Exterior component for secondary battery

A technology for secondary batteries and components, which is applied to battery pack parts, battery boxes/coatings, structural parts, etc. It can solve problems such as failure to maintain electrical insulation, short circuit of secondary batteries, insufficient acquisition, etc., and achieve excellent electrical insulation. Insulation, maintenance of electrical insulation, and the effect of suppressing short-circuiting of tab leads

Inactive Publication Date: 2016-12-21

TOPPAN PRINTING CO LTD

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] However, the method described in Patent Document 1 can prevent a short circuit between the tab lead and the metal foil used as the barrier layer of the exterior member, but the film thickness becomes thicker due to the addition of an intermediate layer.

[0010] Lithium-ion secondary batteries, which have become popular in recent years, have the danger of degraded battery performance, heat generation, and fire due to failure to maintain electrical insulation. Therefore, it is necessary to prevent secondary batteries from short-circuiting.

However, on the other hand, the actual situation is that effective means for preventing a short circuit between the tab lead and the secondary battery exterior member while reducing the thickness of the exterior member in this way have not yet been sufficiently obtained.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0097] The details of the present invention will be described below through examples, but the present invention is not limited by the following description.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Login to View More

Abstract

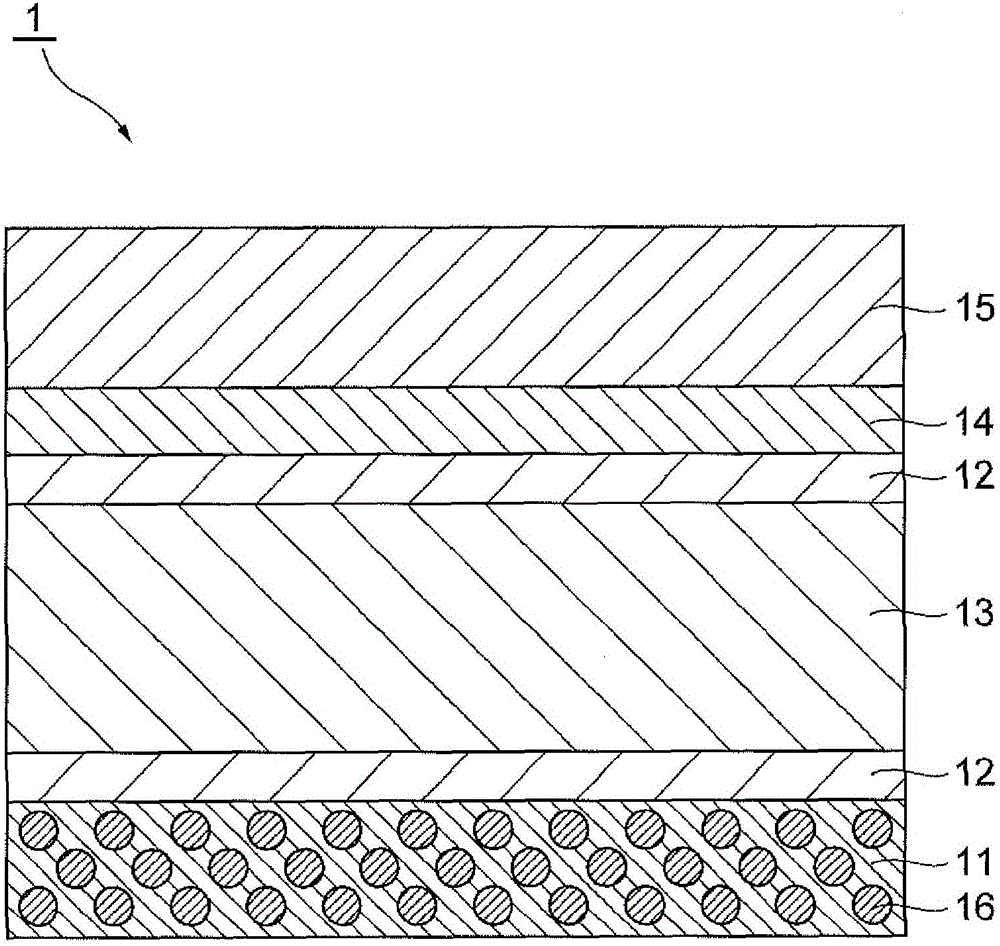

The present invention pertains to an exterior component for a secondary battery. The exterior component comprises a substrate layer, a barrier layer and a sealing layer in order, wherein the barrier layer is made of metal coil and is at least provided with an anticorrosion treating layer at the sealing layer side, the sealing layer is directly formed on the anticorrosion treating layer, the thickness of the sealing layer is 5-30 [mu]m, and the sealing layer comprises a compound having a high melting point.

Description

technical field [0001] The present invention relates to an exterior member for a secondary battery. Background technique [0002] In recent years, the spread of portable devices such as mobile phones, smartphones, and music player portable devices, hybrid electric vehicles, electric vehicles, etc. is advancing. Secondary batteries typified by nickel-hydrogen batteries, lithium ion batteries, and the like are used as batteries for supplying electricity as their power sources and power sources. For secondary batteries, light weight and compactness are required in portable equipment applications, and in vehicle applications, they are connected in parallel or in series to increase energy and output power, and multilayers are developed. Light weight and compactness are further demanded. [0003] Therefore, for secondary batteries, metal cans and laminated film exterior members are used depending on the application and usage environment, and the laminated film exterior member ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M2/02H01M50/105H01M50/119H01M50/121H01M50/129H01M50/133H01M50/141H01M50/145H01M50/186H01M50/193

CPCH01M50/124H01M50/116H01M50/19H01M50/197H01G11/16H01G11/80B32B27/08B32B2307/306B32B2307/546B32B15/20B32B2553/00B32B15/18B32B27/34B32B27/32B32B27/36B32B2264/102B32B7/12B32B15/088B32B15/085B32B15/09B32B27/20B32B2307/7265B32B2307/714Y02E60/10H01M50/133H01M50/105H01M50/141H01M50/121H01M50/186H01M50/129H01M50/193H01M50/145H01M50/119H01G11/78Y02E60/13B32B2264/107B32B2457/10

Inventor 台洋

Owner TOPPAN PRINTING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com