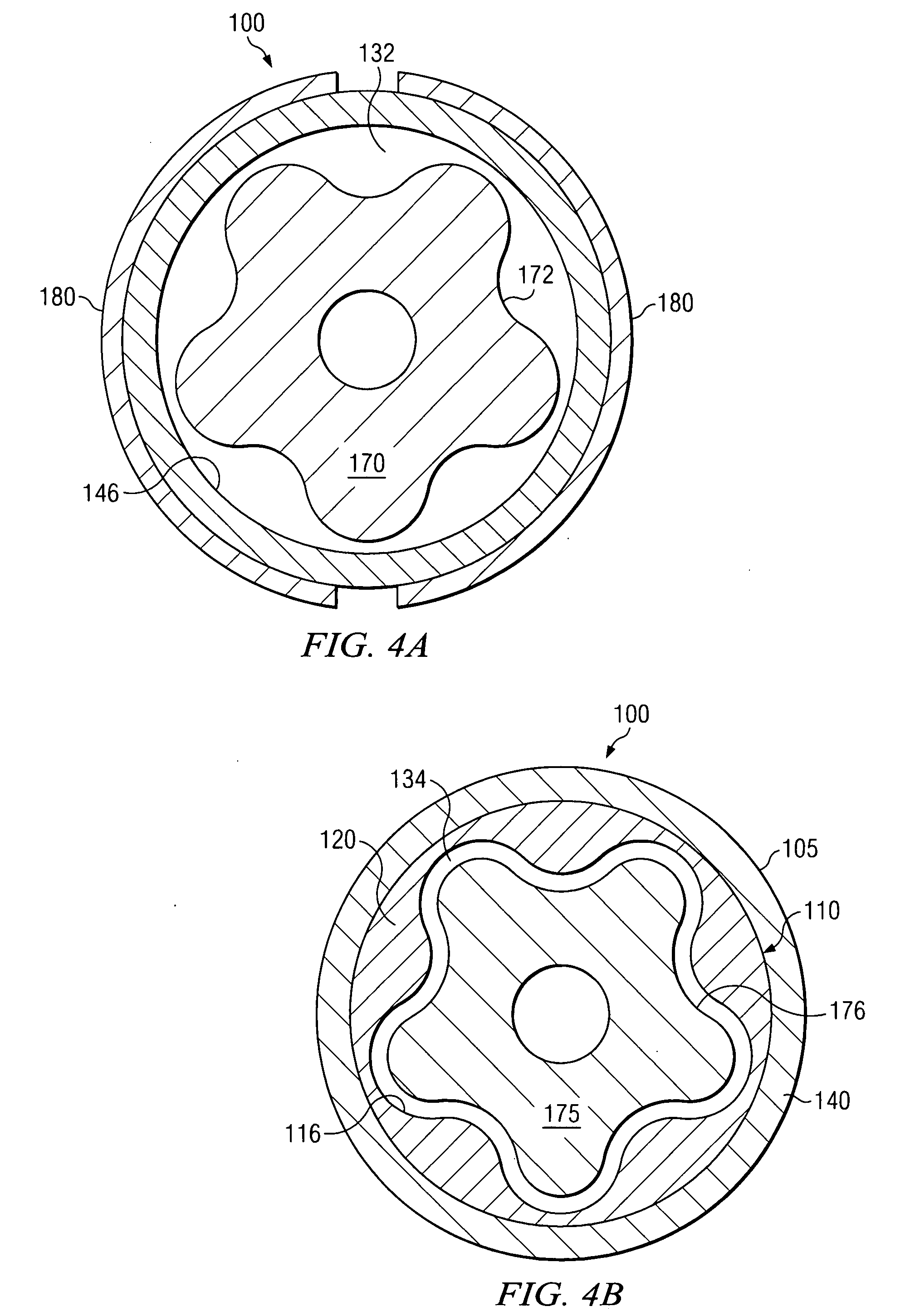

A Moineau style stator includes a helical reinforcement component that provides an internal helical cavity. A resilient liner is deployed on an inner surface of the helical reinforcement component. The helical reinforcement component includes a solder or braze material and is typically metallurgically bonded to an inner wall of a stator tube. In exemplary embodiments, the helical reinforcement component includes a composite mixture of solder and aggregate. Exemplary embodiments of this invention address the heat build up and subsequent elastomer breakdown in the lobes of prior arts stators by providing a helical reinforcement component. Solder reinforced stators tend to be less expensive to fabricate than reinforced stators of the prior art.

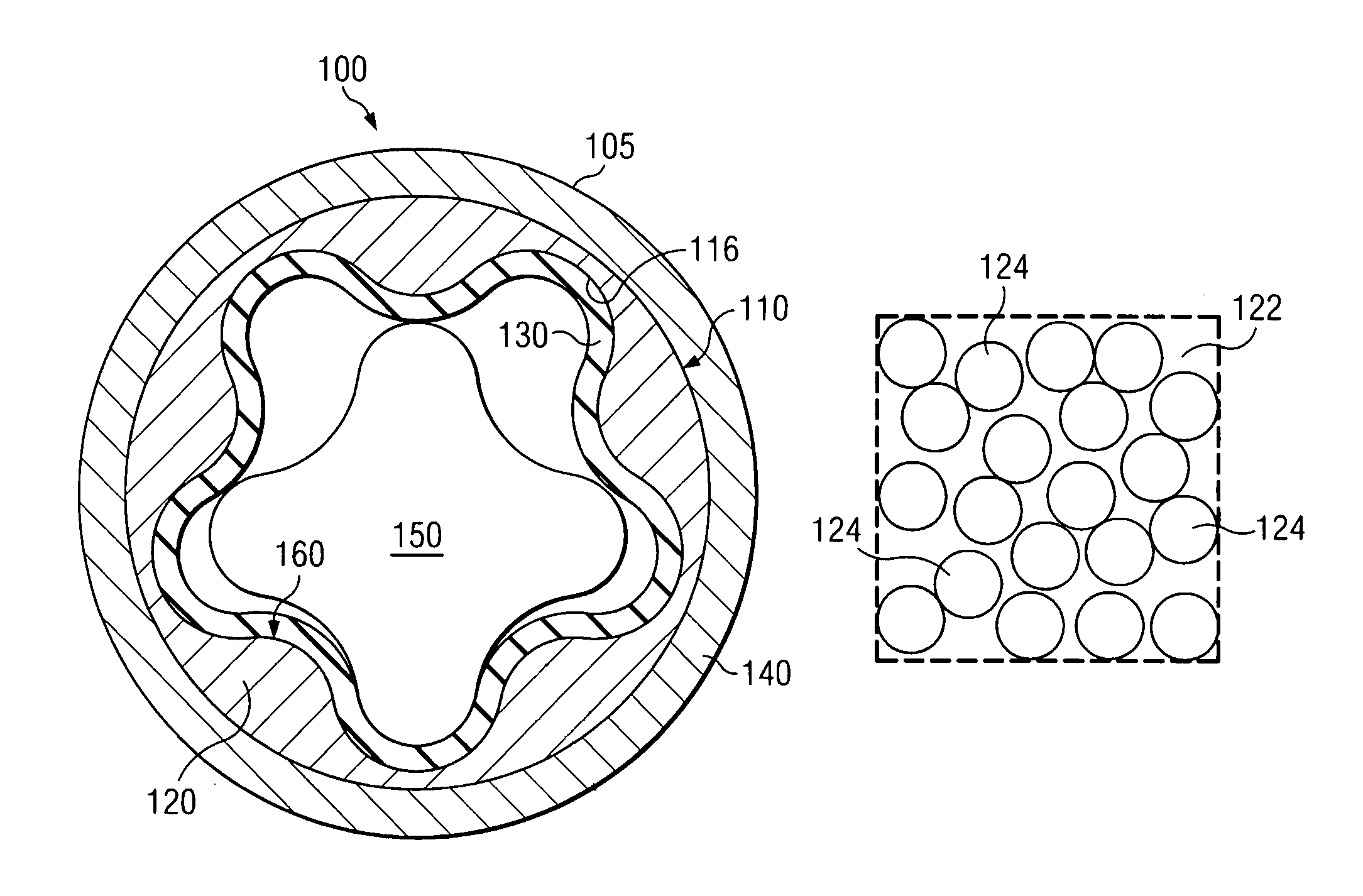

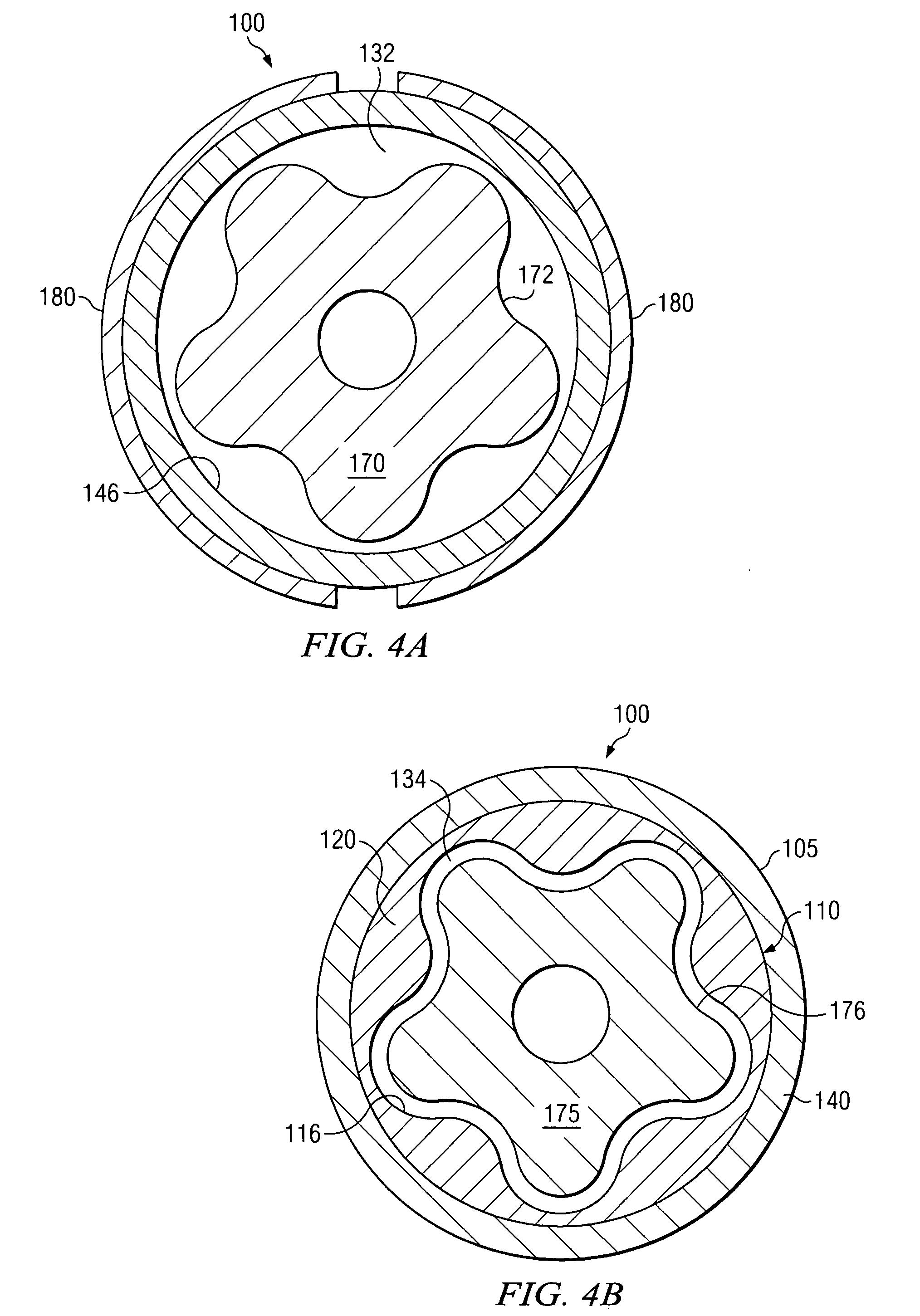

Moineu stator including a skeletal reinforcement

ActiveUS20080304991A1Extended service lifeNot easy to layerOscillating piston enginesEngine of intermeshing engagement typeElastomerInterference fit

A Moineau style stator includes a helical cavity component having reinforced helical lobes. The lobes are reinforced with a three-dimensional network of physically bonded aggregate particles. The network of bonded aggregate provides a porous skeletal-like structural reinforcement. Pore volume between the bonded aggregate particles may optionally be partially or substantially filled with an elastomer. An elastomer liner is typically deployed on an inner surface of the helical lobes to promote a rotational interference fit with a rotor.

