Electroconductive porous body, solid polymer fuel cell, and method for manufacturing electroconductive porous body

A technology of porous bodies and conductive materials, which is applied in the manufacture of fuel cells, battery electrodes, conductive/antistatic filaments, etc., can solve problems such as difficulty in application, damage, and weak pressure resistance of carbon fibers, and achieve excellent electrode performance and conductivity Excellent, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] The first spinning solution was spun by an electrospinning method under the following conditions, and continuous precursor fibers were directly deposited on a stainless steel cylinder as a counter electrode to form a porous precursor fiber sheet in the form of a nonwoven fabric.

[0147] (Electrospinning conditions)

[0148] Electrode: metal nozzle (inner diameter: 0.33mm) and stainless steel cylinder

[0149] Injection amount: 2g / hour

[0150] The distance between the tip of the nozzle and the stainless steel cylinder: 10cm

[0151] Applied voltage: 10kV

[0152] Temperature / humidity: 25℃ / 35%RH

[0153] After that, solvent replacement was performed by immersing the precursor fibrous porous sheet in a water bath. Next, after removing moisture using a hot air drier set at 60°C, heat treatment was performed for 1 hour using a hot air drier set at 150°C to cure epoxy resin, which is a highly carbonizable organic material, to obtain The precursor fibers solidify the po...

