Anti-fatigue vehicle gear processing technology

A technology for automotive gears and treatment processes, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve problems such as gear fatigue damage, reduce transmission performance, etc., achieve performance improvement, increase service life, and enhance structural performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

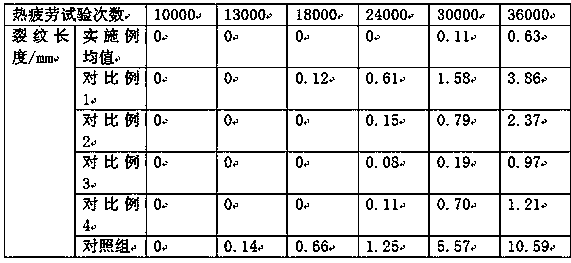

Examples

Embodiment 1

[0020] A treatment process for fatigue-resistant automotive gears, comprising the following steps:

[0021] (1) Cleaning:

[0022] Use lye to soak and clean the car gears for 20 minutes, then take them out, then soak the car gears in absolute ethanol for 3 minutes, take them out, and dry them to a constant weight.

[0023] (2) Solid solution modification treatment:

[0024] Carry out solid solution modification treatment on automotive gears in an electric heating furnace. The process conditions of the solid solution modification treatment are: heat up to 225 °C at a heating rate of 1.5 °C / s, keep it warm for 5 minutes, and then inject neon and nitrogen Mixed gas, then heated to 980°C at a heating rate of 0.3°C / s, heat preservation treatment for 45min, then lowered to 335°C at a cooling rate of 0.6°C / s, kept at a temperature of 40min, and then continued to reduce to 70°C at the same cooling rate ℃, heat preservation, and then soak the automobile gear in the impregnating solut...

Embodiment 2

[0033] A treatment process for fatigue-resistant automotive gears, comprising the following steps:

[0034] (1) Cleaning:

[0035] Use lye to soak and clean the car gears for 25 minutes, then take them out, then soak the car gears in absolute ethanol for 3 minutes, take them out, and dry them to a constant weight.

[0036] (2) Solid solution modification treatment:

[0037] Carry out solid solution modification treatment on automotive gears in an electric heating furnace. The process conditions of the solution modification treatment are as follows: heat up to 225 °C at a heating rate of 1.5 °C / s, keep it warm for 8 minutes, and then inject neon and nitrogen Mixed gas, then heated to 980°C at a heating rate of 0.3°C / s, heat preservation treatment for 50min, then lowered to 335°C at a cooling rate of 0.6°C / s, kept at a temperature of 40min, and then continued to reduce to 70°C at the same cooling rate ℃, heat preservation, and then soak the automobile gear in the impregnating ...

Embodiment 3

[0046] A treatment process for fatigue-resistant automotive gears, comprising the following steps:

[0047] (1) Cleaning:

[0048] Use lye to soak and clean the car gears for 22 minutes, then take them out, then put the car gears in absolute ethanol for 3 minutes, take them out, and dry them to a constant weight.

[0049] (2) Solid solution modification treatment:

[0050]Carry out solid solution modification treatment on automotive gears in an electric heating furnace. The process conditions of the solution modification treatment are as follows: heat up to 225 °C at a heating rate of 1.5 °C / s, keep it warm for 6 minutes, and then inject neon and nitrogen Mixed gas, then heated to 980°C at a heating rate of 0.3°C / s, heat preservation treatment for 49min, then lowered to 335°C at a cooling rate of 0.6°C / s, kept at a temperature of 40min, and then continued to reduce to 70°C at the same cooling rate ℃, heat preservation, and then soak the automobile gear in the impregnating so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com