Owner:SMITH INT INC

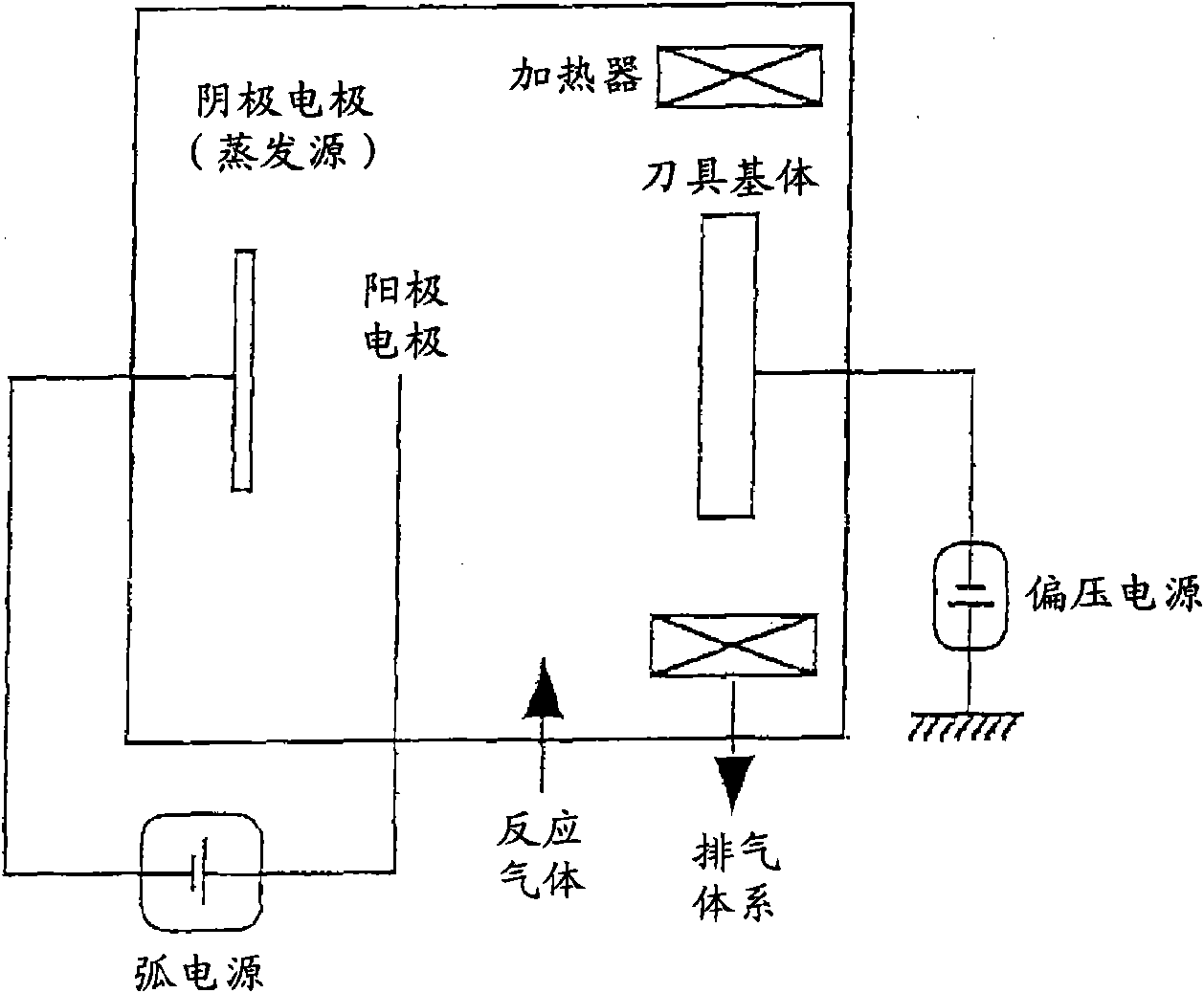

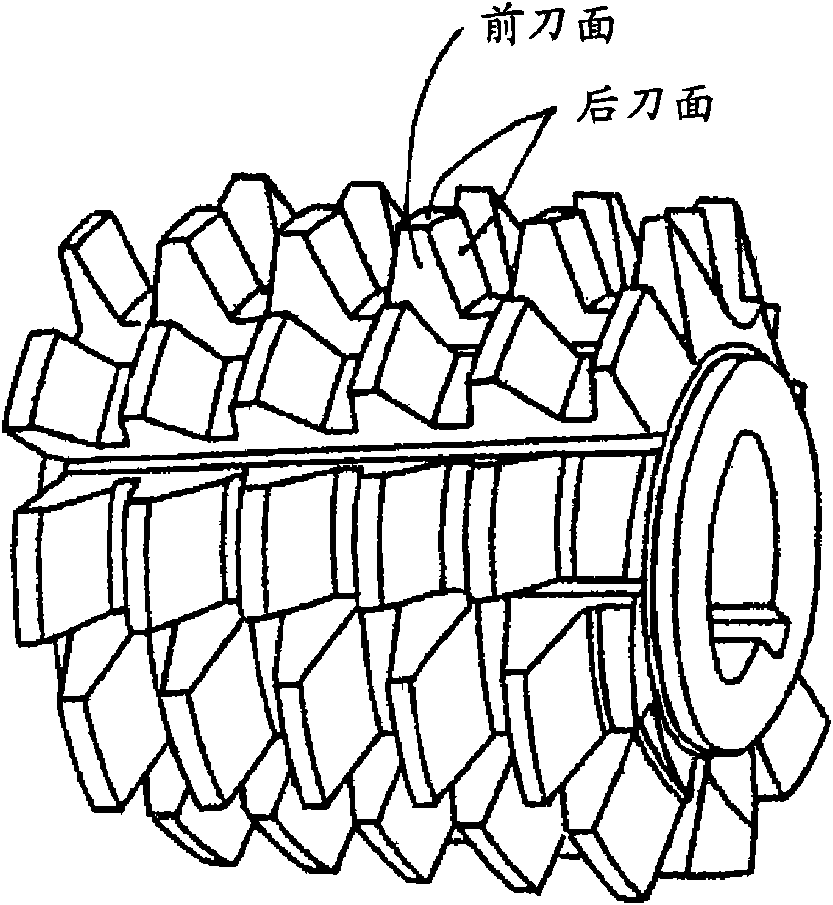

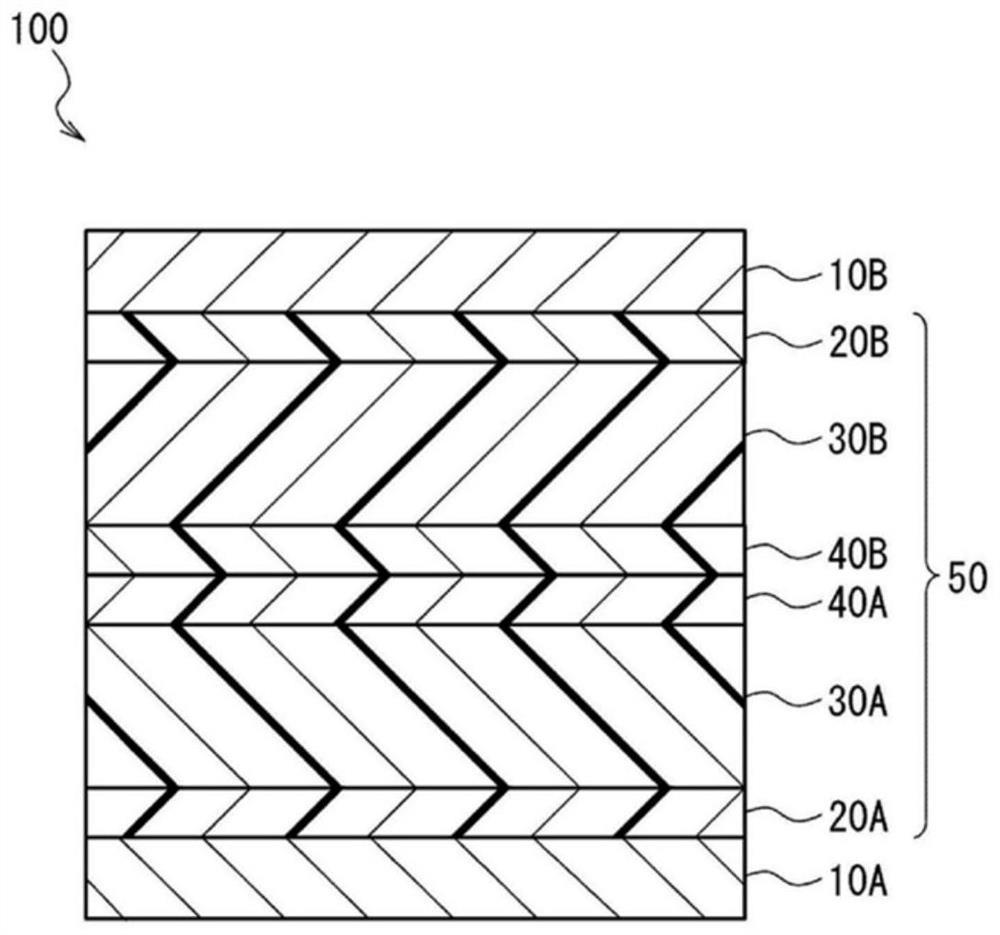

Surface-coated cutting tool

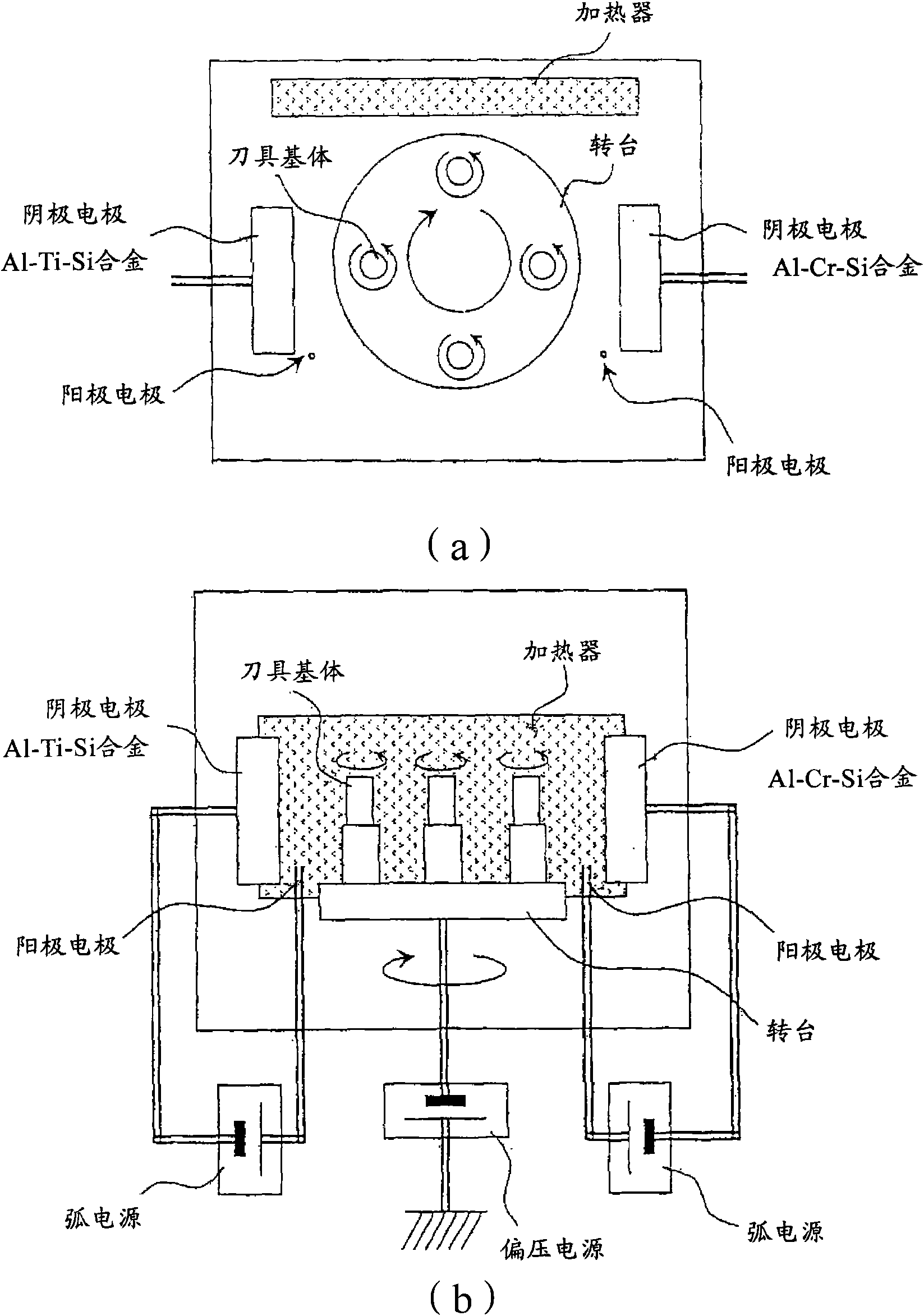

ActiveCN101678467AExcellent high temperature hardnessExcellent high temperature toughnessMilling cuttersVacuum evaporation coatingThin layerCemented carbide

A surface-coated cutting tool which has excellent chipping resistance and wearing resistance in high-speed cutting processing such as high-speed gear cutting processing, high-speed milling processing,and high-speed drilling processing. The surface-coated cutting tool comprises a tool base, e.g., a cemented carbide base, cermet base, or high-speed tool steel base, and at least a hard coating layerformed on a surface of the tool base and having a multilayer structure composed of a thin layer (A) and a thin layer (B) alternating therewith. The thin layer (A) is constituted of an (Al,Cr,Si)N layer satisfying the empirical formula ¢AlXCrYSiZ!N (wherein 0.2 <= X <= 0.45, 0.4 <= Y <= 0.75, 0.01 <=Z <= 0.2, and X+Y+Z=1 in terms of atomic ratio), and the thin layer (B) is constituted of an (Al,Ti,Si)N layer satisfying the empirical formula ¢AlUTiVSiW!N (wherein 0.05 <= U <= 0.75, 0.15 <= V <= 0.94, 0.01 <= W <= 0.1, and U+V+W=1 in terms of atomic ratio).

Owner:MITSUBISHI MATERIALS CORP

Braze or solder reinforced Moineau stator

InactiveUS7950914B2Extended service lifeImprove efficiencyOscillating piston enginesEngine of intermeshing engagement typeElastomerMaterials science

A Moineau style stator includes a helical reinforcement component that provides an internal helical cavity. A resilient liner is deployed on an inner surface of the helical reinforcement component. The helical reinforcement component includes a solder or braze material and is typically metallurgically bonded to an inner wall of a stator tube. In exemplary embodiments, the helical reinforcement component includes a composite mixture of solder and aggregate. Exemplary embodiments of this invention address the heat build up and subsequent elastomer breakdown in the lobes of prior arts stators by providing a helical reinforcement component. Solder reinforced stators tend to be less expensive to fabricate than reinforced stators of the prior art.

Owner:SMITH INT INC

Moineau stator including a skeletal reinforcement

ActiveUS7878774B2Extended service lifeNot easy to layerOscillating piston enginesEngine of intermeshing engagement typeElastomerInterference fit

A Moineau style stator includes a helical cavity component having reinforced helical lobes. The lobes are reinforced with a three-dimensional network of physically bonded aggregate particles. The network of bonded aggregate provides a porous skeletal-like structural reinforcement. Pore volume between the bonded aggregate particles may optionally be partially or substantially filled with an elastomer. An elastomer liner is typically deployed on an inner surface of the helical lobes to promote a rotational interference fit with a rotor.

Owner:SMITH INT INC

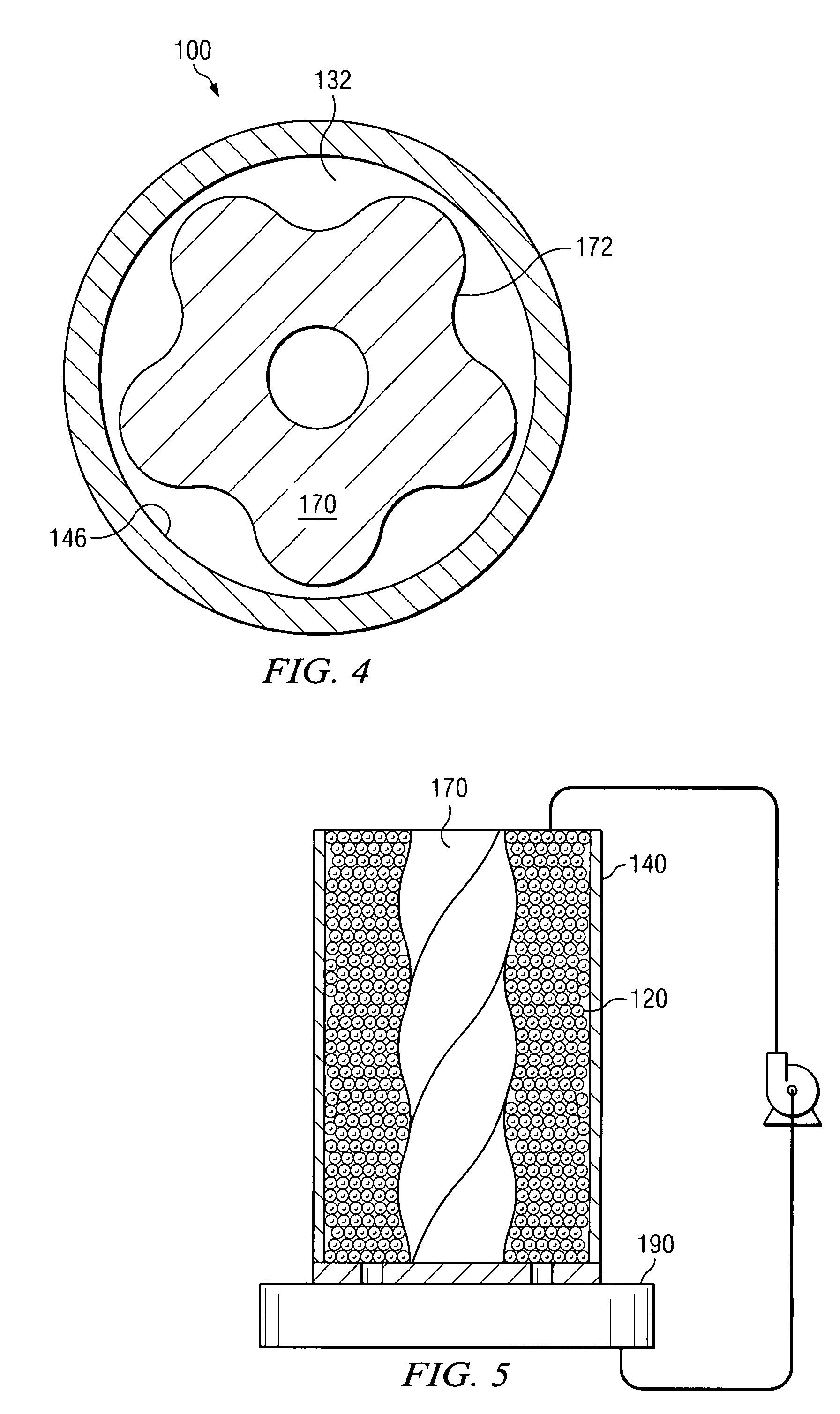

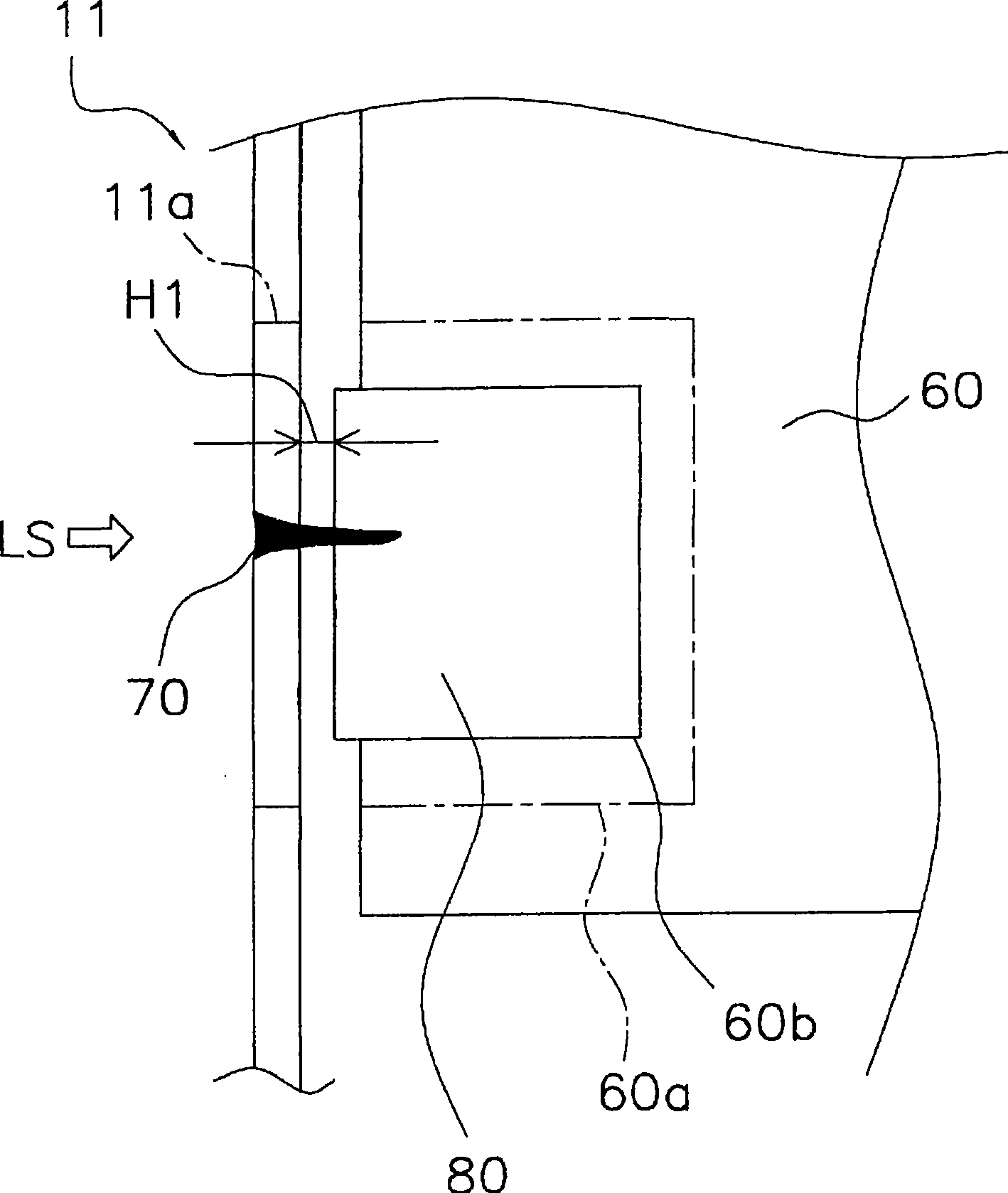

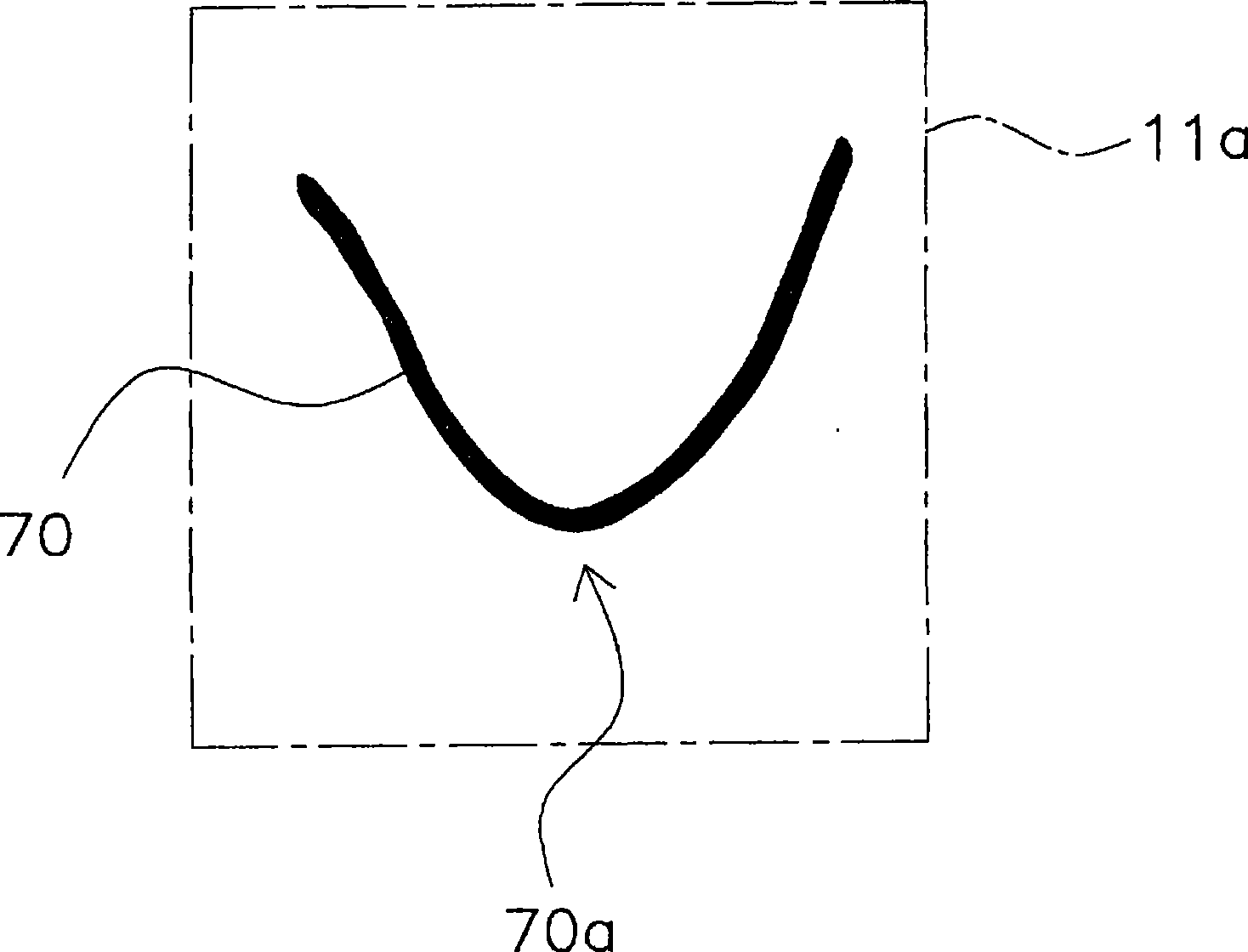

Method for producing compressor, and compressor

InactiveCN101395379ALow costAvoid deformationPositive displacement pump componentsPositive-displacement liquid enginesEngineeringLaser beams

A compressor where welding between a casing and an inner component or welding between a barrel casing and an end casing has sufficient strength and the welding has low strain achieved by suppressing an influence of heat by welding. A method of producing the compressor (1, 101) has a positioning process and a welding process. The compressor has the casing (10, 11, 111) and the inner component (60, 125) received in the casing. The casing has at its inner surface (11s, 111s) a first section (11a, 11w, 111w), and the inner component has a second section (60a, 61, 125b). The second section faces the first section. The first section and the second section are made to face each other in the positioning process. In the laser welding process, a laser beam is applied to at least a portion of the part where the first section and the second section are faced each other to laser-weld the casing and the inner component together.