Embodiment 2

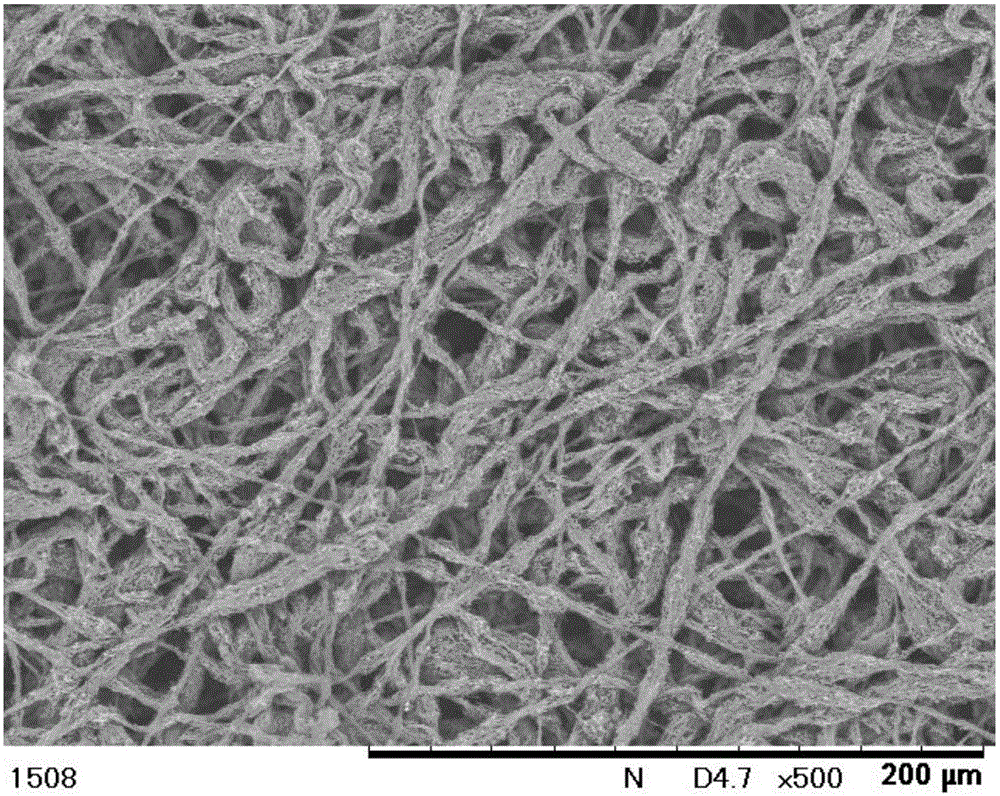

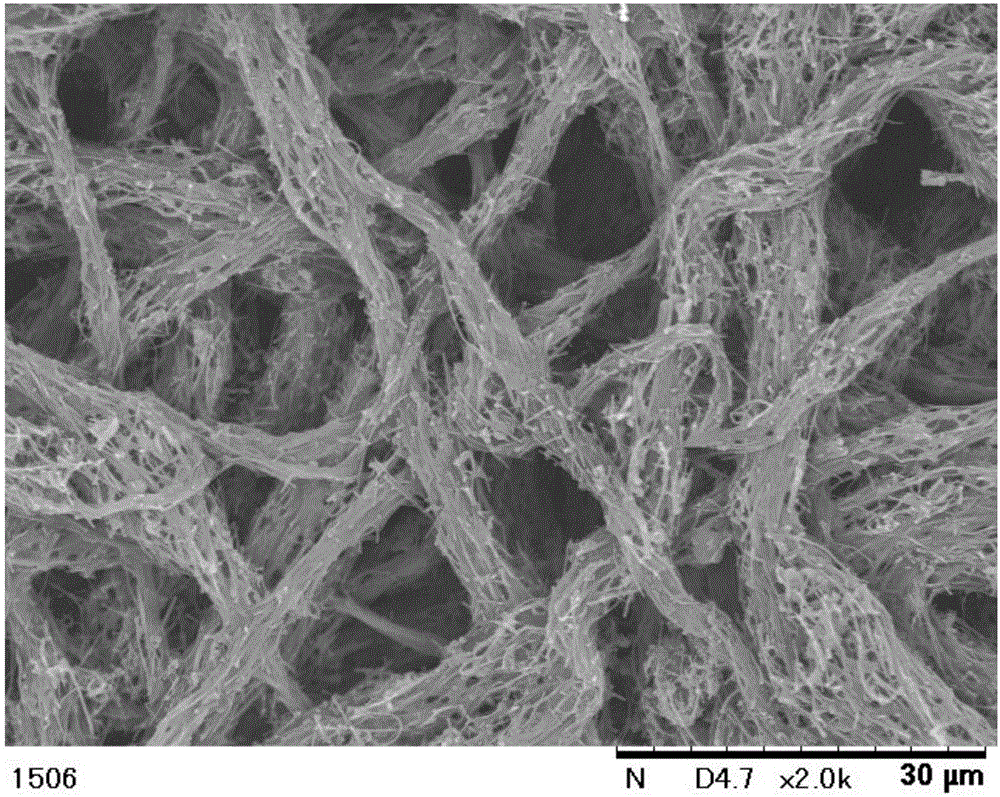

[0159] In the same manner as in Example 1 except that the second spinning solution was used, a one-layer conductive porous sheet having a nonwoven fabric structure (mass per unit area: 67 g / m 2 , thickness: 193μm, porosity: 81%). In addition, conductive porous sheets such as Figure 5 , 6 As shown, CB is dispersed throughout including the interior, and only porous continuous fibrous materials (average fiber diameter: 2.6 μm, The mass ratio of the total amount of CB:EP carbide and THV carbide = 66:34, specific surface area: 443m 2 / g), and the fibrous materials are also combined with carbides of EP and THV. In addition, the physical properties of the conductive porous sheet are shown in Table 1.

Embodiment 3

[0185] The sixth spinning solution was spun by an electrospinning method under the following conditions, and continuous precursor fibers were directly accumulated on a stainless steel cylinder as a counter electrode to form a porous precursor fiber sheet in the form of a nonwoven fabric.

[0186] (Electrospinning conditions)

[0187] Electrode: metal nozzle (inner diameter: 0.33mm) and stainless steel cylinder

[0188] Injection amount: 4g / hour

[0189] The distance between the tip of the nozzle and the stainless steel barrel: 14cm

[0190] Applied voltage: 10kV

[0191] Temperature / humidity: 25℃ / 30%RH

[0192] Thereafter, heat treatment was performed for 1 hour using a hot air drier set at 150° C. to cure the epoxy resin, which is a highly carbonizable organic material, to obtain a precursor fiber-cured porous sheet.

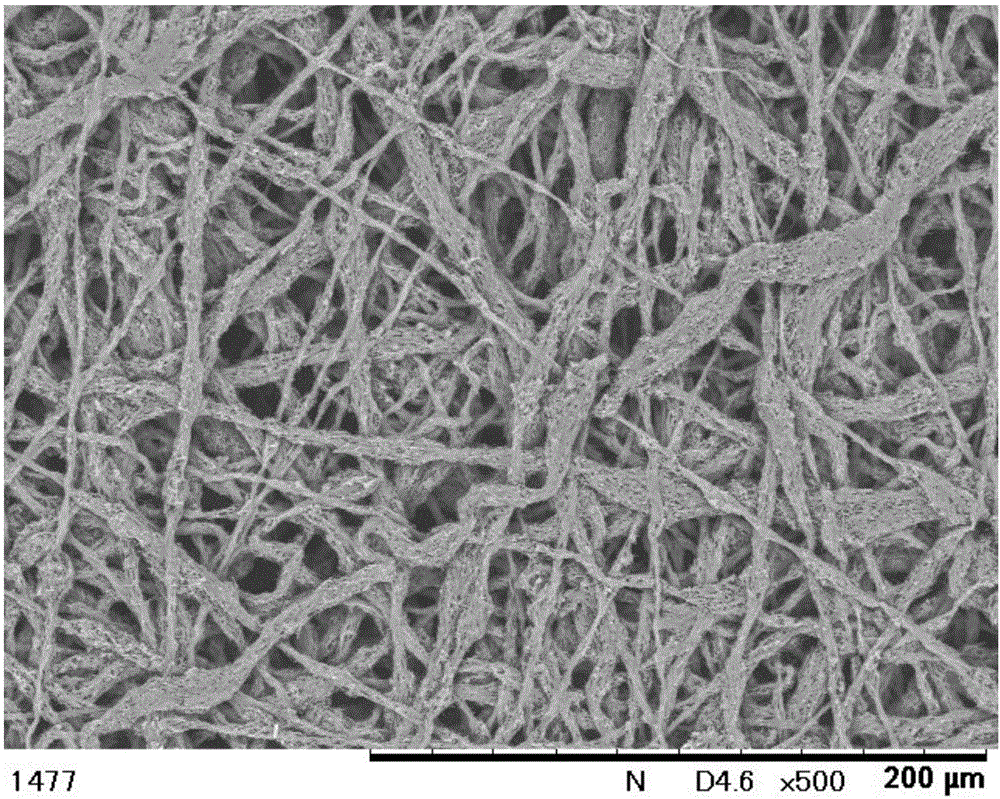

[0193] After that, the precursor fiber-cured porous sheet was subjected to a carbonization and firing treatment (temperature increase rate: 10° C. / min) at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com