Waterproof, wear-resistant, and flame-retardant super adhesive tape

A tape and strong technology, applied in the field of waterproof, wear-resistant and flame-retardant strong tape, can solve the problems of not having waterproof, wear-resistant and flame-retardant properties, and achieve excellent weather resistance, waterproof sealing performance, strong tensile ability, and full thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

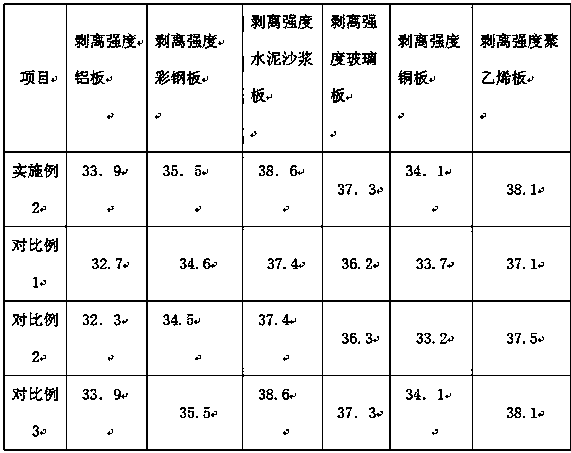

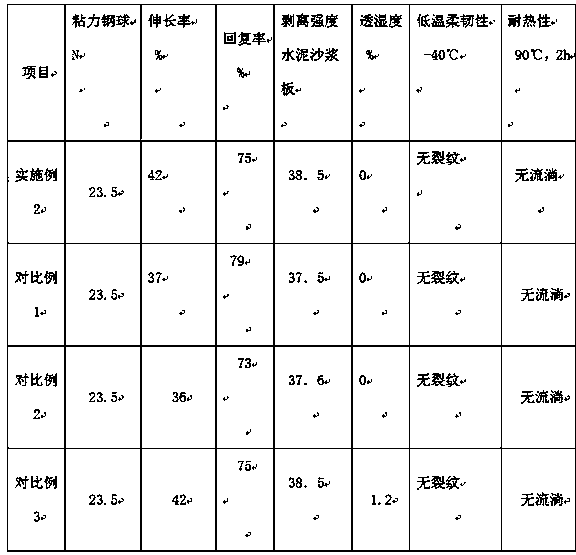

Examples

Embodiment 1

[0016] A waterproof, wear-resistant and flame-retardant strong adhesive tape, comprising an adhesive layer, a middle layer and an outer layer, the outer layer is a polyvinyl chloride waterproof layer, the middle layer is a flame-retardant fiber cloth layer, and the flame-retardant fiber cloth layer is heat-sealed on the outer layer On the top, the adhesive layer is applied to the flame-retardant fiber cloth layer, and the raw material components and proportions of the adhesive layer are: 3 parts of polyvinyl alcohol, 38 parts of propyl methacrylate, 28 parts of styrene, vinyl acetate 11 parts of rubber powder, 13 parts of allyl methyl ethyl phosphate, 4 parts of glycidyl acrylate, 1 part of dibenzoyl peroxide, 4 parts of sodium dodecylbenzenesulfonate, 13 parts of tricresyl phosphate, Aluminum 15 parts, ethyl acetate 15 parts.

[0017] Further, the flame-retardant fiber cloth layer is made of 30% high-strength glass fibers, 40% basalt fiber filaments, and 30% flame-retardant p...

Embodiment 2

[0022] A waterproof, wear-resistant and flame-retardant strong adhesive tape, comprising an adhesive layer, a middle layer and an outer layer, the outer layer is a polyvinyl chloride waterproof layer, the middle layer is a flame-retardant fiber cloth layer, and the flame-retardant fiber cloth layer is heat-sealed on the outer layer On the top, the adhesive layer is applied to the flame-retardant fiber cloth layer, and the raw material components and proportions of the adhesive layer are: 3 parts of polyvinyl alcohol, 37 parts of propyl methacrylate, 25 parts of styrene, vinyl acetate 11 parts of rubber powder, 13 parts of allyl methyl ethyl phosphate, 3 parts of glycidyl acrylate, 1 part of dibenzoyl peroxide, 4 parts of sodium dodecylbenzenesulfonate, 13 parts of tricresyl phosphate, 17 parts of aluminum, 2 parts of ethyl acetate.

[0023] Further, the flame-retardant fiber cloth layer is made of 30% high-strength glass fibers, 40% basalt fiber filaments, and 30% flame-retard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com