Owner:DAIKIN IND LTD

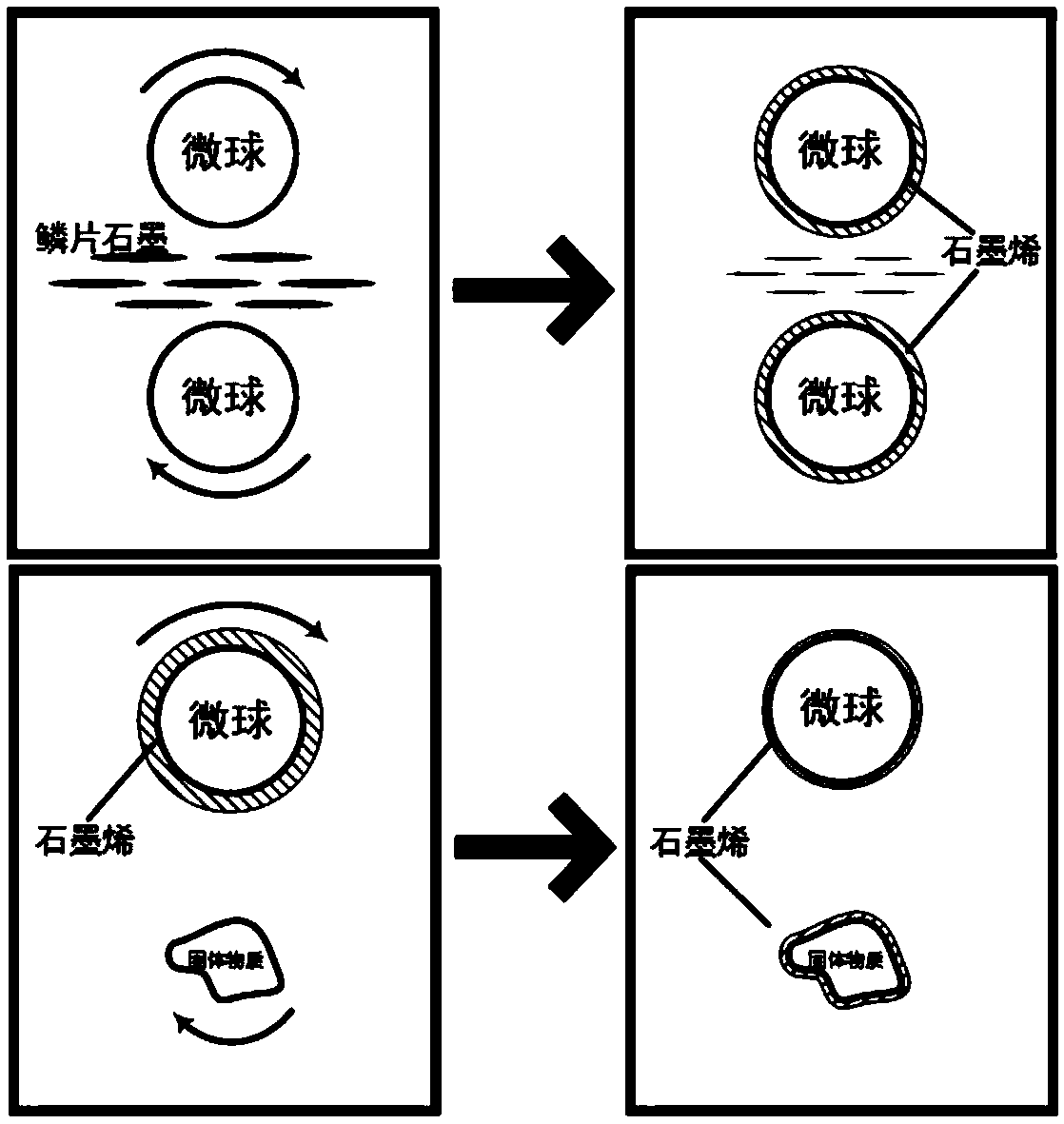

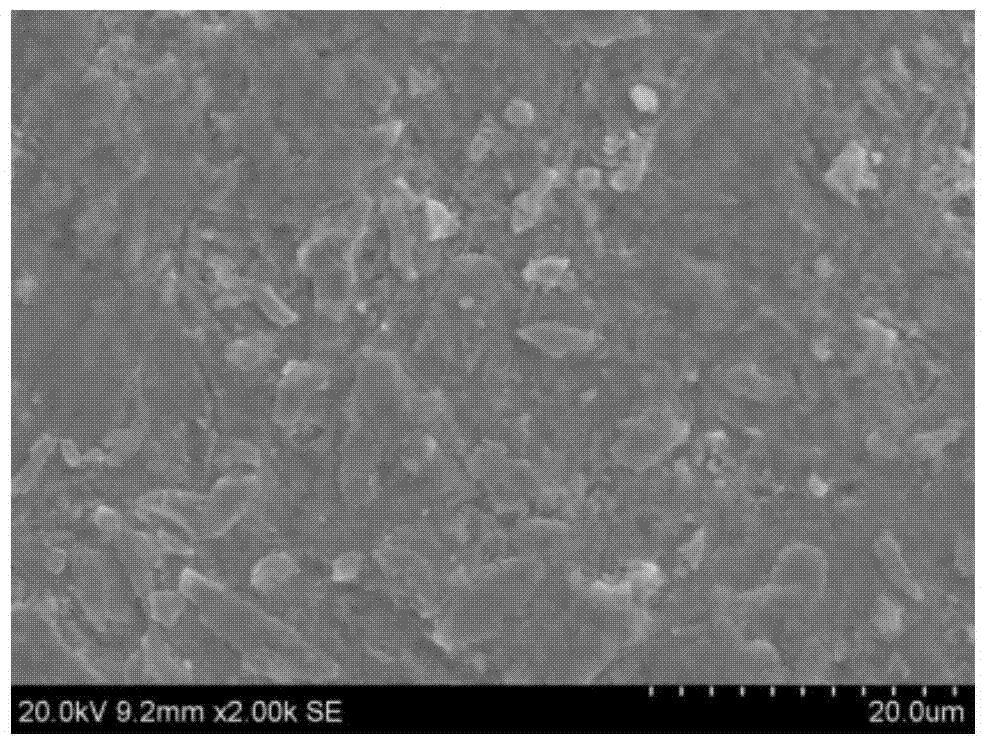

Full-solid preparation method of graphene uniformly coated on surface of irregular micro-nanoparticles

ActiveCN109273702AImprove qualityEasy to separateMaterial nanotechnologyHybrid capacitor electrodesAll solid stateMaterials preparation

The invention discloses an all-solid-state material preparation method for uniformly coating dense graphene on the surface of irregular micro-nano particles, belonging to the technical field of new energy materials and preparation thereof. The graphite powder layers are separated from each other and adhered to the surface of the coated microspheres during the friction process by the shear force generated during the ball milling process, and the graphite layers are continuously thinned under the continuous physical friction, and finally the thin graphene coated microspheres shell is formed. Thesize difference between the coated product and graphite powder was used to screen the coated product. Furthermore, the transfer graphene can be obtained by mixing the microsphere-coated product withother irregular nanoparticle solid powder samples to form grapheme-Solid powder composites for use in various fields. The whole process does not involve any chemical reaction, simple process, low cost, green environmental protection, high product purity and simple post-treatment, raw materials can be used repeatedly, suitable for industrial production.

Owner:西安一九零八新能源科技有限公司

Tissue culture fast propagation method for garcinia paucinervis

InactiveCN105684913APromote divisionImprove flowPlant tissue cultureHorticulture methodsSucroseSaccharum

The invention belongs to the technical field of tissue culture production and relates to a tissue culture fast propagation method for garcinia paucinervis.The method includes the following steps of 1, disinfection of an explant; 2, callus culture; 3, callus bud differentiation; 4, bud rooting.The formula of a root inducing medium is MS + 6-8g / L agar + 25-29g / L saccharose + 0.8-2.5mg / L indoleacetic acid + 0.5-1.5mg / L kinetin + 0.8-1.5mg / L activated carbon + 0.1-0.5mg / L metaxamin + 0.5-1.5mg / L compound sodium nitrophenolate + 0.3-0.8mg / L vitamin D2 + 0.15-0.35mg / L microcystin.The tissue culture fast propagation method has the advantages that propagation cost can be reduced, the growth period is short, the propagation rate is high, management is convenient, industrial production and automatic monitoring are benefited, and manpower, material resources and land for field crops are greatly saved.

Owner:覃伟

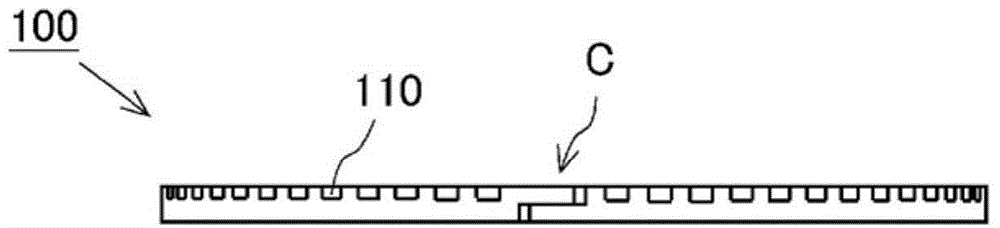

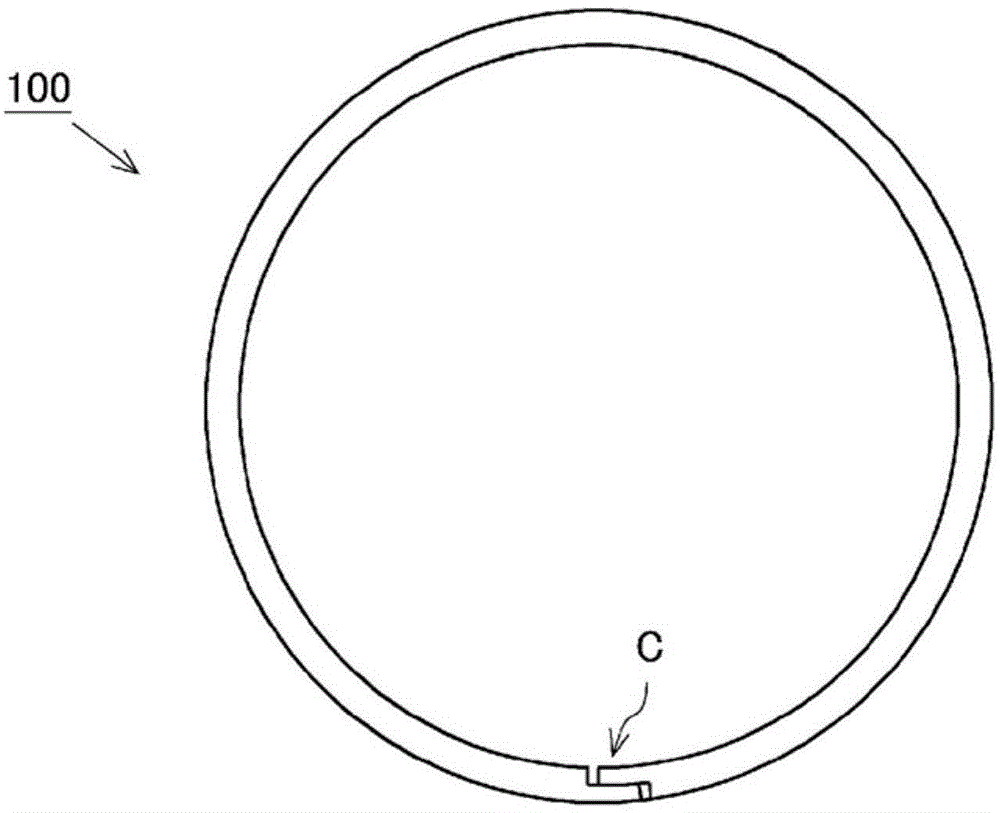

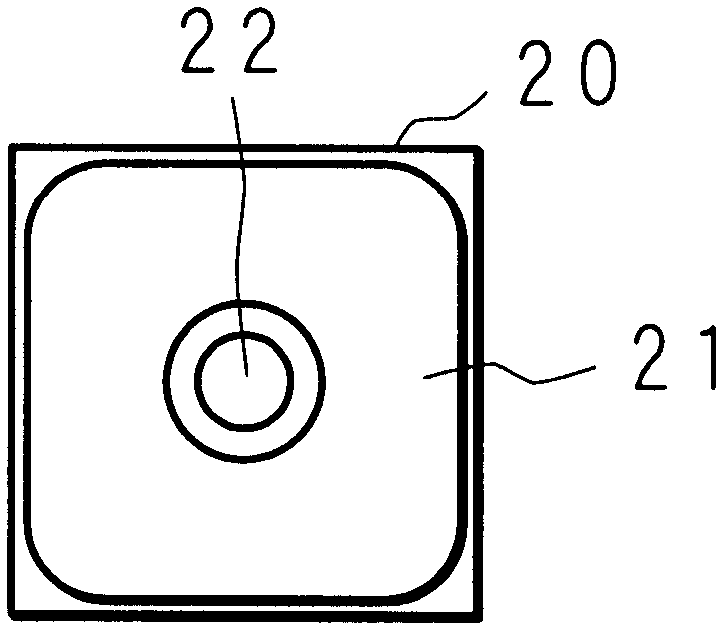

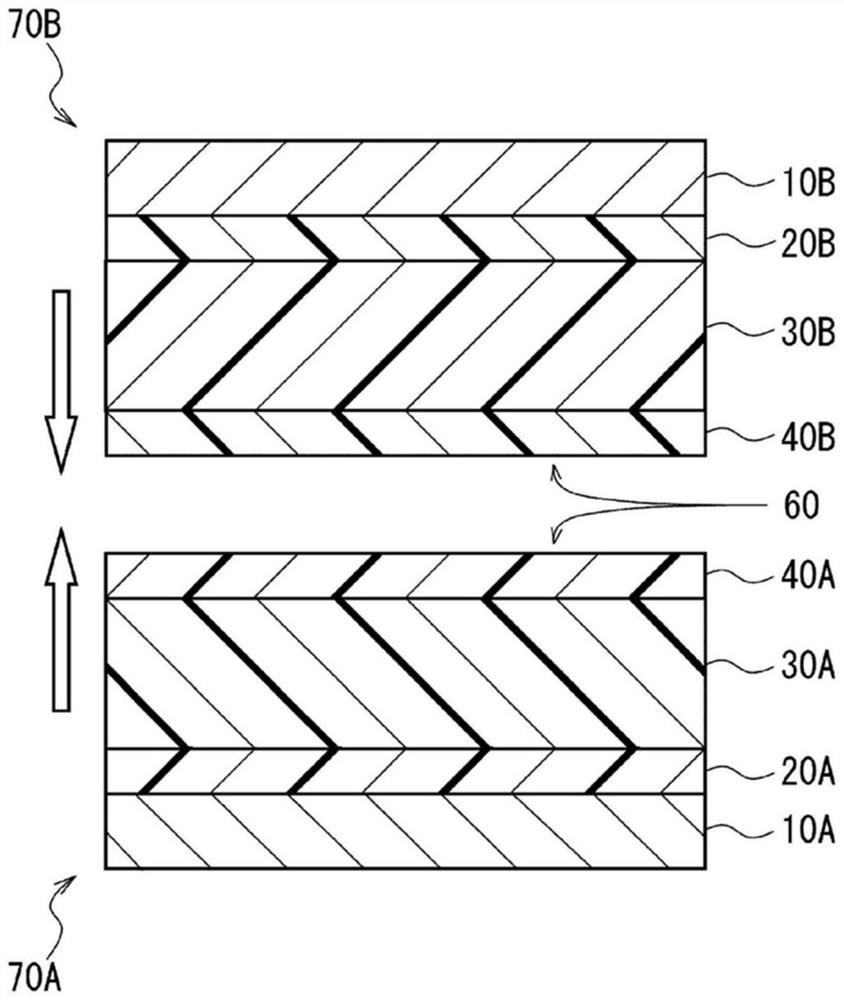

Seal ring

Provided is a seal ring which can reduce the amount of leakage of fluid to be sealed, the leakage flowing from a high-pressure region to a low-pressure region. A seal ring (100) is mounted in an annular groove (210) provided in the outer periphery of a shaft (200). The seal ring (100) seals the annular gap between the shaft (200) and a housing (300), the shaft (200) and the housing (300) rotating relative to each other, and separates a low-pressure region (L) and a high-pressure region (H) in which fluid to be sealed is present. When the shaft (200) and the housing (300) rotate relative to each other, a side surface of the seal ring (100), the side surface facing the low-pressure region, and a side surface of the annular groove slide on each other. The seal ring (100) is provided with a side surface groove (110) which is provided in a side surface of the seal ring (100), the side surface facing the low-pressure region (L), and which extends from the position at which the side surface groove (110) is exposed to the low-pressure region (L), toward the inner peripheral surface side of the seal ring (100) to a position not reaching the inner peripheral surface.

