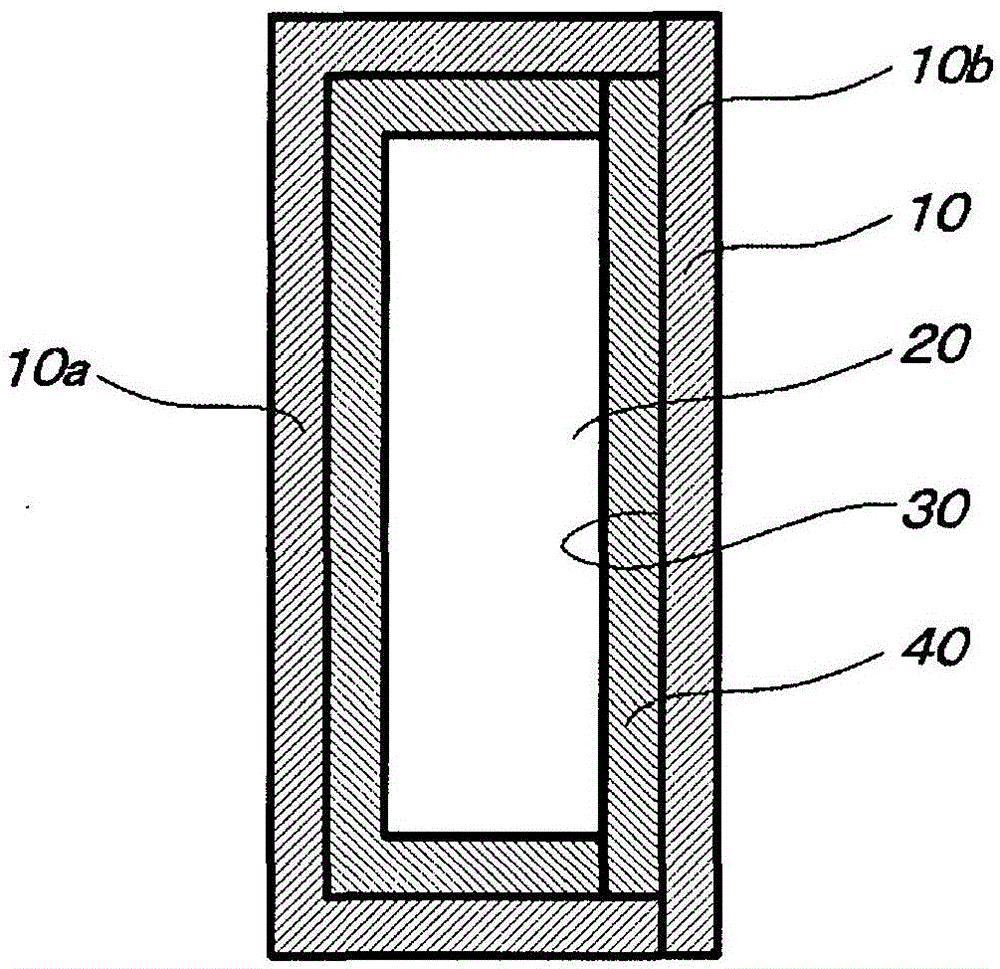

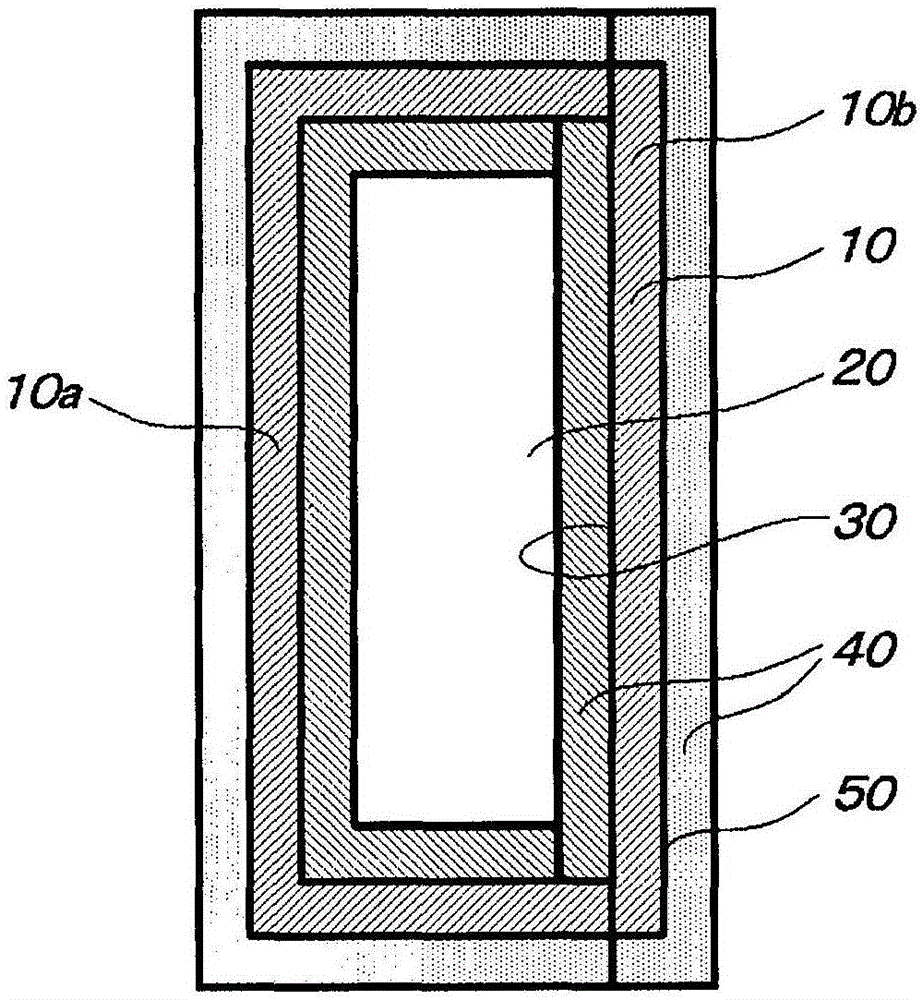

Mold for molding expanded resin and process for producing same

A technology of foaming resin and manufacturing method, applied in the direction of coating, etc., can solve problems such as lack of adhesion to aluminum molds, difficulties in mold construction, construction difficulties, etc., and achieve good constructability, good thermal efficiency, and high thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 50 parts by mass of linear dimethyl polysiloxane with a viscosity of 20,000 mPa·s at 25° C., 50 parts by mass of calcium carbonate, methyl tri(methyl trimethylpolysiloxane) and 10 parts by mass of ethyl ethyl ketoxime) silane, 1 part by mass of 3-aminopropyltriethoxysilane, and 0.1 part by mass of dibutyltin dilaurate until uniform, and then mixed with 30 parts by mass of xylene to prepare the viscosity at 25°C A liquid room temperature curable silicone rubber composition of 5 Pa·s.

[0053] In the mold cavity volume is 0.05m 3 , The inner wall surface (whole surface) of the aluminum foamed polystyrene molding mold main body with a thickness of 20 mm is coated with the above-mentioned liquid room temperature curable silicone rubber composition by 2 coats of brushes, and placed in the air at room temperature ( 25° C.) for 24 hours, a silicone rubber layer (coating layer) with a thickness of 2 mm and a JIS-A hardness of 60 specified in JIS K 6249 was formed on the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com