Cone phenolic resin composites structural parts whole-blank precast-products lapping forming technique

A composite material and molding process technology, applied in the field of composite material processing, can solve the problems of irregular and uneven shrinkage of rubber sleeves, uneven thickness, waste of raw materials, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

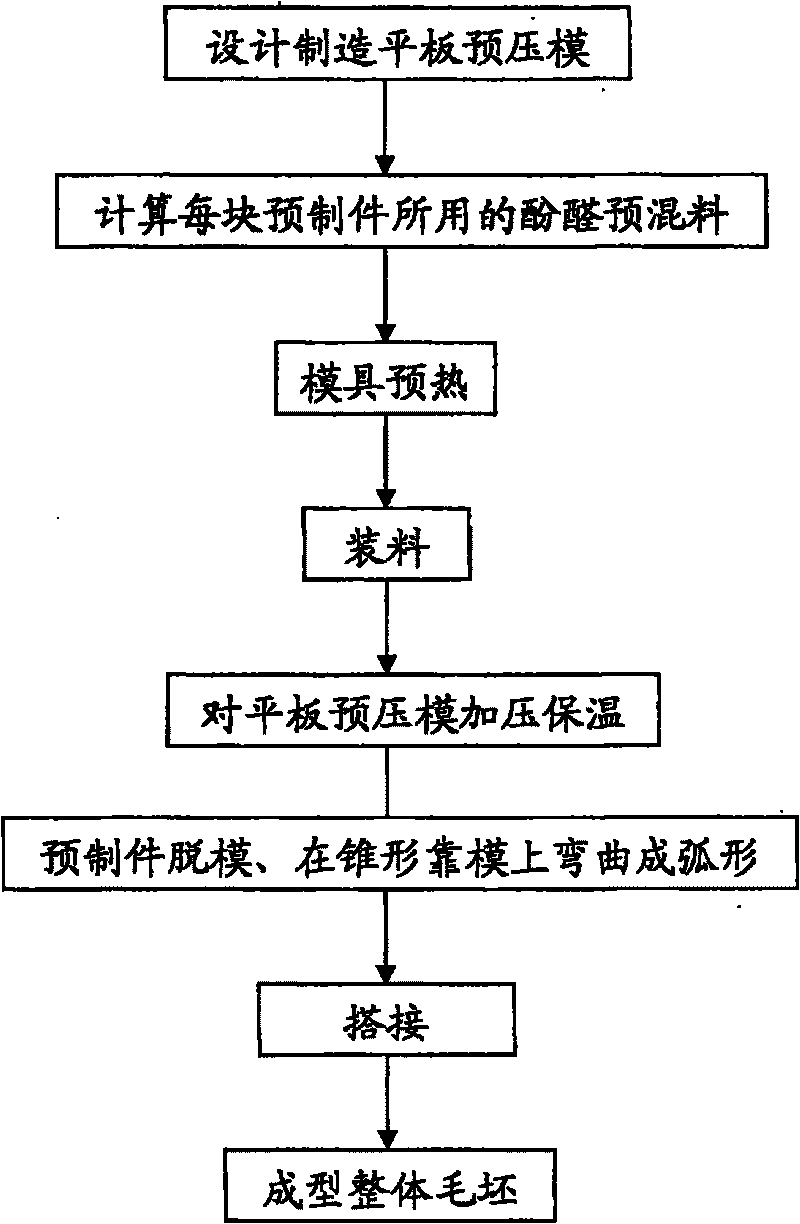

[0025] Processing flow such as figure 1 shown.

[0026] A product has a large end diameter of 900mm, a small end of 700mm, a height of 1200mm, a thickness of 10mm, a machining allowance of 10mm, and a product density of 1.65g / cm 3 , the lap width is 200mm, and the whole blank is divided into two pieces, based on which the flat pre-compression mold is designed. The cavity size of the flat pre-compression mold is 1620mm at the big end, 1300mm at the small end, 1200mm wide and 150mm deep. According to the prefabricated According to the formula s*(d+l)*g for calculating the loading amount of a piece, 58kg of phenolic premix is used for each prefabricated piece; the flat pre-compression mold is installed on the hydraulic press, and the flat pre-compression mold and the integral molding female mold are simultaneously Preheat to 60°C; evenly load 58kg of phenolic premix into the flat pre-compression mold, close the mold with a hydraulic press, pressurize at 1MPa, keep warm for 15 ...

Embodiment 2

[0028] A product has a large end diameter of 1200mm, a small end of 1000mm, a height of 1600mm, a thickness of 12mm, a machining allowance of 10mm, and a product density of 1.65g / cm 3 , the overlapping width is 200mm, and the whole blank is divided into 4 pieces, based on which the flat pre-compression mold is designed. According to the formula s*(d+l)*g for the calculation of the loading amount of each piece, 62kg of phenolic premix is used for each prefabricated piece; the flat pre-compression mold is installed on the hydraulic press, and the flat pre-compression mold and the integral molding female mold are simultaneously Preheat to 70°C; evenly load 62kg of phenolic premix into the flat pre-compression mold, close the mold with a hydraulic press, pressurize at 2MPa, keep warm for 20min, open the mold and take out the prefabricated part, apply force manually on the conical master The prefabricated part is bent into an arc-shaped prefabricated part and cooled naturally for...

Embodiment 3

[0030] A product has a large end diameter of 600mm, a small end of 500mm, a height of 600mm, a thickness of 10mm, a machining allowance of 10mm, and a product density of 1.65g / cm 3 , the lap joint width is 200mm, and the whole blank can be divided into 2 parts unevenly. Based on this, two flat-plate pre-compression molds are designed. The cavity size of the first flat-plate pre-compression model is 1100mm at the big end, 943mm at the small end, and 600mm wide. The depth is 150mm, the size of the second flat plate pre-compression model cavity is 1185mm at the big end, 1028mm at the small end, 600mm wide, and 150mm deep. Use 20kg of phenolic premix for the prefabricated part, and 22kg of phenolic premix for the second prefabricated part; install the first flat precompression mold on the hydraulic press, and preheat the flat precompression mold and integral molding female mold to 50 at the same time ℃; Evenly load 20kg of phenolic premix into the first flat pre-compression mold, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com