Owner:NOK CORP

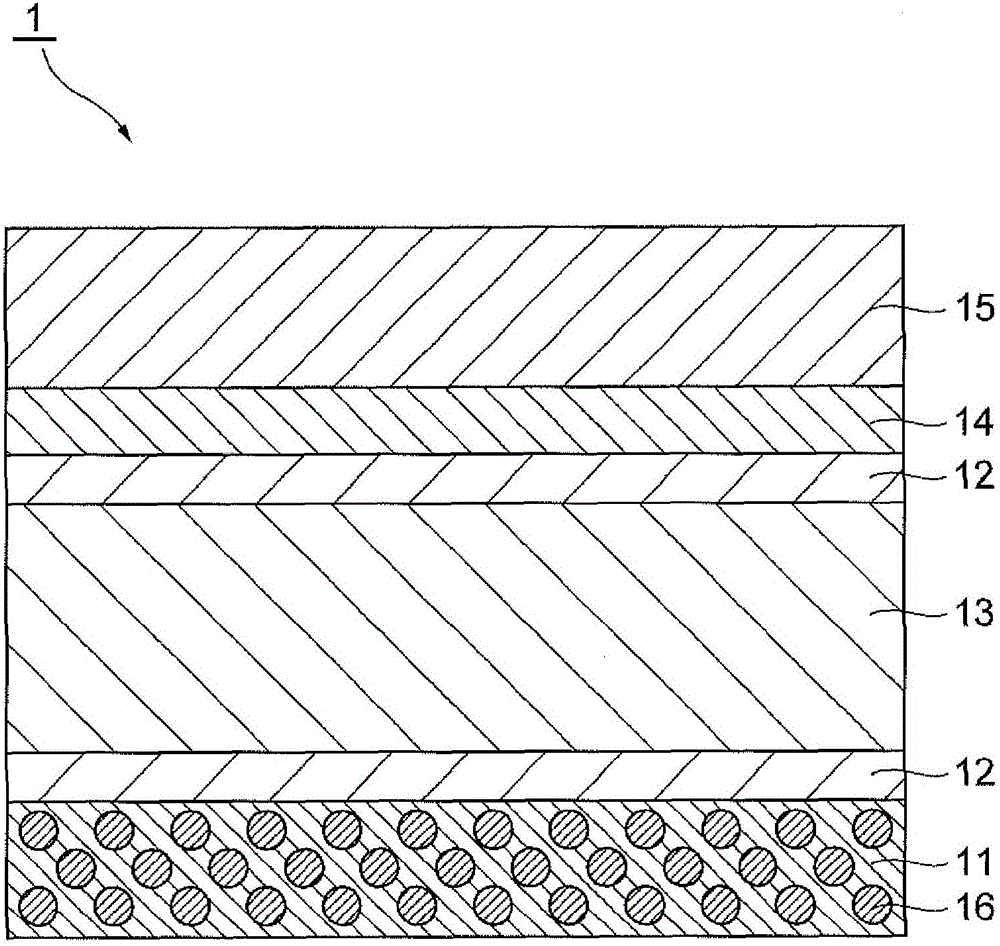

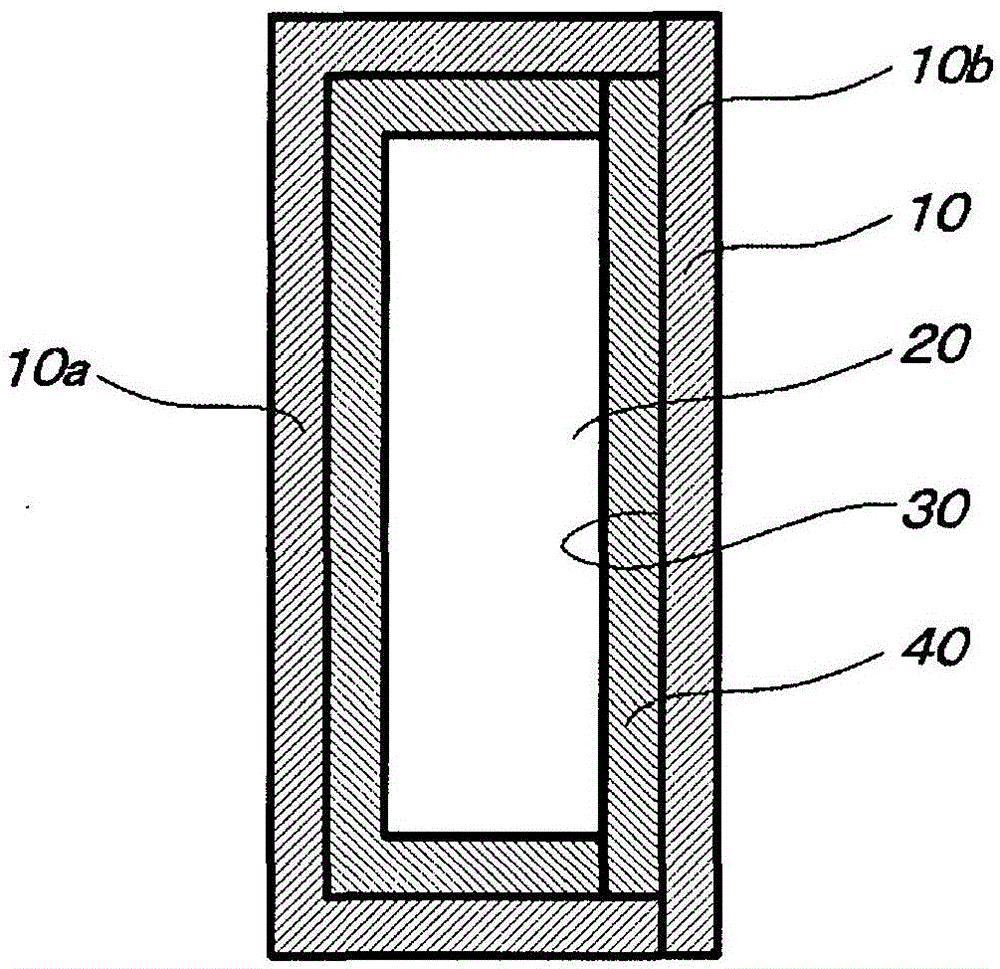

Exterior component for secondary battery

InactiveCN106252532AFull thicknessImprove insulation performanceProtecting/adjusting hybrid/EDL capacitorSynthetic resin layered productsMelting pointMetal

The present invention pertains to an exterior component for a secondary battery. The exterior component comprises a substrate layer, a barrier layer and a sealing layer in order, wherein the barrier layer is made of metal coil and is at least provided with an anticorrosion treating layer at the sealing layer side, the sealing layer is directly formed on the anticorrosion treating layer, the thickness of the sealing layer is 5-30 [mu]m, and the sealing layer comprises a compound having a high melting point.

Owner:TOPPAN PRINTING CO LTD

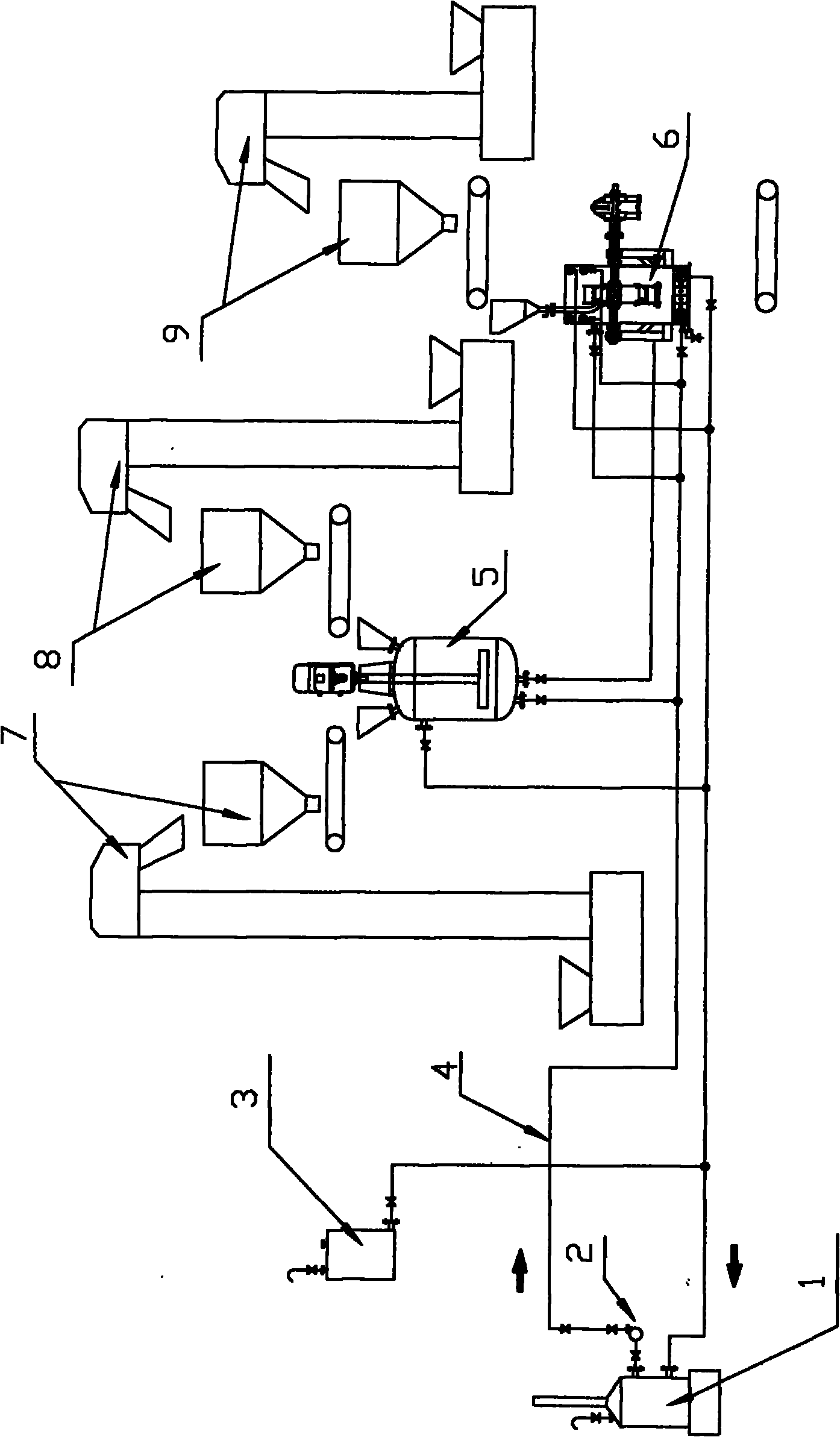

Preparation method of coated controlled-release fertilizer and coating equipment thereof

ActiveCN102093133AHigh strengthHigh nutrient contentFertilizer mixturesControl releaseTemperature difference

The invention discloses a preparation method of a coated controlled-release fertilizer and coating equipment thereof, which belong to the field of fertilizers and preparation of fertilizers, in particular to a preparation method and equipment of a fertilizer. The method is characterized in that: fertilizer particles are soaked into coating liquid for coating, wherein the temperature of the coating liquid is higher than that of the fertilizer particles. By adopting a soaking type coating method, the fertilizer particles are instantaneously coated by the coating liquid under the action of adsorption force produced by the temperature difference between the coating liquid and the fertilizer particles, so that an entire shell is formed by quick cooling, and coating is completed. The nutrient content of a coated finished product can be increased, the using amount of a coating material is reduced, and high coating intensity is achieved.

Owner:山东良永环保科技有限公司

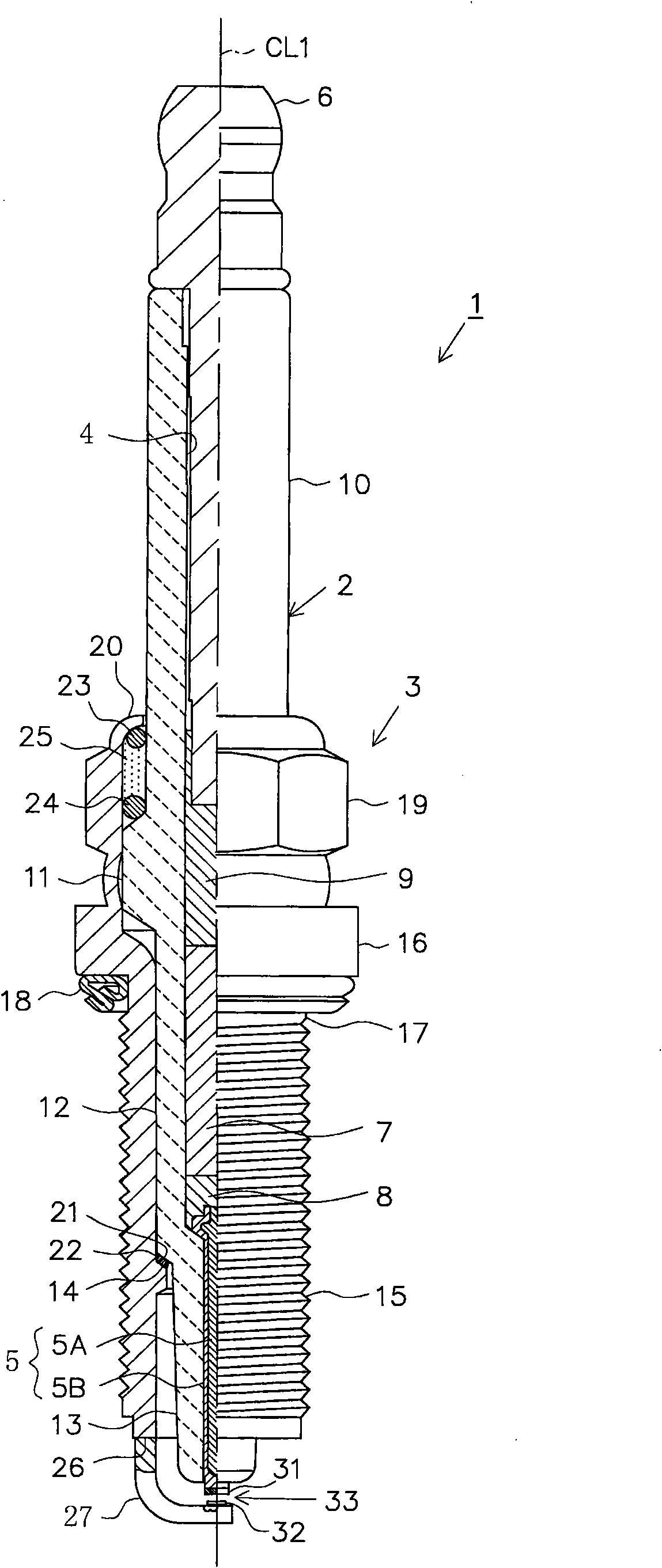

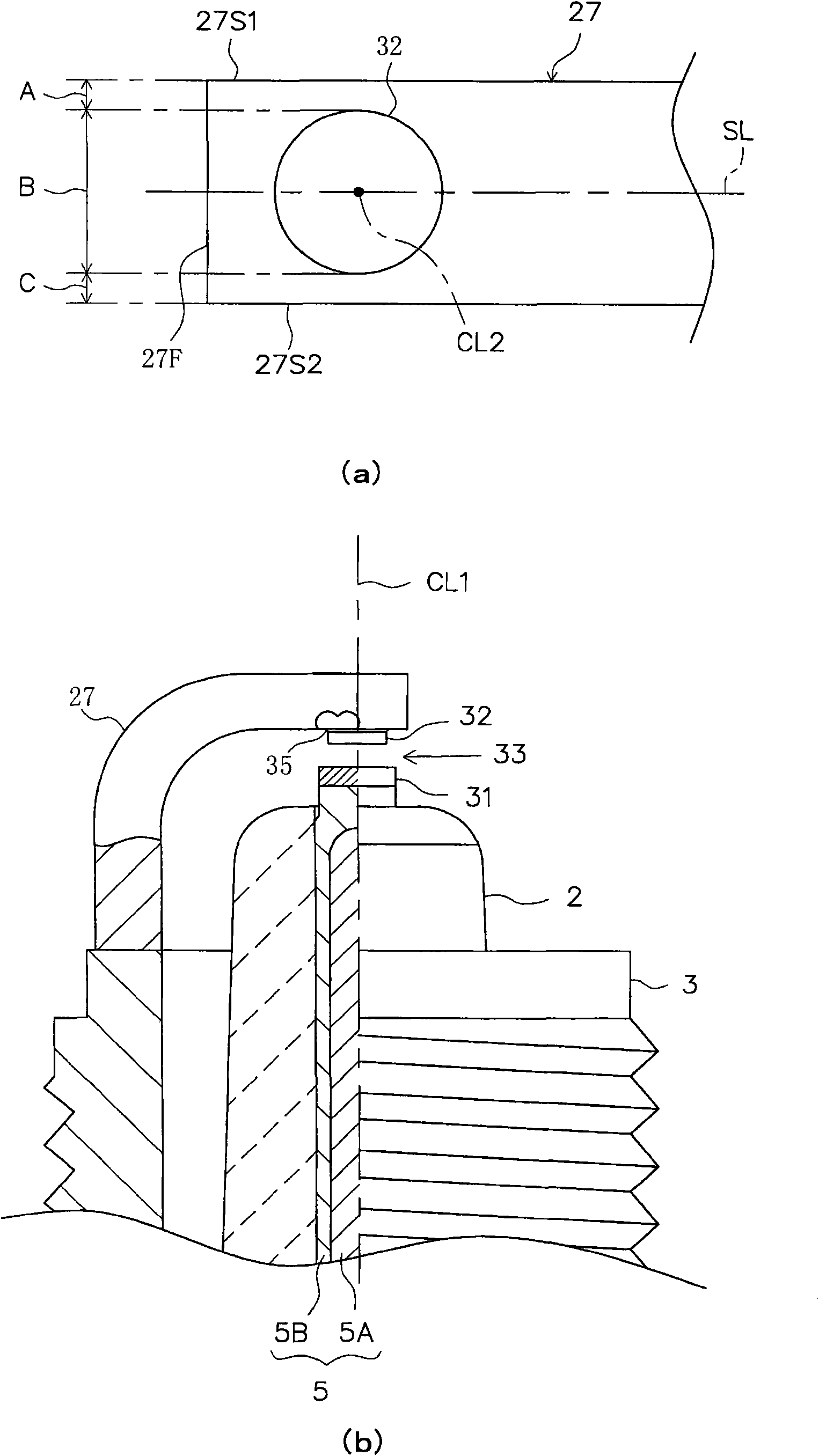

Spark plug and method of manufacturing the same

ActiveCN102122797AAvoid dischargeReduced durabilitySparking plugs manufactureEngineeringProjection plane

The present invention provides a spark plug in which a noble metal tip having a relatively large diameter is joined to a ground electrode, and which can restrain an increase in cost while sufficiently ensuring separation resistance of the noble metal tip, as well as a method of manufacturing the same. A spark plug including a noble metal tip joined to a ground electrode and forming a spark discharge gap in cooperation with a center electrode. A surface of the noble metal tip which forms the gap has an area of 0.9 mm2 or greater. The noble metal tip (32) is joined to the ground electrode (27) via a fusion zone (35) formed by irradiating at least one surface among a distal end surface and side surfaces of the ground electrode with a laser beam or an electron beam. Further, as viewed on a projection plane orthogonal to a center axis of the noble metal tip and on which the noble metal tip and the fusion zone are projected along the center axis, an overlapping region between the noble metal tip (32) and the fusion zone accounts for 70% or more of a projected region of the noble metal tip.

Owner:NGK SPARK PLUG CO LTD

Surface protection method for zirconium hydride

ActiveCN103484844AExcellent hydrogen resistanceUniform thicknessSolid/suspension decomposition chemical coatingZirconium hydrideHydrogen

The invention relates to a method for preparing a hydrogen-permeation resistant coating on the surface of zirconium hydride. The method particularly adopts the technical scheme that an in situ oxidization method for the preparation of a bottom layer is adopted, a sol-gel method is adopted and a nanometer oxide coating is prepared on the bottom layer, and finally an oxide coating with a composite structure is obtained. The method includes the following steps: firstly, the zirconium hydride is subjected to in situ oxidization in an oxidizing gas, so as to prepare a zirconia bottom layer, then the zirconium hydride is placed in a zirconium oxychloride precursor sol, and the sol is solidified and sintered through adopting a segmented heat processing technology. Through the adoption of the method, the prepared composite coating on the surface of the zirconium hydride is tightly combined with a base body, and is proper in thickness, excellent in thermal shock resistance and better in high-temperature oxidation resistance.

