Full-solid preparation method of graphene uniformly coated on surface of irregular micro-nanoparticles

A technology with micro-nano particles and uniform surface, applied in the field of new energy material preparation, can solve the problems such as the inability to distribute graphene evenly, performance loss, size limitation, etc., and achieve the effects of low cost, small investment and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

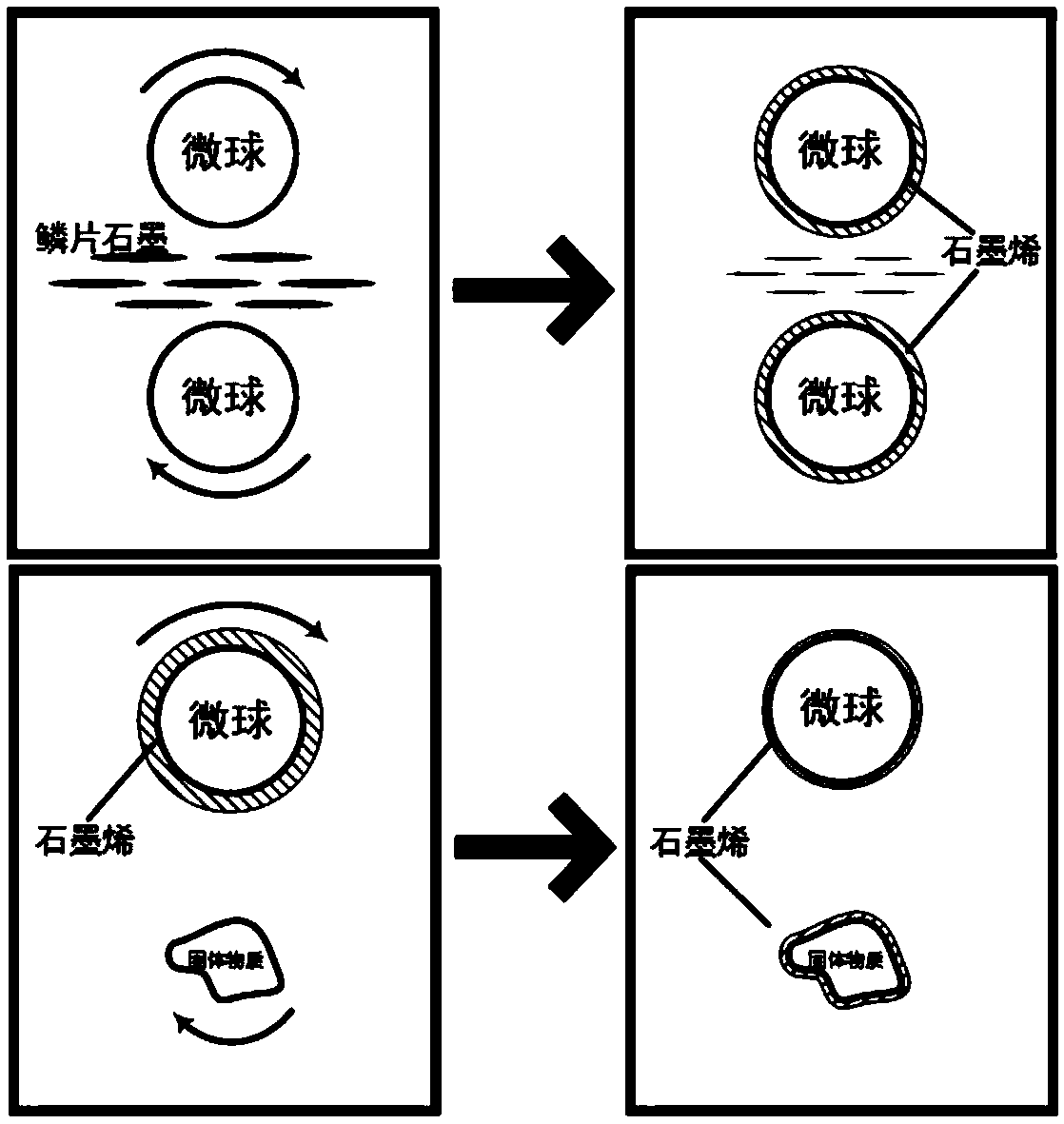

[0037] An all-solid-state preparation method for uniformly coating graphene on the surface of irregular micro-nano particles, comprising the following steps:

[0038] Step 1, preparing graphene-coated microsphere shell-core structure;

[0039] Step 2, transfer of the graphene-coated microsphere shell-core structure to the surface of the irregular micro-nano particles to form graphene-coated irregular micro-nano particles.

[0040] Step 1 specifically includes the following steps:

[0041] 1) mixing flake graphite powder and coated hard microspheres to obtain mixture A;

[0042] 2) Put the mixture A into the agate ball mill jar, during the ball milling process, the graphite flakes rub against the microspheres, and the graphene with different thicknesses is transferred and coated on the surface of the hard microspheres to obtain the mixture B;

[0043] 3) The graphite powder in the mixture B is sieved out to obtain a microsphere shell-core structure C coated with graphene of d...

Embodiment 1

[0068] a) Weigh 30 g of flake graphite (16 mesh, carbon content ≥ 99%), and 60 g of copper balls (diameter 400 μm) and mix evenly;

[0069] b) Put the above mixture into an agate ball mill jar, and mix it with a ball mill in an air atmosphere, set the rotation speed to 250rpm, and mill for 10 hours;

[0070] c) sieve out residual flake graphite in b) the resulting mixture (the aperture of the sieve is 0.03mm), leaving copper balls coated with graphene of different thicknesses;

[0071] d) Place the coated copper balls obtained in c) in a clean agate ball mill jar, add 120 g of clean copper balls of the same specification (400 μm in diameter) and mix evenly;

[0072] e) Set the ball milling parameters to a rotating speed of 250 rpm and a time of 12 hours to obtain a uniform thin-layer graphene-coated copper ball product.

Embodiment 2

[0074] a) Weigh 50g of the obtained graphene-copper spherical shell-core coating sample in Example 1 and place it in a stainless steel ball mill jar;

[0075] b) In a glove box (inert atmosphere), add 2 g of lithium aluminum hydride powder into the ball milling jar, seal the ball milling jar, and fill the jar with argon. Set the ball milling parameters as a rotating speed of 450rpm and a time of 12h;

[0076] c) Sieve the mixture obtained in b) in a glove box (the sieve aperture is 0.02 mm), remove the copper balls, and obtain a graphene-coated lithium aluminum hydride composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com