Owner:INNER MONGOLIA UNIV OF TECH

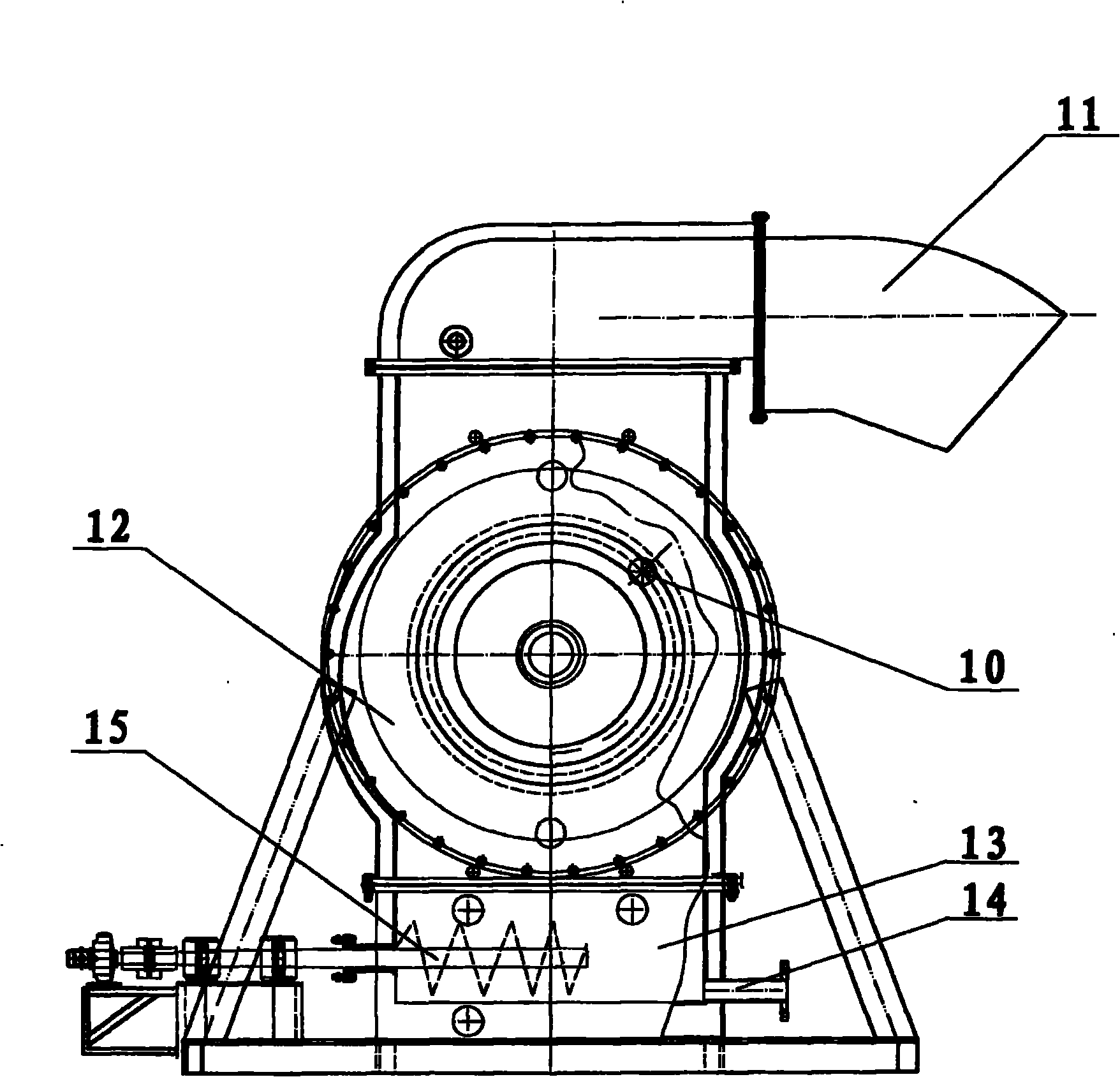

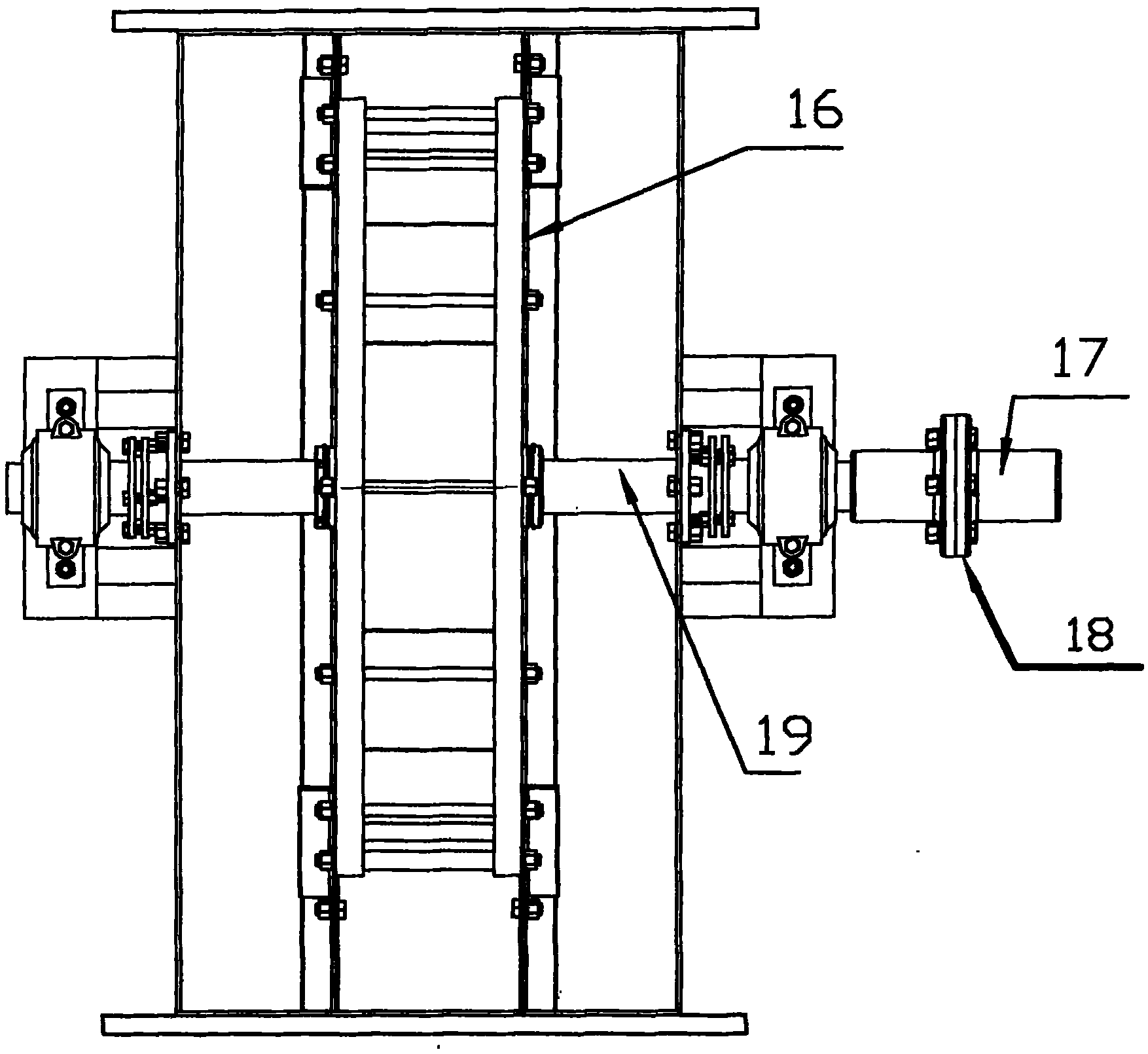

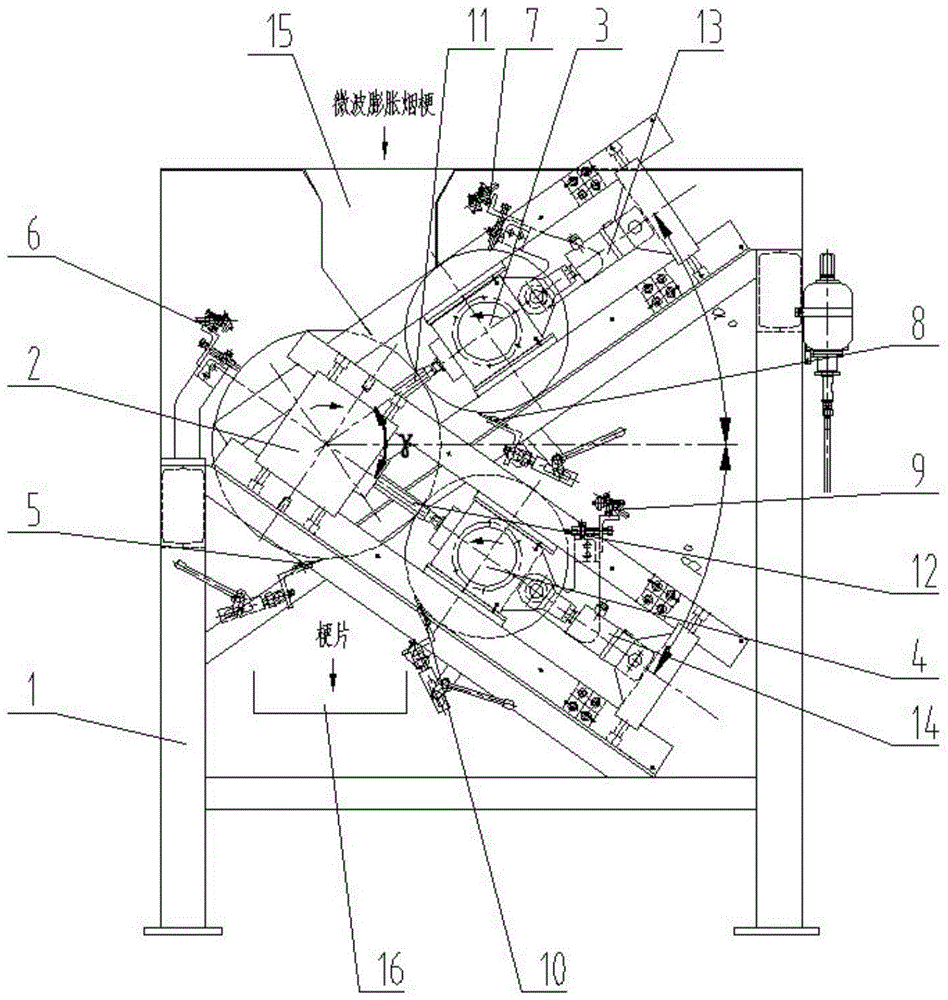

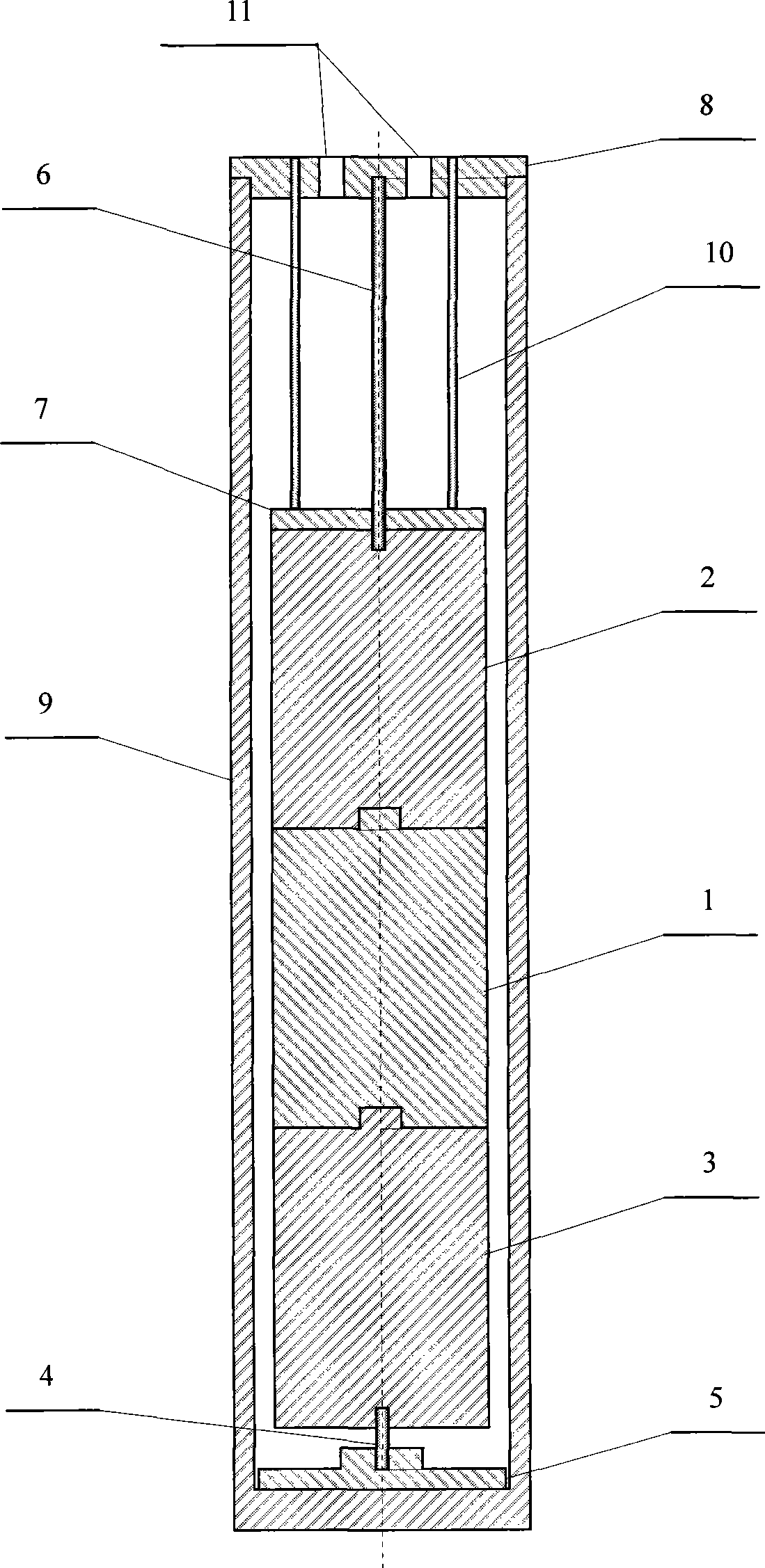

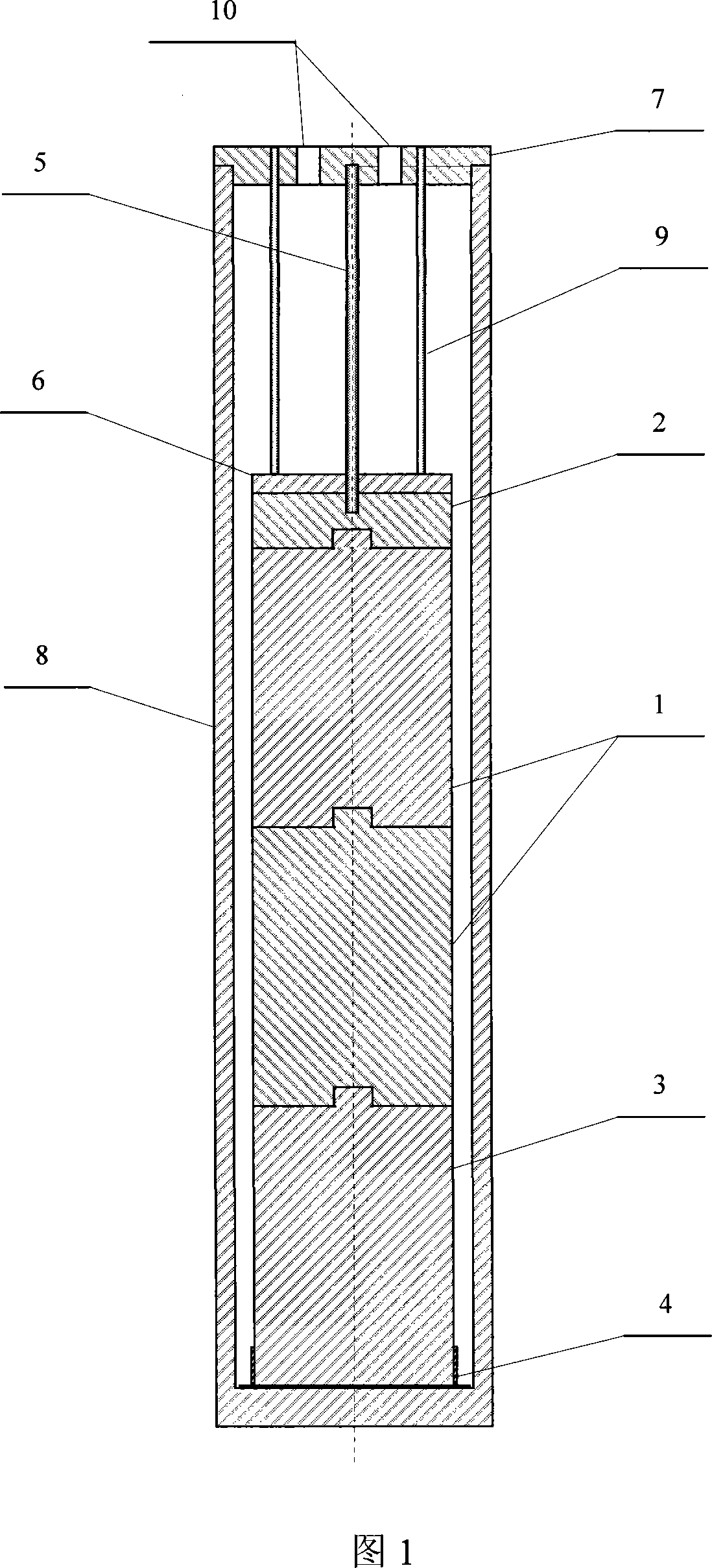

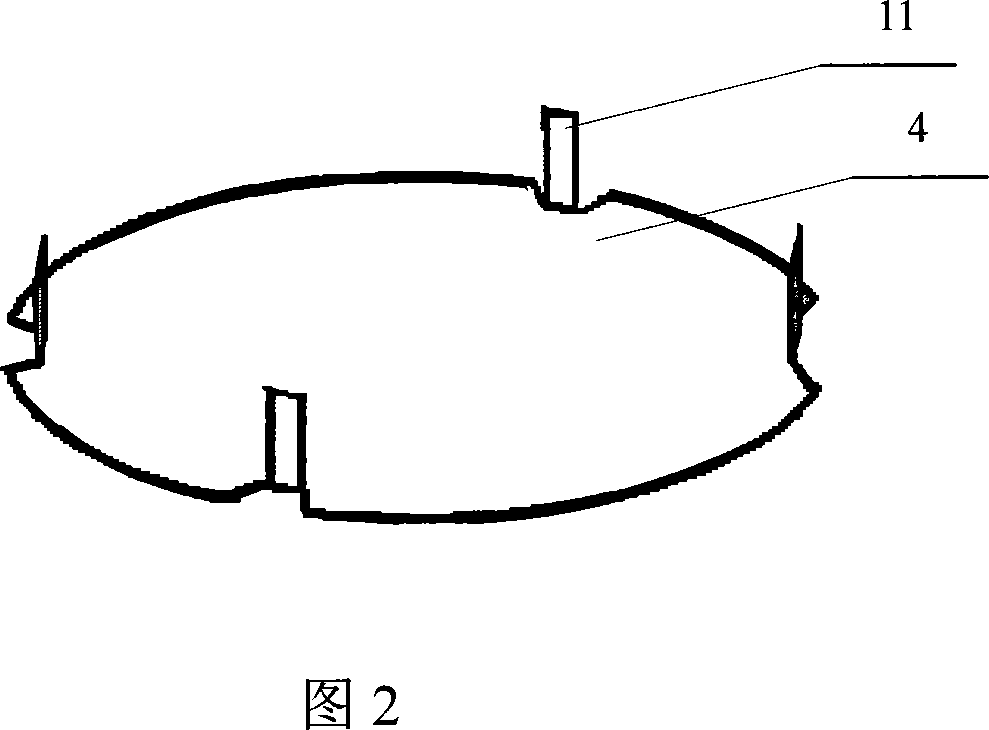

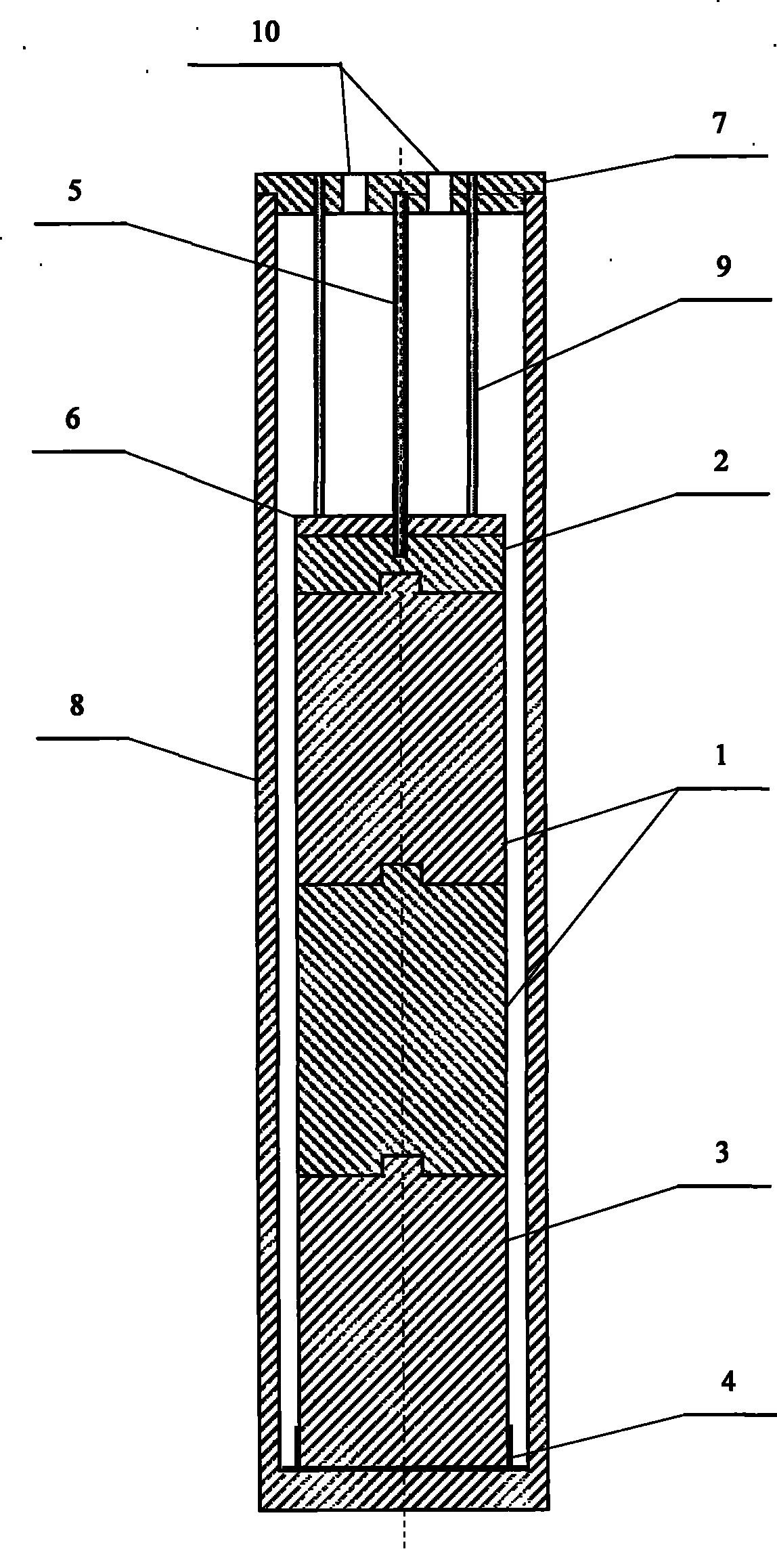

Integrated stem pressing device capable of achieving continuous rolling

ActiveCN104886760AThe overall thickness is thinFull thicknessTobacco treatmentEngineeringContinuous rolling

The invention relates to a device for pressing expanded tobacco stems into pieces and belongs to the technical field of tobacco manufacturing. The device comprises a machine frame (1), a fixed roller (2), an upper movable roller (3), a lower movable roller (4), a fixed roller scraper (5), a fixed roller lubricating system (6), an upper movable roller lubricating system (7), an upper movable roller scraper (8), a lower movable roller lubricating system (9), a lower movable roller scraper (10), a first pressing gap adjustment device (11), a second pressing gap adjustment device (12), an upper movable roller hydraulic system (13), a lower movable roller hydraulic system (14), a stem sorting device (15) and a stem piece arrangement device (16). According to the device, piece pressing can be conducted on expanded tobacco stems twice continuously; the thickness of pieces obtained through pressing reaches 0.2-0.4 mm; the shapes of the pieces are good, and cut stems are completely consistent with tobacco shreds in shape; the utilization rate of the expanded tobacco stems can be effectively increased, and the areas occupied for storing the expanded tobacco stems and the transportation cost of the expanded tobacco stems are reduced.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

Preparation apparatus of graphite metal wrap for thermal isostatic pressing

The invention relates to technology for preparing a high-performance graphite sealing material, in particular to a device for preparing a graphite metal clad for hot isostatic pressing. The device is provided with a graphite column, a metal bar, a graphite gasket, a metal gasket, a graphite crucible cover, a graphite crucible and a pouring gate, wherein the graphite column is arranged in the graphite crucible; the lower surface of the graphite column is contacted with the bottom of the graphite crucible through the metal gasket; gaps for filling metal are reserved on the upper surface and lateral sides of the graphite column; the metal bar is inserted between the upper surface of the graphite column and the graphite crucible cover arranged on the top of the graphite crucible; the graphite gasket is arranged on the upper surface of the graphite column; the upper surface of the graphite gasket is provided with the metal bar; and the graphite crucible cover is provided with the pouring gate. In the device, the metal graphite to be steeped is placed in the center of the bottom of the graphite crucible by axial fixation and radial fixation methods, so as to reduce immersion allowance of metal silver and manufacturing cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

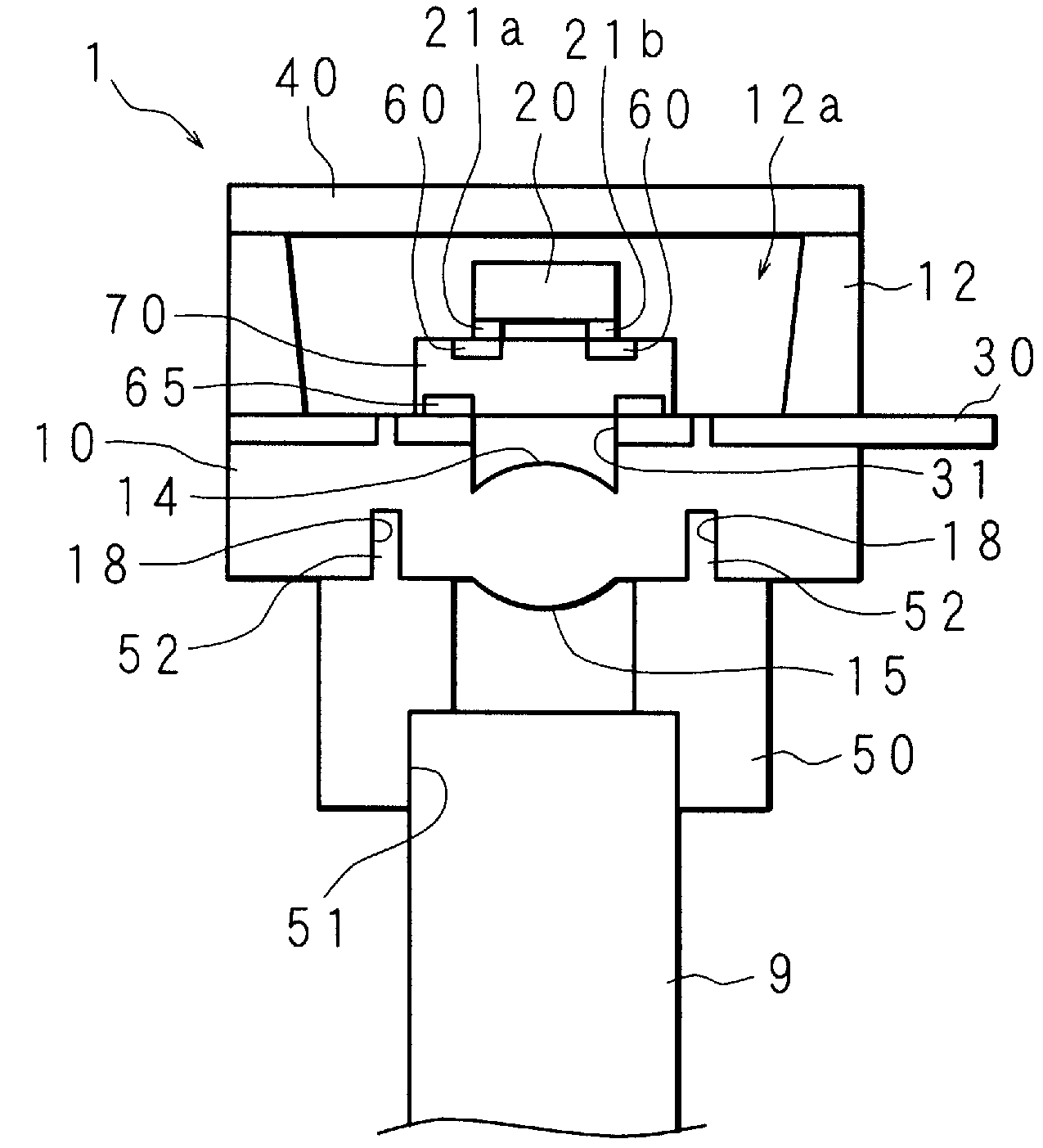

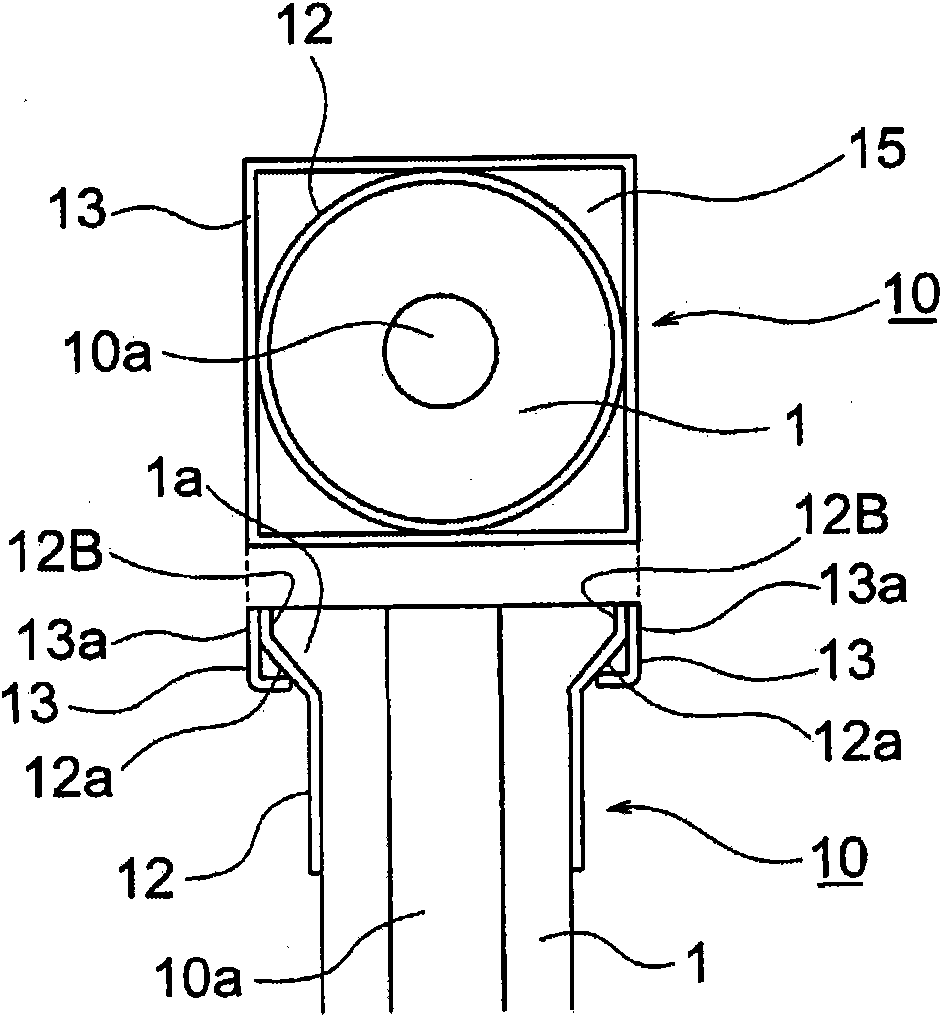

Optical communication module

ActiveCN102511116AFull thicknessReduce in quantityLaser detailsSolid-state devicesMiniaturizationLead frame

Disclosed is an optical communication module in which the thickness of an electrically conductive plate such as a lead frame needs not to be reduced and the size of a lens needs not to be reduced when the size of a photoelectronic element such as a laser diode or a photo diode is reduced. A laser diode (20) is connected and fixed to an electrically conductive plate (60) that is arranged on the upper surface of a light-permeable light-passing table (70), and the light-passing table (70) is connected and fixed to an electrically conductive plate (30) that is arranged on the upper surface of a light-permeable base (10). A first lens (14) and a second lens (15) are respectively formed on the upper surface and the lower surface of the base (10) in an integral manner. The laser diode (20) enables the sending of an optical signal through a gap of the electrically conductive plate (60), the light-permeable light-passing table (70), an opening of an electrically conductive plate (65), an opening (31) of the electrically conductive plate (30), the first lens (14), the light-permeable base (10) and the second lens (15).

Owner:AUTONETWORKS TECH LTD +2

Mold for molding expanded resin and process for producing same

InactiveCN105939830AEasy to manufactureHigh insulation performanceCoatingsHardnessExpanded polystyrene

A mold for molding an expanded resin, wherein a silicone rubber layer (40) having a JIS-A hardness of 20 to 70 is formed as a heat-insulating layer at least on a part or the whole of the inner wall surface that forms a cavity (20) of a mold main body (10) which is for use in molding an expanded resin and which is made of an aluminum material. This mold for molding an expanded resin is effectively usable in molding expanded polystyrene or the like by a bead molding method, and can produce a molded product of an expanded resin with high thermal efficiency by virtue of high heat insulation performance. Further, the mold can be easily produced with good execution efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

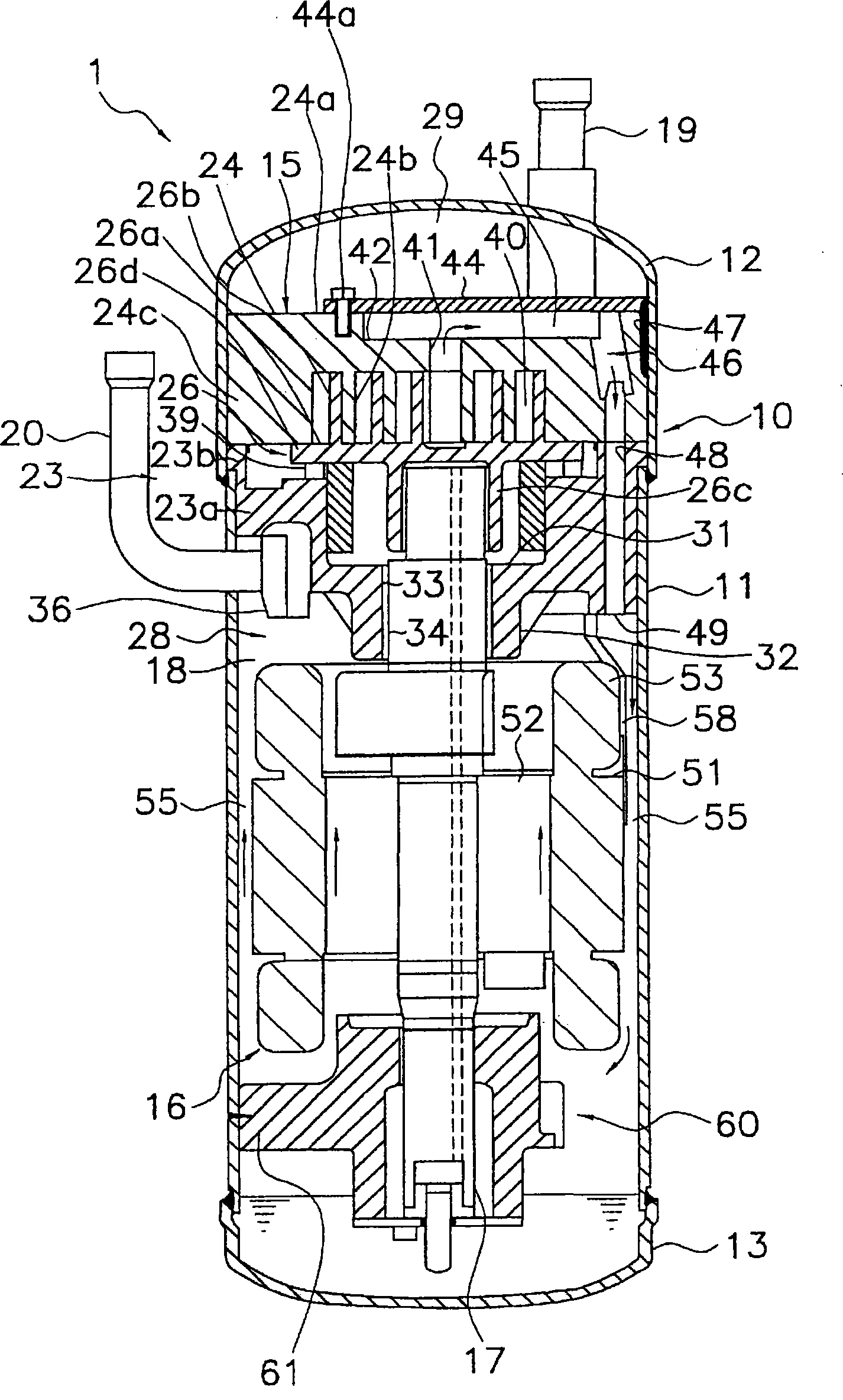

Thermal storage device and air conditioner provided with thermal storage device

ActiveCN103140727AFull flexibilityFull thicknessHeat storage plantsCompression machines with non-reversible cycleEngineeringHardness

A thermal storage device, which is arranged so as to surround a compressor (6), and which is for storing heat generated by the compressor (6), is provided with: a thermal storage tank (32) which accommodates a heat storage material (36) for storing the heat generated by the compressor (6); and an adhesive member (52) which has a hardness of not more than 50 on the Asker-C hardness scale, has a thermal conductivity of at least 0.43W / mK, has a thickness of 1-5mm, is arranged in a position facing the compressor (6), and which is for adhering to the compressor (6). The thermal storage tank (32) and the compressor (6) are adhered and fixed so as to be pressed together by a band or a screw, and thus the size of an air layer forming an insulator is reduced, and the heat generated by the compressor (6) can be efficiently transferred to the heat storage material and stored.

Owner:PANASONIC CORP

Immersion nozzle for continuous casting

Provided is an immersion nozzle for continuous casting, in which the neck part of a cylindrical refractory object can be prevented from being damaged due to a pressing force or a stress by forming a metal case provided for the cylindrical refractory in a double structure configured from an outer part and an inner part. The immersion nozzle for continuous casting comprises an inner metal case (12)provided onto a part or the entire of the outer surface of the cylindrical refractory object (1), a tapered metal part (12a) so formed on the inner metal case (12) as to correspond to the tapered part (11a) of the cylindrical refractory object (1), and an outer metal case (13) provided outside of the inner metal case (12). At least parts of the metal cases (12, 13) are joined to each other.

Owner:SHINAGAWA REFRACTORIES CO LTD

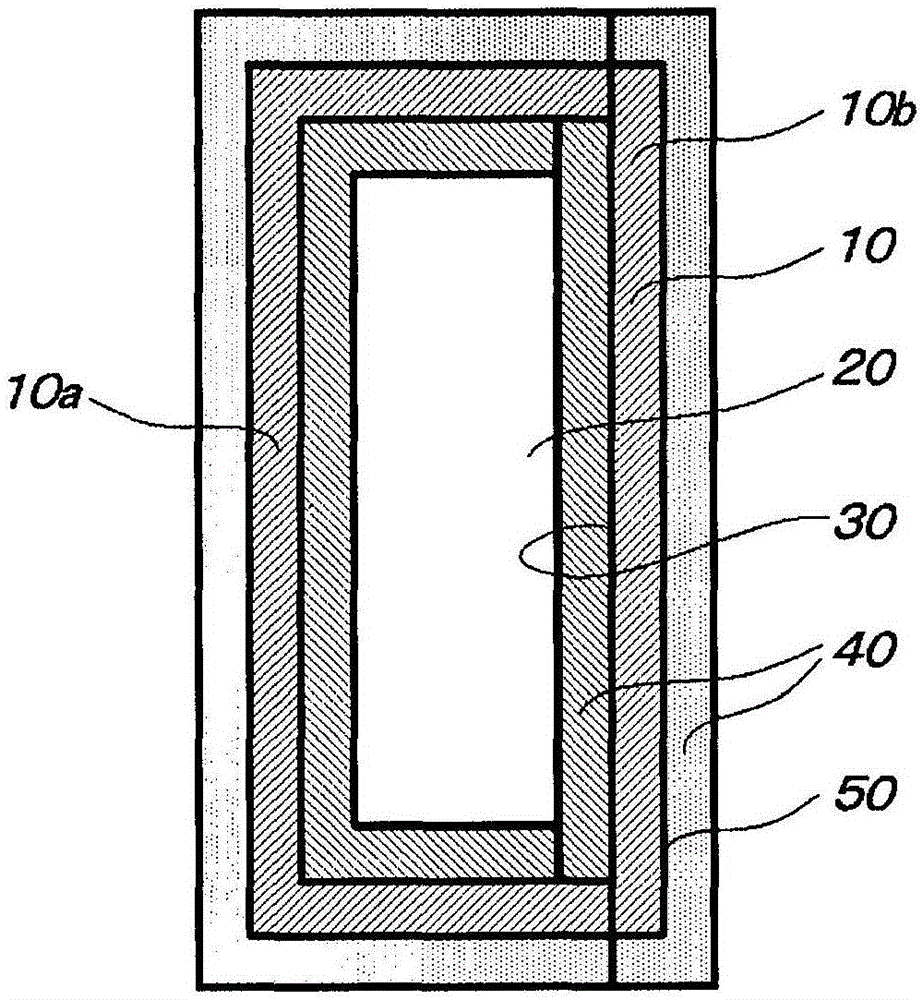

Metal-cladded laminate plate, and circuit board

ActiveCN112469560AFull thicknessExcellent dielectric propertiesInsulating substrate metal adhesion improvementSynthetic resin layered productsDielectric lossPolymer chemistry

A metal-cladded laminate plate which comprises a resin laminate comprising multiple polyimide layers and a metal layer laminated on at least one surface of the resin laminate, wherein the resin laminate satisfies the following requirements: (i) the whole thickness is 40 to 200 [mu]m; (ii) the resin laminate includes a first polyimide layer that comes in contact with the metal layer and a second polyimide layer that is laminated on the first polyimide layer directly or indirectly; (iii) the ratio of the thickness of the second polyimide layer to the whole thickness of the resin laminate is 70 to 97%; and (iv) an E1 value, which is a measure indicating a dielectric property and is calculated in accordance with the equation: E1 = tick mark Epsilon1*TanEpsilon1 [wherein Epsilon1 represents a dielectric constant at 10 GHz as measured with a split-post dielectric resonator (SPDR); and Tan Epsilon 1 represents a dielectric loss tangent at 10 GHz as measured with a split-post dielectric resonator (SPDR)], is less than 0.009.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

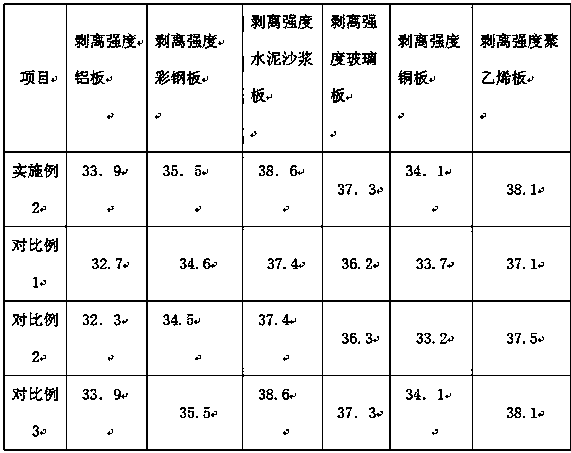

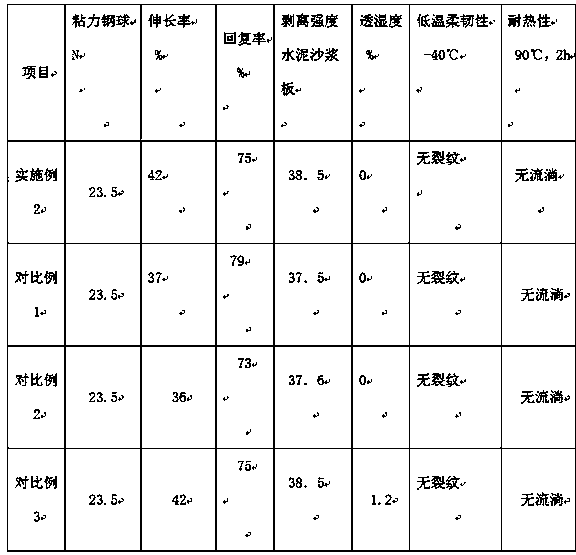

Waterproof, wear-resistant, and flame-retardant super adhesive tape

InactiveCN108864976AImprove stabilityHigh mechanical strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesFiberWear resistant

The invention discloses a waterproof, wear-resistant and flame-retardant supper adhesive tape. The adhesive tape comprises an adhesive layer, a middle layer and an outer layer. The outer layer is a polyvinyl chloride waterproof layer; the middle layer is a flame-retardant fiber cloth layer, and the flame-retardant fiber cloth layer is heat sealed on the outer layer; and the adhesive layer is applied to the flame retardant fiber cloth layer. The tape provided by the invention has high stability and can be continuously adhered; the tape does not easily peel off, the wound tape is prevented fromedge warping so that the replacement frequency is effectively reduced; the tape has high mechanical strength, strong tensile strength, and enough thickness; the tape is anti-aging, waterproof, flame-retardant and wear-resistant; and the tape is easy to be applied to bundling or repairing wires, filling construction joints, and material bonding.

Owner:阜南县力韦包装材料有限公司

Preparation apparatus of graphite metal wrap for thermal isostatic pressing

The invention relates to technology for preparing a high-performance graphite sealing material, in particular to a device for preparing a graphite metal clad for hot isostatic pressing. The device is provided with a graphite column, metal bars, a graphite gasket, a graphite crucible cover, a graphite crucible and a pouring gate, wherein the graphite column is arranged in the graphite crucible; gaps for filling metal are reserved on the periphery of the graphite column; the metal bar is inserted between the upper surface of the graphite column and the graphite gasket arranged on the bottom of the graphite crucible; a metal bar is inserted between the upper surface of the graphite column and the graphite crucible cover arranged on the top of the graphite crucible; the upper surface of the graphite column is provided with the graphite gasket; the metal bars pass through the graphite gasket; and the graphite crucible cover is provided with the pouring gate. In the device, the graphite column is hung in the graphite crucible through axial fixation and radial fixation methods, so as to reduce immersion allowance of metal silver and manufacture cost; and because the thickness of the silver clad on the outer surface of the graphite column is reduced, the cracking after pouring is reduced and the rate of finished products is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

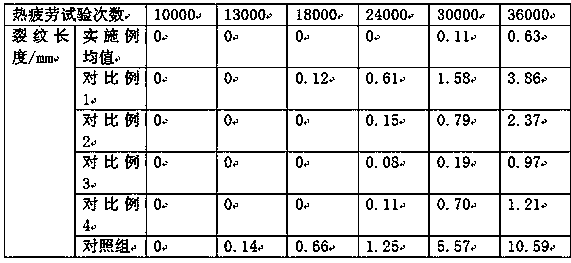

Anti-fatigue vehicle gear processing technology

InactiveCN109022724ASurface treatment process optimizationImprove organizational structureSolid state diffusion coatingFurnace typesSurface layerGear wheel

The invention discloses an anti-fatigue vehicle gear processing technology, and relates to the technical field of gears. The anti-fatigue vehicle gear processing technology comprises the following steps that (1), cleaning is conducted; (2) solid solution modification processing is conducted; and (3) temper modification processing is conducted. The anti-fatigue vehicle gear processing technology isresearched by a plurality of experiments. The vehicle gear surface processing technology is greatly optimized. The vehicle gear organization structure can be effectively improved. The surface layer can be strengthened. Vehicle gear surface layer components, organization and performance are significantly improved.

Owner:含山县林头宝兴铸造厂

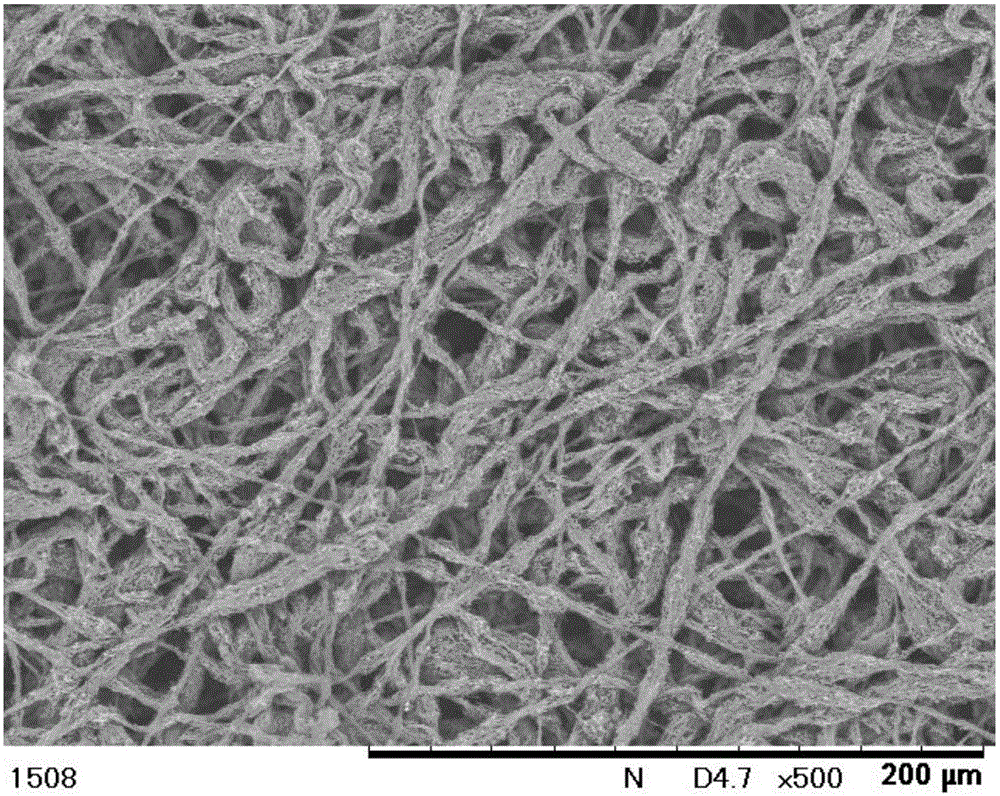

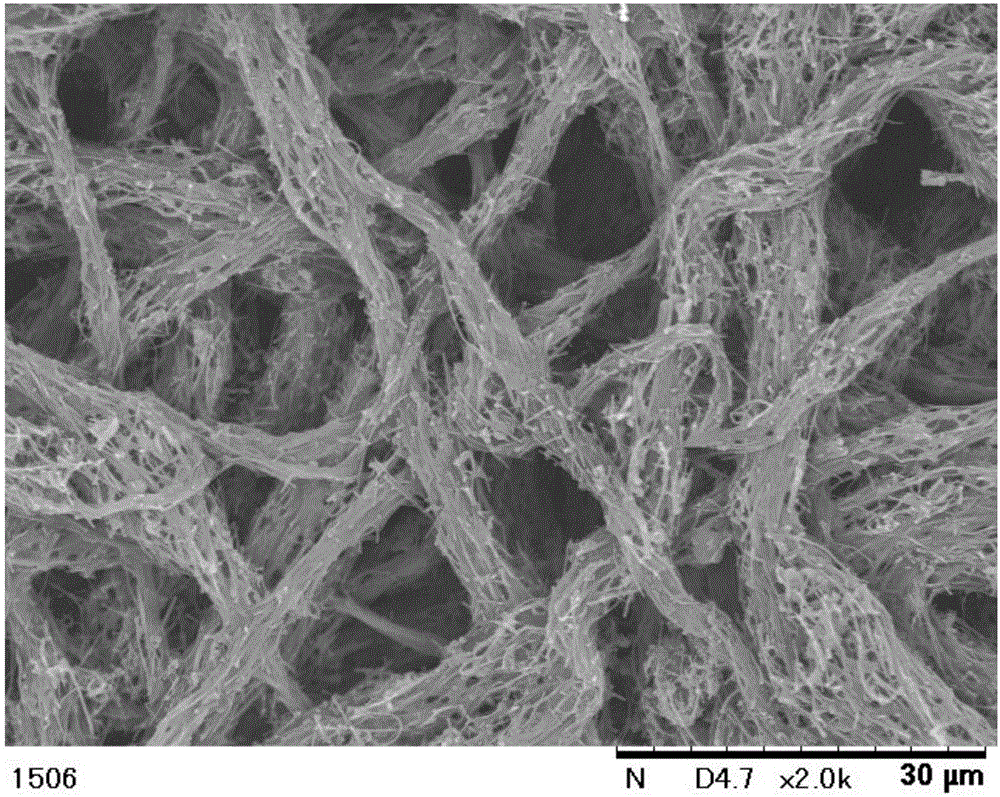

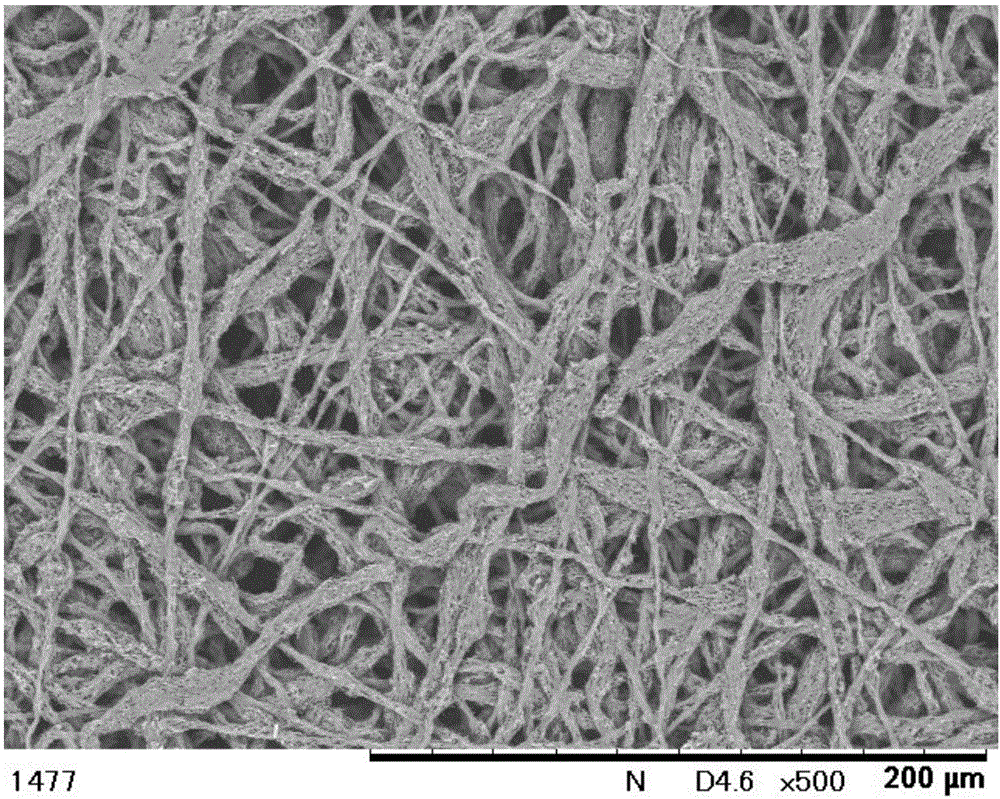

Electroconductive porous body, solid polymer fuel cell, and method for manufacturing electroconductive porous body

InactiveCN106133968ATake advantage of porosityFull thicknessElectroconductive/antistatic filament manufactureCell electrodesFiberFuel cells

The present invention addresses the problem of providing: an electroconductive porous body that has a large specific surface area, that does not readily break under pressure, and that can be applied to a variety of applications; a solid polymer fuel cell; and a method for manufacturing an electroconductive porous body. This electroconductive porous body is obtained by aggregating a fibrous material having a first electroconductive material and a second electroconductive material that links spaces in the first electroconductive material, the electroconductive porous body having a specific surface area of 100 m2 / g or above, and a thickness retention rate of 60% or above after application of pressure at 2 MPa. Such an electroconductive porous body can be manufactured by spinning a spinning solution containing the first electroconductive material and a carbonizable organic material, forming a precursor fiber porous body in which precursor fibers are aggregated, and subsequently carbonizing the carbonizable organic material to obtain the second electroconductive material.

Owner:JAPAN VILENE CO LTD

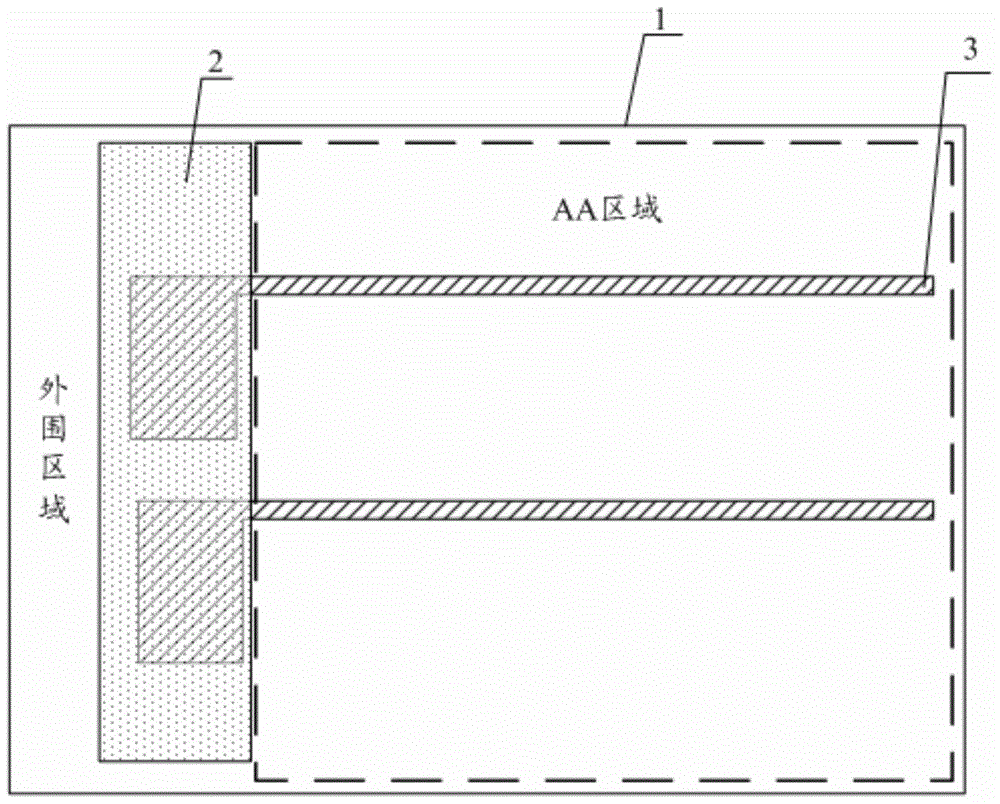

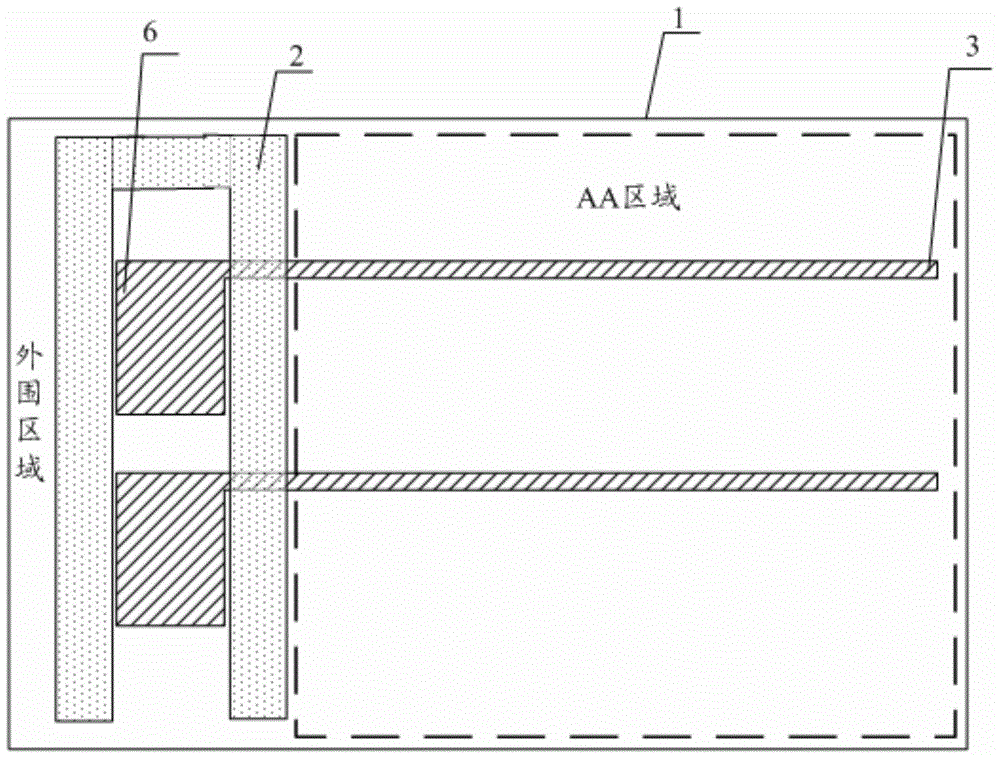

A display substrate and display device

ActiveCN103969859BFull thicknessFull thickness (covers the entire AA area) and uniform thicknessStatic indicating devicesNon-linear opticsDisplay deviceComputer science

The invention discloses a substrate for display and a display device. The problem that when PI liquid is sprayed on a display area, a PI film formed by the PI liquid is bad due to slits among a plurality of independent connecting areas of the display area is solved. The substrate for display comprises a lining substrate body, a peripheral common electrode and a plurality of common electrode lines, the peripheral common electrode is located in the peripheral area of the lining substrate body and extends in the first direction, the common electrode lines are located in the display area of the lining substrate body and at least extend to the area where the peripheral common electrode is located in the second direction crossing with the first direction, and the peripheral common electrode and the common electrode lines are arranged on different layers. The peripheral common electrode and the common electrode lines are insulated in the crossing area, and are connected in the peripheral area in a via hole bridging mode.

Owner:BOE TECH GRP CO LTD +1

Preparation apparatus of graphite metal wrap for thermal isostatic pressing

The invention relates to technology for preparing a high-performance graphite sealing material, in particular to a device for preparing a graphite metal clad for hot isostatic pressing. The device is provided with a graphite column, metal bars, a graphite gasket, a graphite crucible cover, a graphite crucible and a pouring gate, wherein the graphite column is arranged in the graphite crucible; gaps for filling metal are reserved on the periphery of the graphite column; the metal bar is inserted between the upper surface of the graphite column and the graphite gasket arranged on the bottom of the graphite crucible; a metal bar is inserted between the upper surface of the graphite column and the graphite crucible cover arranged on the top of the graphite crucible; the upper surface of the graphite column is provided with the graphite gasket; the metal bars pass through the graphite gasket; and the graphite crucible cover is provided with the pouring gate. In the device, the graphite column is hung in the graphite crucible through axial fixation and radial fixation methods, so as to reduce immersion allowance of metal silver and manufacture cost; and because the thickness of the silver clad on the outer surface of the graphite column is reduced, the cracking after pouring is reduced and the rate of finished products is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

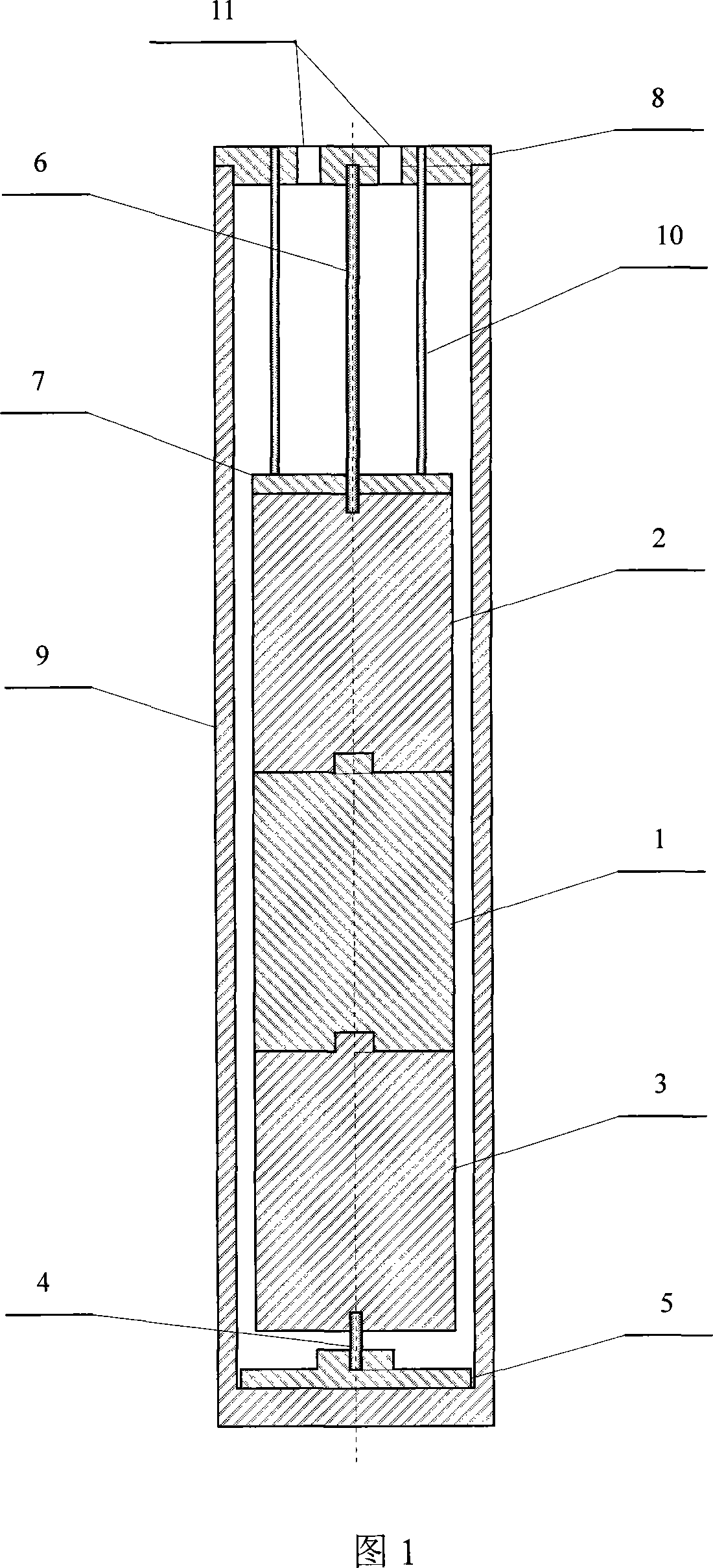

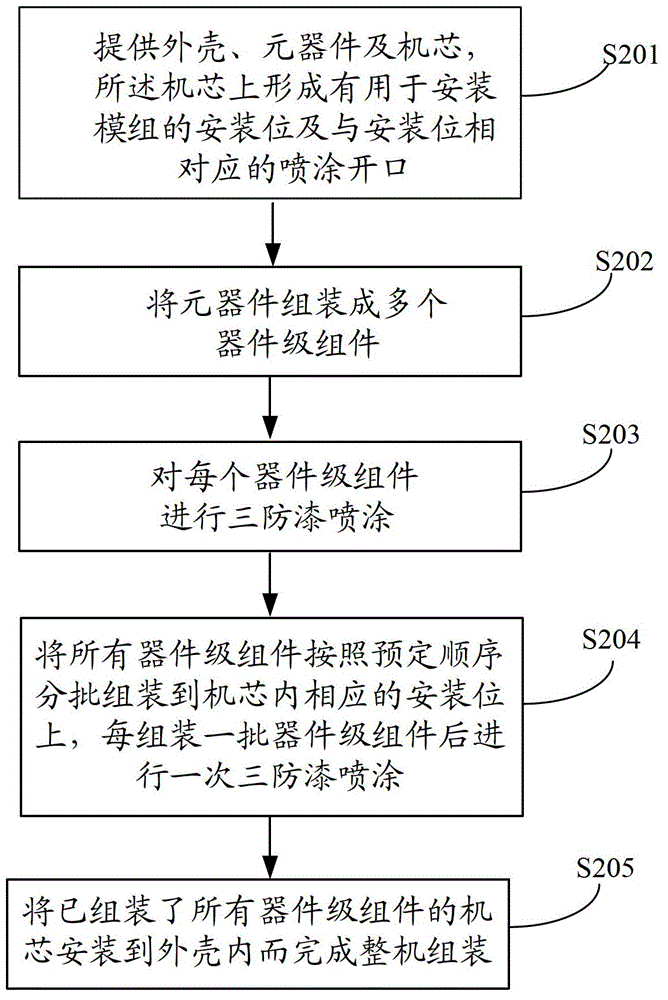

Method for manufacturing electronic equipment

ActiveCN102753001BImprove operational reliabilityEffective thicknessElectrical componentsHigh humidityModular design

The invention discloses a method for manufacturing electronic equipment. The method comprises the following steps of: providing parts to be assembled into the electronic equipment, wherein the parts comprise components and a shell; assembling the components into a plurality of modules; performing conformal coating spraying on each module; assembling the sprayed modules in the shell; and performing conformal coating spraying on the modules in the shell. The method for manufacturing the electronic equipment has the advantages that the components are modularized and then individually sprayed, the components are sprayed repeatedly in the overall assembly process, and the components of the electronic equipment can be comprehensively protected by multilayer spraying which comprises individual spraying and overall spraying, so the whole protection performance of the electronic equipment is effectively improved; and on the premise that the international protection (IP) grade is not improved, the operation reliability of the electronic equipment in service environment such as high dust content, high humidity and high corrosive pollution can be improved.

Owner:SHENZHEN INVT ELECTRIC

Preparation apparatus of graphite metal wrap for thermal isostatic pressing

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

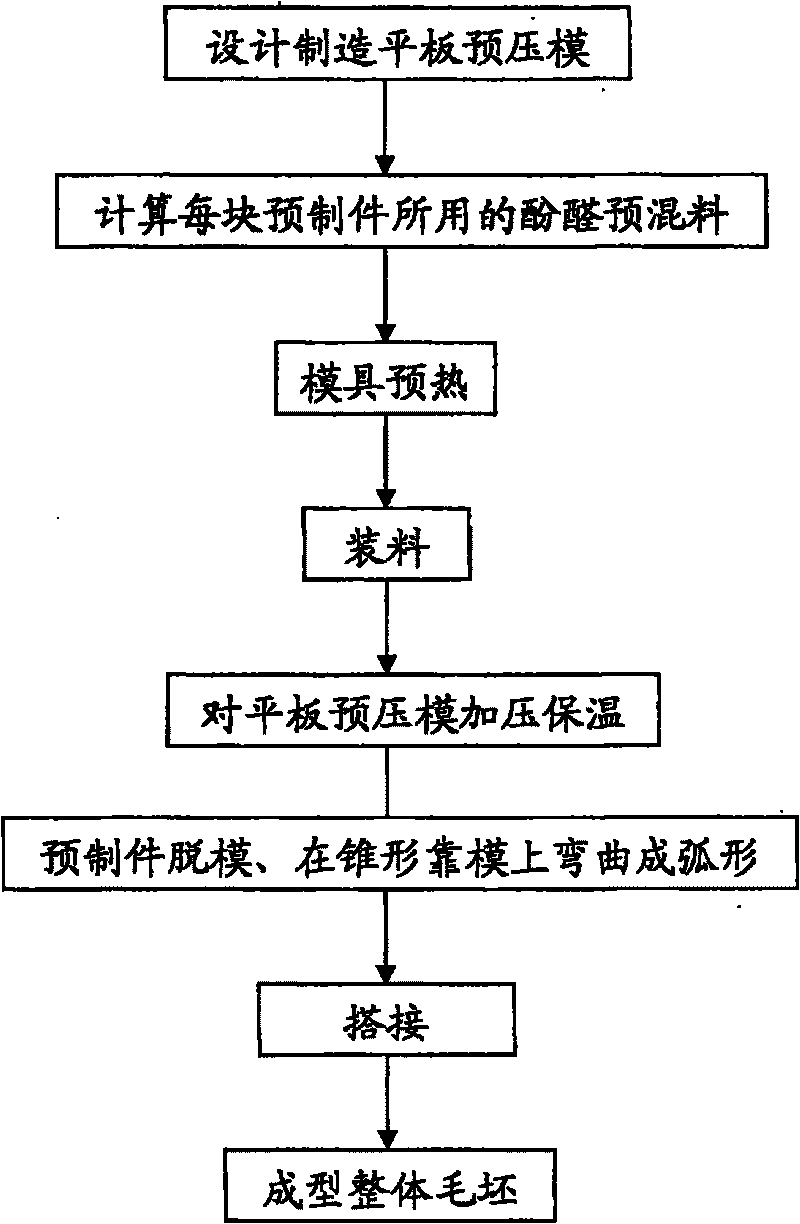

Cone phenolic resin composites structural parts whole-blank precast-products lapping forming technique

The invention relates to a related joint forming process of a conical metlbond composite material structure and an overall blank preformed unit. The shape of the conical metlbond composite material structure is unfolded and differentiated, and the related joint width of the preformed unit is taken as the basis of the size, thus a tablet prepressing mold can be designed and manufactured; the chargeamount of each preformed unit is calculated; metlbond premix compound is horizontally and evenly added in the preheated prepressing mold, a hydraulic press pressurizes on the preformed unit, demoulding is carried out after holding the temperature for 10-30 minutes; the preformed unit after demoulding is immediately bent into an arc preformed unit by a conical explorator; cooling is carried out for 15-30 minutes; the preformed unit is put in the preheated overall forming mold for related joint, the overall blank is obtained by sealing the preformed unit by a gum cover and pumping to be in vacuum. By adopting the process, one third of the metlbond premix compound can be saved in production, the production cost is greatly reduced; the original processing period of 4 days is reduced to 2.5 days, thus improving the production efficiency; the loading difficulty and labor intensity are lowered, the controllability of the process is improved, the thickness of the product is even and complete,and the stability of the product quality is greatly improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

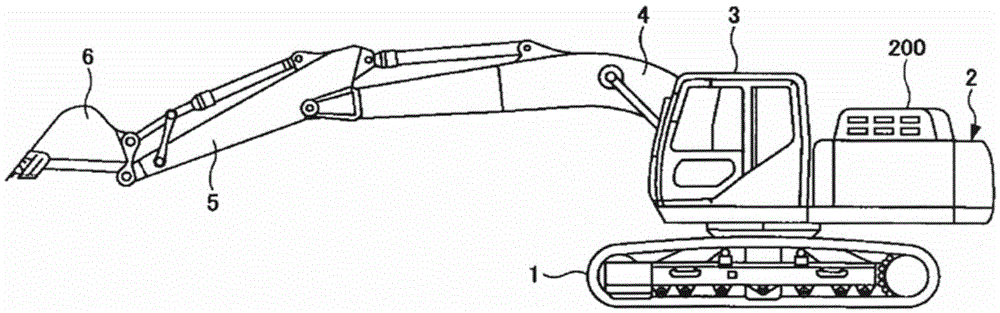

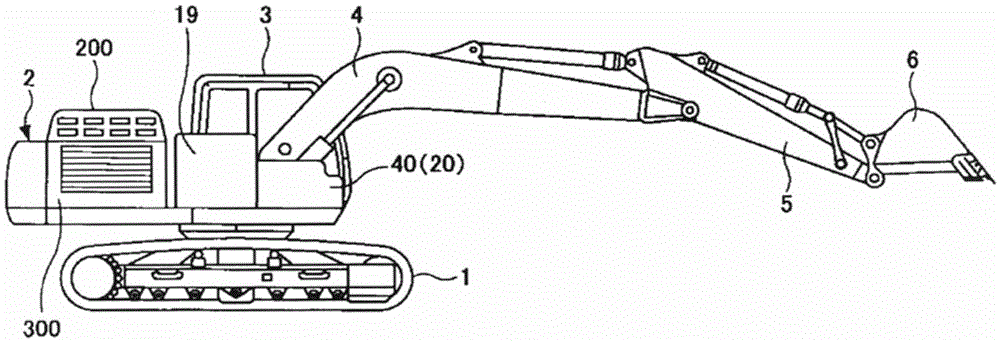

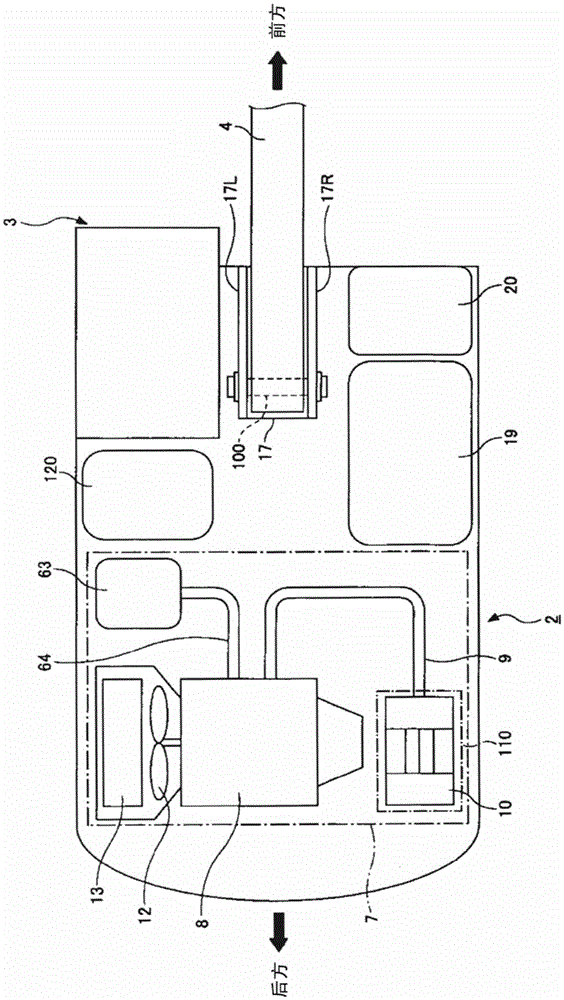

Navvy cover

Owner:SUMITOMO CONSTRUCTION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com